Analysis of Selected Spark Plasma Sintering Parameters on the Mechanical Properties of Sintered X30Cr13 Steel

Abstract

1. Introduction

2. Purpose of Work

3. Research Material and Methods

- m1—dry sample mass,

- m3—mass of sample weighed above water after soaking,

- m4—mass of sample weighed in water after soaking,

- gw—water density, dependent on ambient temperature.

4. Analysis of Test Results

5. Conclusions

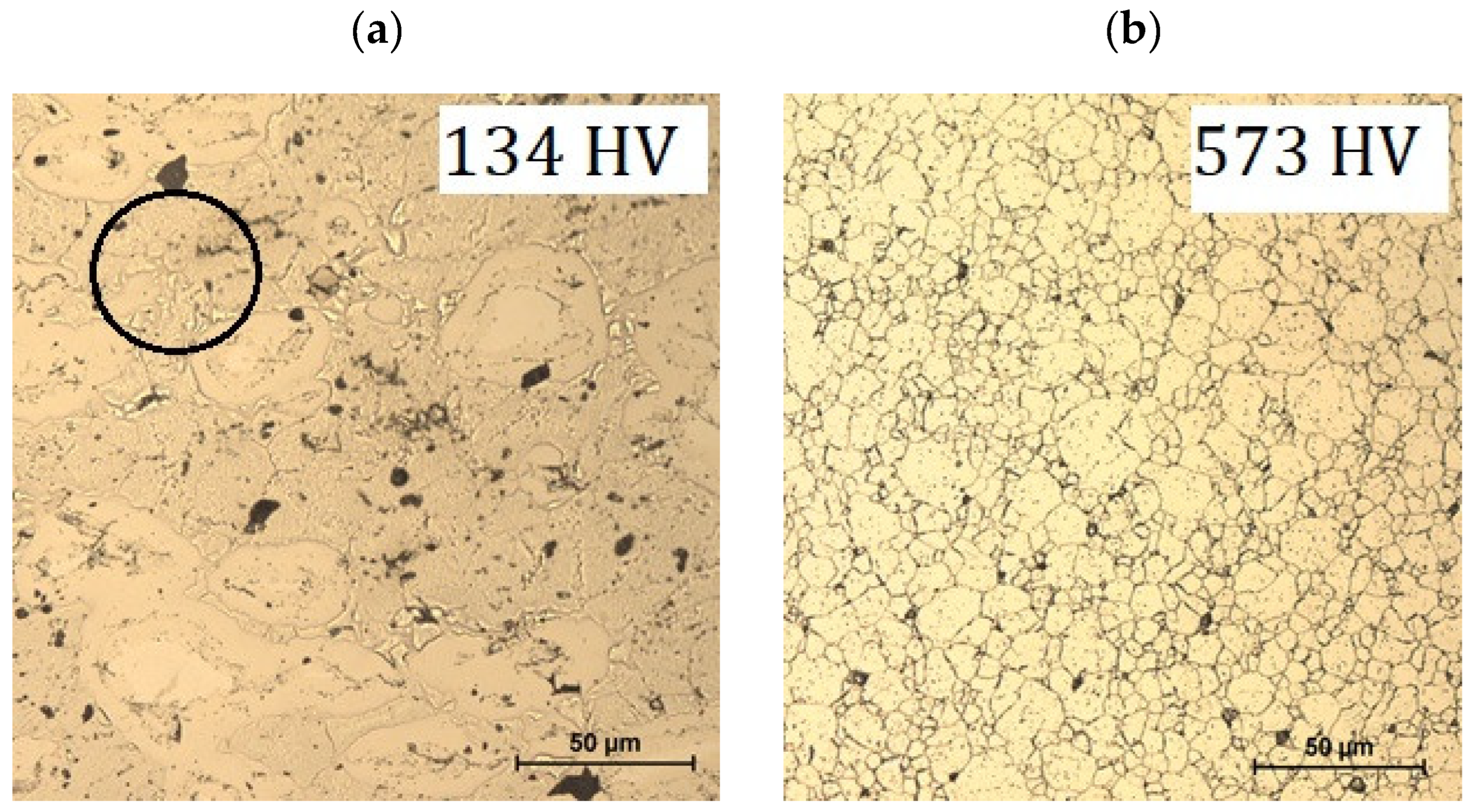

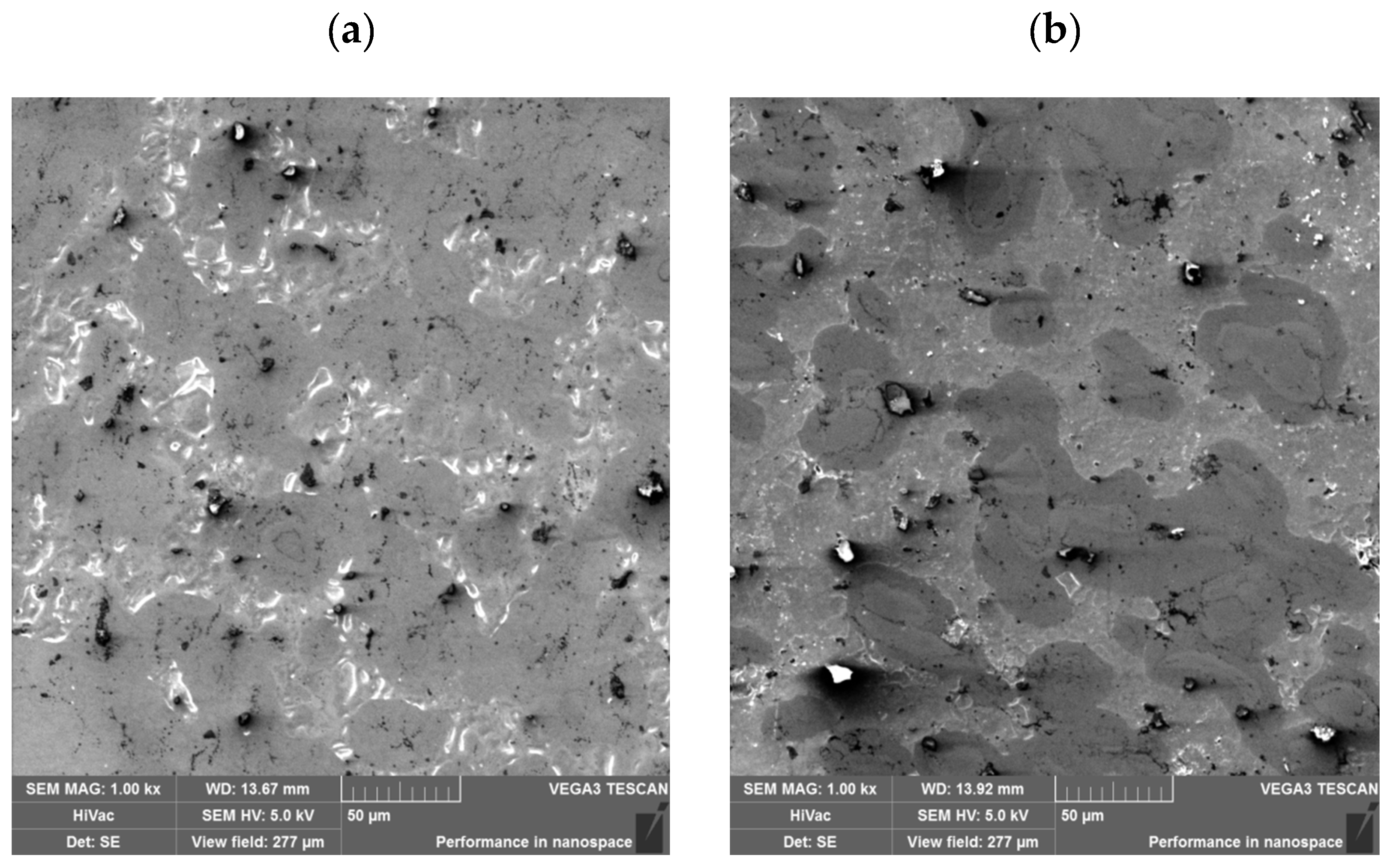

- The way the powder is prepared for the SPS sintering process as well as the grain size have a significant impact on the structure and mechanical properties of the final product.

