The Influence of Various Chemical Modifications of Sheep Wool Fibers on the Long-Term Mechanical Properties of Sheep Wool/PLA Biocomposites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Raw Materials

2.2. Preparation of Materials and Raw Materials

- Denaturation of wool proteins under the influence of 5% HNO3 (200 mL solution per 10 g of wool—xanthoproteic reaction);

- Incorporation of iron atoms into peptide chains, under the influence of iron and its salts (FeCl2)—4.5 g FeCl2 along with 4.5 g Fe per 200 mL H2O;

- Incorporation of cyclic hydrocarbons into peptide chains, under the influence of tar (wood tar)—10 g of wool immersed in a solution of 10 g tar in 200 mL methanol.

2.3. Method of Producing PLA/Wool Fiber Biocomposite Samples

- Modification/drying of the modifier;

- Drying of PLA granules;

- Compounding (mixing) of the modifier with the PLA matrix in a short twin-screw extruder L/D 25:Section I—PLA feed 170 °C melting PLA (water-cooled feed), Section II—170 °C (side feed of sheep wool), Section III—175 °C (mixing and homogenization), Section IV—180 °C (regranulation), with a compound speed of 100 rpm;

- Filling the injection chamber (chamber temperature of 215 °C for pure polylactide, reduced to 180 °C for composites with wool addition) with granulate (4.0 g) (4 min of melting PLA/sheep wool mass);

- Placing the chamber in the axis of the piston with the mold (mold temperature 80 °C) (using a mold temperature of 80 °C in PLA/sheep wool composite research is fully justified because it optimizes crystallinity, mechanical properties, and interfacial adhesion by leveraging the nucleating effect of wool fibers, in line with literature recommendations for natural fiber-reinforced PLA);

- Starting extrusion with 10 kilo Newtons of force for 10 s;

- Removing the finished sample from the mold.

2.4. Types of PLA/Wool Fiber Biocomposite Samples Tested

- Control sample: pure PLA;

- Control sample: PLA matrix/modifier unmodified sheep wool;

- Experimental sample: PLA matrix/modifier modified wool (with tar)—5% reinforcement;

- Experimental sample: PLA matrix/modifier modified wool (with tar)—15% reinforcement;

- Experimental sample: PLA matrix/modifier modified wool (with iron and iron chloride)—5% reinforcement;

- Experimental sample: PLA matrix/modifier modified wool (with iron and iron chloride)—15% reinforcement;

- Experimental sample: PLA matrix/modifier modified wool (with HNO3)—5% reinforcement;

- Experimental sample: PLA matrix/modifier modified wool (with HNO3)—15% reinforcement.

