Experimental Study on Hybrid Additive and Subtractive Manufacturing Processes for Improving Surface Quality

Abstract

1. Introduction

2. Materials and Methods

2.1. Filament Material

- Density (1.29 g/cm3);

- Tensile modulus (2980 MPa);

- Tensile stress at yield (51 MPa);

- Izod impact strength (4.7 kJ/m2).

2.2. Object of the Study

2.3. Testing Algorithm

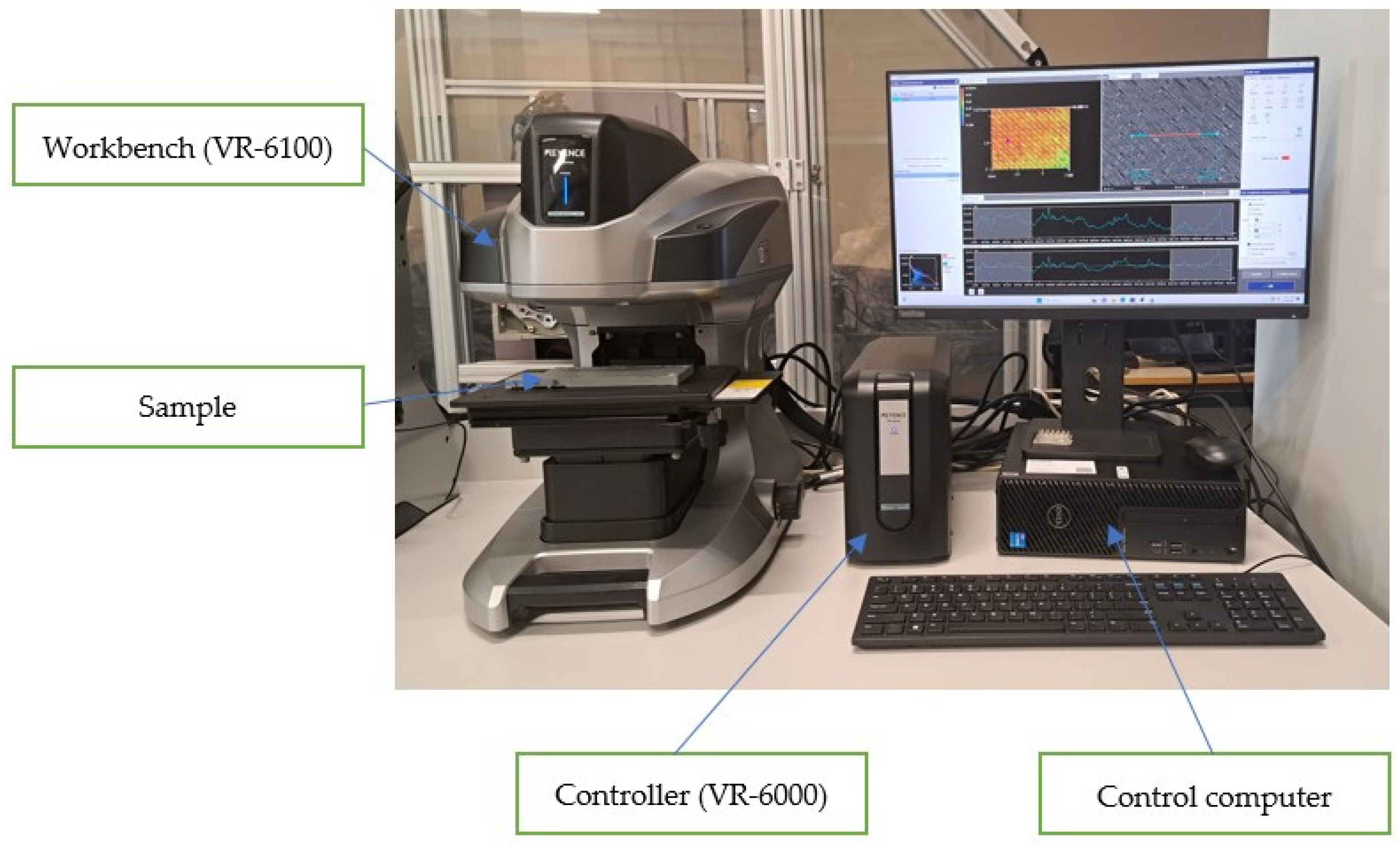

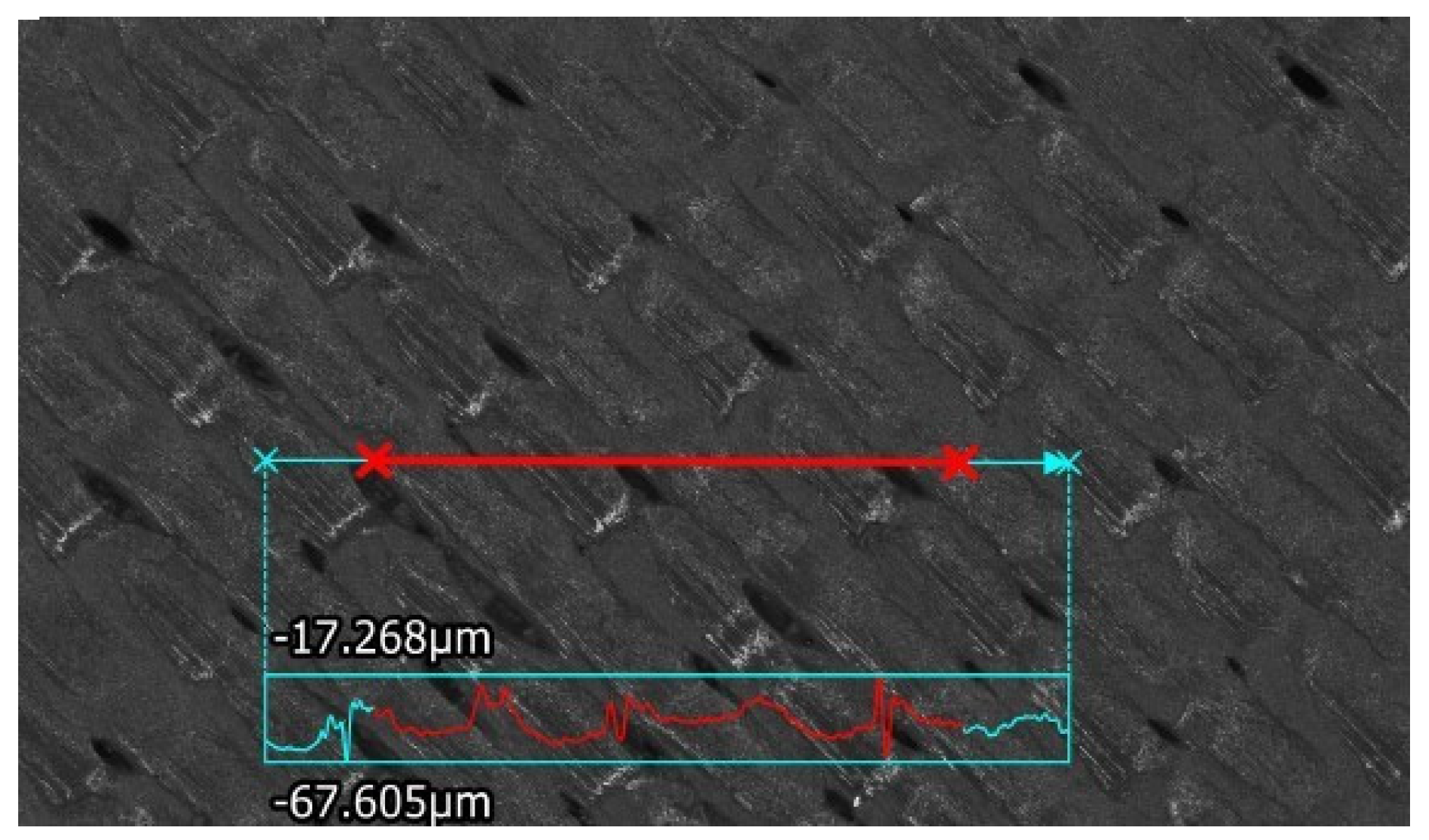

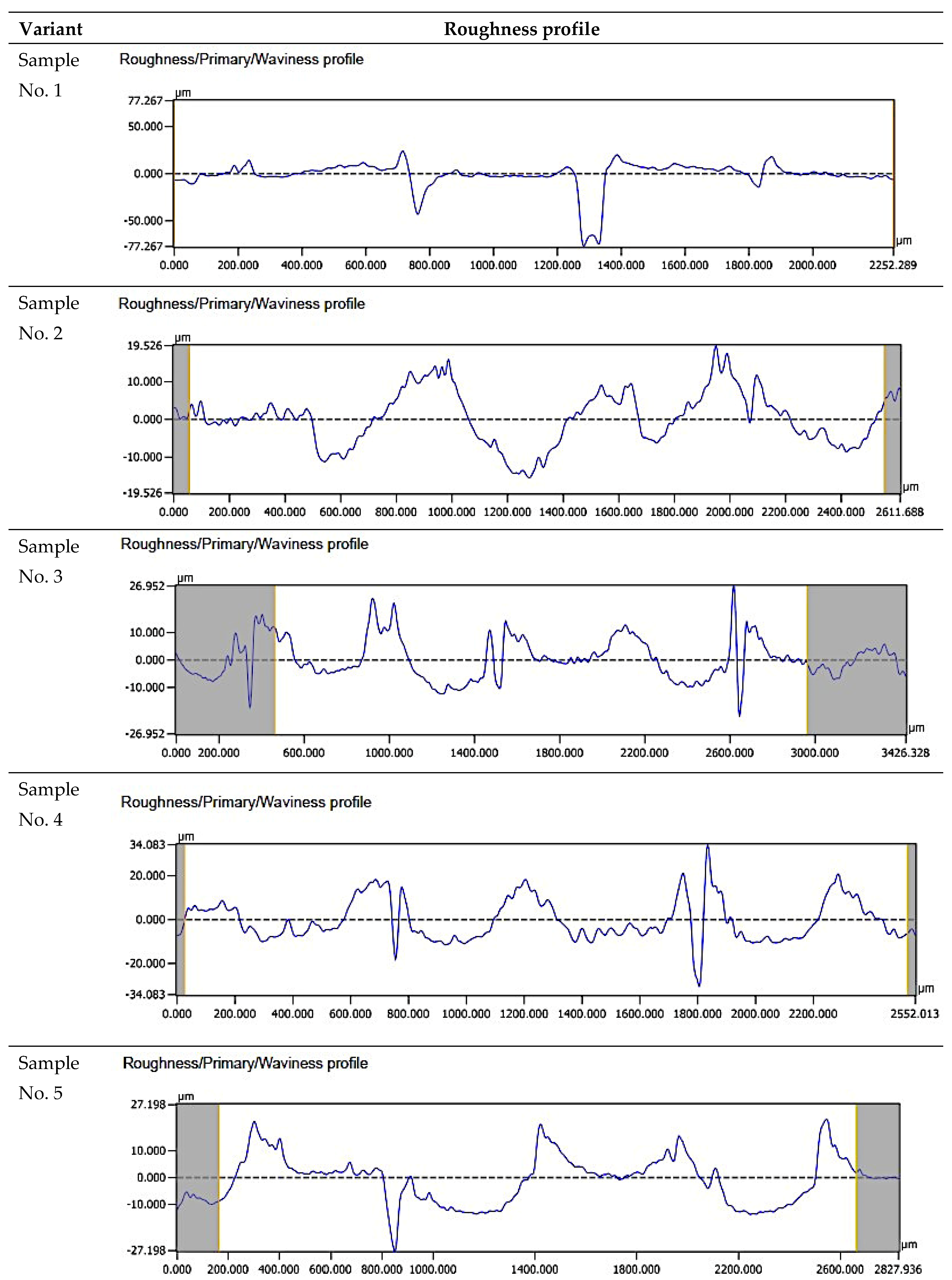

