Enhancing Tensile Performance of Cemented Tailings Backfill Through 3D-Printed Polymer Lattices: Mechanical Properties and Microstructural Investigation

Abstract

1. Introduction

2. Test Raw Materials and Test Methods

2.1. Test Raw Materials

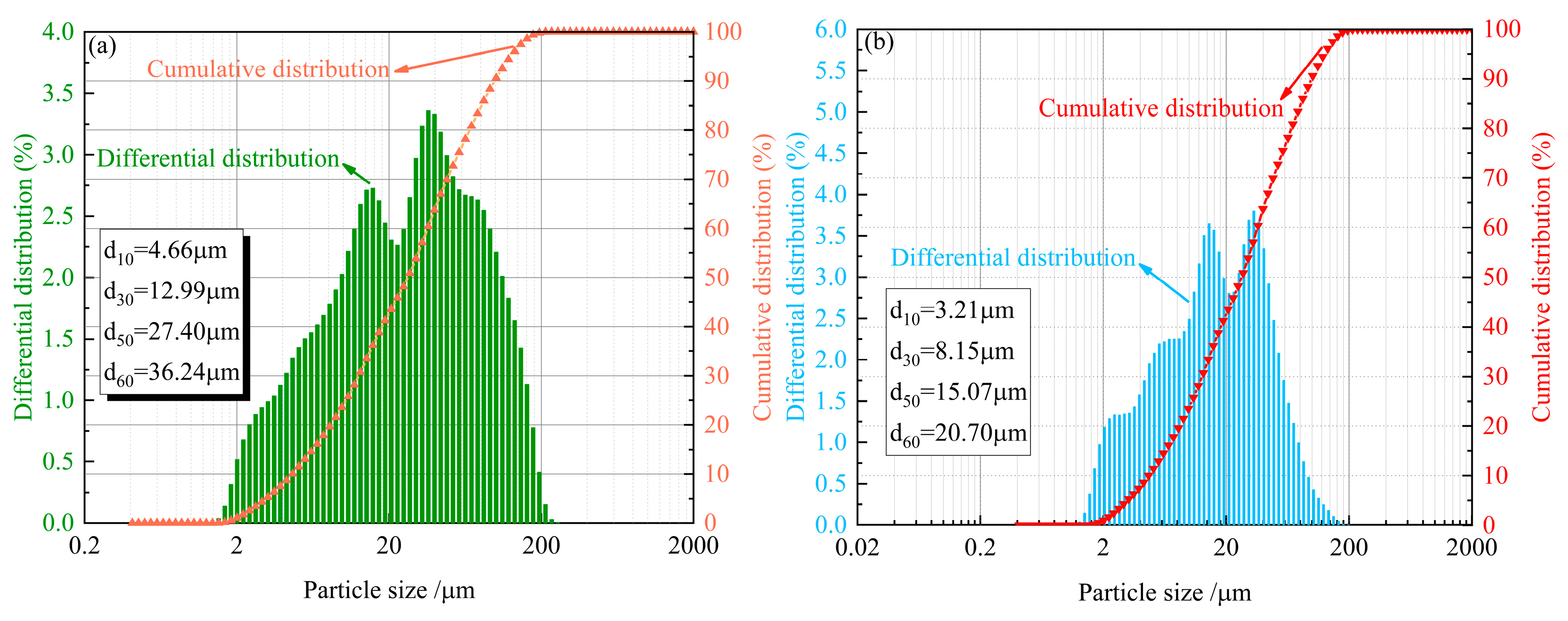

2.1.1. Tailings and Cementitious Materials

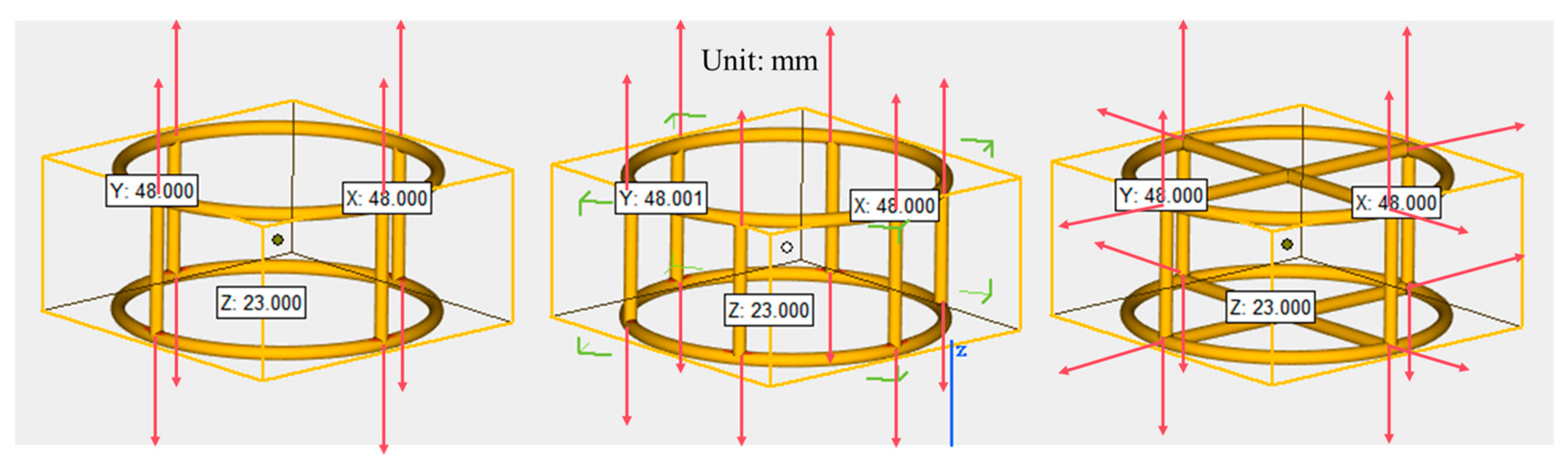

2.1.2. The Properties of 3D-Printed Polymers

2.2. Test Method

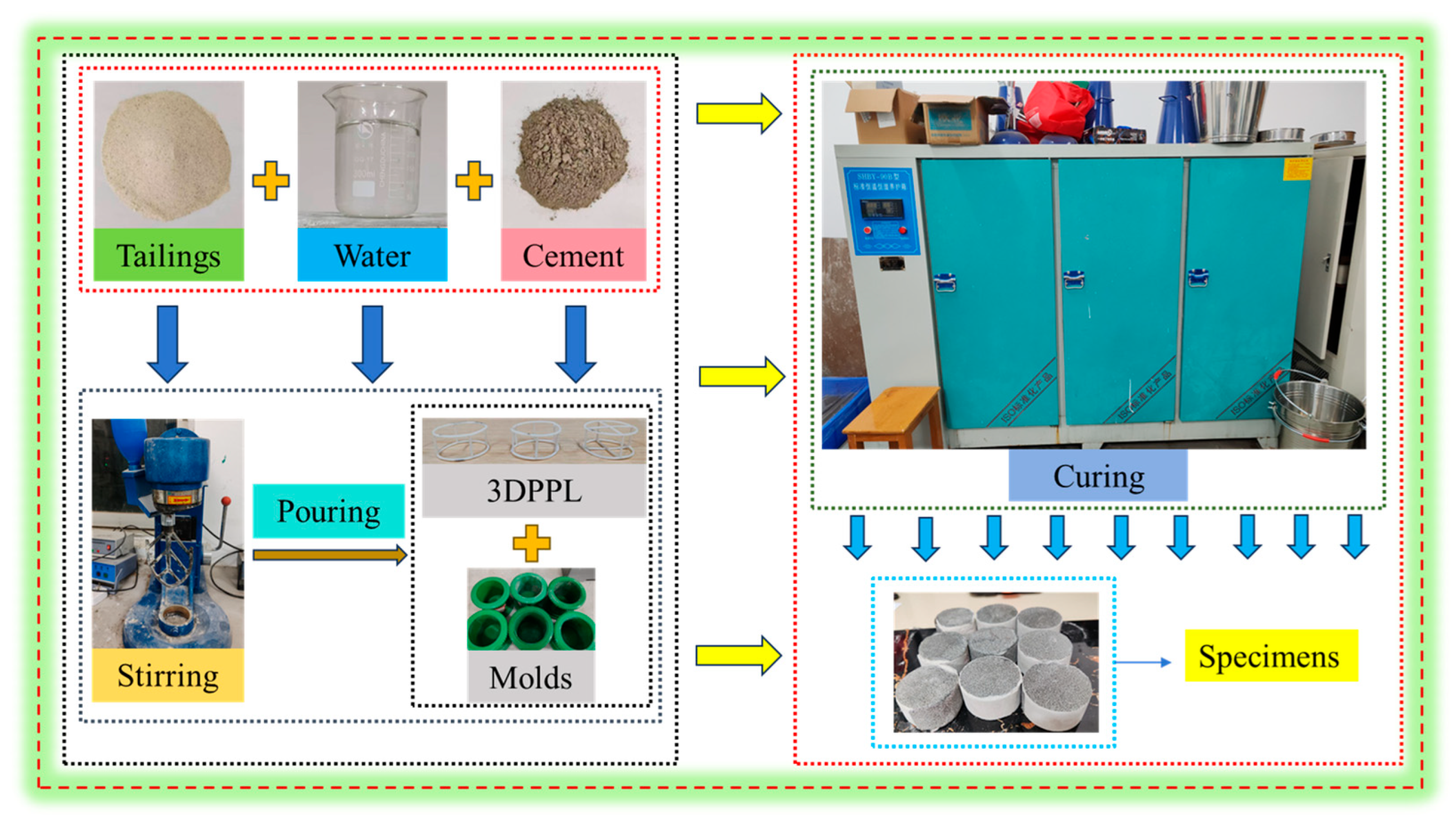

The CTB Preparation Process with 3DPPL Added

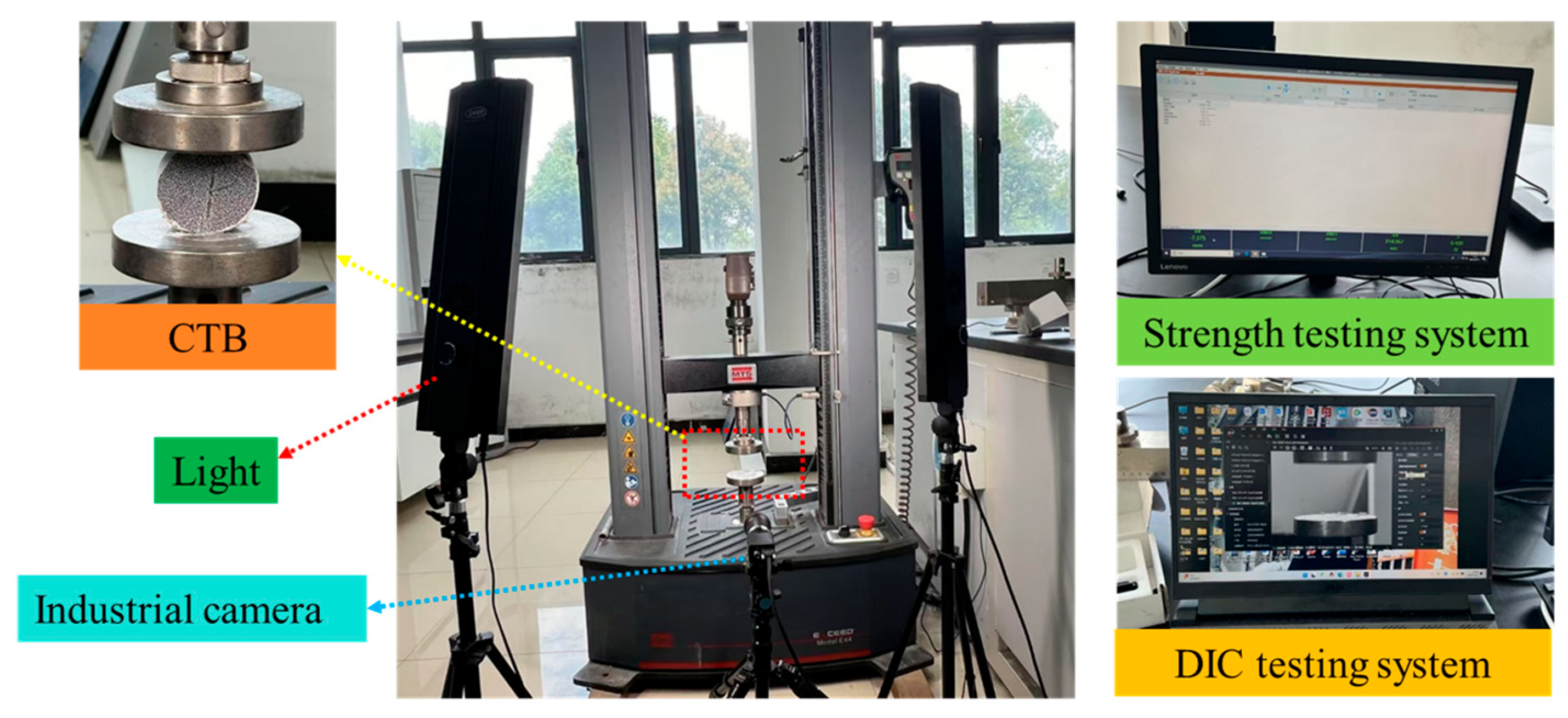

2.3. Strength Test and DIC Analysis

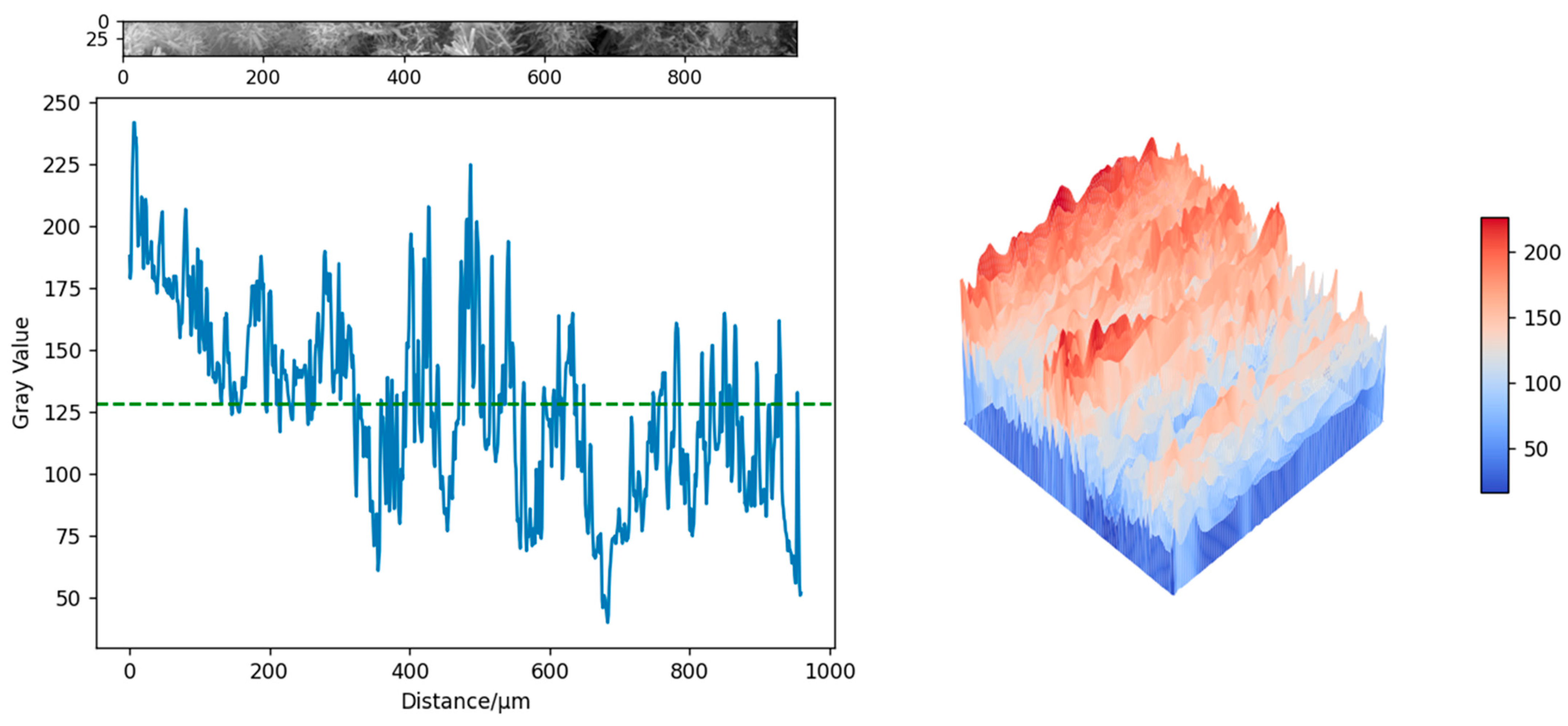

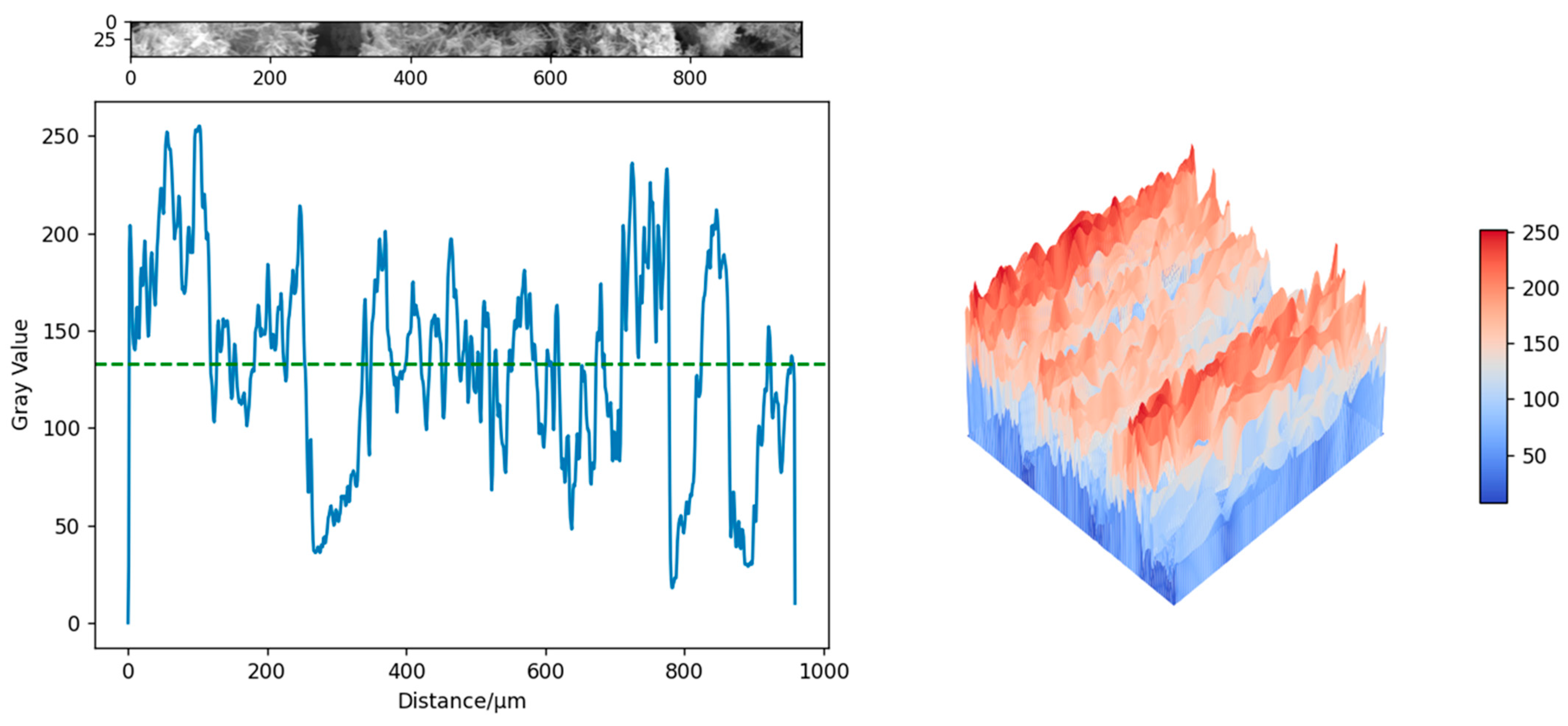

2.4. Microstructure Analysis Was Conducted Through SEM

3. Results and Discussion

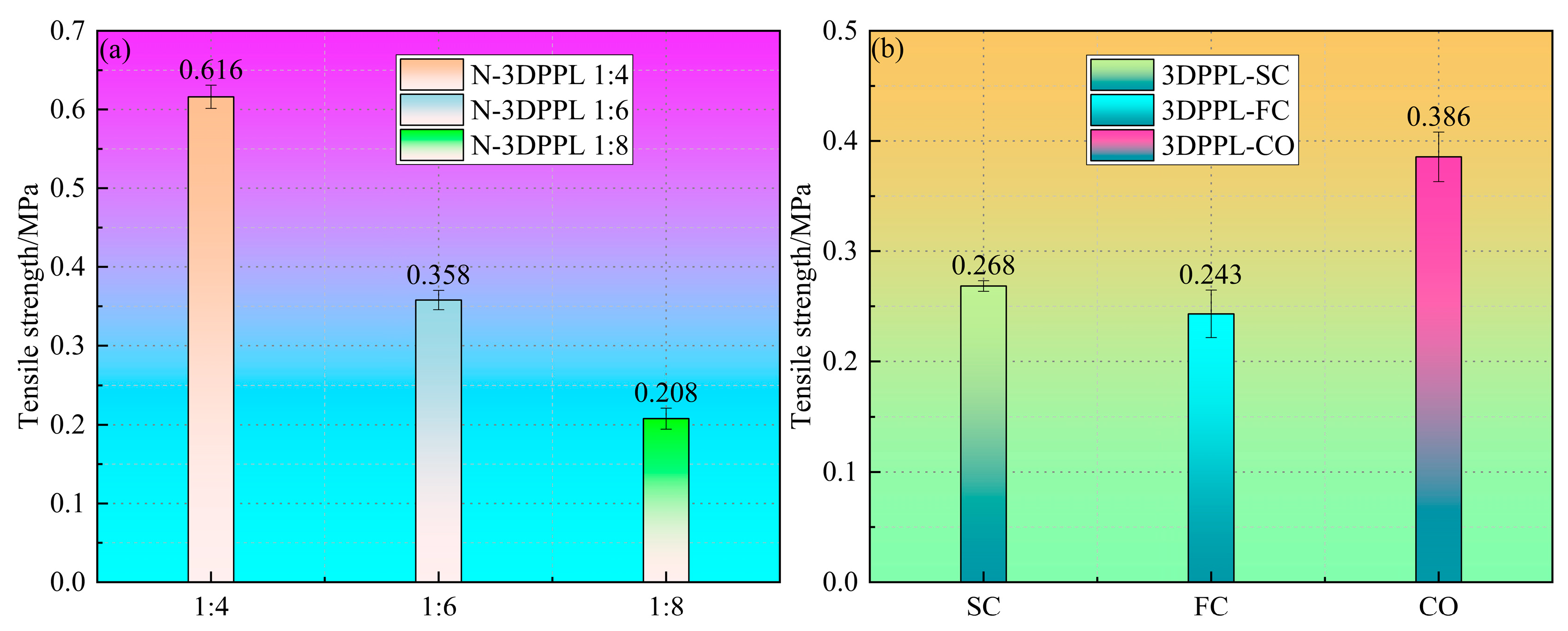

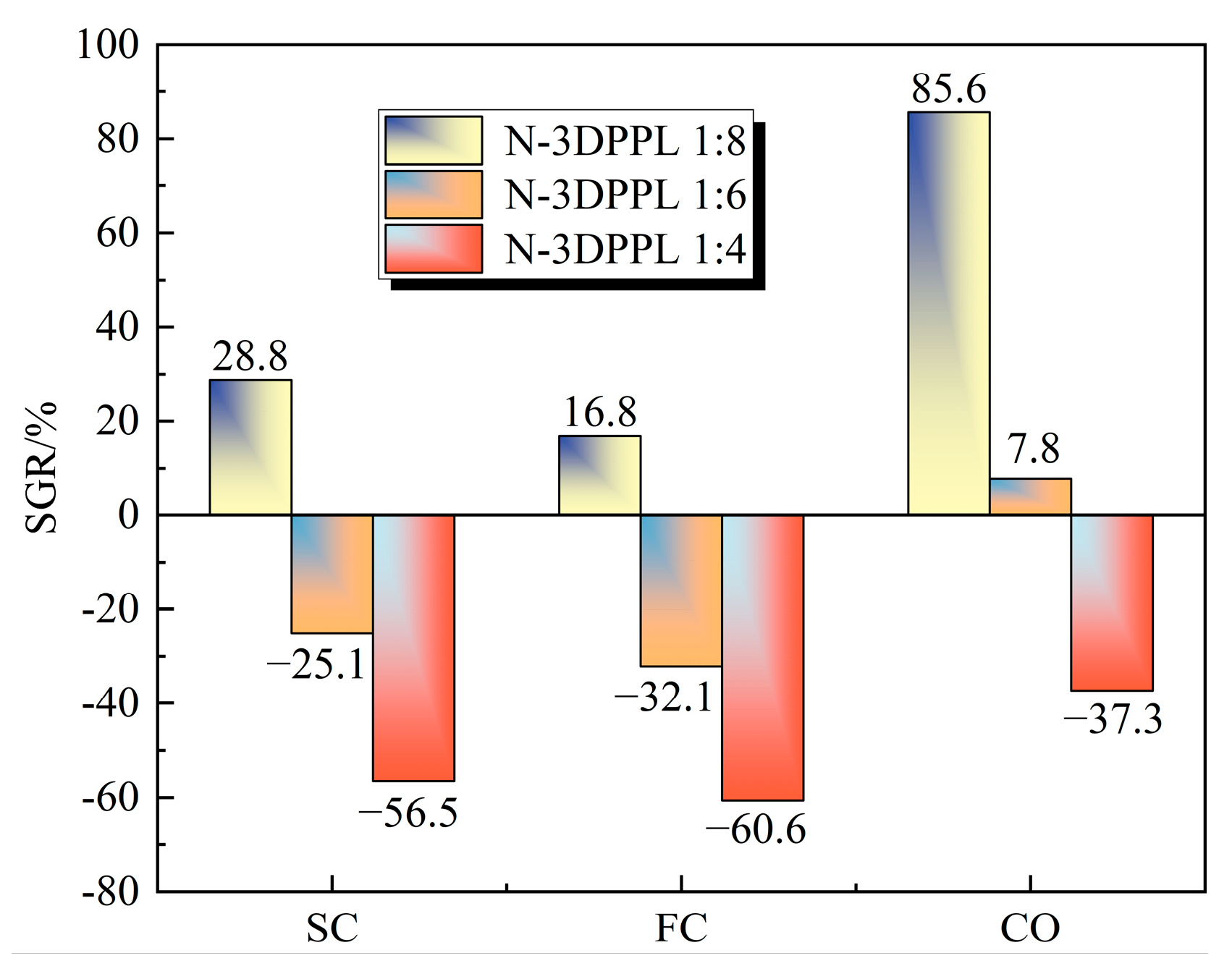

3.1. The Tensile Strength of All CTB

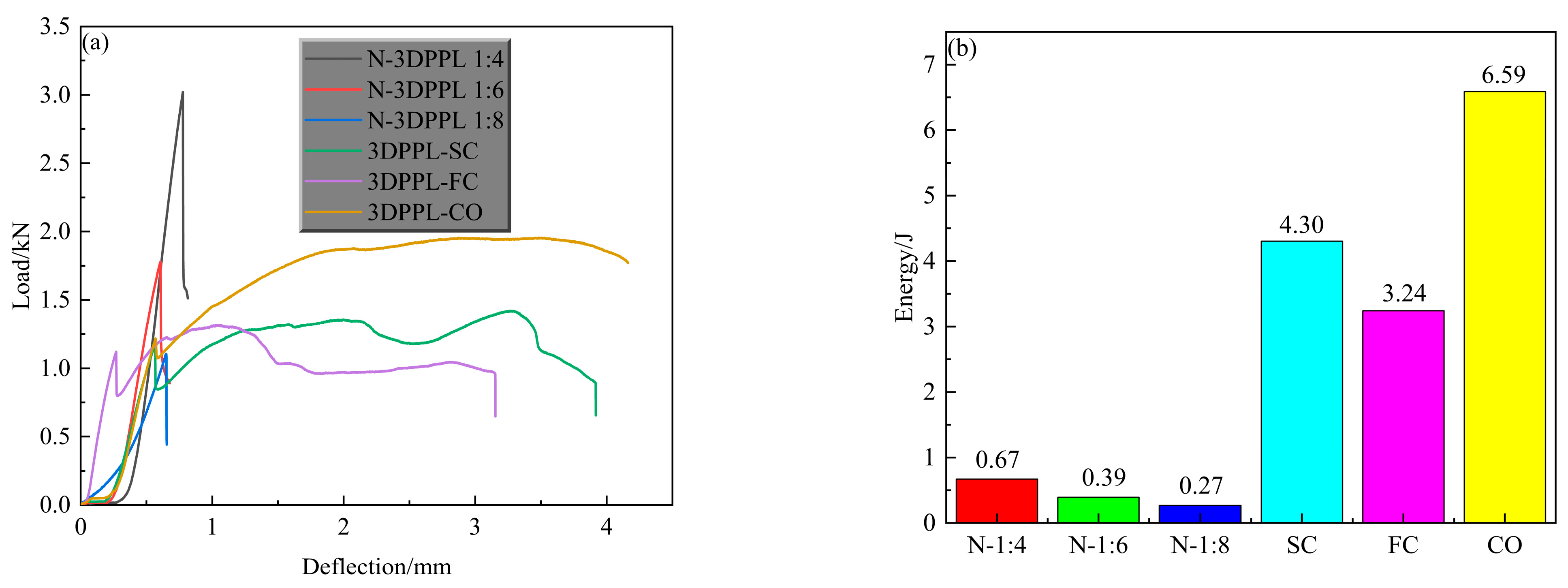

3.2. The Load–Deflection Curves Obtained from the Brazilian Tensile Test

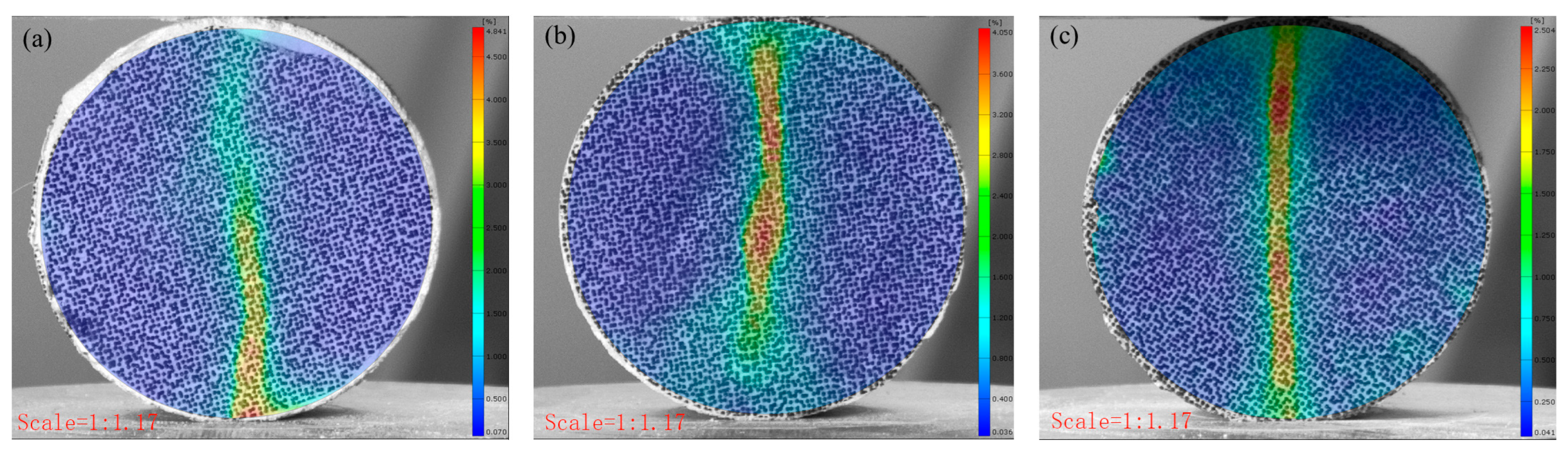

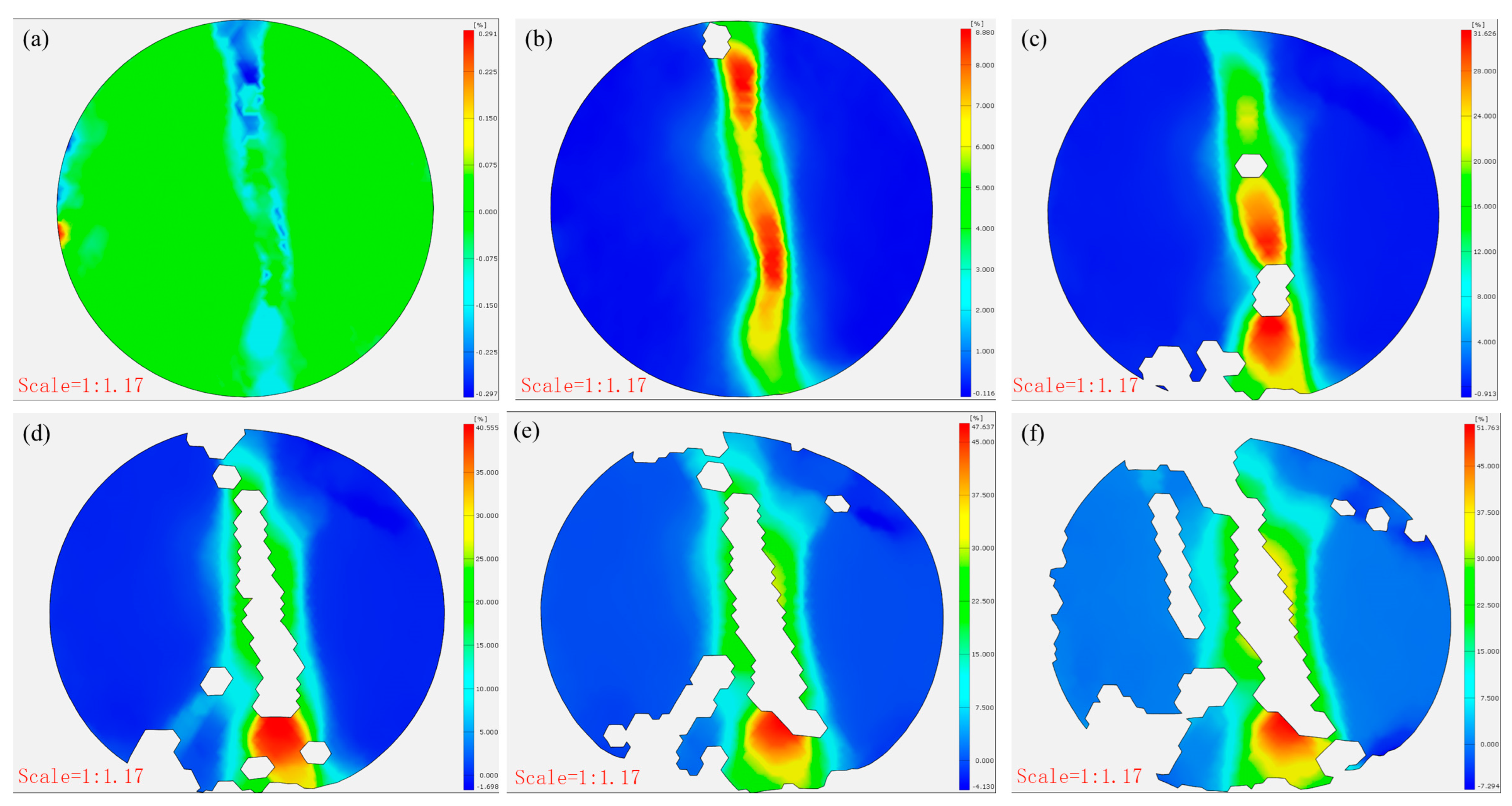

