Machine Learning-Based Prediction of Time Required to Reach the Melting Temperature of Metals in Domestic Microwaves Using Dimensionless Modeling and XGBoost

Abstract

1. Introduction

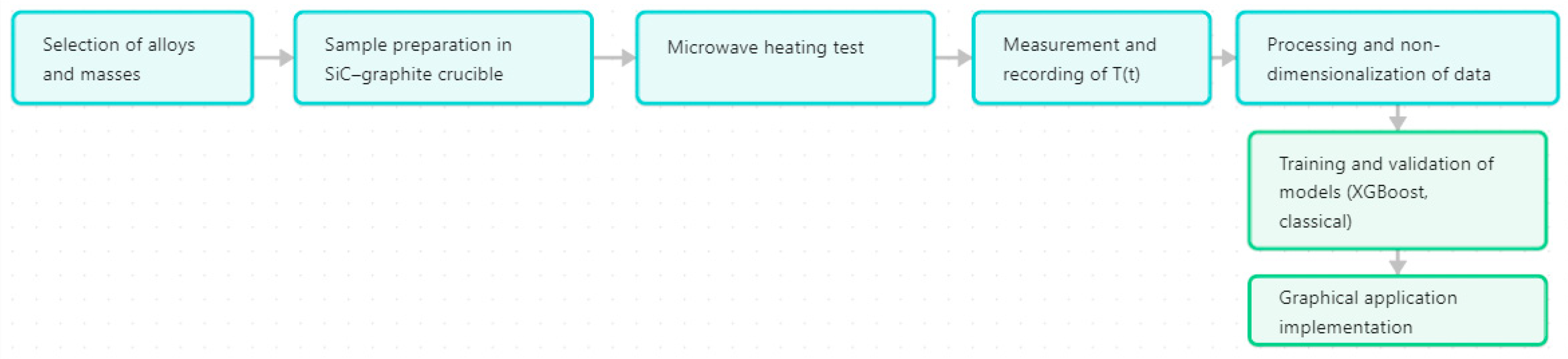

