Full-Factorial Rheological Investigation of Carbopol ETD2020 for Embedded Printing: Effects of pH and Carbomer Concentration

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Rheological Measurements

3. Results and Discussion

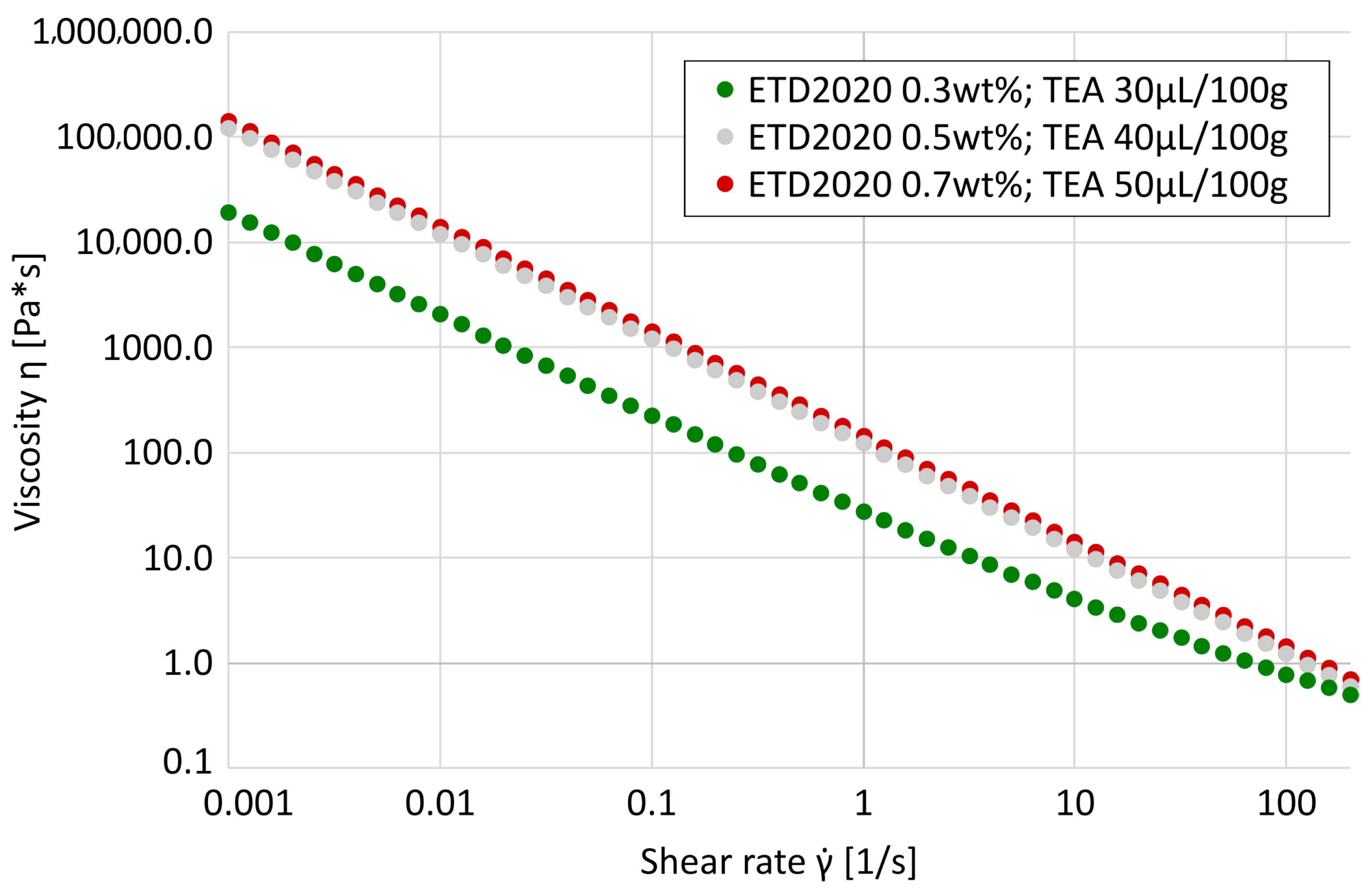

3.1. Viscosity Behavior

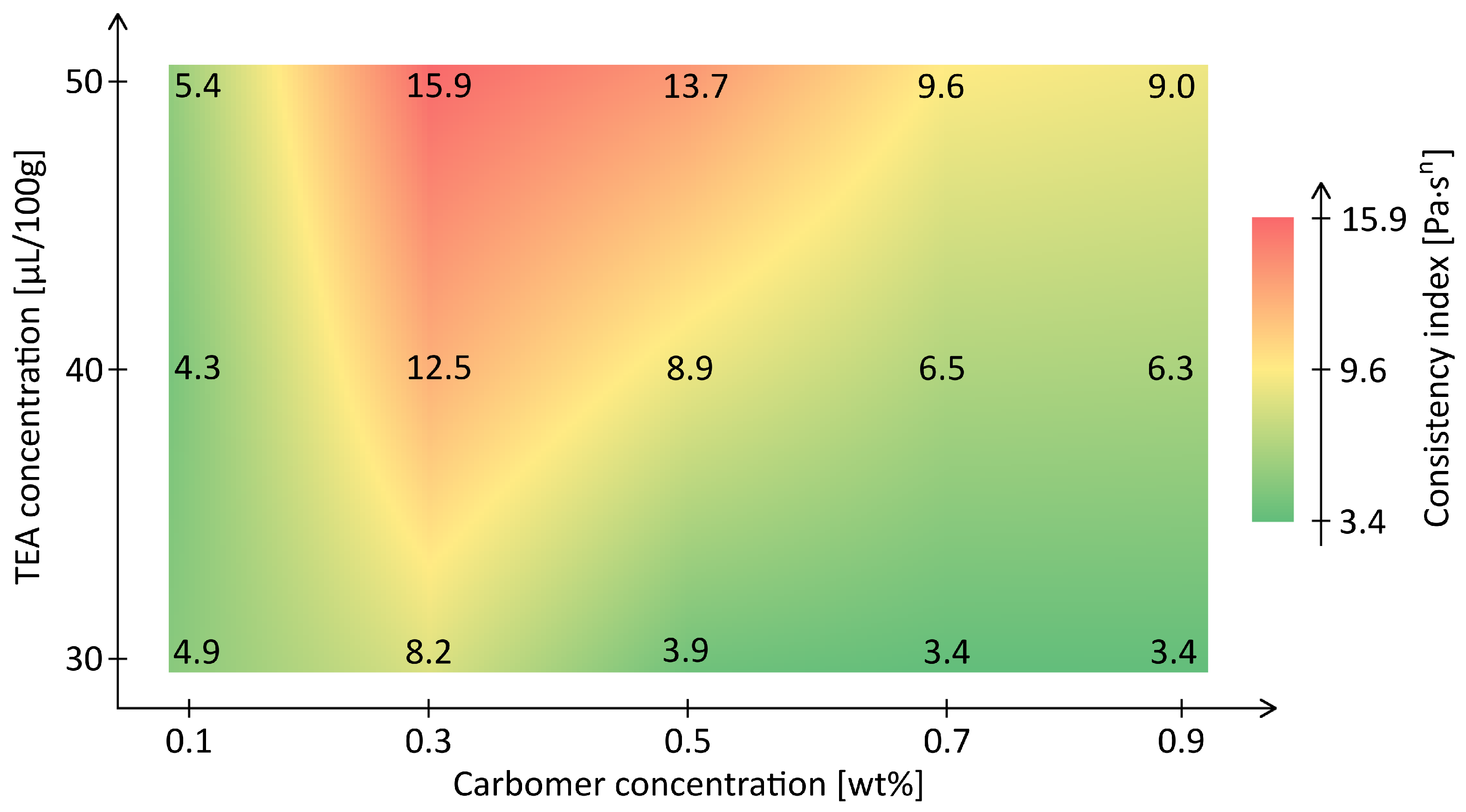