3.3. The Failure Behavior of CTB Through DIC Analysis

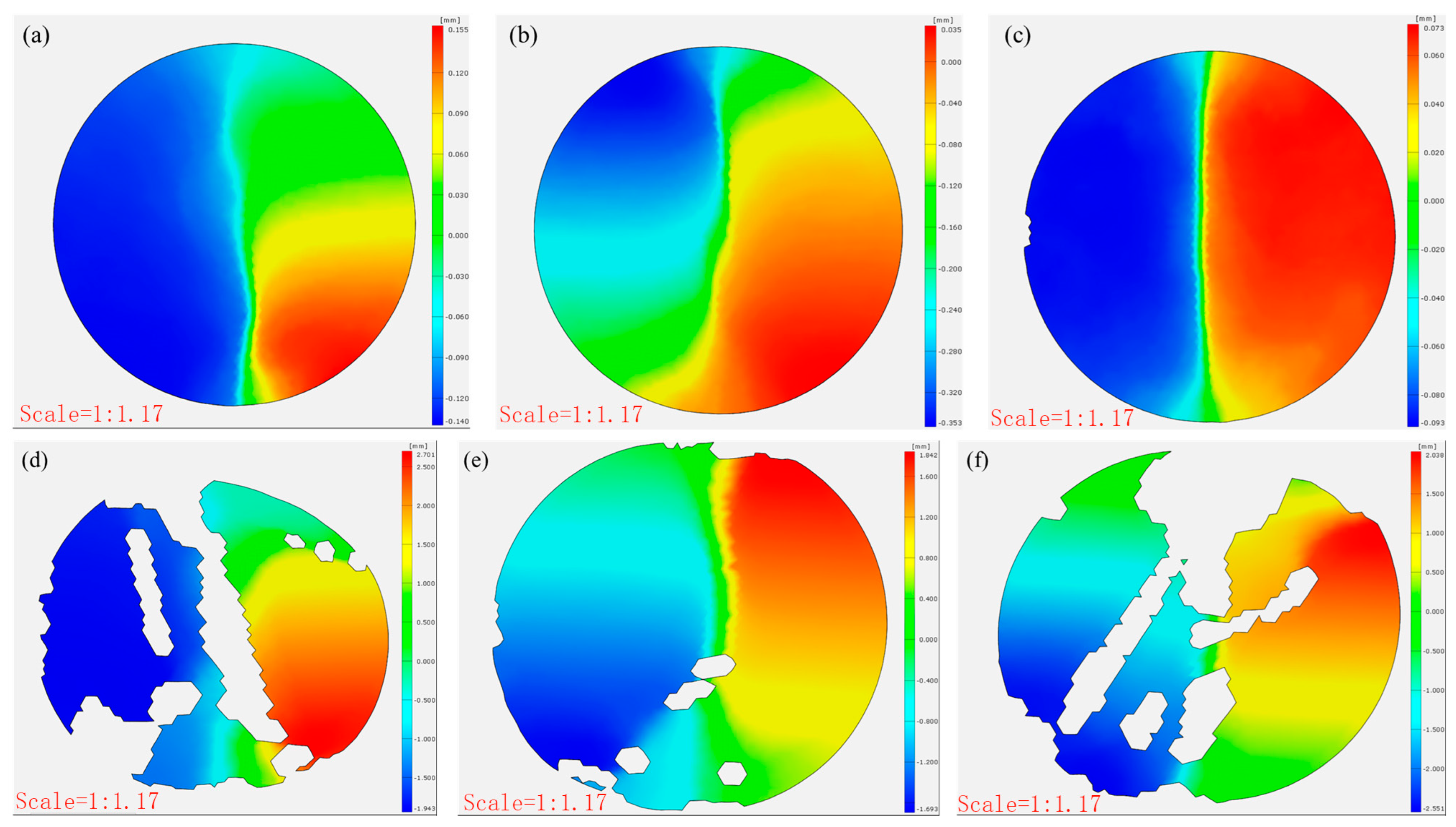

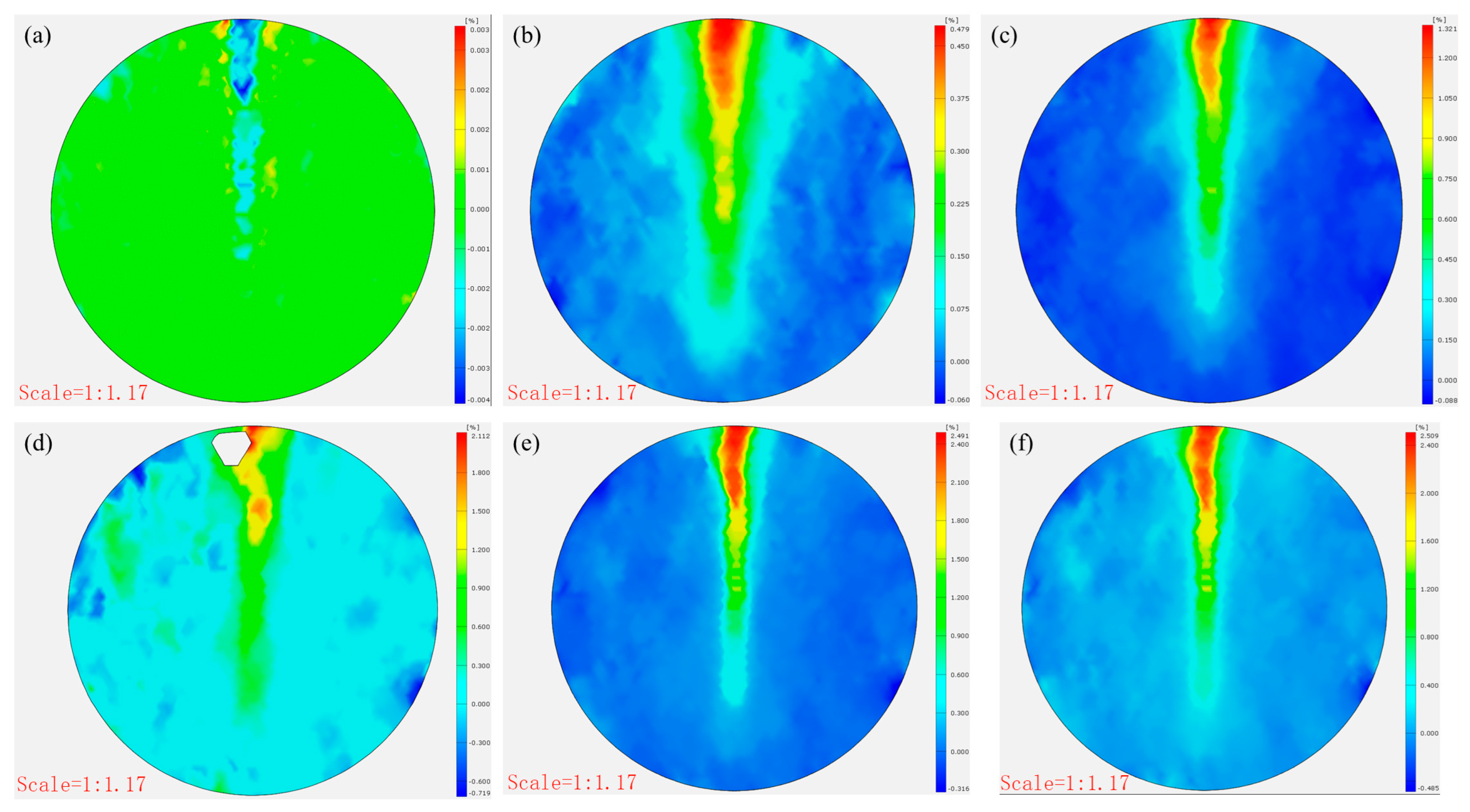

3.4. The Strain and Displacement Analysis of CTB Based on DIC Analysis

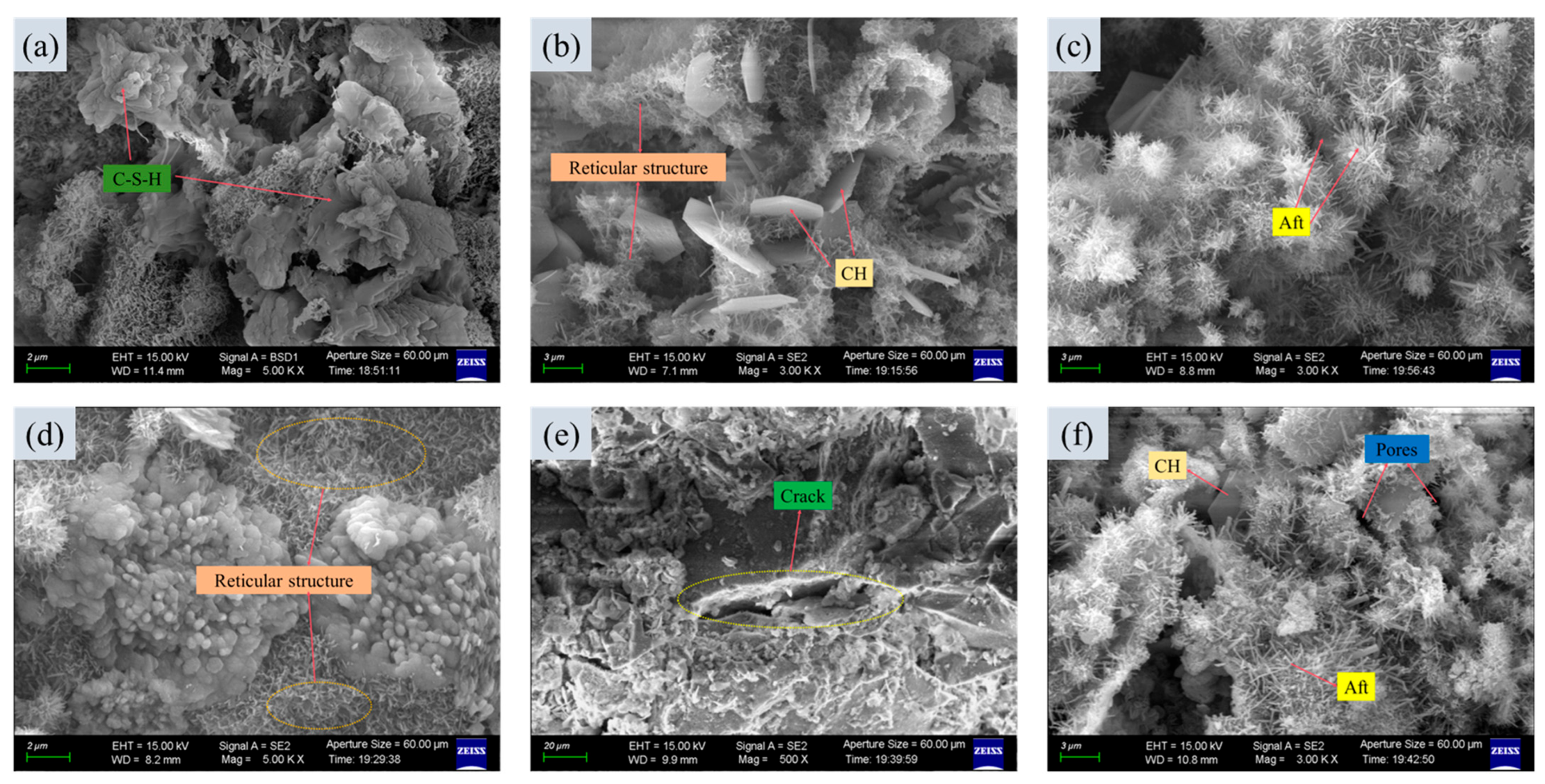

3.5. The Microscopic Analysis Through SEM

4. Conclusions

5. The Advantage of 3DPPL Application

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qiu, J.; Xiang, J.; Zhang, W.; Zhao, Y.; Sun, X.; Gu, X. Effect of microbial-cemented on mechanical properties of iron tailings backfill and its mechanism analysis. Constr. Build. Mater. 2022, 318, 126001. [Google Scholar] [CrossRef]

- Khalil, A.; Ait-Khouia, Y.; Beniddar, H.; EI Ghorfi, M. Sustainable reprocessing of Pb–Zn mine tailings through froth flotation for resource recovery and environmental remediation in abandoned mining regions. Miner. Eng. 2025, 222, 109132. [Google Scholar] [CrossRef]

- Meng, X.; Tang, Z.; Gao, P.; Zhang, Y. Mechanistic Analysis of Hydrogen Mineral Phase-Transformed Iron Ore Tailings in Cementitious Materials: A Study on Hydration Kinetics, Mechanical Properties, and Microstructural Characteristics. Constr. Build. Mater. 2025, 475, 141260. [Google Scholar] [CrossRef]

