Shrinkage Behavior of Strength-Gradient Multilayered Zirconia Materials

Abstract

1. Introduction

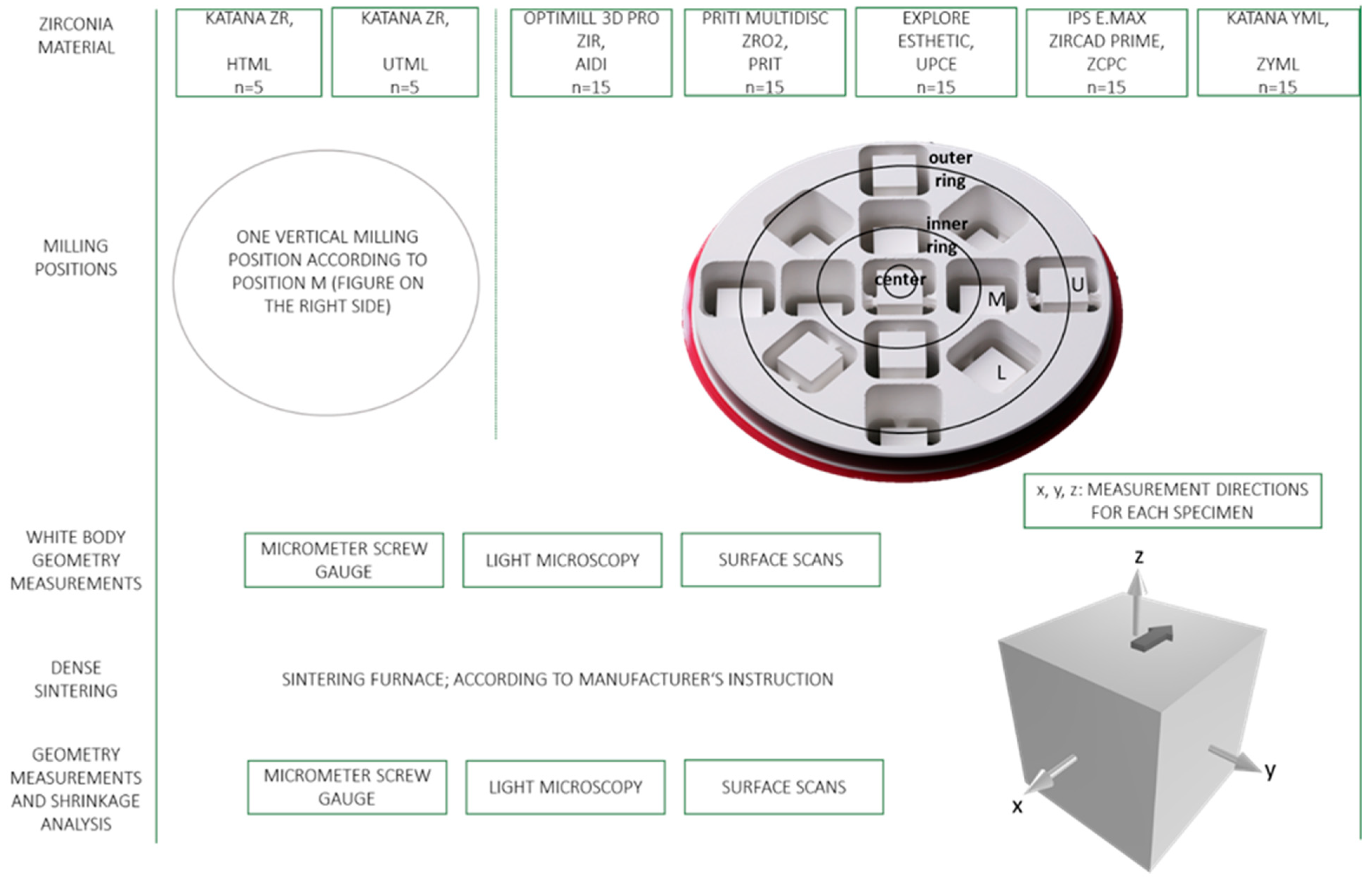

2. Materials and Methods

2.1. Specimen Preparation

2.2. Micrometer Screw Gauge

2.3. Light Microscopy

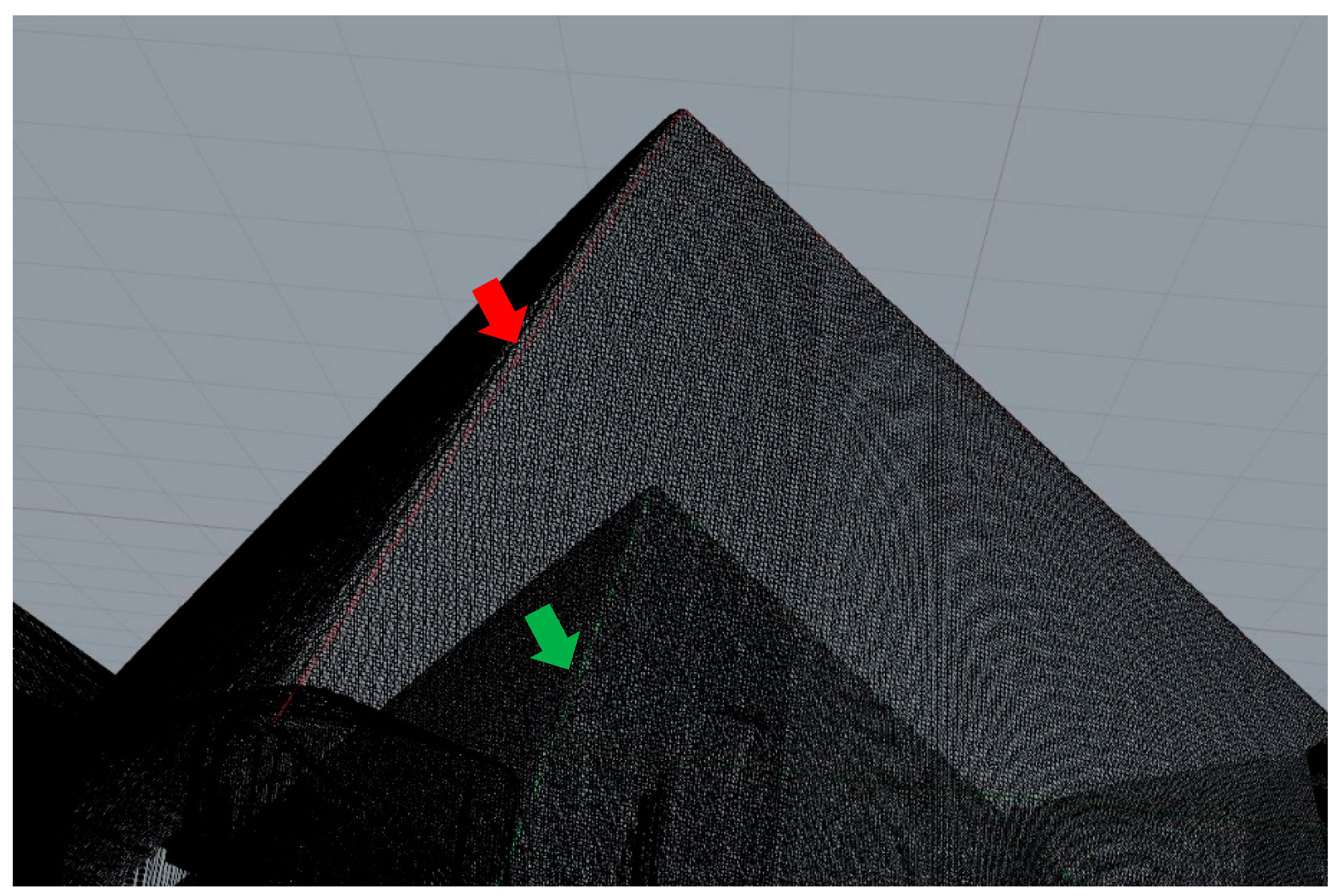

2.4. Surface Scans

2.5. Statistical Analysis

3. Results

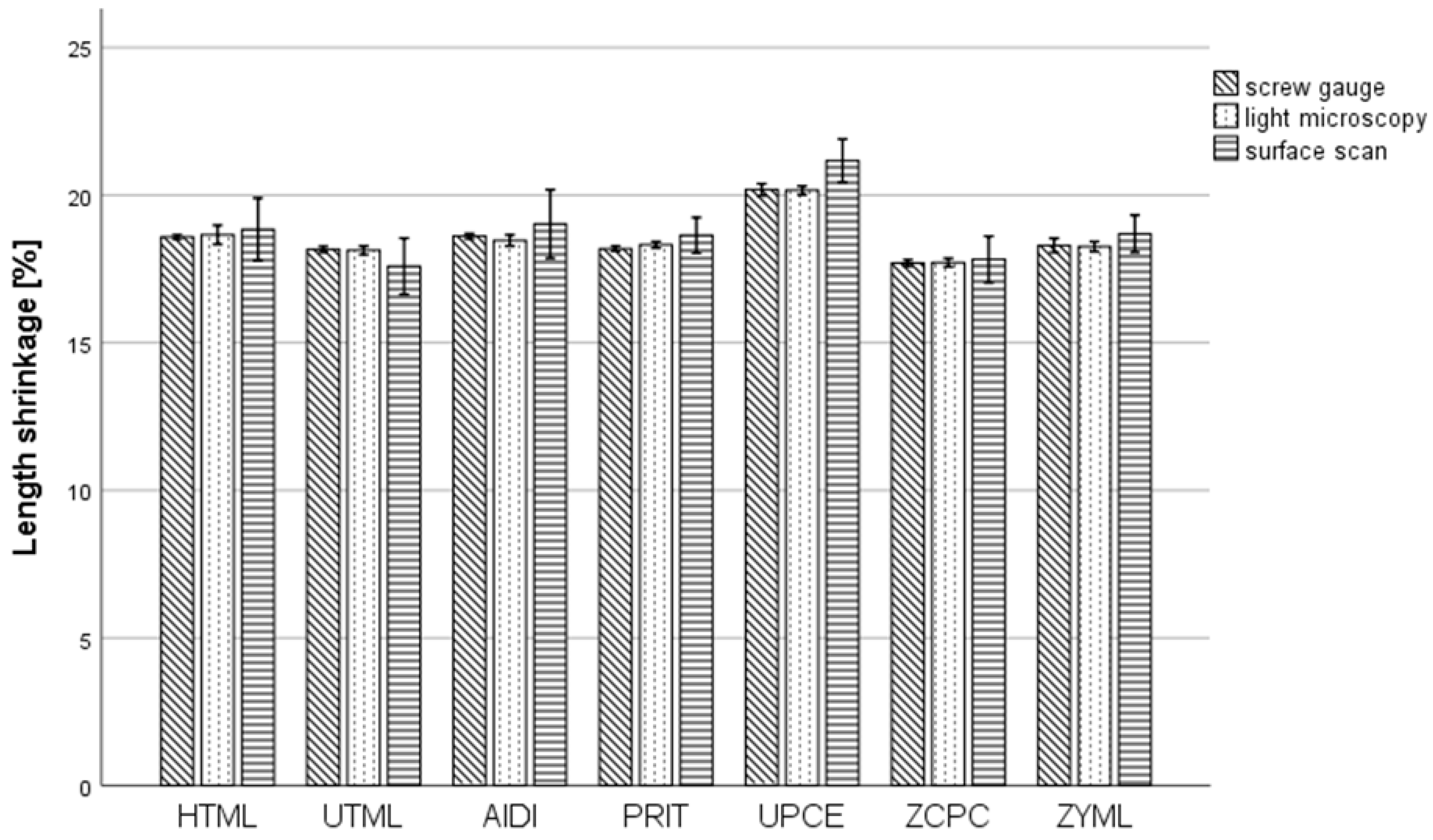

3.1. Global Analysis

3.2. Impact of Zirconia Materials and Test Methods Within Pooled Data (Vertical, Horizontal Position, and Measurement Direction)

3.3. Impact of the Horizontal, Vertical Position, and Measurement Point for Each Zirconia Material and Each Method, Separately

4. Discussion

5. Conclusions

- The zirconia material itself had the most substantial impact on linear shrinkage, followed by the measurement method applied.

- Among the tested materials, UPCE demonstrated the highest shrinkage values (20.1–21.1%), while ZCPC exhibited the lowest (17.7–17.8%), depending on measurement method.

- The monolayer 3Y-TZP material HTML showed higher shrinkage values (18.6–18.8%) than the monolayer 5Y-TZP material UTML (17.6–18.2%).

