Ultra-High Strength and Specific Strength in Ti61Al16Cr10Nb8V5 Multi-Principal Element Alloy: Quasi-Static and Dynamic Deformation and Fracture Mechanisms

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

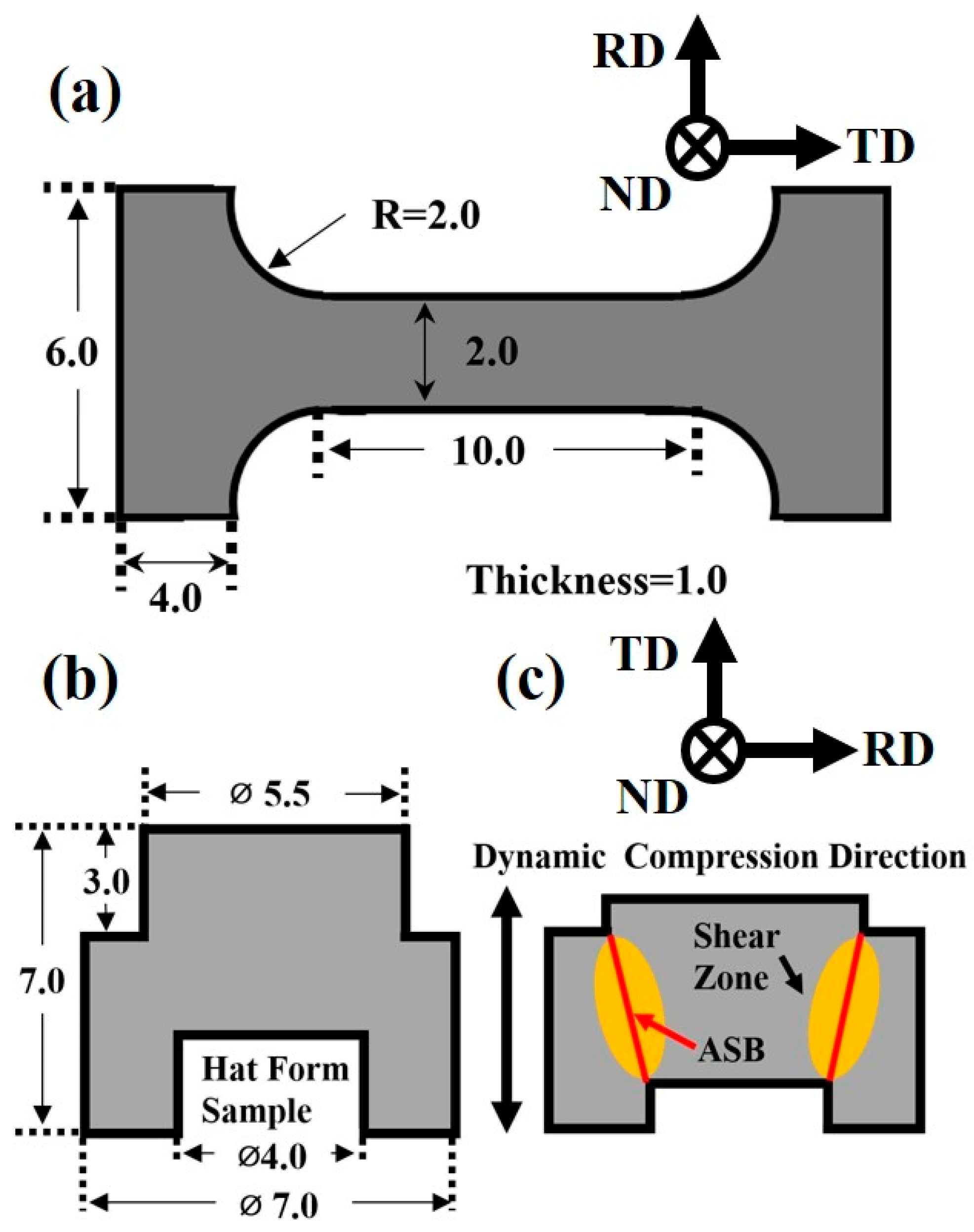

2.2. Experimental Methods

3. Experiment Results

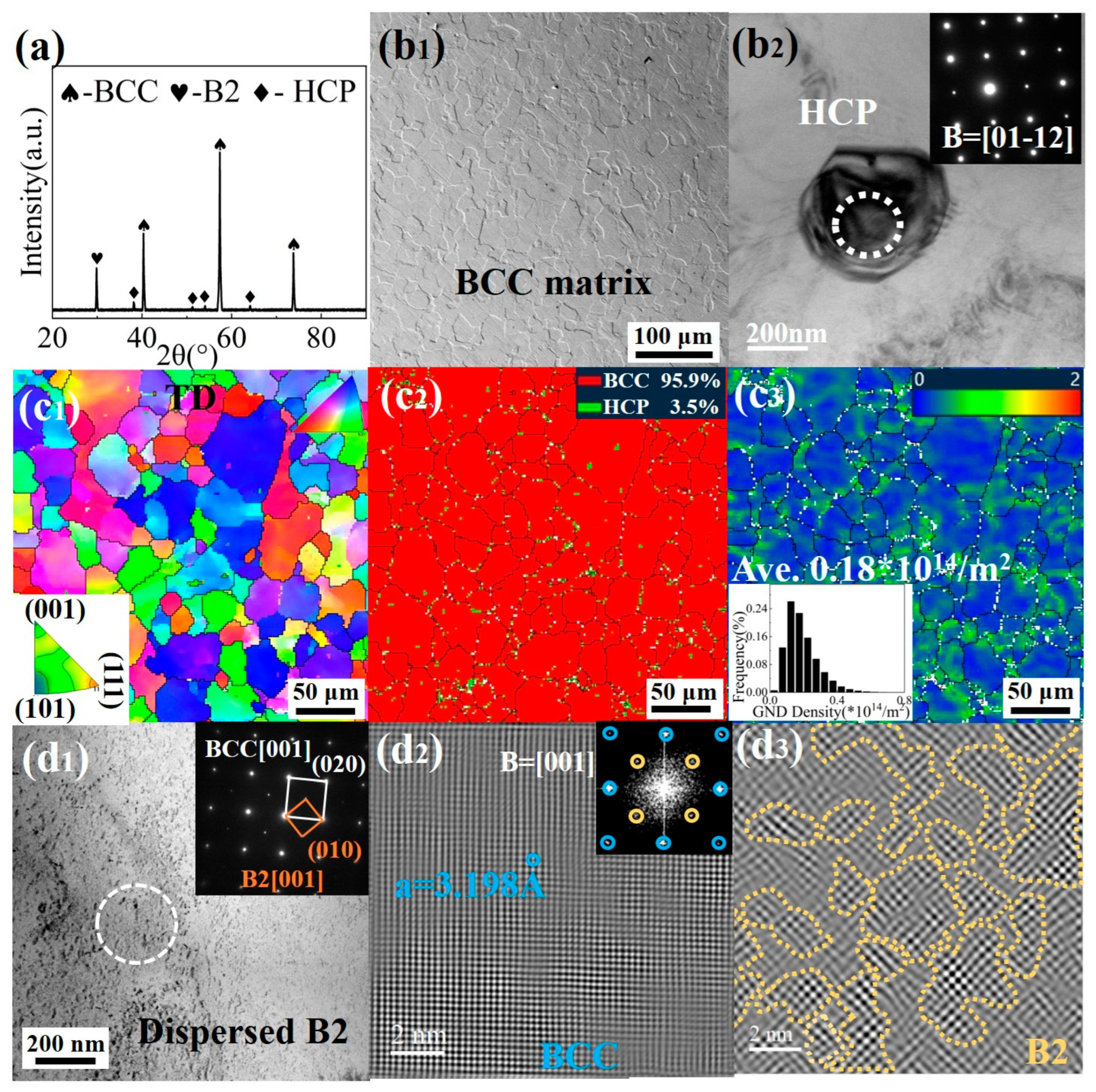

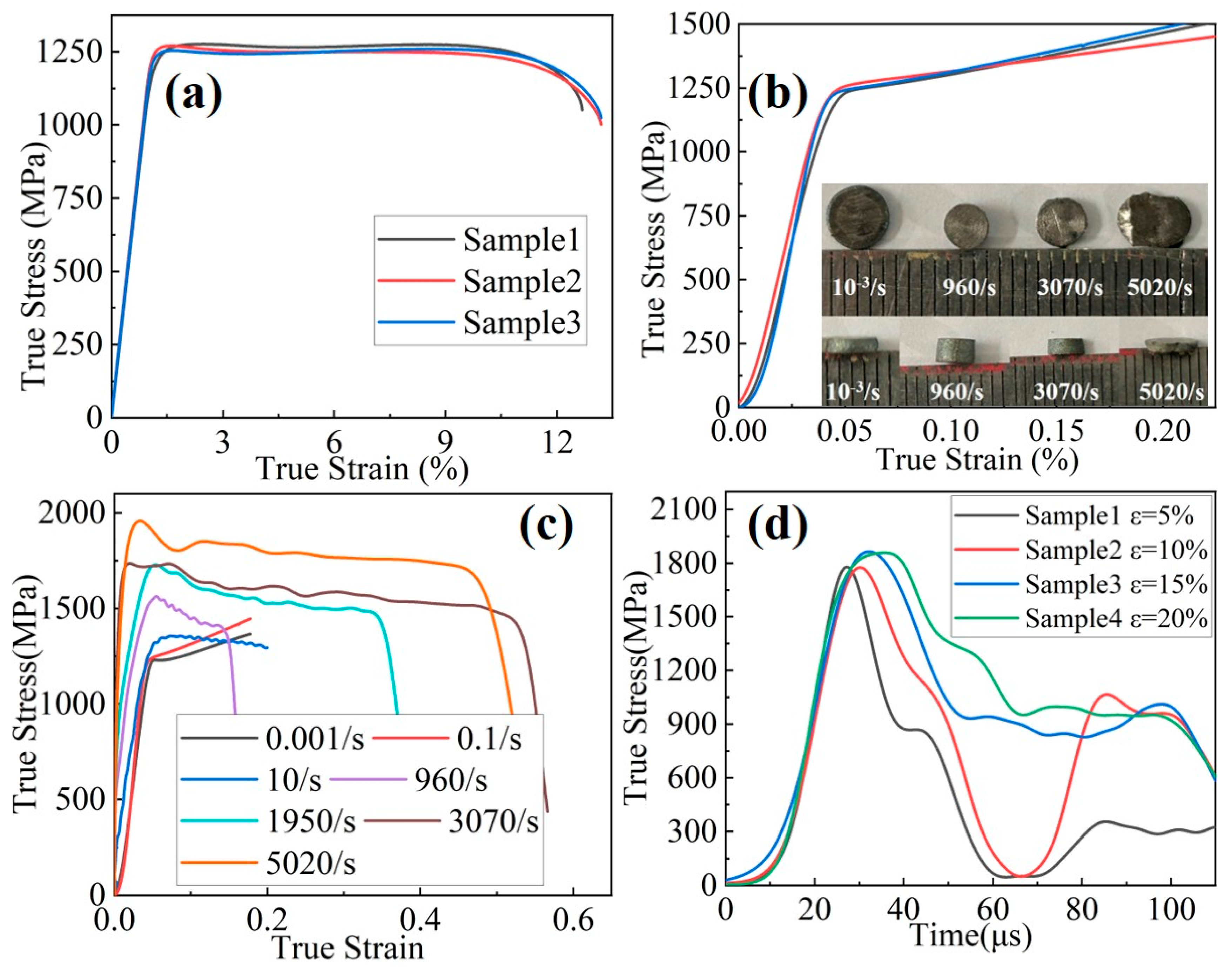

3.1. Microstructure and Mechanical Properties of Ti61V5 Alloy

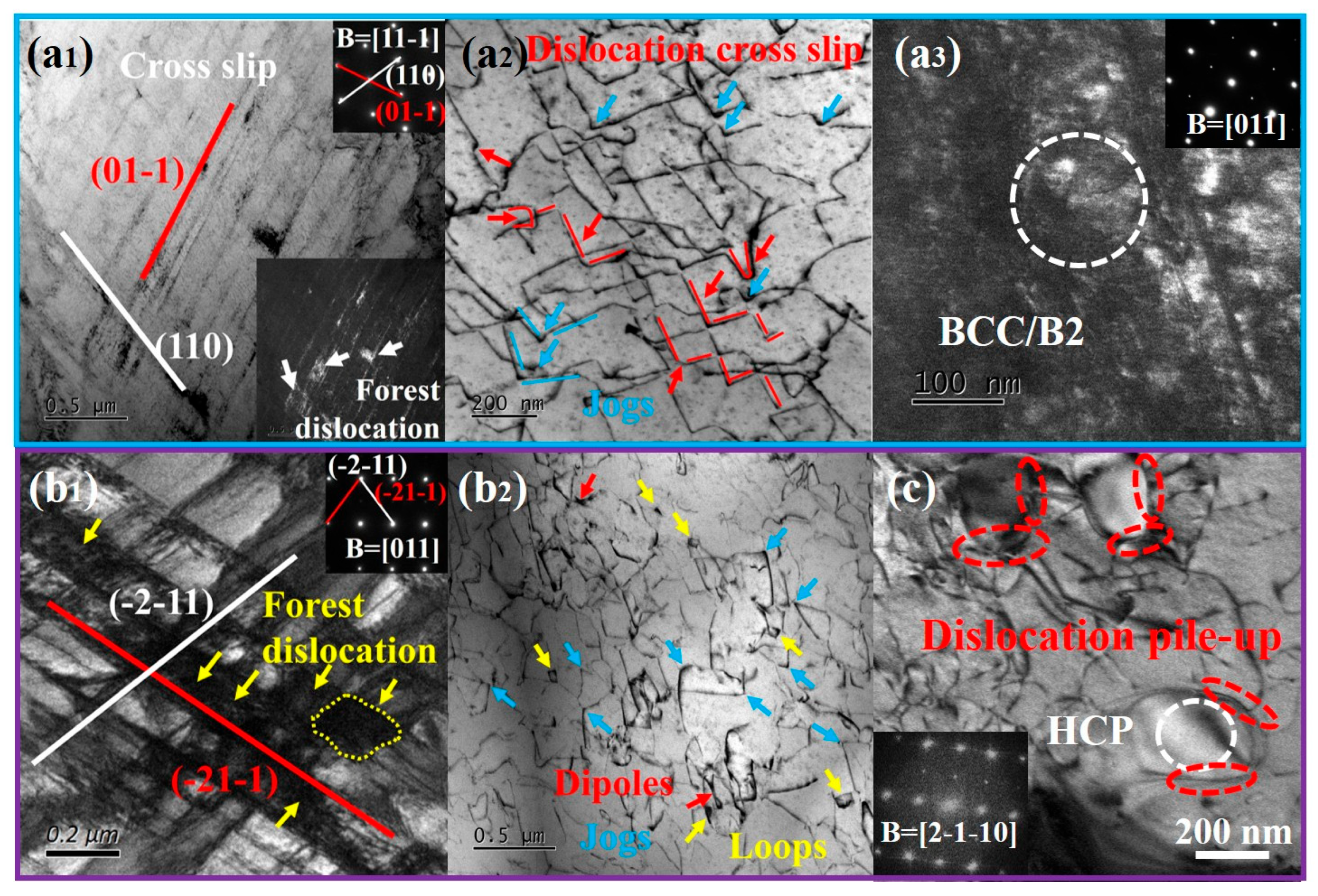

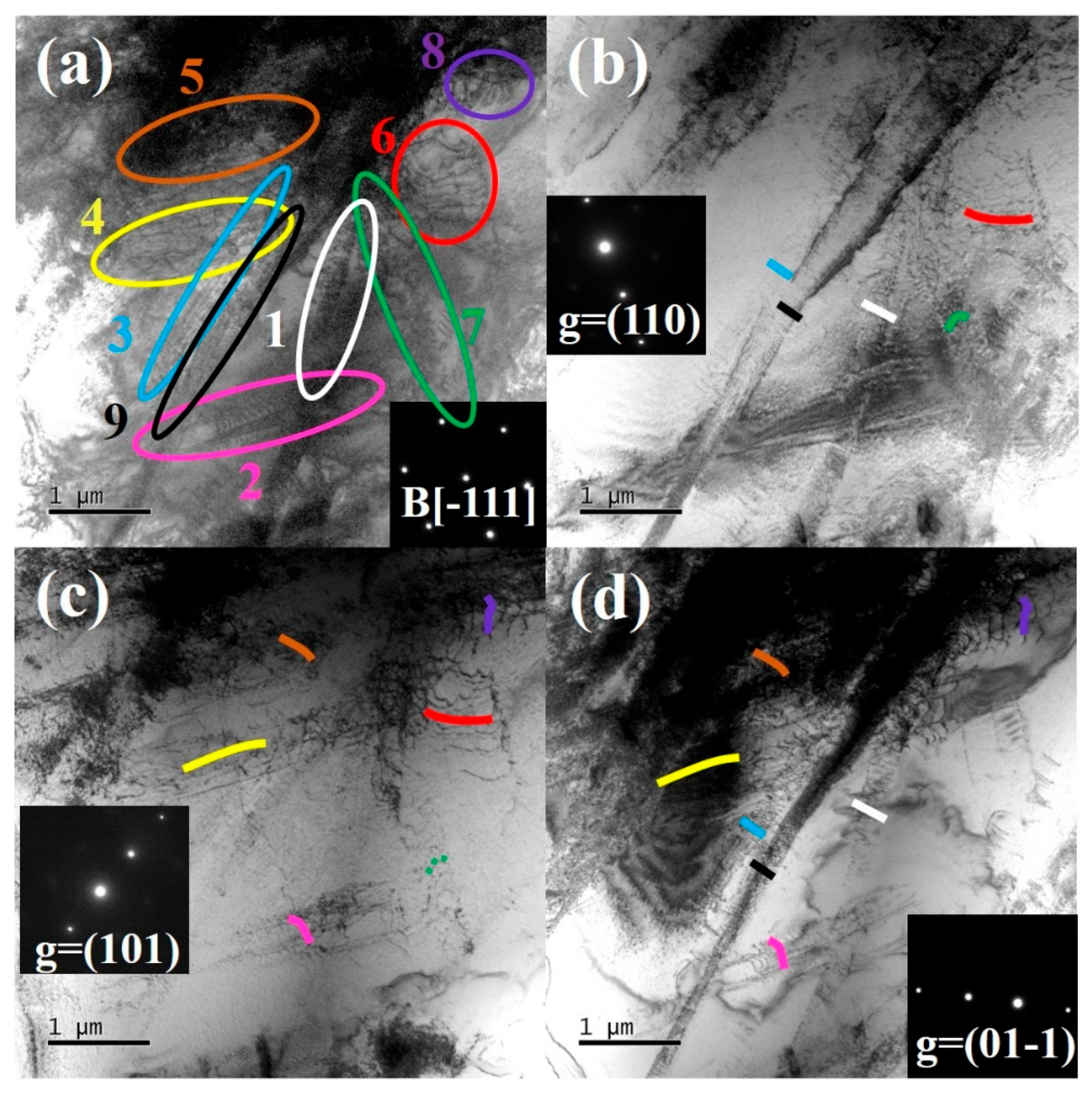

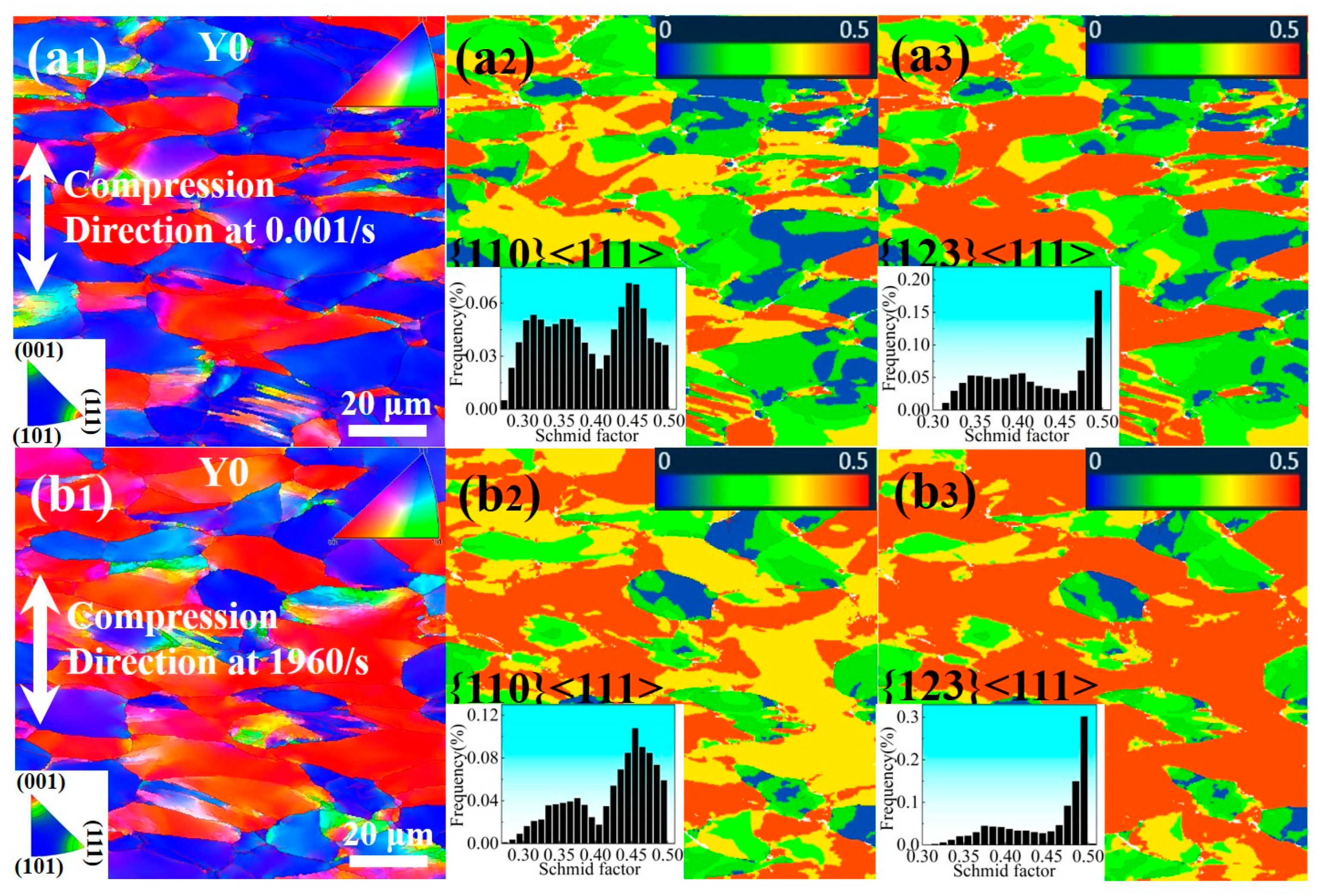

3.2. Plastic Deformation Mechanisms of Ti61V5 Alloy at Low Strain Rates

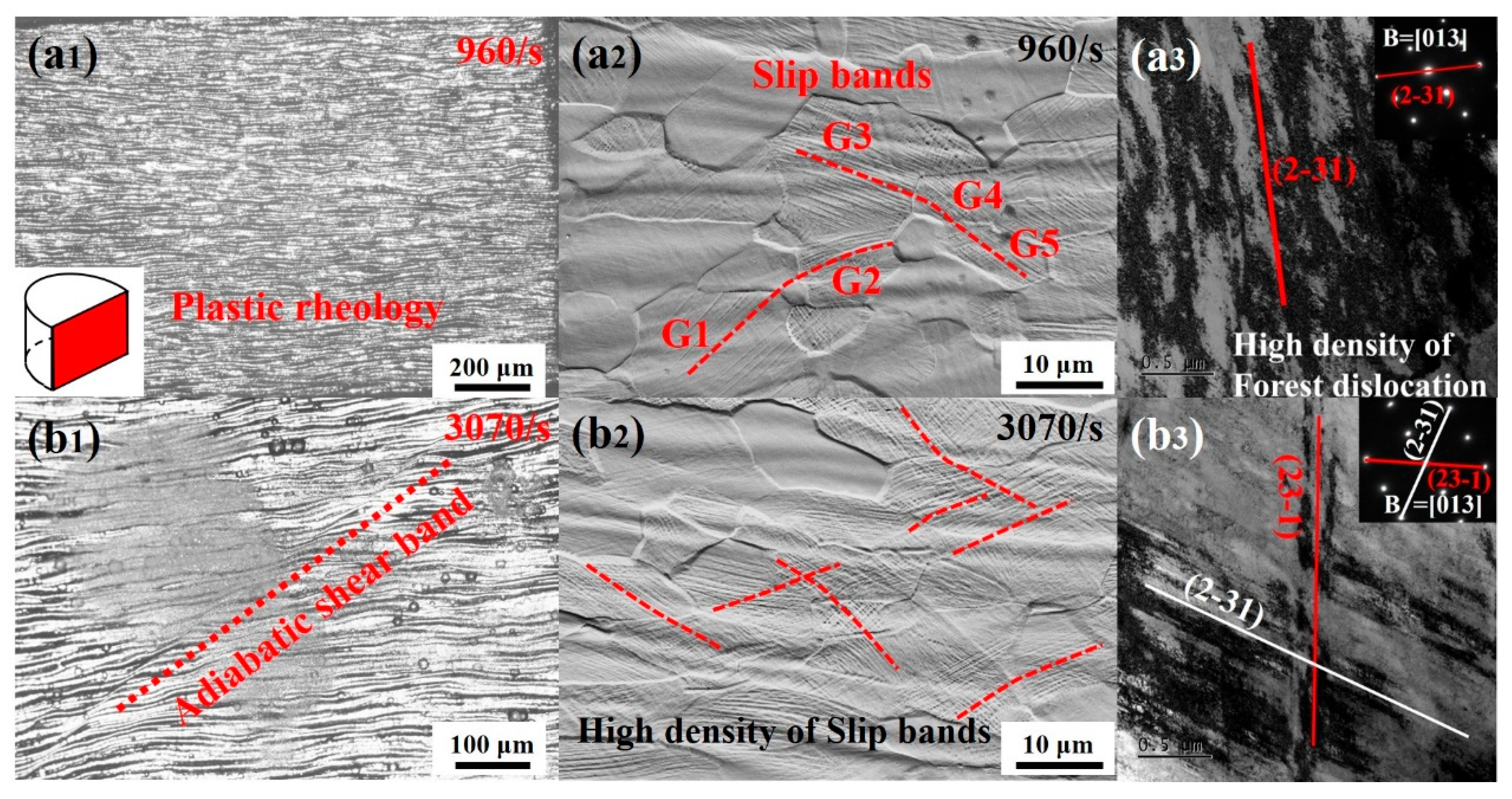

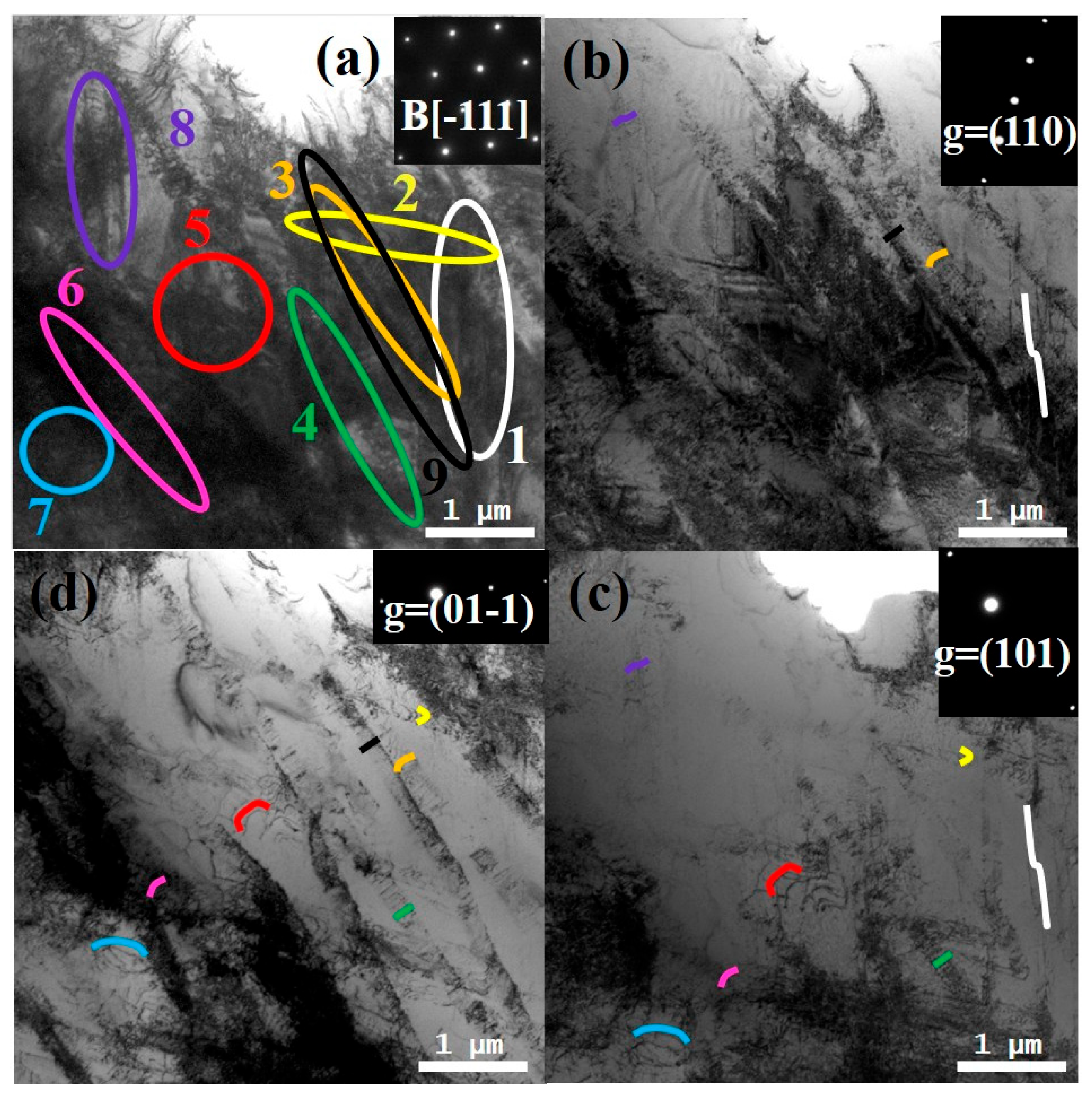

3.3. Plastic Deformation Mechanisms of Ti61V5 Alloy at High Strain Rates

3.4. Shear Band and Crack Evolution in Ti61V5 Alloy After Forced Shear Deformation

4. Discussion

4.1. Evolution of Dislocation Mechanisms in Ti61V5 Alloy Under Varying Strain Rates