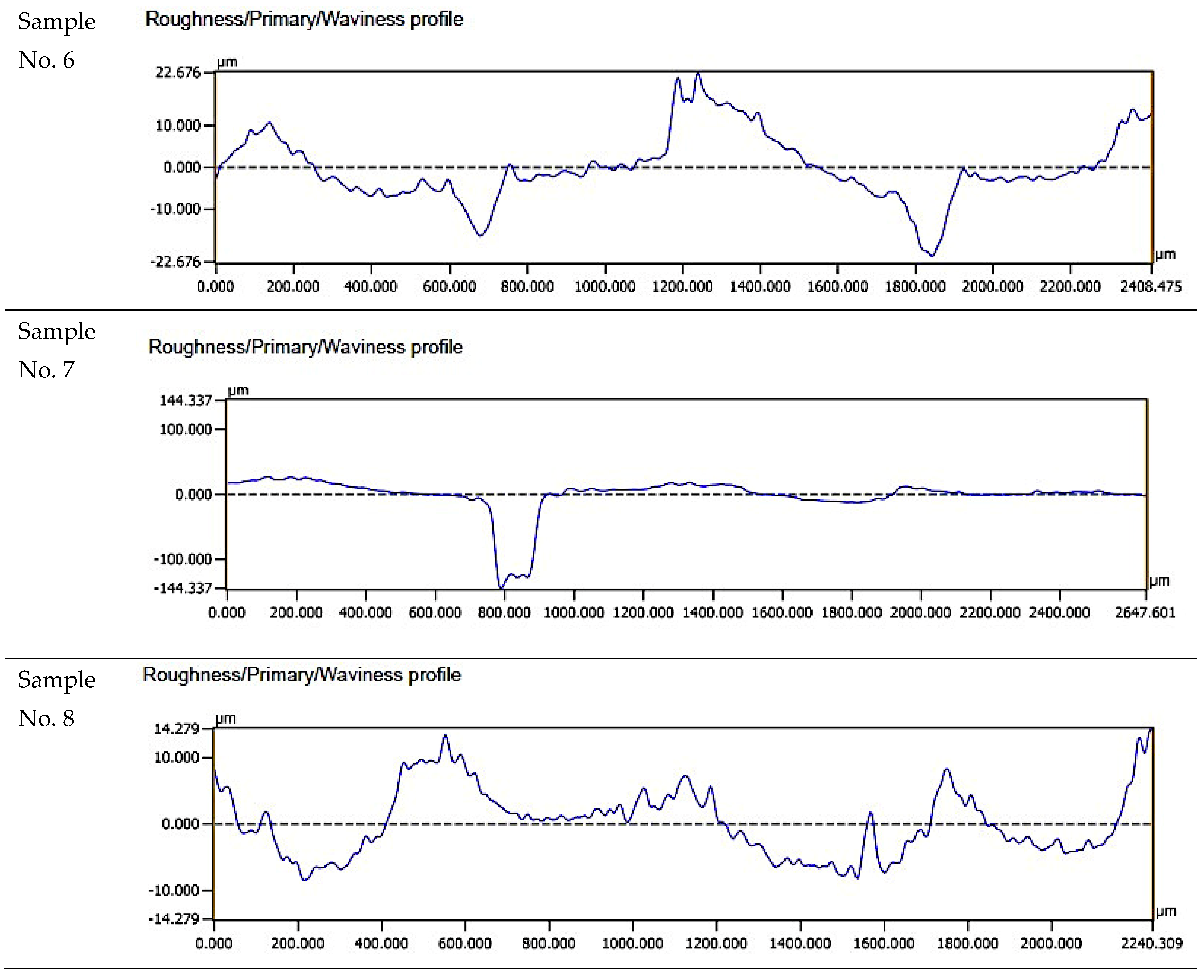

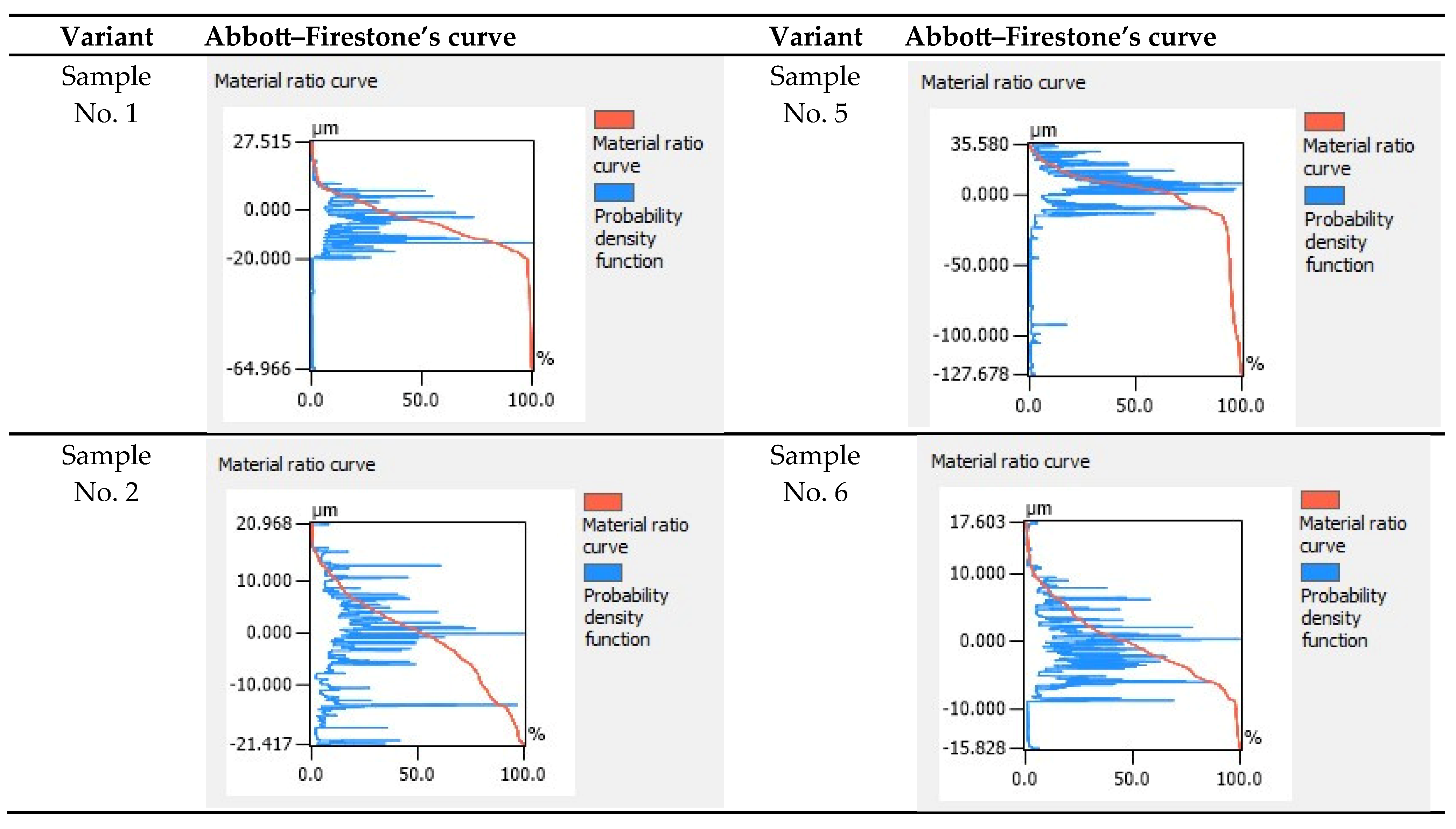

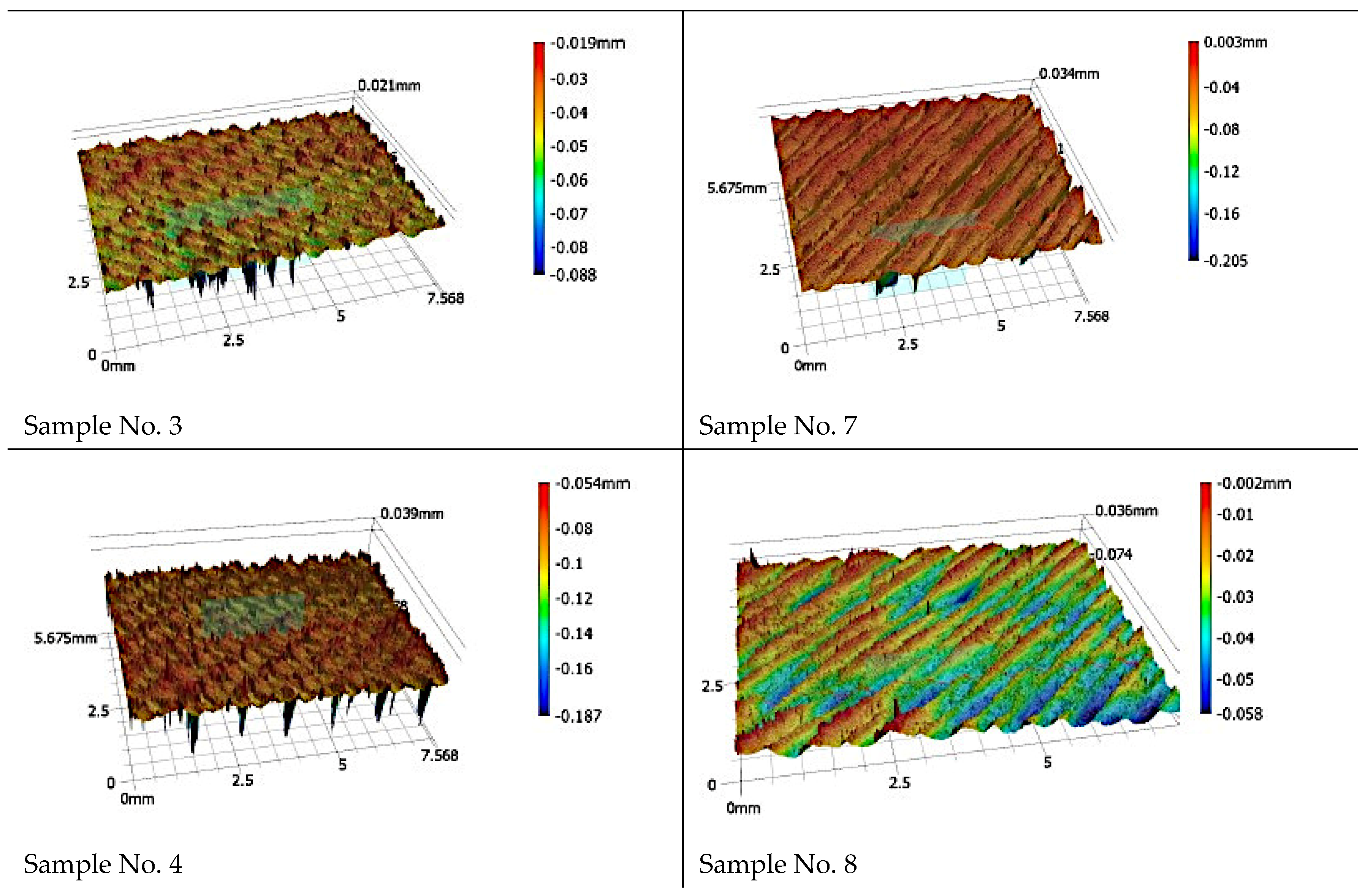

- Analysis of the surface topography of samples after the printing stage using a Keyence VR 6100 profilometer (KEYENCE CORPORATION, Osaka, Japan).

