Dynamic Mechanical Properties and Damage Constitutive Model of Frozen–Thawed Basalt Fiber-Reinforced Concrete Under Wide Strain Rate Range

Abstract

1. Introduction

2. Freeze–Thaw Cycle Tests and Compression Mechanics Tests

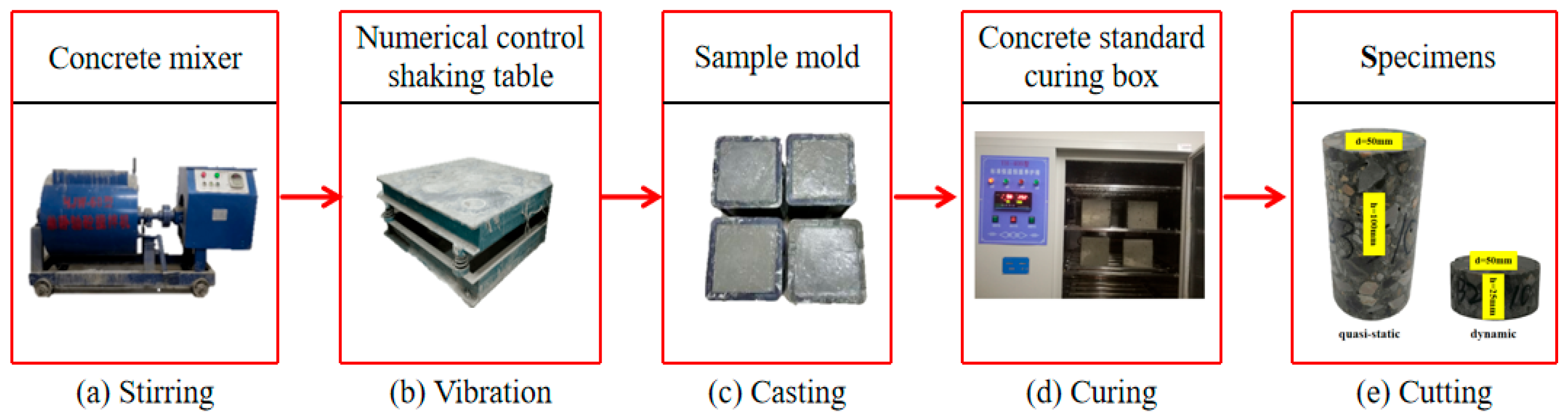

2.1. Specimen Preparation

2.2. Test Method

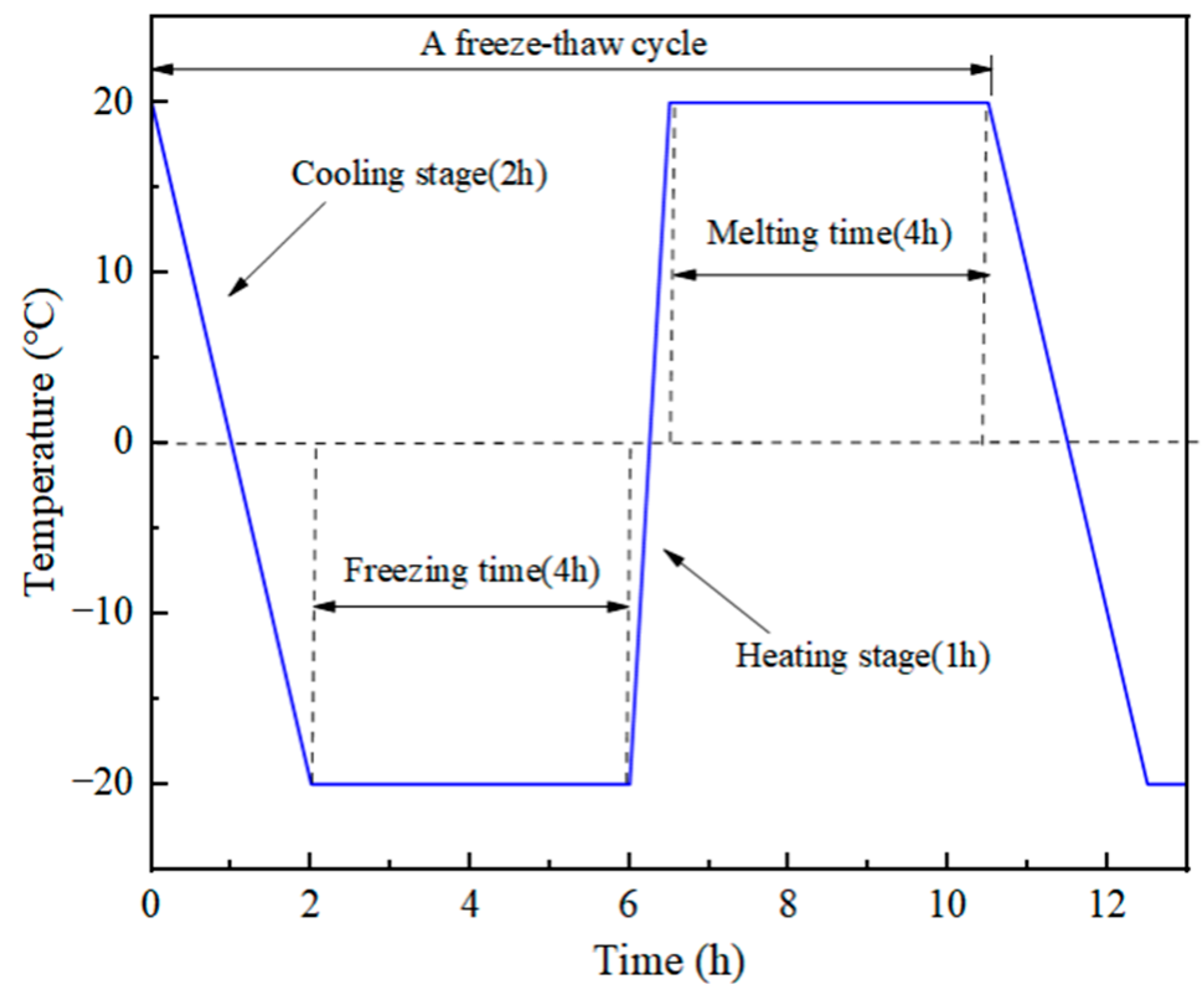

2.2.1. Freeze–Thaw Cycle Tests

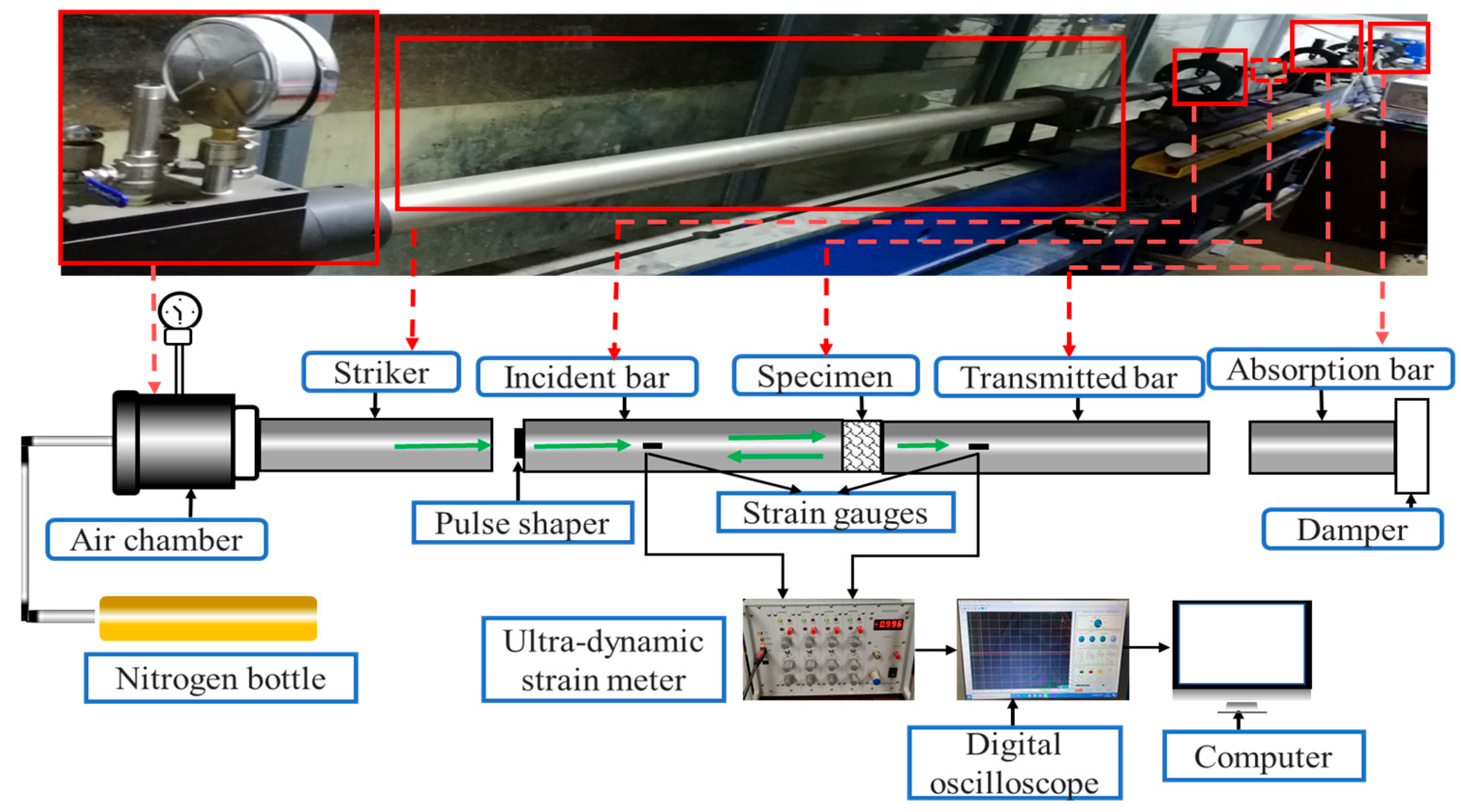

2.2.2. Quasi-Static and Dynamic Compression Tests

3. Results and Discussion

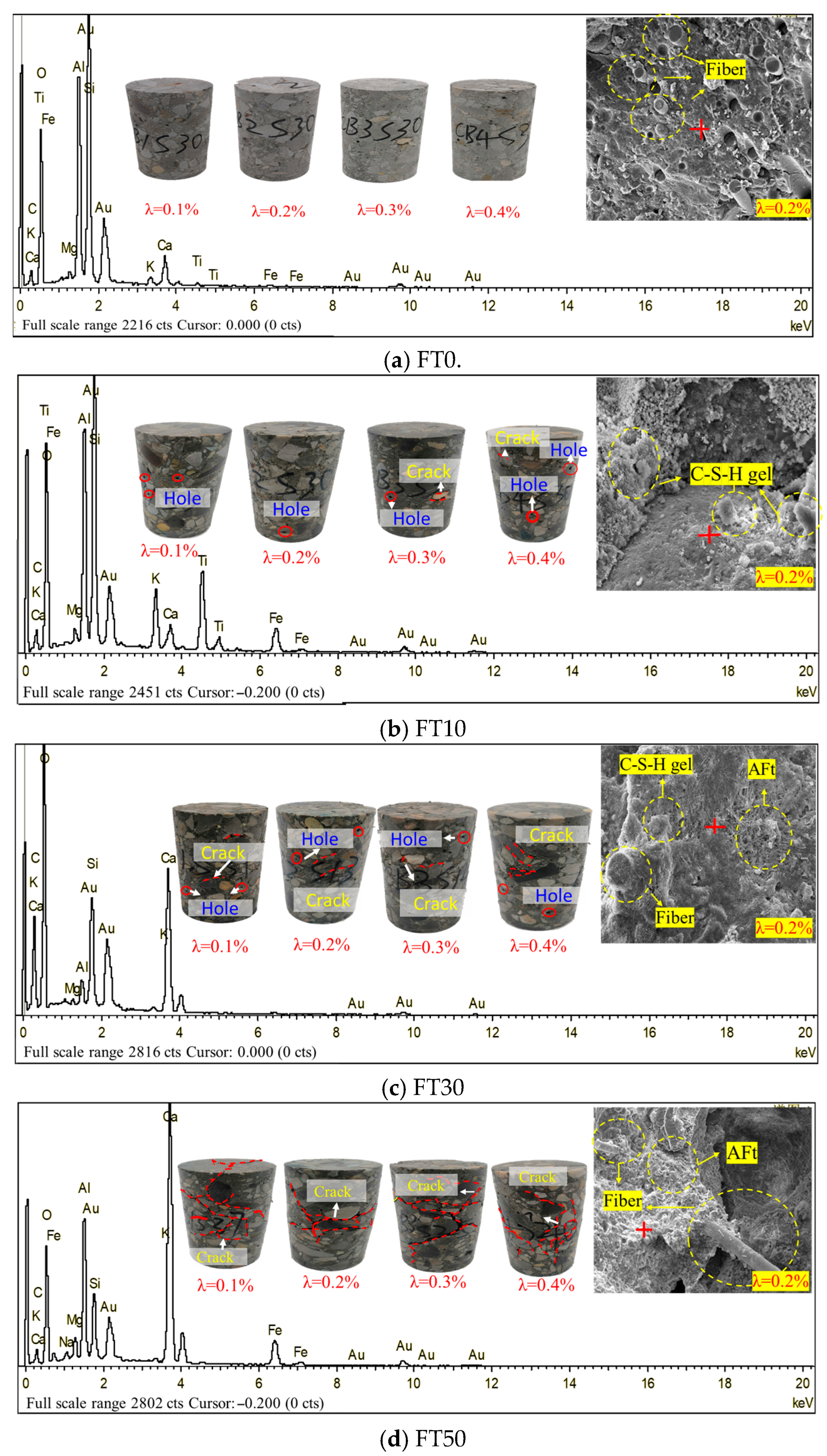

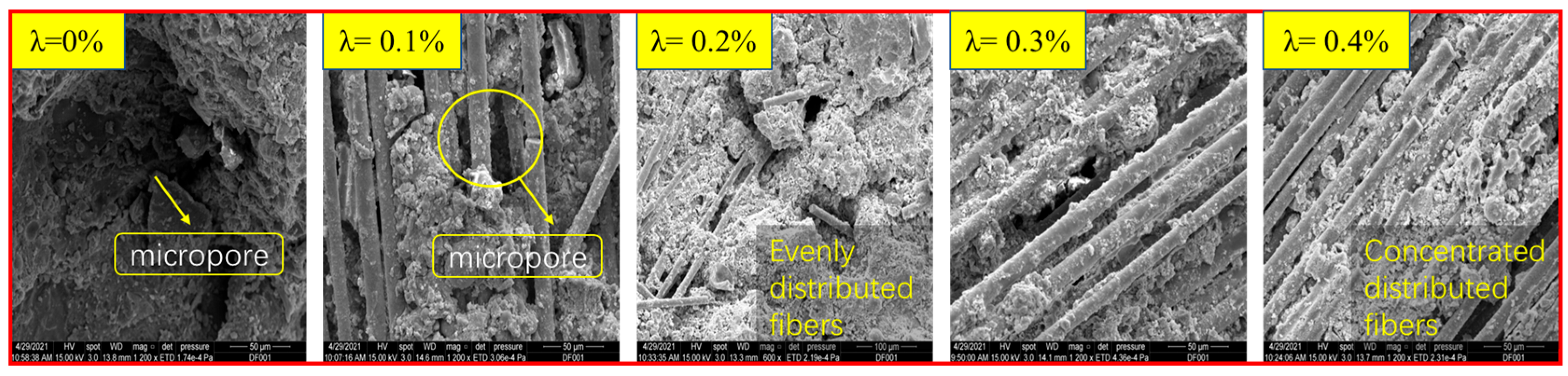