2.5. Method of Aging Biocomposite Samples

2.6. Research Methods

3. Results

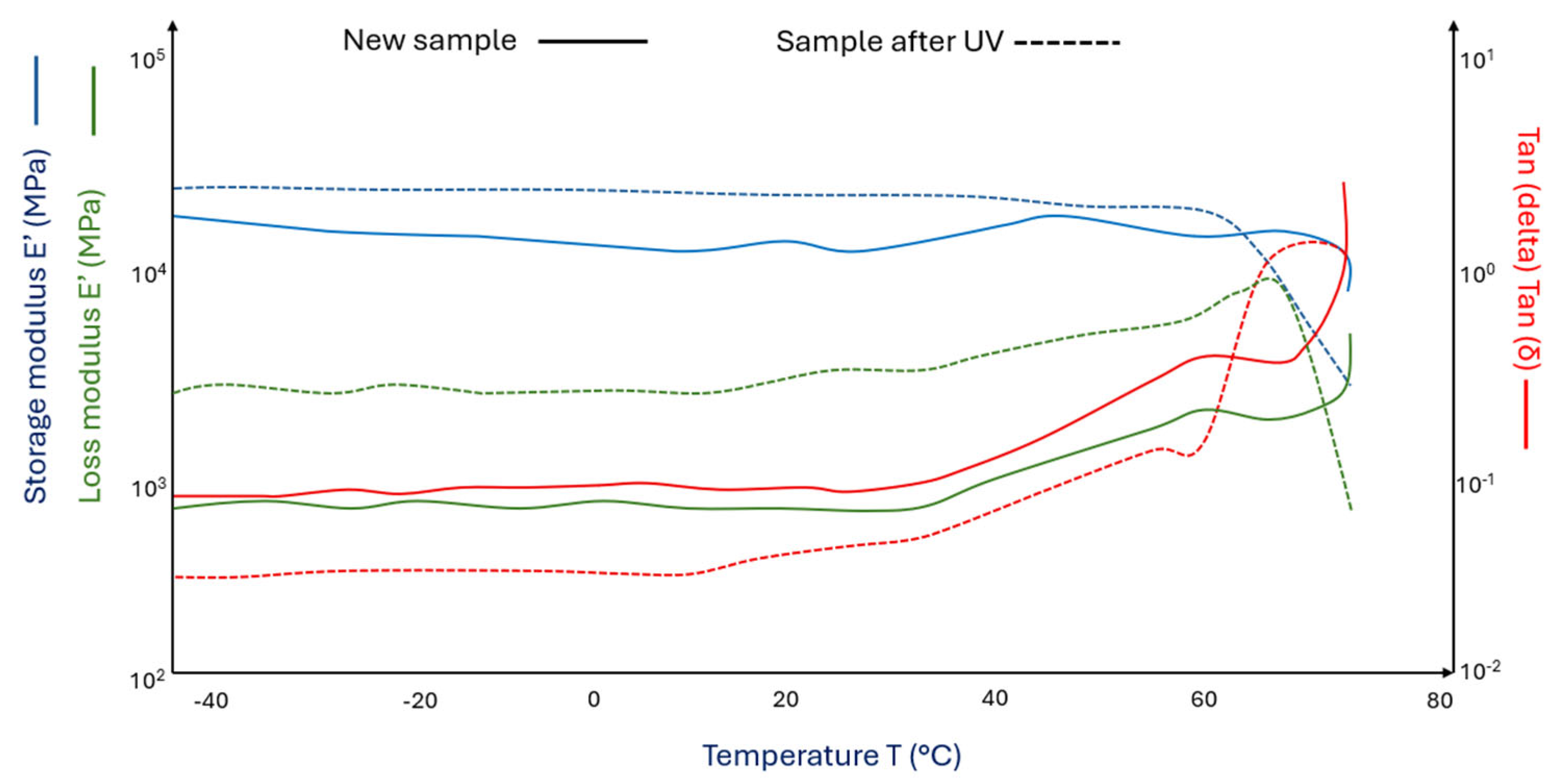

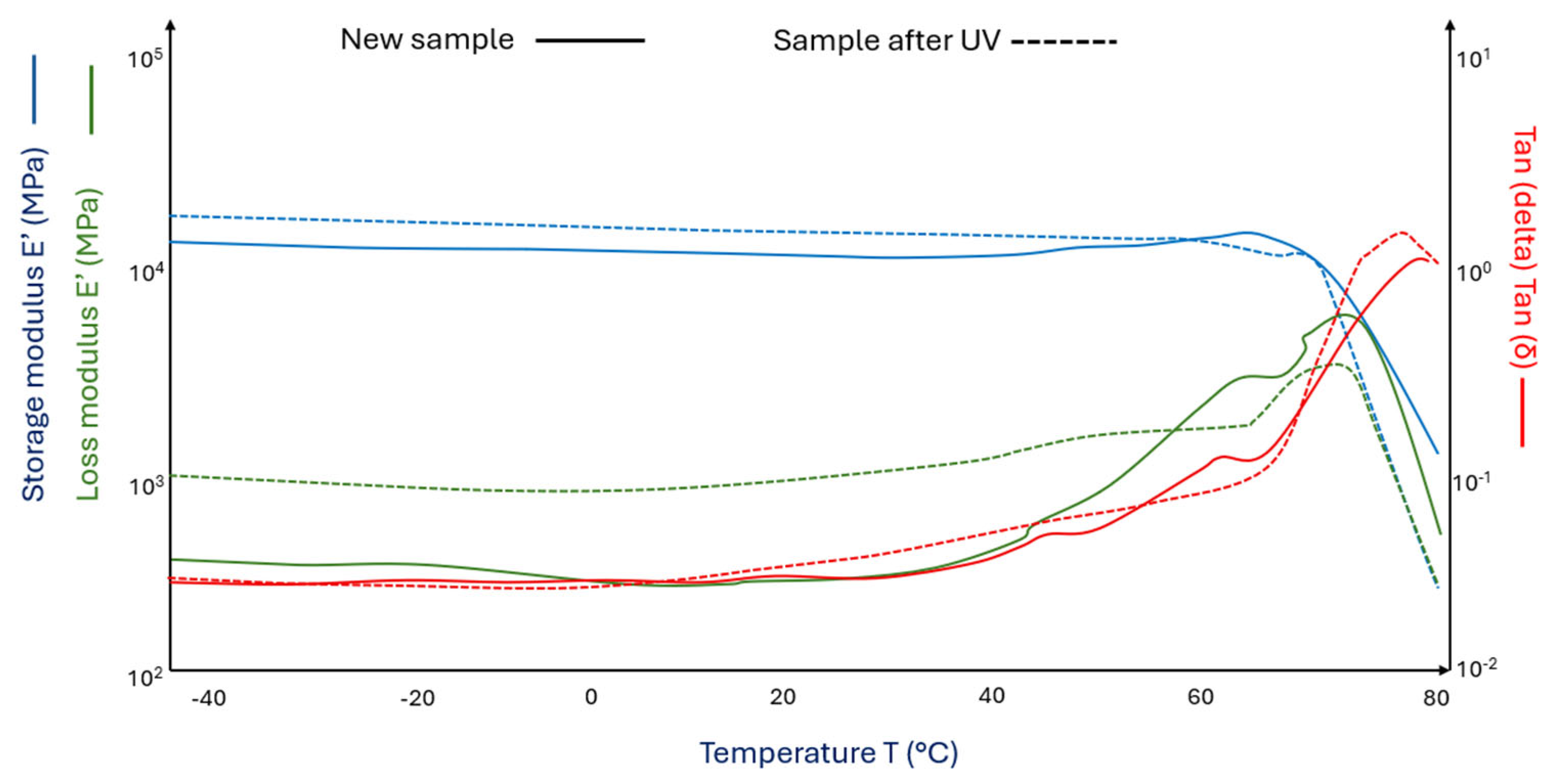

