Issues Relative to the Welding of Nickel and Its Alloys

Abstract

1. Introduction

2. Classification, Features and Applications of Ni and Ni-Based Alloys

2.1. Classifying Ni and Its Alloys

2.1.1. CP Ni

- Batch soft-annealing in bell-type furnaces: 705–760 °C; 2–6 h; AC.

- Continuous soft-annealing: 815–925 °C; 5 min; AC/WQ.

- Stress relieving: 480–705 °C; 30–120 min; AC.

- Stress equalizing: 260–480 °C; 1–2 h; AC.

- Postweld annealing: 705 °C; AC.

2.1.2. SSS Ni-Based Alloys

- Ni-Cu based alloys

- Soft annealing: 700–900 °C;

- Tempering: 550–650 °C.

- Soft material (140–180 HBW)—as-forged and quenched or annealed forgings, annealed or hot-rolled rods, large cold-drawn rods, and soft-temper wire and strip:

- o

- Age hardening: 580–610 °C; 16 h;

- o

- Furnace cooling: 12 °C/h down to 480 °C;

- o

- Air cooling.

- Moderately cold-worked material—cold-drawn rods, half-hard strip, cold-upset pieces, and intermediate-temper wire:

- o

- Age hardening: 580–610 °C; 8 h;

- o

- Furnace cooling: 12 °C/h down to 480 °C;

- o

- Air cooling.

- Fully cold-worked material (260–325 HBW, 25–35 HC)—spring-temper strip, spring wire, or heavily cold-worked pieces such as small, cold-formed balls:

- o

- Age hardening: 520–540 °C; 6 h;

- o

- Furnace cooling: 12 °C/h down to 480 °C;

- o

- Air cooling.

- Ni-Mo-based alloys

- Ni-Fe-based alloys

- Ni-Cr-Fe alloys

- Ni-Cr-Fe alloys exhibit remarkable strength at elevated temperatures and possess the capability to withstand oxidation, carburization, and various forms of high-temperature corrosion. The most recognized is alloy 800 (UNS N08800), along with its variants 800H (UNS N08810) and 800HT (UNS N08811). (Recently, such alloys have been categorized as stainless steels due to their elevated Fe content accompanied mainly by Ni and Cr). Stainless steel 800H exhibits exceptional high-temperature strength and high resistance to high-temperature oxidation.

- Ni-Cr-Fe (along with Mo and Cu) alloys that offer outstanding corrosion resistance in certain applications. Arguably, the most recognized is alloy 825 (UNS N08825), known for its high resistance to sulphuric acid. Alloy G3 (UNS N06985) provides high corrosion resistance against commercial phosphoric acids and various complex solutions with strong oxidizing acids.

- Cr (11.5–17%)-Fe alloys with carefully controlled carbon content. Can be heat-treated to a magnetic martensite structure and are therefore known as martensitic stainless steels.

- Cr (17–27%)-Fe alloys with low carbon content. They are non-hardenable by heat treatment. Their crystal structure is magnetic ferrite and therefore are known as ferritic stainless steels.

- Cr (16–26%)-Ni (6–22%)-Fe alloys with low carbon content. They are non-hardenable by heat-treatment. They exhibit crystal structure of nonmagnetic austenite and are therefore called austenitic stainless steels.

- Annealing—softens the material. Proper treatment takes 15 min in about 1010 °C.

- Solutioning—dissolves the carbides and increases grain size, which is good for creep resistance and rupture strength. Proper treatment takes 1 to 2 h at 1090–1150 °C.

- Solution-treatment: 1100–1200 °C.

- Annealing: 1000–1100 °C.

- Soft annealing: 980–1150 °C; 30–60 min.

- Solutioning: 1150 °C; 2 h.

- Annealing: 925–1010 °C; 1 h.

- Air cooling.

- Age hardening: 620 °C; 8 h.

- Furnace cool to 650 °C.

- Hold at 650 °C until furnace time for the entire age-hardening cycle equals 18 h.

- Air cooling.

- Annealing: 1035–1065 °C; 1 h.

- Air cooling.

- Age hardening: 760 °C; 10 h.

- Furnace cool to 650 °C.

- Hold at 650 °C until furnace time for the entire age-hardening cycle equals 20 h.

- Air cooling.

- Annealing: 1010 °C; 2 h.

- Water Quenching.

- Age hardening: 780–800 °C; 6–8 h.

- Air cooling.

- Ni-Cr-Mo-W alloys

- ▪ Solution-treatment: 980–1040 °C 0.5–4 h; for sizes up to 25 mm WQ or AC, for sizes above 25 mm WQ.

- ▪ Age-hardening: 730–750 °C for 8 h; Furnace cooling: 55 °C/h for 2 h; Age-hardening: 610–630 °C for 8 h; AC or WQ.

- ▪ Precipitation temperature: 760 °C.

- ▪ Batch annealing in bell-type furnaces: Cool rapidly through the range between 760 and 540 °C to ensure freedom from sensitization. Alloys 800H and 800HT are not susceptible to thermal cracking.

- The first: 1150 °C for 10 min, air cooling.

- The second: 1150 °C for 2–4 h, air cooling.

- Solution annealing: 1107–1135 °C.

- Soft annealing: 1065 ± 14 °C; 30 min; WQ.

- Ni-Fe-Cr-Mo alloys

- Solution-treatment: 1120 ± 14 °C, 30 min, WQ.

- Solution-treatment: 1100–1180 °C; rapid air cool/water quench.

- Solution-treatment: 1135–1163 °C; 30 min; water quench.

- Annealing: 1180–1200 °C; water quench.

- Ni-Cr-Co-Mo alloys

- Continuous soft-annealing: 1120–1175 °C; 30–60 min; air cool/water quench

- Batch soft-annealing in bell-type furnaces: 1120–1175 °C; 1–3 h; air cool

- Intermediate annealing: 1040 °C

- Solution-treatment according to ASME SB 176: 1140–1232 °C—to achieve an austenitic matrix without carbide precipitates.

2.1.3. PS Ni-Based Alloys

- Ni-Cu-Al-Ti alloys

- ▪

- Soft material (140–180 HBW)—as-forged and quenched or annealed forgings, annealed or hot-rolled rods, large cold-drawn rods, and soft-temper wire and strip:

- o

- Age hardening: 580–610 °C; 16 h.

- o

- Furnace cooling: 12 °C/h down to 480 °C.

- o

- Air cooling.

- ▪

- Moderately cold-worked material—cold-drawn rods, half-hard strip, cold-upset pieces and intermediate-temper wire:

- o

- Age hardening: 580–610 °C; 8 h.

- o

- Furnace cooling: 12 °C/h down to 480 °C.

- o

- Air cooling.

- ▪

- Fully cold-worked material (260–325 HBW, 25–35 HC)—spring-temper strip, spring wire or heavily cold-worked pieces such as small, cold-formed balls:

- o

- Age hardening: 520–540 °C; 6 h.

- o

- Furnace cooling: 12 °C/h down to 480 °C.

- o

- Air cooling.

- Ni-Cr-Al-Ti

- Ni-Fe-Cr-Nb-Al-Ti

2.1.4. The Specialty Ni-Based Alloys

- Ni-aluminides

- (a) Transformation of martensite

- (b) heat treatment

- Oxygen dispersion strengthened Ni alloys

3. Welding Characteristics of Ni and Ni-Based Alloys

- Weldability

- Weldability tests

- -

- Butt joint with full penetration,

- -

- T-joint with full penetration,

- -

- Branch connection with full penetration,

- -

- Fillet welds [149].

- transverse tensile test (2 specimens),

- transverse bend test (4 specimens),

- impact test (2 set of 3 specimens),

- hardness test (1 specimen),

- macroscopic examination (2 specimens).

- Radiographic Testing:

- ASTM E165: Standard Practice for Radiographic Examination of Welds.

- ASTM E1032: Standard Practice for Radiographic Examination of Weldments Using Industrial X-ray Film.

- Ultrasonic Testing:

- ASTM E709: Standard Practice for Ultrasonic Inspection of Weldments.

- Other NDT Methods:

- ASTM E1312: Standard Practice for Electromagnetic (Eddy-Current) Examination of Ferromagnetic.

- ASTM E2261: Standard Practice for Examination of Welds Using the Alternating Current Field.

- Welding techniques employed for connecting Ni and Ni-based alloys

- -

- Diffusion bonding

- -

- Plasma arc welding

- -

- GTAW

- -

- Existing processes are costly and time-consuming.

- -

- Nickel-based super alloy products are high value.

- -

- Tool wear and failure are noted as a common issue.

- -

- During tensile tests, achieving failure outside FSW/P stir zone is possible.

- -

- Lack of commonality in FSW/P efforts.

- ▪

- Travel Speed: 0.42 mm/s.

- ▪

- Temperature Control: 800 to 850 °C.

- ▪

- Axial Force: 62 kN (based on visual quality).

- ▪

- Rotational speed: 50–100 RPM (output variable from temperature control).

- ▪

- Tool: MegaStir PCBN Q60 FSW Tools w/4 and 6 mm pin length.

- ▪

- Full solution anneal.

- ▪

- Step 1: 1010 °C for 2 h then air cooled.

- ▪

- Step 2: 788 °C for 8 h then air cooled.

- ▪

- The FSP nugget was harder than the base material after FSP.

- ▪

- After heat treatment, microhardness slightly varied from the base material to the nugget.

- ▪

- Both post-heat treatment thermal exposure methods used exhibited similar observations.

- ▪

- Upon 760 °C exposure, hardness increase was observed.

- ▪

- Upon 871 °C exposure, a reduction in hardness was noted due mainly to coarsening of the γ′ precipitates (~200 ± 150 nm).

- ▪

- All these observations were similar for both the base metal and the processed region.

- ▪

- Mo-rich phases should be prevalent in 871 °C but not in 760 °C.

- ▪

- M6C occurs from 780 °C to 1080 °C.

- ▪

- Processed region tensile properties were similar to the base metal, resulting in a joint efficiency of 100%.

- ▪

- All the cross-weld FSP samples failed in the base metal.

- ▪

- The lowest local strain was observed in the processed region.

- ▪

- The highest local strain was noted in the base metal.

- ▪

- Grain boundary fracture and sample failure were primarily in the banded region.

- ▪

- As FSP (before creep testing), mostly, MC and M23C6 precipitates in the banded region.

- ▪

- Differences appear after creep testing, including:

- -

- Presence of Mo-rich phases along grain boundary (GB) and grain

- -

- interior.

- -

- Platelet like phase could be µ phase ((Ni,Co)7Mo6) or σ (FeCrMo.CrCo).

- Ni-based superalloys can be successfully friction stir welded and processed

- Low rotation speeds and processing temperatures are important to successful FSW/P of nickel-based superalloys.

- FSW/P of solution annealed Haynes 282 significantly increases hardness in the stir zone. However, the standard two-step heat treatment yields similar hardness from the base material through the FSW/P regions.

- FSW/P of Haynes 282 plus post-solution anneal + FSW/P two-step heat treatment (standard fabrication process) yields FSW/P mechanical properties (creep and tensile) that can meet base material properties.

- FSW/P can heal defects in cast material.

- Inconel 617 is similarly processable by FSW/P but appears to require higher processing temperatures.

- Differences between various welding processes and their correlations with the weldability of Ni-based alloys.

- SMAW—uses a consumable, flux-coated electrode to create an arc, shielding the weld pool with the flux. It is suitable for various materials and positions, but has slower welding speeds and less precise control than other arc methods [183,184,186,187,188,189,190,191,192,193,194,197,198,199,200,201,202,203,204]. It can be utilized for welding Ni-based alloys, but precise choice of electrodes and settings is essential, particularly for precipitation-hardened alloys. Ni alloys typically melt at lower temperatures than steel, and require less heat input when welding compared to steel. Excessive heat application may result in problems such as the loss of alloying elements and heightened distortion. Choosing the appropriate electrode is essential for attaining the desired characteristics of the weld. Ni-based electrodes are frequently employed, and their formulation must be selected to complement the base metal and the intended welding properties. The SMAW process can affect the weld microstructure, with elements such as heat input and cooling rate impacting grain size and phase development. In certain situations, post-weld heat treatment might be required to enhance characteristics such as strength and toughness. In dissimilar welding of Ni-based alloys to different materials, selecting the appropriate electrode and welding parameters is even more essential. Particular attention must be paid to the risk of cracking or other problems at the junction. The SMAW process for nickel alloys may be susceptible to specific defects, including porosity or cracking. Effective welding methods, such as controlling parameters and preparing joints, are crucial to reduce these problems [196,205,206,207,208,209,210,211,212,213,214,215,216,217,218,219,220,221,222,223,224,225,226,227,228]