- Jin, J.; Chen, Y.; Li, M.; Liu, T.; Qin, Z.; Liu, Q.; Liang, B.; Zhao, J.; Zuo, S. Preparation of self-consolidating cemented backfill with tailings and alkali activated slurry: Performance evaluation and environmental impact. Constr. Build. Mater. 2024, 438, 137088. [Google Scholar] [CrossRef]

- Sun, X.; Xiang, J.; Xiong, B.; Kong, X.; Qiu, J. Combined biological and cement solidification of lead-zinc tailings for backfill preparation and its environmental effects. Constr. Build. Mater. 2024, 420, 135601. [Google Scholar] [CrossRef]

- Zhang, X.; Xue, X.; Ding, D.; Sun, P.; Li, J.; He, Y. A study of the mechanical properties, environmental effect, and microscopic mechanism of phosphorus slag-based uranium tailings backfilling materials. J. Clean. Prod. 2024, 446, 141306. [Google Scholar] [CrossRef]

- Benkirane, O.; Haruna, S.; Fall, M. Strength and microstructure of cemented paste backfill modified with nano-silica particles and cured under non-isothermal conditions. Powder Technol. 2023, 419, 118311. [Google Scholar] [CrossRef]

- Wu, J.; Wong, H.S.; Yin, Q.; Ma, D. Effects of aggregate strength and mass fraction on mesoscopic fracture characteristics of cemented rockfill from gangue as recycled aggregate. Compos. Struct. 2023, 311, 116851. [Google Scholar] [CrossRef]

- Liu, Z.; Gan, D.; Sun, H.; Xue, Z.; Zhang, Y. Dynamic impact performance of cemented tailings backfill in a water-bearing environment: Coupling effects and damage characteristics. Soil Dyn. Earthq. Eng. 2025, 191, 109249. [Google Scholar] [CrossRef]

- Chen, Q.; Sun, S.; Liu, Y.; Qi, C.; Zhou, H.; Zhang, Q. Immobilization and leaching characteristics of fluoride from phosphogypsum-based cemented paste backfill. Int. J. Miner. Metall. Mater. 2021, 28, 1440–1452. [Google Scholar] [CrossRef]

- Chen, W.; Chen, L.; Yin, S. Effect of bacteria-fly-ash based binder on cemented tailings backfill: Mechanical strength, solidified mechanism and economic benefits. Constr. Build. Mater. 2024, 448, 138292. [Google Scholar] [CrossRef]