4.2. Evolution of Deformation Mechanisms in Ti61V5 Alloy Under Varying Strain Rates

4.3. Comparative Mechanical Properties and Application Prospects of Ti61V5 Alloy

5. Conclusions

- (1)

- The Ti61V5 alloy consists of an equiaxed BCC matrix with an average grain size of ~35 μm. Nano-sized B2 precipitates are uniformly dispersed within the matrix, and approximately 3.5% of the microstructure comprises an HCP phase. The measured density is ~4.82 g/cm3. Quasi-static mechanical testing reveals a yield strength of 1110 MPa, an ultimate tensile strength of 1260 MPa, and an elongation of 12.8%, corresponding to an ultra-high specific strength of ~262 MPa·cm3/g. Dynamic compression tests indicate a pronounced strain-rate-strengthening effect, with the alloy achieving a flow stress of 1850 MPa and a compressive strain of 50% at a strain rate of 5020/s. These results suggest that the Ti61V5 alloy possesses high strength, exceptional specific strength, and good ductility, offering significant potential for applications in military armor and aerospace structures.

- (2)

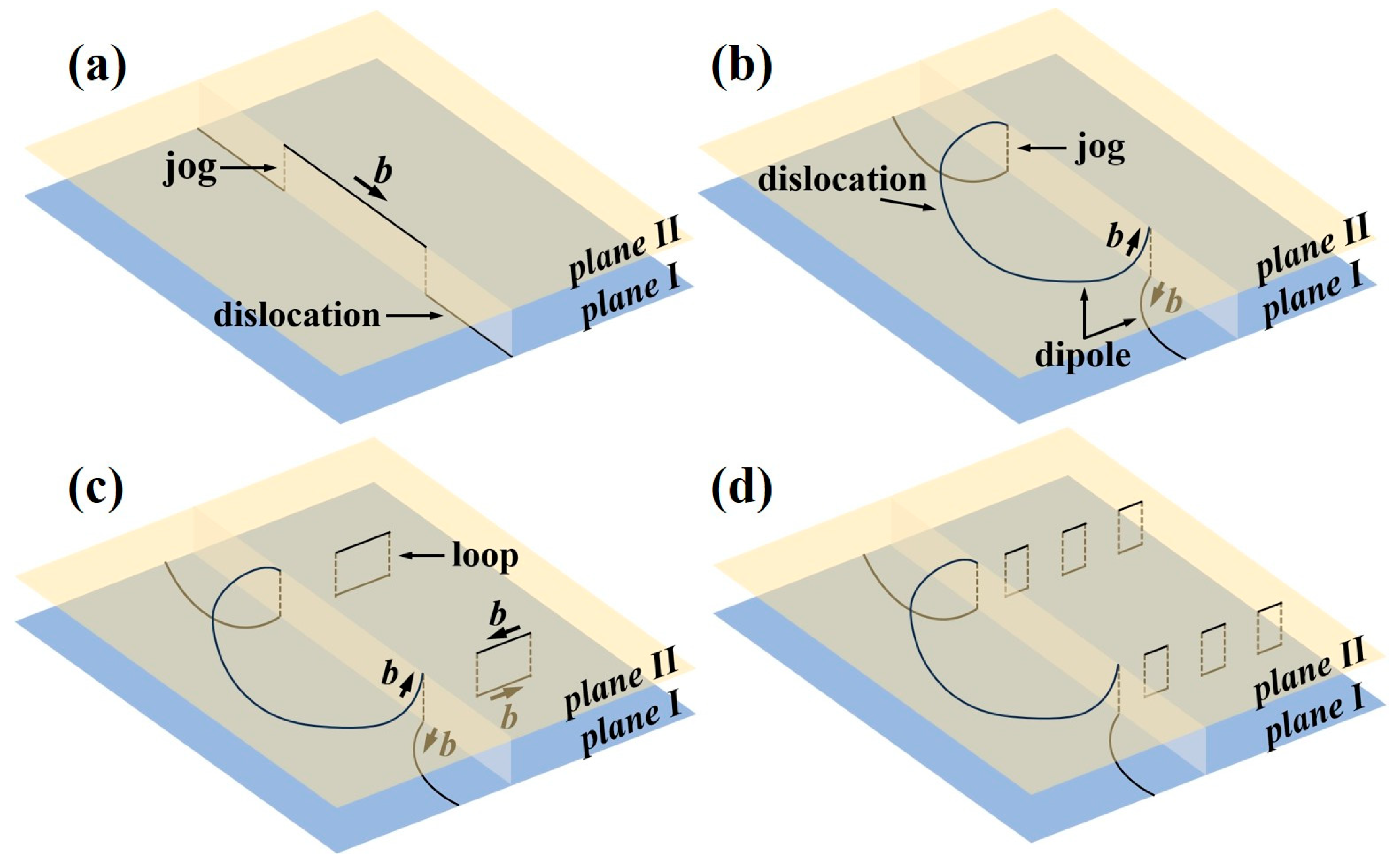

- At low strain rates (0.001/s–10/s), the strain rate sensitivity coefficient (m) is approximately 0.0088, and plastic deformation is dominated by dislocation slip. The alloy initially activates slip bands along the close-packed {011} planes. Cross-slip interactions between slip bands lead to the formation of jogs, dislocation loops, and forest dislocations. With increasing strain, slip along the {112} planes is also activated. These slip systems bypass obstacles such as precipitates and dislocation structures through cross-slip and climb, resulting in a high density of mixed dislocations predominantly governed by screw components. Moreover, the B2 phase contributes to strengthening via dislocation shearing mechanisms, while the HCP phase strengthens the matrix through a dislocation bypass mechanism.

- (3)

- At high strain rates (960/s–5020/s), the strain rate sensitivity coefficient increases significantly to ~0.0985, accompanied by intense dislocation interactions. In addition to {011} and {112} planes, the alloy also activates high-index slip systems {123} under the combined effects of high temperature and stress. This leads to a substantial increase in jogs and the forest dislocation density, which effectively impedes dislocation motion and enhances strength. A notable increase in the fraction of edge dislocation-dominated mixed dislocations is also observed, indicating that more dislocations bypass obstacles through climb and cross-slip, thereby improving plastic deformability. Additionally, localized BCC→O′ martensitic transformations occur in some grains, and the dislocation and stacking fault density within the HCP precipitates increases significantly.