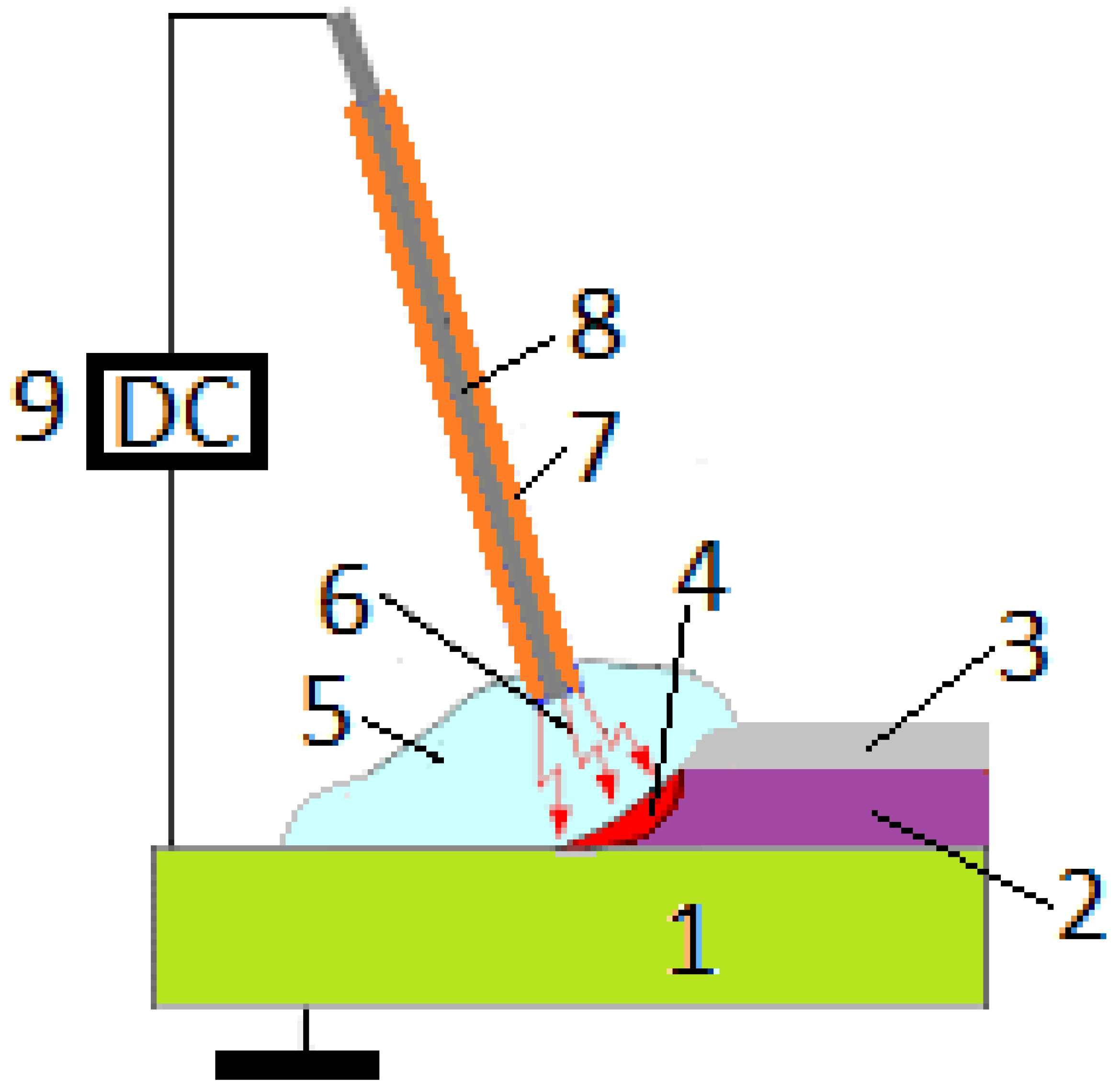

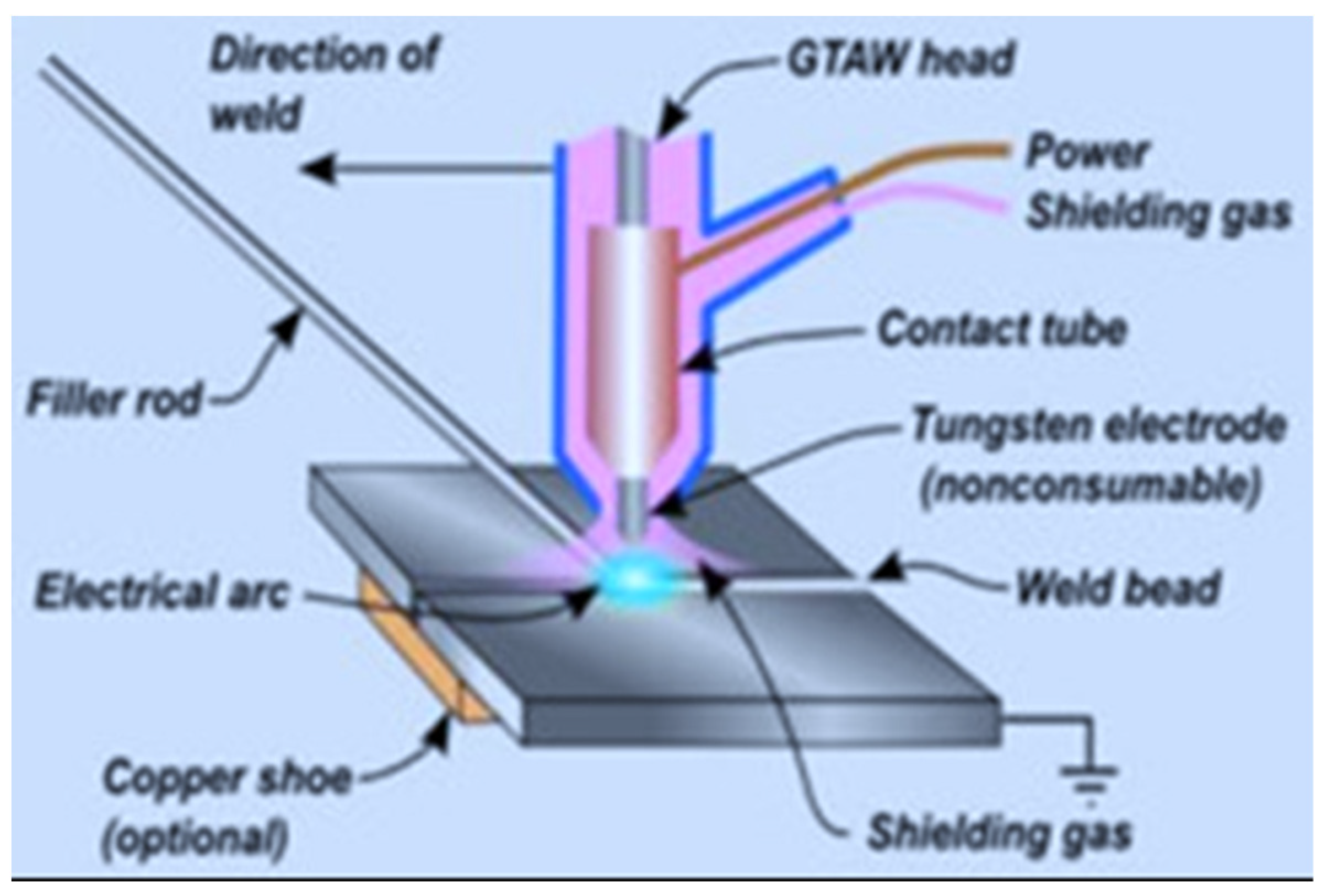

- GTAW—uses a non-consumable tungsten electrode and inert shielding gas to create a precise, controlled arc, often requiring a skilled operator. It is excellent for joining thin sections of Ni-based alloys and other materials [185,199,229,230]. The arc formed between the tungsten and the workpiece generates the necessary heat for melting the base materials. A filler metal can be added to the weld pool as needed. The process is shielded by an inert gas, typically argon or helium, to protect the molten weld from contamination. GTAW/TIG is known for its precision and ability to create high-quality welds, making it suitable for a variety of materials and applications. Commonly employed for welding thin and non-ferrous materials, such as nickel alloys, because of its accuracy and capacity to regulate heat input [196,198,229,231,232]. GTAW (Gas Tungsten Arc Welding) factors such as current, travel speed, and shielding gas greatly influence the microstructure and weldability of nickel (Ni) alloys. These factors affect grain size, phase development, and the occurrence of defects like cracks or porosity, which in turn influence mechanical characteristics such as strength, hardness, and ductility [233,234,235,236].

- PAW—is similar to GTAW but uses a more concentrated arc and a plasma gas to create a higher energy, more focused weld. This process can be automated and is used for thicker sections of Ni-based alloys [184,185,237]. It is suitable for welding nickel alloys, offering high energy concentration and deep infiltration [195,238,239,240]. The PAW process parameters strongly influence the microstructure and weldability of Ni-based alloys. These consist of welding current, welding speed, plasma gas flow rate, and the composition of the shielding gas. Tuning these parameters is essential for producing a quality weld that exhibits the required mechanical attributes and microstructural properties [195,196,239,241,242,243,244,245,246].

- GMAW—uses a continuous, consumable wire electrode and shielding gas to create the arc. It is a faster process than SMAW and GTAW, making it suitable for high-volume production [197,198,200]. Such an alternative, appropriate gas-shielded method is frequently employed for the thicker parts of nickel alloys [196,205,247]. GMAW (Gas Metal Arc Welding) of nickel alloys is affected by various process parameters that impact both the microstructure and weldability. Essential parameters consist of welding current, voltage, travel speed, shielding gas flow rate, and wire feed rate. Adjusting these parameters is essential for attaining the intended weld characteristics, including strength, ductility, and crack resistance [248,249,250,251,252,253,254,255].

- FCAW—utilizes a continuous, flux-cored wire electrode that provides shielding gas and filler metal. It is versatile, suitable for outdoor welding, and can be used on dirty or contaminated surfaces [183,184,185,202,203,220,256,257,258,259]. The weldability and microstructure of nickel-based alloys during FCAW are greatly affected by the composition of the filler metal and welding parameters. Factors such as current, voltage, travel speed, and shielding gas composition, along with the type and proportion of alloying elements in the filler wire, significantly influence the microstructure, mechanical properties, and crack resistance of the weld [250,260,261,262].

- SAW—uses a submerged arc, shielded by a blanket of flux. It is highly productive and suitable for thick plates of Ni-based alloys [186,187,188,189,190,191,192,193,194,256,263,264]. It is typically limited to solid-solution strengthened nickel alloys because of the risk of cracking in precipitation-hardened alloys [196,205,245]. The microstructure and weldability of Ni-based alloys in submerged arc welding (SAW) are affected by various essential factors, such as chemical composition, heat input, and welding conditions. These elements influence the solidification characteristics, grain patterns, phase development, and ultimately, the mechanical attributes and corrosion resistance of the weld [217,245,265,266,267].

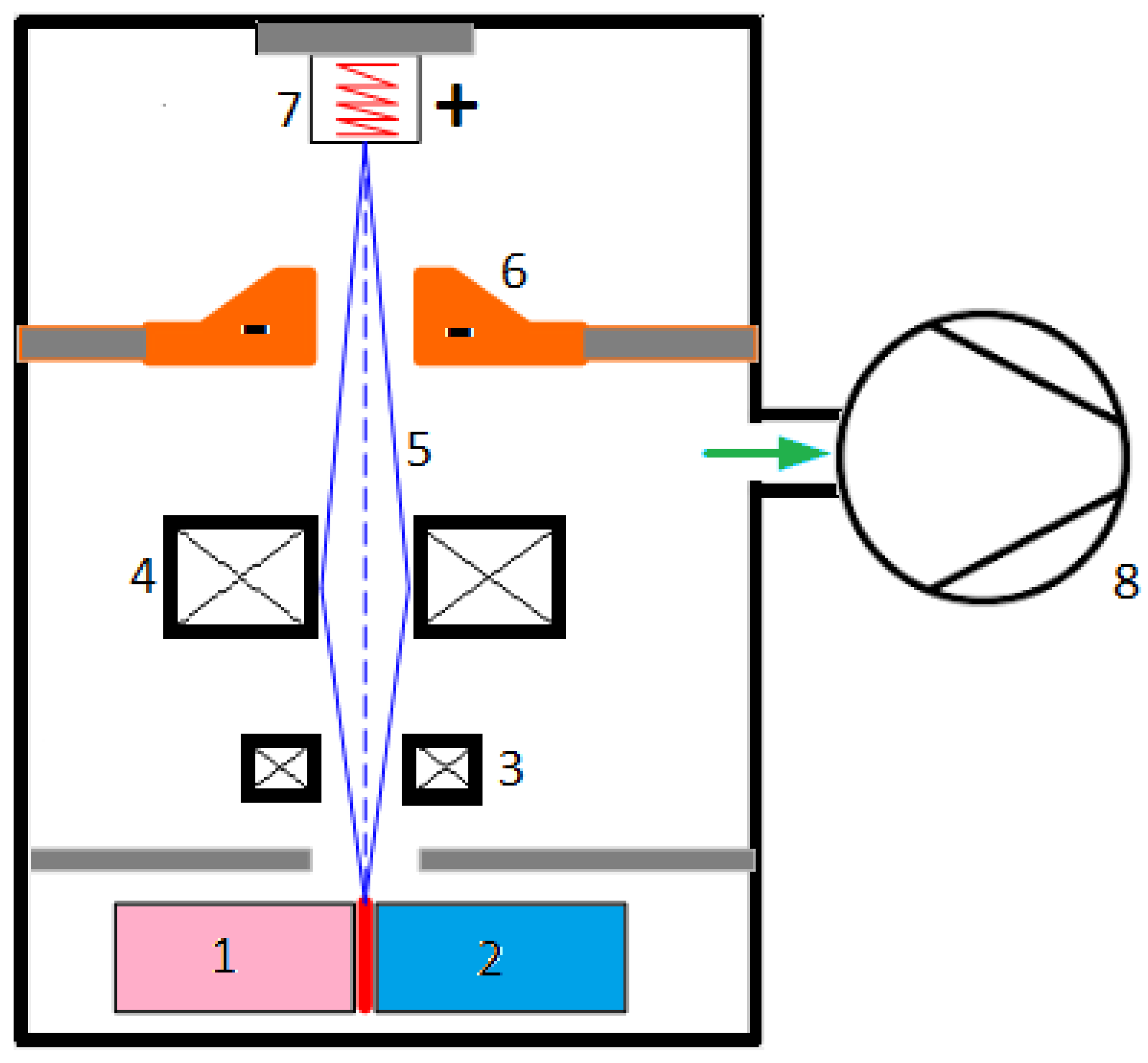

- EBW—uses a focused beam of high-energy electrons to melt and fuse metals, offering high precision and deep penetration, especially for Ni-based alloys [268,269,270]. It is very effective for welding nickel-based superalloys, creating deep, narrow welds with little distortion [5,195,271,272,273,274]. According to [245], EBW results in a joint that features deep penetration, a narrow fusion zone and heat-affected zone, along with minimal residual stresses thanks to a more uniform heat distribution, making EBW joints potentially better than conventional welded joints. In IN825, EBW joints are generally superior to GTAW welds, as the increased heat input resulted in a coarser microstructure and crack formation. However, when process parameters are not fine-tuned, achieving welds without cracks becomes challenging. This is especially difficult in single-crystal alloys, since GTA welds are typically free of cracks, whereas EBW welds contain stray grains that cause cracking. The unique aspects of the EBW process, including the need for a vacuum chamber, result in superior joint quality, even when contrasted with LBW. A comparison of laser and electron beam welding on thick joints composed of precipitation-strengthened Waspaloy and Udimet 720Li showed that the EBW joints exhibited lower porosity, though greater distortion was observed in the joints. The fusion zone also varies in shape and size. The factors influencing the process are categorized into two categories: beam characteristics (such as accelerating voltage and beam current) and joint properties (including welding speed, welding width, vacuum pressure, and preheating temperature). Statistical methods can be employed to merge the parameters efficiently. The combination of various values for beam current, accelerating voltage, welding speed, and beam oscillation showed that the accelerating voltage, along with beam current, significantly influences both the penetration and the width of the beam. The beam oscillation was not as significant; however, it influenced the crack susceptibility for Inconel 718 welded by EBW in the solution-treated state. The oscillation of the elliptical beam enhanced tensile strength and ductility at room temperature regardless of the heat treatment.

