Impact of Early-Age Curing and Environmental Conditions on Shrinkage and Microcracking in Concrete

Abstract

1. Introduction

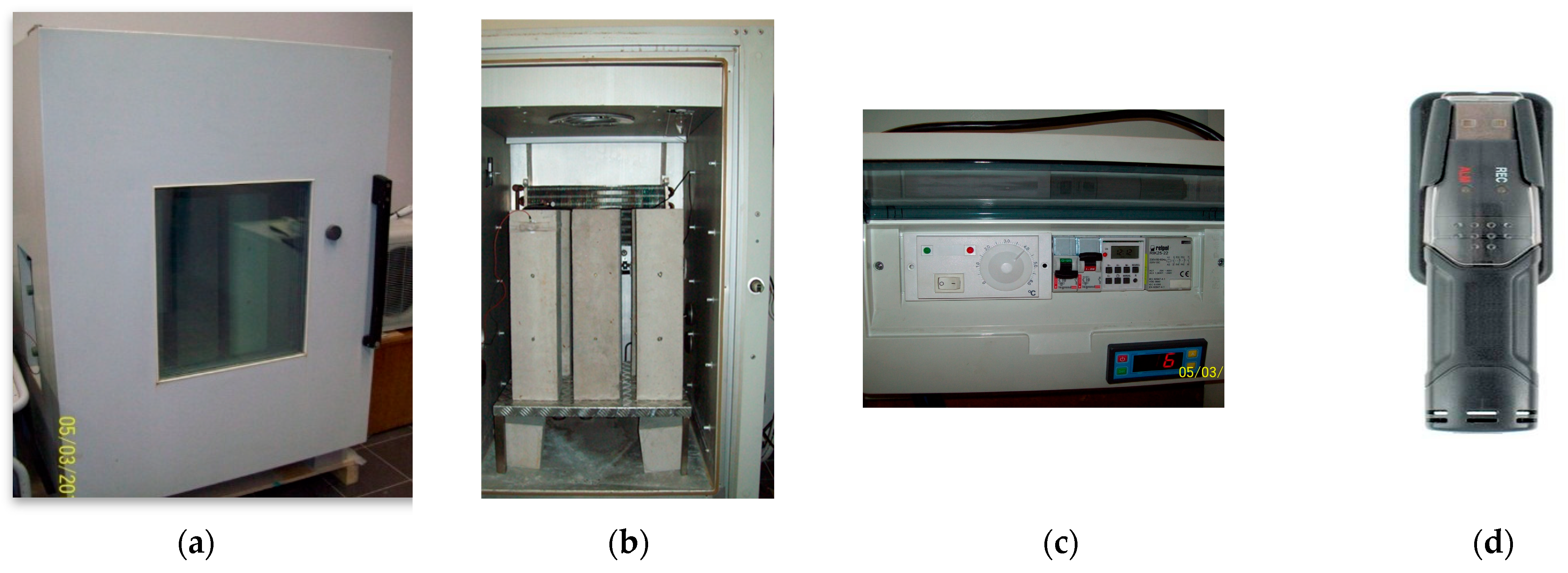

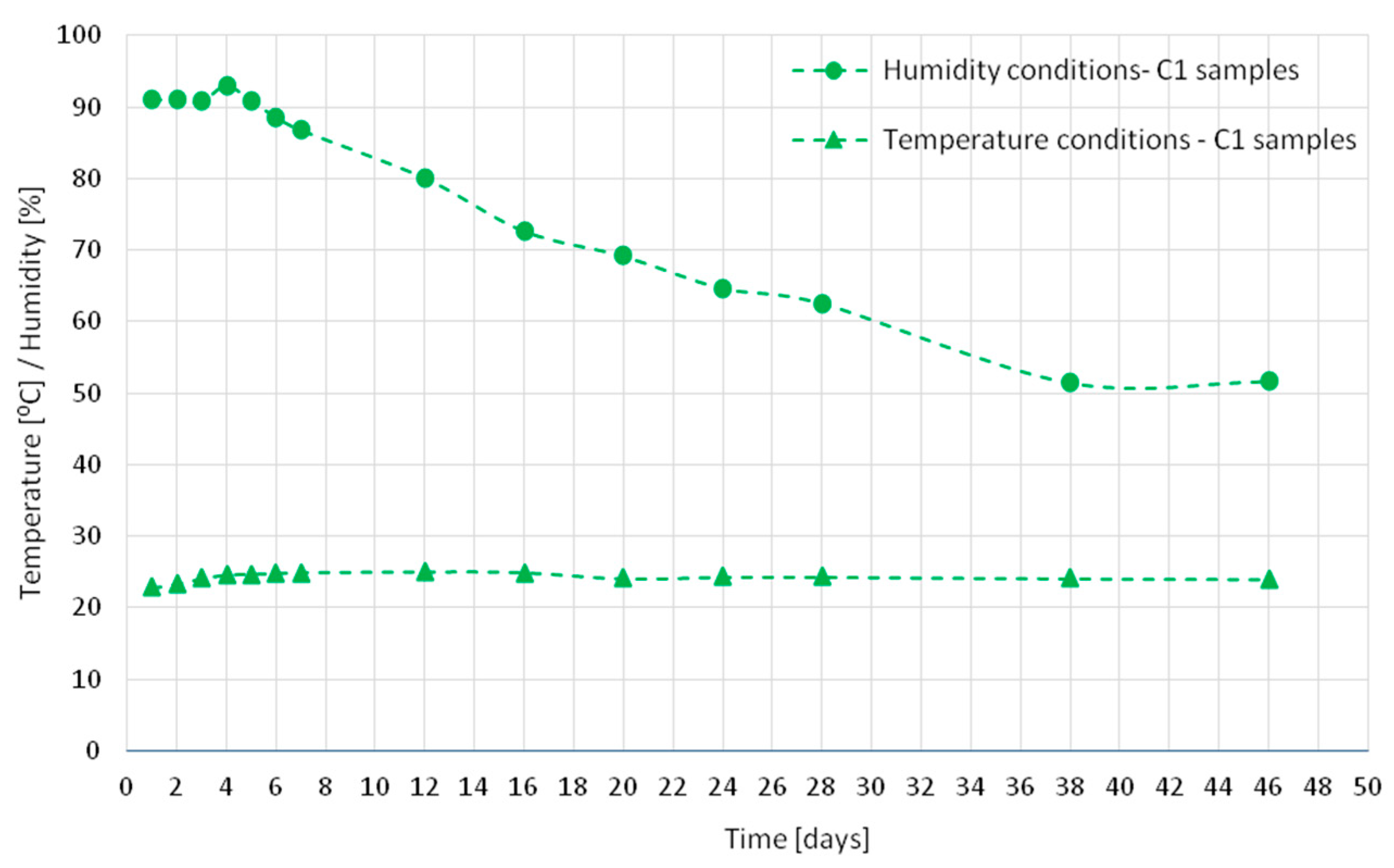

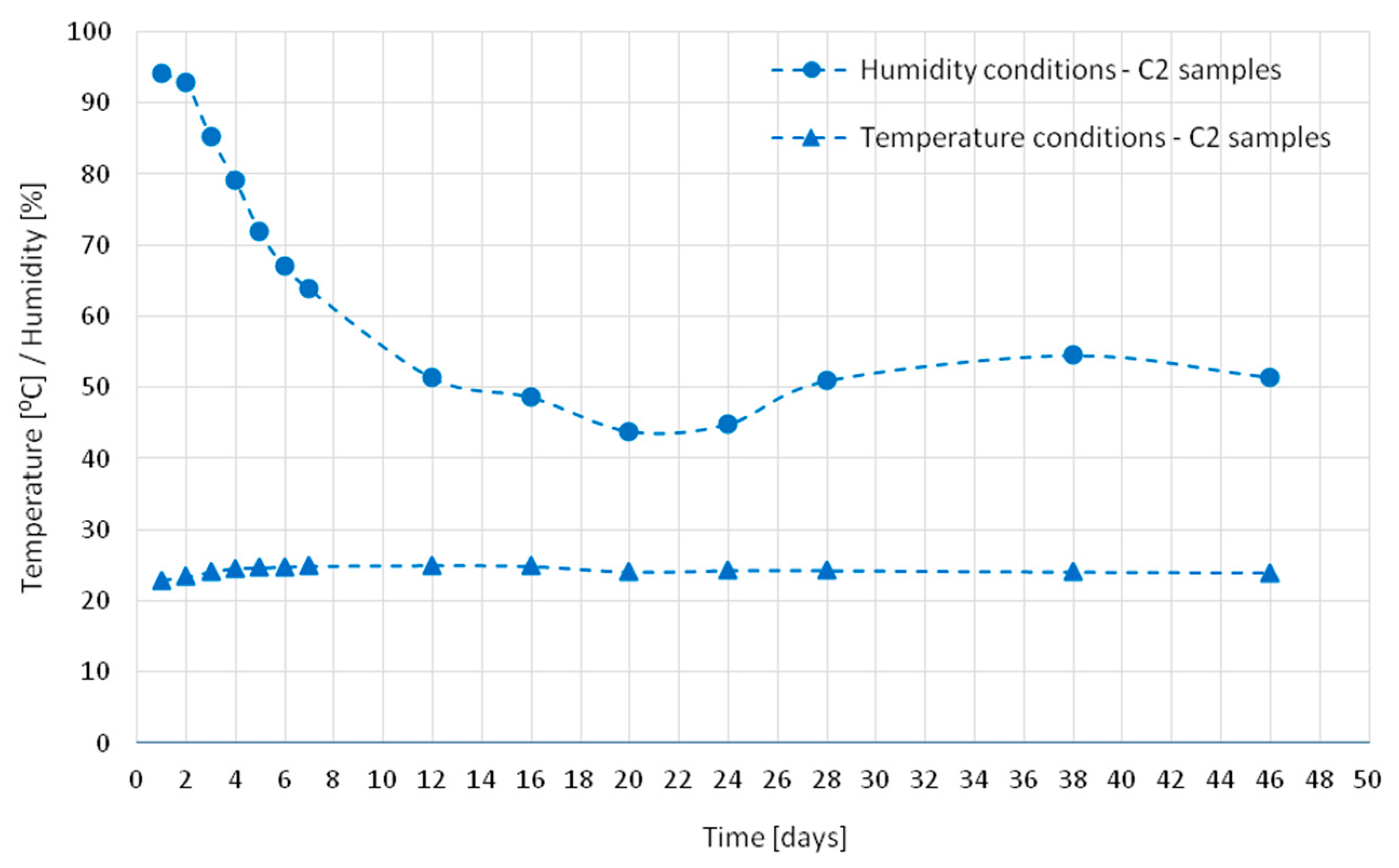

2. Materials and Methods

