Influence of Hollow Glass Microspheres (HGM) on Properties of Alkali-Activated Slag Lightweight High-Strength Concrete Under Varying Lightweight Aggregate (LWA) Dosages

Abstract

1. Introduction

2. Materials and Methods

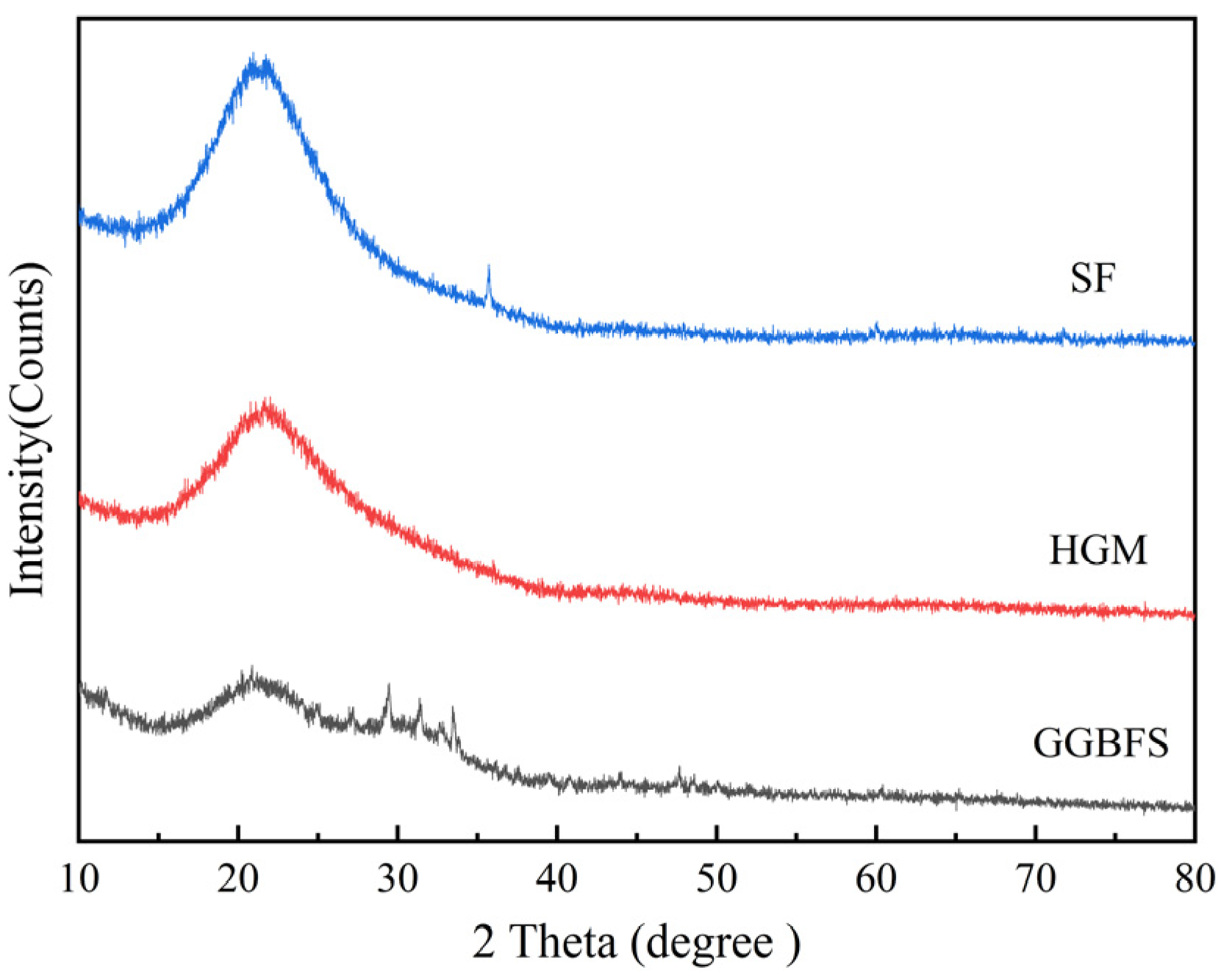

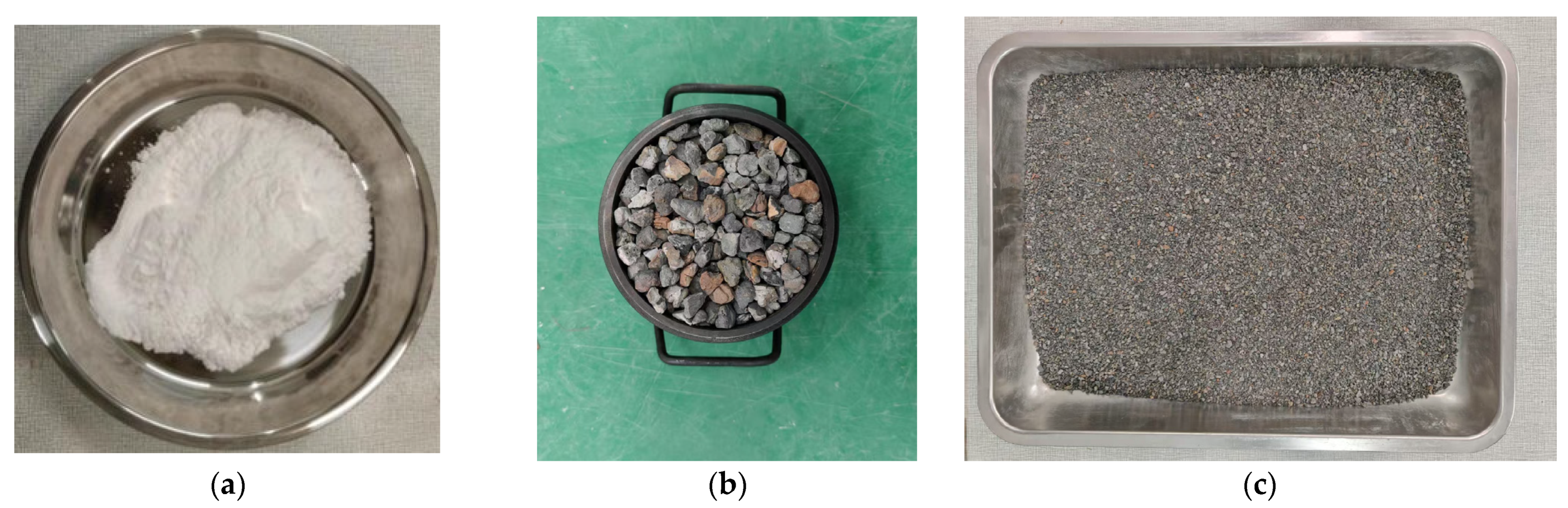

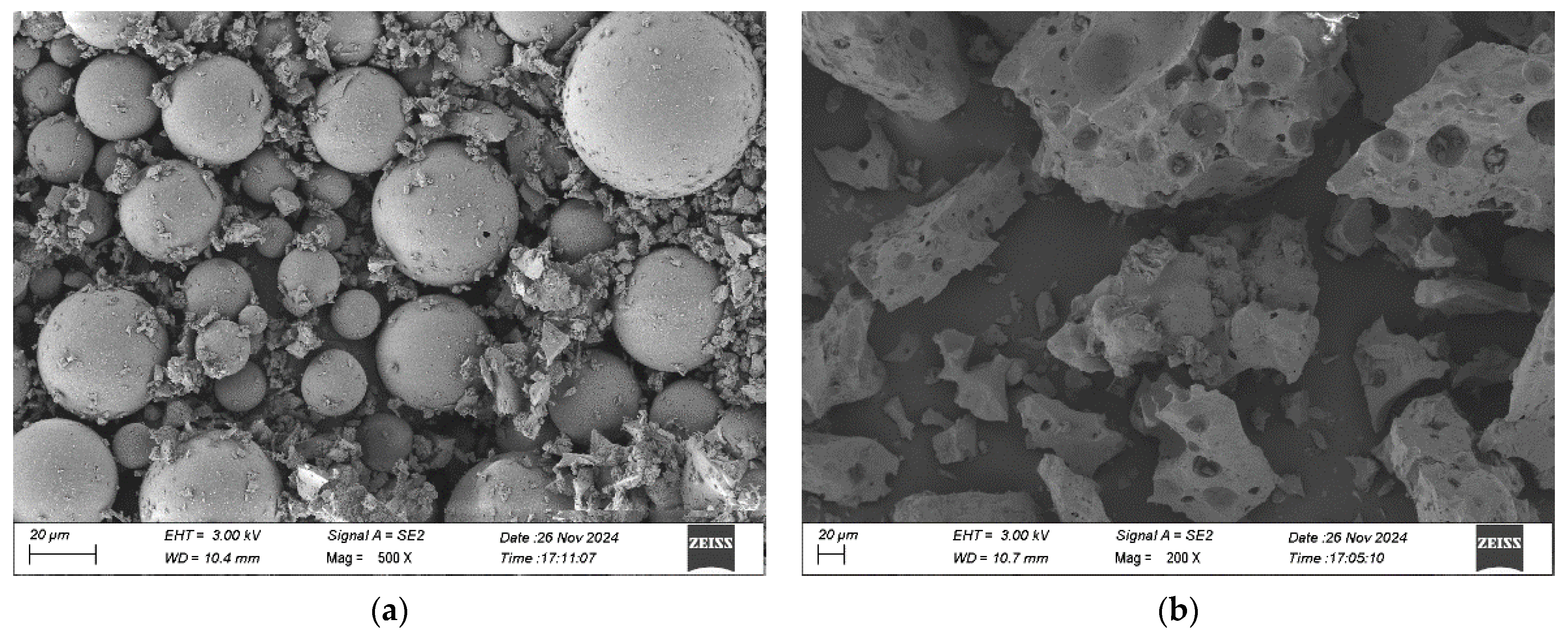

2.1. Materials

2.2. Sample Preparation

2.3. Fluidity Test

2.4. Dry Density Test

2.5. Mechanical and Physical Properties Test

2.6. Microstructure Analysis

3. Results and Discussion

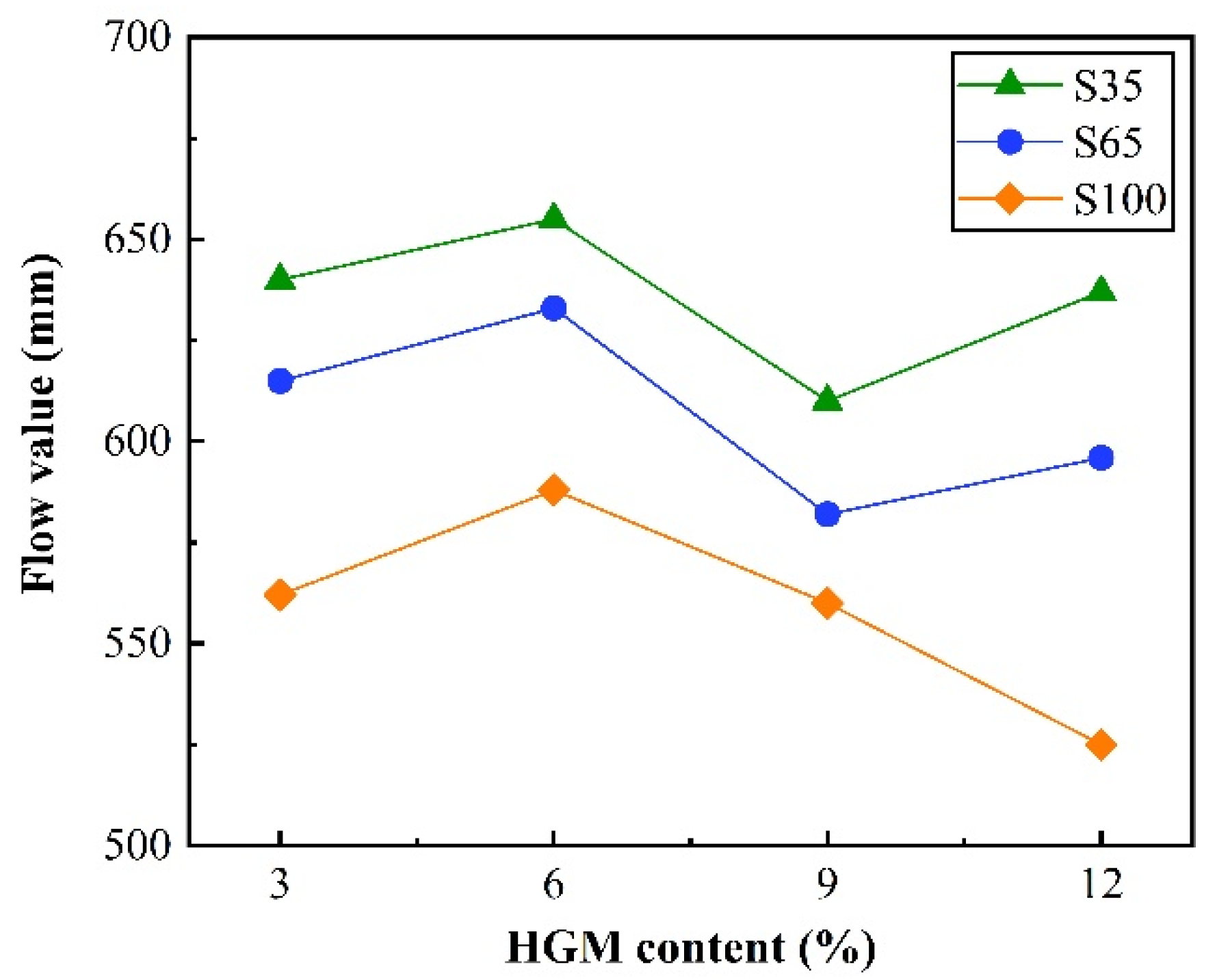

3.1. Flowability

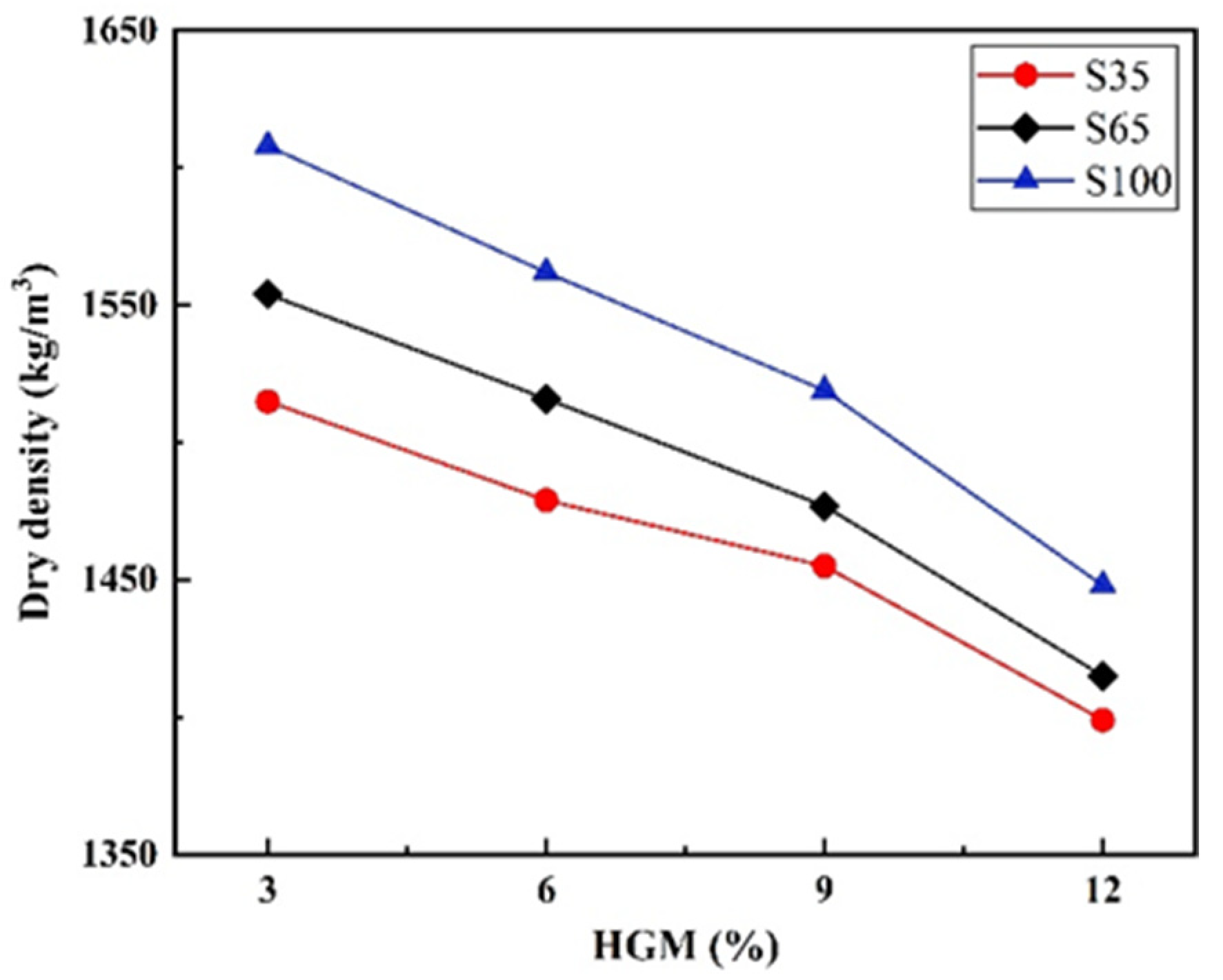

3.2. Dry Density