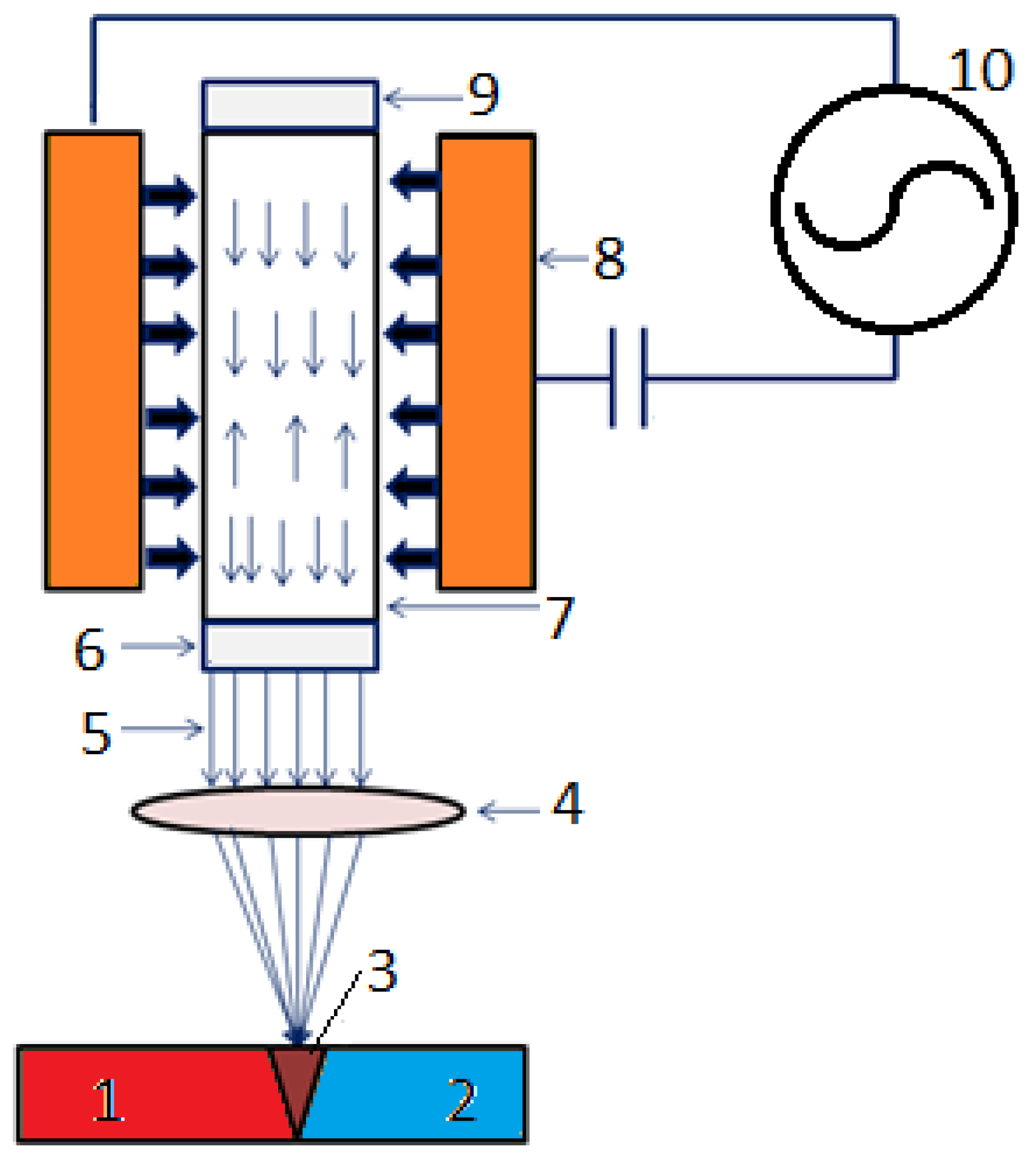

- LBW—utilizes a laser beam to melt and fuse metals, providing high precision and controlled heat input [200,268,269,275,276,277]. Like EBW, LBW provides high power density and accuracy for welding nickel alloys and other materials, especially in aerospace and various high-performance uses [195,278,279,280]. According to [245], the CO2 gas laser formerly used for welding tasks has been replaced by solid-state lasers today, like the Nb:YAG laser. Lately, fiber lasers have become popular due to their ability to enable rapid welding and their notable stability and precision. The fiber laser possessed enhanced melting efficiency and reduced the minimal heat input needed for complete penetration welds of Inconel 617 butt joints relative to the CO2 laser. Gas lasers have been effectively utilized for welding various superalloy joints, including Inconel 625, Inconel 718, and Nimonic. Examples of Nd:YAG laser applications include Inconel 718, Inconel 600, and NiTi shape memory alloy. The Nd:YAG laser demonstrated the ability to produce superior quality joints compared to various other laser types. A higher uniformity of the beads was noted in Inconel 718 joints welded with the Nb:YAG laser compared to the gas laser. This involves reduced residual stresses and the absence of microfissuring, which is a significant concern in laser welding. The Nd:YAG laser offers several benefits, including a high-energy absorption rate due to its low reflectivity, faster welding speeds, and reduced residual stress compared to CO2 lasers. These benefits render the Nd:YAG laser more practical and appropriate for on-site use and factory automation in high-volume manufacturing across various industrial applications. Obtaining smooth welds depends on the selection of laser parameters, the conditions before welding, and the heat treatments after welding.An appropriate adjustment of the laser welding settings ensures the quality of the welds. ANOVA analysis or DOE techniques enable the identification of optimal parameter combinations. The key factors include laser power and welding speed; however, additional elements are also important, including shielding gas flow rate, shielding gas pressure, focal position, and pulsation frequency.

- -

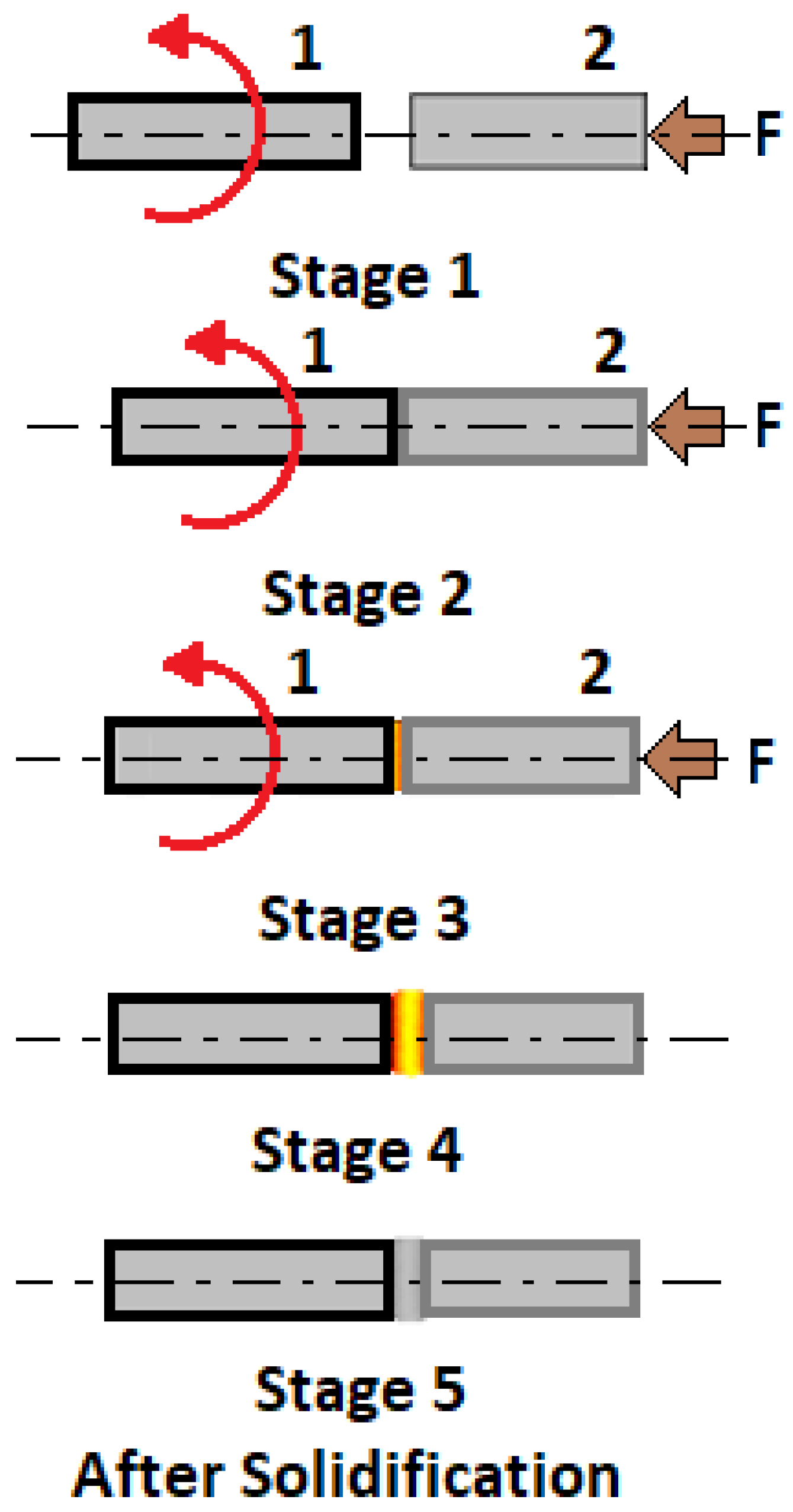

- FRW—creates a weld by applying pressure and rotating two pieces of metal together, producing a solid-state weld without melting. It is good for joining Ni-based alloys and other materials [200,281,282]. It can be realized as the Inertia Friction Welding (IFW) [1] or the Linear Friction Welding (LFW) [283]. The main factors influencing the friction welding of Ni alloys include friction pressure, upset pressure, burn-off length, rotational speed, friction duration, and forge pressure. These factors directly impact the heat input, plastic deformation, and ultimately, the microstructure and mechanical characteristics of the weld [284,285,286,287].

- FSW—uses a rotating tool to stir and consolidate the material being joined, producing a strong, solid-state weld without melting. It is suitable for joining Ni-based alloys and other materials [200,282,288,289]. It generates high-quality welds with little distortion, presenting a favorable alternative for connecting nickel alloys [5,290,291,292]. Friction stir welding (FSW) of Ni-based alloys and others is affected by various essential parameters that impact the microstructure and weldability. These factors encompass rotational speed, welding speed, tool shape, and axial force. Adjusting these parameters is essential for producing high-quality welds with preferred mechanical characteristics [293,294,295,296].

- Application requirements—certain applications may demand the unique properties of a specific process, such as the deep penetration of EBW or the precision of LBW [269].

- The effect of welding processes on the microstructure of Ni-based alloys

- ▪

- Heat Input:—welding processes introduce significant heat into the weld zone, affecting the microstructure. Higher heat input can lead to coarser grain size and potentially the formation of undesirable phases.

- •

- Cooling rate—the cooling rate after welding also influences the microstructure. Slow cooling can promote the formation of larger grains and phases, while rapid cooling can lead to finer microstructures and the formation of martensite.

- •

- Filler metal—the type and composition of the filler metal used in welding can significantly impact the weld microstructure and phase composition.

- F-SMAW, GMAW, GTAW, PAW, FCAW—these processes can result in a microstructure consisting of the primary phase, such as the Ni-based alloy’s base matrix, and potentially secondary phases like carbides or intermetallic compounds. The specific microstructure depends on the alloy’s composition and welding parameters.

- EBW, LBW—these methods can create very fine-grained microstructures due to rapid cooling and high energy density.

- Friction Welding (FRW) and Friction Stir Welding (FSW)—these solid-state welding processes can produce microstructures characterized by deformation bands and grain refinement in the heat-affected zone.