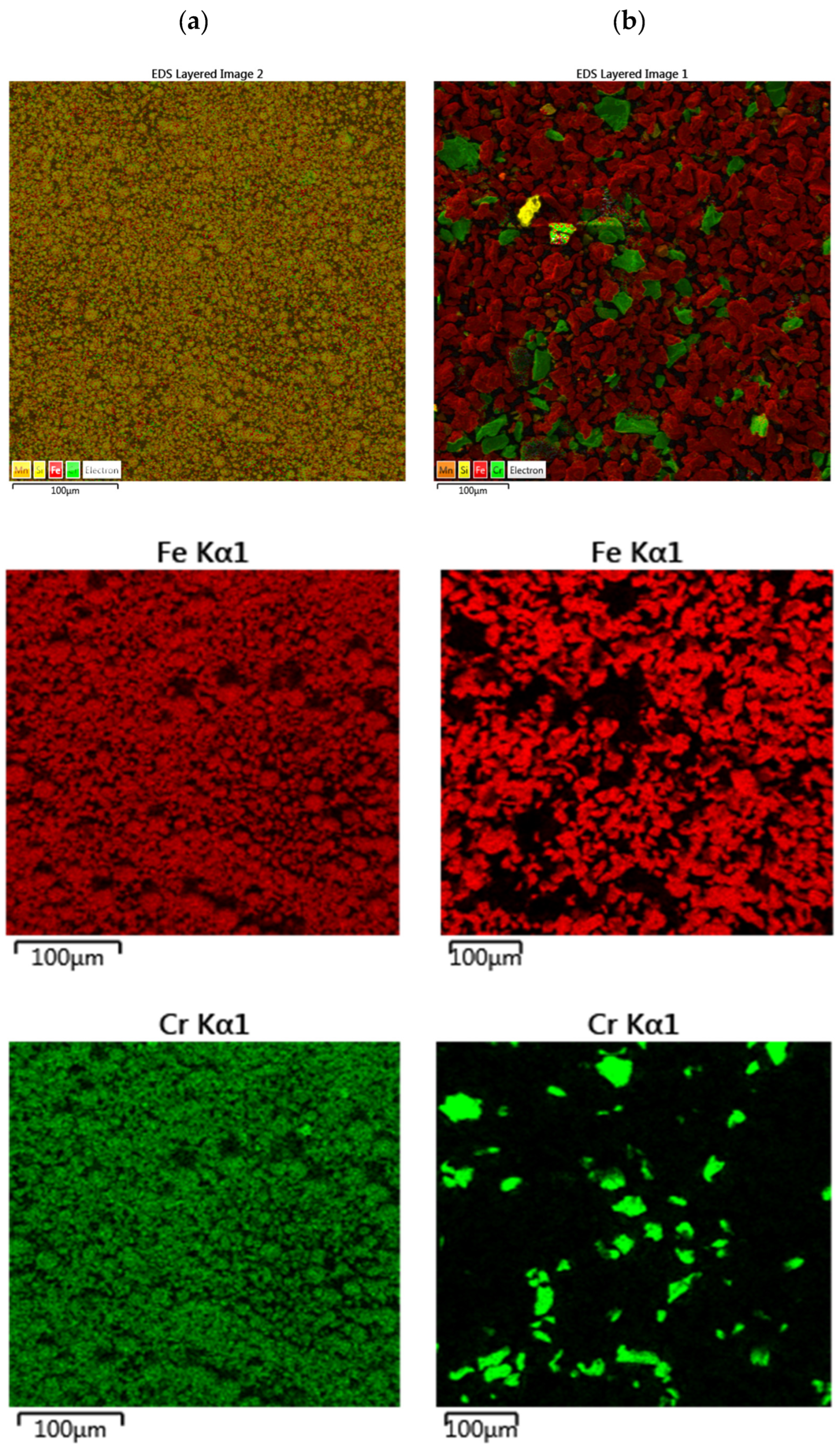

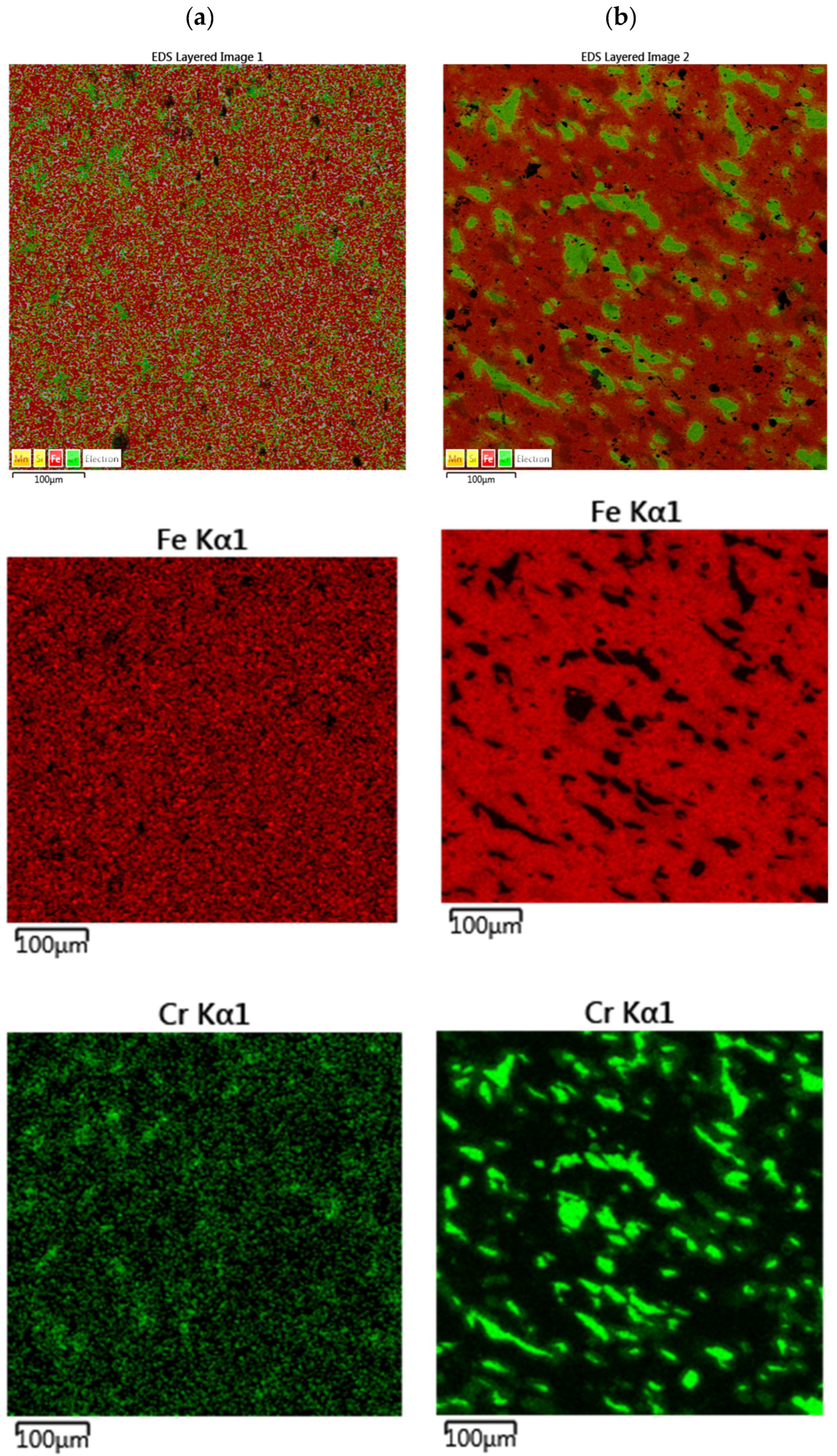

- The commercial blend, derived from steel produced using conventional metallurgical processes, exhibited a well-formed crystalline structure. The proprietary blend showed a non-uniform microstructure and local chemical inhomogeneities, which negatively affected the mechanical properties of the sintered samples.