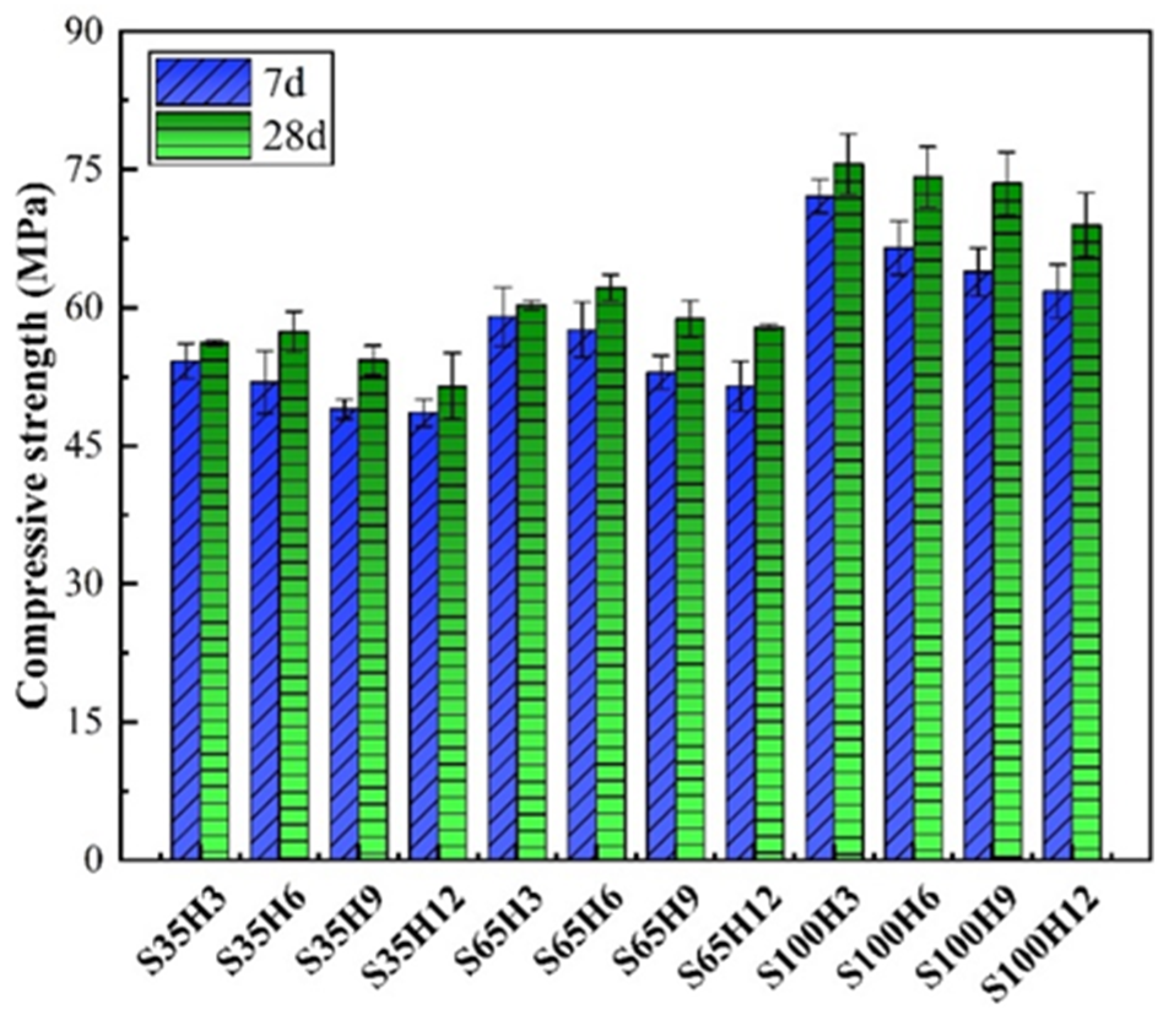

3.3. Compressive Strength

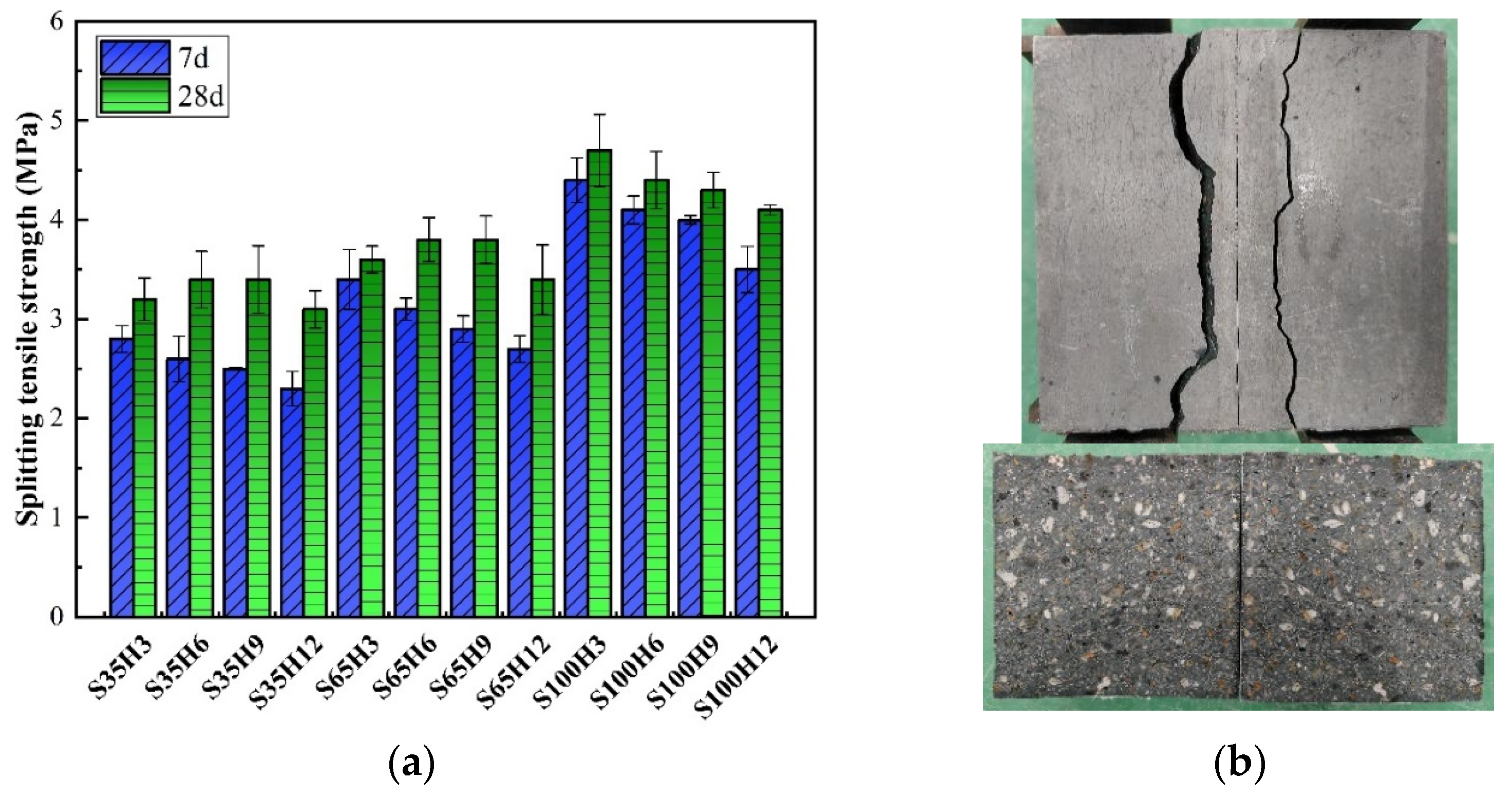

3.4. Splitting Tensile Strength

3.5. Analysis of Damage Mode and Cracks

3.6. Microstructure

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, J.-X. Recent advances in high strength lightweight concrete: From development strategies to practical applications. Constr. Build. Mater. 2023, 400, 132905. [Google Scholar] [CrossRef]

- Zhang, M.-H.; Liu, X.; Chia, K.-S. High-strength high-performance lightweight concrete-a review. In Proceedings of the 9th International Symposium on High Performance Concrete, Rotorua, New Zealand, 9–11 August 2011. [Google Scholar]