- Elevated current, which may cause excessive heat input, leading to a coarser grain structure in the weld zone (WZ) and heat-affected zone (HAZ), which might decrease strength and ductility. It may also elevate the likelihood of solidification cracking, particularly in alloys prone to cracking.

- Low voltage, which might not deliver adequate fusion, resulting in insufficient penetration and possible welding flaws. It may lead to a reduced grain size, yet it might not be enough to obtain the required mechanical properties.

- High travel speed, which lowers heat input, potentially resulting in a finer grain structure in the WZ and HAZ. Nonetheless, it could also decrease penetration and result in insufficient fusion.

- Leisurely pace of travel augments heat input, which may result in a rougher grain structure and heightened likelihood of solidification cracking. It also enables improved integration and infiltration.

- Protective gas in the form of Ar, frequently utilized for GTAW of Ni alloys, offering effective protection against environmental contamination. Alternatively, He provides a greater heat input than argon, which can be beneficial for thicker materials or challenging alloys to weld. Nevertheless, it may also elevate the risk of porosity if not adequately managed. Gas mixtures can also be customized to enhance welding characteristics for specific alloys and uses.

- The kind of tungsten electrode employed (e.g., thoriated, ceriated) can influence arc stability and the qualities of the weld pool.

- The electrode’s angle in relation to the workpiece can affect arc direction, penetration depth, and the shape of the bead.

- Heating Ni alloys beforehand can decrease thermal stresses and enhance weldability, particularly for thicker materials.

- Post-welding heat processing may be essential to enhance the microstructure and boost mechanical properties.

- Elevated current typically results in more heat input, which may create broader weld beads, greater penetration, and coarser grain structures in the Heat Affected Zone (HAZ).

- Increased welding speeds, which may lead to shallower penetration and finer grain structures because of lower heat input and quicker solidification periods.

- The plasma gas flow rate impacts the characteristics of the plasma jet, altering the shape of the weld pool, the penetration depth, and the overall quality of the weld. Increased flow rates may result in greater penetration but could also heighten the chance of porosity.

- Selecting a shielding gas (such as Argon, Helium, or combinations) affects the stability of the weld pool, its oxidation resistance, and the development of particular microstructural phases. It also influences the heat exchange and cooling speed of the weld.

- In powder-fed PAW, the rate of powder feed influences the dilution of the base metal and the makeup of the weld deposit. Accurate regulation of the powder feed rate is crucial for obtaining the targeted chemical composition and mechanical characteristics.

- The gap between the welding torch and the workpiece affects the heat spread and the properties of the weld pool. Keeping a steady torch standoff is crucial for even welding.

- In pulsed PAW, parameters such as frequency and current, which can be modified to regulate heat input, weld pool dimensions, and solidification speed, affect the microstructure and reduce the risk of cracking.

- A higher welding current typically results in deeper weld penetration, but may also raise the risk of cracking, particularly in nickel-based alloys, because of their sensitivity to thermal input.

- Welding voltage influences arc stability and the shape of the weld bead. Increased voltage may produce a broader weld bead, whereas decreased voltage can yield a thinner, more concentrated weld.

- Increased travel speeds lead to reduced heat input and can enhance the microstructure of the weld, though they may also cause incomplete fusion and defects if not managed correctly.

- Shielding gas prevents atmospheric pollutants from affecting the weld pool. The correct flow rate is vital for avoiding porosity and guaranteeing a clean weld.

- The speed of the wire feed directly regulates the quantity of filler metal introduced to the weld, affecting both the size of the weld and the chemical makeup of the weld metal.

- Pre-heating the workpiece, which can lower thermal stresses and avoid cracking, while keeping proper interpass temperatures, aids in controlling heat input during multi-pass welding.

- Increased current and voltage, which typically boost heat input, resulting in a larger weld pool and greater penetration. High current may result in the loss of alloying components and increased porosity. Higher voltage can enhance arc stability and encourage grain development.

- Higher travel speeds decrease heat input, leading to faster cooling and possibly increased hardness. Inadequate travel speed can result in excessive heat input, causing warping and fracturing.

- The selection of shielding gas, which can impact weld penetration, bead formation, and the development of oxides and nitrides, affects the microstructure and mechanical characteristics.

- The makeup of the flux-cored wire, especially the inclusion of elements such as Ni, Cr, Mo, and Nb, can considerably influence the phase changes during cooling, thereby impacting the weld’s strength, hardness, and resistance to corrosion.

- Heat input, depending on current, voltage, and travel speed, is essential in influencing the microstructure and characteristics of the weld. Maximizing heat application is crucial for attaining the preferred penetration, grain structure, and phase arrangement.

- Preheating, which helps decrease thermal stresses and enhances microstructure while keeping the right interpass temperature, is vital to prevent excessive cooling rates or overheating.

- Alloying elements such as Nb, C, and others are vital in influencing the solidification process, phase changes, and the emergence of secondary phases like NbC and Laves phases. These stages can greatly influence the ductility and overall effectiveness of the weld.

- Carbon concentration substantially impacts weldability, influencing phase development and microstructure.

- Ni concentration enhances strength and low-temperature impact toughness by encouraging the development of acicular ferrite.

- The heat supplied during SAW influences the grain size and distribution, phase changes, and the development of acicular ferrite. Increased heat input can result in larger grains and a greater proportion of acicular ferrite, which might enhance hardness and tensile strength, yet could reduce impact toughness and corrosion resistance.

- The rate of welding impacts the cooling rate and solidification duration, which, in turn, affect grain size and microstructure.

- Welding voltage and current influence the energy input and melt pool properties, thereby impacting the weld bead dimensions and depth.

- The makeup of the shielding gas, especially the levels of oxygen and carbon dioxide, can impact oxide formation and alter the microstructure of the welded metal.

- Greater rotational speeds result in elevated friction and heat production at the weld interface. Excessive speed can lead to grain coarsening and diminish weld strength.

- The length of friction directly affects the level of heat generated. Extended friction durations can result in excessive heat and possibly unfavorable microstructural alterations.

- Friction pressure governs the contact force between the moving and fixed components. It affects the speed of heat production and plastic deformation. According to a study published by Springer, greater friction pressure typically results in improved bonding and enhanced tensile strength. Used following the friction stage, this pressure solidifies the weld and guarantees a strong joint. The strain rate during the welding process is also linked to forge pressure.

- Length of burn-off characterizing the quantity of material that is “removed” or displaced during the friction process. It quantifies plastic deformation and material loss, and is affected by friction duration, pressure, and rotational speed.

- Rotation speed impacts the thermal input and material movement during FSW. Elevated speeds can result in greater heat input, which may enhance grain refinement in the stir zone (SZ), but could also lead to issues such as voids or cracking if the speed exceeds certain limits. Reduced speeds can cause inadequate heat generation, resulting in poor mixing and weak connections.

- Welding speed establishes the tool’s dwell time in the weld area, consequently affecting the heat input and material blending. Increased welding speeds may lower heat input, which could result in incomplete mixing and flaws, whereas decreased speeds can raise heat input and potentially cause excess material flow and warping.

- Tool configuration, including the length of the pin, the diameter of the pin, and the diameter of the shoulder, all influencing the flow of the material and the generation of heat. The design of tools is essential for ensuring adequate material blending and reducing flaws. For instance, a wider shoulder diameter can enhance heat input and material flow, whereas a longer pin can influence the depth of the stirred region.

- Axial load regulates the force exerted by the tool on the workpiece, affecting material flow and the occurrence of defects. Increased axial force may enhance material mixing and consolidation; however, too much force can result in tool wear or material ejection.

- Ni-based Alloys—the primary phase in Ni-based alloys is typically the Ni-rich matrix, which can be either a face-centered cubic (FCC) phase or a combination of FCC and other phases depending on the alloy’s composition.

- Welding effects—welding can alter the primary phase by promoting phase transformations or precipitating secondary phases within the matrix.

- Carbides—such as MC or MX, can precipitate in the weld zone, especially in alloys with high carbon content.

- Intermetallic Compounds—such as sigma phase (σ) or chi phase (χ), can also form depending on the alloy composition and welding conditions.

- Oxides—depending on the welding process and atmosphere, oxides can also form in the weld zone, particularly in GTAW or PAW.

- SMAW, GMAW, GTAW—these are the most commonly used arc welding processes. They can induce varying degrees of heat input, affecting the microstructure and phase transformations in Ni-based alloys.

- FCAW—this process, similar to SMAW and GMAW, can be used to weld Ni-based alloys, but its flux composition and welding parameters can influence the weld microstructure.

- EBW, LBW—these welding methods offer high energy density and can result in rapid solidification and fine-grained microstructures.

- FRW, FSW—these solid-state welding processes can produce microstructures with deformation bands and grain refinement in the heat-affected zone.

- Selective laser melting

- Powder Bed: A layer of Ni-based alloy particles is distributed over a fabrication platform.

- Laser Scanning: A laser beam precisely melts the powder based on a 3D model, forming the intended layer.

- Layer-by-Layer Construction: The procedure continues, layer by layer, until the finished component is achieved.

- Inert Atmosphere: SLM is frequently conducted in an inert atmosphere (such as nitrogen or argon) to avoid oxidation.

- Essential factors for SLM for Ni-based alloys:

- Microstructure [359]: SLM can create equiaxed or columnar grain structures based on process parameters such as scanning speed, hatch distance, and laser energy.

- Process Specifications [359]: Enhancing these parameters is essential to reduce flaws such as cracks, pores, and construction defects.

- Advantages of SLM for Ni-based alloys include:

- Geometries that are intricate: SLM allows for the fabrication of complex forms and patterns that are challenging to achieve using conventional techniques [372].

- Exemplary of Ni-based alloys applicable to SLM comprise:

- NiTi: high-quality NiTi alloys can be in situ synthesized with reduced manufacturing defects, the formation of Ni4Ti3 precipitates, and improved pseudoelasticity and microhardness [374].

- Ni-Nb Alloys: Studies have also concentrated on the SLM of binary Ni-Nb alloys as a substitute for Ni-containing superalloys [377].

3.1. The Weldability of CP Ni

- Porosity

- Craking issues

- Cracking during the solidification of weld metal in CP Ni

3.2. Weldability of Ni Alloys

3.2.1. Weldability of SSS Ni Alloys

- -

- Solid solution welding materials: ERNiCrMo-10, ENiCrMo-10;

- -

- Clad Arc Welding Rod: E NiCrMo-10;

- -

- Unclad arc welding electrode: ENiCrMo-10;

- -

- TIG wire: ERNiCrMo-10, ENiCrMo-10;

- -

- MIG/MAG wire: ERNiCrMo-10, ENiCrMo-10.

3.2.2. Cracking

- Cracking during the weld metal solidification in SSS Ni alloys

- -

- appropriate choice of filler metal that can reduce the solidification temperature range of the weld metal;

- -

- base metal containing minimal amounts of elements (P, S, B) that are capable of creating low-melting eutectics;

- -

- minimal heat input while welding, leading to:

- reduced solidification duration resulting from a sharper temperature gradient and

- smaller weld beads that minimize solidification strains,

- -

- appropriate weld shape featuring a low depth-to-width ratio and a convex surface profile due to improved stress distribution and grain structure, as illustrated in Figure 12.

- Liquation cracking in the semi-molten area and heat-affected region of SSS Ni alloys

- Ductility-dip fractures (DDF) of SSS Ni alloys

- -

- utilize Nickel 82, Nickel 625, and 52MSS filler metals, which possess sufficient niobium to create carbides and a finer grain structure that is resistant to DDC,

- -

- filler metals with a high Cr content (approximately 30 wt.%) should be avoided,

- -

- utilize only Ar or He rather than mixtures that include H2 (which is used to enhance the wetting properties of the filler metal),

- -

- reduce constraints and leftover stresses through appropriate joint design and

- -

3.2.3. Weldability of PS Ni-Based Alloys

- -

- Resistance Welding: Employs the electrical resistance of the material to produce heat and form welds. Its control overheat input makes it effective for Rene 41.

- -

- Electron Beam Welding (EBW): Provides accurate regulation of the weld area with reduced heat-affected zones. The vacuum setting minimizes contamination, making it perfect for welds with high integrity.

- -

- Gas Tungsten Arc Welding (GTAW): Needs proper joint alignment and cooling methods, like Cu backing bars or water-cooled jigs, to control heat and avoid cracking.

- -

- Surface Preparation and Filler Material: Make sure surfaces are clean and devoid of contaminants, and choose a suitable filler material to preserve weld strength.

- -

- Welding Settings: Regulate thermal input to avoid grain expansion and maintain the strength of the material [476].

