Enhancing the Mechanical Performance of Dual-Phase Steel Through Multi-Axis Compression and Inter-Critical Annealing

Abstract

1. Introduction

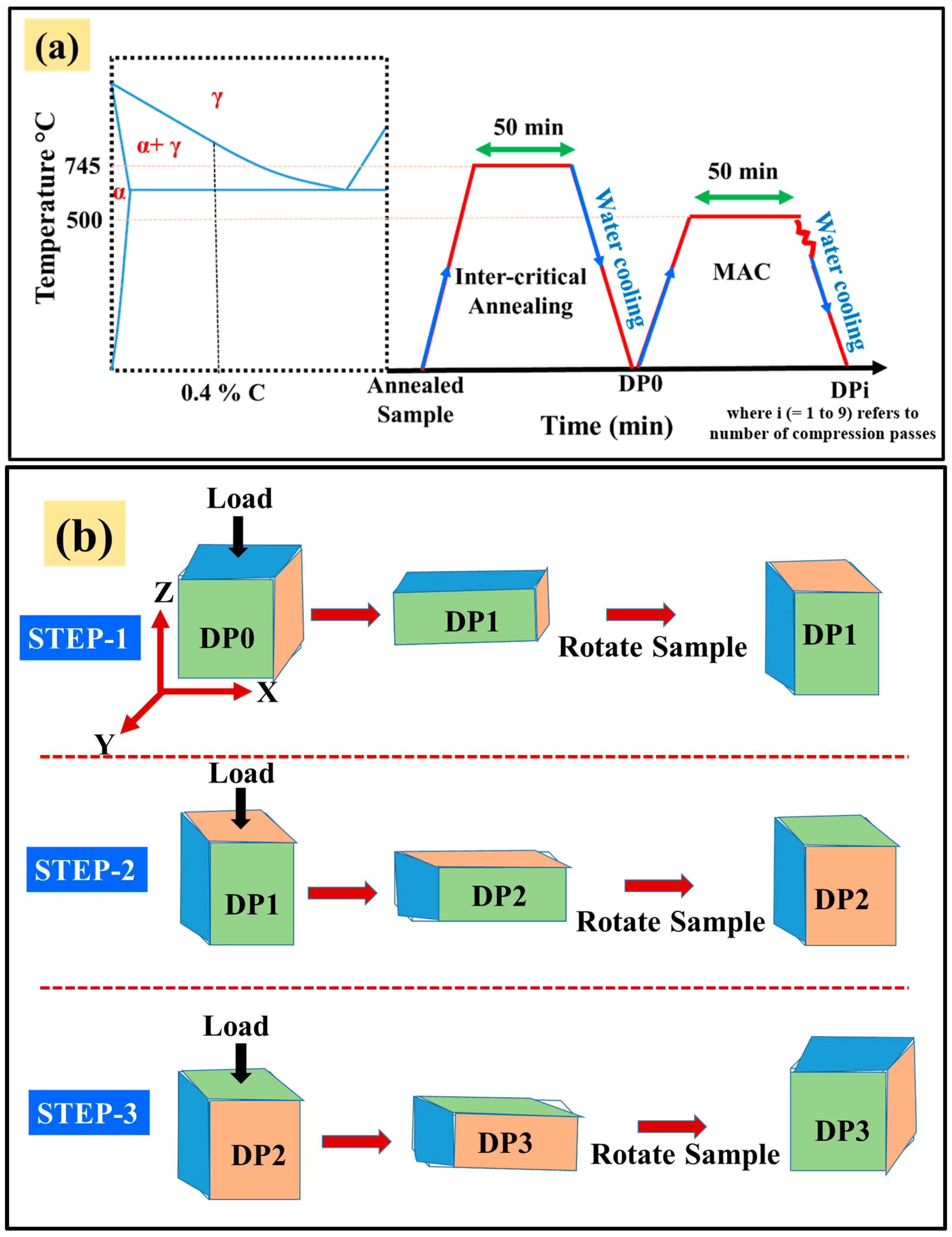

2. Materials and Methods

3. Results and Discussions

3.1. Microstructural Evolution

3.2. Mechanical Properties

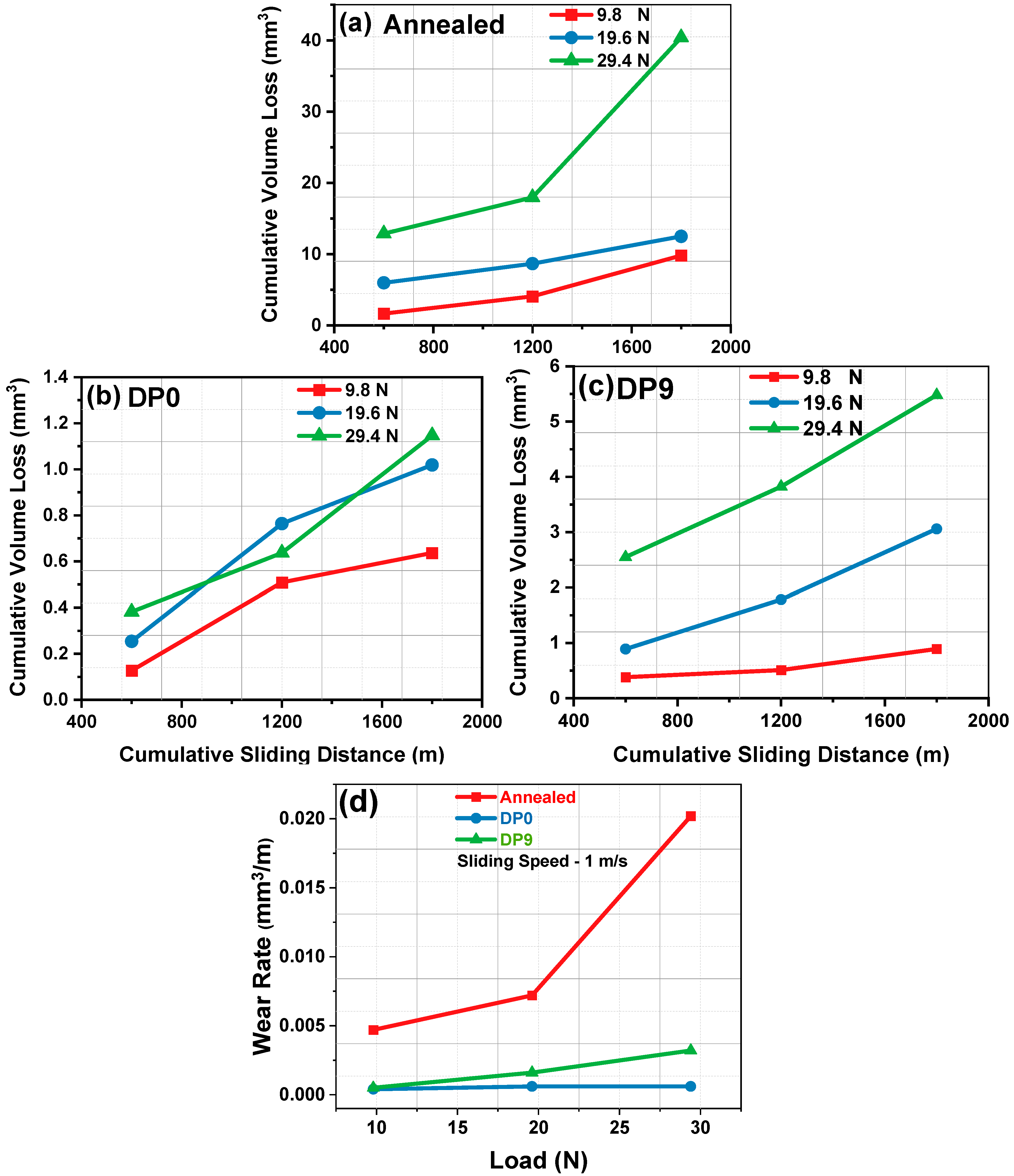

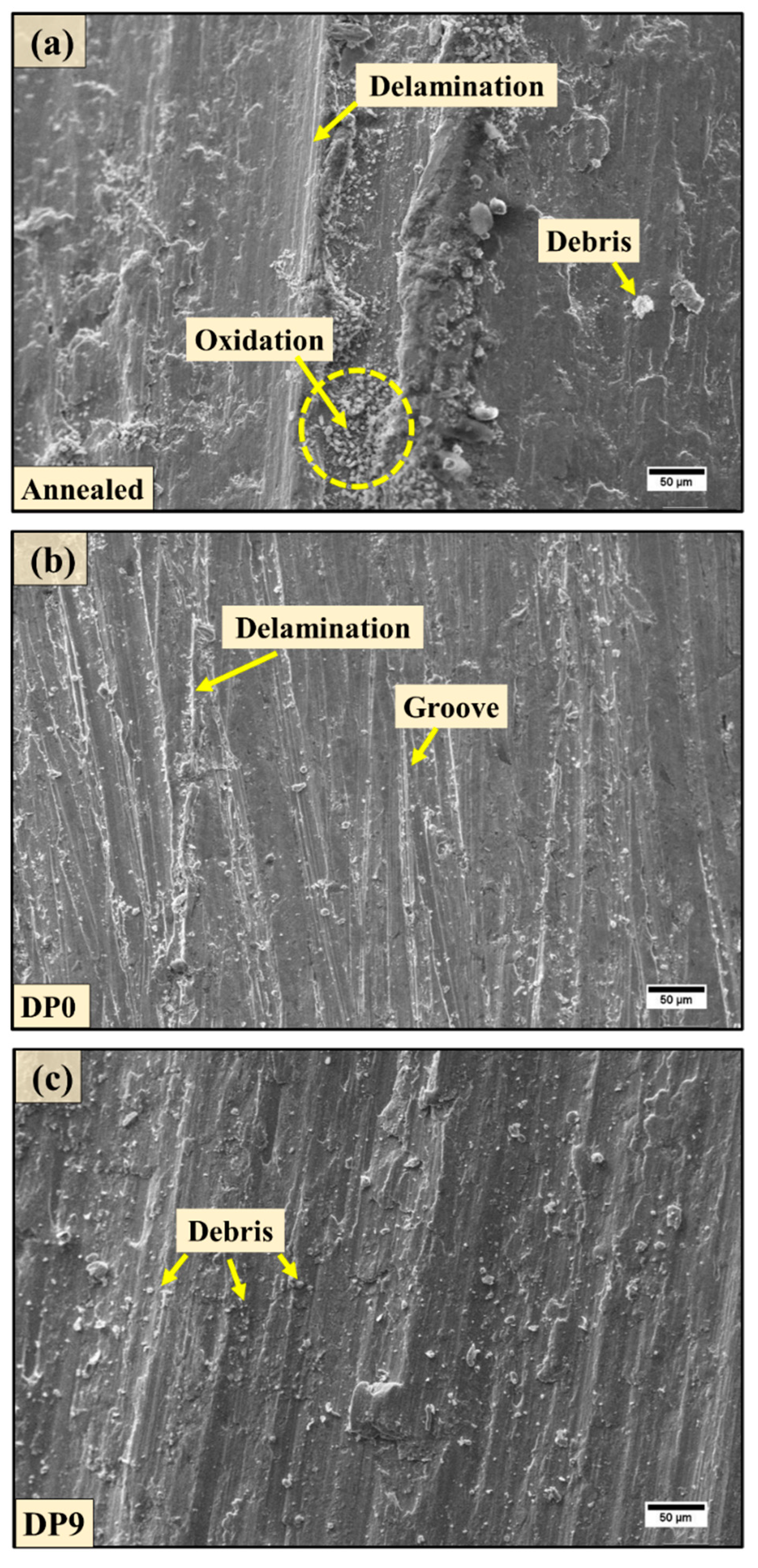

3.3. Wear Behavior and Mechanism

4. Conclusions

- 1.

- The microstructural analysis confirmed progressive grain refinement due to the imposed strain during MAC. The formation of fine substructures in ferrite was observed after six MAC passes (DP6), which further evolved into well-defined fine grains by DP9.

- 2.

- The average grain size was reduced from 66 ± 4 μm in the annealed condition to approximately 18 ± 1 μm in the DP9 sample, attributed to the cumulative strain introduced during MAC.

- 3.