- Rossignolo, J.A.; Agnesini, M.V.; Morais, J.A. Properties of high-performance LWAC for precast structures with Brazilian lightweight aggregates. Cem. Concr. Compos. 2003, 25, 77–82. [Google Scholar] [CrossRef]

- Xiong, G.; Wang, C.; Zhou, S.; Jia, X.; Luo, W.; Liu, J.; Peng, X. Preparation of high strength lightweight aggregate concrete with the vibration mixing process. Constr. Build. Mater. 2019, 229, 116936. [Google Scholar] [CrossRef]

- Liu, H.; Elchalakani, M.; Karrech, A.; Yehia, S.; Yang, B. High strength flowable lightweight concrete incorporating low C3A cement, silica fume, stalite and macro-polyfelin polymer fibres. Constr. Build. Mater. 2021, 281, 122410. [Google Scholar] [CrossRef]

- Sarıdemir, M.; Çelikten, S. Investigation of fire and chemical effects on the properties of alkali-activated lightweight concretes produced with basaltic pumice aggregate. Constr. Build. Mater. 2020, 260, 119969. [Google Scholar] [CrossRef]

- Evangelista, A.C.J.; Tam, V.W. Properties of high-strength lightweight concrete using manufactured aggregate. Proc. Inst. Civ. Civil Eng. Constr. Mater. 2020, 173, 157–169. [Google Scholar] [CrossRef]

- Concrete, R.P.A.; Ahmet, T. Temperature-Dependent Thermal Conductivity of High Strength Lightweight. Int. J. Thermophys. 2010, 31, 1195–1211. [Google Scholar]