2. Materials

2.1. Heating System Configuration

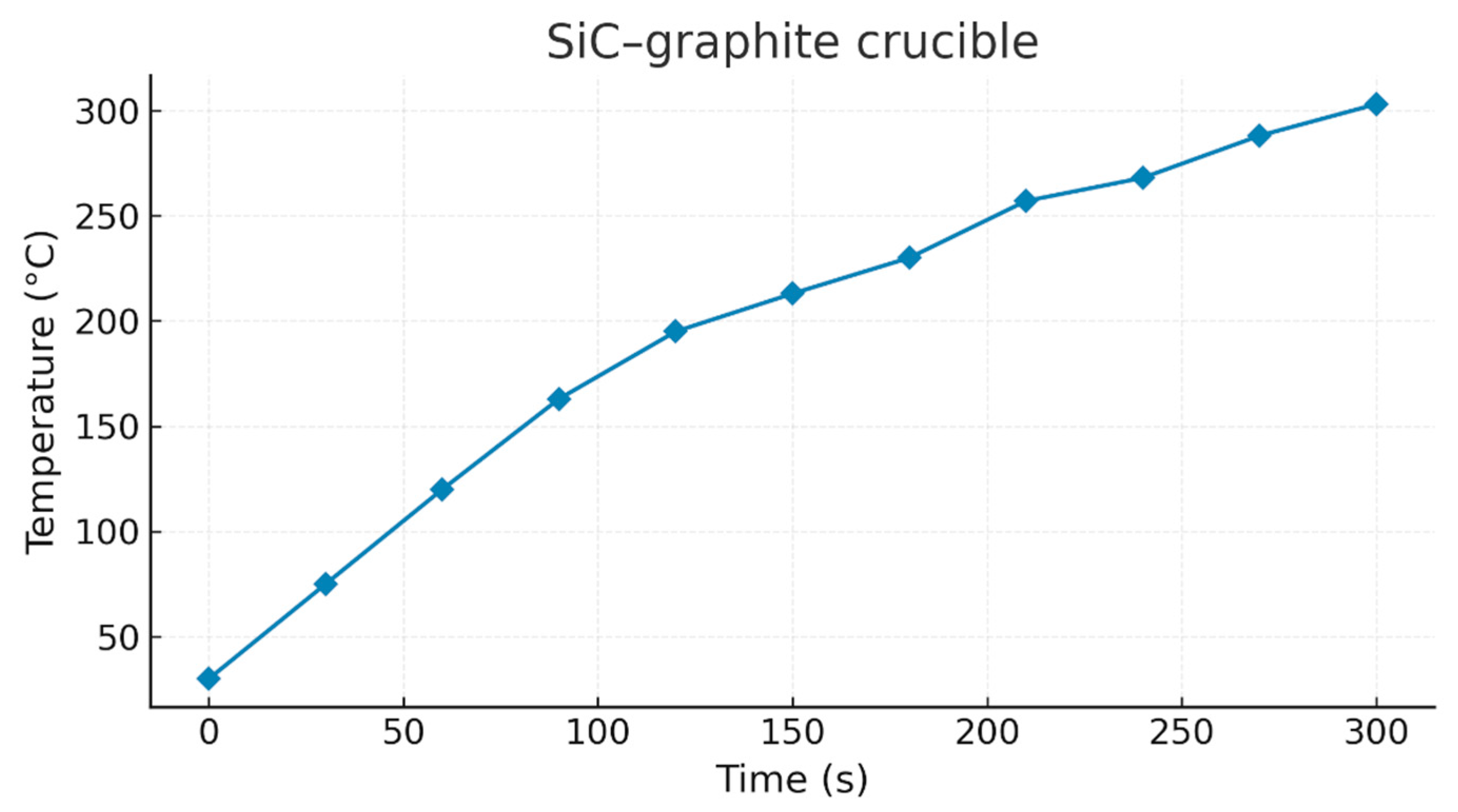

2.2. Selection and Validation of the Susceptor Crucible

2.3. Materials Used and Experimental Conditions