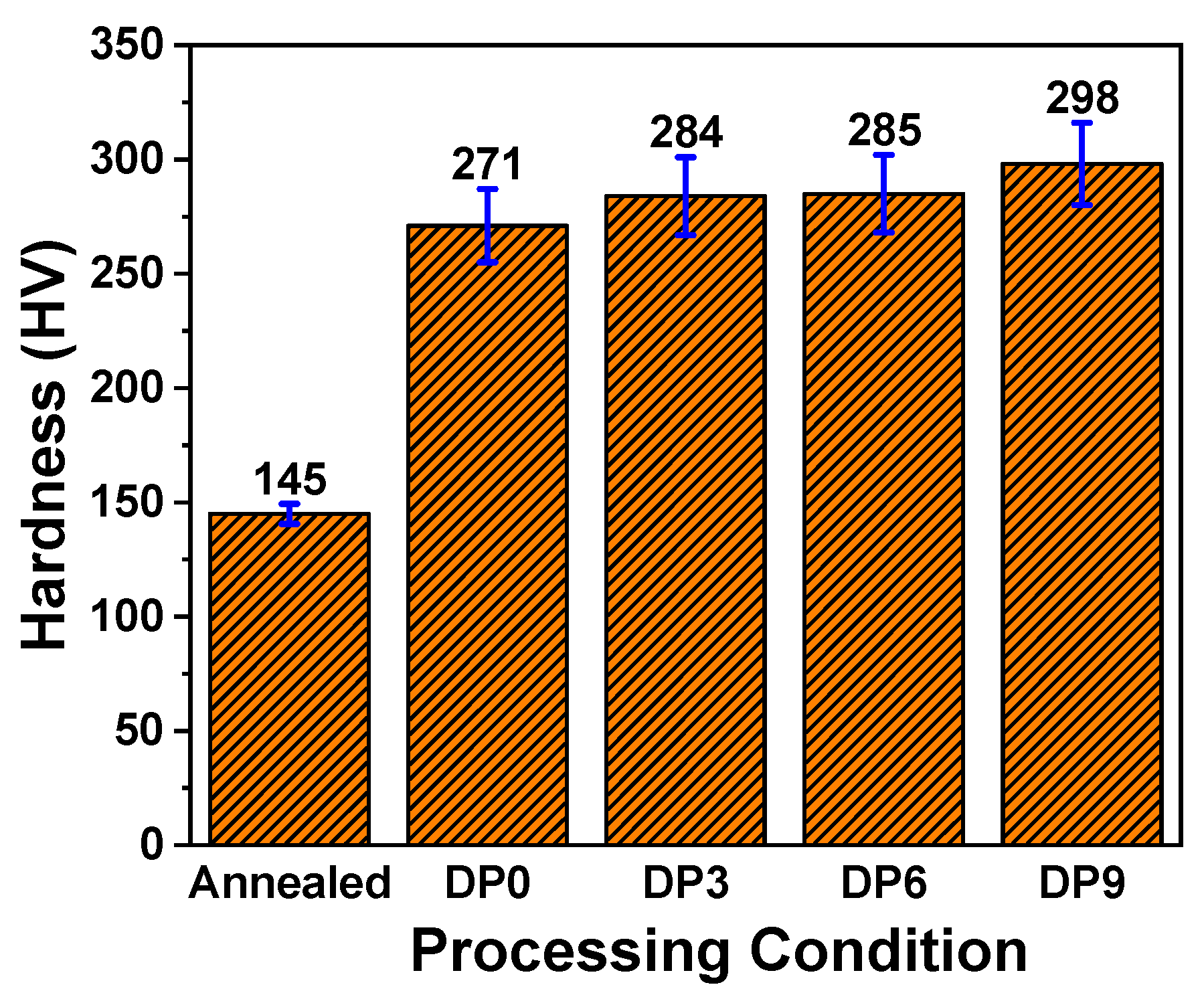

- The hardness of the DP9 sample increased by approximately 87% compared to the annealed sample and 10% compared to the DP0 sample. This improvement is primarily due to strain hardening and grain refinement governed by the Hall–Petch relationship.

- 4.