2.1. Test Elements

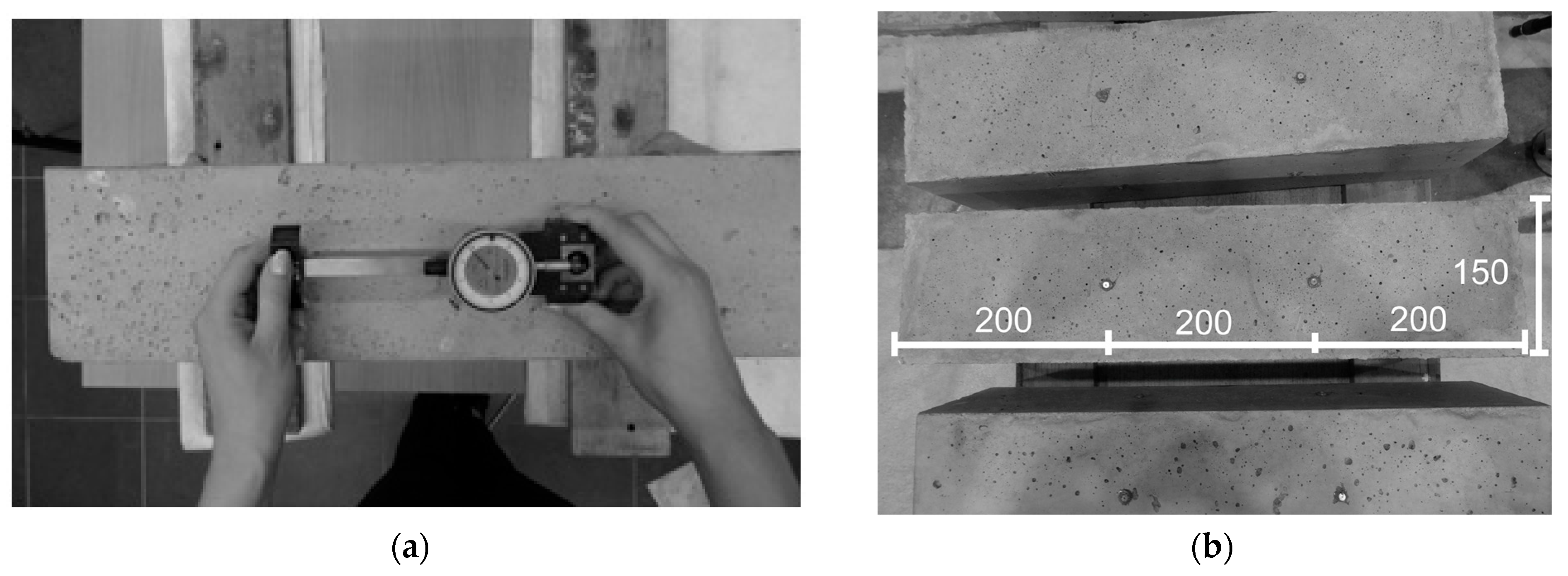

2.2. Research Methods

2.2.1. Strain Measurements and Prediction

2.2.2. Acoustic Emission Signal (Destructive Process) Measurements

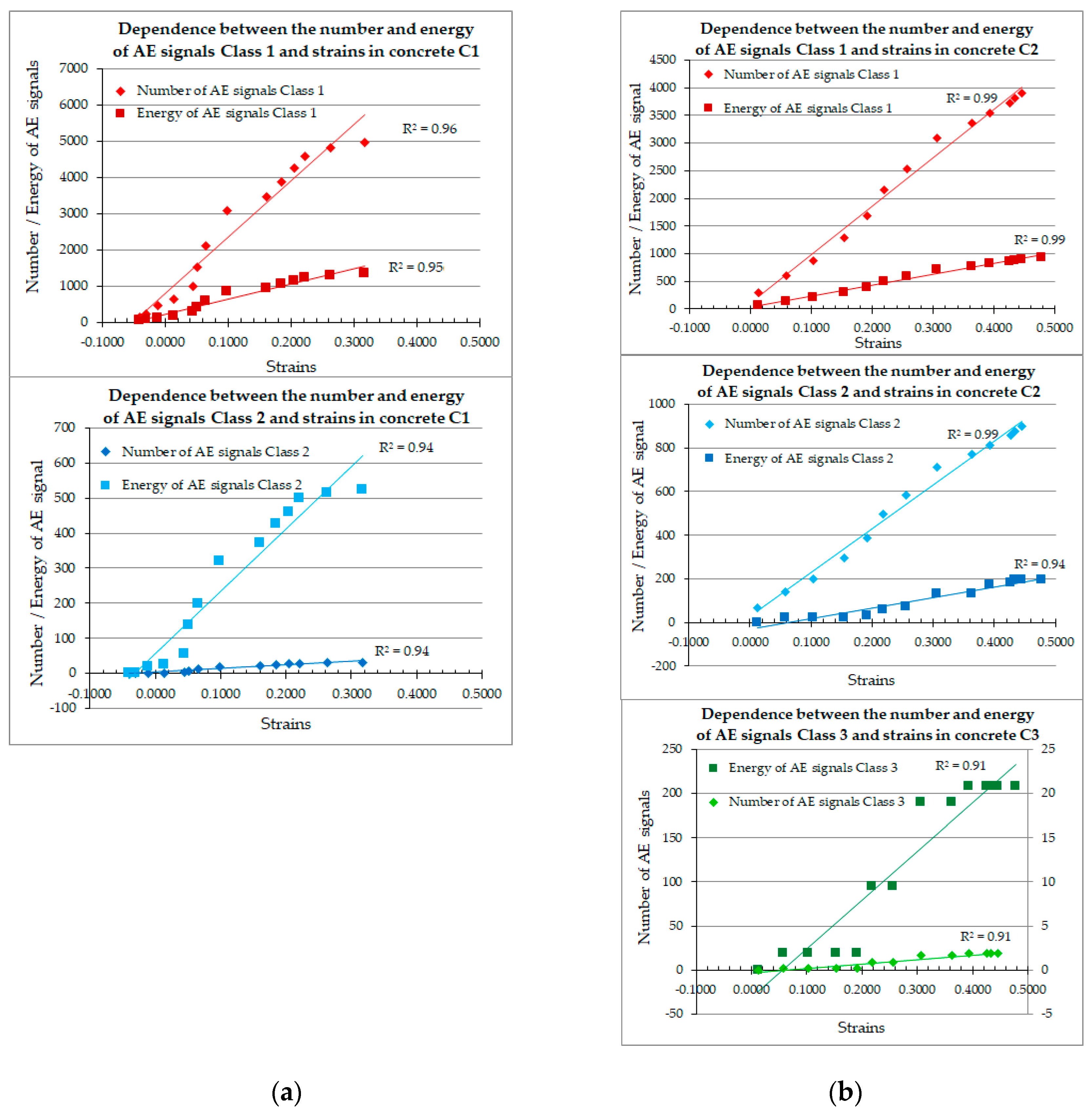

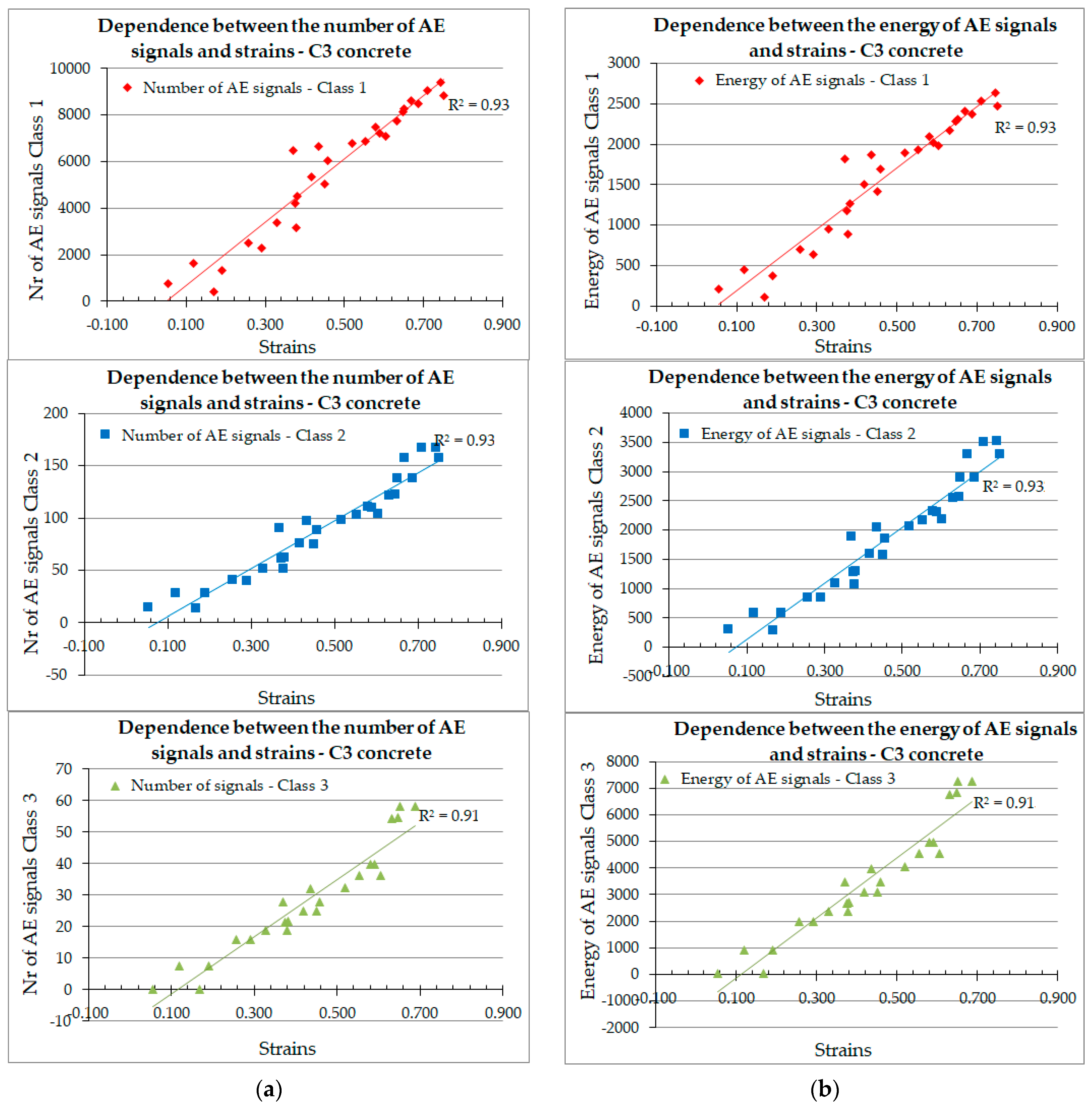

- Class 1 signals indicate microcracks in the cement paste and in contact between the paste surface and aggregate grains.

- Class 2 signals indicate the development of internal microcracks.

- Class 3 signals indicate the formation of microcracks on the concrete surface.