- Wu, D.; Zhao, P.; Cheng, W.; Hao, Z.; Zhang, Y. Effect of microwave on coupled rheological and mechanical properties of cemented tailings backfill. Constr. Build. Mater. 2024, 441, 137558. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, S.; Min, L.; Yin, L.; Rui, H.; Zhang, H. Study on the evolution of mechanical properties of backfill body under the combined action of sulfate erosion and load. Case Stud. Constr. Mater. 2024, 21, e03977. [Google Scholar] [CrossRef]

- Zhao, B.; Wen, J.; Zhai, D.; Tang, R.; Chen, S.; Xin, J. Effect of calcium chloride on the properties of gangue cemented paste backfill: Experimental results of setting time, rheological properties, mechanical strength and microscopic properties. Case Stud. Constr. Mater. 2025, 22, e04331. [Google Scholar] [CrossRef]

- Al-Moselly, Z.; Fall, M. Multiphysical testing of strength development of cemented paste backfill containing superplasticizer. Cem. Concr. Compos. 2024, 154, 105772. [Google Scholar] [CrossRef]

- Haruna, S.; Fall, M. Strength development of cemented tailings materials containing polycarboxylate ether-based superplasticizer: Experimental results on the effect of time and temperature. Can. J. Civ. Eng. 2021, 48, 429–442. [Google Scholar] [CrossRef]

- Zou, S.; Gao, Y.; Zhou, Y.; Sun, H.; Yang, Z.; Yang, C.; Jiang, H. Study on the multi-scale tensile mechanical behavior of fiber reinforced cemented tailings backfill considering surface roughness effects. Constr. Build. Mater. 2025, 462, 139988. [Google Scholar] [CrossRef]

- Huang, Z.; Cao, S.; Yilmaz, E. Investigation on the flexural strength, failure pattern and microstructural characteristics of combined fibers reinforced cemented tailings backfill. Constr. Build. Mater. 2021, 300, 124005. [Google Scholar] [CrossRef]

- Zhao, K.; Shi, Y.; Yan, Y.; Ma, C.; Liu, Y.; Nie, Q. Acoustic emission response precursor characterization of cemented tailings backfill at different loading rates. Constr. Build. Mater. 2025, 473, 141027. [Google Scholar] [CrossRef]

- Yang, L.; Kou, Y.; Li, G.; Chen, M.; Zhu, G.; Song, Z.; Wang, P. Investigation of macro-micro mechanical behaviors and failure mechanisms in cemented tailings backfill with varying proportions of fine. Constr. Build. Mater. 2024, 438, 137098. [Google Scholar] [CrossRef]