- Solidification cracking in weld metal of PS Ni-based alloys

- Liquation cracking in the semi-molten area and in the heat-affected zone PS Ni alloys

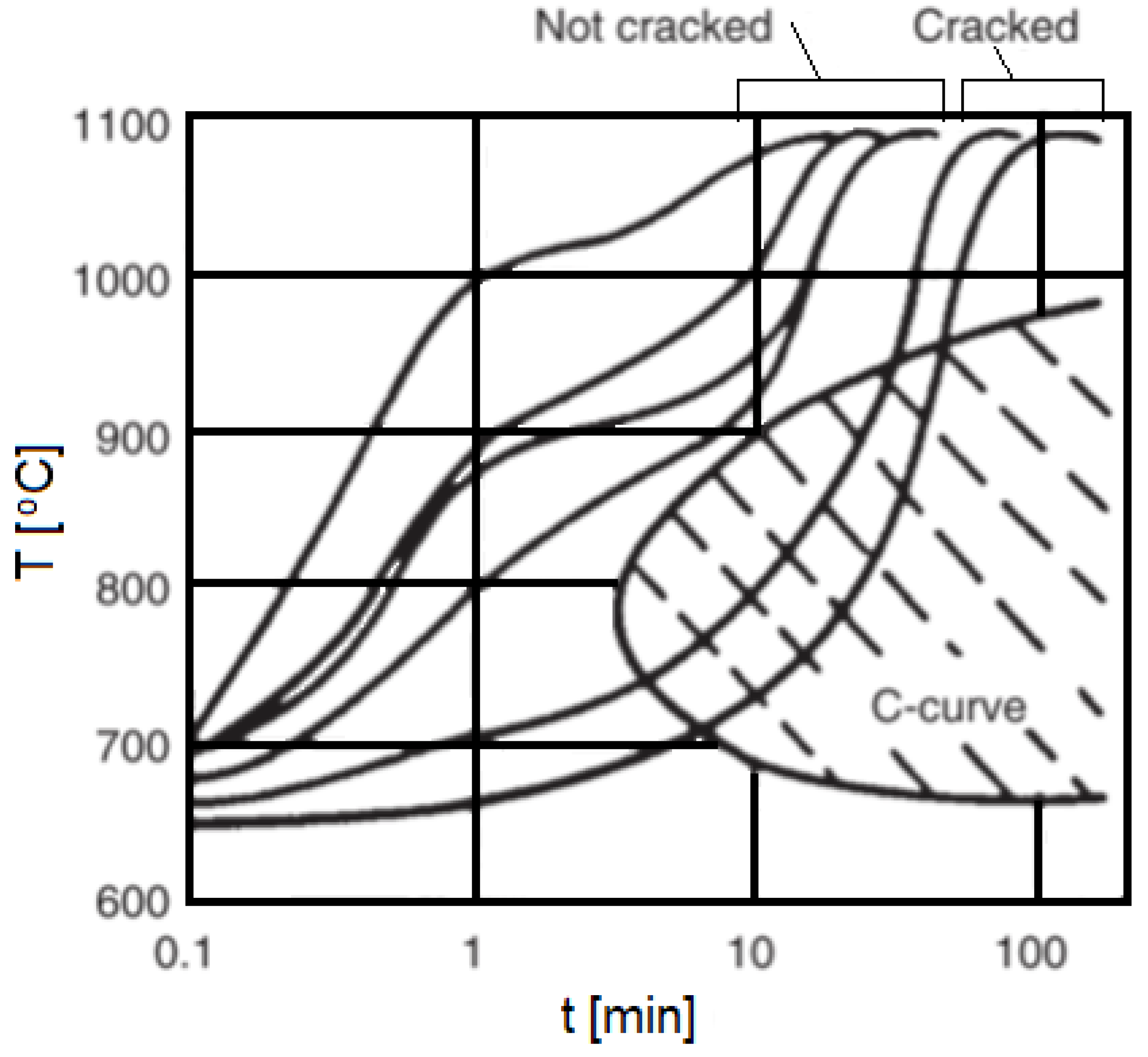

- Strain-age cracking in PS Ni alloys

3.2.4. Weldability of Ni SAs

3.3. Electrodes and Fillers for Welding and Pre- and Post-Welding Processing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CP | Commercial Pure |

| FSW | Friction Stir Welding |

| PS | Precipitation Strengthened |

| SA | Specialty Alloy |

| SSS | Solid-Solution Strengthened |

References

- Mudd, G.M.; Jowitt, S.M. A Detailed Assessment of Global Nickel Resource Trends and Endowments. Econ. Geol. 2014, 109, 1813–1841. [Google Scholar] [CrossRef]

- Davis, J.R. ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys, 1st ed.; ASM International, Ed.; ASM International: Novelty, OH, USA, 2000; ISBN 978-0-87170-685-0. [Google Scholar]

- Lippold, J.C. Welding Metallurgy and Weldability of Nickel-Base Alloys, 1st ed.; Wiley: Hoboken, NJ, USA, 2009; ISBN 978-0-470-08714-5. [Google Scholar]

- Caron, J.L.; Sowards, J.W. Weldability of Nickel-Base Alloys. In Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2014; pp. 151–179. ISBN 978-0-08-096533-8. [Google Scholar]

- Kojundžić, D.; Krnić, N.; Samardžić, I. Weldability of Nickel and Nickel-Based Alloys. In Proceedings of the International Conference on Materials Corrosion, Heat Treatment, Testing and Tribology, MTECH 2021, Šibenik, Croatia, 6–9 October 2021. [Google Scholar]

- Isabellenhütte Heusler GmbH & Co. KG. Pure Nickel—Data Sheet 2020; Isabellenhütte: Swansea, MA, USA, 2020. [Google Scholar]

- Nickel Institute Properties of Nickel 2025. Available online: https://nickelinstitute.org/en/nickel-applications/properties-of-nickel/ (accessed on 16 May 2025).

- Lenntech Chemical Elements Listed by Ionization Energy. 2025. Available online: https://www.lenntech.com/periodic-chart-elements/ionization-energy.htm (accessed on 16 May 2025).

- AWS A30M/A3.0; Standard Welding Terms and Definitions. American Welding Society: Doral, FL, USA, 2010.

- AZOMaterials. Nickel-Properties, Fabrication and Applications of Commercially Pure Nickel; AZOMaterials: Manchester, UK, 2025. [Google Scholar]

- Joseph Sahaya Anand, T. Nickel as an Alternative Automotive Body Materials. J. Mech. Eng. Sci. 2012, 2, 187–197. [Google Scholar] [CrossRef]

- Kopeliovich, D. Commercially Pure Nickel Alloys. 2023. Available online: https://www.substech.com/dokuwiki/doku.php?id=commercially_pure_nickel_alloys (accessed on 16 May 2025).

- Virgamet Alloy 200, Alloy 201, 2.4066, 2.4068, Nickel 200, Nickel 201—Commercially Pure Nickel. 2025. Available online: https://virgamet.com/offer/alloy-200-201-2-4066-2-4068-nickel-200-201-n02200-n02201 (accessed on 16 May 2025).

- Yonezawa, T. 2.08—Nickel Alloys: Properties and Characteristics. In Comprehensive Nuclear Materials; Konings, R.J.M., Ed.; Elsevier: Oxforf, UK, 2012; pp. 233–266. [Google Scholar]

- Geddes, B.; Leon, H.; Huang, X. (Eds.) Superalloys: Alloying and Performance; ASM International: Novelty, OH, USA, 2010; ISBN 978-1-61503-040-8. [Google Scholar]

- Reed, R.C. The Superalloys: Fundamentals and Applications, 1st ed.; Cambridge University Press: Cambridge, UK, 2006; ISBN 978-0-521-85904-2. [Google Scholar]

- Virgamet Alloy 400, 2.4360, UNS N04400, Monel® Alloy 400—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/alloy-monel-400-2-4360-n04400-bs-na13 (accessed on 16 May 2025).

- Virgamet Monel K500, Alloy K500, 2.4375, UNS N05500—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/alloy-monel-k500-2-4375-n05500-na18 (accessed on 16 May 2025).

- Haußmann, L.; Ur Rehman, H.U.; Matschkal, D.; Göken, M.; Neumeier, S. Solid Solution Strengthening of Mo, Re, Ta and W in Ni during High-Temperature Creep. Metals 2021, 11, 1909. [Google Scholar] [CrossRef]

- MetalCor Ni Alloys. 2025. Available online: https://www.metalcor.de/en/datenblatt/ (accessed on 16 May 2025).

- CorrosionMaterials Corrosion Resistant Alloys. 2025. Available online: https://corrosionmaterials.com/alloys/ (accessed on 16 May 2025).

- Virgamet Alloy B2, 2.4617, UNS N10665, Hastelloy® B2-Ni-Mo Alloy. 2025. Available online: https://virgamet.com/offer/alloy-hastelloy-b2-2-4617-uns-n10665-nimo28-nimo28fe5 (accessed on 16 May 2025).

- Virgamet Alloy B3, 2.4600, UNS N10675, Hastelloy® B3—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/hastelloy-alloy-b3-2-4600-uns-n10675-nimo30cr-ni1067 (accessed on 16 May 2025).

- AZOMaterials Nickel-Molybdenum (NiMo) Master Alloy. 2014. Available online: https://www.azom.com/article.aspx?ArticleID=10865 (accessed on 16 May 2025).

- Mehta, K.K.; Mukhopadhyay, P.; Mandal, R.K.; Singh, A.K. Microstructure, Texture, and Orientation-Dependent Flow Behavior of Binary Ni-16Cr and Ni-16Mo Solid Solution Alloys. Met. Mater. Trans. A 2015, 46, 3656–3669. [Google Scholar] [CrossRef]

- Tawancy, H.M. On the Precipitation of Intermetallic Compounds in Selected Solid-Solution-Strengthened Ni-Base Alloys and Their Effects on Mechanical Properties. Metallogr. Microstruct. Anal. 2017, 6, 200–215. [Google Scholar] [CrossRef]

- Yang, C.; Muránsky, O.; Zhu, H.; Thorogood, G.J.; Huang, H.; Zhou, X. On the Origin of Strengthening Mechanisms in Ni-Mo Alloys Prepared via Powder Metallurgy. Mater. Des. 2017, 113, 223–231. [Google Scholar] [CrossRef]

- Kanthal Nickel-Iron (NiFe) Alloys. 2025. Available online: https://www.kanthal.com/en/knowledge-hub/heating-material-knowledge/resistance-alloys-for-lower-temperature-applications2/nickel-iron-alloys/ (accessed on 16 May 2025).

- Nickel Institute Nickel Alloys. 2025. Available online: https://nickelinstitute.org/en/nickel-applications/nickel-alloys/ (accessed on 16 May 2025).

- Sun, F. Achieving High Tensile Strength of Heat-Resistant Ni-Fe-Based Alloy by Controlling Microstructure Stability for Power Plant Application. Crystals 2022, 12, 1433. [Google Scholar] [CrossRef]

- VDM Metals International GmbH VDM Alloy 36 Pernifer 36. 2022. Available online: https://www.vdm-metals.com/fileadmin/user_upload/Downloads/Data_Sheets/Data_Sheet_VDM_Alloy_36.pdf (accessed on 16 May 2025).

- Johnson, A. Ni-Cr-Fe. 1996. Available online: https://sv.rkriz.net/classes/MSE2094_NoteBook/96ClassProj/examples/nicrfe.html (accessed on 16 May 2025).

- SpecialMetals. INCONEL® Welding Products. 2025. Available online: https://www.specialmetals.com/divisions/welding-products/tradenames/inconel (accessed on 16 May 2025).

- Virgamet Inconel. 600, Alloy 600, Material 2.4816, UNS N06600. 2025. Available online: https://virgamet.com/offer/inconel-600-alloy-600-material-2-4816-uns-n06600 (accessed on 16 May 2025).

- Virgamet Alloy 601, 2.4851, UNS N06601, Inconel® 601—Nickel Alloy According to ASTM B166, DIN 17754. 2025. Available online: https://virgamet.com/offer/inconel-alloy-601-24851-uns-n06601-nicr23fe-na49-ncf601 (accessed on 16 May 2025).

- Virgamet Alloy. 625, UNS N06625, 2.4856—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/nickel-alloy-inconel-625-n06625-2-4856-bs3075-na21 (accessed on 16 May 2025).

- Virgamet Alloy. 718, 2.4668, UNS N07718, Inconel® 718—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/alloy-inconel-718-2-4668-n07718-bs2901-na51-ncf718-chn55mbju (accessed on 16 May 2025).

- Virgamet Alloy. 800, Alloy 800H, Alloy 800HT—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/alloy-incoloy-800-800h-800ht-n08800-n08810-n08811-1-4876-1-4958-1-4959 (accessed on 16 May 2025).

- Woite, M. GmbH Material No.: Alloy G3. 2025. Available online: https://woite-edelstahl.com/alloyg3en.html (accessed on 16 May 2025).

- Ashby, M.F. Material Profiles. In Materials and the Environment; Elsevier: Amsterdam, The Netherlands, 2013; pp. 459–595. ISBN 978-0-12-385971-6. [Google Scholar]

- Symons, D.M. Hydrogen Embrittlement of Ni-Cr-Fe Alloys. Met. Mater. Trans. A 1997, 28, 655–663. [Google Scholar] [CrossRef]

- AZOMAterials. Super Alloy HASTELLOY(r) G-3 Alloy (UNS N06985). 2012. Available online: https://www.azom.com/article.aspx?ArticleID=7733#:~:text=Super%20alloys%20or%20high%20performance%20alloys%20have,with%20deformation%20resistance%20and%20high%20surface%20stability.&text=Annealing%20of%20HASTELLOY(r)%20G%2D3%20alloy%20can%20be,rapid%20cooling%20of%20air%20and%20water%20quenching (accessed on 16 May 2025).

- Virgamet Alloy. 825, 2.4858, UNS N08825, Incoloy 825—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/alloy-incoloy-825-2-4858-uns-n08825-nicr21mo-na16 (accessed on 16 May 2025).

- Virgamet ALLOY. 925, UNS N09925, INCOLOY® 925—STOP NIKLU. 2025. Available online: https://virgamet.pl/oferta/alloy-incoloy-925-n09925-h09925-ns2401 (accessed on 16 May 2025).

- NineSteel. Incoloy 926. 2025. Available online: https://www.ninesteel-ss.com/products/incoloy-926 (accessed on 16 May 2025).

- Virgamet Alloy. N86, Nimonic® Alloy 86—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/nickel-alloy-n86-nimonic-86 (accessed on 16 May 2025).

- Virgamet Alloy. 90, UNS N07090, 2.4632, NiCr20Co18Ti—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/nimonic-alloy-90-n07090-2-4632-nicr20co18ti-nickel-alloy (accessed on 16 May 2025).