2.4. Justification for Extending the Model to Different Microwave Powers

3. Results

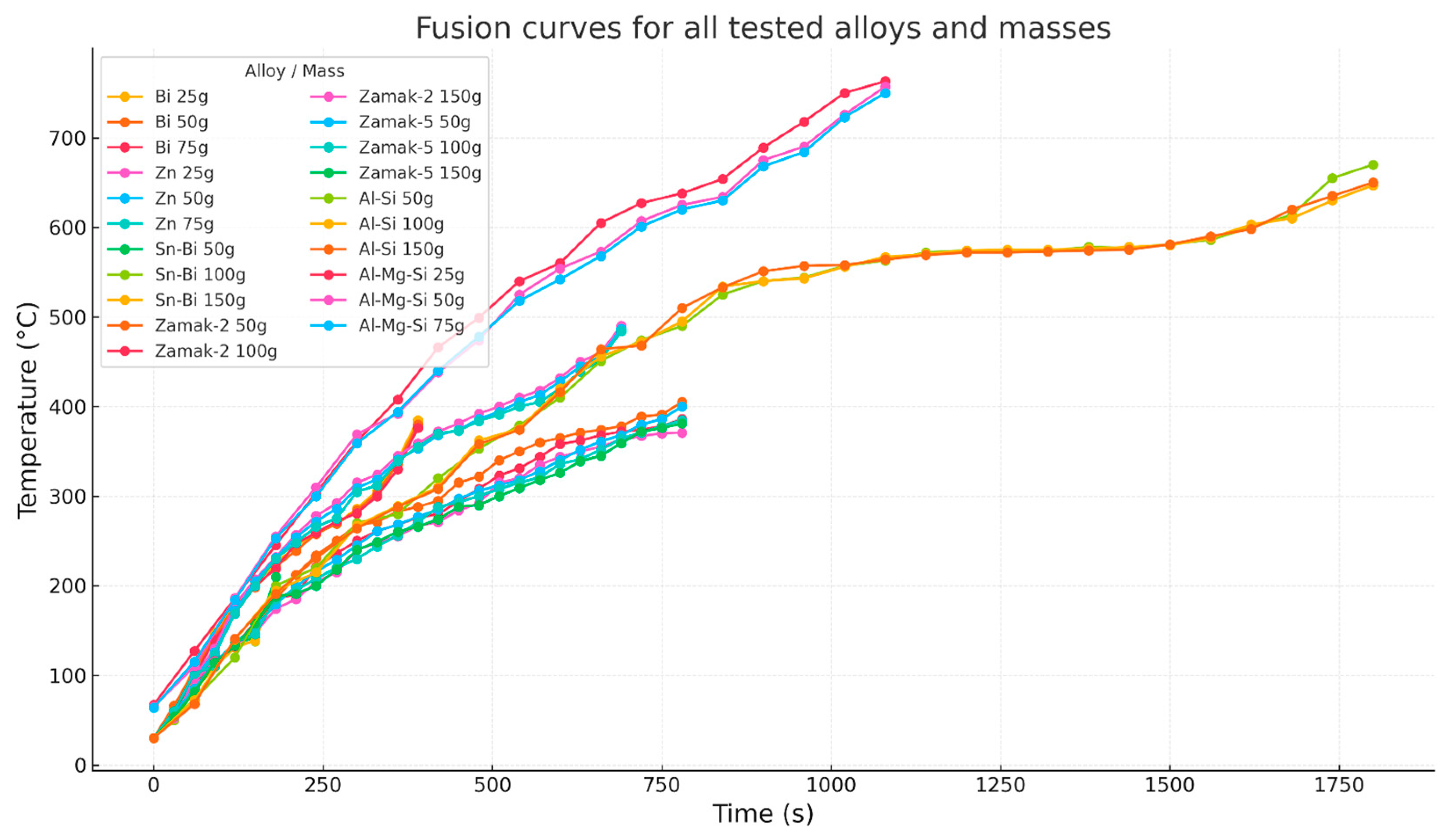

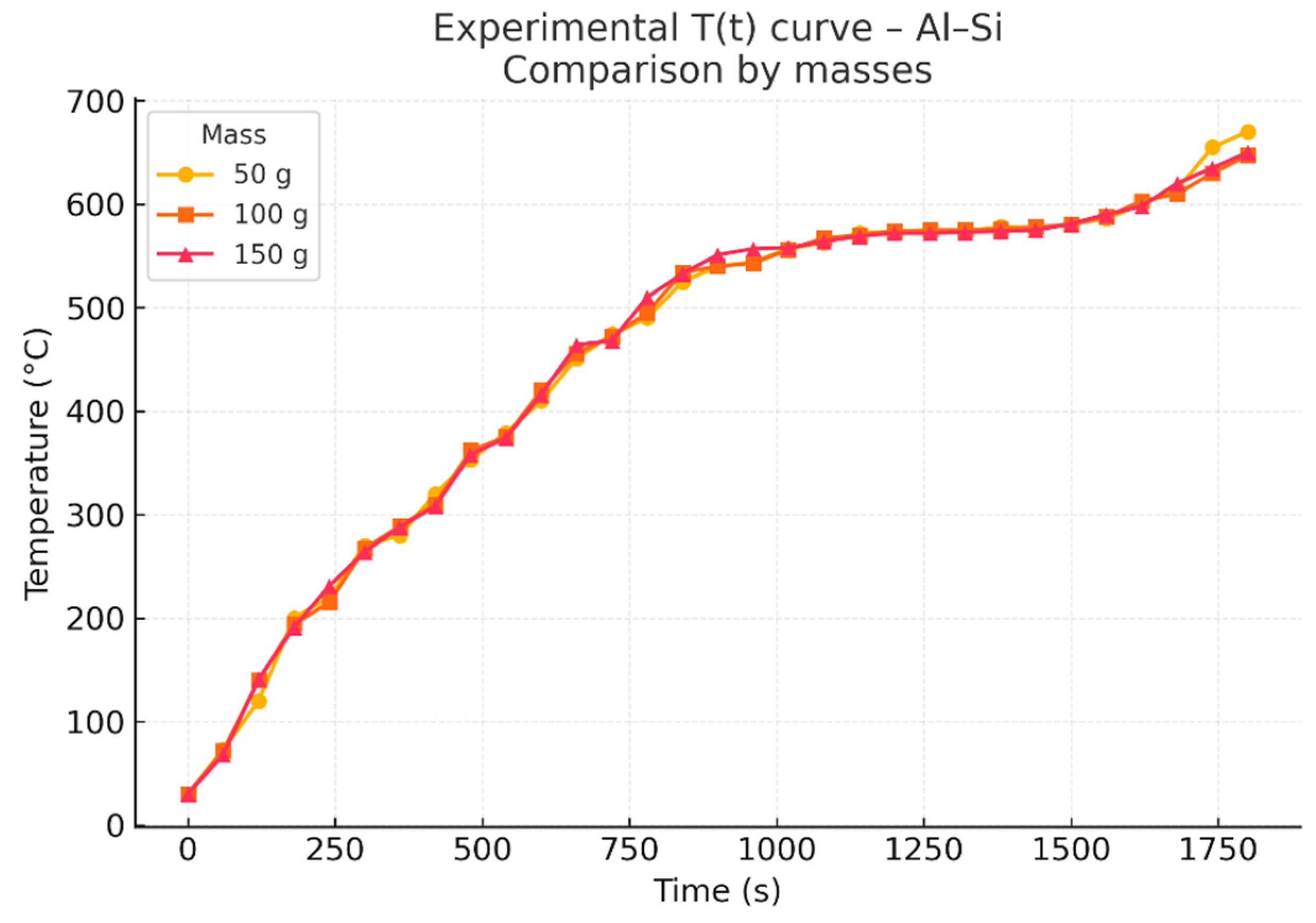

3.1. Experimental Procedure and Data Acquisition

3.2. Processing and Non-Dimensionalization of Thermal Data