- Li, J.; Yilmaz, E.; Cao, S. Influence of solid content, cement/tailings ratio, and curing time on rheology and strength of cemented tailings backfill. Minerals 2020, 10, 922. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Cui, L.; Bi, C.; Wu, A. Insight into the isothermal multiphysics processes in cemented paste backfill: Effect of curing time and cement-to-tailings ratio. Constr. Build. Mater. 2022, 325, 126739. [Google Scholar] [CrossRef]

- Libos, I.L.S.; Cui, L. Effects of curing time, cement content, and saturation state on mode-I fracture toughness of cemented paste backfill. Eng. Fract. Mech. 2020, 235, 107174. [Google Scholar] [CrossRef]

- Pan, H.; Xiao, Q.; Huang, N.; Xiao, A.; Zhu, D. Effect of alkaline rice straw fibers content and curing ages on static mechanical properties of cemented lithium mica tailings backfill. Case Stud. Constr. Mater. 2024, 21, e03450. [Google Scholar] [CrossRef]

- Xin, J.; Liu, L.; Xu, L.; Wang, J.; Qu, H. A preliminary study of aeolian sand-cement-modified gasification slag-paste backfill: Fluidity, microstructure, and leaching risks. Sci. Total Environ. 2022, 830, 154766. [Google Scholar] [CrossRef]

- Jin, J.; Liu, T.; Li, M.; Lv, T.; Zhang, S.; Zuo, S. Mechanical properties and compression damage characteristics of coal gangue-filled backfill cemented by fly ash modified self-consolidating grouts. Case Stud. Constr. Mater. 2025, 22, e04687. [Google Scholar] [CrossRef]

- Zhu, D.; Huang, N.; Li, W.; Li, J.; Wu, X. Effect of different fibers and fiber contents on the mechanical properties and failure behavior of early age cemented lithium feldspar tailings backfill. Dev. Built Environ. 2024, 19, 100495. [Google Scholar] [CrossRef]

- Zou, S.; Guo, W.; Wang, S.; Gao, Y.; Qian, L.; Zhou, Y. Investigation of the dynamic mechanical properties and damage mechanisms of fiber-reinforced cemented tailing backfill under triaxial split-Hopkinson pressure bar testing. J. Mater. Res. Technol. 2023, 27, 105–121. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, B.; Zhu, S.; Han, B.; Zheng, L.; Chen, D.; Liu, Z. Preparation of high-performance and environmentally friendly superfine tailings cemented paste backfill using cellulose nanofibers. Process Saf. Environ. Prot. 2025, 196, 106901. [Google Scholar] [CrossRef]

- Zhu, T.; Chen, Z.; Wang, Z.; Cao, J.; Hao, J.; Zhou, Z. Energy damage evolution and mesoscopic failure mechanism of cemented waste rock tailing backfill under axial compression. Structures 2025, 71, 108057. [Google Scholar] [CrossRef]

- Huang, J.; Wu, C.; Huang, N.; Deng, L.; Zhu, D. Utilization of waste rock from a low-carbon perspective: Mechanical performance analysis of waste rock-cemented tailings backfill. J. CO2 Util. 2025, 94, 103058. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Yu, Z.; Huang, P. Determination of mechanical, flowability, and microstructural properties of cemented tailings backfill containing rice straw. Constr. Build. Mater. 2020, 246, 118520. [Google Scholar] [CrossRef]

- Liu, W.; Yu, H.; Wang, S.; Wei, M.; Wang, X.; Tao, T.; Song, X. Evolution mechanism of mechanical properties of cemented tailings backfill with partial replacement of cement by rice straw ash at different binder content. Powder Technol. 2023, 419, 118344. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, J.; Kirichek, A.; Zhou, H.; Liu, C.; Yang, L. Recycling waste tyre polymer for production of fibre reinforced cemented tailings backfill in green mining. Sci. Total Environ. 2024, 908, 168320. [Google Scholar] [CrossRef]

- Su, L.; Wu, S.; Yang, J.; Zhang, M.; Zhu, W.; Fu, X. Experimental study on the dynamic mechanical properties of polypropylene fibre-reinforced coal gangue-cemented backfill. Constr. Build. Mater. 2025, 459, 139843. [Google Scholar] [CrossRef]

- Zou, S.; Gao, Y.; Zhou, Y.; Sun, H.; Yang, Z.; Yang, C.; Chai, J.; Qian, L. Mechanical Properties of Organic-Inorganic Hybrid Fiber Reinforced Cemented Tailings Backfill Considering Energy Evolution and Damage Fracture Characteristics. J. Mater. Res. Technol. 2025, 35, 4614–4633. [Google Scholar] [CrossRef]

- Yin, S.; Hou, Y.; Chen, X.; Zhang, M.; Du, H.; Gao, C. Mechanical behavior, failure pattern and damage evolution of fiber-reinforced cemented sulfur tailings backfill under uniaxial loading. Constr. Build. Mater. 2022, 332, 127248. [Google Scholar] [CrossRef]

- Wang, J.; Yu, Q.; Xiang, Z.; Fu, J.; Wang, L.; Song, W. Influence of basalt fiber on pore structure, mechanical performance and damage evolution of cemented tailings backfill. J. Mater. Res. Technol. 2023, 27, 5227–5242. [Google Scholar] [CrossRef]

- Hou, Y.; Yang, K.; Yin, S.; Yu, X.; Kou, P.; Wang, Y. Enhancing workability, strength, and microstructure of cemented tailings backfill through mineral admixtures and fibers. J. Build. Eng. 2024, 84, 108590. [Google Scholar] [CrossRef]

- Xue, G.; Yilmaz, E. Strength, acoustic, and fractal behavior of fiber reinforced cemented tailings backfill subjected to triaxial compression loads. Constr. Build. Mater. 2022, 338, 127667. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Wu, C.; Zhu, D. Influence of fiber type and content on the flexural strength of cemented lithium feldspar tailings backfill composites. J. CO2 Util. 2024, 90, 102990. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, T.; Li, Y.; Li, Z.; Li, H.; Zhang, B.; Li, J.; Li, Y.; Ni, W. The effects and solidification characteristics of municipal solid waste incineration fly ash-slag-tailing based backfill blocks in underground mine condition. Constr. Build. Mater. 2024, 420, 135508. [Google Scholar] [CrossRef]

- Wang, A.; Cao, S.; Yilmaz, E. Quantitative analysis of pore characteristics of nanocellulose reinforced cementitious tailings fills using 3D reconstruction of CT images. J. Mater. Res. Technol. 2023, 26, 1428–1444. [Google Scholar] [CrossRef]

- Zhu, T.; Chen, Z.; Cao, J.; Wang, Z.; Hao, J.; Zhou, Z. Crack resistance of cemented waste rock tailings backfill under splitting tensile load: Experimental and numerical investigations. J. Build. Eng. 2025, 99, 111665. [Google Scholar] [CrossRef]

- Zhang, L.; Lai, X.; Pan, J.; Shan, P.; Zhang, Y.; Zhang, Y.; Xu, H.; Cai, M.; Xi, X. Experimental investigation on the mixture optimization and failure mechanism of cemented backfill with coal gangue and fly ash. Powder Technol. 2024, 440, 119751. [Google Scholar] [CrossRef]

- Jiang, X.; Lang, L.; Liu, S.; Mu, F.; Wang, Y.; Zhang, Z.; Han, L.; Duan, S.; Wang, P.; Li, J. Stabilization of iron ore tailing with low-carbon lime/carbide slag-activated ground granulated blast-furnace slag and coal fly ash. Constr. Build. Mater. 2024, 413, 134946. [Google Scholar] [CrossRef]

- Cheng, Y.; Shen, H.; Zhang, J. Understanding the effect of high-volume fly ash on micro-structure and mechanical properties of cemented coal gangue paste backfill. Constr. Build. Mater. 2023, 378, 131202. [Google Scholar] [CrossRef]

- Wang, A.; Cao, S.; Yilmaz, E. Influence of types and contents of nano cellulose materials as reinforcement on stability performance of cementitious tailings backfill. Constr. Build. Mater. 2022, 344, 128179. [Google Scholar] [CrossRef]

- Cao, S.; Che, C.; Zhang, Y.; Shan, C.; Liu, Y.; Zhao, C.; Du, S. Mechanical properties and damage evolution characteristics of waste tire steel fiber-modified cemented paste backfill. Int. J. Min. Sci. Technol. 2024, 34, 909–924. [Google Scholar] [CrossRef]

- Zhu, T.; Chen, Z.; Wang, Z.; Cao, J.; Hao, J.; Zhou, Z. Experimental and DEM analyses of type I fracture characteristics of waste rock aggregate reinforced cemented tailing backfill. Theor. Appl. Fract. Mech. 2025, 135, 104764. [Google Scholar] [CrossRef]

- Wang, B.; Kang, M.; Liu, C.; Yang, L.; Li, Q.; Zhou, S. Experimental study on mechanical and microstructure properties of cemented tailings-waste rock backfill with continuous gradation. J. Build. Eng. 2024, 95, 110146. [Google Scholar] [CrossRef]

- Wu, J.; Jing, H.; Yin, Q.; Meng, B.; Han, G. Strength and ultrasonic properties of cemented waste rock backfill considering confining pressure, dosage and particle size effects. Constr. Build. Mater. 2020, 242, 118132. [Google Scholar] [CrossRef]