3. Results

3.1. Shrinkage Strain

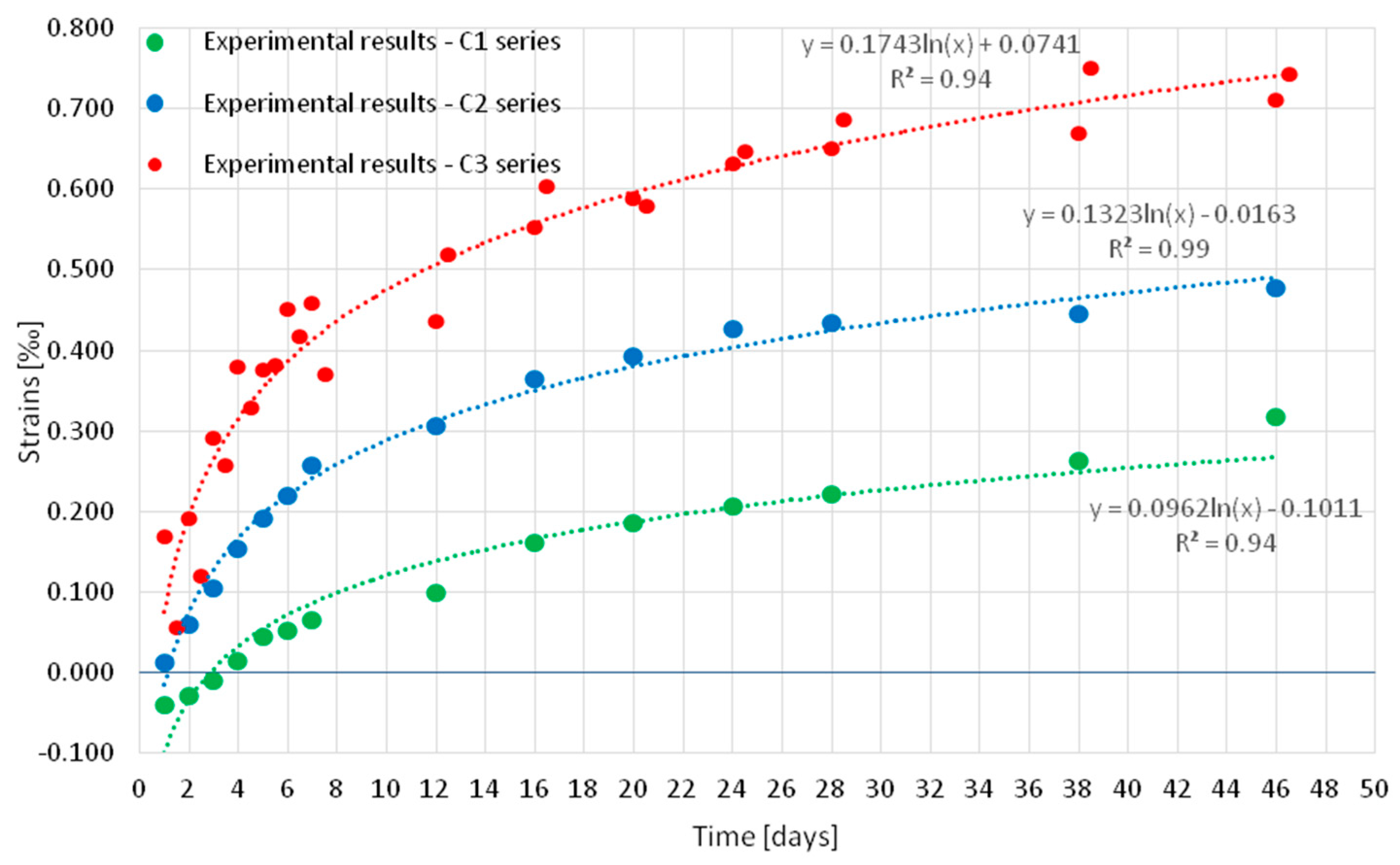

3.1.1. Experimental Results—Strain

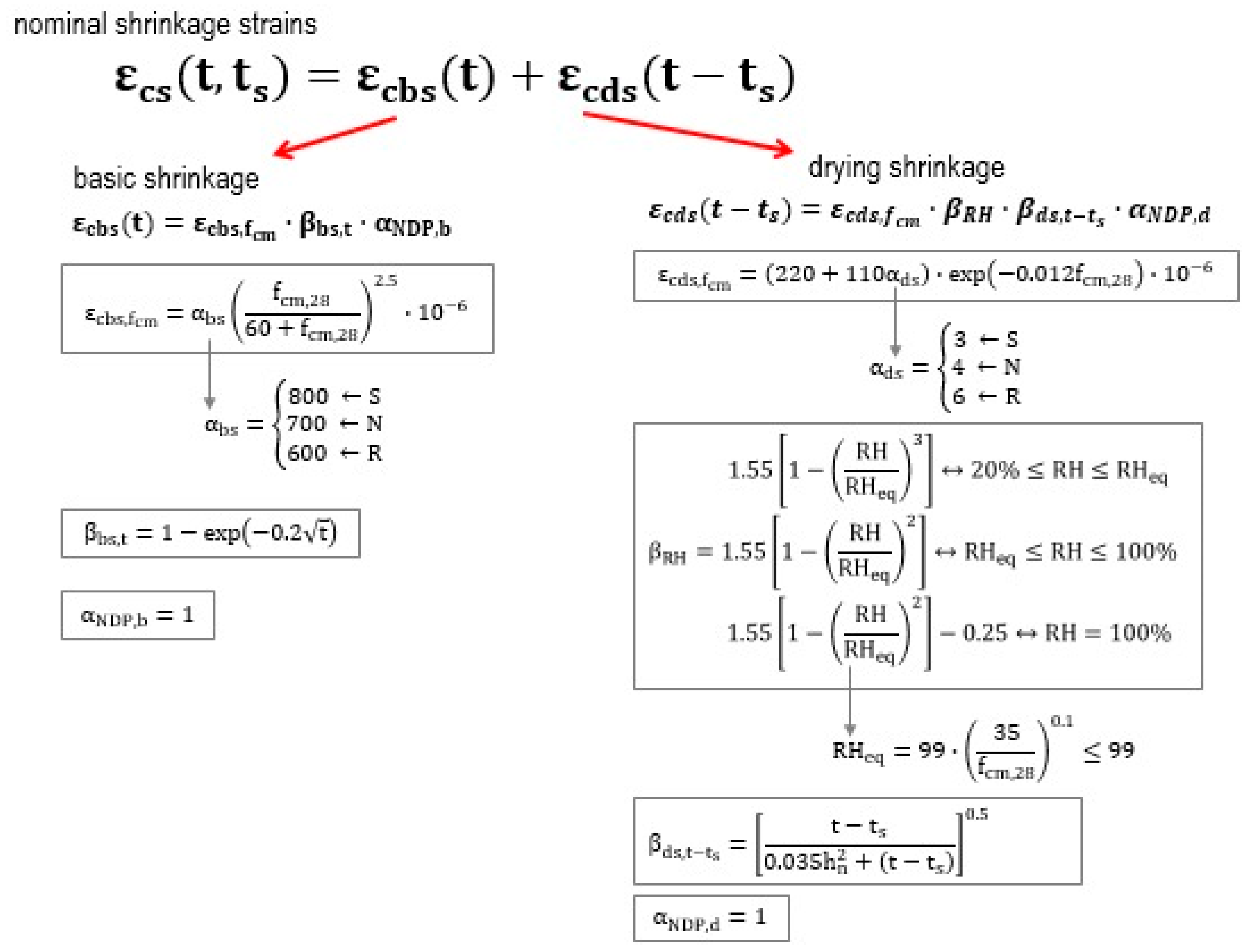

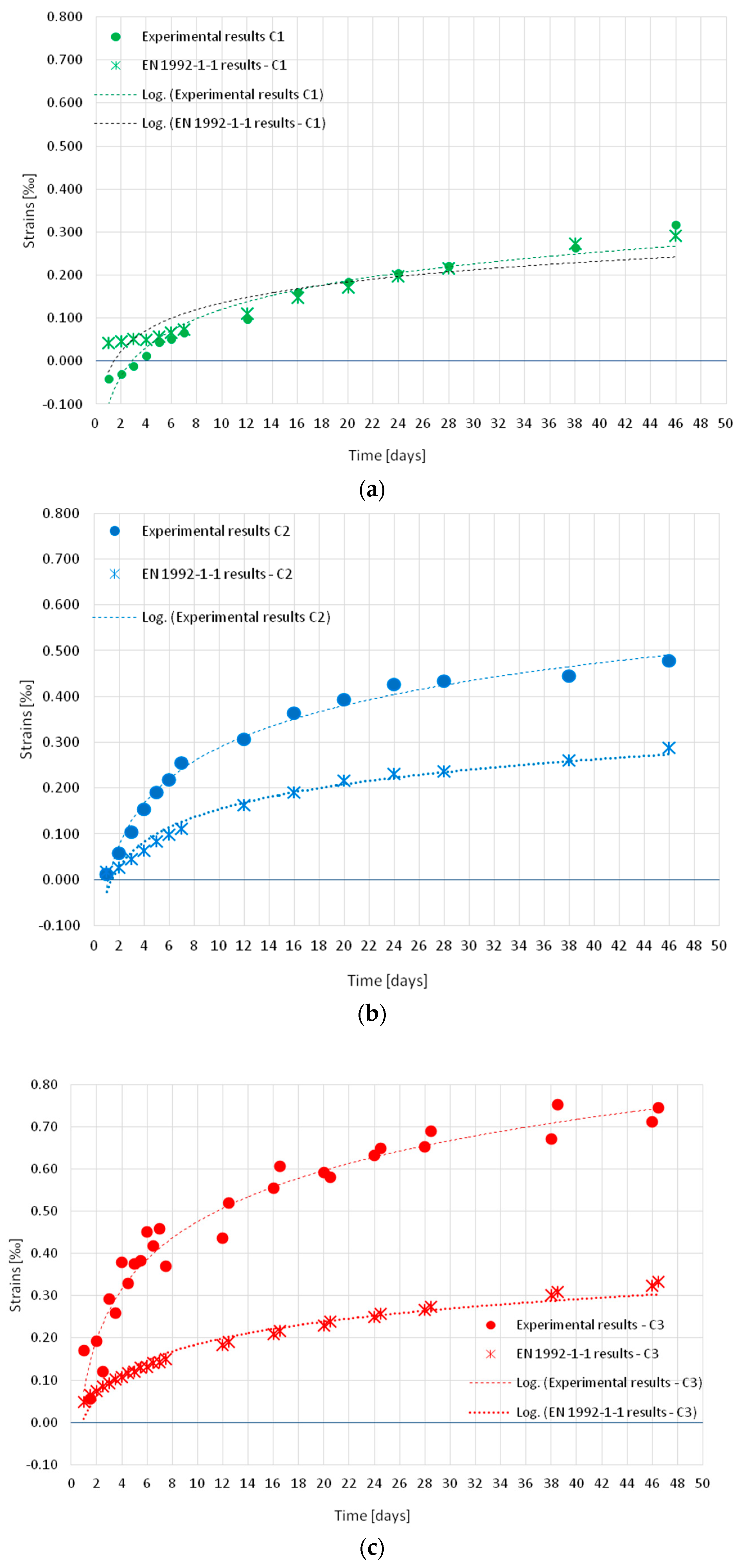

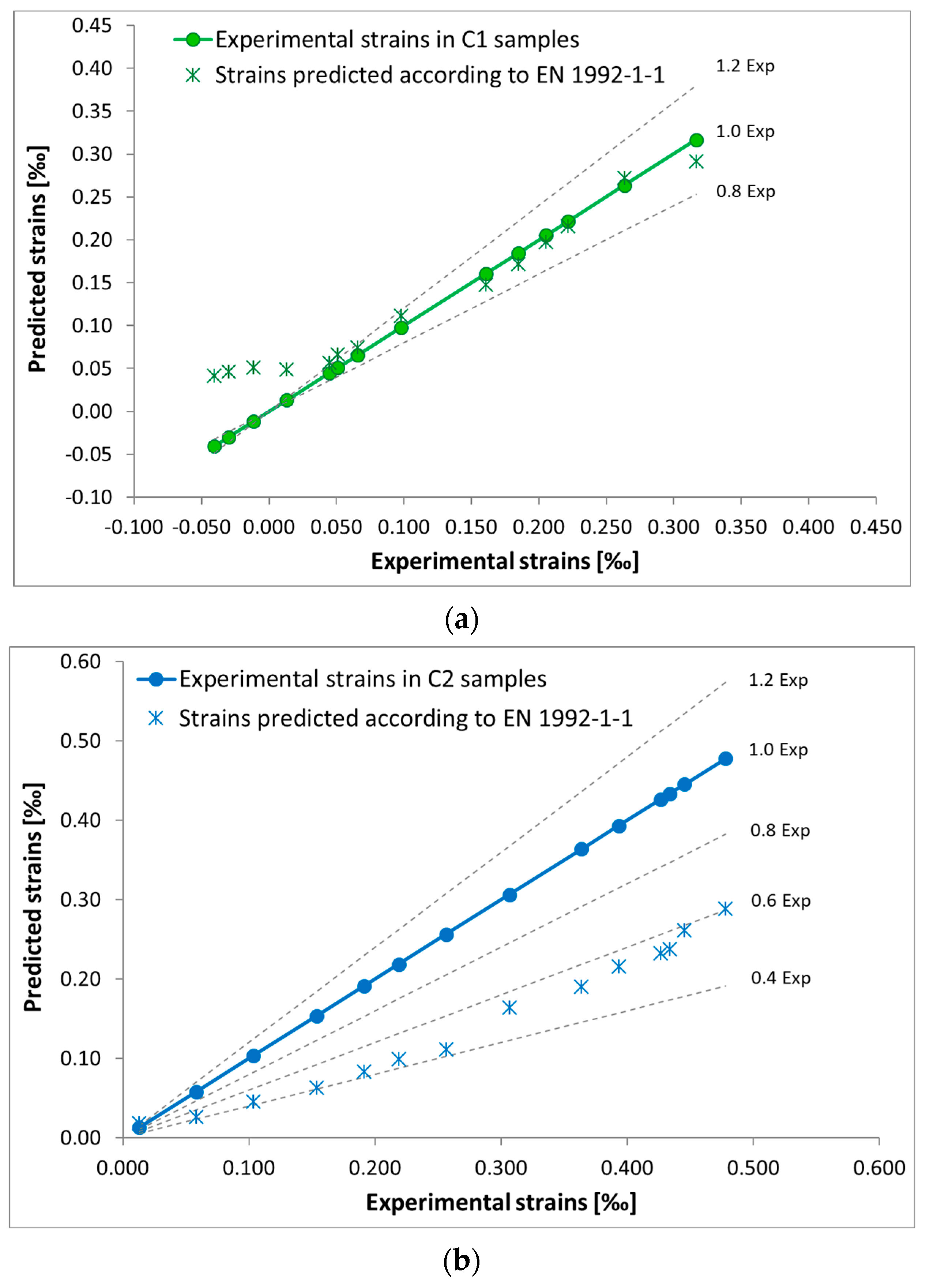

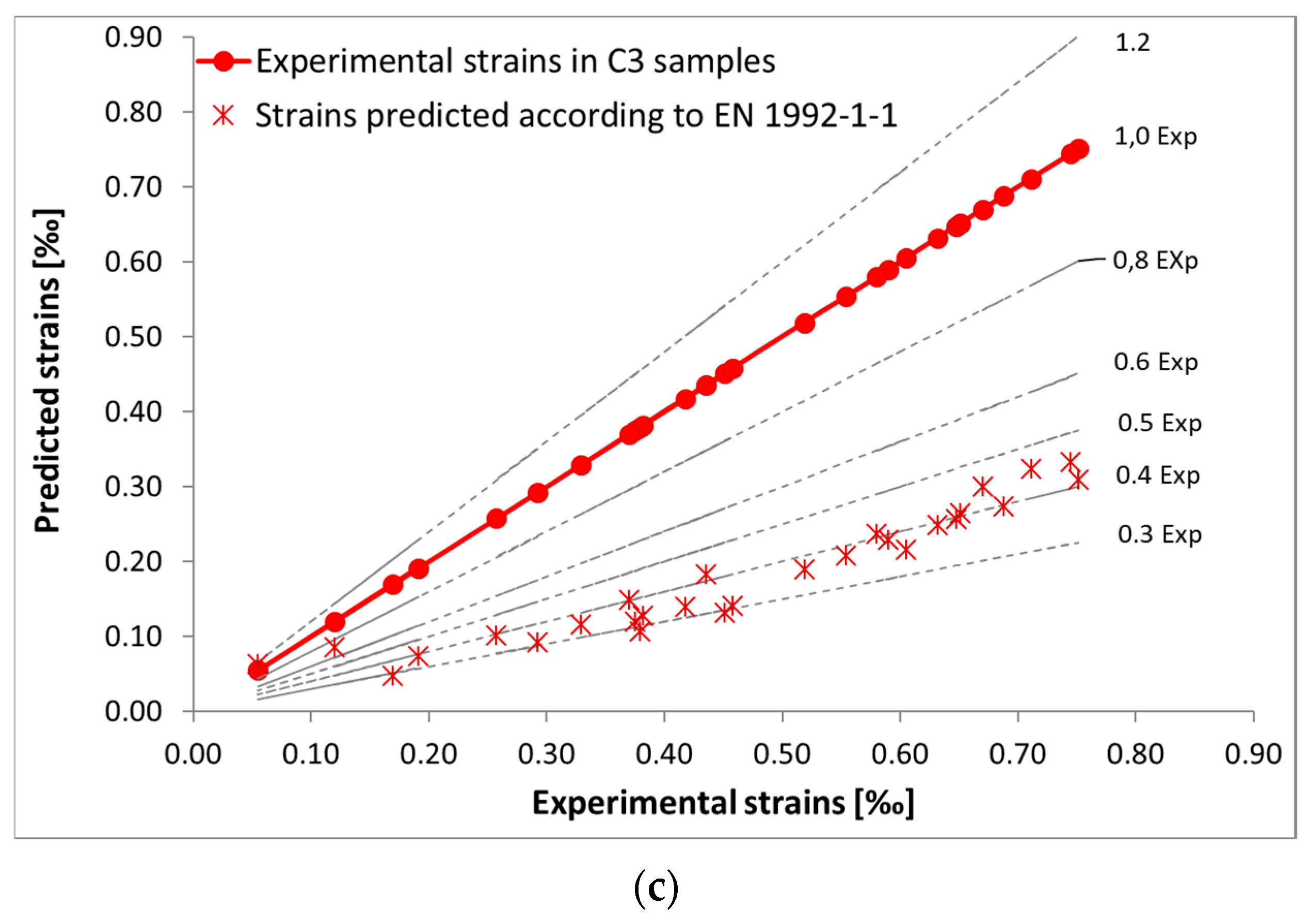

3.1.2. Shrinkage Strain Predicted by the EN 1992-1-1:2023 Standard

3.2. Acoustic Emission Signal Analysis

3.2.1. AE Signal Analysis

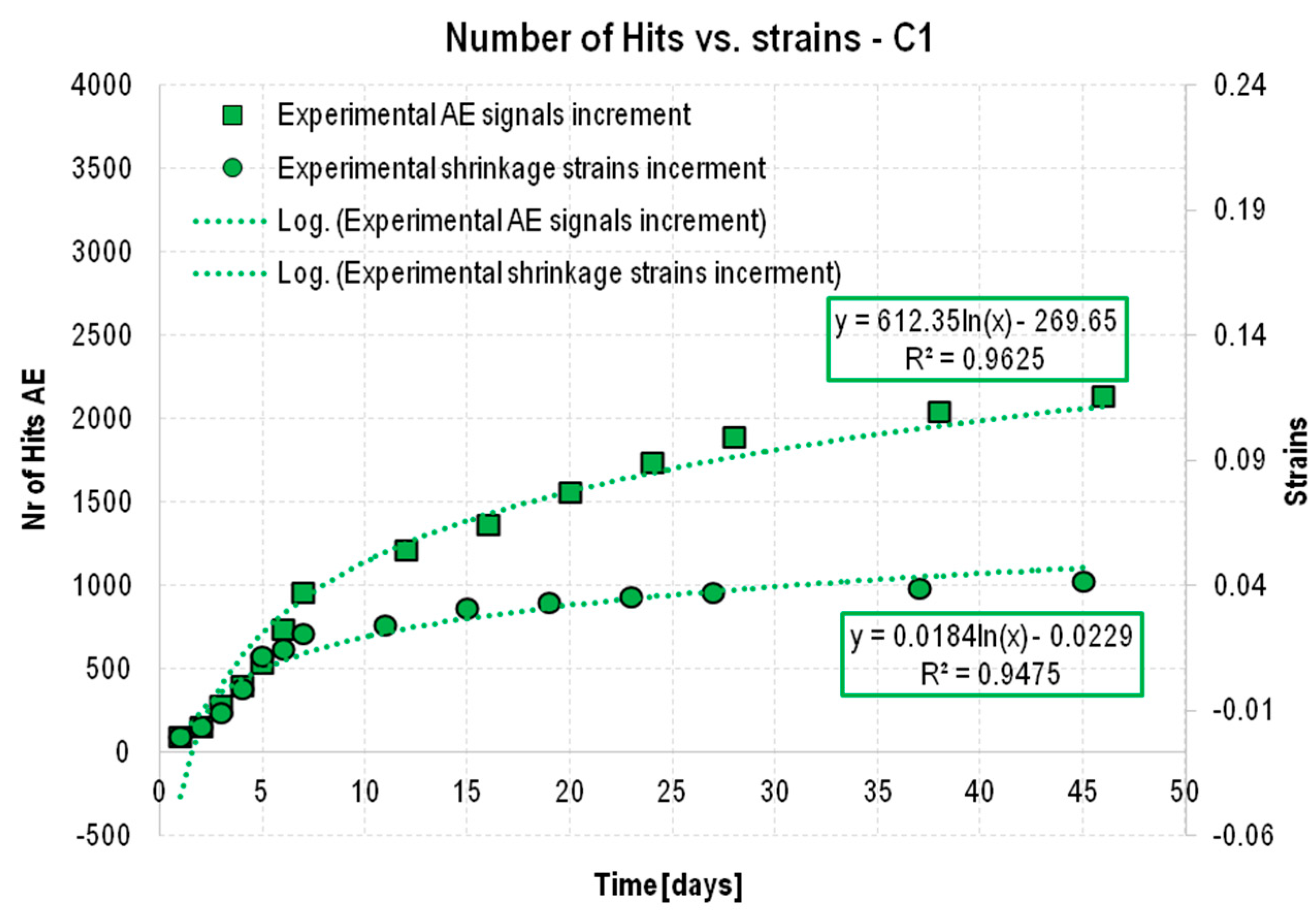

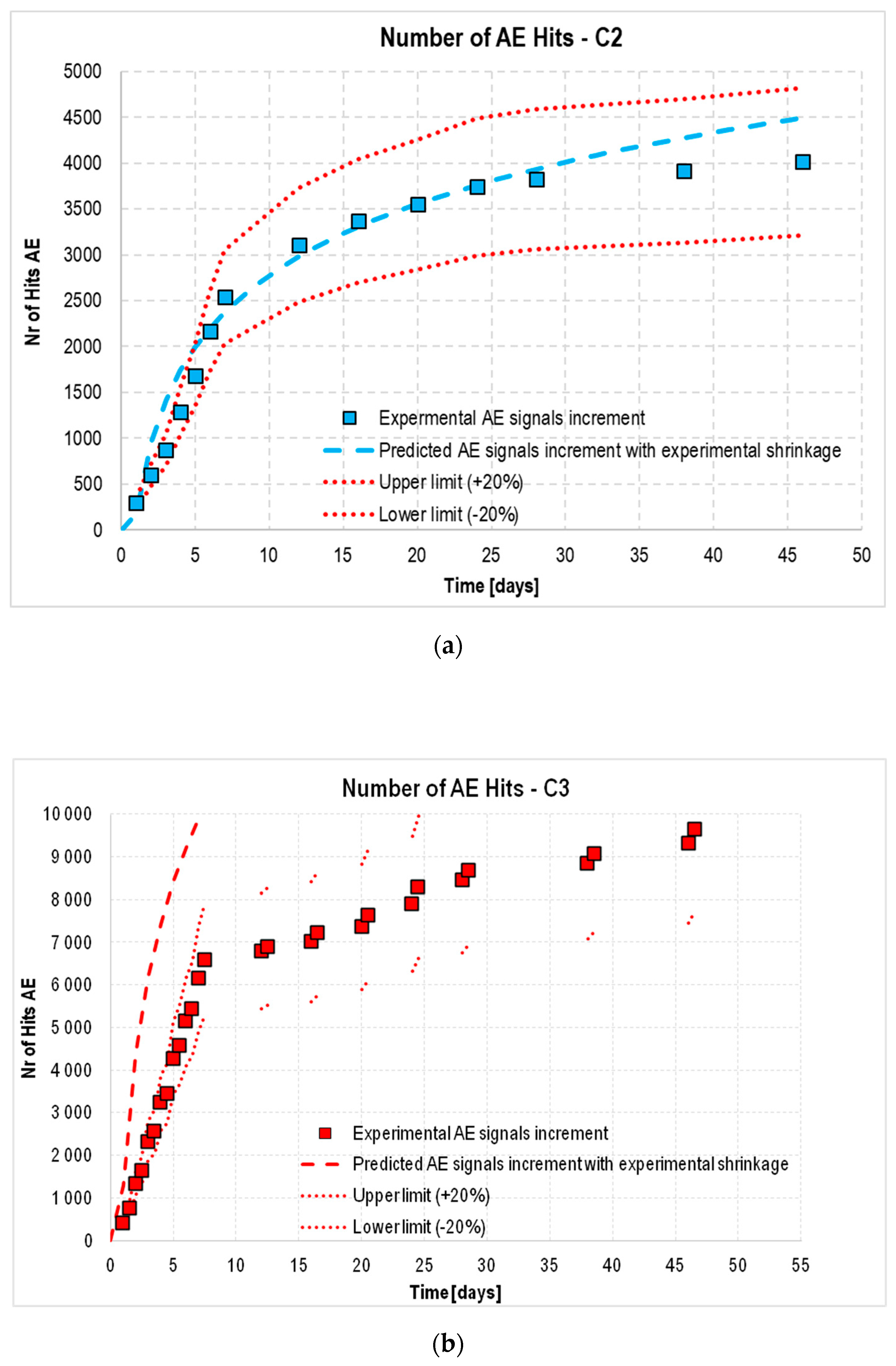

3.2.2. Acoustic Emission–Strain Correlation

- Apply coefficients α and β (Table 5), which allow for the transition from the logarithmic trend line of the increase in contractile strain to the logarithmic trend line of the increase in AE signals.

- In the case of concrete without curing, an additional factor, η (Table 5), should be applied.

- If the concrete has been exposed to variable temperatures, factor γ (Table 5) must also be taken into account.

4. Discussion

5. Conclusions

- The EN 1992-1-1:2023 [24] standard (implemented in Poland as PN-EN 1992-1-1:2024) describes the strain of samples subjected to curing with water well.

- In the case of samples without water curing, for both constant and variable temperature, it is necessary to use the coefficient 1.65, which corrects the values estimated according to the Eurocode 2 standard.

- Shrinkage strain is accompanied by destructive processes: microcracks in the cement paste, development of internal cracks, and the formation of microcracks on the concrete surface, which can be identified using AE (signal classes 1, 2, and 3).

- The number and energy of destructive processes is a linear function of the strain for samples with and without curing in water.

- The total number of destructive processes (AE signals) can be determined as a function of strain, both experimentally measured and standard-predicted (taking into account correction factors for samples without curing in water).