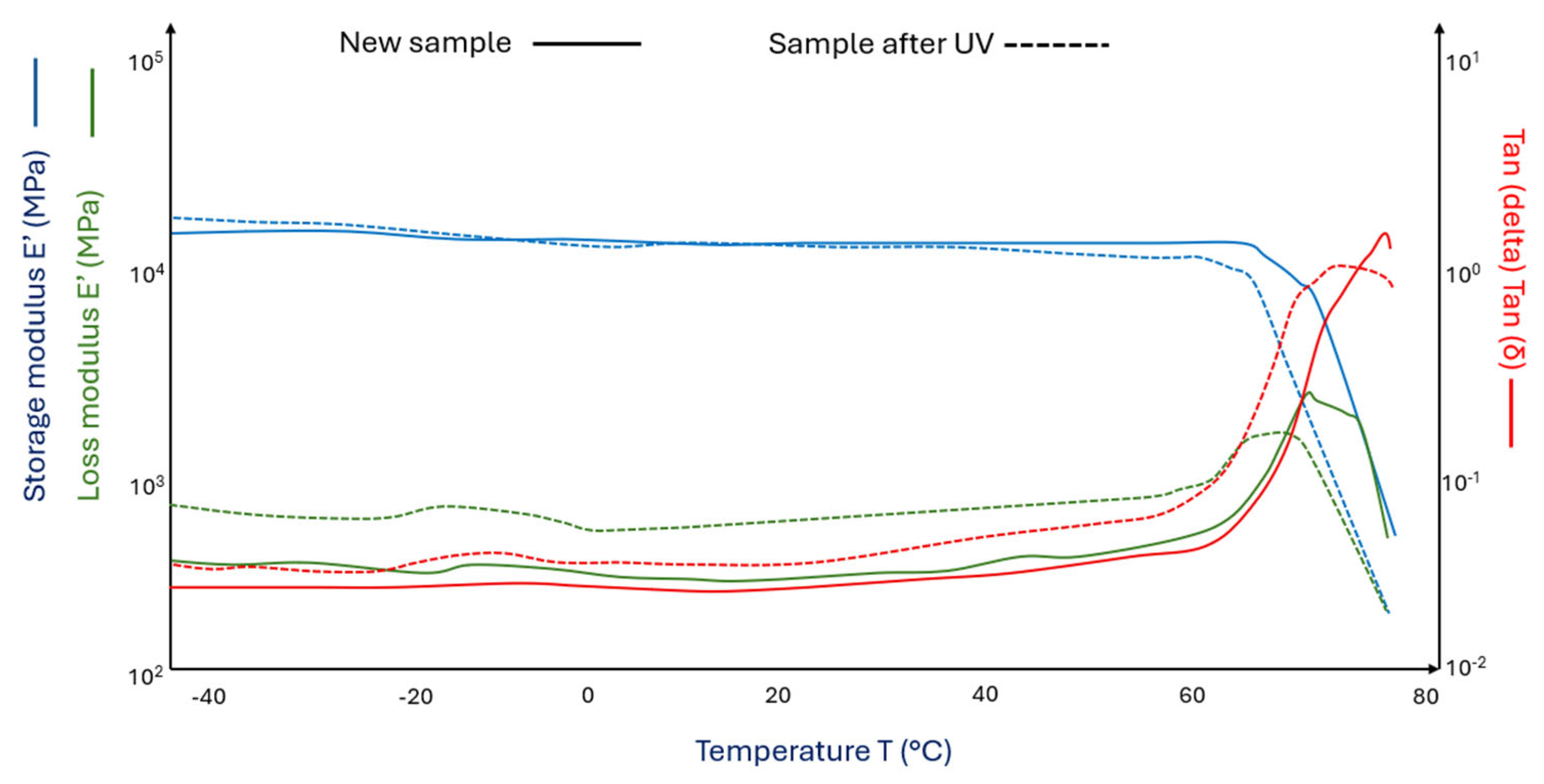

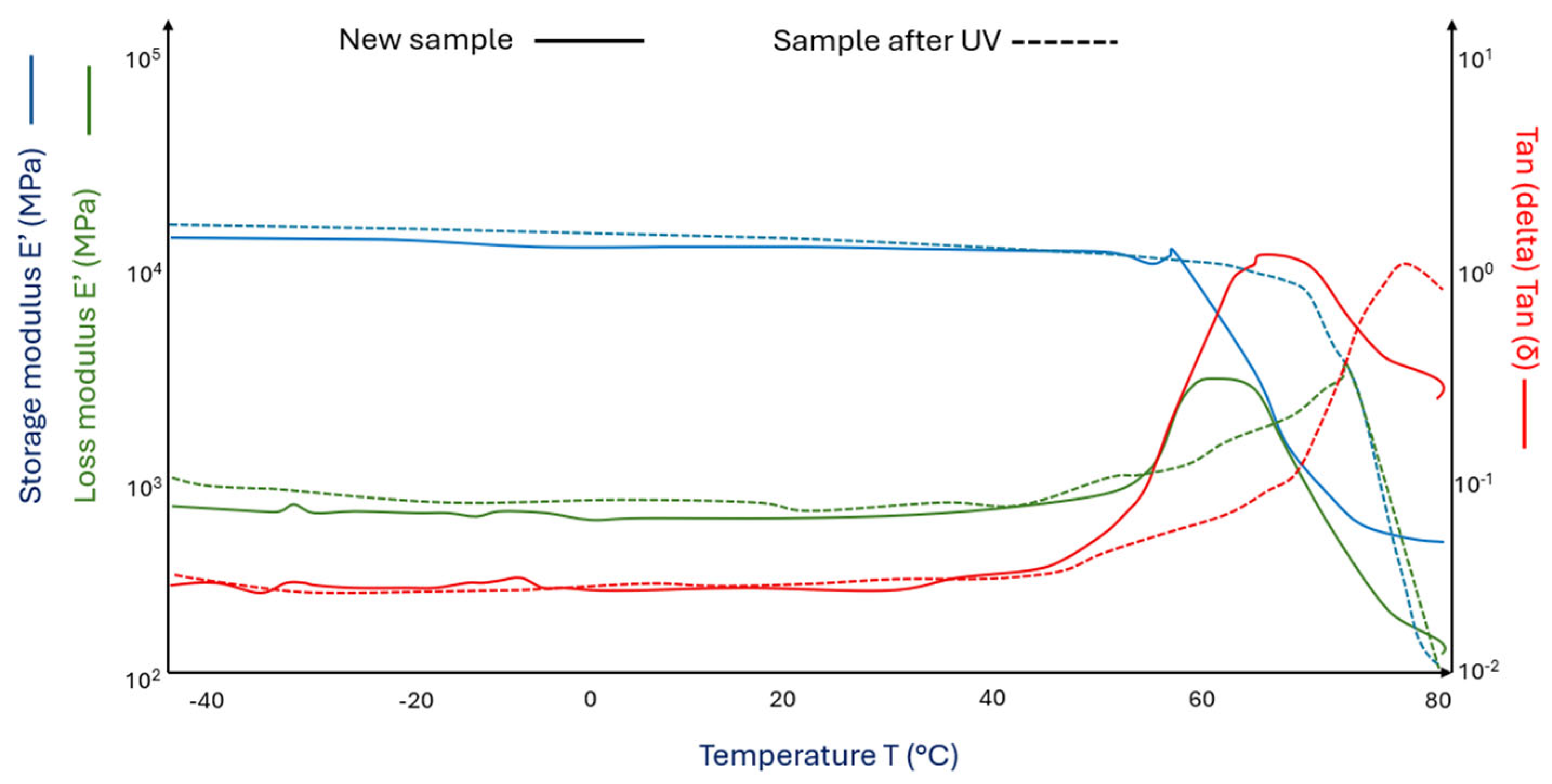