- Virgamet Alloy. C-276, UNS N10276, 2.4819—Otherwise Hastelloy C-276, CrNiMo16-60-16, NiMo16Cr15Fe6W4 According to ASTM B462 and ISO 9722. 2025. Available online: https://virgamet.com/offer/hastelloy-alloy-c276-2-4819-n10276-crnimo156016-nimo16cr15fe6w422 (accessed on 16 May 2025).

- Virgamet Alloy C4, UNS N06455, 2.4610, Hastelloy® C-4—Nickel Alloy According to DIN 17744:2019 i ASME SB366-21. 2025. Available online: https://virgamet.com/offer/alloy-hastelloy-c4-n06455-2-4610-nimo16cr16ti-nimo16cr17ti (accessed on 16 May 2025).

- Aeether Incoloy 926 Alloy. 2025. Available online: https://www.aeether.com/AEETHER/grades/926.html (accessed on 16 May 2025).

- Virgamet Stainless Steel. 1.4529, X1NiCrMoCuN25-20-7, Alloy 926, UNS N08926. 2025. Available online: https://virgamet.com/offer/x1nicrmocun25207-1-4529-alloy-926-6mo-uns-n08926-stainless-steel (accessed on 16 May 2025).

- VDM. Metals International GmbH VDM Alloy 825 Nicofer 4221. 2020. Available online: https://www.vdm-metals.com/fileadmin/user_upload/Downloads/Data_Sheets/Data_Sheet_VDM_Alloy_825.pdf (accessed on 16 May 2025).

- AZOMaterials. Incoloy 825–Properties, Applications, Fabrication, Machinability and Weldability of Incoloy 825. 2012. Available online: https://www.azom.com/article.aspx?ArticleID=4245 (accessed on 16 May 2025).

- Virgamet Alloy. C22, UNS N06022, 2.4602, Hastelloy® C-22—Nickel Alloy According to ASTM B 574-18 and DIN 17750:2021. 2025. Available online: https://virgamet.com/offer/alloy-hastelloy-c22-uns-n06022-nicr21mo14w-2-4602-nw6022 (accessed on 16 May 2025).

- Virgamet Alloy. 59, 2.4605, UNS N06059, Haynes® 59, NiCr23Mo16Al—Nickel Alloy According to ASTM B 366 and Other Standards. 2025. Available online: https://virgamet.com/offer/alloy-59-uns-n06059-2-4605-nicr23mo16al-haynes-59 (accessed on 16 May 2025).

- Virgamet Alloy. 2000, 2.4675, UNS N06200, Hastelloy® C-2000—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/alloy-2000-2-4675-n06200-hastelloy-c2000-nicr23mo16cu (accessed on 16 May 2025).

- Virgamet Alloy. 686, 2.4606, UNS N06686—NICKEL ALLOY. 2025. Available online: https://virgamet.com/offer/inconel-nickel-alloy-686-n06686-2-4606 (accessed on 16 May 2025).

- Virgamet Alloy. 617, 2.4663, UNS N06617, Inconel® 617—Alloy. 2025. Available online: https://virgamet.com/offer/alloy-inconel-haynes-617-na50-24663-nicr23co12mo-n06617 (accessed on 16 May 2025).

- Dong, C.; Chen, Z.; Zhao, Y.; Zhou, Y.; Wu, Y.; Wang, Z. Microstructure Characterization and Strengthening Behavior of a Non-γ’ Phase Nickel-Based Alloy C-HRA-2 after Creep at 650 °C. Mater. Today Commun. 2023, 34, 104980. [Google Scholar] [CrossRef]

- Chen, K.; He, X.; Liu, Z.; Li, G.; Bao, H. Solidification Path and Precipitation Mechanism of a Ni-Cr-Co-Mo Based Heat-Resistant Alloy. Mater. Charact. 2024, 215, 114099. [Google Scholar] [CrossRef]

- CorrosionMaterials Alloy K-500. 2025. Available online: https://corrosionmaterials.com/alloys/alloy-k-500/ (accessed on 16 May 2025).

- Virgamet Alloy 80A, 2.4952, UNS N07080, Nimonic® 80A—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/alloy-nimonic-80a-uns-n07080-na20-2-4952-nicr20tial (accessed on 16 May 2025).

- Virgamet Alloy C-263, 2.4650, Nimonic® Alloy 263, Haynes® 263—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/alloy-c-263-2-4650-nicr20co18ti-n07263-haynes-nimonic-263 (accessed on 16 May 2025).

- AlloyWire Haynes 282. 2025. Available online: https://www.alloywire.com/alloys/haynes-282/ (accessed on 16 May 2025).

- Łyczkowska, K.; Adamiec, J.; Jachym, R.; Kwieciński, K. Properties of the Inconel 713 Alloy Within the High Temperature Brittleness Range. Arch. Foundry Eng. 2017, 17, 103–108. [Google Scholar] [CrossRef]

- Virgamet Waspalloy, 2.4654, Haynes® Waspaloy—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/waspalloy-haynes-waspaloy-n07001-2-4654-nicr20co13mo4ti3al (accessed on 16 May 2025).

- Virgamet René 41, Alloy 41, 2.4973, UNS N07041—Nickel Alloy According to AMS 5399, 5545, 5800, 7469D. 2025. Available online: https://virgamet.com/offer/rene-alloy-41-n07041-2-4973-nicr19como (accessed on 16 May 2025).

- Virgamet Alloy 725, UNS N07725, Inconel® 725—Nickel Alloy. 2025. Available online: https://virgamet.com/offer/alloy-725-n07725-inconel-725 (accessed on 16 May 2025).

- Special Metals Inconel Alloy 706. 2004. Available online: http://specialmetals.ir/images/technical_info/nickel-base-alloy/inconel-alloy-706.pdf (accessed on 16 May 2025).

- Special Metals Incoloy Alloy 909. 2004. Available online: https://www.specialmetals.com/documents/technical-bulletins/incoloy/incoloy-alloy-909.pdf (accessed on 16 May 2025).

- Special Metals Incoloy Alloy 945. 2025. Available online: https://www.specialmetals.com/documents/technical-bulletins/incoloy/incoloy-alloy-945.pdf (accessed on 16 May 2025).

- Hursan What Is Inconel 713? Properties, Applications, and Advantages. 2025. Available online: https://hursan-com.translate.goog/en/what-is-inconel-713-properties-applications-and-advantages/?_x_tr_sl=en&_x_tr_tl=pl&_x_tr_hl=pl&_x_tr_pto=rq (accessed on 16 May 2025).

- Zhang, F.; He, J.; Wu, Y.; Mao, H.; Wang, H.; Liu, X.; Jiang, S.; Nieh, T.G.; Lu, Z. Effects of Ni and Al on Precipitation Behavior and Mechanical Properties of Precipitation-Hardened CoCrFeNi High-Entropy Alloys. Mater. Sci. Eng. A 2022, 839, 142879. [Google Scholar] [CrossRef]

- Zhao, Y.; Cao, S.; Zeng, L.; Xia, M.; Jakse, N.; Li, J. Intermetallics in Ni–Al Binary Alloys: Liquid Structural Origin. Met. Mater. Trans. A 2023, 54, 646–657. [Google Scholar] [CrossRef]

- Jozwik, P.; Polkowski, W.; Bojar, Z. Applications of Ni3Al Based Intermetallic Alloys—Current Stage and Potential Perceptivities. Materials 2015, 8, 2537–2568. [Google Scholar] [CrossRef]

- Meng, Y.; Li, J.; Zhang, S.; Gao, M.; Gong, M.; Chen, H. Wire Arc Additive Manufacturing of Ni-Al Intermetallic Compounds through Synchronous Wire-Powder Feeding. J. Alloys Compd. 2023, 943, 169152. [Google Scholar] [CrossRef]

- Asirvatham, M.C.; Masters, I.; West, G.; Harris, C. Influence of Nickel-Plating on Laser Weldability of Aluminium Busbars for Lithium-Ion Battery Interconnects. J. Mater. Res. Technol. 2025, 36, 4501–4515. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Huang, X.; Zhang, C.; Ren, J.; Lu, X.; Tang, F.; Xue, H. Tensile Mechanical Performance of Al/Ni Dissimilar Metals Bonded by Self-Propagating Exothermic Reaction Based on Molecular Dynamics Simulation. Mater. Today Commun. 2021, 26, 102079. [Google Scholar] [CrossRef]

- Liu, C.T.; White, C.L.; Horton, J.A. Effect of Boron on Grain-Boundaries in Ni3Al. Acta Metall. 1985, 33, 213–229. [Google Scholar] [CrossRef]

- Crawford, G. Nickel Magazine. 2003. Available online: https://www.academia.edu/107987847/Surface_Engineering_of_Corrosion_Environmental_Fracture_Cavitation_and_Impingement_Resistant_Materials (accessed on 16 May 2025).

- Hadi, M.; Kamali, A.R. Investigation on Hot Workability and Mechanical Properties of Modified IC-221M Alloy. J. Alloys Compd. 2009, 485, 204–208. [Google Scholar] [CrossRef]

- Walter, J.L.; Cline, H.E. The Effect of Solidification Rate on Structure and High-Temperature Strength of the Eutectic NiAl-Cr. Met. Trans. 1970, 1, 1221–1229. [Google Scholar] [CrossRef]

- Cline, H.E.; Walter, J.L. The Effect of Alloy Additions on the Rod-Plate Transition in the Eutectic NiAl−Cr. Met. Trans. 1970, 1, 2907–2917. [Google Scholar] [CrossRef]

- Cline, H.E.; Walter, J.L.; Lifshin, E.; Russell, R.R. Structures, Faults, and the Rod-Plate Transition in Eutectics. Met. Trans. 1971, 2, 189–194. [Google Scholar] [CrossRef]

- Johnson, D.R.; Chen, X.F.; Oliver, B.F.; Noebe, R.D.; Whittenberger, J.D. Processing and Mechanical Properties of In-Situ Composites from the NiAlCr and the NiAl(Cr,Mo) Eutectic Systems. Intermetallics 1995, 3, 99–113. [Google Scholar] [CrossRef]

- Rahaei, M.B.; Jia, D. Processing Behavior of Nanocrystalline NiAl during Milling, Sintering and Mechanical Loading and Interpretation of Its Intergranular Fracture. Eng. Fract. Mech. 2014, 132, 136–146. [Google Scholar] [CrossRef]

- Yang, J.-M.; Jeng, S.M.; Bain, K.; Amato, R.A. Microstructure and Mechanical Behavior of In-Situ Directional Solidified NiAl/Cr(Mo) Eutectic Composite. Acta Mater. 1997, 45, 295–308. [Google Scholar] [CrossRef]

- Whittenberger, J.D.; Raj, S.V.; Locci, I.E.; Salem, J.A. Elevated Temperature Strength and Room-Temperature Toughness of Directionally Solidified Ni-33Al-33Cr-1Mo. Met. Mater. Trans. A 2002, 33, 1385–1397. [Google Scholar] [CrossRef]

- Cui, C.Y.; Chen, Y.X.; Guo, J.T.; Li, D.X.; Ye, H.Q. Preliminary Investigation of Directionally Solidified NiAl–28Cr–5.5Mo–0.5Hf Composite. Mater. Lett. 2000, 43, 303–308. [Google Scholar] [CrossRef]

- Cui, C.Y.; Guo, J.T.; Ye, H.Q. Effects of Hf Additions on High-Temperature Mechanical Properties of a Directionally Solidified NiAl/Cr(Mo) Eutectic Alloy. J. Alloys Compd. 2008, 463, 263–270. [Google Scholar] [CrossRef]

- Cui, C.Y.; Guo, J.T.; Qi, Y.H.; Ye, H.Q. Deformation Behavior and Microstructure of DS NiAl/Cr(Mo)Alloy Containing Hf. Intermetallics 2002, 10, 1001–1009. [Google Scholar] [CrossRef]

- Guo, J.T.; Cui, C.Y.; Chen, Y.X.; Li, D.X.; Ye, H.Q. Microstructure, Interface and Mechanical Property of the DS NiAl/Cr(Mo,Hf) Composite. Intermetallics 2001, 9, 287–297. [Google Scholar] [CrossRef]

- Guo, J.T.; Cui, C.Y.; Qi, Y.H.; Ye, H.Q. Microstructure and Elevated Temperature Mechanical Behavior of Cast NiAl–Cr(Mo) Alloyed with Hf. J. Alloys Compd. 2002, 343, 142–150. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Guo, J.T.; Zhou, L.Z.; Ye, H.Q. The Effect of Strong Magnetic Field Treatment on Microstructure and Room Temperature Compressive Properties of NiAl–Cr(Mo)–Hf Eutectic Alloy. Mater. Sci. Eng. A 2009, 500, 238–243. [Google Scholar] [CrossRef]

- Guo, J.T.; Sheng, L.Y.; Tian, Y.X.; Zhou, L.Z.; Ye, H.Q. Effect of Ho on the Microstructure and Compressive Properties of NiAl-Based Eutectic Alloy. Mater. Lett. 2008, 62, 3910–3912. [Google Scholar] [CrossRef]

- Guo, J.T.; Huai, K.W.; Gao, Q.; Ren, W.L.; Li, G.S. Effects of Rare Earth Elements on the Microstructure and Mechanical Properties of NiAl-Based Eutectic Alloy. Intermetallics 2007, 15, 727–733. [Google Scholar] [CrossRef]

- Liang, Y.; Guo, J.; Xie, Y.; Zhou, L.; Hu, Z. High Temperature Compressive Properties and Room Temperature Fracture Toughness of Directionally Solidified NiAl-Based Eutectic Alloy. Mater. Des. 2009, 30, 2181–2185. [Google Scholar] [CrossRef]