- (4)

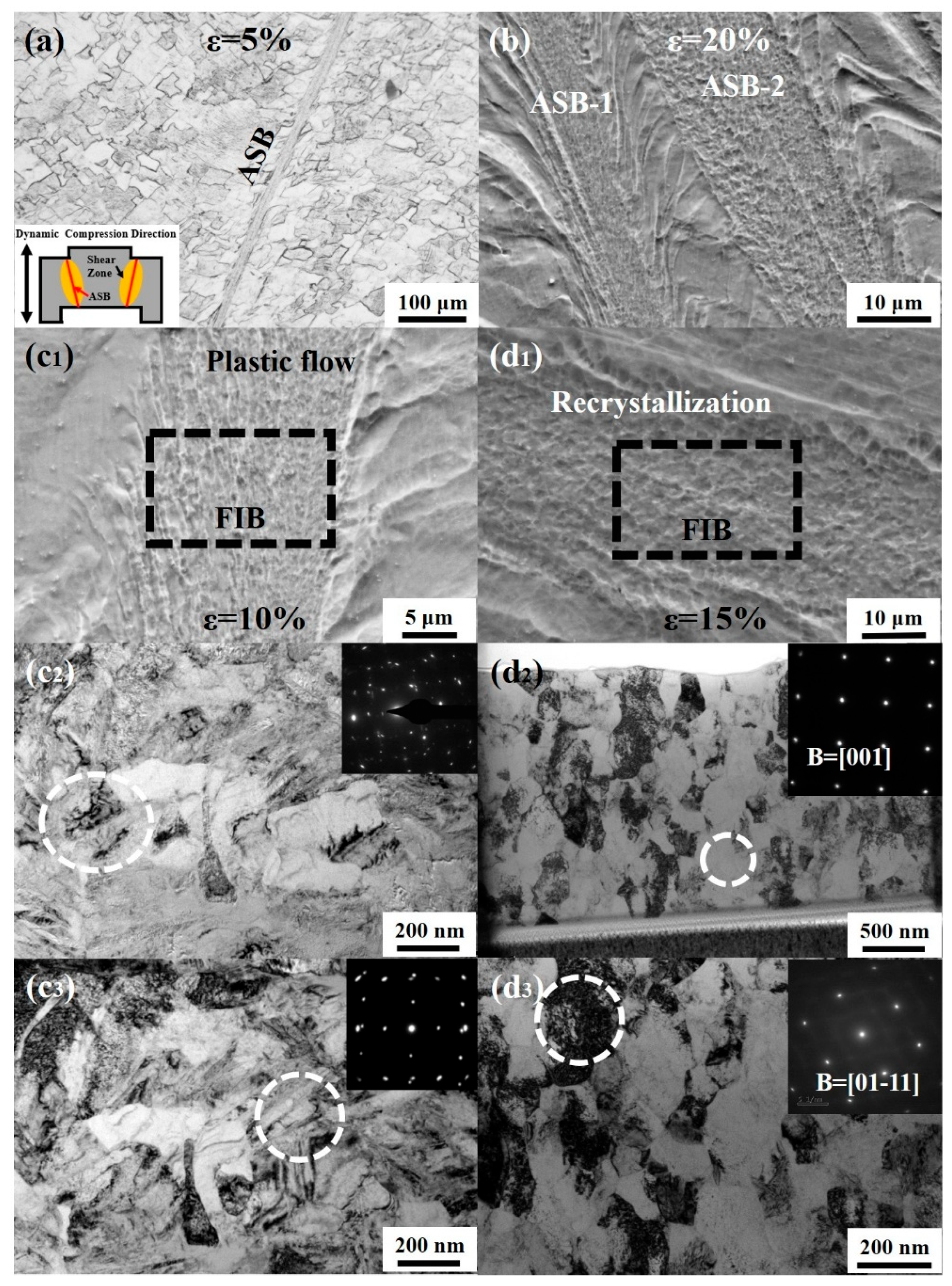

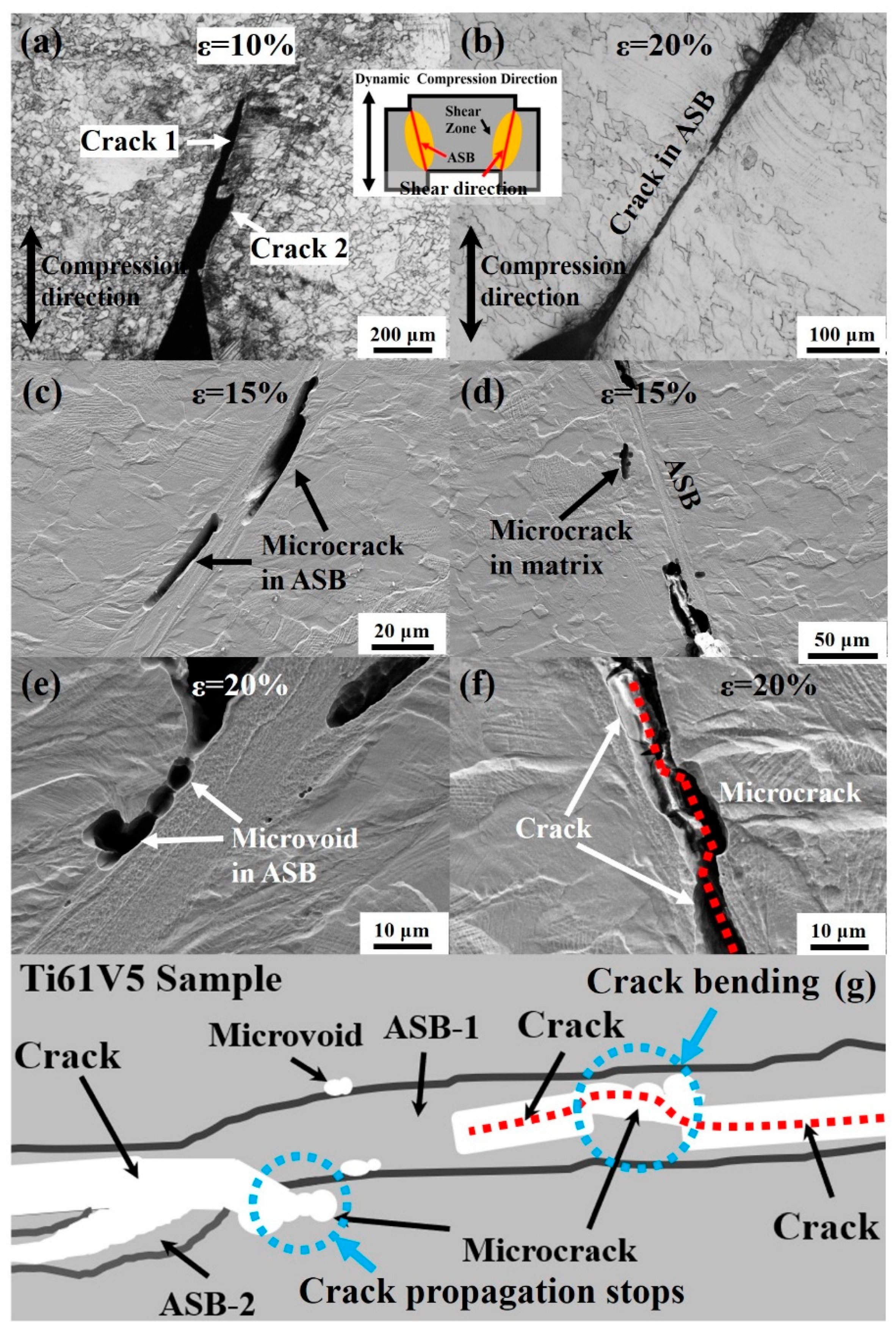

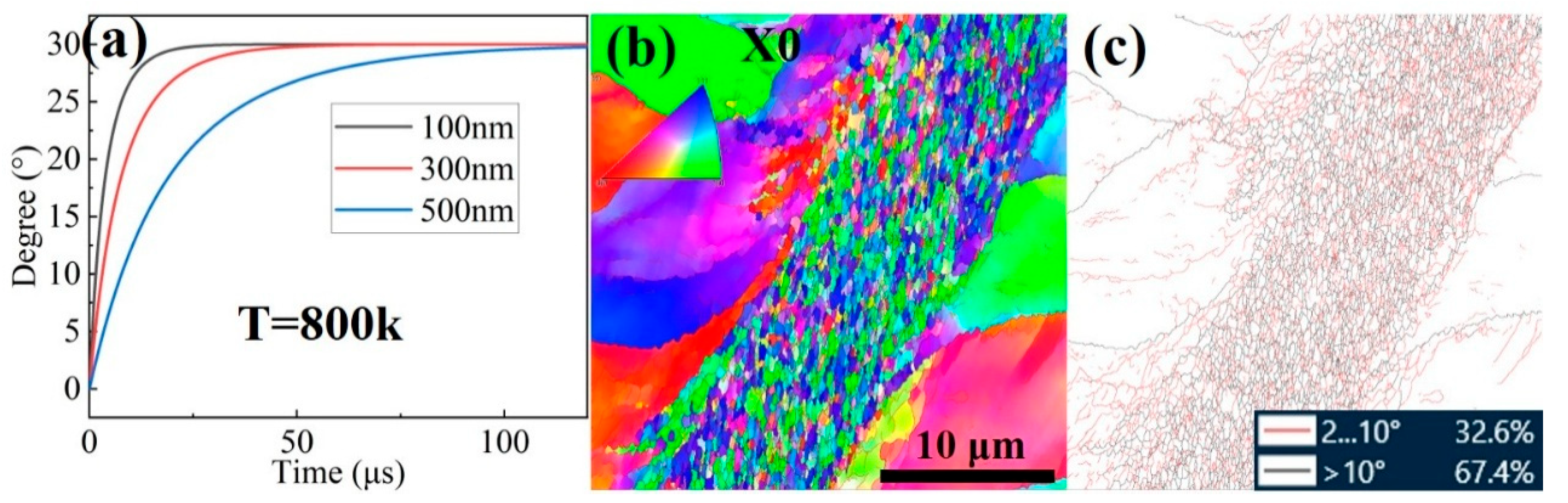

- Forced shear testing reveals the formation of shear bands with widths ranging from 10 to 20 μm, which can be categorized into two types. At lower strains, plastic-flow shear bands dominate, within which grains undergo severe plastic deformation and exhibit amorphous-like structures. At higher strains, a small number of recrystallized shear bands are observed, characterized by the formation of new equiaxed grains with an average size of ~345 nm. This recrystallization behavior is explained well by the mechanism of rotational dynamic recrystallization. Microcracks and microvoids initiate at various locations within the shear bands and gradually expand with increasing strain. Crack propagation may terminate when intersecting with microvoids outside the shear band, whereas interaction with internal microcracks can cause slight deflection followed by continued propagation.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.; Xie, B.; Liu, B.; Cao, Y.; Li, J.; Fang, Q.; Liaw, P.K. A focused review on engineering application of multi-principal element alloy. Front. Mater. 2022, 8, 816309. [Google Scholar] [CrossRef]