3.1. DMA Test Results

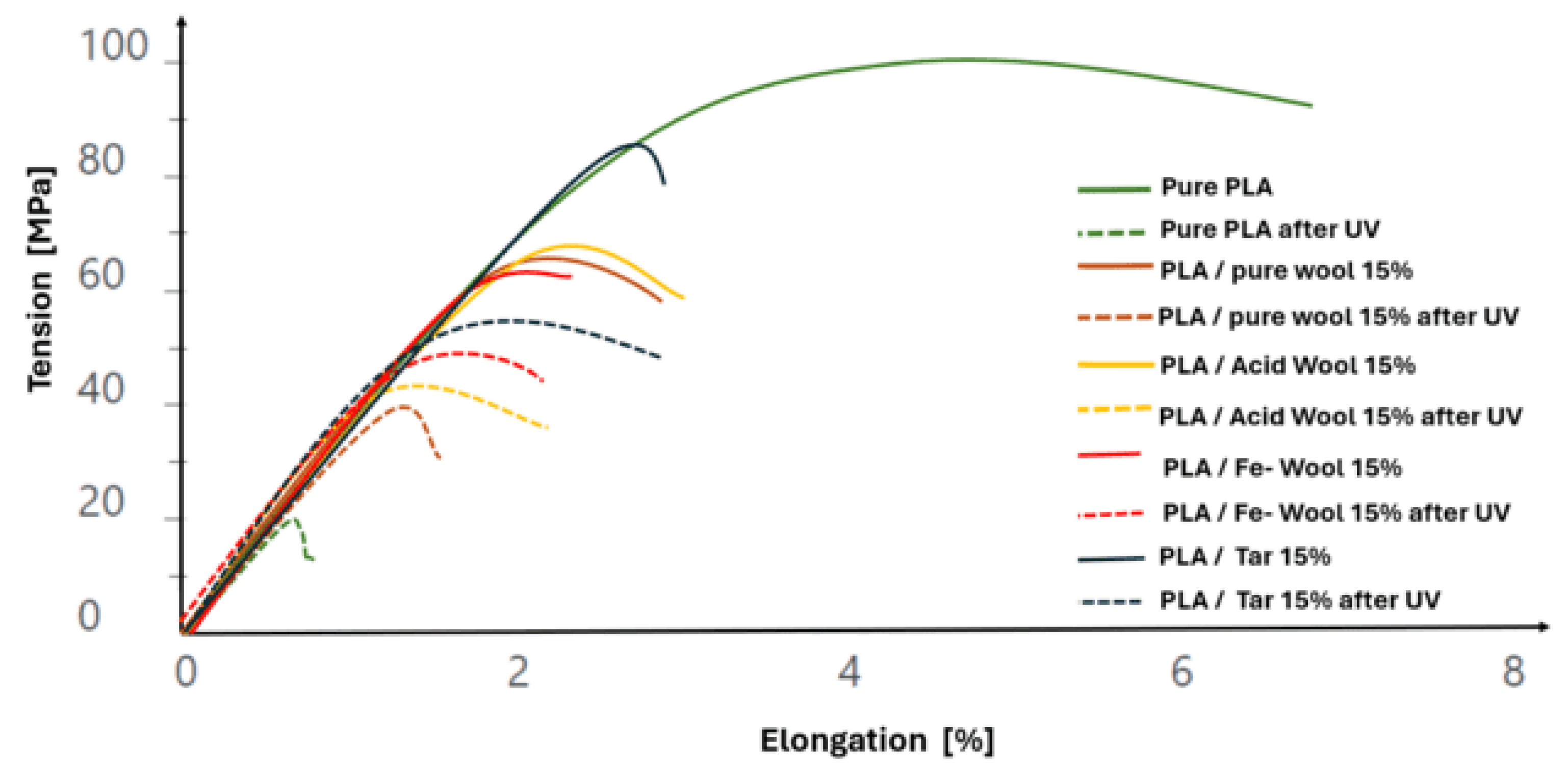

3.2. Results of Flexural Strength Tests