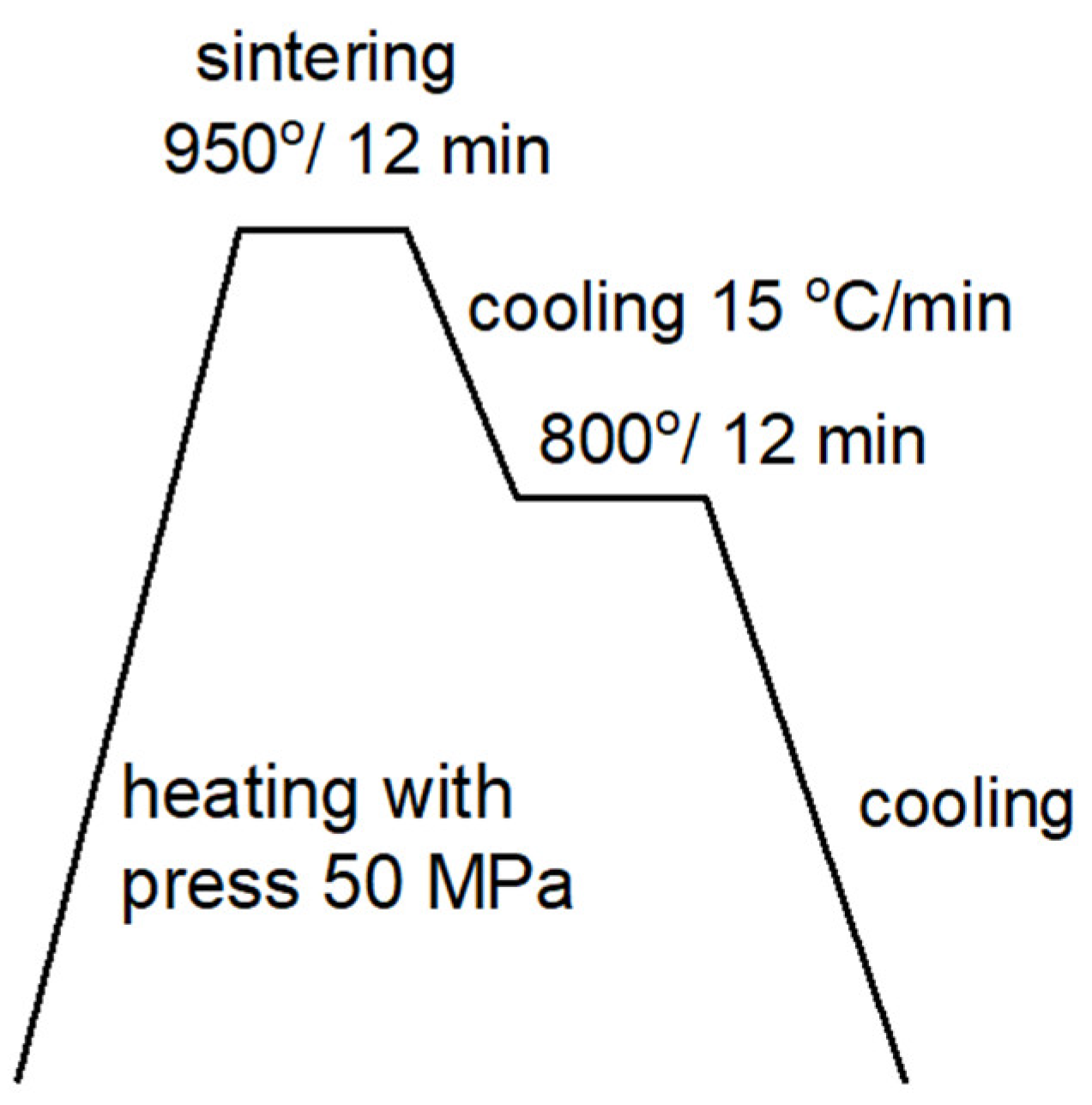

- The sintering temperature was selected based on density measurements of the obtained samples. The sintering time was the variable parameter, ranging from 10 to 14 min.

- The optimal sintering process parameters for the X30Cr13 steel are a sintering temperature of 950 °C and sintering time of 12 min.

- Additional heat treatment of the proprietary blend sample in the form of normalization at 1000 °C for 30 min resulted in a more uniform distribution of Cr in Fe and an increase in hardness by 30 HV.

- -

- The sintering powder can be sourced from waste material generated after processes of manufacturing finished products from the X30Cr13 steel.

- -

- The process time is reduced.

- -

- The waste associated with mechanical processing is eliminated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mainier, F.B. Corrosion in surgical instruments. IOSR J. Eng. 2013, 3, 25–31. [Google Scholar] [CrossRef]

- Marcuci, J.R.J.; De Souza, E.C.; Camilo, C.C.; Di Lorenzo, P.L.; Rollo, J.M.D.D.A. Corrosion and microstructural characterization of martensitic stainless steels submitted to industrial thermal processes for use in surgical tools. Rev. Bras. Eng. Biomed. 2014, 30, 257–264. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Y.; Chen, T.; Dong, C.; Zhang, K.; Bao, X. A short review of medical-grade stainless steel: Corrosion resistance and novel techniques. J. Mater. Res. Technol. 2024, 29, 2788–2798. [Google Scholar] [CrossRef]