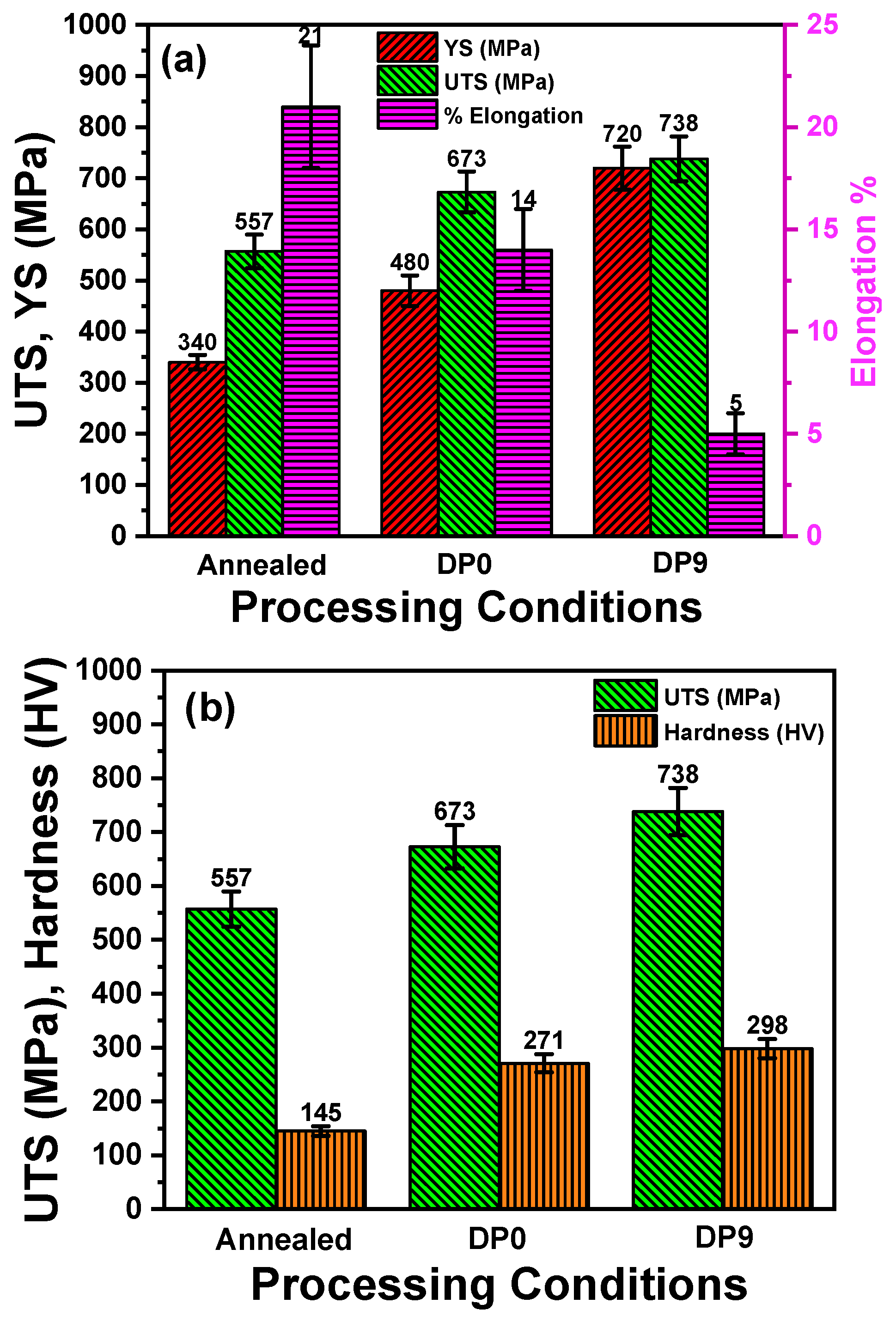

- In comparison to the annealed sample, the ultimate tensile strength of the DP0 and DP9 samples improved from 557 MPa to 673 MPa (by 20%) and 738 MPa (by 32%), respectively, while the yield strength of the same samples enhanced from 340 MPa to 480 MPa (by 41%) and 720 MPa (by 112%), respectively. This enhancement is due to the accumulation of dislocations