- Senkov, O.; Miller, J.; Miracle, D.; Woodward, C. Accelerated exploration of multi-principal element alloys with solid solution phases. Nat. Commun. 2015, 6, 6529. [Google Scholar] [CrossRef]

- Wang, L.; Ouyang, B. Phase Selection Rules of Multi-Principal Element Alloys. Adv. Mater. 2024, 36, 2307860. [Google Scholar] [CrossRef]

- Senkov, O.; Miller, J.; Miracle, D.; Woodward, C. Accelerated exploration of multi-principal element alloys for structural applications. Calphad 2015, 50, 32–48. [Google Scholar] [CrossRef]

- Li, M.; Quek, X.K.; Suo, H.; Wuu, D.; Lee, J.J.; Teh, W.H.; Wei, F.; Made, R.I.; Tan, D.C.C.; Ng, S.R.; et al. Composition driven machine learning for unearthing high-strength lightweight multi-principal element alloys. J. Alloys Compd. 2024, 1008, 176517. [Google Scholar] [CrossRef]

- Kang, K.; Li, A.; Zhang, J.; Xu, M.; Huang, D.; Che, C.; Liu, S.; Jiang, Y.; Li, Y.; Li, G. Revealing the oxidation behavior of AlCrxFeNi lightweight multi-principal element alloys via experimental and first-principles calculations. J. Alloys Compd. 2024, 1008, 176622. [Google Scholar] [CrossRef]

- Maulik, O.; Kumar, D.; Kumar, S.; Dewangan, S.K.; Kumar, V. Structure and properties of lightweight high entropy alloys: A brief review. Mater. Res. Express 2018, 5, 052001. [Google Scholar] [CrossRef]

- Karakulak, E. Characterization of Cu–Ti powder metallurgical materials. Int. J. Miner. Metall. Mater. 2017, 24, 83–90. [Google Scholar] [CrossRef]

- Ding, J.; Xu, H.; Li, X.; Liu, M.; Zhang, T. The similarity of elements in multi-principle element alloys based on a new criterion for phase constitution. Mater. Des. 2021, 207, 109849. [Google Scholar] [CrossRef]

- Zheng, M.; Ding, W.; Cao, W.; Hu, S.; Huang, Q. A quick screening approach for design of multi-principal element alloy with solid solution phase. Mater. Des. 2019, 179, 107882. [Google Scholar] [CrossRef]

- Yao, H.; Qiao, J.; Hawk, J.; Zhou, H.; Chen, M.; Gao, M. Mechanical properties of refractory high-entropy alloys: Experiments and modeling. J. Alloys Compd. 2017, 696, 1139–1150. [Google Scholar] [CrossRef]

- Xiong, W.; Guo, A.X.; Zhan, S.; Liu, C.-T.; Cao, S.C. Refractory high-entropy alloys: A focused review of preparation methods and properties. J. Mater. Sci. Technol. 2023, 142, 196–215. [Google Scholar] [CrossRef]

- Han, Z.; Luan, H.; Liu, X.; Chen, N.; Li, X.; Shao, Y.; Yao, K. Microstructures and mechanical properties of TixNbMoTaW refractory high-entropy alloys. Mater. Sci. Eng. A 2018, 712, 380–385. [Google Scholar] [CrossRef]

- Huang, T.-D.; Wu, S.-Y.; Jiang, H.; Lu, Y.-P.; Wang, T.-M.; Li, T.-J. Effect of Ti content on microstructure and properties of TixZrVNb refractory high-entropy alloys. Int. J. Miner. Metall. Mater. 2020, 27, 1318–1325. [Google Scholar] [CrossRef]

- Feng, R.; Gao, M.C.; Lee, C.; Mathes, M.; Zuo, T.; Chen, S.; Hawk, J.A.; Zhang, Y.; Liaw, P.K. Design of light-weight high-entropy alloys. Entropy 2016, 18, 333. [Google Scholar] [CrossRef]

- Feng, R.; Zhang, C.; Gao, M.C.; Pei, Z.; Zhang, F.; Chen, Y.; Ma, D.; An, K.; Poplawsky, J.D.; Ouyang, L. High-throughput design of high-performance lightweight high-entropy alloys. Nat. Commun. 2021, 12, 4329. [Google Scholar] [CrossRef]

- Feng, R.; Gao, M.C.; Zhang, C.; Guo, W.; Poplawsky, J.D.; Zhang, F.; Hawk, J.A.; Neuefeind, J.C.; Ren, Y.; Liaw, P.K. Phase stability and transformation in a light-weight high-entropy alloy. Acta Mater. 2018, 146, 280–293. [Google Scholar] [CrossRef]

- Li, J.; Zhou, L.; Li, Z.-C. Microstructures and mechanical properties of a new titanium alloy for surgical implant application. Int. J. Miner. Metall. Mater. 2010, 17, 185–191. [Google Scholar] [CrossRef]

- Stepanov, N.; Shaysultanov, D.; Salishchev, G.; Tikhonovsky, M. Structure and mechanical properties of a light-weight AlNbTiV high entropy alloy. Mater. Lett. 2015, 142, 153–155. [Google Scholar] [CrossRef]

- Jeong, I.-S.; Lee, J.-H. Single-phase lightweight high-entropy alloys with enhanced mechanical properties. Mater. Des. 2023, 227, 111709. [Google Scholar] [CrossRef]

- Xiao, Y.; Peng, X. Design of lightweight Ti3Zr1.5NbVx refractory high-entropy alloys with superior mechanical properties. J. Mater. Res. Technol. 2023, 27, 330–341. [Google Scholar] [CrossRef]

- Chen, Y.; Zheng, J.; Xu, Z.; Cheng, B.; Li, Y.; Zhang, J. A lightweight TiZrV0.5Nb0.3Al0.2 refractory high-entropy alloys with enhanced strength and ductility at low and high strains loading. Mater. Sci. Eng. A 2025, 922, 147653. [Google Scholar] [CrossRef]

- Liao, Y.; Li, T.; Tsai, P.; Jang, J.; Hsieh, K.; Chen, C.; Huang, J.; Wu, H.-J.; Lo, Y.-C.; Huang, C. Designing novel lightweight, high-strength and high-plasticity Tix(AlCrNb)100-x medium-entropy alloys. Intermetallics 2020, 117, 106673. [Google Scholar] [CrossRef]

- Shao, Y.-L.; Xu, J.; Wang, H.; Zhang, Y.-W.; Jia, J.; Liu, J.-T.; Huang, H.-L.; Zhang, M.; Wang, Z.-C.; Zhang, H.-F. Effect of Ti and Al on microstructure and partitioning behavior of alloying elements in Ni-based powder metallurgy superalloys. Int. J. Miner. Metall. Mater. 2019, 26, 500–506. [Google Scholar] [CrossRef]

- Wu, P.; Liu, R.; Li, W.; Zhang, W.; Wei, J.; Zhou, Q.; Wei, T.; Kardani, A.; Lin, Z.; Xiao, Y. Interface optimization by introducing Ti for strengthening graphene network/copper composites: New insight from MD simulations. Carbon 2025, 236, 120109. [Google Scholar] [CrossRef]

- Kong, L.; Cheng, B.; Wan, D.; Xue, Y. A review on BCC-structured high-entropy alloys for hydrogen storage. Front. Mater. 2023, 10, 1135864. [Google Scholar] [CrossRef]

- Ozerov, M.; Sokolovsky, V.; Nadezhdin, S.; Zubareva, E.; Zherebtsova, N.; Stepanov, N.; Huang, L.; Zherebtsov, S. Microstructure and mechanical properties of medium-entropy TiNbZr alloy-based composites, reinforced with boride particles. J. Alloys Compd. 2023, 938, 168512. [Google Scholar] [CrossRef]

- Huang, Y.; Yu, X.; Deng, L.; Gao, Y.; Wang, S.; Wang, B. Microstructure and mechanical properties of the (TiZrV)100-xAlx medium-entropy alloys. J. Mater. Res. Technol. 2023, 23, 2824–2835. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, X.-J.; He, G.-Y.; Chiang, F.-K.; Wang, H.; Wu, Y.; Jiang, S.-H.; Zhang, X.-B.; Lu, Z.-P. Novel high-entropy ultra-high temperature ceramics with enhanced ablation resistance. Rare Met. 2024, 43, 6559–6570. [Google Scholar] [CrossRef]

- Wang, S.; He, Y.; Zhang, X.; Wang, J.; Wu, M.; Shu, D.; Tang, H.; Sun, B. The effects of interstitial oxygen on mechanical properties of TiZrNb medium-entropy alloy over a wide temperature range. J. Alloys Compd. 2024, 989, 174394. [Google Scholar] [CrossRef]

- Carruthers, A.; Li, B.; Rigby, M.; Raquet, L.; Mythili, R.; Ghosh, C.; Dasgupta, A.; Armstrong, D.; Gandy, A.; Pickering, E. Novel reduced-activation TiVCrFe based high entropy alloys. J. Alloys Compd. 2021, 856, 157399. [Google Scholar] [CrossRef]