3.3. Preprocessing and Validation of the Dataset

3.4. Experimental and Predictive Modeling Pipeline

3.5. Crucible Selection Method

3.6. Results and Discussion of the Predictive Model

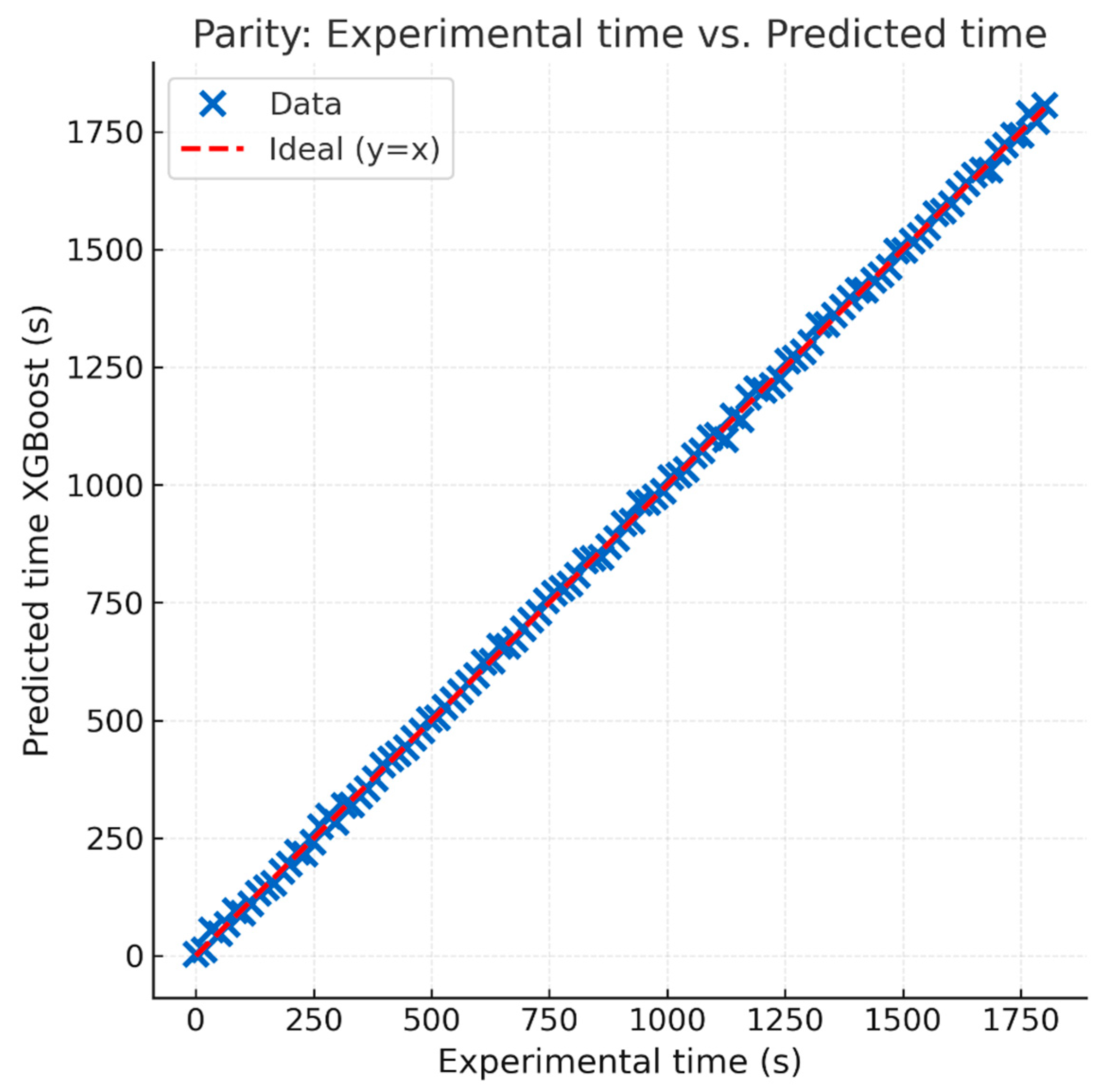

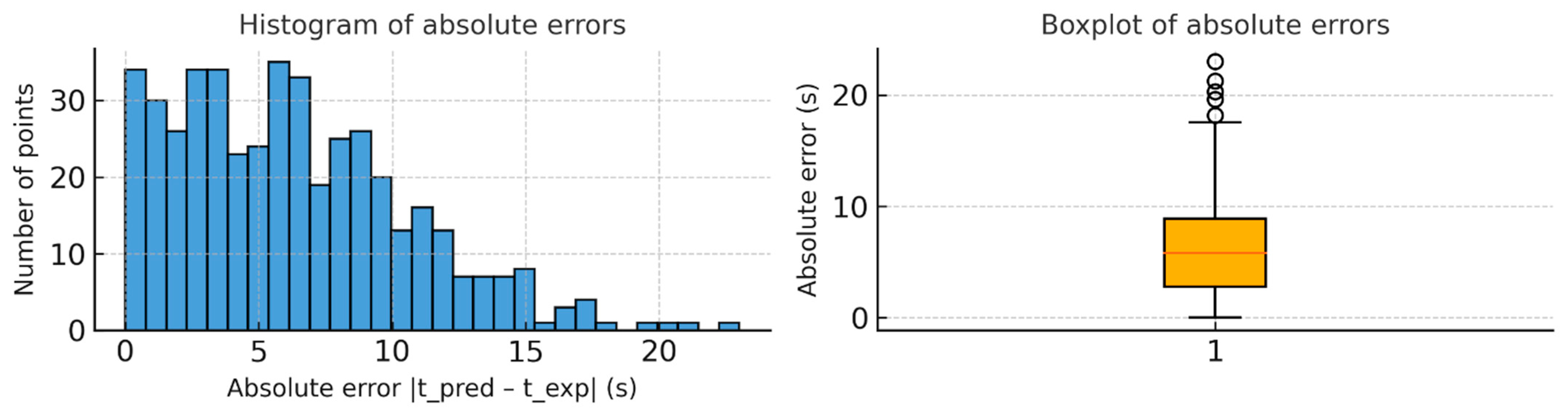

- Mean Absolute Error (MAE): 4.8 s;

- Root Mean Squared Error (RMSE): 6.1 s;

- Coefficient of Determination (R2): 0.9996;

- Mean Relative Error: 1.6%.