- Shang, Z.; Shen, J.; Zhang, J.; Wang, L.; Fu, H. Effect of Withdrawal Rate on the Microstructure of Directionally Solidified NiAl–Cr(Mo) Hypereutectic Alloy. Intermetallics 2012, 22, 99–105. [Google Scholar] [CrossRef]

- Shang, Z.; Shen, J.; Zhang, J.; Wang, L.; Wang, L.; Fu, H. Effect of Microstructures on the Room Temperature Fracture Toughness of NiAl–32Cr–6Mo Hypereutectic Alloy Directionally Solidified at Different Withdrawal Rates. Mater. Sci. Eng. A 2014, 611, 306–312. [Google Scholar] [CrossRef]

- Milenkovic, S.; Schneider, A.; Frommeyer, G. Constitutional and Microstructural Investigation of the Pseudobinary NiAl–W System. Intermetallics 2011, 19, 342–349. [Google Scholar] [CrossRef]

- Barclay, R.S.; Kerr, H.W.; Niessen, P. Off-Eutectic Composite Solidification and Properties in Al-Ni and Al-Co Alloys. J. Mater. Sci. 1971, 6, 1168–1173. [Google Scholar] [CrossRef]

- Shang, Z.; Shen, J.; Wang, L.; Du, Y.; Xiong, Y.; Fu, H. Investigations on the Microstructure and Room Temperature Fracture Toughness of Directionally Solidified NiAl–Cr(Mo) Eutectic Alloy. Intermetallics 2015, 57, 25–33. [Google Scholar] [CrossRef]

- Azarmi, F. Creep Properties of Nickel Aluminide Composite Materials Reinforced with SiC Particulates. Compos. Part. B Eng. 2011, 42, 1779–1785. [Google Scholar] [CrossRef]

- Jha, S.C.; Ray, R.; Gaydosh, D.J. Dispersoids in Rapidly Solidified B2 Nickel Aluminides. Scr. Metall. 1989, 23, 805–810. [Google Scholar] [CrossRef]

- Jha, S.C.; Ray, R.; Whittenberger, J.D. Carbide-Dispersion-Strengthened B2 NiAl. Mater. Sci. Eng. A 1989, 119, 103–111. [Google Scholar] [CrossRef]

- Zhou, L.Z.; Guo, J.T.; Fan, G.J. Synthesis of NiAl–TiC Nanocomposite by Mechanical Alloying Elemental Powders. Mater. Sci. Eng. A 1998, 249, 103–108. [Google Scholar] [CrossRef]

- Krivoroutchko, K.; Kulik, T.; Matyja, H.; Portnoy, V.K.; Fadeeva, V.I. Solid State Reactions in Ni–Al–Ti–C System by Mechanical Alloying. J. Alloys Compd. 2000, 308, 230–236. [Google Scholar] [CrossRef]

- Whittenberger, J.D.; Grahle, P.; Behr, R.; Arzt, E.; Hebsur, M.G. Elevated Temperature Compressive Strength Properties of Oxide Dispersion Strengthened NiAl after Cryomilling and Roasting in Nitrogen. Mater. Sci. Eng. A 2000, 291, 173–185. [Google Scholar] [CrossRef]

- Albiter, A.; Salazar, M.; Bedolla, E.; Drew, R.A.L.; Perez, R. Improvement of the Mechanical Properties in a Nanocrystalline NiAl Intermetallic Alloy with Fe, Ga and Mo Additions. Mater. Sci. Eng. A 2003, 347, 154–164. [Google Scholar] [CrossRef]

- Sheng, L.; Zhang, W.; Guo, J.; Yang, F.; Liang, Y.; Ye, H. Effect of Au Addition on the Microstructure and Mechanical Properties of NiAl Intermetallic Compound. Intermetallics 2010, 18, 740–744. [Google Scholar] [CrossRef]

- Liu, E.; Gao, Y.; Jia, J.; Bai, Y.; Wang, W. Microstructure and Mechanical Properties of in Situ NiAl–Mo2C Nanocomposites Prepared by Hot-Pressing Sintering. Mater. Sci. Eng. A 2014, 592, 201–206. [Google Scholar] [CrossRef]

- Darolia, R.; Dobbs, J.R.; Field, R.D.; Goldman, E.H.; Lahrman, D.F.; Waltson, W.S. NiAl Intermetallic Alloy and Article with Improved High Temperature Strength. U.S. Patent 5,516,380, 14 May 1996. [Google Scholar]

- Chakravorty, S.; Wayman, C.M. The Thermoelastic Martensitic Transformation Inβ′ Ni-Al Alloys: I. Crystallography and Morphology. Met. Trans. A 1976, 7, 555–568. [Google Scholar] [CrossRef]

- Chandrasekaran, M.; Beyer, J.; Delaey, L. Some Questions on the Structure of Martensite and Precursor in Ni(<63at%)-Al Alloys. Scr. Metall. Et Mater. 1992, 27, 1841–1846. [Google Scholar] [CrossRef]

- Hangen, U.D.; Sauthoff, G. The Effect of Martensite Formation on the Mechanical Behaviour of NiAl. Intermetallics 1999, 7, 501–510. [Google Scholar] [CrossRef]

- Kainuma, R.; Ohtani, H.; Ishida, K. Effect of Alloying Elements on Martensitic Transformation in the Binary NiAl(β) Phase Alloys. Met. Mater. Trans. A 1996, 27, 2445–2453. [Google Scholar] [CrossRef]

- Thompson, R.J.; Zhao, J.-C.; Hemker, K.J. Effect of Ternary Elements on a Martensitic Transformation in β-NiAl. Intermetallics 2010, 18, 796–802. [Google Scholar] [CrossRef]

- Ozgen, S.; Adiguzel, O. Molecular Dynamics Simulation of Diffusionless Phase Transformation in a Quenched NiAl Alloy Model. J. Phys. Chem. Solids 2003, 64, 459–464. [Google Scholar] [CrossRef]

- Guo, Y.-F.; Wang, Y.-S.; Wu, W.-P.; Zhao, D.-L. Atomistic Simulation of Martensitic Phase Transformation at the Crack Tip in B2 NiAl. Acta Mater. 2007, 55, 3891–3897. [Google Scholar] [CrossRef]

- Lazarev, N.; Abromeit, C.; Schäublin, R.; Gotthardt, R. Atomic-Scale Simulation of Martensitic Phase Transformations in NiAl. Mater. Sci. Eng. A 2008, 481–482, 205–208. [Google Scholar] [CrossRef]

- Cui, C.Y.; Guo, J.T.; Qi, Y.H.; Ye, H.Q. High Temperature Embrittlement of NiAl Alloy Induced by Hot Isostatic Pressing (HIPing) and Aging. Scr. Mater. 2001, 44, 2437–2441. [Google Scholar] [CrossRef]

- Wang, L.; Shen, J.; Shang, Z.; Fu, H. Microstructure Evolution and Enhancement of Fracture Toughness of NiAl–Cr(Mo)–(Hf,Dy) Alloy with a Small Addition of Fe during Heat Treatment. Scr. Mater. 2014, 89, 1–4. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Jackson, M.R.; Subramanian, P.R.; Zhao, J.-C. A Review of Very-High-Temperature Nb-Silicide-Based Composites. Met. Mater. Trans. A 2003, 34, 2043–2052. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Briant, C.L.; Jackson, M.R.; Subramanian, P.R. Recent Advances in Nb-Silicide in-Situ Composites. In Proceedings of the 15th International Plansee Seminar, Reutte, Austria, 28 May–1 June 2001; Kmeringen, G., Rodhammer, P., Wildner, H., Eds.; Plansee Holding AG: Reutte, Austria, 2001; Volume 1, pp. 404–419. [Google Scholar]

- Frommeyer, G.; Rablbauer, R. High Temperature Materials Based on the Intermetallic Compound NiAl Reinforced by Refractory Metals for Advanced Energy Conversion Technologies. Steel Res. Int. 2008, 79, 507–512. [Google Scholar] [CrossRef]

- Lin Lü, B.; Qing Chen, G.; Qu, S.; Su, H.; Long Zhou, W. Effect of Alloying Elements on Dislocation in NiAl: A First-Principles Study. Phys. B Condens. Matter 2013, 417, 9–12. [Google Scholar] [CrossRef]

- Kawagishi, K.; Yeh, A.; Yokokawa, T.; Kobayashi, T.; Koizumi, Y.; Harada, H. Development of an Oxidation-Resistant High-Strength Sixth-Generation Single-Crystal Superalloy TMS-238. In Superalloys 2012; Huron, E.S., Reed, R.C., Hardy, M.C., Mills, M.J., Montero, R.E., Portella, P.D., Telesman, J., Eds.; Wiley: Hoboken, NJ, USA, 2012; pp. 189–195. ISBN 978-0-470-94320-5. [Google Scholar]

- Yuan, Y.; Kawagishi, K.; Koizumi, Y.; Kobayashi, T.; Yokokawa, T.; Harada, H. Creep Deformation of a Sixth Generation Ni-Base Single Crystal Superalloy at 800 °C. Mater. Sci. Eng. A 2014, 608, 95–100. [Google Scholar] [CrossRef]

- Carter, T.J. Common Failures in Gas Turbine Blades. Eng. Fail. Anal. 2005, 12, 237–247. [Google Scholar] [CrossRef]

- Xu, R.; Geng, Z.; Wu, Y.; Chen, C.; Ni, M.; Li, D.; Zhang, T.; Huang, H.; Liu, F.; Li, R.; et al. Microstructure and Mechanical Properties of In-Situ Oxide-Dispersion-Strengthened NiCrFeY Alloy Produced by Laser Powder Bed Fusion. Adv. Powder Mater. 2022, 1, 100056. [Google Scholar] [CrossRef]

- TWI Global. What Is an Oxide Dispersion Strengthened (ODS) Alloy? TWI Global: Cambridge, UK, 2025; Available online: https://www.twi-global.com/technical-knowledge/faqs/faq-what-is-an-oxide-dispersion-strengthened-ods-alloy (accessed on 16 May 2025).

- TWI Global. What Are the Common Properties of Oxide Dispersion Strengthened (ODS) Alloys? 2025. Available online: https://www.twi-global.com/technical-knowledge/faqs/faq-what-are-the-common-properties-of-oxide-dispersion-strengthened-ods-alloys (accessed on 16 May 2025).

- Pasebani, S.; Dutt, A.K.; Burns, J.; Charit, I.; Mishra, R.S. Oxide Dispersion Strengthened Nickel Based Alloys via Spark Plasma Sintering. Mater. Sci. Eng. A 2015, 630, 155–169. [Google Scholar] [CrossRef]

- Yalcin, M.Y.; Derin, B.; Aydogan, E. Development and Additive Manufacturing of Oxide Dispersion Strengthened Inconel 718: Thermochemical and Experimental Studies. J. Alloys Compd. 2022, 914, 165193. [Google Scholar] [CrossRef]

- Avery, R.E.; Tuthill, A.H. Guidelines for the Welded Fabrication of Nickel Alloys for Corrosion Resistant Service; Book Series; no. 11 012; Nickel Development Institute: Toronto, ON, Canada, 1994. [Google Scholar]

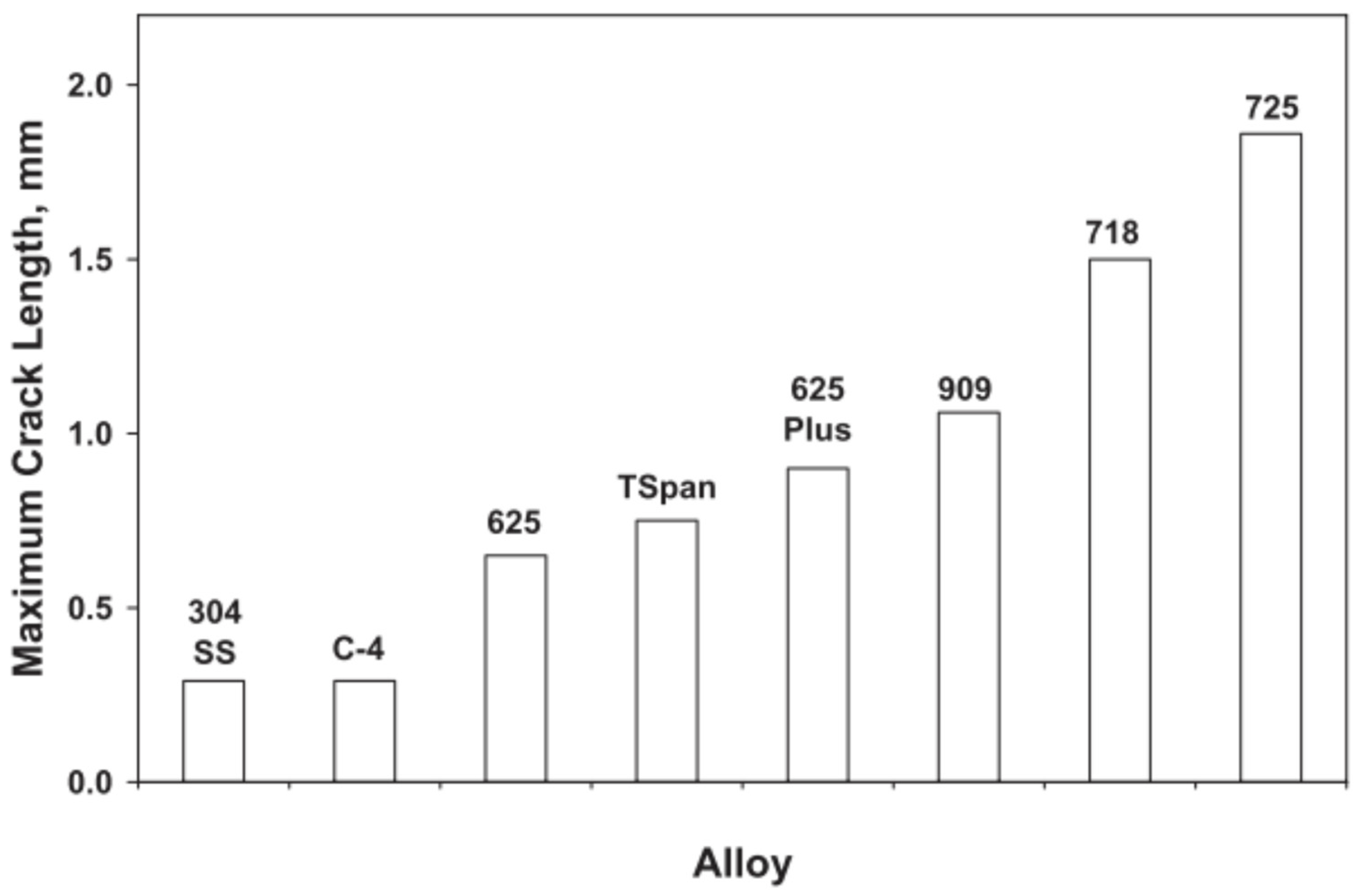

- Xia, C.; Kou, S. Evaluating Susceptibility of Ni-Base Alloys to Solidification Cracking by Transverse-Motion Weldability Test. Sci. Technol. Weld. Join. 2020, 25, 690–697. [Google Scholar] [CrossRef]

- Choudhury, B.; Chandrasekaran, M. Investigation on Welding Characteristics of Aerospace Materials—A Review. Mater. Today: Proc. 2017, 4, 7519–7526. [Google Scholar] [CrossRef]

- INFITALAB. 5 Types Of Welding Tests for Quality Assurance. 2025. Available online: https://infinitalab.com/welding/5-types-of-welding-tests-for-quality-assurance/ (accessed on 16 May 2025).