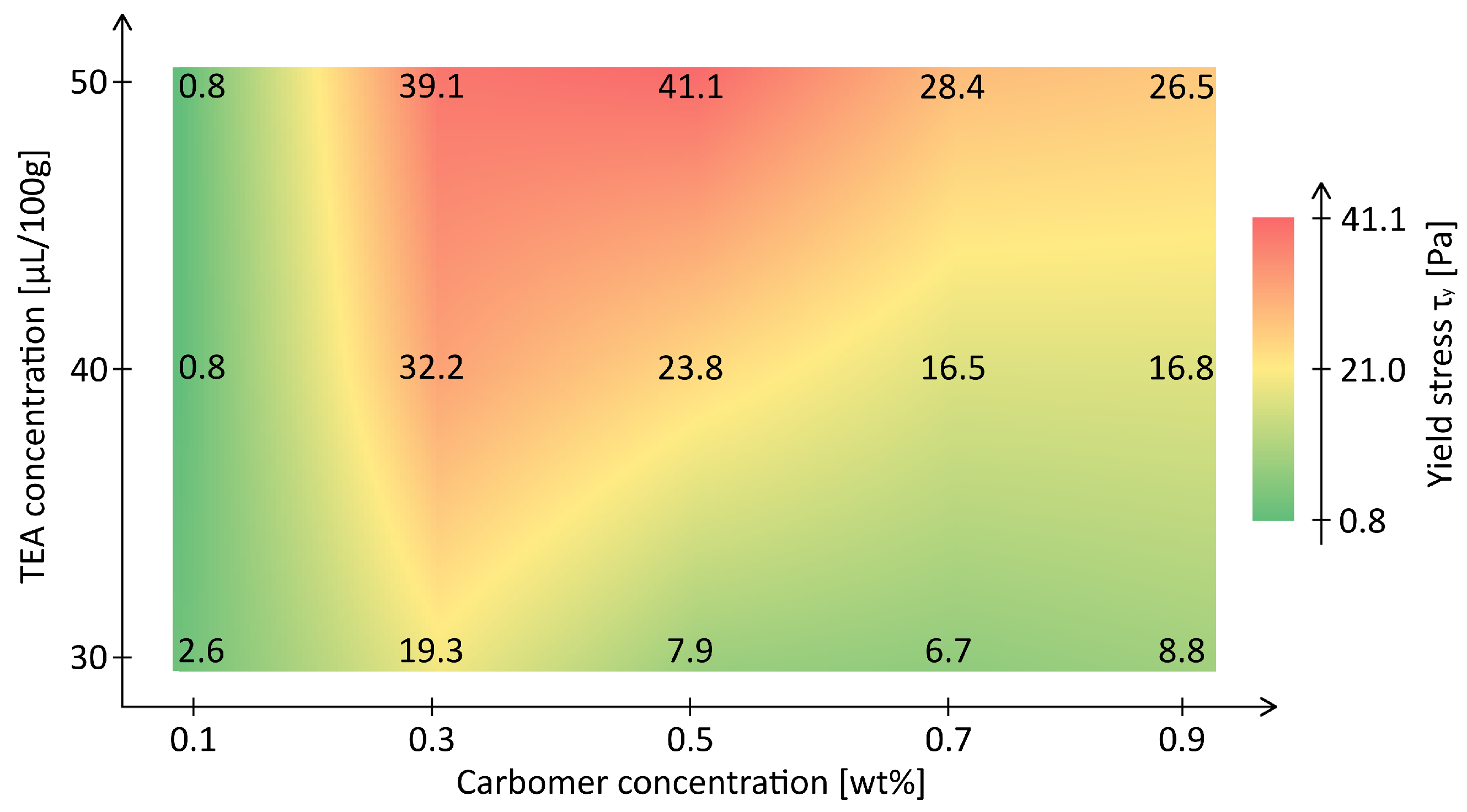

3.2. Herschel–Bulkley Model Parameters and Fit Quality

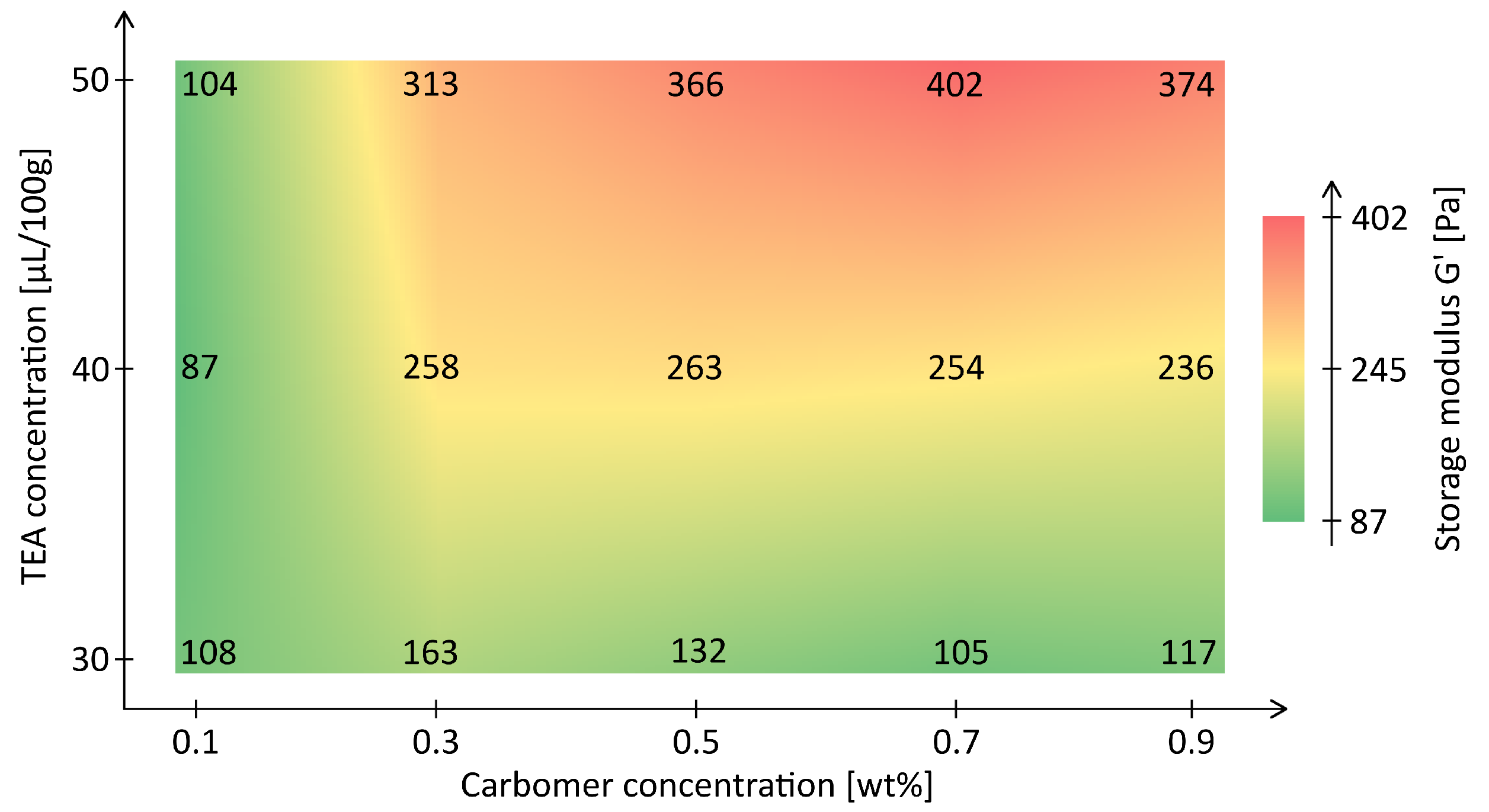

3.3. Storage and Loss Moduli

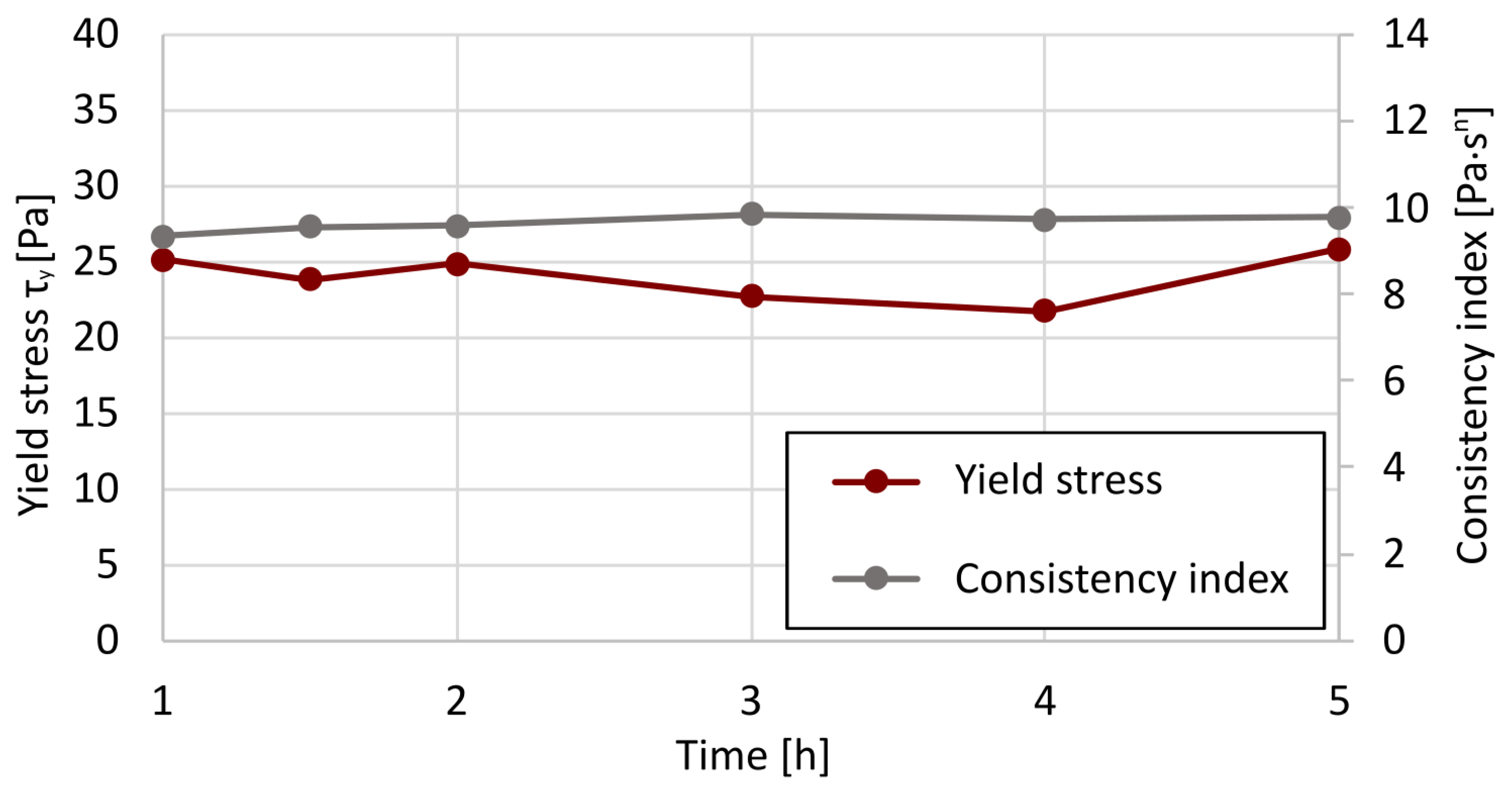

3.4. Time Dependency of Rheological Properties

4. Conclusions

4.1. General Trends and Model Accuracy

4.2. Design Window and Suitability for Printing

4.3. Network Formation and Elasticity

4.4. Limitations and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Heatmaps: Consistency and Flow Index

References

- Calais, T.; Castillo Ugalde, A.; Chooi An Rong, A.; Valdivia y Alvarado, P. Freeform liquid 3D printing of hydraulically enhanced dielectric actuators. Mater. Today Proc. 2022, 70, 83–89. [Google Scholar] [CrossRef]

- Gangwar, S.; Saxena, P.; Susana Garcia Morales, D.; Biermann, T.; Lachmayer, R. Quality analysis of material jetted silicone material for soft robotics application. Mater. Lett. 2024, 355, 135566. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, B.; Cui, W.; Zhou, N. Freeform Fabrication of Pneumatic Soft Robots via Multi–Material Jointed Direct Ink Writing. Macromol. Mater. Eng. 2022, 307, 2100813. [Google Scholar] [CrossRef]

- Romero, R.G.T.; Colton, M.B.; Thomson, S.L. 3D-Printed Synthetic Vocal Fold Models. J. Voice Off. J. Voice Found. 2021, 35, 685–694. [Google Scholar] [CrossRef] [PubMed]