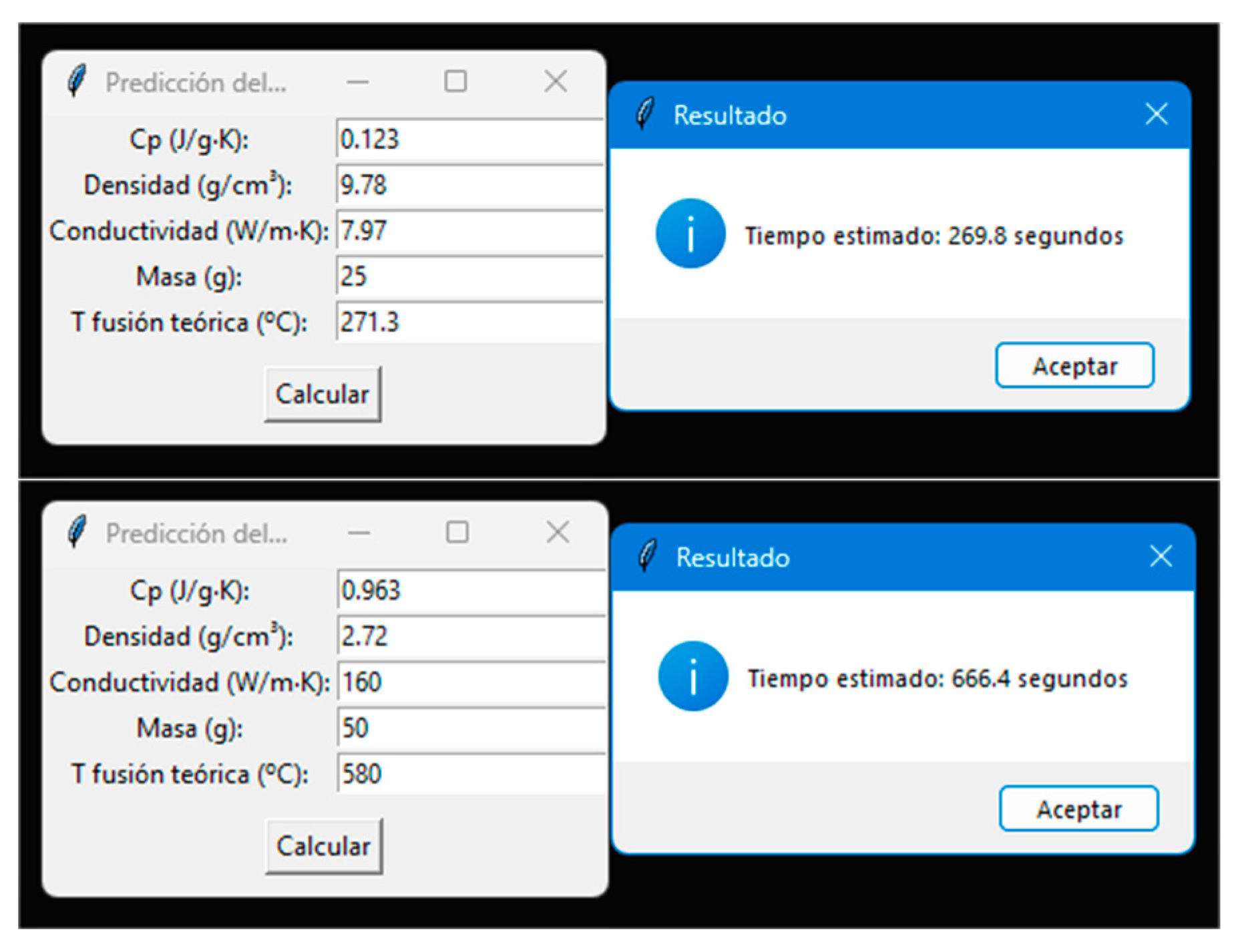

3.7. Interactive Application and Technology Transfer

4. Discussion

5. Conclusions

- This study demonstrates, with experimental and predictive rigor, that it is possible to reach the melting temperature of industrial metals and low-melting-point alloys (<700 °C) in a domestic 700 W microwave oven, using a hybrid silicon carbide and graphite crucible as a thermal susceptor. This methodology eliminates the need for industrial equipment and democratizes access to thermal testing in experimental metallurgy. It is important to note that the model predicts the time to reach the theoretical melting temperature, not the total time required for complete melting.