during MAC, which impede dislocation motion and strengthen the material.

- 5.

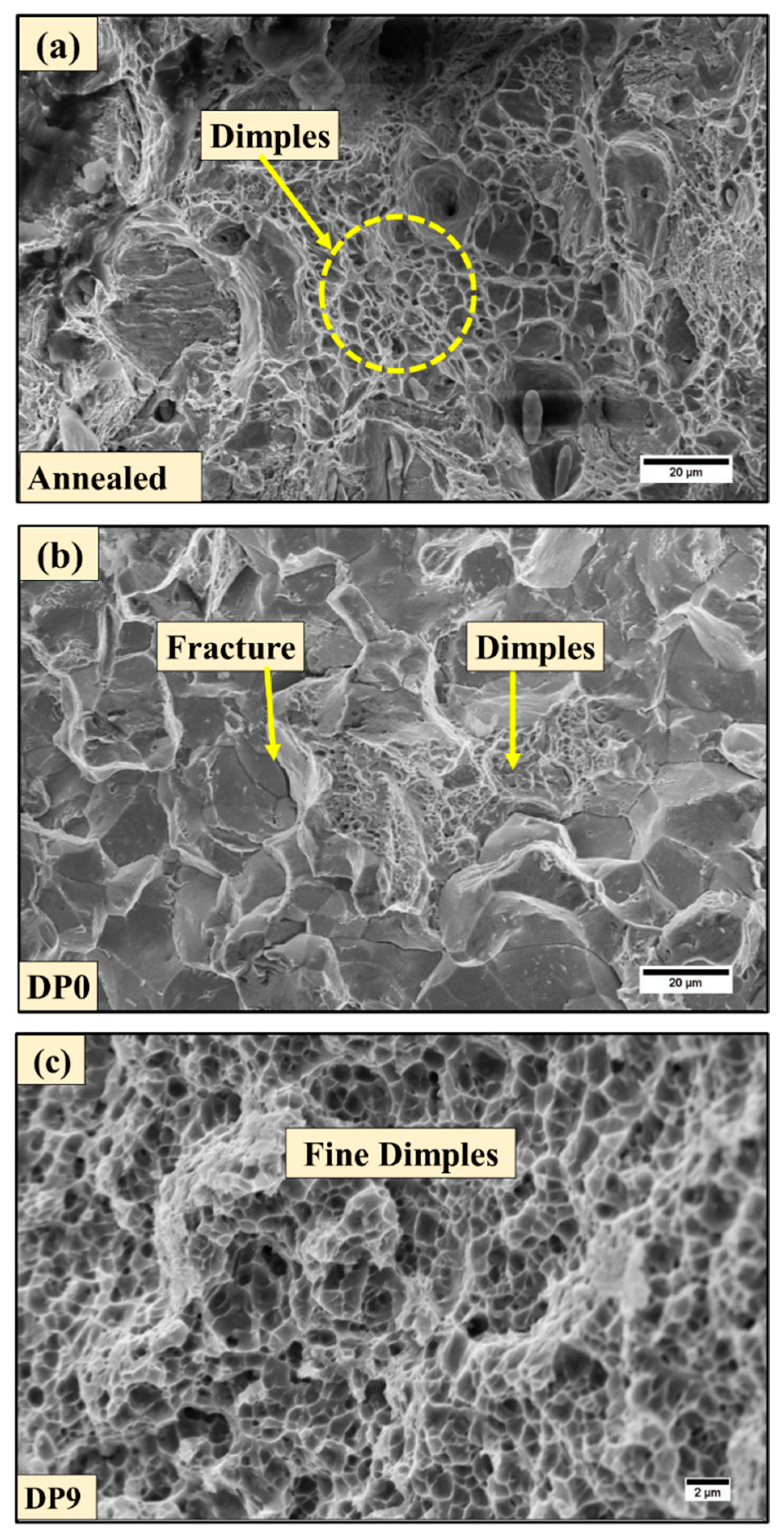

- Fractographic analysis revealed a ductile failure mode in the annealed sample, while DP0 and DP9 exhibited a mixed fracture mode. In DP9, the presence of finer dimples indicates increased strength and reduced ductility because of microstructural refinement.

- 6.