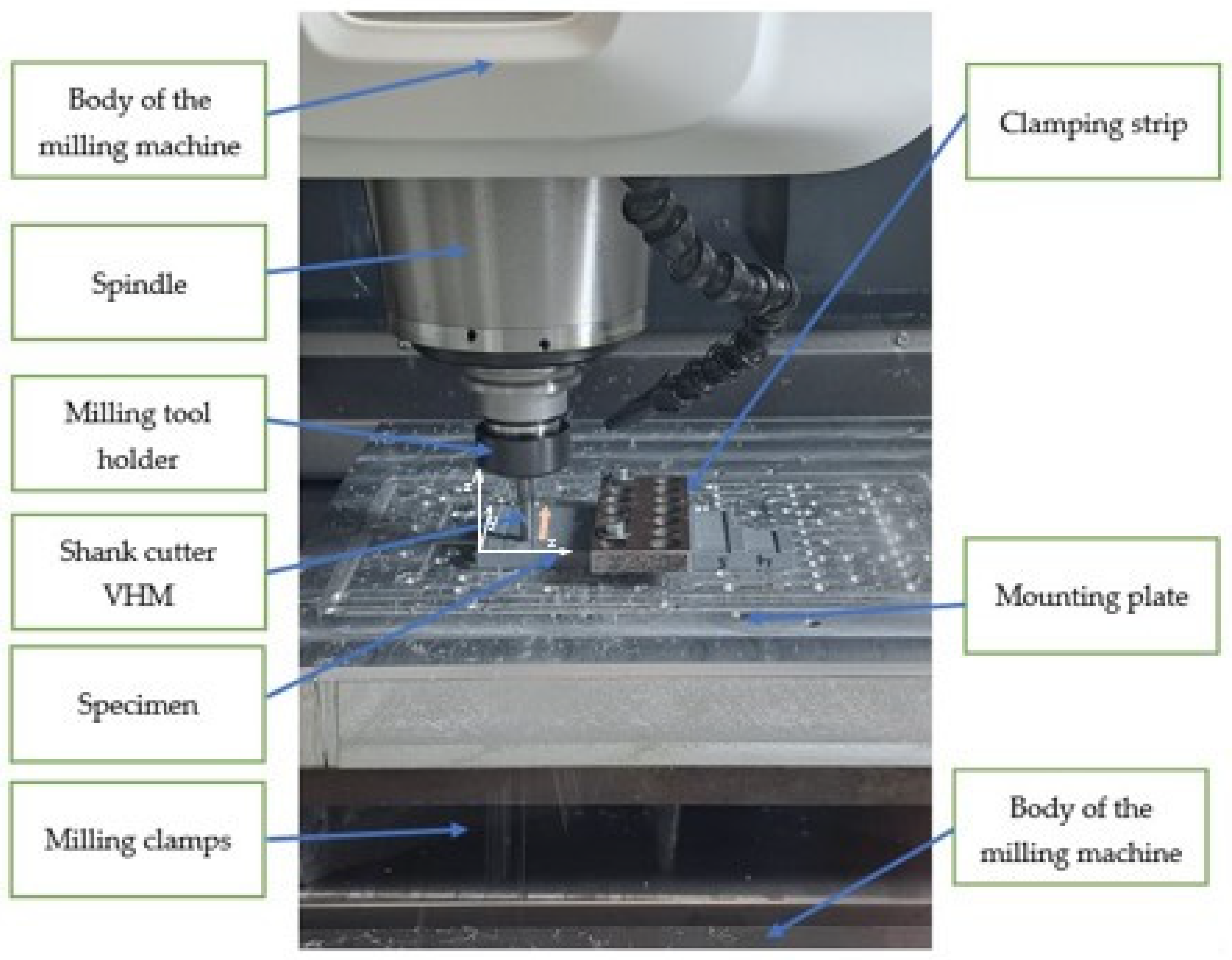

- Milling operation using a CMX 600V Vertical Machining Centre (DMG, Pleszew, Poland).

- Examination of the surface roughness of the specimen after milling using a Keyence VR 6100 profilometer (KEYENCE CORPORATION, Osaka, Japan).

- Analysis of photographs of the microstructure of the groove surfaces of the samples using a Keyence VR 6100 profilometer (KEYENCE CORPORATION, Osaka, Japan) and Motic inverted microscope (Motic, Xiamen, China).

3. Results

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chu, W.-S.; Kim, C.-S.; Lee, H.-T.; Choi, J.-O.; Park, J.-I.; Song, J.-H.; Jang, K.-H.; Ahn, S.-H. Hybrid Manufacturing in Micro/Nano Scale: A Review. Int. J. Precis. Eng. Manuf.-Green Technol. 2014, 1, 75–92. [Google Scholar] [CrossRef]

- Basile, V.; Modica, F.; Rebaioli, L.; Surace, R.; Fassi, I. Process Chains for Micro-Manufacturing: Modeling and Case Studies. J. Manuf. Mater. Process. 2023, 7, 215. [Google Scholar] [CrossRef]

- Zhu, Z.; Dhokia, V.G.; Nassehi, A.; Newman, S.T. A Review of Hybrid Manufacturing Processes–State of the Art and Future Perspectives. Int. J. Comput. Integr. Manuf. 2013, 26, 596–615. [Google Scholar] [CrossRef]

- Grzesik, W. Hybrid manufacturing of metallic parts integrated additive and subtractive processes. Mechanik 2018, 91, 468–475. [Google Scholar] [CrossRef]

- Koruba, P.; Boratyński, T.; Jurewicz, P.; Koenig, G.; Szaroleta, M.; Reiner, J.; Chlebus, E.; Dworak, A. Design and Applications Analysis of Laser Cladding Technology for Aviation Industry. Adv. Mech. Mater. Eng. 2018, 35, 309–321. [Google Scholar] [CrossRef][Green Version]

- Wen, J.; Xie, F.; Liu, X.; Yue, Y. Evolution and Development Trend Prospect of Metal Milling Equipment. Chin. J. Mech. Eng. 2023, 36, 33. [Google Scholar] [CrossRef]

- Global 3D Printing Industry Market Size. Available online: https://www.statista.com/statistics/315386/global-market-for-3d-printers/ (accessed on 23 March 2025).

- Krimpenis, A.A.; Noeas, G.D. Application of Hybrid Manufacturing Processes in Microfabrication. J. Manuf. Process. 2022, 80, 328–346. [Google Scholar] [CrossRef]

- Merklein, M.; Junker, D.; Schaub, A.; Neubauer, F. Hybrid Additive Manufacturing Technologies–An Analysis Regarding Potentials and Applications. Phys. Procedia 2016, 83, 549–559. [Google Scholar] [CrossRef]

- Li, F.; Chen, S.; Shi, J.; Tian, H.; Zhao, Y. Evaluation and Optimization of a Hybrid Manufacturing Process Combining Wire Arc Additive Manufacturing with Milling for the Fabrication of Stiffened Panels. Appl. Sci. 2017, 7, 1233. [Google Scholar] [CrossRef]

- Kapil, S.; Legesse, F.; Kulkarni, P.; Joshi, P.; Desai, A.; Karunakaran, K.P. Hybrid-Layered Manufacturing Using Tungsten Inert Gas Cladding. Prog. Addit. Manuf. 2016, 1, 79–91. [Google Scholar] [CrossRef]

- Xinhong, X.; Haiou, Z.; Guilan, W.; Guoxian, W. Hybrid Plasma Deposition and Milling for an Aeroengine Double Helix Integral Impeller Made of Superalloy. Robot. Comput.-Integr. Manuf. 2010, 26, 291–295. [Google Scholar] [CrossRef]

- Pan, Z.; Ding, D.; Wu, B.; Cuiuri, D.; Li, H.; Norrish, J. Arc Welding Processes for Additive Manufacturing: A Review. In Transactions on Intelligent Welding Manufacturing, Proceedings of the 2017 International Workshop on Intelligentized Welding Manufacturing, Shanghai, China, 23–26 June 2017; Chen, S., Zhang, Y., Feng, Z., Eds.; Springer: Singapore, 2018; pp. 3–24. [Google Scholar]

- Djurović, S.; Lazarević, D.; Ćirković, B.; Mišić, M.; Ivković, M.; Stojčetović, B.; Petković, M.; Ašonja, A. Modeling and Prediction of Surface Roughness in Hybrid Manufacturing–Milling after FDM Using Artificial Neural Networks. Appl. Sci. 2024, 14, 5980. [Google Scholar] [CrossRef]