- Kai, M.; Ma, Y.; Zhai, G.; Ma, H.; Li, G.; Hu, J.; Wang, H.; Cao, Z. Simultaneous strength-plasticity enhancement of dual-phase light-weight medium entropy alloy. J. Alloys Compd. 2022, 923, 166406. [Google Scholar] [CrossRef]

- Laube, S.; Chen, H.; Kauffmann, A.; Schellert, S.; Müller, F.; Gorr, B.; Müller, J.; Butz, B.; Christ, H.-J.; Heilmaier, M. Controlling crystallographic ordering in Mo–Cr–Ti–Al high entropy alloys to enhance ductility. J. Alloys Compd. 2020, 823, 153805. [Google Scholar] [CrossRef]

- Wong, K.-K.; Hsu, H.-C.; Wu, S.-C.; Ho, W.-F. Structure and properties of Ti-rich Ti–Zr–Nb–Mo medium-entropy alloys. J. Alloys Compd. 2021, 868, 159137. [Google Scholar] [CrossRef]

- Yang, L.; Wang, B.-Y.; Lin, J.-G.; Zhao, H.-J.; Ma, W.-Y. Ductile fracture behavior of TA15 titanium alloy at elevated temperatures. Int. J. Miner. Metall. Mater. 2015, 22, 1082–1091. [Google Scholar] [CrossRef]

- Lin, P.; Huang, J.; Zhang, X.; Chou, H.; Chuang, W.; Liu, T.; Liao, Y.; Jang, J. Room-and elevated-temperature nano-scaled mechanical properties of low-density Ti-based medium entropy alloy. Mater. Sci. Eng. A 2020, 798, 140140. [Google Scholar] [CrossRef]

- Li, X.; Liu, S.; Luan, J.; Ju, J.; Xiao, B.; Ke, H.; Wang, W.; Yang, T. Developing strong-yet-ductile light-weight medium-entropy alloy via the unusual oxide doping effect. Scr. Mater. 2024, 248, 116141. [Google Scholar] [CrossRef]

- Cao, T.; Zhang, Q.; Wang, L.; Wang, L.; Xiao, Y.; Yao, J.; Liu, H.; Ren, Y.; Liang, J.; Xue, Y. Dynamic deformation behaviors and mechanisms of CoCrFeNi high-entropy alloys. Acta Mater. 2023, 260, 119343. [Google Scholar] [CrossRef]

- Zhang, R.; Zhao, S.; Ding, J.; Chong, Y.; Jia, T.; Ophus, C.; Asta, M.; Ritchie, R.O.; Minor, A.M. Short-range order and its impact on the CrCoNi medium-entropy alloy. Nature 2020, 581, 283–287. [Google Scholar] [CrossRef]

- Briffod, F.; Bleuset, A.; Shiraiwa, T.; Enoki, M. Effect of crystallographic orientation and geometrical compatibility on fatigue crack initiation and propagation in rolled Ti-6Al-4V alloy. Acta Mater. 2019, 177, 56–67. [Google Scholar] [CrossRef]

- Ding, Q.; Zhang, Y.; Chen, X.; Fu, X.; Chen, D.; Chen, S.; Gu, L.; Wei, F.; Bei, H.; Gao, Y. Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature 2019, 574, 223–227. [Google Scholar] [CrossRef]

- Han, G.; Jones, I.; Smallman, R. Direct evidence for Suzuki segregation and Cottrell pinning in MP159 superalloy obtained by FEG (S) TEM/EDX. Acta Mater. 2003, 51, 2731–2742. [Google Scholar] [CrossRef]

- Jiang, W.; Yuan, S.; Cao, Y.; Zhang, Y.; Zhao, Y. Mechanical properties and deformation mechanisms of a Ni2Co1Fe1V0.5Mo0.2 medium-entropy alloy at elevated temperatures. Acta Mater. 2021, 213, 116982. [Google Scholar] [CrossRef]

- Jiang, W.; Cao, Y.; Yuan, S.; Zhang, Y.; Zhao, Y. Creep properties and deformation mechanisms of a Ni2Co1Fe1V0.5Mo0.2 medium-entropy alloy. Acta Mater. 2023, 245, 118590. [Google Scholar] [CrossRef]

- Godfrey, A.; Liu, Q. Stored energy and structure in top-down processed nanostructured metals. Scr. Mater. 2009, 60, 1050–1055. [Google Scholar] [CrossRef]

- Madec, R.; Devincre, B.; Kubin, L.; Hoc, T.; Rodney, D. The role of collinear interaction in dislocation-induced hardening. Science 2003, 301, 1879–1882. [Google Scholar] [CrossRef]

- Krenn, C.; Roundy, D.; Morris, J., Jr.; Cohen, M. Ideal strengths of bcc metals. Mater. Sci. Eng. A 2001, 319, 111–114. [Google Scholar] [CrossRef]

- Maresca, F.; Curtin, W.A. Theory of screw dislocation strengthening in random BCC alloys from dilute to “High-Entropy” alloys. Acta Mater. 2020, 182, 144–162. [Google Scholar] [CrossRef]

- Kinslow, R. High-Velocity Impact Phenomena; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Eleti, R.R.; Stepanov, N.; Yurchenko, N.; Zherebtsov, S.; Maresca, F. Cross-kink unpinning controls the medium-to high-temperature strength of body-centered cubic NbTiZr medium-entropy alloy. Scr. Mater. 2022, 209, 114367. [Google Scholar] [CrossRef]

- Zheng, Y.; Alam, T.; Banerjee, R.; Banerjee, D.; Fraser, H.L. The influence of aluminum and oxygen additions on intrinsic structural instabilities in titanium-molybdenum alloys. Scr. Mater. 2018, 152, 150–153. [Google Scholar] [CrossRef]

- Song, B.; Xiao, W.; Ma, C.; Zhou, L. Tuning the strength and ductility of near β titanium alloy Ti-5321 by ω and O′ intermediate phases via low-temperature aging. Mater. Sci. Eng. A 2022, 855, 143919. [Google Scholar] [CrossRef]

- Li, T.; Lai, M.; Kostka, A.; Salomon, S.; Zhang, S.; Somsen, C.; Dargusch, M.S.; Kent, D. Composition of the nanosized orthorhombic O′ phase and its direct transformation to fine α during ageing in metastable β-Ti alloys. Scr. Mater. 2019, 170, 183–188. [Google Scholar] [CrossRef]

- Zheng, Y.; Banerjee, D.; Fraser, H.L. A nano-scale instability in the β phase of dilute Ti–Mo alloys. Scr. Mater. 2016, 116, 131–134. [Google Scholar] [CrossRef]

- Kassner, M.; Barrabes, S. New developments in geometric dynamic recrystallization. Mater. Sci. Eng. A 2005, 410, 152–155. [Google Scholar] [CrossRef]

- He, Y.; Zhang, Z.; Yang, S.; Wang, H.; Cheng, X.; Liu, L.; Jia, X. Deformation and fracture mechanism of Ti-6Al-4V target at high and hyper velocity impact. Int. J. Impact Eng. 2022, 169, 104312. [Google Scholar] [CrossRef]

- Guan, X.; Chen, Q.; Qu, S.; Cao, G.; Wang, H.; Feng, A.; Chen, D. Adiabatic shear instability in a titanium alloy: Extreme deformation-induced phase transformation, nanotwinning, and grain refinement. J. Mater. Sci. Technol. 2023, 150, 104–113. [Google Scholar] [CrossRef]

- Ahmed, M.; Wexler, D.; Casillas, G.; Savvakin, D.G.; Pereloma, E.V. Strain rate dependence of deformation-induced transformation and twinning in a metastable titanium alloy. Acta Mater. 2016, 104, 190–200. [Google Scholar] [CrossRef]

- Guo, P.; Zhao, Y.; Zeng, W.; Hong, Q. The effect of microstructure on the mechanical properties of TC4-DT titanium alloys. Mater. Sci. Eng. A 2013, 563, 106–111. [Google Scholar] [CrossRef]

- Li, J.; Zhou, J.; Feng, A.; Huang, S.; Meng, X.; Sun, Y.; Sun, Y.; Tian, X.; Huang, Y. Investigation on mechanical properties and microstructural evolution of TC6 titanium alloy subjected to laser peening at cryogenic temperature. Mater. Sci. Eng. A 2018, 734, 291–298. [Google Scholar] [CrossRef]

- Ren, D.; Su, H.; Zhang, H.; Wang, J.; Jin, W.; Yang, R. Effect of cold rotary-swaging deformation on microstructure and tensile properties of TB9 titanium alloy. Acta Met. Sin 2018, 55, 480–488. [Google Scholar]

- Youssef, K.M.; Zaddach, A.J.; Niu, C.; Irving, D.L.; Koch, C.C. A novel low-density, high-hardness, high-entropy alloy with close-packed single-phase nanocrystalline structures. Mater. Res. Lett. 2015, 3, 95–99. [Google Scholar] [CrossRef]

- Tseng, K.; Yang, Y.; Juan, C.; Chin, T.; Tsai, C.; Yeh, J. A light-weight high-entropy alloy Al20Be20Fe10Si15Ti35. Sci. China Technol. Sci. 2018, 61, 184–188. [Google Scholar] [CrossRef]

- Sanchez, J.M.; Vicario, I.; Albizuri, J.; Guraya, T.; Garcia, J.C. Phase prediction, microstructure and high hardness of novel light-weight high entropy alloys. J. Mater. Res. Technol. 2019, 8, 795–803. [Google Scholar] [CrossRef]

