Femtosecond Laser Irradiation Induced Heterojunctions Between Graphene Oxide and Silver Nanowires

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

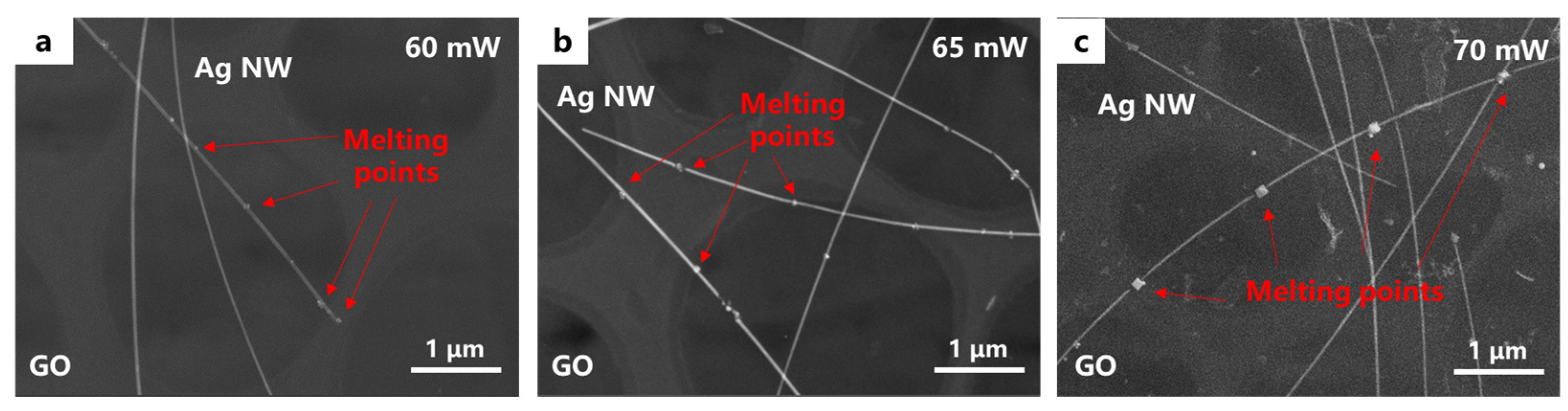

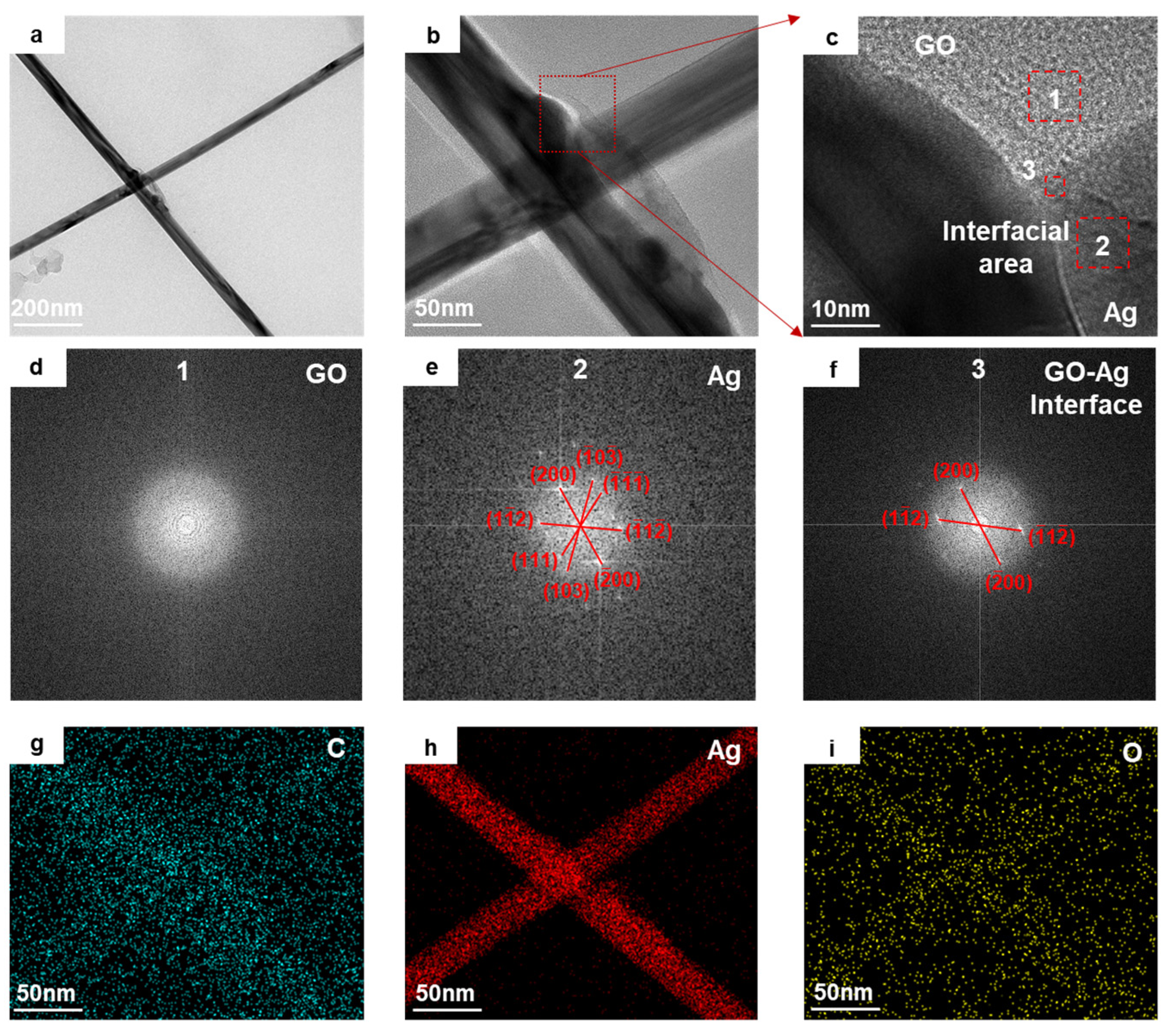

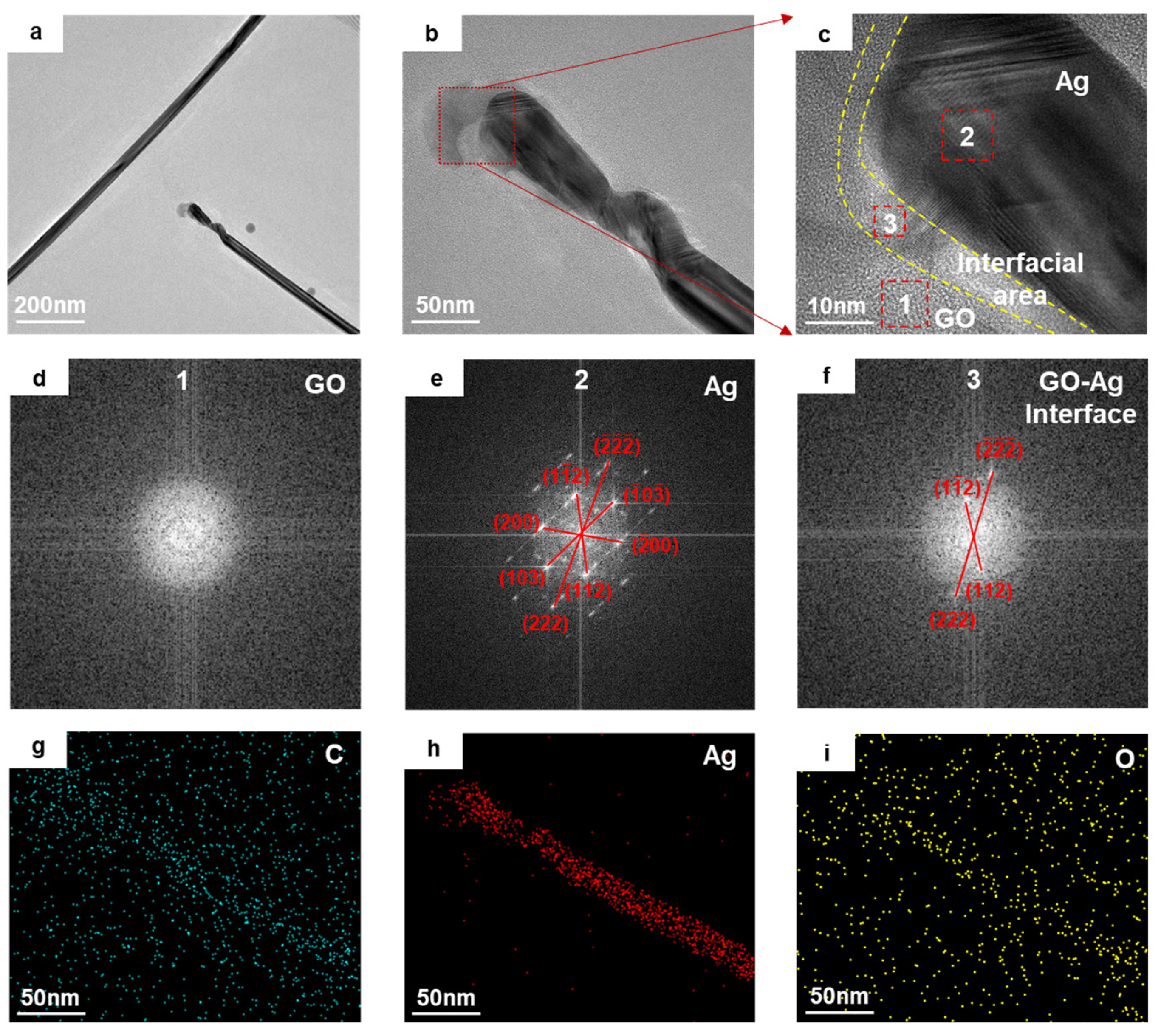

3.1. Characterization of Heterojunctions Between Ag NW-GO

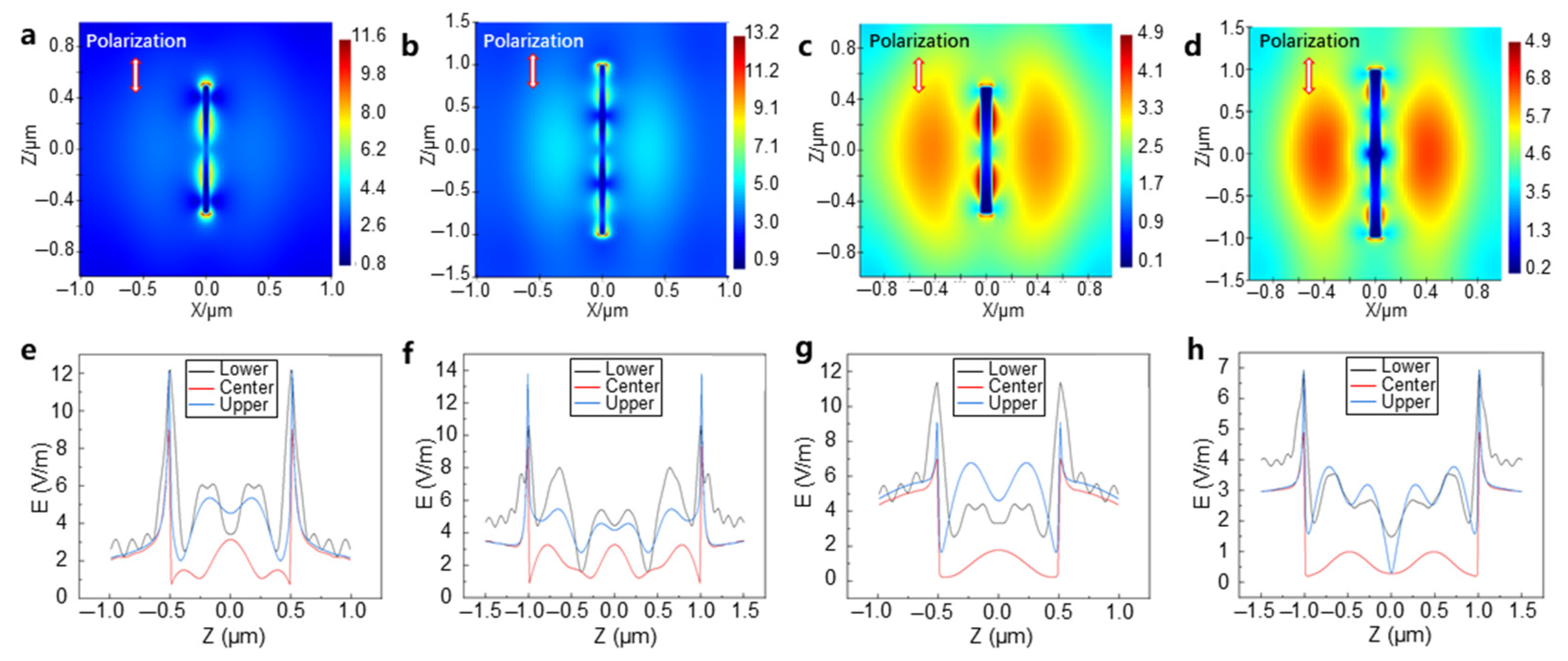