- Measurements using a micrometer screw gauge or digital light microscopy resulted in more consistent and less variable shrinkage values compared to surface scan techniques.

- Shrinkage values recorded across the upper, middle, and lower vertical layers of the strength-gradient multilayered zirconia disks did not significantly differ in the global analysis. This supports the assumption of a uniform shrinkage behavior in strength-gradient multilayer zirconia materials for clinically relevant restorations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Borik, M.; Gerasimov, M.; Lomonova, E.; Milovich, F.; Myzina, V.; Ryabochkina, P.; Sidorova, N.; Tabachkova, N. Mechanical properties and transformation hardening mechanism in yttria, ceria, neodymia and ytterbia co-doped zirconia based solid solutions. Mater. Chem. Phys. 2019, 232, 28–33. [Google Scholar] [CrossRef]

- Belli, R.; Hurle, K.; Schürrlein, J.; Petschelt, A.; Werbach, K.; Peterlik, H.; Rabe, T.; Mieller, B.; Lohbauer, U. Relationships between fracture toughness, Y2O3 fraction and phases content in modern dental Yttria-doped zirconias. J. Eur. Ceram. Soc. 2021, 41, 7771–7782. [Google Scholar] [CrossRef]

- Wiedenmann, F.; Pfefferle, R.; Reichert, A.; Jerman, E.; Stawarczyk, B. Impact of high-speed sintering, layer thickness and artificial aging on the fracture load and two-body wear of zirconia crowns. Dent. Mater. 2020, 36, 846–853. [Google Scholar] [CrossRef] [PubMed]

- Antón, X.; Stawarczyk, B.; Reymus, M.; Joda, T.; Liebermann, A. Impact of high-speed sintering on accuracy and fit of 4 mol% yttria-stabilized tetragonal zirconia polycrystals. Int. J. Prosthodont. 2021, 34, 775–783. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Keul, C.; Eichberger, M.; Figge, D.; Edelhoff, D.; Lümkemann, N. Three generations of zirconia: From veneered to monolithic. Part I. Quintessence Int. 2017, 48, 369–380. [Google Scholar]

- Vardhaman, S.; Borba, M.; Kaizer, M.R.; Kim, D.K.; Zhang, Y. Optical and Mechanical Properties of the Multi-Transition Zones of a Translucent Zirconia. J. Esthet. Restor. Dent. 2025, 37, 525–532. [Google Scholar] [CrossRef]