- Both DP0 and DP9 samples demonstrated superior wear resistance compared to the annealed sample. However, the DP9 sample exhibited slightly lower wear resistance than DP0, likely due to the fragmentation of martensite induced by high accumulated strain, which could act as crack initiation sites during sliding wear.

- 7.

- The annealed sample displayed significant wear debris, deep scars, and delamination features due to its poor wear resistance. In contrast, the DP samples, particularly DP0, exhibited smoother worn surfaces with reduced debris, highlighting the beneficial effects of martensite formation and grain refinement on wear resistance.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pereira, R.; Peixinho, N.; Costa, S.L. A Review of Sheet Metal Forming Evaluation of Advanced High-Strength Steels (AHSS). Metals 2024, 14, 394. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, H.; Shen, G.; Peng, Y.; Wu, L.; Wu, Y.; Mao, J.; Shi, B. Effect of compressive load on texture evolution and anisotropic behavior of dual-phase steel under biaxial loading in complete σ11-σ22 space. J. Mater. Res. Technol. 2023, 27, 5140–5153. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Ayres, J.; Penney, D.; Evans, P.; Underhill, R. Effect of intercritical annealing on the mechanical properties of dual-phase steel. Ironmak. Steelmak. 2022, 49, 821–827. [Google Scholar] [CrossRef]

- Khan, M.S.; Soleimani, M.; Midawi, A.R.H.; Aderibigbe, I.; Zhou, Y.N.; Biro, E. A review on heat affected zone softening of dual-phase steels during laser welding. J. Manuf. Process. 2023, 102, 663–684. [Google Scholar] [CrossRef]

- Rana, A.K.; Paul, S.K.; Dey, P.P. Effect of martensite volume fraction on cyclic plastic deformation behavior of dual phase steel: Micromechanics simulation study. J. Mater. Res. Technol. 2019, 8, 3705–3712. [Google Scholar] [CrossRef]

- Najafi, Y.; Mazaheri, Y.; Ragheb, Z.D.; Daiy, H. Multi-stage strain-hardening behavior of dual-phase steels: A review. J. Mater. Res. Technol. 2024, 31, 3860–3882. [Google Scholar] [CrossRef]

- Kalhor, A.; Soleimani, M.; Mirzadeh, H.; Uthaisangsuk, V. A review of recent progress in mechanical and corrosion properties of dual phase steels. Arch. Civ. Mech. Eng. 2020, 20, 1–14. [Google Scholar] [CrossRef]

- Singh, A.K.; Bhattacharya, B.; Biswas, S. High strength, ductility and sheet formability by normalizing and quenching of low carbon microalloyed dual-phase steel. Mater. Sci. Eng. A 2024, 890, 145848. [Google Scholar] [CrossRef]

- Liu, L.; Maresca, F.; Vermeij, T.; Hoefnagels, J.P.M.; Geers, M.G.D.; Kouznetsova, V.G. An integrated experimental-numerical study of martensite/ferrite interface damage initiation in dual-phase steels. Scr. Mater. 2024, 239, 115798. [Google Scholar] [CrossRef]

- Edalati, K.; Ahmed, A.Q.; Akrami, S.; Ameyama, K.; Aptukov, V.; Asfandiyarov, R.N.; Ashida, M.; Astanin, V.; Bachmaier, A.; Beloshenko, V. Severe plastic deformation for producing Superfunctional ultrafine-grained and heterostructured materials: An interdisciplinary review. J. Alloys Compd. 2024, 1002, 174667. [Google Scholar]

- Mao, Q.; Li, Y.; Liu, Y.; Li, J.; Jiang, W.; Zhou, Z.; Zhao, Y.; Zhu, Y. A new severe plastic deformation technique of combined extrusion and torsion to prepare bulk ultrafine grained copper. J. Mater. Process. Technol. 2024, 333, 118600. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Straumal, B.; Langdon, T.G. Using severe plastic deformation to produce nanostructured materials with superior properties. Annu. Rev. Mater. Res. 2022, 52, 357–382. [Google Scholar] [CrossRef]

- Edalati, K.; Bachmaier, A.; Beloshenko, V.A.; Beygelzimer, Y.; Blank, V.D.; Botta, W.J.; Bryła, K.; Čížek, J.; Divinski, S.; Enikeev, N.A. Nanomaterials by severe plastic deformation: Review of historical developments and recent advances. Mater. Res. Lett. 2022, 10, 163–256. [Google Scholar] [CrossRef]

- Padap, A.K.; Chaudhari, G.P.; Pancholi, V.; Nath, S.K. Warm multiaxial forging of AISI 1016 steel. Mater. Des. 2010, 31, 3816–3824. [Google Scholar] [CrossRef]

- Agrawal, R.; Mukhopadhyay, A. The use of machine learning and metaheuristic algorithm for wear performance optimization of AISI 1040 steel and investigation of corrosion resistance. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 237, 701–717. [Google Scholar] [CrossRef]

- Kayali, Y.; Kenar, A. Effect of diffusion annealing on wear and cohesion behaviours of boronized AISI 1040 steel. Tribol. Int. 2023, 184, 108428. [Google Scholar] [CrossRef]