- Tejo-Otero, A.; Colly, A.; Courtial, E.J.; Fenollosa-Artés, F.; Buj-Corral, I.; Marquette, C.A. Soft-tissue-mimicking using silicones for the manufacturing of soft phantoms by fresh 3D printing. Rapid Prototyp. J. 2022, 28, 285–296. [Google Scholar] [CrossRef]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Mengüç, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D printing of strain sensors within highly stretchable elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef]

- Hinton, T.J.; Hudson, A.; Pusch, K.; Lee, A.; Feinberg, A.W. 3D Printing PDMS Elastomer in a Hydrophilic Support Bath via Freeform Reversible Embedding. ACS Biomater. Sci. Eng. 2016, 2, 1781–1786. [Google Scholar] [CrossRef]

- Karyappa, R.; Hashimoto, M. Freeform Polymer Precipitation in Microparticulate Gels. ACS Appl. Polym. Mater. 2021, 3, 908–919. [Google Scholar] [CrossRef]

- Biermann, T.; Ziebehl, A.; Grabe, T.; Röttger, J.; Ley, P.P.; Wolf, A.; Lachmayer, R. Magnetically actuated solid body PDMS lens. In Proceedings of the Optical Components and Materials XVIII, Online, 6–12 March 2021; Digonnet, M.J., Jiang, S., Eds.; SPIE: Bellingham, WA, USA, 2021; p. 30. [Google Scholar] [CrossRef]

- Karyappa, R.; Zhang, D.; Zhu, Q.; Ji, R.; Suwardi, A.; Liu, H. Newtonian liquid-assisted material extrusion 3D printing: Progress, challenges and future perspectives. Addit. Manuf. 2024, 79, 103903. [Google Scholar] [CrossRef]

- Wu, W.; DeConinck, A.; Lewis, J.A. Omnidirectional printing of 3D microvascular networks. Adv. Mater. 2011, 23, H178–H183. [Google Scholar] [CrossRef]

- O’Bryan, C.S.; Bhattacharjee, T.; Marshall, S.L.; Gregory Sawyer, W.; Angelini, T.E. Commercially available microgels for 3D bioprinting. Bioprinting 2018, 11, e00037. [Google Scholar] [CrossRef]

- Chen, S.; Tan, W.S.; Bin Juhari, M.A.; Shi, Q.; Cheng, X.S.; Chan, W.L.; Song, J. Freeform 3D printing of soft matters: Recent advances in technology for biomedical engineering. Biomed. Eng. Lett. 2020, 10, 453–479. [Google Scholar] [CrossRef] [PubMed]

- Grosskopf, A.K.; Truby, R.L.; Kim, H.; Perazzo, A.; Lewis, J.A.; Stone, H.A. Viscoplastic Matrix Materials for Embedded 3D Printing. ACS Appl. Mater. Interfaces 2018, 10, 23353–23361. [Google Scholar] [CrossRef]

- Bhattacharjee, T.; Zehnder, S.M.; Rowe, K.G.; Jain, S.; Nixon, R.M.; Sawyer, W.G.; Angelini, T.E. Writing in the granular gel medium. Sci. Adv. 2015, 1, e1500655. [Google Scholar] [CrossRef] [PubMed]

- O’Bryan, C.S.; Bhattacharjee, T.; Niemi, S.R.; Balachandar, S.; Baldwin, N.; Ellison, S.T.; Taylor, C.R.; Sawyer, W.G.; Angelini, T.E. Three-dimensional printing with sacrificial materials for soft matter manufacturing. MRS Bull. 2017, 42, 571–577. [Google Scholar] [CrossRef]

- Teves, S.; Biermann, T.; Ziebehl, A.; Eckert, J.G.; Hill, O.; Xia, P.; Wollweber, M.; Ripken, T.; Bigall, N.C.; Lachmayer, R. Active-mixing printhead for on-the-fly composition adjustment of multi component materials in Direct Ink Writing. Addit. Manuf. Lett. 2024, 10, 100217. [Google Scholar] [CrossRef]

- Friedrich, L.M.; Seppala, J.E. Simulated filament shapes in embedded 3D printing. Soft Matter 2021, 17, 8027–8046. [Google Scholar] [CrossRef]

- Dinkgreve, M.; Denn, M.M.; Bonn, D. “Everything flows?”: Elastic effects on startup flows of yield-stress fluids. Rheol. Acta 2017, 56, 189–194. [Google Scholar] [CrossRef]