- Kajzer, A.; Antonowicz, M.; Ziębowicz, B. Studies of the corrosion resistance properties of bone screws made from 316l stainless steel in ringer’s solution. Arch. Metall. Mater. 2018, 63, 323–328. [Google Scholar]

- Sultana, N.; Nishina, Y.; Nizami, M.Z.I. Surface Modifications of Medical Grade Stainless Steel. Coatings 2024, 14, 248. [Google Scholar] [CrossRef]

- Wachowicz, J.; Rosiński, M.; Mątewski, D. Unlimited possibilities of sintering by SPS. Mechanik 2016, 89, 1558–1560. [Google Scholar] [CrossRef]

- Omori, M. Sintering, consolidation, reaction and crystal growth by the spark plasma system (SPS). Mater. Sci. Eng. A 2000, 287, 183–188. [Google Scholar] [CrossRef]

- Mamedov, V. Spark plasma sintering as advanced PM sintering method. Powder Metall. 2002, 45, 322–328. [Google Scholar] [CrossRef]

- Munir, Z.A.; Ohyanagi, M. Perspectives on the spark plasma sintering process. J. Mater. Sci. 2021, 56, 1–15. [Google Scholar] [CrossRef]

- Hulbert, D.M.; Anders, A.; Andersson, J.; Lavernia, E.J.; Mukherjee, A.K. A discussion on the absence of plasma in spark plasma sintering. Scr. Mater. 2009, 60, 835–838. [Google Scholar] [CrossRef]

- Xu, P.; Pan, Y.; Sun, Q.; Fan, Z.; Liu, A.; Xie, S.; Huang, L. Densification, grain growth, and mechanical properties of titanium carbide ceramics. Int. J. Appl. Ceram. Technol. 2025, 22, e15100. [Google Scholar] [CrossRef]

- Khosravi Zeydabadi, R.; Sobhani, M. Enhanced properties of the Cu-10 wt% graphite composites by two-step spark plasma sintering method at the presence of Al addition. Results Mater. 2025, 26, 100686. [Google Scholar] [CrossRef]

- Le Cloarec, J.; Marinel, S.; Estournès, C.; Dehmas, M.; Manière, C. Ti–6Al–4V complex shape production by spark plasma sintering with ceramic–metal sacrificial powder and interface 3D printing. Prog. Addit. Manuf. 2024, 10, 3321–3334. [Google Scholar] [CrossRef]

- Garbiec, D. Iskrowe spiekanie plazmowe (SPS): Teoria i praktyka. Inżynieria Mater. 2015, 1, 10–14. [Google Scholar] [CrossRef]

- Shang, X.; Lin, Y.; Hou, K.; Zhong, Y.; Cao, C. Effects of spark plasma sintering parameters on sintering mechanism of yttrium hydride. J. Mater. Sci. Technol. 2025, 229, 106–115. [Google Scholar] [CrossRef]

- Kelly, J.P.; Graeve, O.A. Spark Plasma Sintering as an Approach to Manufacture Bulk Materials: Feasibility and Cost Savings. JOM 2015, 67, 29–33. [Google Scholar] [CrossRef]

- Pellizzari, M.; Fedrizzi, A.; Zadra, M. Influence of processing parameters and particle size on the properties of hot work and high speed tool steels by Spark Plasma Sintering. Mater. Des. 2011, 32, 1796–1805. [Google Scholar] [CrossRef]

- Deirmina, F.; Pellizzari, M. Strengthening mechanisms in an ultrafine grained powder metallurgical hot work tool steel produced by high energy mechanical milling and spark plasma sintering. Mater. Sci. Eng. A 2019, 743, 349–360. [Google Scholar] [CrossRef]

- Hu, Q.; Wang, M.; Chen, Y.; Si, Z.; Zhang, D. Effects of sintering temperatures on the microstructure and mechanical properties of S390 powder metallurgy high-speed steel. Front. Mater. 2023, 10, 1198776. [Google Scholar] [CrossRef]

- Pellizzari, M.; Fedrizzi, A.; Zadra, M. Spark Plasma co-Sintering of hot work and high speed steel powders for fabrication of a novel tool steel with composite microstructure. Powder Technol. 2011, 214, 292–299. [Google Scholar] [CrossRef]