- Applied Technical Services Lab. Welding Testing. Destructive Weld Testing. 2025. Available online: https://atslab.com/testing-and-analysis/welding-testing/destructive-weld-testing/ (accessed on 16 May 2025).

- Body & Paint Center Inc. Destructive Weld Testing Explained. 2025. Available online: https://bodyandpaintcenter.com/destructive-weld-testing-explained/ (accessed on 16 May 2025).

- Tulsa Welding School. Tensile Strength Testing in Welding; Tulsa Welding School: Tulsa, OK, USA, 2025; Available online: https://www.tws.edu/blog/welding/tensile-strength-testing-in-welding/ (accessed on 16 May 2025).

- Inspection for Industry LLC. What Is Weld Destructive Testing? 2025. Available online: https://www.inspection-for-industry.com/weld-destructive-testing.html (accessed on 16 May 2025).

- NextGen Material. Testing Top 10 Most Common ASTM Standards for Metal Testing. 2024. Available online: https://www.nextgentest.com/blog/top-10-most-common-astm-standards-for-metal-testing/ (accessed on 16 May 2025).

- D3.6M:2017; Underwater Welding Code. American Welding Society: Doral, FL, USA, 2017. Available online: https://www.slideshare.net/slideshow/aws-d36-m-2017/250421738 (accessed on 16 May 2025).

- Red River. What Are the Grades of Pressure Vessel Material? Red River: Chantilly, VA, USA, 2025; Available online: https://www.redriver.team/what-are-the-grades-of-pressure-vessel-material/ (accessed on 16 May 2025).

- MechTest. Mechanical Testing: Everything You Need to Know. 2025. Available online: https://mechtest.com.au/information/mechanical-testing-everything-you-need-to-know (accessed on 16 May 2025).

- Tijs, B.H.A.H.; Turon, A.; Bisagni, C. Characterization and Analysis of Conduction Welded Thermoplastic Composite Joints Considering the Influence of Manufacturing. Compos. Struct. 2024, 348, 118505. [Google Scholar] [CrossRef]

- Biodpi Bend. Testing: Evaluation of Strength and Ductility of Materials. 2025. Available online: https://biopdi.com/bend-testing/ (accessed on 16 May 2025).

- Dascau, H. Destructive Testing of Welded Joints—Overview of Standard Requirements and Most Common Errors. 2025. Available online: https://www.google.com/url?sa=i&url=https%3A%2F%2Fproject-trust.eu%2Fimg%2Fdocuments%2Fpublic-articles%2FTRUST%2520-%2520Public%2520Article_ISIM.pdf&psig=AOvVaw1Qd0JO4QnJIXt44IssCJY1&ust=1749284187609000&source=images&cd=vfe&opi=89978449&ved=0CAQQn5wMahcKEwjAsv7FrdyNAxUAAAAAHQAAAAAQBA (accessed on 16 May 2025).

- Kubik, K. Destructive Testing of Welded Joints—Overview of Standard Requirements and Most Common Errors. 2025. Available online: https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=https://project-trust.eu/img/documents/public-articles/TRUST%2520-%2520Public%2520Article_Lukasiewicz_Instytut.pdf&ved=2ahUKEwiG35_AsNyNAxVjA9sEHYBfJu4QFnoECBgQAQ&usg=AOvVaw3BMJPHGKFg3eGw7u8D9Ics (accessed on 16 May 2025).

- WERMAC. ASTM—Nondestructive Testing Standards. 2025. Available online: https://www.wermac.org/societies/astm_ndt_std_part1.html (accessed on 16 May 2025).

- ASTM. ASTM Nondestructive Testing Standards. 2025. Available online: https://www.scribd.com/document/381202794/ASTM-Nondestructive-Testing-Standards-pdf (accessed on 16 May 2025).

- One Stop NTD. Standards and Specifications for Welding. 2021. Available online: https://www.onestopndt.com/ndt-articles/standards-and-specifications-for-welding (accessed on 16 May 2025).

- Rzeszow University of Technology. Non-Destructive Testing (NDT) Laboratory; Rzeszow University of Technology: Rzeszów, Poland, 2025; Available online: https://kois.prz.edu.pl/en/laboratories/non-destructive-testing-ndt-laboratory (accessed on 16 May 2025).

- ANSI. Non-Destructive Weld Testing Standards. 2025. Available online: https://webstore.ansi.org/industry/safety-standards/welding-safety/non-destructive-weld-testing (accessed on 16 May 2025).

- One Stop NDT. What Are NDT Standards for Welding? 2025. Available online: https://www.onestopndt.com/ndt-faq/what-are-ndt-standards-for-welding (accessed on 16 May 2025).

- Hinshaw, E.B. Welding of Nickel Alloys. In Welding, Brazing, and Soldering; Olson, D.L., Siewert, T.A., Liu, S., Edwards, G.R., Eds.; ASM International: Almere, The Netherlands, 1993; pp. 740–751. ISBN 978-1-62708-173-3. [Google Scholar]

- American Welding Society Welding Handbook. Volume 5 Part 2: Materials and Applications, 9th ed.; O’Brien, A., Ed.; American Welding Society: Miami, FL, USA, 2015; ISBN 978-0-87171-856-3. [Google Scholar]

- Janaki Ram, G.D.; Venugopal Reddy, A.; Prasad Rao, K.; Madhusudhan Reddy, G. Control of Laves Phase in Inconel 718 GTA Welds with Current Pulsing. Sci. Technol. Weld. Join. 2004, 9, 390–398. [Google Scholar] [CrossRef]

- Kumar, S.A.; Sathiya, P. Experimental Investigation of the A-TIG Welding Process of Incoloy 800H. Mater. Manuf. Process. 2015, 30, 1154–1159. [Google Scholar] [CrossRef]

- Sivakumar, J.; Vasudevan, M.; Korra, N.N. Effect of Activated Flux Tungsten Inert Gas (A-TIG) Welding on the Mechanical Properties and the Metallurgical and Corrosion Assessment of Inconel 625. Weld. World 2021, 65, 1061–1077. [Google Scholar] [CrossRef]

- Sonar, T.; Balasubramanian, V.; Malarvizhi, S.; Venkateswaran, T.; Sivakumar, D. Effect of Heat Input on Evolution of Microstructure and Tensile Properties of Gas Tungsten Constricted Arc (GTCA) Welded Inconel 718 Alloy Sheets. Metallogr. Microstruct. Anal. 2020, 9, 369–392. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Kumar, B.M.; Krishnan, M.G.; Dev, S.; Bhalodi, A.J.; Arivazhagan, N.; Narayanan, S. Studies on the Weldability, Microstructure and Mechanical Properties of Activated Flux TIG Weldments of Inconel 718. Mater. Sci. Eng. A 2015, 639, 234–244. [Google Scholar] [CrossRef]

- Hanif, M.; Shah, A.H.; Shah, I.; Mumtaz, J. Optimization of Bead Geometry during Tungsten Inert Gas Welding Using Grey Relational and Finite Element Analysis. Materials 2023, 16, 3732. [Google Scholar] [CrossRef]

- Davila-Iniesta, E.M.; López-Islas, J.A.; Villuendas-Rey, Y.; Camacho-Nieto, O. Automatic Segmentation of Gas Metal Arc Welding for Cleaner Productions. Appl. Sci. 2025, 15, 3280. [Google Scholar] [CrossRef]

- Ferro, P.; Zambon, A.; Bonollo, F. Investigation of Electron-Beam Welding in Wrought Inconel 706—Experimental and Numerical Analysis. Mater. Sci. Eng. A 2005, 392, 94–105. [Google Scholar] [CrossRef]

- Janaki Ram, G.D.; Venugopal Reddy, A.; Prasad Rao, K.; Reddy, G.M.; Sarin Sundar, J.K. Microstructure and Tensile Properties of Inconel 718 Pulsed Nd-YAG Laser Welds. J. Mater. Process. Technol. 2005, 167, 73–82. [Google Scholar] [CrossRef]

- Sidharth, D.; KV, P.P. Microstructure and Properties of Inconel 718 and AISI 416 Laser Welded Joints. J. Mater. Process. Technol. 2019, 266, 52–62. [Google Scholar] [CrossRef]

- Sun, J.; Ren, W.; Nie, P.; Huang, J.; Zhang, K.; Li, Z. Study on the Weldability, Microstructure and Mechanical Properties of Thick Inconel 617 Plate Using Narrow Gap Laser Welding Method. Mater. Des. 2019, 175, 107823. [Google Scholar] [CrossRef]

- Brien, A.O.; Guzman, C. Welding Handbook, Welding Processes, Part 2, 9th ed.; American Welding Society: Miami, FL, USA, 2014. [Google Scholar]

- Damodaram, R.; Raman, S.G.S.; Rao, K.P. Microstructure and Mechanical Properties of Friction Welded Alloy 718. Mater. Sci. Eng. A 2013, 560, 781–786. [Google Scholar] [CrossRef]

- Lemos, G.V.B.; Hanke, S.; Dos Santos, J.F.; Bergmann, L.; Reguly, A.; Strohaecker, T.R. Progress in Friction Stir Welding of Ni Alloys. Sci. Technol. Weld. Join. 2017, 22, 643–657. [Google Scholar] [CrossRef]

- Lemos, G.V.B.; Meinhardt, C.P.; Dias, A.R.D.P.; Reguly, A. Friction Stir Welding in Corrosion Resistant Alloys. Sci. Technol. Weld. Join. 2021, 26, 227–235. [Google Scholar] [CrossRef]

- Cabibbo, M.; Forcellese, A.; Santecchia, E.; Paoletti, C.; Spigarelli, S.; Simoncini, M. New Approaches to Friction Stir Welding of Aluminum Light-Alloys. Metals 2020, 10, 233. [Google Scholar] [CrossRef]

- Smith, C.; Grant, G. Integrated Process Improvement Using Laser Processing and Friction Stir Processing for Nickel Alloys Used in Fossil Energy Power Plant Applications. 2023. Available online: https://netl.doe.gov/sites/default/files/netl-file/23FECM_19_Smith.pdf (accessed on 16 May 2025).

- Sharma, A.; Miura, T.; Morisada, Y.; Ushioda, K.; Singh, S.; Fujii, H. Friction Stir Welding of Haynes 282 Ni Superalloy by Using a Novel Hemispherical Tool. Sci. Rep. 2024, 14, 27826. [Google Scholar] [CrossRef]

- Lippold, J.C.; Rodelas, J.M.; Rule, J.R. Friction Stir Processing of Ni-Base Alloys. In Proceedings of the 1st International Joint Symposium on Joining and Welding; Elsevier: Amsterdam, The Netherlands, 2013; pp. 369–376, ISBN 978-1-78242-163-4. [Google Scholar]

- Sonar, T.; Balasubramanian, V.; Malarvizhi, S.; Venkateswaran, T.; Sivakumar, D. Multi-Response Mathematical Modelling, Optimization and Prediction of Weld Bead Geometry in Gas Tungsten Constricted Arc Welding (GTCAW) of Inconel 718 Alloy Sheets for Aero-Engine Components. Multiscale Multidiscip. Model. Exp. Des. 2020, 3, 201–226. [Google Scholar] [CrossRef]

- Sabhadiya, J. 10 Types of Welding Explained: MIG, TIG, SMAW & More. 2025. Available online: https://www.mechdaily.com/types-of-welding (accessed on 16 May 2025).

- Chinoy, N. Increasing Weld Speeds in GTAW. 2019. Available online: https://b2bpurchase.com/increasing-weld-speeds-in-gtaw/#:~:text=G%20as%20Tungsten%20Arc%20Welding%20 (accessed on 16 May 2025).

- Mohamed, A.M.; Moatasem, M.K. Effects of Welding Parameters on Characterization and Mechanical Properties of Steel 37 Weldments. J. Eng. Sci. Assiut Univ. Fac. Eng. 2020, 48, 212–221. [Google Scholar]