- Abdollahi, S.; Davis, A.; Miller, J.H.; Feinberg, A.W. Expert-guided optimization for 3D printing of soft and liquid materials. PLoS ONE 2018, 13, e0194890. [Google Scholar] [CrossRef]

- Mohammadigoushki, H.; Shoele, K. Cavitation Rheology of Model Yield Stress Fluids Based on Carbopol. Langmuir ACS J. Surfaces Colloids 2023, 39, 7672–7683. [Google Scholar] [CrossRef]

- Varges, P.R.; Costa, C.M.; Fonseca, B.S.; Naccache, M.F.; de Souza Mendes, P. Rheological Characterization of Carbopol® Dispersions in Water and in Water/Glycerol Solutions. Fluids 2019, 4, 3. [Google Scholar] [CrossRef]

- Contreras, M.D.; Sánchez, R. Application of a factorial design to the study of specific parameters of a Carbopol ETD 2020 gel. Part I. Viscoelastic parameters. Int. J. Pharm. 2002, 234, 139–147. [Google Scholar] [CrossRef] [PubMed]

- Kelessidis, V.C.; Hatzistamou, V. Preparation Methodology and Rheological Properties of Yield Pseudoplastic Transparent Fluids. J. Dispers. Sci. Technol. 2011, 32, 380–388. [Google Scholar] [CrossRef]

- Jørgensen, L.; Le Merrer, M.; Delanoë-Ayari, H.; Barentin, C. Yield stress and elasticity influence on surface tension measurements. Soft Matter 2015, 11, 5111–5121. [Google Scholar] [CrossRef] [PubMed]

- Shafiei, M.; Bryant, S.; Balhoff, M.; Huh, C.; Bonnecaze, R.T. Hydrogel Formulation for Sealing Cracked Wellbores for CO2 Storage. Appl. Rheol. 2017, 27, 64433. [Google Scholar] [CrossRef]

- Contreras, M.D.; Sanchez, R. Application of a factorial design to the study of the flow behavior, spreadability and transparency of a Carbopol ETD 2020 gel. Part II. Int. J. Pharm. 2002, 234, 149–157. [Google Scholar] [CrossRef]

- Hu, R.; Wang, A.; Hartnett, J.P. Surface tension measurement of aqueous polymer solutions. Exp. Therm. Fluid Sci. 1991, 4, 723–729. [Google Scholar] [CrossRef]

- Jaworski, Z.; Spychaj, T.; Story, A.; Story, G. Carbomer microgels as model yield-stress fluids. Rev. Chem. Eng. 2022, 38, 881–919. [Google Scholar] [CrossRef]

- Arratia, P.E.; Kukura, J.; Lacombe, J.; Muzzio, F.J. Mixing of shear–thinning fluids with yield stress in stirred tanks. AIChE J. 2006, 52, 2310–2322. [Google Scholar] [CrossRef]

- Biermann, T.; Mesecke, L. Rheology Data of Lubrizol Carbopol ETD2020. LUIS 2024. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biermann, T.; Mesecke, L.; Teves, S.; Ziesche, I.; Lachmayer, R. Full-Factorial Rheological Investigation of Carbopol ETD2020 for Embedded Printing: Effects of pH and Carbomer Concentration. Materials 2025, 18, 3164. https://doi.org/10.3390/ma18133164

Biermann T, Mesecke L, Teves S, Ziesche I, Lachmayer R. Full-Factorial Rheological Investigation of Carbopol ETD2020 for Embedded Printing: Effects of pH and Carbomer Concentration. Materials. 2025; 18(13):3164. https://doi.org/10.3390/ma18133164

Chicago/Turabian StyleBiermann, Tobias, Lennart Mesecke, Simon Teves, Ivo Ziesche, and Roland Lachmayer. 2025. "Full-Factorial Rheological Investigation of Carbopol ETD2020 for Embedded Printing: Effects of pH and Carbomer Concentration" Materials 18, no. 13: 3164. https://doi.org/10.3390/ma18133164

APA StyleBiermann, T., Mesecke, L., Teves, S., Ziesche, I., & Lachmayer, R. (2025). Full-Factorial Rheological Investigation of Carbopol ETD2020 for Embedded Printing: Effects of pH and Carbomer Concentration. Materials, 18(13), 3164. https://doi.org/10.3390/ma18133164