- Takva, Ç.; Top, S.M.; Gökgöz, B.İ.; Gebel, Ş.; Ilerisoy, Z.Y.; Ilcan, H.; Şahmaran, M. Applicability of 3D concrete printing technology in building construction with different architectural design decisions in housing. J. Build. Eng. 2024, 98, 111257. [Google Scholar] [CrossRef]

- Wu, H.J.; Diao, J.B.; Li, X.R.; Yue, D.M.; He, G.H.; Jiang, X.B.; Li, P.P. Hydrogel-based 3D printing technology: From interfacial engineering to precision medicine. Adv. Colloid Interface Sci. 2025, 341, 103481. [Google Scholar] [CrossRef] [PubMed]

- Shahpasand, R.; Talebian, A.; Mishra, S.S. Investigating environmental and economic impacts of the 3D printing technology on supply chains: The case of tire production. J. Clean. Prod. 2023, 390, 135917. [Google Scholar] [CrossRef]

- Chakraborty, S.; Biswas, M.C. 3D printing technology of polymer-fiber composites in textile and fashion industry: A potential roadmap of concept to consumer. Compos. Struct. 2020, 248, 112562. [Google Scholar] [CrossRef]

- Fang, R.C.; Wang, B.X.; Pan, J.J.; Liu, J.Q.; Wang, Z.H.; Wang, Q.; Ling, X.Z. Effect of concrete surface roughness on shear strength of frozen soil–concrete interface based on 3D printing technology. Constr. Build. Mater. 2023, 366, 130158. [Google Scholar] [CrossRef]

- Kantaros, A.; Piromalis, D. Fabricating lattice structures via 3D printing: The case of porous bio-engineered scaffolds. Appl. Mech. 2021, 2, 289–302. [Google Scholar] [CrossRef]

- Silva, R.G.; Estay, C.S.; Pavez, G.M.; Viñuela, J.Z.; Torres, M.J. Influence of geometric and manufacturing parameters on the compressive behavior of 3D printed polymer lattice structures. Materials 2021, 14, 1462. [Google Scholar] [CrossRef]

- Kantaros, A. 3D printing in regenerative medicine: Technologies and resources utilized. Int. J. Mol. Sci. 2022, 23, 14621. [Google Scholar] [CrossRef]

- Zou, S.; Cao, S.; Yilmaz, E. Enhancing flexural property and mesoscopic mechanism of cementitious tailings backfill fabricated with 3D-printed polymers. Constr. Build. Mater. 2024, 414, 135009. [Google Scholar] [CrossRef]

- Yaya, N.S.; Cao, S.; Yilmaz, E. Effect of 3D printed skeleton shapes on strength behavior, stress evolution and microstructural response of cement-based tailings backfills. Constr. Build. Mater. 2024, 432, 136699. [Google Scholar] [CrossRef]

- Zhang, H.; Cao, S.; Yilmaz, E. Polymer shape effect on damage evolution, internal defects and crack propagation of 3D-printed polymer-based cementitious backfill. Constr. Build. Mater. 2023, 406, 133386. [Google Scholar] [CrossRef]

- Li, J.; Cao, S.; Song, W. Flexural behavior of cementitious backfill composites reinforced by various 3D printed polymeric lattices. Compos. Struct. 2023, 323, 117489. [Google Scholar] [CrossRef]

- Qin, S.; Cao, S.; Yilmaz, E. Employing U-shaped 3D printed polymer to improve flexural properties of cementitious tailings backfills. Constr. Build. Mater. 2022, 320, 126296. [Google Scholar] [CrossRef]

- Qin, S.; Cao, S.; Yilmaz, E.; Li, J. Influence of types and shapes of 3D printed polymeric lattice on ductility performance of cementitious backfill composites. Constr. Build. Mater. 2021, 307, 124973. [Google Scholar] [CrossRef]

- Xue, G.; Yilmaz, E.; Song, W.; Yilmaz, E. Influence of fiber reinforcement on mechanical behavior and microstructural properties of cemented tailings backfill. Constr. Build. Mater. 2019, 213, 275–285. [Google Scholar] [CrossRef]

- Grice, T. Underground mining with backfill. In Proceedings of the 2nd Annual Summit œ Mine Tailings Disposal Systems, Brisbane, Australia, 24 November 1998; Volume 696, pp. 24–25. [Google Scholar]

- Hu, L.; Zheng, B.; Zhu, D.; Yang, Z.; Huang, N. Enhancing bending performance of cemented lithium feldspar tailings backfill with 3D printing polymer lattices: Effects of unit shapes and materials. Case Stud. Constr. Mater. 2025, 22, e04463. [Google Scholar] [CrossRef]

- Gao, Y.; Yu, Z.; Cheng, Z.; Chen, W.; Zhang, T.; Wu, J. Influence of industrial graphene oxide on tensile behavior of cemented waste rock backfill. Constr. Build. Mater. 2023, 371, 130787. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, L.; Liu, S.; Wei, X.; Zhao, Y.; Li, M. A comparative study on the workability, mechanical properties and microstructure of cemented fine tailings backfill with different binder. Constr. Build. Mater. 2024, 455, 139189. [Google Scholar] [CrossRef]

- Zhang, N.; Hedayat, A.; Sosa, H.G.B.; Bernal, R.P.H.; Tupa, N.; Morales, I.Y.; Loza, R.S.C. On the incorporation of class F fly-ash to enhance the geopolymerization effects and splitting tensile strength of the gold mine tailings-based geopolymer. Constr. Build. Mater. 2021, 308, 125112. [Google Scholar] [CrossRef]

- Liu, B.; Chen, Y.; Li, D.; Wang, Y.; Geng, S.; Qian, K. Study on the fracture behavior and anisotropy of 3D-printing PVA fiber-reinforced concrete. Constr. Build. Mater. 2024, 447, 138051. [Google Scholar] [CrossRef]

- Vemuganti, S.; Soliman, E.; Taha, M.M.R. Manipulating interfacial bond for controlling load transfer in 3D printed fiber reinforced polymer composites. J. Reinf. Plast. Compos. 2024. [CrossRef]

- Liu, Y.; Zhang, Z.; Shi, C.; Zhu, D.; Li, N.; Deng, Y. Development of ultra-high performance geopolymer concrete (UHPGC): Influence of steel fiber on mechanical properties. Cem. Concr. Compos. 2020, 112, 103670. [Google Scholar] [CrossRef]

- Wang, T.; Wu, K.; Wu, M. Development of green binder systems based on flue gas desulfurization gypsum and fly ash incorporating slag or steel slag powders. Constr. Build. Mater. 2020, 265, 120275. [Google Scholar] [CrossRef]

- Zhu, W.; Yang, L.; Hou, C.; Zhu, G.; Liu, X.; Liang, P. Effect of chloride salts on shear behavior of cemented tailings backfill (CTB) mixed with mine water in coastal regions. Int. J. Rock Mech. Min. Sci. 2025, 192, 106157. [Google Scholar] [CrossRef]

- Zuo, L.; Huang, N.; Wang, G.; Zhu, D. Influence of polypropylene fiber length and geometric shape on the compressive strength of cemented lepidolite tailings backfill. Front. Mater. 2024, 11, 1452843. [Google Scholar] [CrossRef]

- Mendoza, F.; Lu, R. Basics of image analysis. In Hyperspectral Imaging Technology in Food and Agriculture; Springer: New York, NY, USA, 2015; pp. 9–56. [Google Scholar]

| Polymer Material | Material Harness | Breaking Strength | Bending Strength | Bending Modulus | Tensile Strength | Heat Distortion Temperature |

|---|---|---|---|---|---|---|

| WR | 87 | 70 MPa | 84 MPa | 2.8 GPa | 60 MPa | 46 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Deng, L.; Gao, H.; Wu, C.; Li, J.; Zhu, D. Enhancing Tensile Performance of Cemented Tailings Backfill Through 3D-Printed Polymer Lattices: Mechanical Properties and Microstructural Investigation. Materials 2025, 18, 3314. https://doi.org/10.3390/ma18143314

Huang J, Deng L, Gao H, Wu C, Li J, Zhu D. Enhancing Tensile Performance of Cemented Tailings Backfill Through 3D-Printed Polymer Lattices: Mechanical Properties and Microstructural Investigation. Materials. 2025; 18(14):3314. https://doi.org/10.3390/ma18143314

Chicago/Turabian StyleHuang, Junzhou, Lan Deng, Haotian Gao, Cai Wu, Juan Li, and Daopei Zhu. 2025. "Enhancing Tensile Performance of Cemented Tailings Backfill Through 3D-Printed Polymer Lattices: Mechanical Properties and Microstructural Investigation" Materials 18, no. 14: 3314. https://doi.org/10.3390/ma18143314

APA StyleHuang, J., Deng, L., Gao, H., Wu, C., Li, J., & Zhu, D. (2025). Enhancing Tensile Performance of Cemented Tailings Backfill Through 3D-Printed Polymer Lattices: Mechanical Properties and Microstructural Investigation. Materials, 18(14), 3314. https://doi.org/10.3390/ma18143314