- Chauhan, P.; Yebaji, S.; Nadakuduru, V.N.; Shanmugasundaram, T. Development of a novel light weight Al35Cr14Mg6Ti35V10 high entropy alloy using mechanical alloying and spark plasma sintering. J. Alloys Compd. 2020, 820, 153367. [Google Scholar] [CrossRef]

- Li, B.; Ji, P.; Chen, B.; Wang, F.; Ma, W.; Zhang, X.; Ma, M.; Liu, R. The effect of Zr addition on the microstructure evolution and mechanical properties of hot-rolled TiAlNbZr alloy. Mater. Sci. Eng. A 2021, 828, 142114. [Google Scholar] [CrossRef]

- Zhang, Y.; Bu, Z.; Yao, T.; Yang, L.; Li, W.; Li, J. Novel BCC Ti-Al-Nb-Zr medium-entropy alloys with ultrahigh specific strength and ductility. J. Alloys Compd. 2023, 936, 168290. [Google Scholar] [CrossRef]

- Li, D.; Dong, Y.; Zhang, Z.; Zhang, Q.; Chen, S.; Jia, N.; Wang, H.; Wang, B.; Jin, K.; Xue, Y. An as-cast Ti-V-Cr-Al light-weight medium entropy alloy with outstanding tensile properties. J. Alloys Compd. 2021, 877, 160199. [Google Scholar] [CrossRef]

- He, F.; Wang, Z.; Niu, S.; Wu, Q.; Li, J.; Wang, J.; Liu, C.T.; Dang, Y. Strengthening the CoCrFeNiNb0.25 high entropy alloy by FCC precipitate. J. Alloys Compd. 2016, 667, 53–57. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Qian, M.; Shi, Z.; Song, T.; Huang, L.; Zou, J. Compositional design of strong and ductile (tensile) Ti-Zr-Nb-Ta medium entropy alloys (MEAs) using the atomic mismatch approach. Mater. Sci. Eng. A 2019, 742, 762–772. [Google Scholar] [CrossRef]

- Li, Z.; Fu, L.; Peng, J.; Zheng, H.; Ji, X.; Sun, Y.; Ma, S.; Shan, A. Improving mechanical properties of an FCC high-entropy alloy by γ′ and B2 precipitates strengthening. Mater. Charact. 2020, 159, 109989. [Google Scholar] [CrossRef]

- Lin, C.-M.; Juan, C.-C.; Chang, C.-H.; Tsai, C.-W.; Yeh, J.-W. Effect of Al addition on mechanical properties and microstructure of refractory AlxHfNbTaTiZr alloys. J. Alloys Compd. 2015, 624, 100–107. [Google Scholar] [CrossRef]

- George, E.P.; Curtin, W.A.; Tasan, C.C. High entropy alloys: A focused review of mechanical properties and deformation mechanisms. Acta Mater. 2020, 188, 435–474. [Google Scholar] [CrossRef]

- Wang, L.; Chen, S.; Cao, T.; Wang, B.; Wang, L.; Ren, Y.; Liang, J.; Xue, Y. Lightweight Zr1.2V0.8NbTixAly high-entropy alloys with high tensile strength and ductility. Mater. Sci. Eng. A 2021, 814, 141234. [Google Scholar] [CrossRef]

- Zheng, C.; Wang, F.; Cheng, X.; Liu, J.; Liu, T.; Zhu, Z.; Yang, K.; Peng, M.; Jin, D. Capturing of the propagating processes of adiabatic shear band in Ti–6Al–4V alloys under dynamic compression. Mater. Sci. Eng. A 2016, 658, 60–67. [Google Scholar] [CrossRef]

- Cheng, F.; Wang, H.; Li, Z.; Cheng, X.; Zheng, D.; Zhang, S.; Hu, X.; Zhang, H.; Liu, M. Dynamic compression deformation behavior of laser directed energy deposited α+ β duplex titanium alloy with basket-weave morphology. Addit. Manuf. 2023, 61, 103336. [Google Scholar] [CrossRef]

- Xu, X.; Ali, T.; Wang, L.; Cheng, H.; Zhou, Z.; Ning, Z.; Liu, X.; Liu, A.; Zhang, B.; Cheng, X. Research on dynamic compression properties and deformation mechanism of Ti6321 titanium alloy. J. Mater. Res. Technol. 2020, 9, 11509–11516. [Google Scholar]

- Hu, H.; Xu, Z.; Dou, W.; Huang, F. Effects of strain rate and stress state on mechanical properties of Ti-6Al-4V alloy. Int. J. Impact Eng. 2020, 145, 103689. [Google Scholar] [CrossRef]

- Alaghmandfard, R.; Dharmendra, C.; Odeshi, A.G.; Mohammadi, M. Dynamic mechanical properties and failure characteristics of electron beam melted Ti-6Al-4V under high strain rate impact loadings. Mater. Sci. Eng. A 2020, 793, 139794. [Google Scholar] [CrossRef]

| True Stress (MPa) | 0.001/s | 0.1/s | 10/s | 960/s | 1950/s | 3070/s | 5020/s |

|---|---|---|---|---|---|---|---|

| Yield Stress | 1190 | 1210 | 1230 | 1470 | 1630 | 1670 | 1810 |

| Ultimate Stress | 1270 | 1280 | 1350 | 1560 | 1690 | 1760 | 1910 |

| Flow Stress | 1290 | 1310 | 1330 | 1460 | 1550 | 1630 | 1810 |

| g/b | ±1/2[111] | ±1/2[-111] | ±1/2[1-11] | ±1/2[1-11] |

|---|---|---|---|---|

| (110) | √ | × | × | √ |

| (101) | √ | × | √ | × |

| (01-1) | × | × | √ | √ |

| Dislocation No. | Burgers Vector (b) | Dislocation Line Direction (u) | Dislocation Character |

|---|---|---|---|

| 1 (Dislocation Array) | ±1/2[11-1] | [1,15,19] | Mixed-Edge dominated |

| 2 (Dislocation Array) | ±1/2[1-11] | [01-2] | Mixed-Screw dominated |

| 3 (Dislocation Array) | ±1/2[11-1] | [01-2] | Mixed-Screw dominated |

| 4 | ±1/2[1-11] | [-132] | Edge |

| 5 | ±1/2[1-11] | [1-11] | Mixed-Screw dominated |

| 6 (Dislocation Array) | ±1/2[111] | [-3,19,15] | Mixed-Screw dominated |

| 7 | ±1/2[111] | [012] | Mixed-Screw dominated |

| 8 | ±1/2[1-11] | [-12-1] | Mixed-Screw dominated |

| 9 (Dislocation Array) | ±1/2[11-1] | [01-2] | Mixed-Screw dominated |

| Dislocation No. | Burgers Vector (b) | Dislocation Line Direction (u) | Dislocation Character |

|---|---|---|---|

| 1 | ±1/2[111] | [2-3-1] | Mixed-Edge dominated |

| 2 (Dislocation Array) | ±1/2[1-11] | [2-3-1] | Mixed-Edge dominated |

| 3 (Dislocation Array) | ±1/2[11-1] | [021] | Mixed-Edge dominated |

| 4 (Dislocation Array) | ±1/2[1-11] | [021] | Mixed-Edge dominated |

| 5 | ±1/2[1-11] | [021] | Mixed-Edge dominated |

| 6 (Dislocation Array) | ±1/2[1-11] | [021] | Mixed-Edge dominated |

| 7 | ±1/2[1-11] | [011] | Mixed-Edge dominated |

| 8 | ±1/2[111] | [1,15,11] | Mixed-Edge dominated |

| 9 (Dislocation Array) | ±1/2[11-1] | [021] | Mixed-Screw dominated |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.-Y.; Zhang, Z.-H.; Liu, Y.-F.; Cheng, Y.-C.; Jia, X.-T.; Wang, Q.; Zhou, J.-Z.; Cheng, X.-W. Ultra-High Strength and Specific Strength in Ti61Al16Cr10Nb8V5 Multi-Principal Element Alloy: Quasi-Static and Dynamic Deformation and Fracture Mechanisms. Materials 2025, 18, 3245. https://doi.org/10.3390/ma18143245

He Y-Y, Zhang Z-H, Liu Y-F, Cheng Y-C, Jia X-T, Wang Q, Zhou J-Z, Cheng X-W. Ultra-High Strength and Specific Strength in Ti61Al16Cr10Nb8V5 Multi-Principal Element Alloy: Quasi-Static and Dynamic Deformation and Fracture Mechanisms. Materials. 2025; 18(14):3245. https://doi.org/10.3390/ma18143245

Chicago/Turabian StyleHe, Yang-Yu, Zhao-Hui Zhang, Yi-Fan Liu, Yi-Chen Cheng, Xiao-Tong Jia, Qiang Wang, Jin-Zhao Zhou, and Xing-Wang Cheng. 2025. "Ultra-High Strength and Specific Strength in Ti61Al16Cr10Nb8V5 Multi-Principal Element Alloy: Quasi-Static and Dynamic Deformation and Fracture Mechanisms" Materials 18, no. 14: 3245. https://doi.org/10.3390/ma18143245

APA StyleHe, Y.-Y., Zhang, Z.-H., Liu, Y.-F., Cheng, Y.-C., Jia, X.-T., Wang, Q., Zhou, J.-Z., & Cheng, X.-W. (2025). Ultra-High Strength and Specific Strength in Ti61Al16Cr10Nb8V5 Multi-Principal Element Alloy: Quasi-Static and Dynamic Deformation and Fracture Mechanisms. Materials, 18(14), 3245. https://doi.org/10.3390/ma18143245