3.1. Macro and Micro Damage Characteristics and Evolution Laws of BFRC Under Freeze–Thaw Cycling

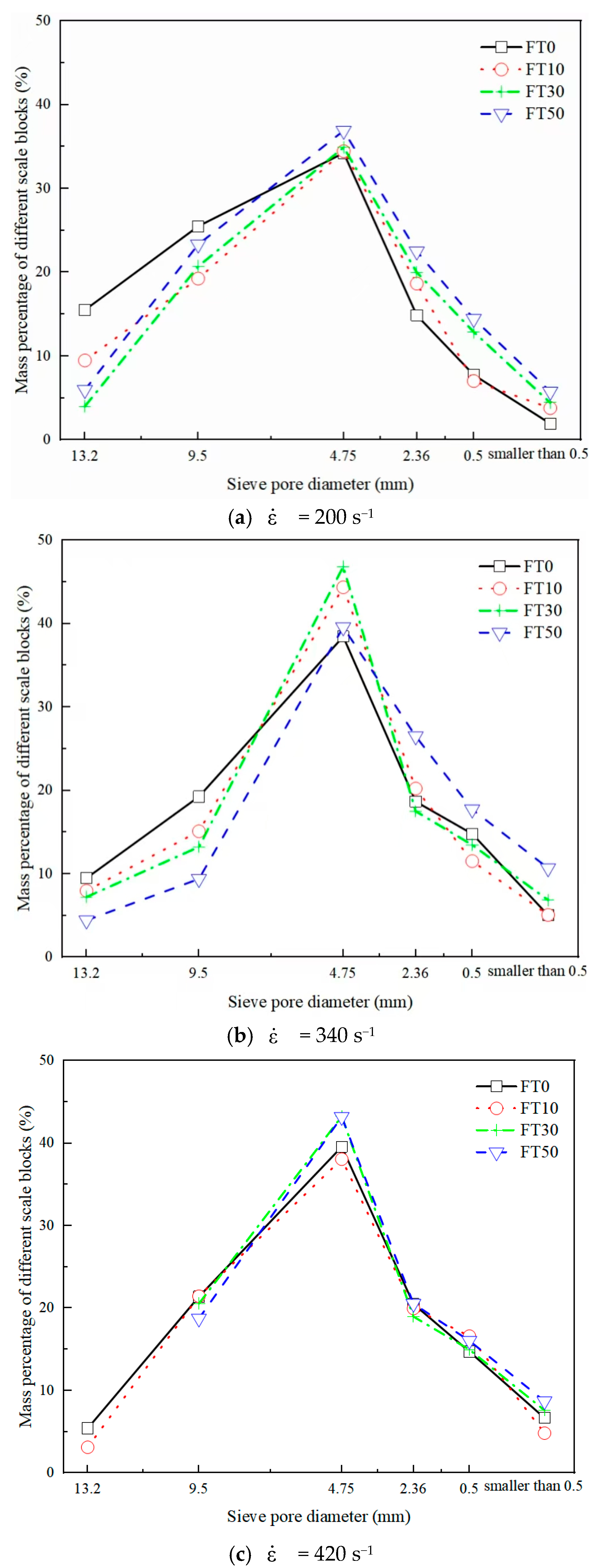

3.2. Dynamic Failure Patterns and Block Size Distributions

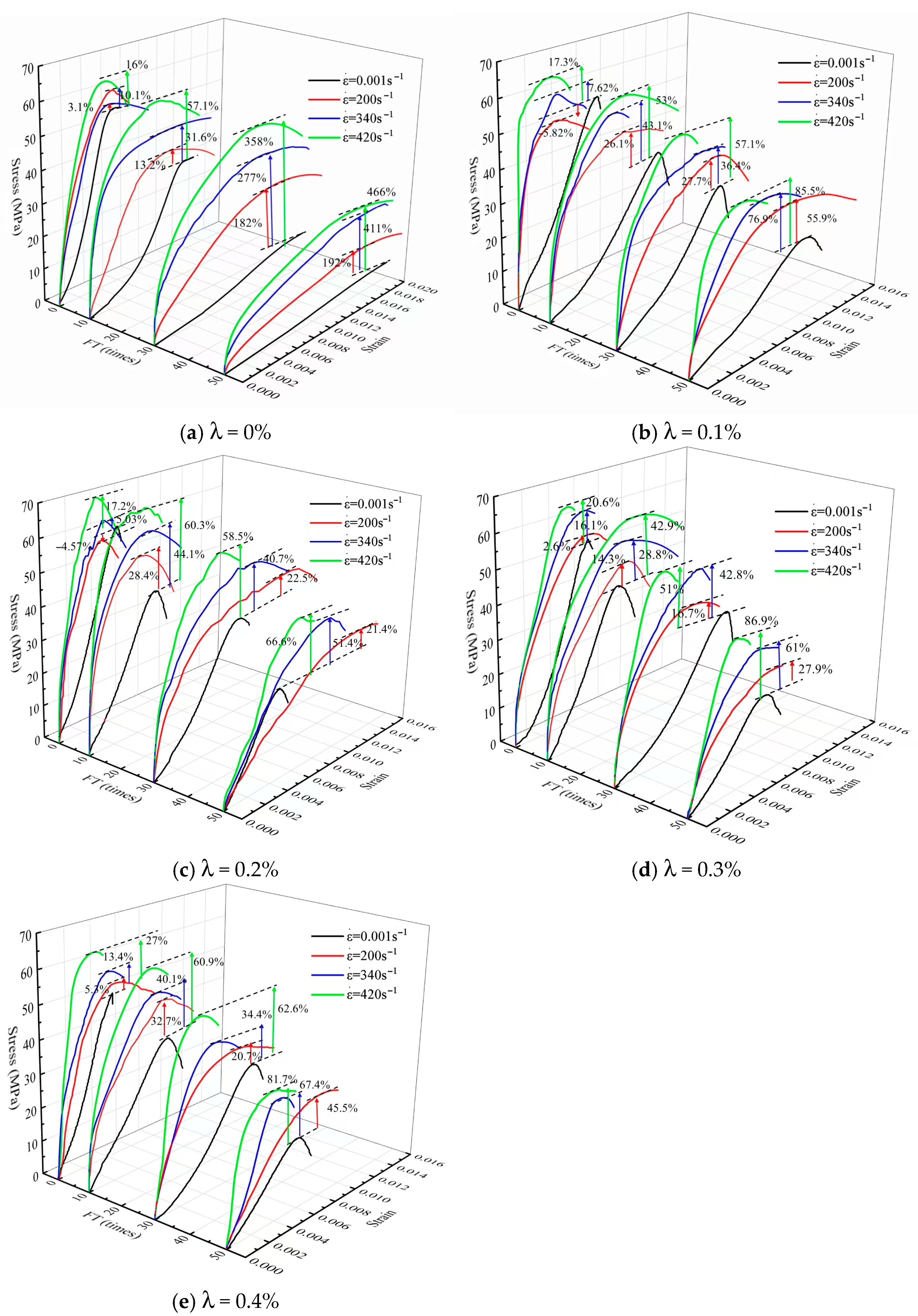

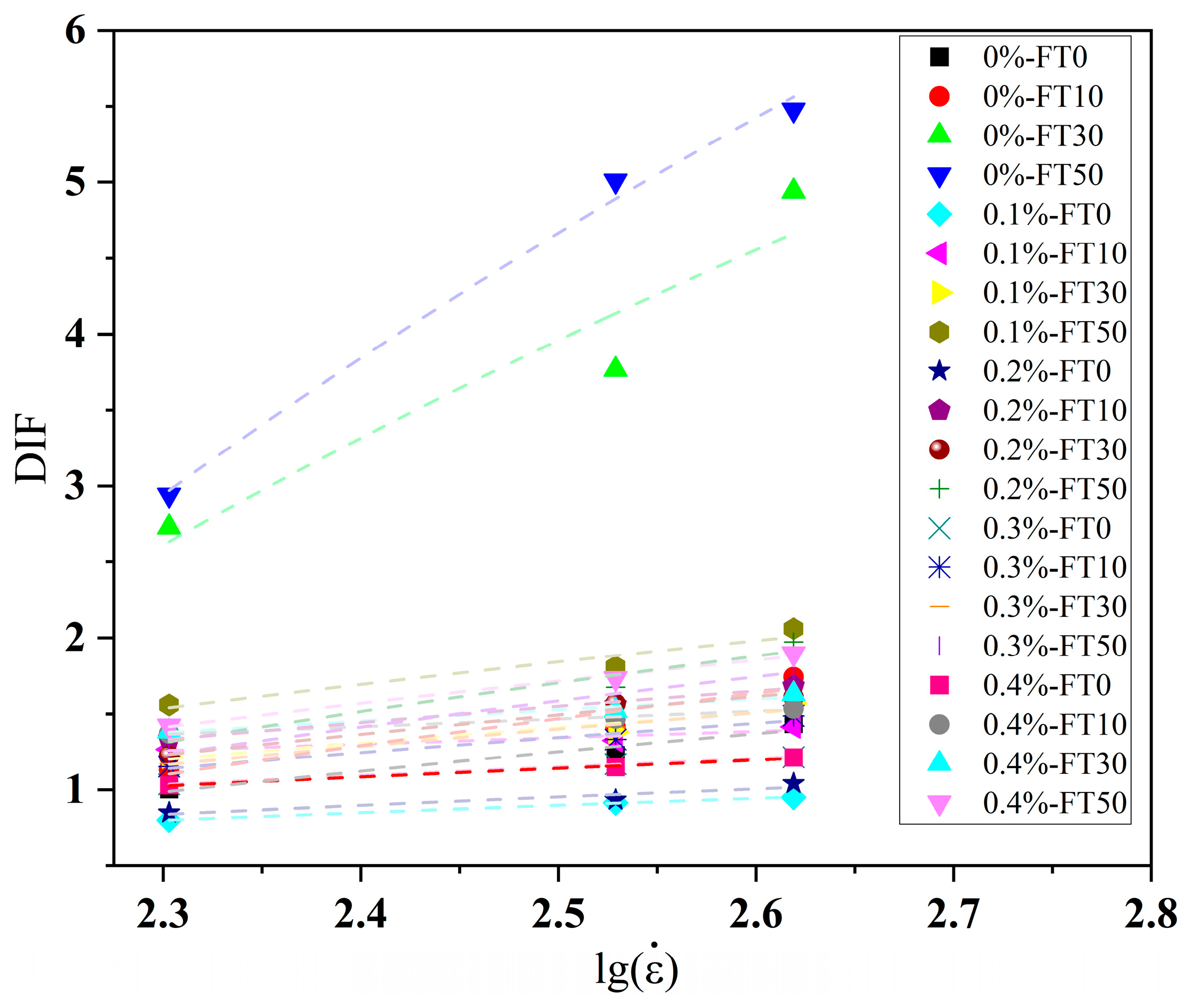

3.3. Influence of Freeze–Thaw Cycles and Strain Rates on Mechanical Properties

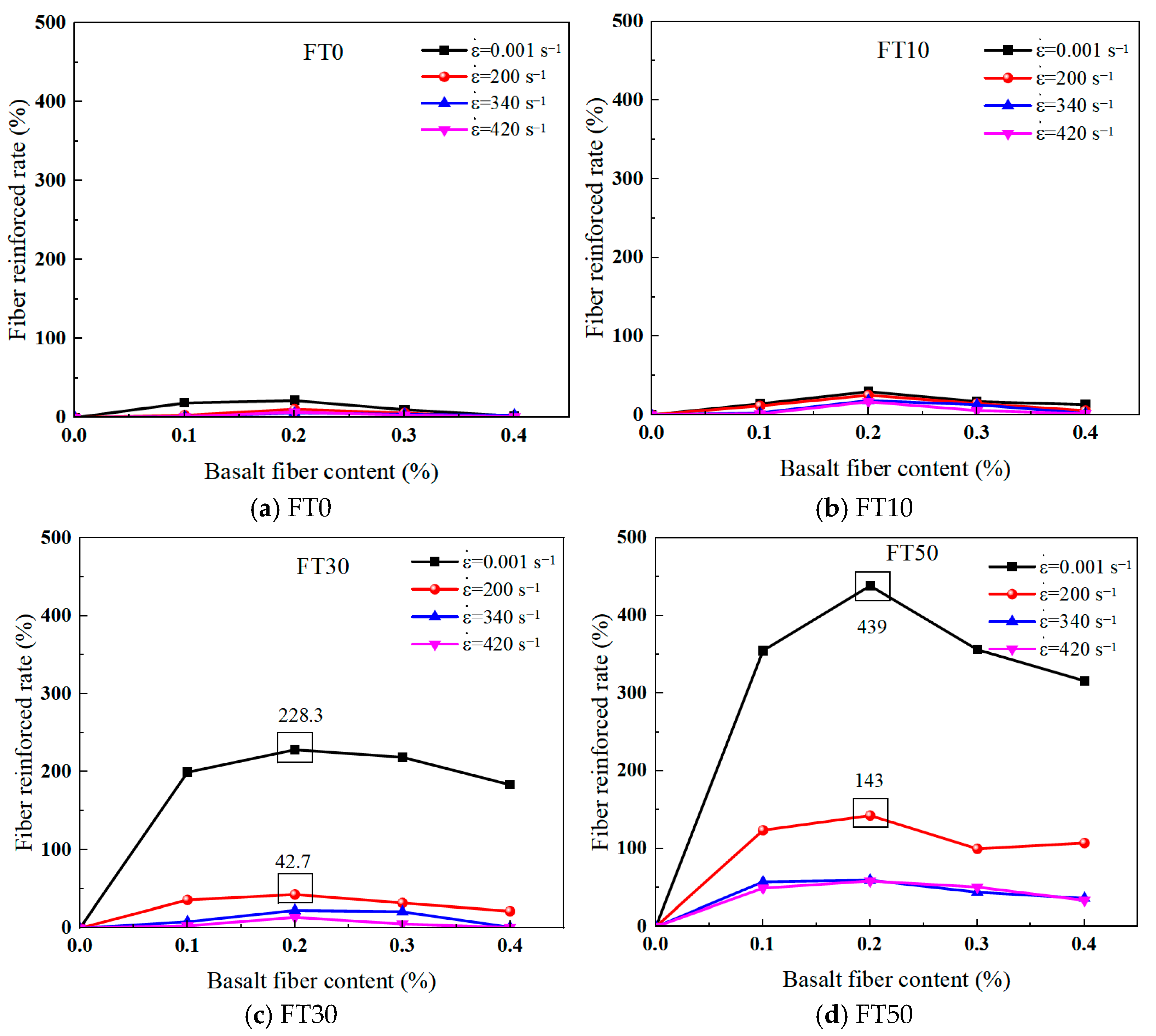

3.4. Influence of Basalt Fiber on Compressive Strength

4. Damage Constitutive Model of BFRC Considering Both Freeze–ThawFreeze-Thaw Action and Strain Rate Effect

4.1. Ottosen Nonlinear Elastic Static Constitutive Model

4.2. Freeze–Thaw Damage Factor