- Singh, S.S.; Awale, A.S.; Nahak, B. Assessment the Surface Characteristics of Heat-Treated AISI 1040 Steel Using Magnetic Nondestructive Techniques. Russ. J. Nondestruct. Test. 2022, 58, 369–380. [Google Scholar] [CrossRef]

- S R, H.; Sathyashankara, S.; Ramakrishna Vikas, S.; Achutha, K.U.; Raviraj, S.; Rao U, S. Dependence of pre-treatment structure on spheroidization and turning characteristics of AISI1040 steel. Cogent Eng. 2023, 10, 2219095. [Google Scholar] [CrossRef]

- ASTM E92-17; Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Hyde, T.H.; Sun, W.; Williams, J.A. Requirements for and use of miniature test specimens to provide mechanical and creep properties of materials: A review. Int. Mater. Rev. 2007, 52, 213–255. [Google Scholar] [CrossRef]

- ASTM G99-17; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Con-shohocken, PA, USA, 2017.

- Nakao, Y.; Miura, H. Nano-grain evolution in austenitic stainless steel during multi-directional forging. Mater. Sci. Eng. A 2011, 528, 1310–1317. [Google Scholar] [CrossRef]

- Akbarian, S.; Zarei-Hanzaki, A.; Abedi, H.R.; Unnikrishnan, R.; Moat, R. Substructure Development and Deformation Twinning Stimulation through Regulating the Processing Path during Multi-Axial Forging of Twinning Induced Plasticity Steel. Adv. Eng. Mater. 2018, 20, 1800453. [Google Scholar] [CrossRef]

- Padap, A.K.; Chaudhari, G.P.; Nath, S.K.; Pancholi, V. Ultrafine-grained steel fabricated using warm multiaxial forging: Microstructure and mechanical properties. Mater. Sci. Eng. A 2009, 527, 110–117. [Google Scholar] [CrossRef]

- Ogatsu, K.; Ogawa, T.; Chen, T.-T.; Sun, F.; Adachi, Y. Dramatic improvement in strength–ductility balance of dual-phase steels by optimizing features of ferrite phase. J. Mater. Res. Technol. 2025, 35, 289–297. [Google Scholar] [CrossRef]

- Singh, P.P.; Mula, S.; Ghosh, S. Grain refinement, strain hardening and fracture in thermomechanically processed ultra-strong microalloyed steel. Mater. Today Commun. 2024, 38, 107582. [Google Scholar] [CrossRef]

- Ghosh, A.; Ghosh, M.; Gudimetla, K.; Kalsar, R.; Kestens, L.A.I.; Kondaveeti, C.S.; Singh Pugazhendhi, B.; Ravisankar, B. Development of ultrafine grained Al–Zn–Mg–Cu alloy by equal channel angular pressing: Microstructure, texture and mechanical properties. Arch. Civ. Mech. Eng. 2020, 20, 7. [Google Scholar] [CrossRef]

- Ghosh, A.; Ghosh, M.; Shankar, G. On the role of precipitates in controlling microstructure and mechanical properties of Ag and Sn added 7075 alloys during artificial ageing. Mater. Sci. Eng. A 2018, 738, 399–411. [Google Scholar] [CrossRef]

- Muñoz, J.A.; Khelfa, T.; Komissarov, A.; Cabrera, J.-M. Ductility and plasticity of ferritic-pearlitic steel after severe plastic deformation. Mater. Sci. Eng. A 2021, 805, 140624. [Google Scholar] [CrossRef]

- Kumar, H.; Tiwari, M.; Manna, R.; Khan, D. A modified Johnson-Cook model to determine plastic flow behavior of Fe-30Mn-9Al-0.8 C low-density steel during warm multiaxial forging. Mater. Today Commun. 2024, 38, 108270. [Google Scholar] [CrossRef]

- Raabe, D.; Sun, B.; Kwiatkowski Da Silva, A.; Gault, B.; Yen, H.-W.; Sedighiani, K.; Thoudden Sukumar, P.; Souza Filho, I.R.; Katnagallu, S.; Jägle, E.; et al. Current Challenges and Opportunities in Microstructure-Related Properties of Advanced High-Strength Steels. Metall. Mater. Trans. A 2020, 51, 5517–5586. [Google Scholar] [CrossRef]

- Rai, P.K.; Kumar, D.S.; Balachandran, G. Effect of composition and inter-critical annealing parameters on microstructure and mechanical properties of DP steel. Sādhanā 2022, 47, 122. [Google Scholar] [CrossRef]

- Badkoobeh, F.; Mostaan, H.; Rafiei, M.; Bakhsheshi-Rad, H.R.; Berto, F. Microstructural Characteristics and Strengthening Mechanisms of Ferritic–Martensitic Dual-Phase Steels: A Review. Metals 2022, 12, 101. [Google Scholar] [CrossRef]

- Yadav, A.P.; Padap, A.K. Effects of multi-axial compression and double-step aging on the microstructure and mechanical properties of Al alloy 7075. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024, 09544089241253671. [Google Scholar] [CrossRef]