- Lümkemann, N.; Stawarczyk, B. Impact of hydrothermal aging on the light transmittance and flexural strength of colored yttria-stabilized zirconia materials of different formulations. J. Prosthet. Dent. 2021, 125, 518–526. [Google Scholar] [CrossRef]

- Alqutaibi, A.Y.; Ghulam, O.; Krsoum, M.; Binmahmoud, S.; Taher, H.; Elmalky, W.; Zafar, M.S. Revolution of Current Dental Zirconia: A Comprehensive Review. Molecules 2022, 27, 1699. [Google Scholar] [CrossRef]

- Ban, S. Development and characterization of ultra-high translucent zirconia using new manufacturing technology. Dent. Mater. J. 2023, 42, 1–10. [Google Scholar] [CrossRef]

- Sulaiman, T.A.; Suliman, A.A.; Abdulmajeed, A.A.; Zhang, Y. Zirconia restoration types, properties, tooth preparation design, and bonding. A narrative review. J. Esthet. Restor. Dent. 2024, 36, 78–84. [Google Scholar] [CrossRef]

- Arellano Moncayo, A.M.; Peñate, L.; Arregui, M.; Giner-Tarrida, L.; Cedeño, R. State of the Art of Different Zirconia Materials and Their Indications According to Evidence-Based Clinical Performance: A Narrative Review. Dent. J. 2023, 11, 18. [Google Scholar] [CrossRef] [PubMed]

- Michailova, M.; Elsayed, A.; Fabel, G.; Edelhoff, D.; Zylla, I.M.; Stawarczyk, B. Comparison between novel strength-gradient and color-gradient multilayered zirconia using conventional and high-speed sintering. J. Mech. Behav. Biomed. Mater. 2020, 111, 103977. [Google Scholar] [CrossRef] [PubMed]

- Čokić, S.M.; Cóndor, M.; Vleugels, J.; Van Meerbeek, B.; Van Oosterwyck, H.; Inokoshi, M.; Zhang, F. Mechanical properties–translucency–microstructure relationships in commercial monolayer and multilayer monolithic zirconia ceramics. Dent. Mater. 2022, 38, 797–810. [Google Scholar] [CrossRef] [PubMed]

- Strasser, T.; Wertz, M.; Koenig, A.; Koetzsch, T.; Rosentritt, M. Microstructure, composition, and flexural strength of different layers within zirconia materials with strength gradient. Dent. Mater. 2023, 39, 463–468. [Google Scholar] [CrossRef]

- Koo, P.J.; Lee, J.H.; Ha, S.R.; Seo, D.G.; Ahn, J.S.; Choi, Y.S. Changes in the Properties of Different Zones in Multilayered Translucent Zirconia Used in Monolithic Restorations During Aging Process. J. Funct. Biomater. 2025, 16, 96. [Google Scholar] [CrossRef]

- Oh, G.J.; Yun, K.D.; Lee, K.M.; Lim, H.P.; Park, S.W. Sintering behavior and mechanical properties of zirconia compacts fabricated by uniaxial press forming. J. Adv. Prosthodont. 2010, 2, 81–87. [Google Scholar] [CrossRef]

- Cesar, P.F.; Miranda, R.B.d.P.; Santos, K.F.; Scherrer, S.S.; Zhang, Y. Recent advances in dental zirconia: 15 years of material and processing evolution. Dent. Mater. 2024, 40, 824–836. [Google Scholar] [CrossRef]

- Ding, H.; Tsoi, J.K.; Kan, C.W.; Matinlinna, J.P. A simple solution to recycle and reuse dental CAD/CAM zirconia block from its waste residuals. J. Prosthodont. Res. 2021, 65, 311–320. [Google Scholar] [CrossRef]

- ISO 18675:2022; Dentistry-Machinable Ceramic Blanks. International Organization for Standardization: Geneva, Switzerland, 2022.

- Mosa, M.O.; Ibraheem, A.F.; Hussein, H.M. Digital Evaluation of the Trueness and Fitting Accuracy of a Three-Unit Fixed Zirconium Bridge Fabricated from Different Types of Zirconia and Different Marginal Cement Space Thickness. Eur. J. Gen. Dent. 2024, 13, 30–36. [Google Scholar] [CrossRef]

- Yazigi, C.; Busch, R.; Kern, M. Zirconia restorations and the tool diameter compensation. Int. J. Comput. Dent. 2023, 26, 257–264. [Google Scholar]

- Winter, A.; Schurig, A.; Odenthal, A.L.; Schmitter, M. Impact of different layers within a blank on mechanical properties of multi-layered zirconia ceramics before and after thermal aging. Dent. Mater. 2022, 38, e147–e154. [Google Scholar] [CrossRef] [PubMed]

- Rosentritt, M.; Preis, V.; Schmid, A.; Strasser, T. Multilayer zirconia: Influence of positioning within blank and sintering conditions on the in vitro performance of 3-unit fixed partial dentures. J. Prosthet. Dent. 2022, 127, 141–145. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.L.; Jiang, Y.Y.; Wei, Y.R.; Swain, M.V.; Yao, M.F.; Li, D.S.; Wei, T.; Jian, Y.T.; Zhao, K.; Wang, X.D. The influence of yttria content on the microstructure, phase stability and mechanical properties of dental zirconia. Ceram. Int. 2022, 48, 5361–5368. [Google Scholar] [CrossRef]