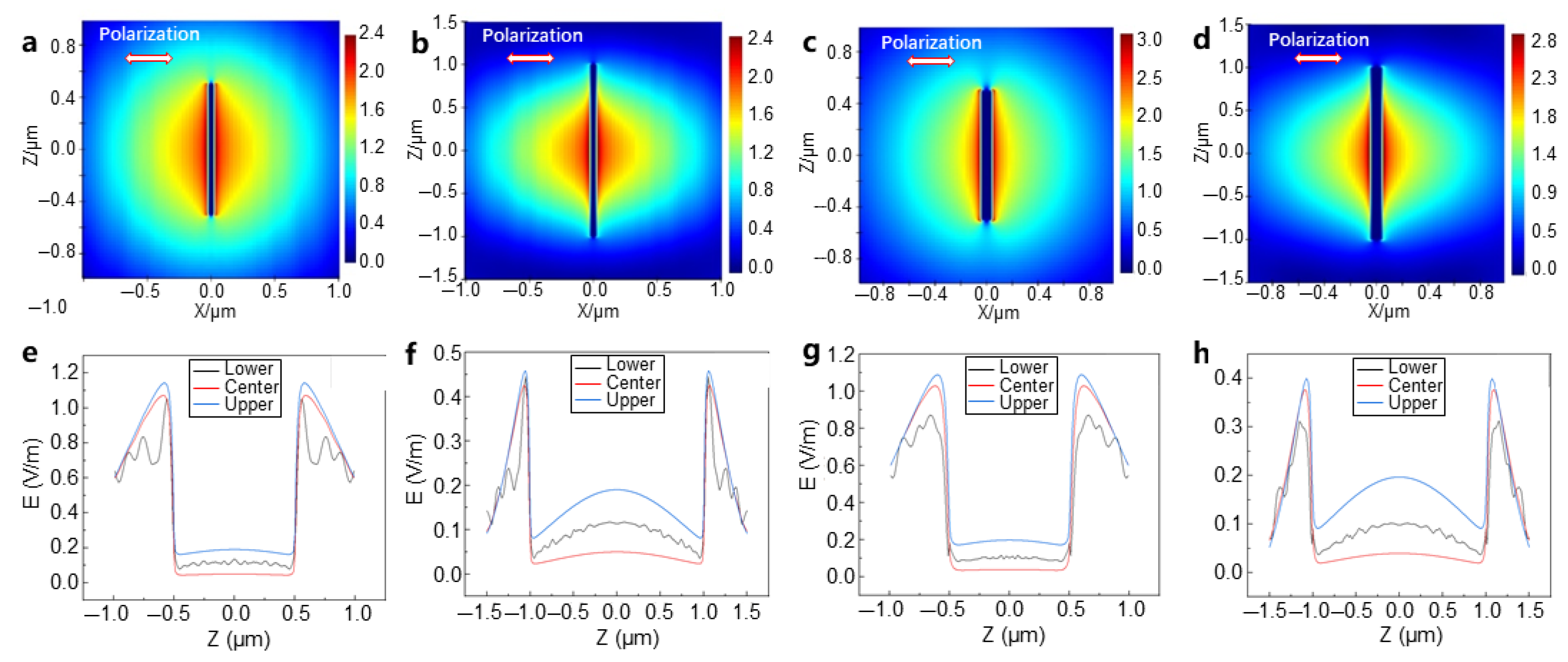

3.2. Electric Field Simulation of Heterojunctions Between Ag NW and GO

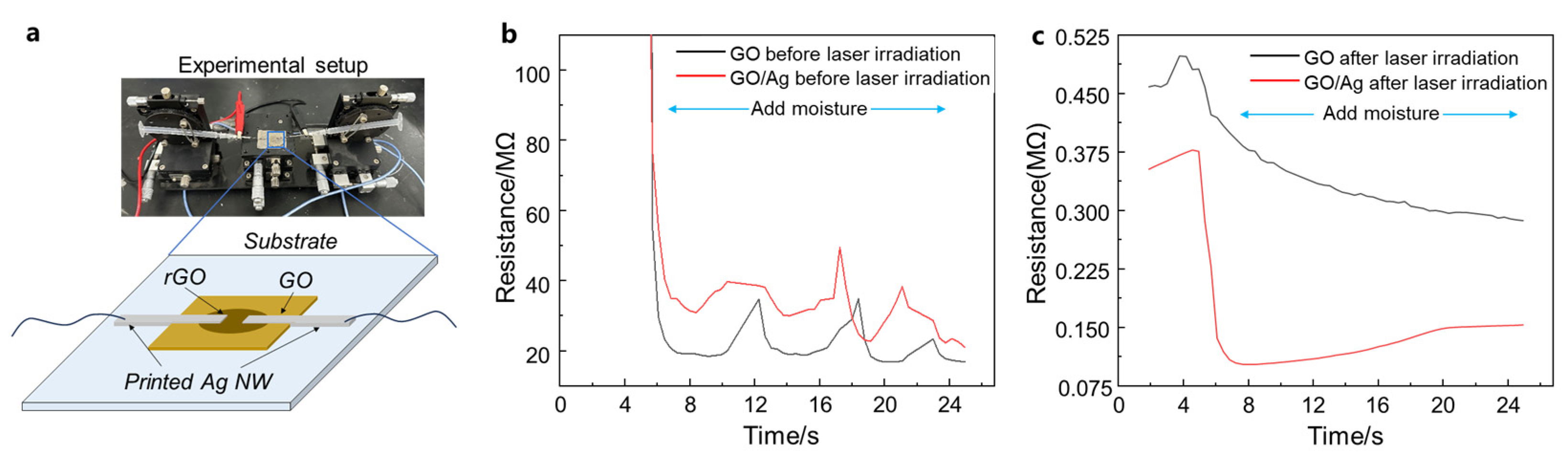

3.3. Electrical Properties of Ag NW-GO Heterostructures

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Xu, Z.; Zhan, J.; Li, P.; Gao, C. Superb Electrically Conductive Graphene Fibers via Doping Strategy. Adv. Mater. 2016, 28, 7941–7947. [Google Scholar] [CrossRef] [PubMed]