- Jabłońska, M.; Jurczak, W.; Ozimina, D.; Adamiak, M. Increasing the Operational Reliability of a Ship by Using a Composite Impeller in the Event of Hydrophore Pump Failure. Eksploat. I Niezawodn.-Maint. Reliab. 2023, 25, 18. [Google Scholar] [CrossRef]

- Iacob, D.V.; Zisopol, D.G.; Minescu, M. Technical-Economical Study on the Optimization of FDM Parameters for the Manufacture of PETG and ASA Parts. Polymers 2024, 16, 2260. [Google Scholar] [CrossRef]

- Akhoundi, B.; Nabipour, M.; Hajami, F.; Shakoori, D. An Experimental Study of Nozzle Temperature and Heat Treatment (Annealing) Effects on Mechanical Properties of High-temperature Polylactic Acid in Fused Deposition Modeling. Polym. Eng. Sci. 2020, 60, 979–987. [Google Scholar] [CrossRef]

- Ullah, I.; Wasif, M.; Tufail, M. Analysis of Shrinkage and Dimensional Accuracy of Additively Manufactured Tooling for the Composite Manufacturing. Int. J. Interact. Des. Manuf. 2024, 18, 673–684. [Google Scholar] [CrossRef]

- Nyamuchiwa, K.; Palad, R.; Panlican, J.; Tian, Y.; Aranas, C. Recent Progress in Hybrid Additive Manufacturing of Metallic Materials. Appl. Sci. 2023, 13, 8383. [Google Scholar] [CrossRef]

- Milton, S.; Morandeau, A.; Chalon, F.; Leroy, R. Influence of Finish Machining on the Surface Integrity of Ti6Al4V Produced by Selective Laser Melting. Procedia CIRP 2016, 45, 127–130. [Google Scholar] [CrossRef]

- Ituarte, I.F.; Chekurov, S.; Salmi, M.; Tuomi, J.; Partanen, J. Post-Processing Opportunities of Professional and Consumer Grade 3D Printing Equipment: A Comparative Study. Int. J. Rapid Manuf. 2015, 5, 58–75. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, X.; Stringer, J. Support Structures for Additive Manufacturing: A Review. J. Manuf. Mater. Process. 2018, 2, 64. [Google Scholar] [CrossRef]

- Yuan, J.; Chen, C.; Yao, D.; Chen, G. 3D Printing of Oil Paintings Based on Material Jetting and Its Reduction of Staircase Effect. Polymers 2020, 12, 2536. [Google Scholar] [CrossRef] [PubMed]

- Solomon, I.J.; Sevvel, P.; Gunasekaran, J. A Review on the Various Processing Parameters in FDM. Mater. Today Proc. 2021, 37, 509–514. [Google Scholar] [CrossRef]

- Hou, J.-U.; Kim, D.; Ahn, W.-H.; Lee, H.-K. Copyright Protections of Digital Content in the Age of 3D Printer: Emerging Issues and Survey. IEEE Access 2018, 6, 44082–44093. [Google Scholar] [CrossRef]

- Nuñez, P.J.; Rivas, A.; García-Plaza, E.; Beamud, E.; Sanz-Lobera, A. Dimensional and Surface Texture Characterization in Fused Deposition Modelling (FDM) with ABS Plus. Procedia Eng. 2015, 132, 856–863. [Google Scholar] [CrossRef]

- Ewald, A.; Möller, M.; Schlattmann, J. Adapted Approach of the Product Development Process for Hybrid Manufactured Parts. In Proceedings of the Laser in Manufacturing Conference, Munich, Germany, 26–29 June 2017. [Google Scholar]

- Ghabezi, P.; Sam-Daliri, O.; Flanagan, T.; Walls, M.; Harrison, N.M. Circular Economy Innovation: A Deep Investigation on 3D Printing of Industrial Waste Polypropylene and Carbon Fibre Composites. Resour. Conserv. Recycl. 2024, 206, 107667. [Google Scholar] [CrossRef]

- Silva, D.; Garrido, J.; Lekube, B.; Arrillaga, A. On-Board and Port 3D Printing to Promote a Maritime Plastic Circular Economy. J. Clean. Prod. 2023, 407, 137151. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The Status, Challenges, and Future of Additive Manufacturing in Engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Popov, V.V.; Fleisher, A. Hybrid Additive Manufacturing of Steels and Alloys. Manuf. Rev. 2020, 7, 6. [Google Scholar] [CrossRef]

- Šajgalík, M.; Kušnerová, M.; Harničárová, M.; Valíček, J.; Czán, A.; Czánová, T.; Drbúl, M.; Borzan, M.; Kmec, J. Analysis and Prediction of the Machining Force Depending on the Parameters of Trochoidal Milling of Hardened Steel. Appl. Sci. 2020, 10, 1788. [Google Scholar] [CrossRef]

- Waszczuk, K.P.; Skowronek, H.; Karolczak, P.; Kowalski, M.; Kołodziej, M. Influence of the Trochoidal Tool Path on Quality Surface of Groove Walls. Adv. Sci. Technol. Res. J. 2019, 13, 38–42. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Lamikiz, A.; Muñoa, J.; Salgado, M.A.; Sánchez, J.A. Improving the High-Speed Finishing of Forming Tools for Advanced High-Strength Steels (AHSS). Int. J. Adv. Manuf. Technol. 2006, 29, 49–63. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Buonadonna, P.; El Mohtadi, R.; Loi, G.; Aymerich, F.; Carta, M. Optimizing Milling Parameters for Enhanced Machinability of 3D-Printed Materials: An Analysis of PLA, PETG, and Carbon-Fiber-Reinforced PETG. J. Manuf. Mater. Process. 2024, 8, 131. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Buonadonna, P.; Loi, G.; El Mohtadi, R.; Carta, M.; Aymerich, F. Surface Quality Related to Face Milling Parameters in 3D Printed Carbon Fiber-Reinforced PETG. J. Compos. Sci. 2024, 8, 128. [Google Scholar] [CrossRef]

- Lalegani Dezaki, M.; Mohd Ariffin, M.K.A.; Ismail, M.I.S. Effects of CNC Machining on Surface Roughness in Fused Deposition Modelling (FDM) Products. Materials 2020, 13, 2608. [Google Scholar] [CrossRef]

- Jabłońska, M.; Łastowska, O. Enhancing of Surface Quality of FDM Moulded Materials through Hybrid Techniques. Materials 2024, 17, 4250. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Printability and Tensile Performance of 3D Printed Polyethylene Terephthalate Glycol Using Fused Deposition Modelling. Polymers 2019, 11, 1220. [Google Scholar] [CrossRef]

- Wahab Hashmi, A.; Singh Mali, H.; Meena, A. Improving the Surface Characteristics of Additively Manufactured Parts: A Review. Mater. Today Proc. 2023, 81, 723–738. [Google Scholar] [CrossRef]

- Zmarzły, P.; Klamka, M.; Szwej, W.; Wróblewska, E. Examination of the flatness and surface topography of thin wall models manufactured using fused deposition modeling technology. Zarządzanie Przedsiębiorstwem. Enterp. Manag. 2023, 26, 27–32. [Google Scholar] [CrossRef]

- ISO 21920-2:2023; Geometrical Product Specifications (GPS)-Surface Texture: Profile-Part 2: Terms, Definitions and Surface Texture Parameters. (ISO 21920-2:2021, Corrected Version 2022-06); ISO: Geneva, Switzerland, 2023.