- Baldi, A.; Comba, A.; Ferrero, G.; Italia, E.; Michelotto Tempesta, R.; Paolone, G.; Mazzoni, A.; Breschi, L.; Scotti, N. External gap progression after cyclic fatigue of adhesive overlays and crowns made with high translucency zirconia or lithium silicate. J. Esthet. Restor. Dent. 2022, 34, 557–564. [Google Scholar] [CrossRef]

| Abbreviation | Material | Manufacturer | Zirconia Type | Geometry d: 98 mm × h: | Color/ Shade | Batch/LOT |

|---|---|---|---|---|---|---|

| HTML | Katana Zr, HTML Plus | Kuraray Noritake (Tokyo, Japan) | 3Y-TZP | 18 mm | A3 | EGLGB |

| UTML | Katana Zr, UTML | Kuraray Noritake | 5Y-TZP | 18 mm | A3 | EGZJZ |

| AIDI | Optimill 3D PRO Zir | Aidite (Qinhuangdao, China) | 4Y-TZP/ 5Y-TZP | 20 mm | A3 standard | 26640000 |

| PRIT | Priti Multidisc ZrO2 Multicolor | pritidenta (Leinfelden-Echterdingen, Germany) | 3Y-TZP/ 5Y-TZP | 20 mm | A light, translucent | T0924 AL 20T |

| UPCE | Explore Esthetic | UPCERA (Shenzhen, China) | 4Y-TZP/ 5Y-TZP | 20 mm | A3 | L2220506019-006 L2211203009-013 |

| ZCPC | IPS e.max ZirCAD Prime | Ivoclar Vivadent (Schaan, Liechtenstein) | 3Y-TZP/ 5Y-TZP | 20 mm | A3 | Z02R88 |

| ZYML | Katana YML | Kuraray Noritake (Tokyo, Japan) | 3Y-TZP/ 5Y-TZP | 22 mm | A3 | EGRKE |

| Material | Vertical Position | Horizontal Position | Specimen Axis | Length Shrinkage in % (Mean ± SD) | ||