- Gurao, N.P.; Kumar, P.; Sarkar, A.; Brokmeier, H.-G.; Suwas, S. Simulation of Deformation Texture Evolution During Multi Axial Forging of Interstitial Free Steel. J. Mater. Eng. Perform. 2013, 22, 1004–1009. [Google Scholar] [CrossRef]

- Kim, M.-S.; Kim, J.G.; Kwon, S.-C.; Jeong, D.H.; Lee, S.; Jeong, H.-T.; Choi, S.-H. Evolution of the microstructure and mechanical properties of interstitial-free steel during multi-axial diagonal forging. Mater. Sci. Eng. A 2022, 846, 143242. [Google Scholar] [CrossRef]

- Kalhor, A.; Karimi Taheri, A.; Mirzadeh, H.; Uthaisangsuk, V. Processing, microstructure adjustments, and mechanical properties of dual phase steels: A review. Mater. Sci. Technol. 2021, 37, 561–591. [Google Scholar] [CrossRef]

- Wu, J.; Bao, L.; Gu, Y.; Li, Q.; Liu, J. The strengthening and toughening mechanism of dual martensite in quenching-partitioning steels. Mater. Sci. Eng. A 2020, 772, 138765. [Google Scholar] [CrossRef]

- Koohdar, H.; Roshanzadeh, F.; Nayebpashaee, N.; Jafarian, H.R. Effect of intercritical annealing and subsequent ageing on the microstructure and mechanical properties of a medium Ni–Mn low carbon steel. J. Mater. Res. Technol. 2022, 20, 3656–3666. [Google Scholar] [CrossRef]

- Naseri, M.; Myasnikova, A.; Gholami, D.; Imantalab, O.; Mikhailov, D.; Amra, M.; Shaburova, N.; Efimova, M.; Orlov, A.; Hosseini, S.; et al. Regulating of wear properties through microstructure engineering in novel cost-effective Fe30Ni25Cr25Mo10Al10 high-entropy alloy processed by cyclic closed-die forging. J. Alloy. Metall. Syst. 2024, 7, 100101. [Google Scholar] [CrossRef]

- Tang, H.; Sun, J.; He, J.; Wu, P. Research Progress of Interface Conditions and Tribological Reactions: A Review. J. Ind. Eng. Chem. 2021, 94, 105–121. [Google Scholar] [CrossRef]

- Guo, X.-F.; Jia, L.; Lu, Z.-L.; Xie, H.; Kondoh, K. Mechanical and tribological property of Cu/CrB2 composites under dry sliding condition. Mater. Sci. Technol. 2024, 40, 561–568. [Google Scholar] [CrossRef]

- Saghafian, H.; Kheirandish, S. Correlating microstructural features with wear resistance of dual phase steel. Mater. Lett. 2007, 61, 3059–3063. [Google Scholar] [CrossRef]

- Tyagi, R.; Nath, S.K.; Ray, S. Development of wear resistant medium carbon dual phase steels and their mechanical properties. Mater. Sci. Technol. 2004, 20, 645–652. [Google Scholar] [CrossRef]

| Elements | C | Mn | Si | P | S | Fe |

|---|---|---|---|---|---|---|

| wt.% | 0.40 | 0.72 | 0.28 | 0.020 | 0.018 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dwivedi, P.; Padap, A.K.; Maheshwari, S.; Mohammad, F.K.; Mohsin, M.E.A.; Hossain, S.S.; Altammar, H.; Siddiquee, A.N. Enhancing the Mechanical Performance of Dual-Phase Steel Through Multi-Axis Compression and Inter-Critical Annealing. Materials 2025, 18, 3139. https://doi.org/10.3390/ma18133139

Dwivedi P, Padap AK, Maheshwari S, Mohammad FK, Mohsin MEA, Hossain SS, Altammar H, Siddiquee AN. Enhancing the Mechanical Performance of Dual-Phase Steel Through Multi-Axis Compression and Inter-Critical Annealing. Materials. 2025; 18(13):3139. https://doi.org/10.3390/ma18133139

Chicago/Turabian StyleDwivedi, Pooja, Aditya Kumar Padap, Sachin Maheshwari, Faseeulla Khan Mohammad, Mohammed E. Ali Mohsin, SK Safdar Hossain, Hussain Altammar, and Arshad Noor Siddiquee. 2025. "Enhancing the Mechanical Performance of Dual-Phase Steel Through Multi-Axis Compression and Inter-Critical Annealing" Materials 18, no. 13: 3139. https://doi.org/10.3390/ma18133139

APA StyleDwivedi, P., Padap, A. K., Maheshwari, S., Mohammad, F. K., Mohsin, M. E. A., Hossain, S. S., Altammar, H., & Siddiquee, A. N. (2025). Enhancing the Mechanical Performance of Dual-Phase Steel Through Multi-Axis Compression and Inter-Critical Annealing. Materials, 18(13), 3139. https://doi.org/10.3390/ma18133139