3.3. Density Results and Analysis

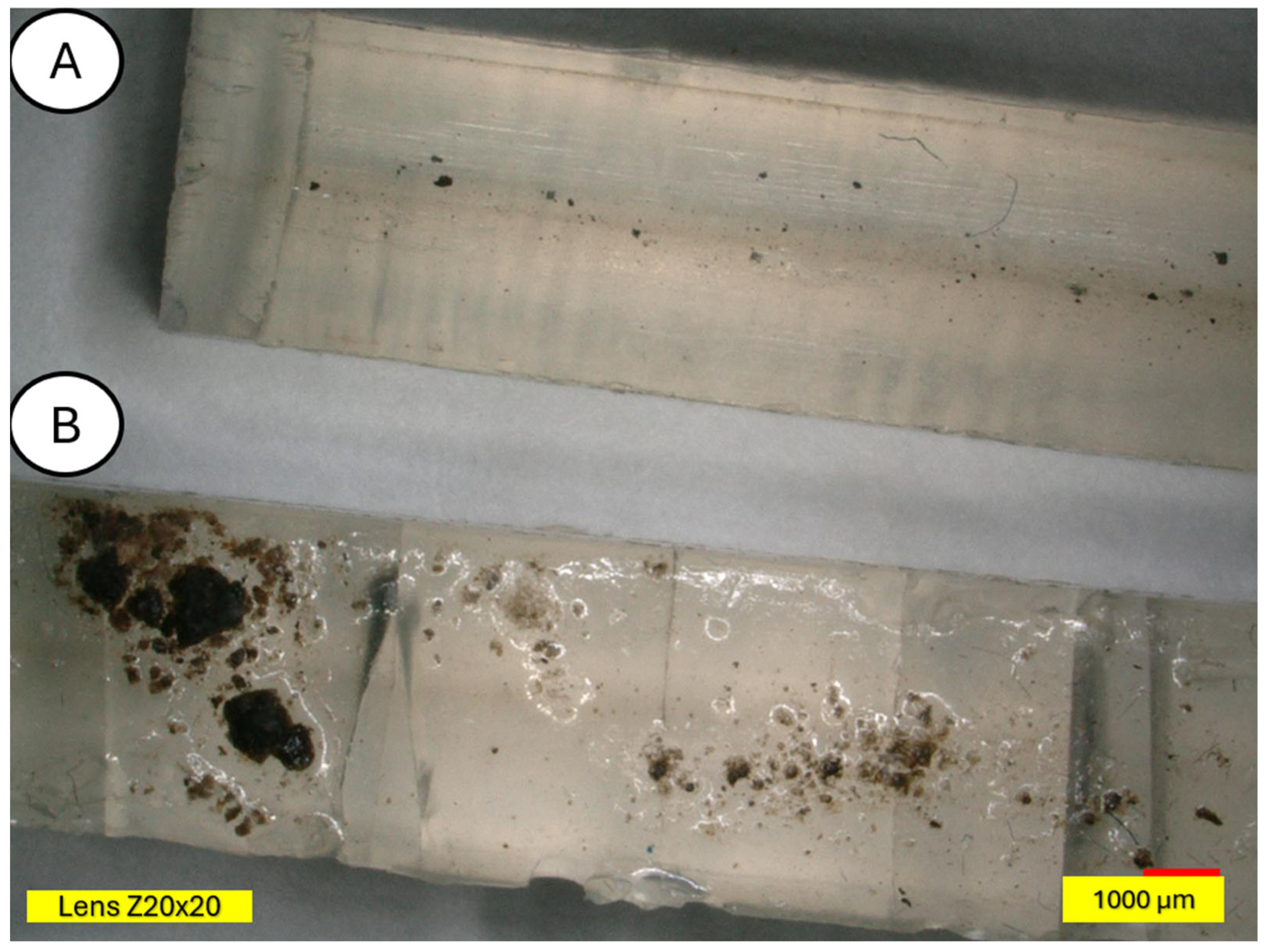