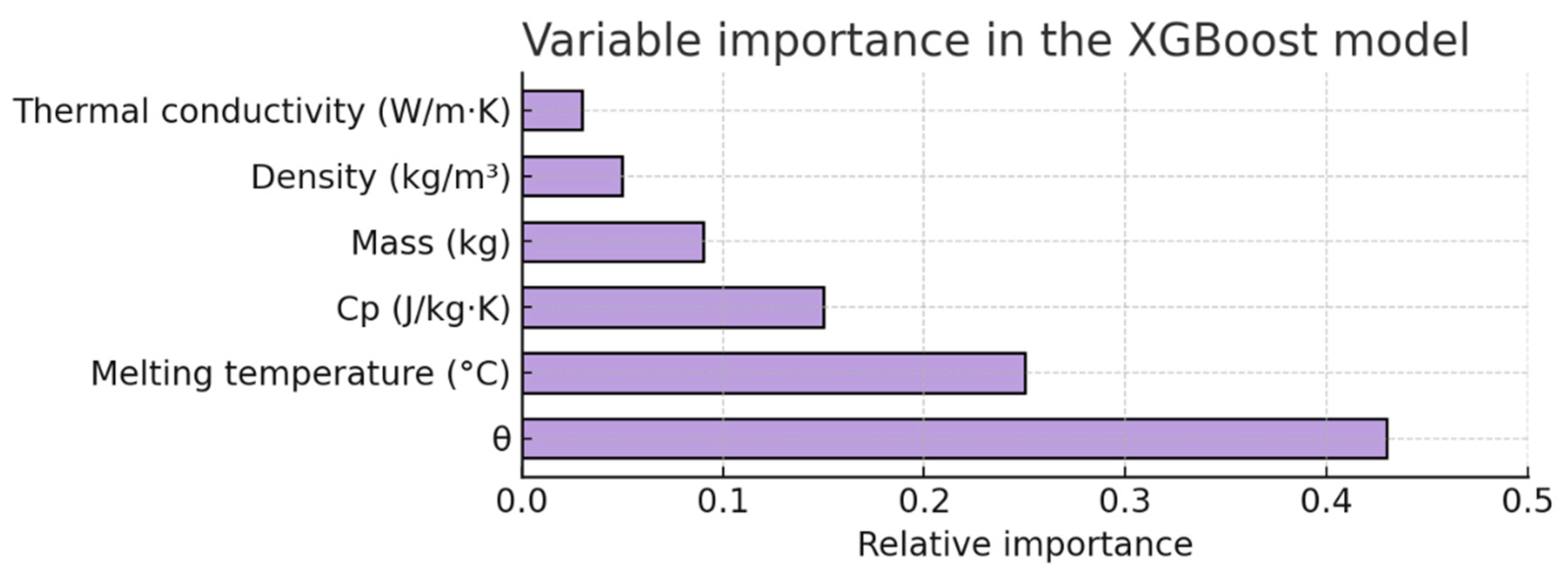

- The proposed dimensionless model, based on the variables θ (normalized temperature) and τ (relative time), enables a generalizable prediction of the heating process up to the melting temperature, within the range of tested alloys and masses, as long as basic thermal properties are available (Cp, λ, Tf, ρ, m).

- The XGBoost algorithm, trained on the dimensionless model, delivered excellent performance, with a mean relative error below 1.6% (MAE ≈ 4.8 s, RMSE ≈ 6.1 s, R2 = 0.9996), validated on more than 250 experimental records. This result positions the model as a robust, reproducible, and open-access tool for thermal prediction in metallurgy.

- An operational Python script (tpredicho.py) with a graphical interface was developed, allowing any user—without programming or machine learning knowledge—to estimate the time required to reach the melting temperature of their sample, customizing parameters in real time. This strengthens the educational and technology transfer potential of the system.

- The analytical extrapolation of the model to other powers (600–1100 W) was experimentally validated, maintaining its predictive reliability under comparable experimental conditions (geometry, mass, crucible). This versatility broadens the applicability of the system to different domestic and academic environments.

- Overall, this work represents a significant advance in the thermal modeling of metals using machine learning and lays the foundations for a new low-cost paradigm for accessible metallurgical experimentation, aligned with the principles of open science, reproducible teaching, and energy sustainability. Future developments could extend the model to materials with higher melting points and optimize the prediction for different geometries and susceptors, thus contributing to the consolidation of the materials informatics approach in metallurgy.

- The scope of the model is currently limited to low-melting-point metals and alloys (<700 °C), as used in the experimental validation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Clark, D.E.; Folz, D.C.; West, J.K. Processing materials with microwave energy. Mater. Sci. Eng. A 2000, 287, 153–158. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.W. Microwave processing: Fundamentals and applications. Compos. Part A Appl. Sci. Manuf. 1999, 30, 1055–1071. [Google Scholar] [CrossRef]

- Roy, R.; Agrawal, D.; Cheng, J.; Gedevanishvili, S. Full sintering of powdered-metal bodies in a microwave field. Nature 1999, 399, 668–670. [Google Scholar] [CrossRef]

- Metaxas, A.C.; Meredith, R.J. Industrial Microwave Heating; Peter Peregrinus Ltd.: London, UK, 1983. [Google Scholar]

- Chen, T.; Guestrin, C. XGBoost: A scalable tree boosting system. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar] [CrossRef]

- Oghbaei, M.; Mirzaee, O. Microwave versus conventional sintering: A review of fundamentals, advantages and applications. J. Alloys Compd. 2010, 494, 175–189. [Google Scholar] [CrossRef]

- Sutton, W.H. Microwave processing of ceramics: An overview. MRS Proc. 1992, 269, 3–20. [Google Scholar] [CrossRef]