|---|---|---|---|---|---|---|

| Micrometer Screw Gauge | Light Microscopy | Surface Scans | ||||

| HTML | Middle | Center | x | 18.6 | 18.5 | 19.7 |

| y | 18.6 | 18.5 | 20.0 | |||

| z | 18.5 | 18.2 | 18.9 | |||

| Inner ring | x | 18.6 ± 0.00 | 18.7 ± 0.04 | 19.2 ± 2.02 | ||

| y | 18.6 ± 0.00 * | 18.8 ± 0.10 | 18.6 ± 0.73 | |||

| z | 18.5 ± 0.03 | 18.5 ± 0.30 | 17.6 ± 1.64 | |||

| Outer ring | x | 18.6 ± 0.02 | 19.2 ± 0.50 * | 18.6 ± 0.29 * | ||

| y | 18.7 ± 0.06 * | 18.7 ± 0.01 * | 19.5 ± 0.39 | |||

| z | 18.5 ± 0.04 * | 18.4 ± 0.10 | 18.4 ± 1.14 | |||

| UTML | Middle | Center | x | 18.1 | 18.2 | 17.8 |

| y | 18.2 | 18.2 | 16.1 | |||

| z | 18.1 | 17.9 | 16.0 | |||

| Inner ring | x | 18.2 ± 0.02 * | 18.1 ± 0.14 * | 17.9 ± 0.13 * | ||

| y | 18.2 ± 0.04 * | 18.2 ± 0.12 | 18.0 ± 1.29 | |||

| z | 18.1 ± 0.04 * | 17.9 ± 0.09 | 17.5 ± 1.10 | |||

| Outer ring | x | 18.3 ± 0.22 * | 18.3 ± 0.08 | 17.9 ± 0.01 | ||

| y | 18.2 ± 0.03 * | 18.2 ± 0.15 * | 16.9 ± 0.35 * | |||

| z | 18.1 ± 0.10 | 18.1 ± 0.05 | 18.7 ± 0.69 | |||

| ZYML | Middle | Center | x | 18.4 | 18.0 | 17.7 |

| y | 18.2 | 18.2 | 20.1 | |||

| z | 18.1 | 18.0 | 18.3 | |||

| Inner ring | x | 18.6 ± 0.12 * | 18.3 ± 0.07 * | 19.3 ± 0.85 | ||

| y | 18.0 ± 0.09 | 18.4 ± 0.09 | 18.5 ± 0.73 | |||

| z | 18.3 ± 0.02 | 18.1 ± 0.01 | 19.2 ± 0.38 * | |||

| Outer ring | x | 18.2 ± 0.10 * | 18.3 ± 0.15 | 19.1 ± 0.18 * | ||

| y | 18.4 ± 0.06 | 18.7 ± 0.35 | 18.9 ± 0.84 | |||

| z | 18.2 ± 0.06 * | 18.1 ± 0.03 * | 18.7 ± 1.04 | |||

| Upper | Center | x | 18.8 | 18.5 | 18.5 | |

| y | 17.7 | 18.2 | 18.9 | |||

| z | 18.2 | 18.1 | 17.9 | |||

| Inner ring | x | 18.5 ± 0.05 * | 18.3 ± 0.04 | 19.0 ± 0.47 | ||

| y | 18.2 ± 0.10 * | 18.3 ± 0.03 * | 18.6 ± 0.06 * | |||

| z | 18.2 ± 0.07 | 18.1 ± 0.08 | 18.5 ± 0.07 | |||

| Outer ring | x | 18.6 ± 0.12 * | 18.1 ± 0.05 | 19.3 | ||

| y | 18.1 ± 0.01 | 18.3 ± 0.01 * | 17.8 | |||

| z | 18.2 ± 0.03 | 18.1 ± 0.26 * | 18.2 | |||

| Lower | Center | x | 18.6 | 18.1 | 19.2 | |

| y | 18.1 | 18.3 | 18.5 | |||

| z | 18.3 | 18.1 | 19.1 | |||

| Inner ring | x | 18.7 ± 0.27 * | 18.4 ± 0.04 | 18.8 ± 0.22 | ||

| y | 17.9 ± 0.02 | 18.3 ± 0.02 | 18.1 ± 0.38 | |||

| z | 18.3 ± 0.03 | 18.3 ± 0.03 * | 18.7 ± 0.78 | |||

| Outer ring | x | 18.6 ± 0.13 * | 18.3 ± 0.08 * | 19.1 ± 0.21 | ||

| y | 18.2 ± 0.10 | 18.3 ± 0.15 | 17.7 ± 0.88 | |||

| z | 18.3 ± 0.03 * | 18.2 ± 0.06 * | 18.5 ± 0.25 * | |||

| PRIT | Middle | Center | x | 18.2 | 18.2 | 18.4 |

| y | 18.2 | 18.3 | 18.7 | |||

| z | 18.1 | 18.3 | 18.2 | |||

| Inner ring | x | 18.2 ± 0.07 | 18.2 ± 0.02 | 19.5 ± 1.10 | ||

| y | 18.2 ± 0.05 * | 18.2 ± 0.06 * | 18.8 ± 0.25 * | |||

| z | 18.1 ± 0.08 * | 18.4 ± 0.12 * | 18.8 ± 0.54 * | |||

| Outer ring | x | 18.2 ± 0.02 | 18.3 ± 0.05 | 18.2 | ||

| y | 18.2 ± 0.04 * | 18.4 ± 0.16 * | 18.6 | |||

| z | 18.2 ± 0.06 * | 18.2 ± 0.05 * | 19.4 | |||

| Upper | Center | x | 18.2 | 18.2 | 18.6 | |

| y | 18.2 | 18.2 | 18.7 | |||

| z | 18.2 | 18.2 | 17.9 | |||

| Inner ring | x | 18.1 ± 0.01 | 18.5 ± 0.02 * | 19.3 ± 1.01 | ||

| y | 18.3 ± 0.07 | 18.3 ± 0.06 * | 18.5 ± 0.47 | |||

| z | 18.1 ± 0.08 * | 18.2 ± 0.04 * | 18.7 ± 0.99 | |||