- Lakshman, S.S.V.; Karthick, A.; Dinesh, C. Evaluation of Mechanical Properties of 3D Printed PETG and Polyamide (6) Polymers. Chem. Phys. Impact 2024, 8, 100491. [Google Scholar] [CrossRef]

- Seno Flores, J.D.; de Assis Augusto, T.; Lopes Vieira Cunha, D.A.; Gonçalves Beatrice, C.A.; Henrique Backes, E.; Costa, L.C. Sustainable Polymer Reclamation: Recycling Poly(Ethylene Terephthalate) Glycol (PETG) for 3D Printing Applications. J. Mater. Sci. Mater. Eng. 2024, 19, 16. [Google Scholar] [CrossRef]

- Czyżewski, P.; Marciniak, D.; Nowinka, B.; Borowiak, M.; Bieliński, M. Influence of Extruder’s Nozzle Diameter on the Improvement of Functional Properties of 3D-Printed PLA Products. Polymers 2022, 14, 356. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Bagheri, A.; Domínguez-Fernández, A.; Casado-López, R. Influence of Infill and Nozzle Diameter on Porosity of FDM Printed Parts with Rectilinear Grid Pattern. Procedia Manuf. 2019, 41, 288–295. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021(En); Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2021. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso-astm:52900:ed-2:v1:en:sec:3.7.4 (accessed on 1 April 2025).

- Domingues, W.V.; Arce, R.P.; Frose, L.R. Additive Manufacturing and Computational Simulation: A Review of Integrated Technologies and Applications. In Proceedings of the AEA—Brazilian Society of Automotive Engineering—SIMEA 2023, Sao Paulo, Brazil, 16–17 August 2023. [Google Scholar] [CrossRef]

- DIN 69871-1:1995-10; Tool Shanks with 7/24 Taper for Automatic Tool Exchange—Part 1: Type A, Type AD, Type B and with Data Media. Beuth Verlag: Berlin, Germany, 1995.

- Sandvik Coromant. CoroKey Cutting Tool Guide 2010. Technical Publication, Sandvik Coromant, 2010. Available online: https://www.machinery.co.uk/content/news/sandvik-coromant-release-2010-corokey-cutting-tool-guide (accessed on 4 May 2025).

- PN-EN ISO 4288:2011; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture. ISO: Warsaw, Poland, 2011.

| Parameter | Value |

|---|---|

| Filament | PETG |

| Extruder temperature is maintained during printer operation, Et | 225 °C |

| Temperature of the platform for all extruded filament layers, Pt | 70 °C |

| Infill density of the sample, Id | 100% |

| Number of outer layers of the printed object, n | 4 |

| Solid bottom layers | 4 |

| Solid top layers | 4 |

| Filament layer height, Lh | 0.1 and 0.2 mm |

| Height of the first layer, Lh1 | 0.25 mm |

| Width of the first layer, Wh | 0.4 mm |

| Infill pattern inside the sample, Ip | linear |

| Feed rate during which the filament layer is extruded, Vfeed | 90 mm/s; 100 mm/s; 110 mm/s; 120 mm/s |

| Head | VR-6100 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Camera | Low magnification (wide field of view) | High magnification (high resolution) | |||||||

| Magnification | 12× | 25× | 38× | 50× | 40× | 80× | 120× | 160× | |

| Field of view | Horizontal (mm) | 24 | 12 | 8 | 6 | 7.6 | 3.8 | 2.5 | 1.9 |

| Vertical (mm) | 18 | 9 | 6 | 4.5 | 5.7 | 2.9 | 1.9 | 1.4 | |

| Height measurement | Display resolution 0.1 µm | ||||||||

| Height measurement range | 50 mm | 30 mm | |||||||

| XY measurable range | 92 × 86 mm | ||||||||

| MODEL | CMX 600V |

|---|---|

| Max spindle speed (rpm) | 12,000 |

| Power supply (V) | 230 |

| Max. workpiece height (mm) | 630 |

| Max. workpiece length (mm) | 900 |

| Max. workpiece width (mm) | 560 |

| Max. workpiece weight (kg) | 600 |

| Working surface (mm) | 900 × 560 |

| Mass of machine (kg) | 5000 |

| Total power requirement (kVA) | 32 |

| Type of Cutter | Tool Designation | Size | Number of Blades | Manufacturer | Recommendation | Machining Parameters |

|---|---|---|---|---|---|---|

| Tool No. 1—Rotary burr (Figure 4) | ||||||

| Carbon roughing end mill | 116001.020 | 8.0 × 25 × 8 × 63 | Data not available | Karnasch Professional Tools, Mannhei, Germany | VHM milling cutter for composites: Carbon fibre-reinforced plastics CFK, CFRP; Glass fibre-reinforced plastics GFK, GFRP; Aluminium CFK and aluminium CFRP, Honeycomb composites, CFK, CFK, CFRP, GRP. | n = 6000 rpm Vf = 1000 mm/min ap = 0.35 mm fz = 0.04 mm/tooth |

| Tool No. 2—Single-edge spiral burr cutter (Figure 5) | ||||||

| VHM helical cutter for plastics | Solid Carbide (VHM) | 8.0 × 27 × 60 | z = 1 | STB Tools, Swarzędz, Poland | VHM milling cutter for plastics, aluminium and its alloys, copper, and other light metals. | n = 6000 rpm Vf = 1000 mm/min ap = 0.35 mm fz = 0.16 mm/tooth |

| Tool No. 3—Spiral endmill (Figure 6) | ||||||

| Spiral endmill for metal | NFPa 0641-512-100-080 HSS | 8.0 × 19 × 10 × 69 | z = 4 | FENES S.A., Siedlce, Poland | HSS spiral endmill for finishing and semi-finishing work on metals, stainless steel, cast-iron, aluminium alloys, copper, and other light metals. | n = 1000 rpm Vf = 400 mm/min ap = 0.35 mm fz = 0.1 mm/tooth |

| Sample No. | Groove No. | Lh (mm) | Vfeed (mm/s) | Tool No. | n (rpm) | Vf (mm/min) |