- Zhang, Y.; Haghani, A. A gradient boosting method to improve travel time prediction. Transp. Res. Part. C Emerg. Technol. 2015, 58, 308–324. [Google Scholar] [CrossRef]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Butler, K.T.; Davies, D.W.; Cartwright, H.; Isayev, O.; Walsh, A. Machine learning for molecular and materials science. Nature 2018, 559, 547–555. [Google Scholar] [CrossRef] [PubMed]

- Ward, L.; Agrawal, A.; Choudhary, A.; Wolverton, C. A general-purpose machine learning framework for predicting properties of inorganic materials. npj Comput. Mater. 2016, 2, 16028. [Google Scholar] [CrossRef]

- Ramprasad, R.; Batra, R.; Pilania, G.; Mannodi-Kanakkithodi, A.; Kim, C. Machine learning in materials informatics: Recent applications and prospects. npj Comput. Mater. 2017, 3, 54. [Google Scholar] [CrossRef]

- Agrawal, A.; Choudhary, A. Perspective: Materials informatics and big data: Realization of the “fourth paradigm” of science in materials science. APL Mater. 2016, 4, 053208. [Google Scholar] [CrossRef]

| Alloy | Cp (J/g·K) | Melting T (°C) | Density (g/cm3) | λ (W/m·K) | m1 (g) | m2 (g) |

|---|---|---|---|---|---|---|

| Bi | 0.123 | 271.3 | 9.78 | 7.97 | 25 | 50 |

| Zn | 0.388 | 419.5 | 7.13 | 116 | 25 | 50 |

| Sn–Bi (57%Bi) | 0.167 | 138 | 8.6 | 18 | 50 | 100 |

| Zamak-2 | 0.419 | 384.5 | 6.7 | 113 | 50 | 100 |

| Zamak-5 | 0.419 | 383 | 6.8 | 109 | 50 | 100 |

| Al–Si (11.7% Si) | 0.963 | 578 | 2.68 | 140 | 50 | 100 |

| Al–Mg–Si (6000) | 0.963 | 580 | 2.72 | 160 | 50 | 100 |

| Statistic | Absolute Error (s) | Relative Error (%) |

|---|---|---|

| count | 447 | 426 |

| mean | 4.8 | 1.57 |

| std | 6.1 | 1.78 |

| min | 0.0 | 0.0003 |

| 25% | 1.3 | 0.39 |

| 50% | 3.2 | 0.98 |

| 75% | 6.0 | 2.11 |

| max | 66.8 | 12.8 |

| Hyperparameter | Value | Description |

|---|---|---|

| learning_rate | 0.1 | Step size shrinkage |

| n_estimators | 100 | Number of boosting rounds (trees) |

| max_depth | 4 | Maximum depth of individual trees |

| subsample | 0.8 | Fraction of training data used per tree |

| colsample_bytree | 0.8 | Fraction of features used per tree |

| reg_alpha | 0 | L1 regularization term |

| reg_lambda | 1 | L2 regularization term |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreno Labella, J.J.; González Fernández de Castro, M.; Saiz Sevilla, V.; Panizo Laiz, M.; Martín Álvarez, Y. Machine Learning-Based Prediction of Time Required to Reach the Melting Temperature of Metals in Domestic Microwaves Using Dimensionless Modeling and XGBoost. Materials 2025, 18, 3400. https://doi.org/10.3390/ma18143400

Moreno Labella JJ, González Fernández de Castro M, Saiz Sevilla V, Panizo Laiz M, Martín Álvarez Y. Machine Learning-Based Prediction of Time Required to Reach the Melting Temperature of Metals in Domestic Microwaves Using Dimensionless Modeling and XGBoost. Materials. 2025; 18(14):3400. https://doi.org/10.3390/ma18143400

Chicago/Turabian StyleMoreno Labella, Juan José, Milagrosa González Fernández de Castro, Víctor Saiz Sevilla, Miguel Panizo Laiz, and Yolanda Martín Álvarez. 2025. "Machine Learning-Based Prediction of Time Required to Reach the Melting Temperature of Metals in Domestic Microwaves Using Dimensionless Modeling and XGBoost" Materials 18, no. 14: 3400. https://doi.org/10.3390/ma18143400

APA StyleMoreno Labella, J. J., González Fernández de Castro, M., Saiz Sevilla, V., Panizo Laiz, M., & Martín Álvarez, Y. (2025). Machine Learning-Based Prediction of Time Required to Reach the Melting Temperature of Metals in Domestic Microwaves Using Dimensionless Modeling and XGBoost. Materials, 18(14), 3400. https://doi.org/10.3390/ma18143400