| Outer ring | x | 18.1 ± 0.06 | 18.4 ± 0.15 | 18.2 ± 0.27 | ||

| y | 18.1 ± 0.05 * | 18.5 ± 0.02 | 18.9 ± 0.66 | |||

| z | 18.1 ± 0.09 | 18.3 ± 0.02 * | 18.3 ± 0.31 * | |||

| Lower | Center | x | 18.1 | 18.5 | 18.9 | |

| y | 18.1 | 18.4 | 18.5 | |||

| z | 18.1 | 18.4 | 18.8 | |||

| Inner ring | x | 18.2 ± 0.00 | 18.3 ± 0.15 * | 17.8 ± 1.55 | ||

| y | 18.2 ± 0.10 * | 18.3 ± 0.03 * | 18.1 ± 0.77 | |||

| z | 18.2 ± 0.06 | 18.3 ± 0.15 | 18.7 ± 0.28 | |||

| Outer ring | x | 18.2 ± 0.06 | 18.4 ± 0.04 * | 18.6 ± 0.03 * | ||

| y | 18.4 ± 0.20 | 18.3 ± 0.00 * | 18.6 ± 0.30 | |||

| z | 18.2 ± 0.00 * | 18.2 ± 0.06 * | 19.0 ± 0.57 | |||

| UPCE | Middle | Center | x | 20.2 | 20.1 | 21.6 |

| y | 20.2 | 20.1 | 20.3 | |||

| z | 19.1 | 19.9 | 21.3 | |||

| Inner ring | x | 20.2 ± 0.00 | 20.1 ± 0.00 | 21.5 ± 0.03 | ||

| y | 20.3 ± 0.06 | 20.1 ± 0.06 | 20.1 ± 0.18 * | |||

| z | 20.1 ± 0.04 | 20.0 ± 0.12 | 21.3 ± 0.25 | |||

| Outer ring | x | 20.2 ± 0.00 * | 20.0 ± 0.05 * | 21.4 ± 0.53 | ||

| y | 20.2 ± 0.00 * | 20.4 ± 0.18 * | 20.5 ± 0.47 * | |||

| z | 20.1 ± 0.02 * | 20.1 ± 0.07 | 22.5 ± 1.00 * | |||

| Upper | Center | x | 20.3 | 20.1 | 20.5 | |

| y | 20.3 | 20.3 | 20.9 | |||

| z | 20.3 | 20.1 | 20.7 | |||

| Inner ring | x | 20.3 ± 0.04 | 20.1 ± 0.01 | 20.8 ± 0.21 | ||

| y | 20.2 ± 0.01 * | 20.3 ± 0.01 | 21.4 ± 0.50 | |||

| z | 20.2 ± 0.06 | 20.2 ± 0.05 | 22.3 ± 1.40 * | |||

| Outer ring | x | 20.3 ± 0.06 | 20.2 ± 0.11 * | 21.1 ± 0.44 | ||

| y | 20.3 ± 0.06 | 20.2 ± 0.03 | 20.6 ± 0.53 * | |||

| z | 20.3 ± 0.28 * | 20.1 ± 0.27 * | 22.0 ± 0.88 | |||

| Lower | Center | x | 20.2 | 20.0 | 21.5 | |

| y | 20.2 | 20.4 | 21.0 | |||

| z | 20.2 | 20.2 | 20.5 | |||

| Inner ring | x | 20.1 ± 0.06 * | 20.4 ± 0.35 | 21.1 ± 0.44 | ||

| y | 20.2 ± 0.08 * | 20.2 ± 0.13 * | 20.7 ± 0.31 * | |||

| z | 20.3 ± 0.51 | 20.2 ± 0.04 | 21.2 ± 0.10 * | |||

| Outer ring | x | 20.1 ± 0.14 | 20.2 ± 0.20 * | 21.3 ± 1.46 | ||

| y | 20.1 ± 0.18 | 20.1 ± 0.02 * | 20.7 ± 0.01 * | |||

| z | 20.1 ± 0.02 * | 20.2 ± 0.07 | 21.2 ± 0.35 * | |||

| AIDI | Middle | Center | x | 18.6 | 18.5 | 18.1 |

| y | 18.6 | 18.4 | 18.2 | |||

| z | 18.7 | 18.5 | 20.7 | |||

| Inner ring | x | 18.5 ± 0.01 | 18.5 ± 0.18 | 18.7 ± 0.58 | ||

| y | 18.6 ± 0.02 | 18.4 ± 0.20 | 18.4 ± 0.10 * | |||

| z | 18.6 ± 0.02 * | 18.4 ± 0.11 | 19.1 ± 1.18 | |||

| Outer ring | x | 18.6 ± 0.04 * | 18.1 ± 0.01 | 19.3 ± 0.89 * | ||

| y | 18.6 ± 0.07 | 18.3 ± 0.13 | 21.1 ± 1.91 | |||

| z | 18.6 ± 0.02 * | 18.4 ± 0.07 | 19.7 ± 0.51 * | |||

| Upper | Center | x | 18.6 | 18.6 | 18.1 | |

| y | 18.7 | 18.4 | 17.4 | |||

| z | 18.8 | 18.5 | 19.8 | |||

| Inner ring | x | 18.6 ± 0.08 | 18.6 ± 0.40 | 18.7 ± 0.37 | ||

| y | 18.6 ± 0.04 * | 18.5 ± 0.06 * | 18.4 ± 1.65 | |||

| z | 18.7 ± 0.05 * | 18.4 ± 0.08 | 18.7 ± 0.36 | |||

| Outer ring | x | 18.6 ± 0.02 | 18.4 ± 0.05 * | 19.8 ± 0.50 * | ||

| y | 18.6 ± 0.05 * | 18.5 ± 0.14 * | 19.7 ± 0.52 | |||

| z | 18.7 ± 0.08 | 18.5 ± 0.07 * | 18.6 ± 2.63 | |||

| Lower | Center | x | 18.5 | 18.4 | 19.5 | |

| y | 18.5 | 18.5 | 16.5 | |||

| z | 18.8 | 18.8 | 21.6 | |||

| Inner ring | x | 18.5 ± 0.03 | 18.3 ± 0.03 | 19.1 ± 0.44 | ||