- For samples without water curing, class 3 signals should be recorded, which indicate processes related to the formation of microcracks on the surface that may affect the durability of the elements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education Limited: London, UK, 2011; ISBN 978-0-273-75580-7. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill: New York, NY, USA, 2014. [Google Scholar]

- Kaszyńska, M.; Zielinski, A. Effect of lightweight aggregate on minimizing autogenous shrinkage in self-consolidating concrete. Procedia Eng. 2015, 108, 608–615. [Google Scholar] [CrossRef]

- Yang, S. Effect of different types of recycled concrete aggregates on equivalent concrete strength and drying shrinkage properties. Applied Sciences. Appl. Sci. 2018, 8, 2190. [Google Scholar] [CrossRef]

- Kheir, J.; Hilloulin, B.; Loukili, A.; De Belie, N. Chemical shrinkage of low water to cement (w/c) ratio CEM I and CEM III cement pastes incorporating silica fume and filler. Materials 2021, 14, 1164. [Google Scholar] [CrossRef]

- Ge, H.; Sun, Z.; Lu, Z.; Yang, H.; Zhang, T.; He, N. Influence and mechanism analysis of different types of water reducing agents on volume shrinkage of cement mortar. J. Build. Eng. 2024, 82, 108204. [Google Scholar] [CrossRef]

- Linek, M.; Nita, P.; Wolka, P.; Żebrowski, W. Application of natural mineral additives in construction. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 022006. [Google Scholar] [CrossRef]

- Raczkiewicz, W.; Koteš, P.; Konečný, P. Influence of the Type of Cement and the Addition of an Air-Entraining Agent on the Effectiveness of Concrete Cover in the Protection of Reinforcement against Corrosion. Materials 2021, 14, 4657. [Google Scholar] [CrossRef]

- Skarżyński, Ł.; Suchorzewski, J. Mechanical and fracture properties of concrete reinforced with recycled and industrial steel fibers using Digital Image Correlation technique and X-ray micro computed tomography. Constr. Build. Mater. 2018, 183, 283–299. [Google Scholar] [CrossRef]

- Czajkowska, A.; Raczkiewicz, W.; Bacharz, M.; Bacharz, K. Influence of maturing conditions of steel-fibre reinforced concrete on its selected parameters. Constr. Optim. Energy Potential 2020, 9, 47–54. [Google Scholar] [CrossRef]

- Kaszyńska, M.; Zieliński, A. Influence of mixture composition on shrinkage cracking of lightweight self-consolidating concrete. Brittle Matrix Compos. 2008, 9, 113–122. [Google Scholar] [CrossRef]

- Penttala, V. Causes and mechanisms of deterioration in reinforced concrete. In Failure, Distress and Repair of Concrete Structures; Woodhead Publishing: Cambridge, UK, 2009; pp. 3–31. [Google Scholar] [CrossRef]

- Bissonnette, B.; Pierre, P.; Pigeon, M. Influence of key parameters on drying shrinkage of cementitious materials. Cem. Concr. Res. 1999, 29, 1655–1662. [Google Scholar] [CrossRef]

- Soliman, A.M.; Nehdi, M.L. Effect of drying conditions on autogenous shrinkage in ultra-high performance concrete at early-age. Mater. Struct. 2011, 44, 878–899. [Google Scholar] [CrossRef]

- Fairbairn, E.M.R.; Azenha, M. Thermal Cracking of Massive Concrete Structures: State of the Art Report of the RILEM Technical Committee 254-CMS; RILEM State-of-the-Art Reports; Springer: Cham, Switzerland, 2019; Volume 27. [Google Scholar] [CrossRef]

- Linek, M. Low-shrink airfield cement concrete with respect to thermal resistance. MATEC Web Conf. 2017, 133, 07002. [Google Scholar] [CrossRef][Green Version]

- Ghanem, H.; Ramadan, R.; Khatib, J.; Elkordi, A. A Review on Chemical and Autogenous Shrinkage of Cementitious Systems. Materials 2024, 17, 283. [Google Scholar] [CrossRef]

- Zhong, H. A review on the Shrinkage Properties of Concrete and Influencing Factors. Adv. Res. 2024, 25, 192–201. [Google Scholar] [CrossRef]

- Tran, N.P.; Gunasekara, C.; Law, D.W.; Houshyar, S.; Setunge, S.; Cwirzen, A. A critical review on drying shrinkage mitigation strategies in cement-based materials. J. Build. Eng. 2021, 38, 102210. [Google Scholar] [CrossRef]

- Ding, X.H.; Luo, B.; Zhou, H.T.; Chen, Y.H. Generalized Solutions for Advection–Dispersion Transport Equations Subject to Time- and Space-Dependent Internal and Boundary Sources. Comput. Geotechnics. 2025, 178, 106944. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Baweja, S. Creep and shrinkage prediction model for analysis and design of concrete structures: Model B3. Mater. Struct. 1995, 28, 357–365. [Google Scholar]

- Bažant, Z.P.; Hubler, M.H.; Wendner, R. Model B4 for creep, drying shrinkage and autogenous shrinkage of normal and high-strength concretes with multi-decade applicability. Mater. Struct. 2015, 48, 753–770. [Google Scholar] [CrossRef]

- PN-EN 1992-1-1:2008; Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. Polish Committee for Standardization: Warsaw, Poland, 2008.

- EN 1992-1-1:2023; Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings, Bridges and Civil Engineering Structures. Polish Committee for Standardization: Warsaw, Poland, 2023.

- Zieliński, A.; Schindler, A.K.; Kaszyńska, M. Cracking risk of high-performance cement composites due to restrained autogenous shrinkage with and without soaked lightweight aggregate. Arch. Civ. Eng. 2023, LXIX, 603–618. [Google Scholar]

- Raczkiewicz, W.; Bacharz, M.; Bacharz, K.; Teodorczyk, M. Reinforcement Corrosion Testing in Concrete and Fiber Reinforced Concrete Specimens Exposed to Aggressive External Factors. Materials 2023, 16, 1174. [Google Scholar] [CrossRef]

- Michałowska-Maziejuk, D.; Goszczyńska, B.; Trąmpczyński, W. Accelerated method of reinforced concrete component strenghtening with carbon fiber strips. In Proceedings of the IABSE Conference—Creativity and Collaboration, Bath, UK, 19–20 April 2017. [Google Scholar]

- Federowicz, K.; Kaszyńska, M.; Zieliński, A.; Hoffmann, M. Effect of Curing Methods on Shrinkage Development in 3D-Printed Concrete. Materials 2020, 13, 2590. [Google Scholar] [CrossRef]

- PN EN 1992-1-1:2024; Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings, Bridges and Civil Engineering Structures. Polish Committee for Standardization: Warsaw, Poland, 2024.

- Flaga, K. The influence of concrete shrinkage on durability of reinforced structural members. Bull. Pol. Acad. Sci. 2025, 63, 15–22. [Google Scholar] [CrossRef]

- Flaga, K. Concrete Shrinkage and Its Influence on the Capacity, Serviceability of RC and Prestressed Structures; Monograph No. 73; Cracow University of Technology: Cracow, Poland, 2002; pp. 1–67. (In Polish) [Google Scholar]

- Holt, E. Contribution of mixture design to chemical and autogenous shrinkage of concrete at early ages. Cem. Concr. Res. 2005, 35, 464–472. [Google Scholar] [CrossRef]

- Bischoff, P.H. Effects of shrinkage on tension stiffening and cracking in reinforced concrete. Can. J. Civ. Eng. 2001, 28, 363–374. [Google Scholar] [CrossRef]

- Kossakowski, P.; Ślusarczyk, J. A case study of pre-service cracks in the concrete decks of a two-level basement car park. Arch. Civ. Eng. 2017, 63, 79–97. [Google Scholar] [CrossRef]

- Godycki-Ćwirko, T.; Korzeniowski, P.; Piotrkowski, P. Emergency Cracking of Tank Walls Caused by Shrinkage. Inżynier Budownictwa 2009, 10, 67–71. (In Polish) [Google Scholar]

- Kovler, K.; Zhutovsky, S. Overview and future trends of shrinkage research. Mater. Struct. 2006, 39, 827–847. [Google Scholar] [CrossRef]

- Emborg, M. Thermal Stresses in Concrete Structures at Early Ages. Ph.D. Dissertation, Luleå University of Technology, Luleå, Sweden, 1989. [Google Scholar]