|---|---|---|---|---|---|---|

| 1 | 1 | 0.1 | 120 | 1 | 6000 | 900 |

| 1 | 2 | 0.1 | 120 | 2 | 6000 | 900 |

| 1 | 3 | 0.1 | 120 | 3 | 1000 | 400 |

| 2 | 4 | 0.1 | 90 | 1 | 6000 | 900 |

| 2 | 5 | 0.1 | 90 | 2 | 6000 | 900 |

| 2 | 6 | 0.1 | 90 | 3 | 1000 | 400 |

| 3 | 7 | 0.1 | 100 | 1 | 6000 | 900 |

| 3 | 8 | 0.1 | 100 | 2 | 6000 | 900 |

| 3 | 9 | 0.1 | 100 | 3 | 1000 | 400 |

| 4 | 10 | 0.1 | 110 | 1 | 6000 | 900 |

| 4 | 11 | 0.1 | 110 | 2 | 6000 | 900 |

| 4 | 12 | 0.1 | 110 | 3 | 1000 | 400 |

| 5 | 13 | 0.2 | 90 | 1 | 6000 | 900 |

| 5 | 14 | 0.2 | 90 | 2 | 6000 | 900 |

| 5 | 15 | 0.2 | 90 | 3 | 1000 | 400 |

| 6 | 16 | 0.2 | 100 | 1 | 6000 | 900 |

| 6 | 17 | 0.2 | 100 | 2 | 6000 | 900 |

| 6 | 18 | 0.2 | 100 | 3 | 1000 | 400 |

| 7 | 19 | 0.2 | 110 | 1 | 6000 | 900 |

| 7 | 20 | 0.2 | 110 | 2 | 6000 | 900 |

| 7 | 21 | 0.2 | 110 | 3 | 1000 | 400 |

| 8 | 22 | 0.2 | 120 | 1 | 6000 | 900 |

| 8 | 23 | 0.2 | 120 | 2 | 6000 | 900 |

| 8 | 24 | 0.2 | 120 | 3 | 1000 | 400 |

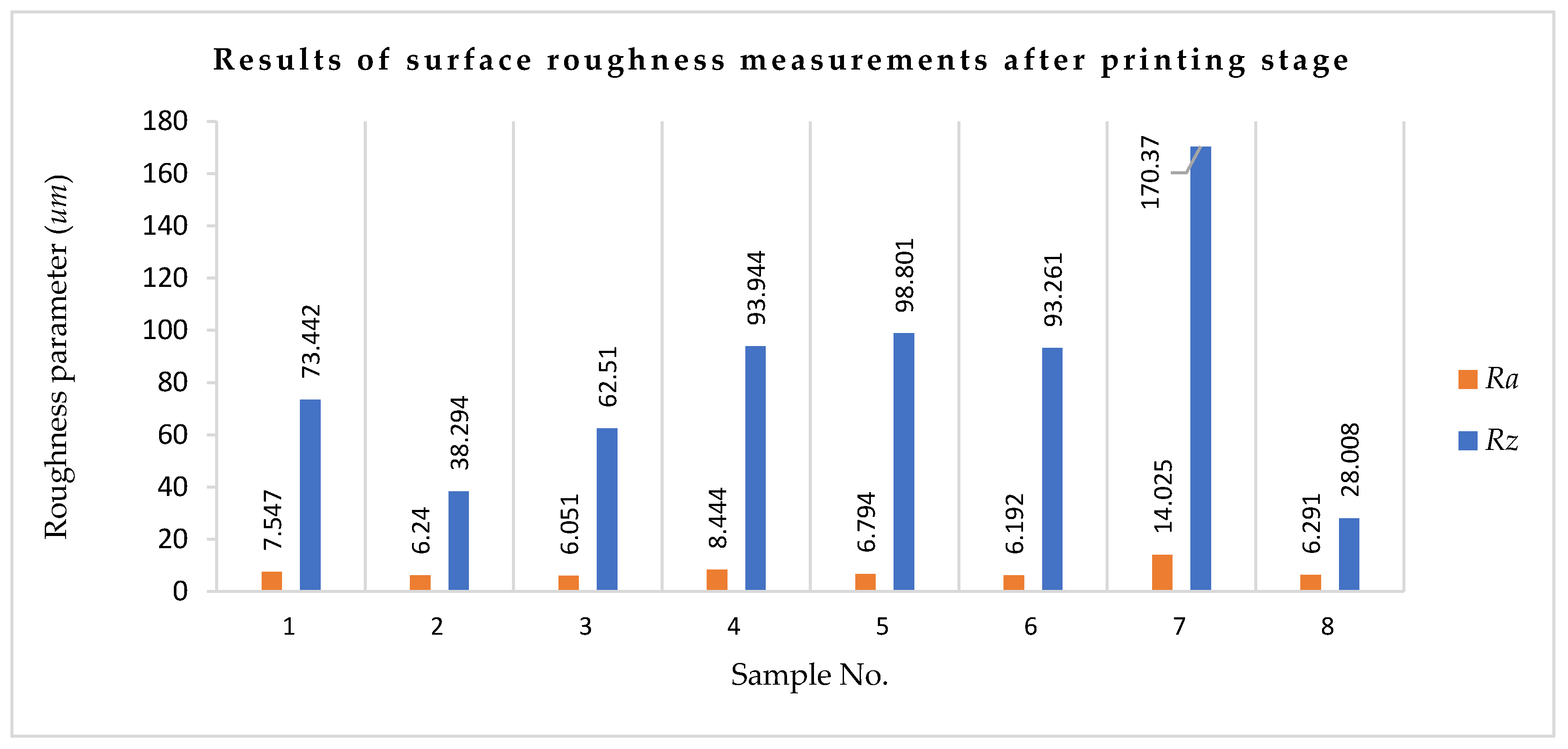

| Sample No. | Ra (μm) | Rz (μm) | Lh (mm) | Vfeed (mm/s) | ||

|---|---|---|---|---|---|---|

| σ | σ | |||||

| 1 | 7.547 | 1.300 | 73.442 | 40.802 | 0.1 | 120 |

| 2 | 6.240 | 0.815 | 38.294 | 3.731 | 0.1 | 90 |

| 3 | 6.051 | 1.321 | 62.510 | 47.422 | 0.1 | 100 |

| 4 | 8.444 | 1.042 | 93.944 | 79.600 | 0.1 | 110 |

| 5 | 6.794 | 0.699 | 98.801 | 62.835 | 0.2 | 90 |

| 6 | 6.192 | 0.620 | 93.261 | 66.700 | 0.2 | 100 |

| 7 | 14.025 | 1.047 | 170.37 | 14.893 | 0.2 | 110 |

| 8 | 6.291 | 0.342 | 28.008 | 4.533 | 0.2 | 120 |

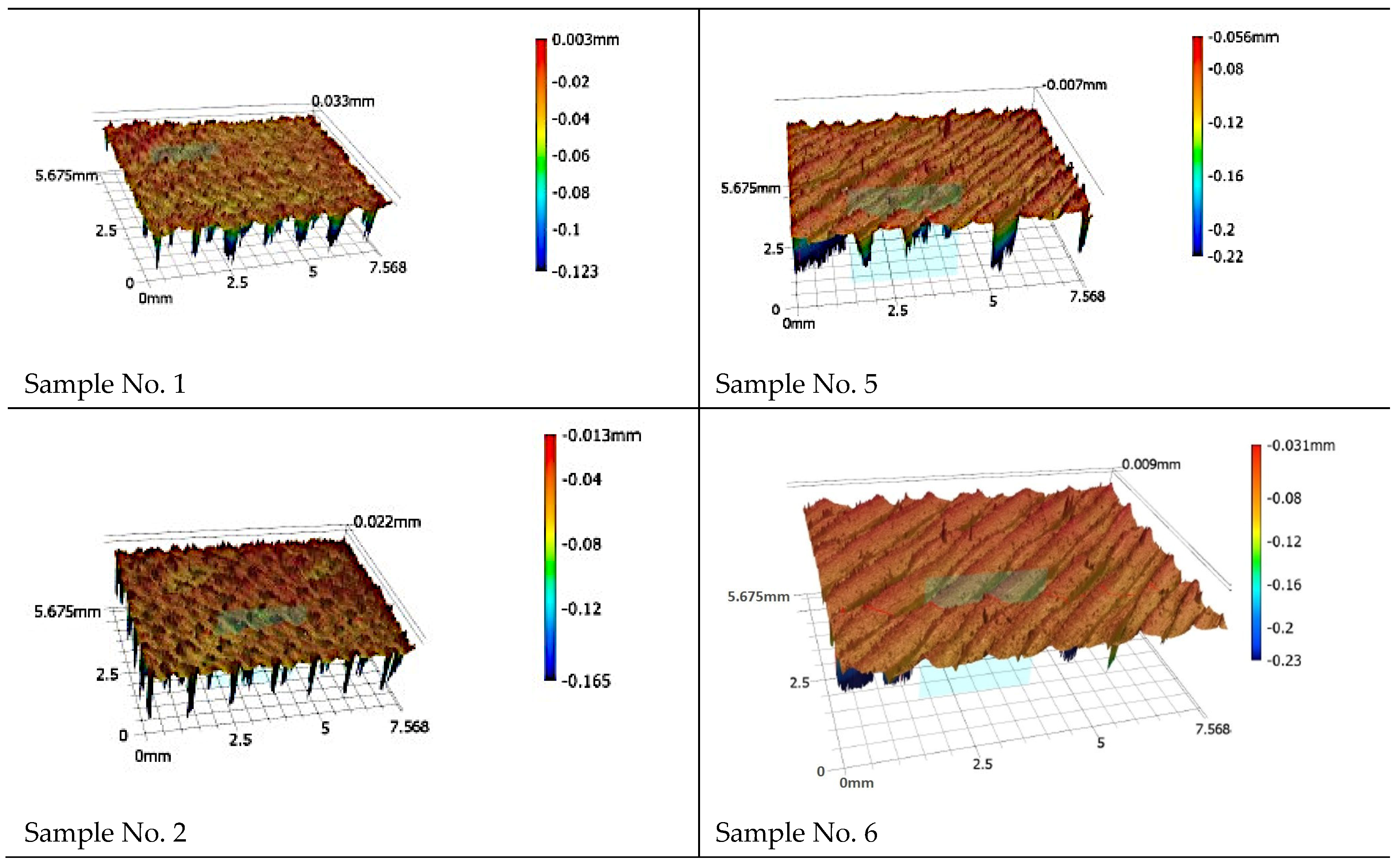

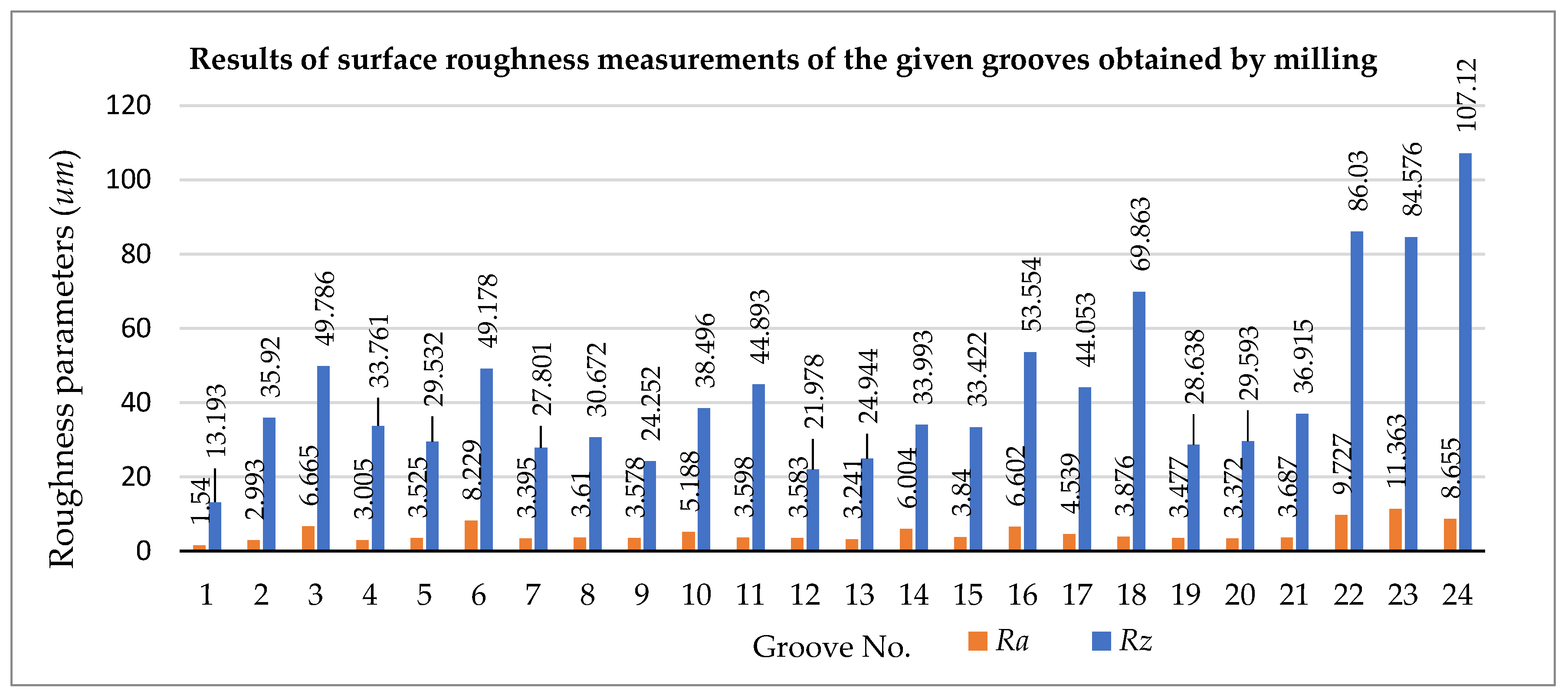

| Sample No. | Groove No. | Ra (μm) | Rz (μm) | ||

|---|---|---|---|---|---|

| σ | σ | ||||

| 1 | 1 | 1.54 | 0.157 | 13.193 | 2.396 |

| 2 | 2.993 | 0.565 | 35.920 | 9.487 | |

| 3 | 6.665 | 1.631 | 49.786 | 14.877 | |

| 2 | 4 | 3.005 | 0.774 | 33.761 | 16.192 |

| 5 | 3.525 | 0.650 | 29.532 | 8.407 | |

| 6 | 8.229 | 1.159 | 49.178 | 4.425 | |

| 3 | 7 | 3.395 | 0.709 | 27.801 | 9.792 |

| 8 | 3.610 | 0.628 | 30.672 | 6.449 | |

| 9 | 3.578 | 0.537 | 24.252 | 5.194 | |

| 4 | 10 | 5.188 | 1.811 | 38.496 | 8.396 |

| 11 | 3.598 | 0.590 | 44.893 | 22.319 | |

| 12 | 3.583 | 0.661 | 21.978 | 5.475 | |

| 5 | 13 | 3.241 | 0.524 | 24.944 | 6.647 |

| 14 | 6.004 | 0.663 | 33.993 | 4.285 | |

| 15 | 3.840 | 0.994 | 33.422 | 14.278 | |

| 6 | 16 | 6.602 | 0.540 | 53.554 | 8.001 |