| y | 18.5 ± 0.06 * | 18.3 ± 0.03 | 19.5 ± 1.87 | |||

| z | 18.6 ± 0.01 * | 18.5 ± 0.27 * | 18.7 ± 0.23 | |||

| Outer ring | x | 18.5 ± 0.02 * | 18.6 ± 0.34 * | 18.2 ± 0.36 | ||

| y | 18.5 ± 0.03 * | 18.5 ± 0.03 | 19.0 ± 0.94 | |||

| z | 18.6 ± 0.04 | 18.8 ± 0.42 | 18.6 ± 0.52 | |||

| ZCPC | Middle | Center | x | 17.8 | 17.5 | 17.5 |

| y | 17.6 | 17.7 | 18.6 | |||

| z | 17.7 | 17.7 | 18.0 | |||

| Inner ring | x | 17.7 ± 0.06 | 18.0 ± 0.20 * | 17.7 ± 0.55 | ||

| y | 17.7 ± 0.09 * | 17.9 ± 0.05 | 18.8 ± 0.32 | |||

| z | 17.6 ± 0.13 | 17.6 ± 0.03 | 17.9 ± 0.15 | |||

| Outer ring | x | 17.6 ± 0.01 * | 17.7 ± 0.06 | 17.1 ± 0.73 | ||

| y | 17.6 ± 0.04 | 17.8 ± 0.05 * | 17.8 ± 1.42 | |||

| z | 17.7 ± 0.00 | 17.6 ± 0.13 * | 18.6 ± 0.04 | |||

| Upper | Center | x | 17.7 | 17.9 | 17.7 | |

| y | 17.8 | 17.7 | 20.4 | |||

| z | 17.7 | 17.8 | 17.9 | |||

| Inner ring | x | 17.7 ± 0.11 | 17.6 ± 0.00 | 17.1 ± 0.15 | ||

| y | 17.6 ± 0.08 * | 17.8 ± 0.14 * | 17.4 ± 0.99 * | |||

| z | 17.8 ± 0.04 | 17.8 ± 0.20 * | 18.3 ± 0.42 * | |||

| Outer ring | x | 17.6 ± 0.06 | 17.7 ± 0.07 * | 17.8 ± 0.12 * | ||

| y | 17.8 ± 0.28 | 17.8 ± 0.10 | 16.6 ± 0.58 * | |||

| z | 17.7 ± 0.14 * | 17.6 ± 0.15 | 17.9 ± 0.90 | |||

| Lower | Center | x | 17.8 | 17.9 | 17.5 | |

| y | 17.7 | 17.6 | 17.9 | |||

| z | 17.7 | 17.8 | 18.2 | |||

| Inner ring | x | 17.6 ± 0.06 | 17.7 ± 0.15 * | 17.5 ± 0.61 * | ||

| y | 17.8 ± 0.14 | 17.7 ± 0.00 | 17.7 ± 0.20 | |||

| z | 17.6 ± 0.05 * | 17.5 ± 0.01 * | 18.0 ± 0.63 * | |||

| Outer ring | x | 17.7 ± 0.11 * | 17.7 ± 0.24 * | 17.6 ± 0.10 * | ||

| y | 17.7 ± 0.22 * | 17.6 ± 0.10 | 16.8 ± 0.82 | |||

| z | 17.8 ± 0.24 | 17.7 ± 0.14 | 18.6 ± 0.30 | |||

| Zirconia Material | Micrometer Screw Gauge | Light Microscopy | Surface Scan |

|---|---|---|---|

| Mean ± SD | Mean ± SD | Mean ± SD | |

| HTML | 18.6 ± 0.07 deA | 18.7 ± 0.32 deA | 18.8 ± 1.06 bcA |

| UTML | 18.2 ± 0.10 *abA | 18.1 ± 0.15 abA | 17.6 ± 0.95 abA |

| AIDI | 18.6 ± 0.09 eB | 18.5 ± 0.19 cdA | 19.0 ± 1.16 cB |

| PRIT | 18.2 ± 0.08 bcA | 18.3 ± 0.11 *bcB | 18.6 ± 0.61 *bcC |

| UPCE | 20.2 ± 0.20 *fA | 20.1 ± 0.15 eA | 21.1 ± 0.73 *dB |

| ZCPC | 17.7 ± 0.11 aA | 17.7 ± 0.14 aA | 17.8 ± 0.79 aA |

| ZYML | 18.3 ± 0.24 bcdA | 18.3 ± 0.17 bA | 18.7 ± 0.63 cB |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coldea, A.; Meinen, J.; Hoffmann, M.; Elsayed, A.; Stawarczyk, B. Shrinkage Behavior of Strength-Gradient Multilayered Zirconia Materials. Materials 2025, 18, 3217. https://doi.org/10.3390/ma18143217

Coldea A, Meinen J, Hoffmann M, Elsayed A, Stawarczyk B. Shrinkage Behavior of Strength-Gradient Multilayered Zirconia Materials. Materials. 2025; 18(14):3217. https://doi.org/10.3390/ma18143217

Chicago/Turabian StyleColdea, Andrea, John Meinen, Moritz Hoffmann, Adham Elsayed, and Bogna Stawarczyk. 2025. "Shrinkage Behavior of Strength-Gradient Multilayered Zirconia Materials" Materials 18, no. 14: 3217. https://doi.org/10.3390/ma18143217

APA StyleColdea, A., Meinen, J., Hoffmann, M., Elsayed, A., & Stawarczyk, B. (2025). Shrinkage Behavior of Strength-Gradient Multilayered Zirconia Materials. Materials, 18(14), 3217. https://doi.org/10.3390/ma18143217