- Ozhmegov, K.; Kawalek, A.; Garbiec, D.; Dyja, H.; Arbuz, A. Development of alternative method for manufacturing structural zirconium elements for nuclear engineering. Materials 2021, 14, 5006. [Google Scholar] [CrossRef] [PubMed]

- Kawalek, A.; Ozhmegov, K.; Garbiec, D.; Dyja, H.; Arbuz, A. Development of an Alternative Manufacturing Technology for Niobium Components. Materials 2024, 17, 3093. [Google Scholar] [CrossRef]

- Jame, M.S.R.; Ravi Chandran, K.S. Effect of spark plasma sintering on alloying, densification and mechanical properties of C103 niobium alloy. Mater. Sci. Eng. A 2025, 932, 148249. [Google Scholar] [CrossRef]

- Libardi, S.; Zadra, M.; Casari, F.; Molinari, A. Mechanical properties of nanostructured and ultrafine-grained iron alloys produced by spark plasma sintering of ball milled powders. Mater. Sci. Eng. A 2008, 478, 243–250. [Google Scholar] [CrossRef]

- Dadé, M.; Malaplate, J.; Garnier, J.; De Geuser, F.; Barcelo, F.; Wident, P.; Deschamps, A. Influence of microstructural parameters on the mechanical properties of oxide dispersion strengthened Fe-14Cr steels. Acta Mater. 2017, 127, 165–177. [Google Scholar] [CrossRef]

- Steckmeyer, A.; Praud, M.; Fournier, B.; Malaplate, J.; Garnier, J.; Béchade, J.L.; Tournié, I.; Tancray, A.; Bougault, A.; Bonnaillie, P. Tensile properties and deformation mechanisms of a 14Cr ODS ferritic steel. J. Nucl. Mater. 2010, 405, 95–100. [Google Scholar] [CrossRef]

- Fournier, B.; Steckmeyer, A.; Rouffie, A.L.; Malaplate, J.; Garnier, J.; Ratti, M.; Wident, P.; Ziolek, L.; Tournie, I.; Rabeau, V.; et al. Mechanical behaviour of ferritic ODS steels-Temperature dependancy and anisotropy. J. Nucl. Mater. 2012, 430, 142–149. [Google Scholar] [CrossRef]

- Hilger, I.; Boulnat, X.; Hoffmann, J.; Testani, C.; Bergner, F.; De Carlan, Y.; Ferraro, F.; Ulbricht, A. Fabrication and characterization of oxide dispersion strengthened (ODS) 14Cr steels consolidated by means of hot isostatic pressing, hot extrusion and spark plasma sintering. J. Nucl. Mater. 2016, 472, 206–214. [Google Scholar] [CrossRef]

- Pandey, A.; Jayasankar, K.; Parida, P.; Debata, M.; Mishra, B.K.; Saroja, S. Optimization of milling parameters, processing and characterization of nano-crystalline oxide dispersion strengthened ferritic steel. Powder Technol. 2014, 262, 162–169. [Google Scholar] [CrossRef]

- Li, Z.; Lu, Z.; Xie, R.; Lu, C.; Liu, C. Effect of spark plasma sintering temperature on microstructure and mechanical properties of 14Cr-ODS ferritic steels. Mater. Sci. Eng. A 2016, 660, 52–60. [Google Scholar] [CrossRef]

- Pasebani, S.; Charit, I. Effect of alloying elements on the microstructure and mechanical properties of nanostructured ferritic steels produced by spark plasma sintering. J. Alloys Compd. 2014, 599, 206–211. [Google Scholar] [CrossRef]

- Kale, A.B.; Kim, B.K.; Kim, D.I.; Castle, E.G.; Reece, M.; Choi, S.H. An investigation of the corrosion behavior of 316L stainless steel fabricated by SLM and SPS techniques. Mater. Charact. 2020, 163, 110204. [Google Scholar] [CrossRef]

- Flipon, B.; Keller, C.; de la Cruz, L.G.; Hug, E.; Barbe, F. Tensile properties of spark plasma sintered AISI 316L stainless steel with unimodal and bimodal grain size distributions. Mater. Sci. Eng. A 2018, 729, 249–256. [Google Scholar] [CrossRef]

- Jenei, P.; Balázsi, C.; Horváth, Á.; Balázsi, K.; Gubicza, J. The influence of carbon nanotube addition on the phase composition, microstructure and mechanical properties of 316L stainless steel consolidated by spark plasma sintering. J. Mater. Res. Technol. 2019, 8, 1141–1149. [Google Scholar] [CrossRef]