| 17 | 4.539 | 0.557 | 44.053 | 12.837 | |

| 18 | 3.876 | 2.924 | 69.863 | 41.873 | |

| 7 | 19 | 3.477 | 1.050 | 28.638 | 6.713 |

| 20 | 3.372 | 0.575 | 29.593 | 8.090 | |

| 21 | 3.687 | 0.418 | 36.915 | 9.757 | |

| 8 | 22 | 9.727 | 1.212 | 86.030 | 8.190 |

| 23 | 11.363 | 3.984 | 84.576 | 28.040 | |

| 24 | 8.655 | 2.307 | 107.120 | 19.957 | |

| Ra, (μm) | 1.54 | 3.005 | 3.241 | 3.395 | 3.477 | 5.188 | 6.602 | 9.727 |

| Sample No. | 1 | 2 | 5 | 3 | 7 | 4 | 6 | 8 |

| Lh, (mm) | 0.1 | 0.1 | 0.2 | 0.1 | 0.2 | 0.1 | 0.2 | 0.2 |

| Vfeed, (mm/s) | 120 | 90 | 90 | 100 | 110 | 110 | 100 | 120 |

| n, (rpm) | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Vf, (mm/min) | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

| Tool No. 1 | Rotary burr | |||||||

| Ra, (μm) | 2.993 | 3.372 | 3.525 | 3.598 | 3.61 | 4.539 | 6.004 | 11.363 |

| Sample No. | 1 | 7 | 2 | 4 | 3 | 6 | 5 | 8 |

| Lh, (mm) | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.2 |

| Vfeed, (mm/s) | 120 | 110 | 90 | 110 | 100 | 100 | 90 | 120 |

| n, (rpm) | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Vf, (mm/min) | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

| Tool No. 2 | Single-edge spiral burr cutter | |||||||

| Ra, (μm) | 3.578 | 3.583 | 3.687 | 3.84 | 3.876 | 6.665 | 8.229 | 8.655 |

| Sample No. | 3 | 4 | 7 | 5 | 6 | 1 | 2 | 8 |

| Lh, (mm) | 0.1 | 0.1 | 0.2 | 0.2 | 0.2 | 0.1 | 0.1 | 0.2 |

| Vfeed, (mm/s) | 100 | 110 | 110 | 90 | 100 | 120 | 90 | 120 |

| n, (rpm) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Vf, (mm/min) | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Tool No. 3 | Spiral endmill | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jabłońska, M. Experimental Study on Hybrid Additive and Subtractive Manufacturing Processes for Improving Surface Quality. Materials 2025, 18, 3136. https://doi.org/10.3390/ma18133136

Jabłońska M. Experimental Study on Hybrid Additive and Subtractive Manufacturing Processes for Improving Surface Quality. Materials. 2025; 18(13):3136. https://doi.org/10.3390/ma18133136

Chicago/Turabian StyleJabłońska, Monika. 2025. "Experimental Study on Hybrid Additive and Subtractive Manufacturing Processes for Improving Surface Quality" Materials 18, no. 13: 3136. https://doi.org/10.3390/ma18133136

APA StyleJabłońska, M. (2025). Experimental Study on Hybrid Additive and Subtractive Manufacturing Processes for Improving Surface Quality. Materials, 18(13), 3136. https://doi.org/10.3390/ma18133136