- Xin, G.; Yao, T.; Sun, H.; Scott, S.M.; Shao, D.; Wang, G.; Lian, J. Highly Thermally Conductive and Mechanically Strong Graphene Fibers. Science 2015, 349, 1083–1087. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Su, J.; Wang, C.; Fang, C.; He, X.; Lei, W.; Zhang, C.; Huang, Z. Design, Preparation and Measurement of Protein/CNTs Hybrids: A Concise Review. J. Mater. Sci. Technol. 2020, 46, 74–87. [Google Scholar] [CrossRef]

- Nandipati, M.; Fatoki, O.; Desai, S. Bridging Nanomanufacturing and Artificial Intelligence—A Comprehensive Review. Materials 2024, 17, 1621. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Liu, X.; Hu, Y.; Wang, R.; Chen, M.; Wu, J.; Wang, Y.; Kang, S.; Sun, Y.; Zhu, M. Behavior, Remediation Effect and Toxicity of Nanomaterials in Water Environments. Environ. Res. 2019, 174, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zeng, G.; Sun, Q.; Feng, Y.; Wang, X.; Ma, X.; Li, J.; Zhang, H.; Wen, J.; Feng, J.; et al. Flexible Electronic Systems via Electrohydrodynamic Jet Printing: A MnSe@rGO Cathode for Aqueous Zinc-Ion Batteries. ACS Nano 2023, 17, 13256–13268. [Google Scholar] [CrossRef] [PubMed]