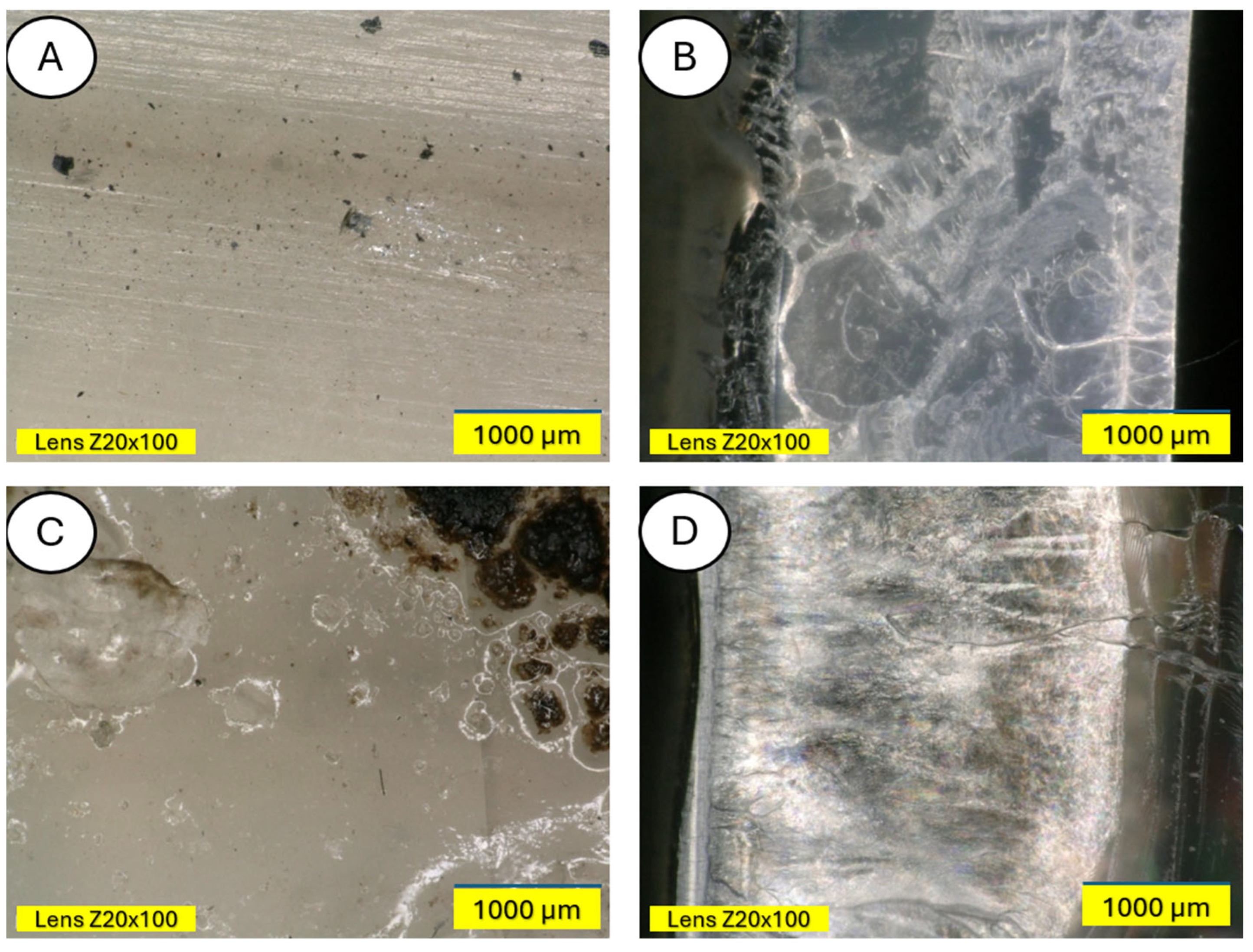

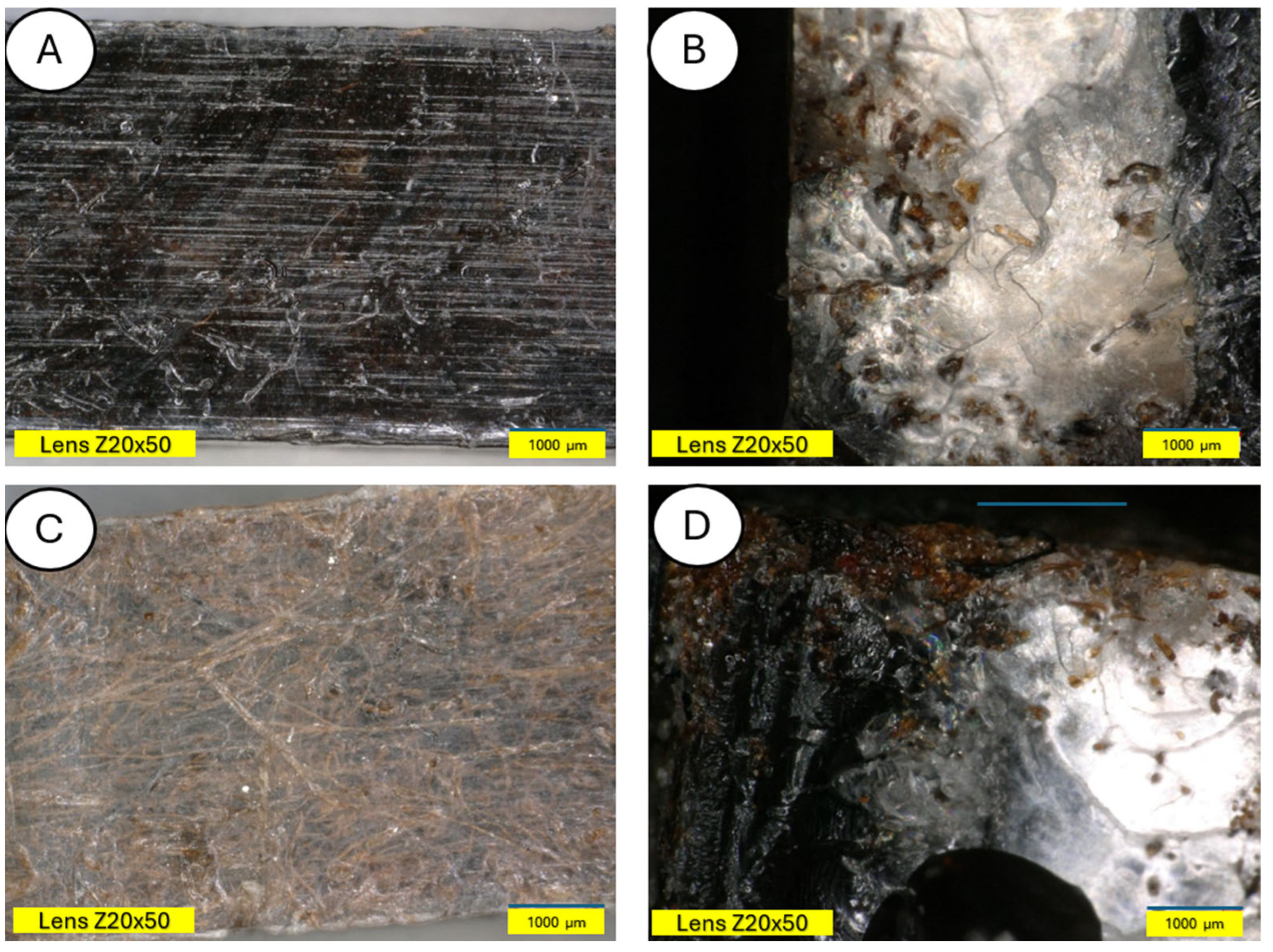