4.3. Dynamic Increase Factor of Compressive Strength

4.4. A Constitutive Model of Freeze–Thaw Damage Considering the Strain Rate Effect and the Fiber Toughening Effect

4.5. Parameter Determination and Model Verification

5. Conclusions

- (1)

- The freeze–thaw cycle has a significant deterioration effect on BFRC, and the deterioration mechanism can be summarized as follows: The water in the internal pores of BFRC repeatedly freezes and melts, and the water–ice phase keeps changing. During this process, the expansion stress of the ice phase causes the initiation and development of fine cracks. Meanwhile, the increasing water phase further hydrates the cement, forming slightly expanded calcium silicate hydrate gel, which further develops the pore system in the microstructure of BFRC. The change mechanism of the internal microstructure of BFRC is the essential driving factor for its freeze–thaw damage deterioration.

- (2)

- BFRC has obvious strain rate strengthening and fiber toughening effects. With the increase in the strain rate, both the elastic modulus and peak stress of BFRC increase. The compressive strength of BFRC first increases and then decreases with the increase in the volume content of basalt fibers. When the volume content of the fibers is 0.2%, the compressive strength of BFRC is the highest. Moreover, due to the interlinking effect and energy absorption and dissipation of the fibers, the toughening effect of the fibers also shows a dependence on the strain rate of the material. That is, the lower the strain rate, the more significant the toughening effect of the fibers.

- (3)

- Based on the Ottosen nonlinear elastic static constitutive model, a constitutive model that comprehensively considers the freeze–thaw damage deterioration effect, strain rate strengthening effect, and fiber toughening effect was constructed. This model can well describe the dynamic mechanical response behavior of BFRC in the range of large strain rates in the freeze–thaw cycle environment and can provide a reference for the structural design of BFRC in cold regions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, C.H.; Du, G.Y.; Guo, Q.; Zhuang, Z.X. Static and dynamic behaviors of basalt fiber reinforced cement-soil after freeze-thaw cycle. KSCE J. Civ. Eng. 2020, 24, 3573–3583. [Google Scholar] [CrossRef]

- Meng, F.D.; Zhai, Y.; Zhang, Y.S.; Li, Y.B.; Dong, Q. Multifractal Characteristics of Sandstone Microstructure after Freeze-Thaw Damage. Chin. J. Undergr. Space Eng. 2023, 19, 1791–1799. [Google Scholar]