- Yang, K.-H.; Song, J.-K.; Lee, J.-S. Properties of alkali-activated mortar and concrete using lightweight aggregates. Mater. Struct. 2010, 43, 403–416. [Google Scholar] [CrossRef]

- Alhnifat, R.S.; Abdel-Jaber, M.t.; Al-Dala’ien, R.N. Behavior of lightweight concrete incorporating pozzolana aggregate and expanded polystyrene beads. Eng. Sci. 2023, 25, 934. [Google Scholar] [CrossRef]

- Cui, H.; Lo, T.Y.; Memon, S.A.; Xu, W. Effect of lightweight aggregates on the mechanical properties and brittleness of lightweight aggregate concrete. Constr. Build. Mater. 2012, 35, 149–158. [Google Scholar] [CrossRef]

- Ke, Y.; Beaucour, A.; Ortola, S.; Dumontet, H.; Cabrillac, R. Influence of volume fraction and characteristics of lightweight aggregates on the mechanical properties of concrete. Constr. Build. Mater. 2009, 23, 2821–2828. [Google Scholar] [CrossRef]

- Shi, Y.; Ma, Q.; Ma, D.; Huang, K.; Gu, Y. Effect of aggregate mix proportion on static and dynamic mechanical properties and pore structure of alkali-activated slag mortar with sludge pottery sand. Sustainability 2023, 15, 2771. [Google Scholar] [CrossRef]

- Pan, H.; Yan, S.; Zhao, Q.; Wang, D. Preparation and properties of ultra-high performance lightweight concrete. Mag. Concr. Res. 2023, 75, 310–323. [Google Scholar] [CrossRef]