- Zeng, G.; Sun, Q.; Horta, S.; Wang, S.; Lu, X.; Zhang, C.; Li, J.; Li, J.; Ci, L.; Tian, Y.; et al. A Layered Bi2Te3@PPy Cathode for Aqueous Zinc Ion Batteries: Mechanism and Application in Printed Flexible Batteries. Adv. Mater. 2024, 36, 2305128. [Google Scholar] [CrossRef] [PubMed]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon Nanotubes: Present and Future Commercial Applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Xing, S.; Lin, L.; Huo, J.; Zou, G.; Sheng, X.; Liu, L.; Zhou, Y.N. Plasmon-Induced Heterointerface Thinning for Schottky Barrier Modification of Core/Shell SiC/SiO2 Nanowires. ACS Appl. Mater. Interfaces 2019, 11, 9326–9332. [Google Scholar] [CrossRef] [PubMed]

- Huo, J.; Zou, G.; Lin, L.; Wang, K.; Xing, S.; Zhao, G.; Liu, L.; Norman Zhou, Y. Highly Focused Femtosecond Laser Directed Selective Boron Doping in Single SiC Nanowire Device for N-p Conversion. Appl. Phys. Lett. 2019, 115, 133104. [Google Scholar] [CrossRef]

- Lin, L.; Liu, L.; Musselman, K.; Zou, G.; Duley, W.W.; Zhou, Y.N. Plasmonic-Radiation-Enhanced Metal Oxide Nanowire Heterojunctions for Controllable Multilevel Memory. Adv. Funct. Mater. 2016, 26, 5979–5986. [Google Scholar] [CrossRef]

- Jang, Y.R.; Chung, W.H.; Hwang, Y.T.; Hwang, H.J.; Kim, S.H.; Kim, H.S. Selective Wavelength Plasmonic Flash Light Welding of Silver Nanowires for Transparent Electrodes with High Conductivity. ACS Appl. Mater. Interfaces 2018, 10, 24099–24107. [Google Scholar] [CrossRef] [PubMed]

- Park, J.H.; Hwang, G.; Kim, S.; Seo, J.; Park, H.; Yu, K.; Kim, T.; Lee, K.J. Flash-Induced Self-Limited Plasmonic Welding of Silver Nanowire Network for Transparent Flexible Energy Harvester. Adv. Mater. 2017, 29, 1603473. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.G.; Kong, Y.T.; Xu, Z.W.; Yao, X.; Zuo, B.; Li, W.S. High-Performance Flexible Transparent Conductive Films Achieved by Cooperation between 1D Copper Nanowires and 2D Graphene Materials. J. Mater. Chem. C 2017, 5, 5509–5516. [Google Scholar] [CrossRef]

- Xiao, M.; Lin, L.; Xing, S.; Feng, J.; Hui, Z.; Wang, S.; Duley, W.W.; Zhou, Y.N. Nanojoining and Tailoring of Current–Voltage Characteristics of Metal-P Type Semiconductor Nanowire Heterojunction by Femtosecond Laser Irradiation. J. Appl. Phys. 2020, 127, 184901. [Google Scholar] [CrossRef]

- Chen, C.; Yan, L.; Kong, E.; Kong, W.; Zhang, Y. Ultrasonic Nanowelding of Carbon Nanotubes to Metal Electrodes. Nanotechnology 2006, 17, 2192. [Google Scholar] [CrossRef]

- Chen, C.; Lu, Y.; Kong, E.S.; Zhang, Y.; Lee, S. Nanowelded Carbon-Nanotube-Based Solar Microcells. Small 2008, 4, 1313–1318. [Google Scholar] [CrossRef] [PubMed]

- Quintino, L.; Liu, L.; Hu, A.; Miranda, R.M.; Zhou, Y. Fracture Analysis of Ag Nanobrazing of NiTi to Ti Alloy. Soldag. Insp. 2013, 18, 281–286. [Google Scholar] [CrossRef]

- Ghosh, P.; Lu, J.; Chen, Z.; Yang, H.; Qiu, M.; Li, Q. Photothermal-Induced Nanowelding of Metal–Semiconductor Heterojunction in Integrated Nanowire Units. Adv. Electron. Mater. 2018, 4, 1700614. [Google Scholar] [CrossRef]

- Behera, D.R.; Lin Prakash, P.S.; Kundu, P.; Kumar, R.R.; Murty, S.V.S.N.; Kar, S.K.; Panda, S.K. Microstructure Characterization and Formability Assessment of Electron Beam Welded Nb-10Hf-1Ti (Wt.%) Refractory Alloy Sheets. Int. J. Refract. Met. Hard Mater. 2024, 125, 106912. [Google Scholar] [CrossRef]