- Bai, W.F.; Wang, X.; Yuan, C.Y.; Guan, J.F.; Cao, K.L.; Xie, C.P. Study on dynamic mechanical properties and meso-damage mechanism of carbon fibers recycled aggregate concrete under freeze-thaw environment. J. Build. Eng. 2023, 79, 107768. [Google Scholar] [CrossRef]

- Guo, W.N.; Tian, Y.P.; Bao, J.W.; Wang, B.; Lei, D.Y.; Zhang, P.; Cui, Y.F. Experimental investigation on dynamic compressive properties of SHCC after freeze-thaw cycles. J. Mater. Res. Technol. 2023, 24, 8357–8372. [Google Scholar] [CrossRef]

- Banibayat, P.; Patnaik, A. Variability of mechanical properties of basalt fiber reinforced polymer bars manufactured by wet-layup method. Mater. Des. 2014, 56, 898–906. [Google Scholar] [CrossRef]

- Wang, Q.X.; Ding, Y.N.; Randl, N. Investigation on the alkali resistance of basalt fiber and its textile in different alkaline environments. Constr. Build. Mater. 2021, 272, 121670. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.P.; He, Y.Z.; Huang, G.J.; Li, J.B.; Niu, Z.X.; Gao, B. A review on durability of basalt fiber reinforced concrete. Compos. Sci. Technol. 2022, 225, 109519. [Google Scholar] [CrossRef]

- Niu, D.T.; Su, L.; Luo, Y.; Huang, D.G.; Luo, D.M. Experimental study on mechanical properties and durability of basalt fiber reinforced coral aggregate concrete. Constr. Build. Mater. 2020, 237, 117628. [Google Scholar] [CrossRef]

- Yang, Y.; Ning, C.P.; Cheng, R.F.; Li, P.P. Experimental study on freeze-thaw cycling of concrete mixed with steel and basalt fiber. J. Water Resour. Water Eng. 2017, 28, 182–186. [Google Scholar]

- Zeng, Y.S.; Li, X.M.; Tang, A.P.; Zhao, N.; Li, L.; Jia, S.M. Axial compressive behavior of basalt and polyacrylonitrile fibers reinforced lightweight aggregate concrete with industrial waste ceramsite-Lytag after freeze-thaw cycles. J. Build. Eng. 2023, 76, 107402. [Google Scholar] [CrossRef]

- Fu, Q.; Niu, D.; Zhang, J.; Huang, D.G.; Wang, Y.; Hong, M.S.; Zhang, L. Dynamic compressive mechanical behaviour and modelling of basalt-polypropylene fibre-reinforced concrete. Arch. Civ. Mech. Eng. 2018, 18, 914–927. [Google Scholar] [CrossRef]

- Xie, H.Z.; Yang, L.Y.; Zhu, H.A.; Zhang, Q.H. Energy dissipation and fractal characteristics of basalt fiber reinforced concrete under impact loading. Structures 2022, 46, 654–663. [Google Scholar] [CrossRef]

- Li, X.F.; Li, H.B.; Liu, K.; Zhang, Q.B.; Zhou, F.; Huang, L.X.; Zhao, J. Dynamic properties and fracture characteristics of rocks subject to impact loading. Chin. J. Rock Mech. Eng. 2017, 36, 2393–2405. [Google Scholar]

- Yang, S.B.; Kong, X.Z.; Wu, H.; Fang, Q.; Xiang, H.B. Constitutive modelling of UHPCC material under impact and blast loadings. Int. J. Impact Eng. 2021, 153, 103860. [Google Scholar] [CrossRef]

- Wan, W.Z.; Yang, J.; Xu, G.J.; Liu, Y.K. Determination and evaluation of Holmquist-Johnson-Cook constitutive model parameters for ultra-high-performance concrete with steel fibers. Int. J. Impact Eng. 2021, 156, 103966. [Google Scholar] [CrossRef]

- Jia, P.C.; Wu, H.; Wang, R.; Fang, Q. Dynamic responses of reinforced ultra-high performance concrete members under low-velocity lateral impact. Int. J. Impact Eng. 2021, 150, 103818. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Zheng, K.; Bakura, T.J.; Totakhil, P.G. Research on compressive impact dynamic behavior and constitutive model of polypropylene fiber reinforced concrete. Constr. Build. Mater. 2018, 187, 584–595. [Google Scholar] [CrossRef]

- Xu, M.; Wille, K. Numerical Investigation of the Effects of Pulse Shaper, Lateral Inertia, and Friction on the Calculated Strain-Rate Sensitivity of UHP-FRC Using a Split Hopkinson Pressure Bar. J. Mater. Civ. Eng. 2016, 28, 04016114. [Google Scholar] [CrossRef]

- Yang, L.; Lin, X.S.; Li, H.Y.; Gravina, R.J. A new constitutive model for steel fibre reinforced concrete subjected to dynamic loads. Compos. Struct. 2019, 221, 110849. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Q.R.; Wang, R.J.; Xiong, X.B.; Li, Y.; Wang, J.Y. Experimental investigation on the dynamic mechanical properties and microstructure deterioration of steel fiber reinforced concrete subjected to freeze–thaw cycles. Buildings 2022, 12, 2170. [Google Scholar] [CrossRef]

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. Chinese Standard Press: Beijing, China, 2011.

- Al-Rousan, E.T.; Khalid, H.R.; Rahman, M.K. Fresh, mechanical, and durability properties of basalt fiber-reinforced concrete (BFRC): A review. Dev. Built Environ. 2023, 14, 100155. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Chinese Standard Press: Beijing, China, 2019.