- Wang, Q.; Gao, S.C.; Gao, J.C.; Wen, C.C.; Xu, G. Performance of Ultra-High Performance Lightweight Concrete with Pottery Sand and Its Influencing Factors. Bull. Chin. Ceram. Soc. 2023, 42, 1996. [Google Scholar]

- Ranjbar, N.; Kuenzel, C. Cenospheres: A review. Fuel 2017, 207, 1–12. [Google Scholar] [CrossRef]

- Yu, Z.; Du, X.; Zhu, P.; Zhao, T.; Sun, R.; Chen, J.; Wang, N.; Li, W. Surface modified hollow glass microspheres-epoxy composites with enhanced thermal insulation and reduced dielectric constant. Mater. Today Commun. 2022, 32, 104046. [Google Scholar] [CrossRef]

- Aslani, F.; Wang, L. Development of strain-hardening lightweight engineered cementitious composites using hollow glass microspheres. Struct. Concr. 2019, 21, 673–688. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Z.; Wang, Y.; Feng, J. Preparation and properties of alkali activated metakaolin-based geopolymer. Materials 2016, 9, 767. [Google Scholar] [CrossRef]

- Li, X.; Yao, Y.; Zhang, D.; Zhang, Z.; Zhuge, Y. Development of High-Strength Light-Weight Cementitious Composites with Hollow Glass Microspheres. In Nanotechnology in Construction for Circular Economy, Proceedings of the NICOM7, Baku, Azerbaijan, 31 October–4 November 2022; Springer: Singapore, 2022. [Google Scholar]

- Martín, C.M.; Scarponi, N.B.; Villagrán, Y.; Manzanal, D.; Piqué, T.M. Pozzolanic activity quantification of hollow glass microspheres. Cem. Concr. Compos. 2021, 118, 103981. [Google Scholar] [CrossRef]

- Dahal, M.; Liyew, G.; Kim, H.-K.; Pyo, S. Characteristics of ultra-high performance lightweight concrete containing hollow glass microspheres under severe loading conditions. Constr. Build. Mater. 2022, 356, 129312. [Google Scholar] [CrossRef]

- Lu, J.-X.; Shen, P.; Zheng, H.; Ali, H.A.; Poon, C.S. Development and characteristics of ultra high-performance lightweight cementitious composites (UHP-LCCs). Cem. Concr. Res. 2021, 145, 106462. [Google Scholar] [CrossRef]

- Pan, Z.; Ding, X.; Xie, P.; Sanjayan, J. Development of lightweight alkali-activated composites incorporating cenopsheres: Exhibiting high strength/density ratio and low thermal conductivity. Constr. Build. Mater. 2023, 409, 133906. [Google Scholar] [CrossRef]

- Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Li, C.; Sun, H.; Li, L. A review: The comparison between alkali-activated slag (Si + Ca) and metakaolin (Si + Al) cements. Cem. Concr. Res. 2010, 40, 1341–1349. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Puertas, F.; Sobrados, I.; Sanz, J. Structure of calcium silicate hydrates formed in alkaline-activated slag: Influence of the type of alkaline activator. J. Am. Ceram. Soc. 2003, 86, 1389–1394. [Google Scholar] [CrossRef]

- Chen, F.; Zhao, J.; Zhang, B.; Feng, Y.; Chen, C.; Lu, Z.; Yang, J.; Xie, J. Physical, mechanical and microstructural properties of ultra-lightweight high-strength geopolymeric composites. Case Stud. Constr. Mater. 2023, 19, e02446. [Google Scholar] [CrossRef]

- Provis, J.L.; Palomo, A.; Shi, C. Advances in understanding alkali-activated materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.-B. Resistance of alkali-activated slag concrete to acid attack. Cem. Concr. Res. 2003, 33, 1607–1611. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Zheng, X.; Liu, H.; You, S.; Easa, S.; Cheng, K.; Chen, Z.; Ji, T. Cracking resistance and sustainability assessment of alkali-activated slag concrete incorporating lightweight aggregate. Cem. Concr. Compos. 2022, 131, 104556. [Google Scholar] [CrossRef]

- Sakulich, A.R.; Bentz, D.P. Mitigation of autogenous shrinkage in alkali activated slag mortars by internal curing. Mater. Struct. 2013, 46, 1355–1367. [Google Scholar] [CrossRef]

- JGJ/T 12-2019; Technical Standard for Application of Lightweight Aggregate Concrete. China Architecture and Building Press: Beijing, China, 2019.