- Wu, H.; Deng, L.; Pan, X.; Wang, B.; Xiang, H. Study on the microstructure, properties and strengthening mechanisms of electrophoretic deposited carbon-nanotubes/Cu composites. Mater. Charact. 2025, 221, 114786. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, R.B. Development of Low-Density Steel Nanocomposite Using Mechanical Alloying Followed by Spark Plasma Sintering. J. Mater. Eng. Perform. 2025, 34, 8904–8916. [Google Scholar] [CrossRef]

- Obadele, B.A.; Adesina, O.S.; Oladijo, O.P.; Ogunmuyiwa, E.N. Fabrication of functionally graded 316L austenitic and 2205 duplex stainless steels by spark plasma sintering. J. Alloys Compd. 2020, 849, 156697. [Google Scholar] [CrossRef]

- EN 10088-1:2014; Stainless steels—Part 1: List of Stainless Steels. European Committee for Standardization: Brussels, Belgium, 2014.

- ISO 2738:2001; Sintered Metal Materials, Excluding Hardmetals—Permeable Sintered Metal Materials—Determination of Density, Oil Content and Open Porosity. ISO: Genève, Switzerland, 2001.

- EN 10088-2:2014; Stainless Steels—Part 2: Technical Delivery Conditions for Sheet/Plate and Strip of Corrosion Resisting Steels for General Purposes. European Committee for Standardization: Brussels, Belgium, 2014.

| Blend | C | Cr | Mn | Si | Fe |

|---|---|---|---|---|---|

| Proprietary | 0.31 | 14 | 0.6 | 0.5 | 84.59 |

| Commercial | 0.35 | 14 | 1.0 | 1.0 | 83.65 |

| X30Cr13 | 0.26–0.35 | 12–14 | <1.5 | <1 | rest |

| Sintering Time, min | Sintering Temperature, °C | Density g/cm3 |

|---|---|---|

| 10 | 900 | 7.34 |

| 10 | 950 | 7.36 |

| 10 | 1000 | 7.36 |

| Sintering Temperature, °C | Sintering Time, min | Pressure of Sintering/ Pressing, MPa | Atmosphere |

|---|---|---|---|

| 950 | 10 | 50 | Vacuum |

| 950 | 12 | 50 | Vacuum |

| 950 | 14 | 50 | Vacuum |

| Sintering Time, min | Commercial Blend | Proprietary Blend |

|---|---|---|

| Density, g/cm3 (Relative) | ||

| 10 | 7.647 (0.97) | 7.366 (0.93) |

| 12 | 7.659 (0.97) | 7.386 (0.93) |

| 14 | 7.674 (0.97) | 7.448 (0.94) |

| Sample | HV Hardness | |

|---|---|---|

| 1. | From a commercial blend | 556 ± 20.9 |

| 2. | From a proprietary blend | 141.33 ± 5.9 |

| 3. | From a proprietary blend after normalization | 174.1 ± 4.5 |

| 4. | After sintering with additional annealing | 133.8 ± 2.3 |

| 5. | X30Cr13 according to standard [40] | 235 (annealed) |

| 450–550 (quenched and tempered) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulakowska, A.; Bajor, T.; Kawalek, A. Analysis of Selected Spark Plasma Sintering Parameters on the Mechanical Properties of Sintered X30Cr13 Steel. Materials 2025, 18, 3084. https://doi.org/10.3390/ma18133084

Kulakowska A, Bajor T, Kawalek A. Analysis of Selected Spark Plasma Sintering Parameters on the Mechanical Properties of Sintered X30Cr13 Steel. Materials. 2025; 18(13):3084. https://doi.org/10.3390/ma18133084

Chicago/Turabian StyleKulakowska, Anna, Teresa Bajor, and Anna Kawalek. 2025. "Analysis of Selected Spark Plasma Sintering Parameters on the Mechanical Properties of Sintered X30Cr13 Steel" Materials 18, no. 13: 3084. https://doi.org/10.3390/ma18133084

APA StyleKulakowska, A., Bajor, T., & Kawalek, A. (2025). Analysis of Selected Spark Plasma Sintering Parameters on the Mechanical Properties of Sintered X30Cr13 Steel. Materials, 18(13), 3084. https://doi.org/10.3390/ma18133084