- GB/T 50082-2009; Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete. Chinese Standard Press: Beijing, China, 2009.

- Yang, L.Y.; Zhang, F.; Xie, H.Z.; Chen, S.Y.; Lin, C.Y. Dynamic mechanical properties of red sandrock-polypropylene fiber reinforced concrete composite under impact load. KSCE J. Civ. Eng. 2022, 26, 1479–1493. [Google Scholar] [CrossRef]

- Lu, J.G.; Liu, J.N.; Yang, H.H.; Wan, X.S.; Gao, J.J.; Zhang, J.C.; Li, P.C. Experimental investigation on the mechanical properties and pore structure deterioration of fiber-reinforced concrete in different freeze-thaw media. Constr. Build. Mater. 2022, 350, 128887. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Guo, S.L.; Zheng, D.J.; Zhao, L.H.; Lu, Q.; Liu, X.K. Mechanical test and constitutive model of recycled plastic fiber reinforced recycled concrete. Constr. Build. Mater. 2022, 348, 128578. [Google Scholar] [CrossRef]

- Lu, Y.N.; Li, X.P.; Chan, A. Damage constitutive model of single flaw sandstone under freeze-thaw and load. Cold Reg. Sci. Technol. 2019, 159, 20–28. [Google Scholar] [CrossRef]

- Wang, Z.H.; Bai, E.L.; Zhang, T.; Lv, Y. Early-age mechanical properties and constitutive model of polystyrene concrete under impact load. Mater. Today Commun. 2023, 35, 106039. [Google Scholar] [CrossRef]

- Zhu, Z.X.; Xu, D.B.; Wang, L.L. Thermoviscoelastic constitutive equation and time-temperature equivalence of epoxy resin at high strain rates. J. Ningbo Univ. 1988, 1, 58–68. [Google Scholar]

| Fiber Content (%) | Mix Ratio of Each Component of Concrete (kg·m−3) | ||||||

|---|---|---|---|---|---|---|---|

| Cement | Sand | Gravel | Water | Water Reducer | Basalt Fiber | Fly Ash | |

| 0.0 | 286.4 | 621.8 | 1262.6 | 157.5 | 5.4 | 0 | 71.6 |

| 0.1 | 286.4 | 621.8 | 1262.6 | 157.5 | 5.4 | 2.702 | 71.6 |

| 0.2 | 286.4 | 621.8 | 1262.6 | 157.5 | 5.4 | 5.409 | 71.6 |

| 0.3 | 286.4 | 621.8 | 1262.6 | 157.5 | 5.4 | 8.121 | 71.6 |

| 0.4 | 286.4 | 621.8 | 1262.6 | 157.5 | 5.4 | 10.839 | 71.6 |

| Fiber Type | Diameter (μm) | Length (mm) | Density (kg·m−3) | Elastic Modulus (GPa) | Melting Point (℃) | Ultimate Elongation (%) | Tensile Strength (MPa) | Basalt Fiber Picture |

|---|---|---|---|---|---|---|---|---|

| BF | 17.4 | 12 | 2699 | 93–110 | 750 | 3.10 | 4150–4800 |  |

| BF Content (%) | Freeze–Thaw Damage Parameters | Fitting Variance | |

|---|---|---|---|

| p | q | R2 | |

| 0 | 1.020 | 0.048 | 0.994 |

| 0.1 | 0.929 | 0.023 | 0.905 |

| 0.2 | 0.929 | 0.022 | 0.910 |

| 0.3 | 0.996 | 0.016 | 0.973 |

| 0.4 | 0.958 | 0.017 | 0.951 |

| Freeze–Thaw Cycles | A | B | A1 | A2 |

|---|---|---|---|---|

| 0 | −0.434 + 9.116λ − 17.25λ2 | 2.116 − 22.71λ + 44.6λ2 | 1.245 | 0.316 |

| 10 | −0.154 + 8.816λ − 17.25λ2 | 1.586 − 22.22λ + 44.6λ2 | 0.792 | 0.415 |

| 30 | 0.406 + 8.216λ − 17.25λ2 | 0.526 − 21.24λ + 44.6λ2 | 0.981 | 0.125 |

| 50 | 0.966 + 7.616λ − 17.25λ2 | − 0.534 − 20.26λ + 44.6λ2 | 1.284 | 0.768 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, W.; Wang, S.; Lv, X.; Li, Y. Dynamic Mechanical Properties and Damage Constitutive Model of Frozen–Thawed Basalt Fiber-Reinforced Concrete Under Wide Strain Rate Range. Materials 2025, 18, 3337. https://doi.org/10.3390/ma18143337

Liang W, Wang S, Lv X, Li Y. Dynamic Mechanical Properties and Damage Constitutive Model of Frozen–Thawed Basalt Fiber-Reinforced Concrete Under Wide Strain Rate Range. Materials. 2025; 18(14):3337. https://doi.org/10.3390/ma18143337

Chicago/Turabian StyleLiang, Wenbiao, Siyi Wang, Xiao Lv, and Yan Li. 2025. "Dynamic Mechanical Properties and Damage Constitutive Model of Frozen–Thawed Basalt Fiber-Reinforced Concrete Under Wide Strain Rate Range" Materials 18, no. 14: 3337. https://doi.org/10.3390/ma18143337

APA StyleLiang, W., Wang, S., Lv, X., & Li, Y. (2025). Dynamic Mechanical Properties and Damage Constitutive Model of Frozen–Thawed Basalt Fiber-Reinforced Concrete Under Wide Strain Rate Range. Materials, 18(14), 3337. https://doi.org/10.3390/ma18143337