- Rajbhar, M.K.; Das, P.; Satpati, B.; Möller, W.; Ramgir, N.; Chatterjee, S. Moisture Repelling Perovskite Nanowires for Higher Stability in Energy Applications. Appl. Surf. Sci. 2020, 527, 146683. [Google Scholar] [CrossRef]

- Miyamoto, Y.; Komatsu, T. Laser-Induced Epoxide Ring Opening on Graphene Oxide Leading to C–O Single Bonds: An Ab Initio Prediction. Carbon 2025, 233, 119847. [Google Scholar] [CrossRef]

- Zhou, Z.; Gao, X.; Zhang, Y. Effect of Interface Control on Bonding Behavior of Steel and CFRP during Laser Welding. Opt. Laser Technol. 2025, 186, 112706. [Google Scholar] [CrossRef]

- Chen, D.; Liang, J.; Liu, C.; Saldanha, G.; Zhao, F.; Tong, K.; Liu, J.; Pei, Q. Thermally Stable Silver Nanowire–Polyimide Transparent Electrode Based on Atomic Layer Deposition of Zinc Oxide on Silver Nanowires. Adv. Funct. Mater. 2015, 25, 7512–7520. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, J.Y.; Wang, C.; Sun, S.; Lou, J. Cold Welding of Ultrathin Gold Nanowires. Nat. Nanotechnol. 2010, 5, 218–224. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Hu, A.; Li, X.; Wei, J.Q.; Shu, Q.; Wang, K.L.; Yavuz, M.; Zhou, Y.N. Vacuum Brazing of Carbon Nanotube Bundles. Mater. Lett. 2008, 62, 4486–4488. [Google Scholar] [CrossRef]

- Lin, L.; Zou, G.; Liu, L.; Duley, W.W.; Zhou, Y.N. Plasmonic Engineering of Metal-Oxide Nanowire Heterojunctions in Integrated Nanowire Rectification Units. Appl. Phys. Lett. 2016, 108, 203107. [Google Scholar] [CrossRef]

- Feng, J.; Tian, Y.; Wang, S.; Xiao, M.; Hui, Z.; Hang, C.; Duley, W.W.; Zhou, Y.N. Femtosecond Laser Irradiation Induced Heterojunctions between Carbon Nanofibers and Silver Nanowires for a Flexible Strain Sensor. J. Mater. Sci. Technol. 2021, 84, 139–146. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, S.; Tian, Y.; Liu, Y.; Wen, J.; Huang, Y.; Hang, C.; Zheng, Z.; Wang, C. Electrodeposition Fabrication of Cu@Ni Core Shell Nanowire Network for Highly Stable Transparent Conductive Films. Chem. Eng. J. 2020, 390, 124495. [Google Scholar] [CrossRef]

- Feng, Y.; Zhu, J. Copper Nanomaterials and Assemblies for Soft Electronics. Sci. China Mater. 2019, 62, 1679–1708. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, J.; Wang, Z.; Wu, Z.; Wang, S.; Sun, Y.; Meng, Q.; Wen, J.; Wang, S.; Tian, Y. Femtosecond Laser Irradiation Induced Heterojunctions Between Graphene Oxide and Silver Nanowires. Materials 2025, 18, 3393. https://doi.org/10.3390/ma18143393

Feng J, Wang Z, Wu Z, Wang S, Sun Y, Meng Q, Wen J, Wang S, Tian Y. Femtosecond Laser Irradiation Induced Heterojunctions Between Graphene Oxide and Silver Nanowires. Materials. 2025; 18(14):3393. https://doi.org/10.3390/ma18143393

Chicago/Turabian StyleFeng, Jiayun, Zhiyuan Wang, Zhuohuan Wu, Shujun Wang, Yuxin Sun, Qi Meng, Jiayue Wen, Shang Wang, and Yanhong Tian. 2025. "Femtosecond Laser Irradiation Induced Heterojunctions Between Graphene Oxide and Silver Nanowires" Materials 18, no. 14: 3393. https://doi.org/10.3390/ma18143393

APA StyleFeng, J., Wang, Z., Wu, Z., Wang, S., Sun, Y., Meng, Q., Wen, J., Wang, S., & Tian, Y. (2025). Femtosecond Laser Irradiation Induced Heterojunctions Between Graphene Oxide and Silver Nanowires. Materials, 18(14), 3393. https://doi.org/10.3390/ma18143393