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. China Architecture & Building Press: Beijing, China, 2016.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

- Yang, J.; Jeon, D.; Kang, H.; Shang, X.; Moon, J. Hydrophobic treatment on hollow glass microspheres for enhancing the flowability of lightweight high-performance cementitious composites. Constr. Build. Mater. 2023, 409, 133856. [Google Scholar] [CrossRef]

- Lu, J.-X.; Ali, H.A.; Jiang, Y.; Guan, X.; Shen, P.; Chen, P.; Poon, C.S. A novel high-performance lightweight concrete prepared with glass-UHPC and lightweight microspheres: Towards energy conservation in buildings. Compos. Part B Eng. 2022, 247, 110295. [Google Scholar] [CrossRef]

- Sohel, K.; Al-Jabri, K.; Zhang, M.; Liew, J.R. Flexural fatigue behavior of ultra-lightweight cement composite and high strength lightweight aggregate concrete. Constr. Build. Mater. 2018, 173, 90–100. [Google Scholar] [CrossRef]

| CaO | SiO2 | Al2O3 | MgO | K2O | Na2O | Fe2O3 | SO3 | |

|---|---|---|---|---|---|---|---|---|

| GGBFS | 39.29 | 33.06 | 15.04 | 9.96 | 0.43 | 0.32 | 1.9 | |

| SF | 0.67 | 93.7 | 0.3 | 0.69 | 1.17 | 0.79 | 2.38 | 0.3 |

| HGM | 8.04 | 80.1 | 0.75 | 0.18 | 0.03 | 10.61 | 0.05 | 0.24 |

| Bulk Density (kg/m3) | Density (kg/m3) | Tube Crushing Strength (MPa) | 1 h Water Absorption (%) | |

|---|---|---|---|---|

| HGM | 0.39 | 0.60 | 82 | |

| SPS | 827 | 1545 | ||

| SC | 712 | 1307 | 6 | 4.2 |

| Group | GGBFS (kg/m3) | SF (kg/m3) | HGM (kg/m3) | SPS (kg/m3) | SC (kg/m3) | H2O (kg/m3) | Na2O·9SiO2 (kg/m3) | K2CO3 (kg/m3) |

|---|---|---|---|---|---|---|---|---|

| S35H3 | 636.09 | 165.22 | 24.78 | 216.30 | 352.89 | 190.00 | 83.44 | 58.57 |

| S35H6 | 611.30 | 165.22 | 49.57 | 200.85 | 326.75 | 190.00 | 83.44 | 58.57 |

| S35H9 | 586.52 | 165.22 | 74.35 | 185.40 | 300.61 | 190.00 | 83.44 | 58.57 |

| S35H12 | 561.74 | 165.22 | 99.13 | 169.95 | 261.40 | 190.00 | 83.44 | 58.57 |

| S65H3 | 636.09 | 165.22 | 24.78 | 417.15 | 182.98 | 190.00 | 83.44 | 58.57 |

| S65H6 | 611.30 | 165.22 | 49.57 | 386.25 | 169.91 | 190.00 | 83.44 | 58.57 |

| S65H9 | 586.52 | 165.22 | 74.35 | 355.35 | 156.84 | 190.00 | 83.44 | 58.57 |

| S65H12 | 561.74 | 165.22 | 99.13 | 309.00 | 143.77 | 190.00 | 83.44 | 58.57 |

| S100H3 | 636.09 | 165.22 | 24.78 | 633.45 | 0 | 190.00 | 83.44 | 58.57 |

| S100H6 | 611.30 | 165.22 | 49.57 | 587.10 | 0 | 190.00 | 83.44 | 58.57 |

| S100H9 | 586.52 | 165.22 | 74.35 | 540.75 | 0 | 190.00 | 83.44 | 58.57 |

| S100H12 | 561.74 | 165.22 | 99.13 | 478.95 | 0 | 190.00 | 83.44 | 58.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Lu, Z.; Cheng, L.; Sun, J.; Huang, Y.; Cheng, X.; Wang, M. Influence of Hollow Glass Microspheres (HGM) on Properties of Alkali-Activated Slag Lightweight High-Strength Concrete Under Varying Lightweight Aggregate (LWA) Dosages. Materials 2025, 18, 3233. https://doi.org/10.3390/ma18143233

Wang L, Lu Z, Cheng L, Sun J, Huang Y, Cheng X, Wang M. Influence of Hollow Glass Microspheres (HGM) on Properties of Alkali-Activated Slag Lightweight High-Strength Concrete Under Varying Lightweight Aggregate (LWA) Dosages. Materials. 2025; 18(14):3233. https://doi.org/10.3390/ma18143233

Chicago/Turabian StyleWang, Liankun, Zefeng Lu, Long Cheng, Jun Sun, Yao Huang, Xin Cheng, and Minrong Wang. 2025. "Influence of Hollow Glass Microspheres (HGM) on Properties of Alkali-Activated Slag Lightweight High-Strength Concrete Under Varying Lightweight Aggregate (LWA) Dosages" Materials 18, no. 14: 3233. https://doi.org/10.3390/ma18143233

APA StyleWang, L., Lu, Z., Cheng, L., Sun, J., Huang, Y., Cheng, X., & Wang, M. (2025). Influence of Hollow Glass Microspheres (HGM) on Properties of Alkali-Activated Slag Lightweight High-Strength Concrete Under Varying Lightweight Aggregate (LWA) Dosages. Materials, 18(14), 3233. https://doi.org/10.3390/ma18143233