- Issa, M.A. Investigation of cracking in concrete bridge decks at early ages. J. Bridge Eng. 1999, 4, 116–124. [Google Scholar] [CrossRef]

- Tworzewski, P.; Goszczyńska, B. An Application of an Optical Measuring System to Reinforced Concrete Beams Analysis. In Proceedings of the 2016 Prognostics and System Health Management Conference (PHM-Chengdu), Chengdu, China, 19–21 October 2016. [Google Scholar]

- Taffese, W.Z.; Hilloulin, B.; Villagran Zaccardi, Y.; De Schutter, G. Machine Learning in Concrete Durability: Challenges and Pathways Identified by RILEM TC 315-DCS towards Enhanced Predictive Models. Mater. Struct. 2025, 58, 145. [Google Scholar] [CrossRef]

- Mazni, M.; Husain, A.R.; Shapiai, M.I.; Ibrahim, I.S.; Zulkifli, R.; Anggara, D.W. Identification of Concrete Cracks Using Deep Learning Models: A Systematic Review. Appl. Model. Simul. 2024, 8, 1–25. [Google Scholar]

- Niu, Y.; Wang, W.; Su, Y.; Jia, F.; Long, X. Plastic damage prediction of concrete under compression based on deep learning. Acta Mech. 2024, 235, 255–266. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, J.; Zhang, Y.; Liu, J.; Wang, Y. Plastic Damage Prediction of Concrete under Compression Based on Deep Learning. Materials 2023, 16, 1374. [Google Scholar] [CrossRef]

- Inderyas, O.; Tayfur, S.; Arslan, T.; Alver, N. Deep learning-based damage estimation in concrete structures using acoustic emission data. In Proceedings of the NDT-CE 2022—The International Symposium on Nondestructive Testing in Civil Engineering, Zurich, Switzerland, 16–18 August 2022. [Google Scholar]

- Ohtsu, M.; Watanabe, H. Quantitative Damage Estimation of Concrete by Acoustic Emission. Constr. Build. Mater. 2001, 15, 217–224. [Google Scholar] [CrossRef]

- Grosse, C.U.; Ohtsu, M.; Aggelis, D.G.; Shiotani, T. (Eds.) Acoustic Emission Testing: Basics for Research—Applications in Engineering, 2nd ed.; Springer Nature: Cham, Switzerland, 2021; pp. 1–763. [Google Scholar]

- Hoła, J.; Schabowicz, K. State-of-the-art non-destructive methods for diagnostics testing of building structures—Anticipated development trends. Arch. Civ. Mech. Eng. 2010, 10, 5–18. [Google Scholar] [CrossRef]

- Schabowicz, K. Testing of Materials and Elements in Civil Engineering. Materials 2021, 14, 3412. [Google Scholar] [CrossRef] [PubMed]

- Goszczyńska, B.; Świt, G.; Trąmpczyński, W.; Krampikowska, A.; Tworzewska, J.; Tworzewski, P. Experimental validation of concrete crack identification and location with the acoustic emission method. Arch. Civ. Mech. Eng. 2012, 12, 23–28. [Google Scholar] [CrossRef]

- Goszczyńska, B. Analysis of the process of crack initiation and evolution in concrete with acoustic emission testing. Arch. Civ. Mech. Eng. 2014, 14, 134–143. [Google Scholar] [CrossRef]

- Bacharz, M.; Trąmpczyński, W. Identification of Active Destructive Processes in Unloaded Early-Age Concrete with the Use of the Acoustic Emission Method. In Proceedings of the 2016 Prognostics and System Health Management Conference (PHM-Chengdu), Chengdu, China, 19–21 October 2016. [Google Scholar]

- Bacharz, M.; Bacharz, K.; Trąmpczyński, W. The Correlation between Shrinkage and Acoustic Emission Signals in Early Age Concrete. Materials 2022, 15, 5389. [Google Scholar] [CrossRef]

- National Declaration of Cement CEMIII/A 42,5N—LH/HSR/NA Górażdże Performance. Available online: https://www.heidelbergmaterials.pl/pl/cement-hutniczy-pn-b-19808-cem-iii-a-425n-hsr-na (accessed on 7 April 2025).

- National Declaration of Basalt Aggregate “Bazalt-Gracze” Sp. z o.o. Gracze Performance. Available online: https://bazalt-gracze.pl/images/ce_12620_2_8.pdf (accessed on 7 April 2025).

- National Declaration of Basalt Aggregate “Bazalt-Gracze” Sp. z o.o. Gracze Performance. Available online: https://bazalt-gracze.pl/images/ce_12620_8_16.pdf (accessed on 7 April 2025).

- Bacharz, M. Application of the Acoustic Emission Method to the Evaluation of Destructive Processes in Unloaded Concrete. Ph.D. Dissertation, Kielce University of Technology, Kielce, Poland, 27 June 2016. [Google Scholar]

- Topolář, L.; Kocáb, D.; Pazdera, L.; Vymazal, T. Analysis of Acoustic Emission Signals Recorded during Freeze–Thaw Cycling of Concrete. Materials 2021, 14, 1230. [Google Scholar] [CrossRef]

| Performance Properties | Values |

|---|---|

| Components: | |

| 35 ÷ 50% |

| 50 ÷ 65% |

| 0 ÷ 5% |

| Compressive strength: | |

| 42.5 N |

| Above or equal to 10 MPa |

| Between 42.5 MPa and 62.5 MPa |

| Bonding time | Above or equal to 60 min (beginning) |

| Undissolved residue | Below or equal to 5.0% |

| Loss of roasting | Below or equal to 5.0% |

| Stability of volume: | |

| Below or equal to 10 mm |

| Below or equal to 4.0% |

| Chloride content | Below or equal to 0.10% |

| Total alkali content | Below or equal to 1.10% |

| Heat of hydration | Below or equal to 270 J/g |

| Parameter | Basalt Aggregate 2/8 [54] | Basalt Aggregate 8/16 [55] |

|---|---|---|

| Specific gravity [Mg/m3] | 3.18 | 3.17 |

| Water absorption [%] | 0.9 | 0.7 |

| Dust content [%] | 1.5 | 1.5 |

| Frost resistance in the presence of salt [%] | 1 | 1 |

| Resistance to crushing | LA15 | LA15 |

| Resistance to abrasion | MDE10 | MDE20 |

| Resistance to polishing | PSV50 | PSV50 |

| Resistance to surface abrasion | AAV10 | AAV10 |

| Frost resistance | F1 | F1 |

| Reactivity of alkaline | Non-reactive | Non-reactive |

| Symbol | Density g/dm3 | Cone Drop Test [cm] | Air Content [%] | Consistency |

|---|---|---|---|---|

| C1 | 2523 | 2.8 | 1.7 | plastic |

| C2 | 2509 | 2.0 | 1.8 | plastic |

| C3 | 2517 | 1.5 | 1.2 | plastic |

| Concrete Series | Class 1 | Class 2 | Class 3 |

|---|---|---|---|

| C3 | 0.28 | 21.01 | 124.91 |

| Concrete Series | Conditions | α | β | η | γ |

|---|---|---|---|---|---|

| C1 | Cured, temp. = constant | 33,280 | 11,775 | 1.00 | 1.00 |

| C2 | Without cure, temp. = constant | 1.65 | |||

| C3 | Without cure, temp. = cyclic | 0.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bacharz, M.; Bacharz, K.; Trąmpczyński, W. Impact of Early-Age Curing and Environmental Conditions on Shrinkage and Microcracking in Concrete. Materials 2025, 18, 3185. https://doi.org/10.3390/ma18133185

Bacharz M, Bacharz K, Trąmpczyński W. Impact of Early-Age Curing and Environmental Conditions on Shrinkage and Microcracking in Concrete. Materials. 2025; 18(13):3185. https://doi.org/10.3390/ma18133185

Chicago/Turabian StyleBacharz, Magdalena, Kamil Bacharz, and Wiesław Trąmpczyński. 2025. "Impact of Early-Age Curing and Environmental Conditions on Shrinkage and Microcracking in Concrete" Materials 18, no. 13: 3185. https://doi.org/10.3390/ma18133185

APA StyleBacharz, M., Bacharz, K., & Trąmpczyński, W. (2025). Impact of Early-Age Curing and Environmental Conditions on Shrinkage and Microcracking in Concrete. Materials, 18(13), 3185. https://doi.org/10.3390/ma18133185