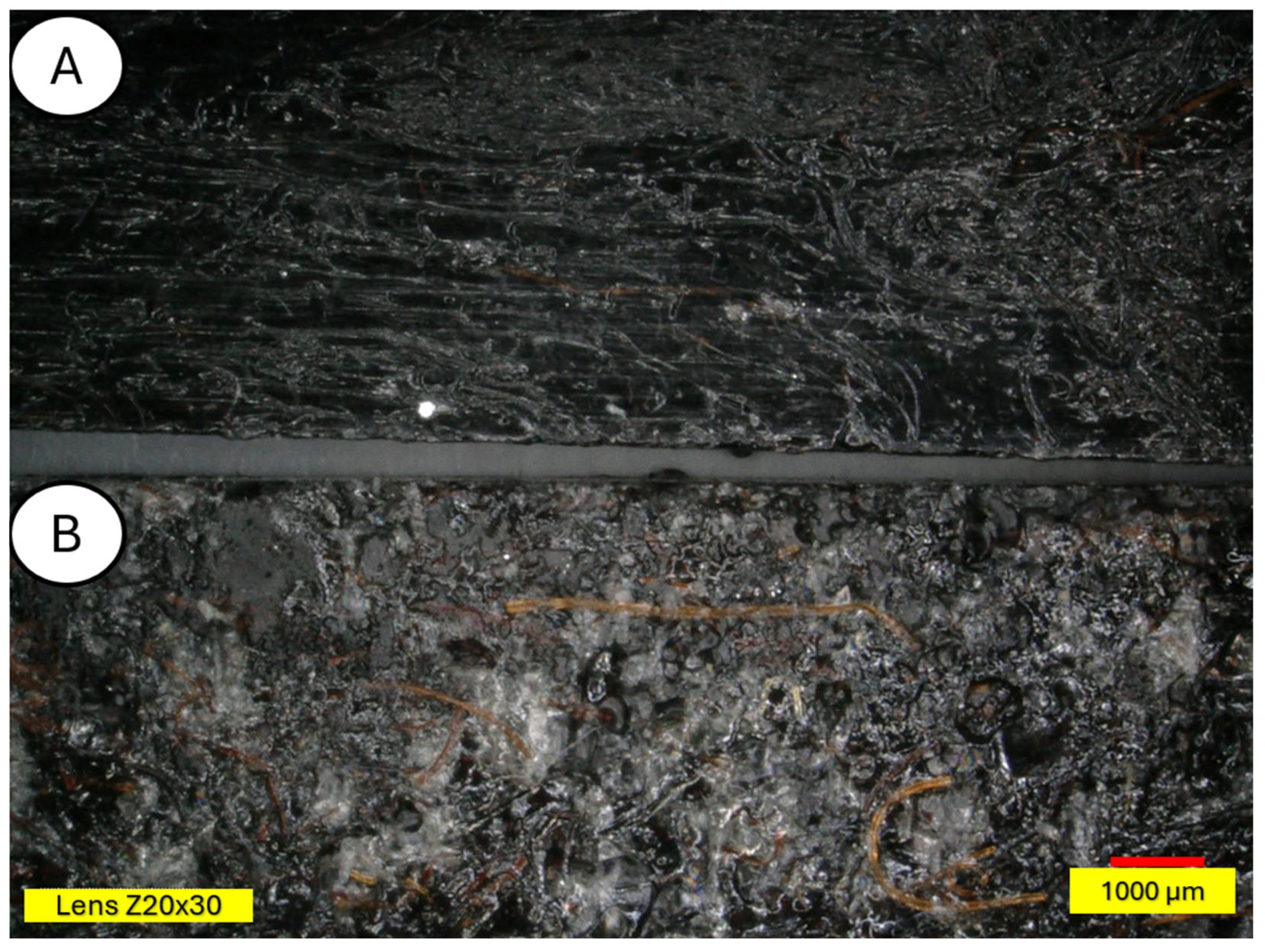

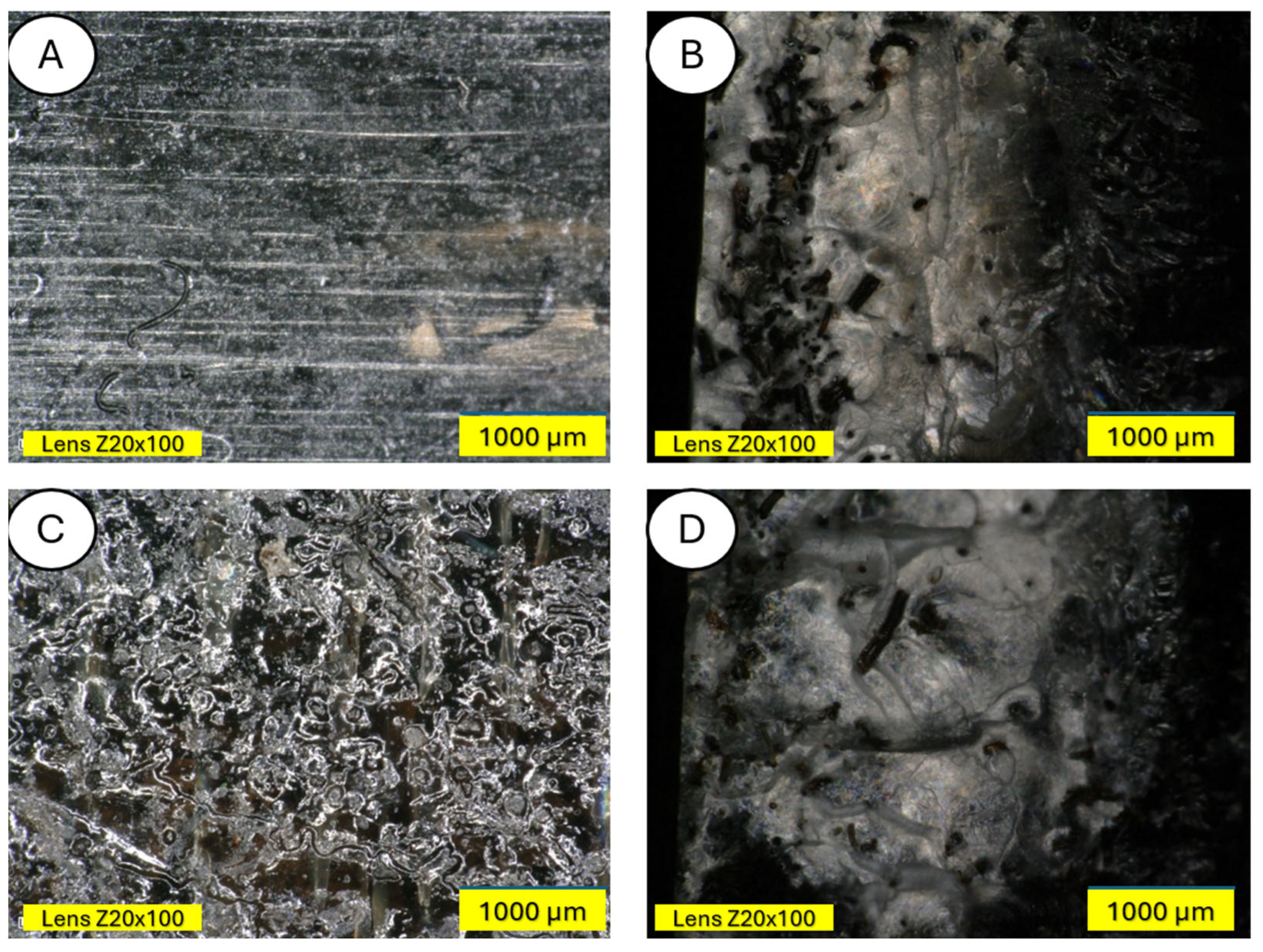

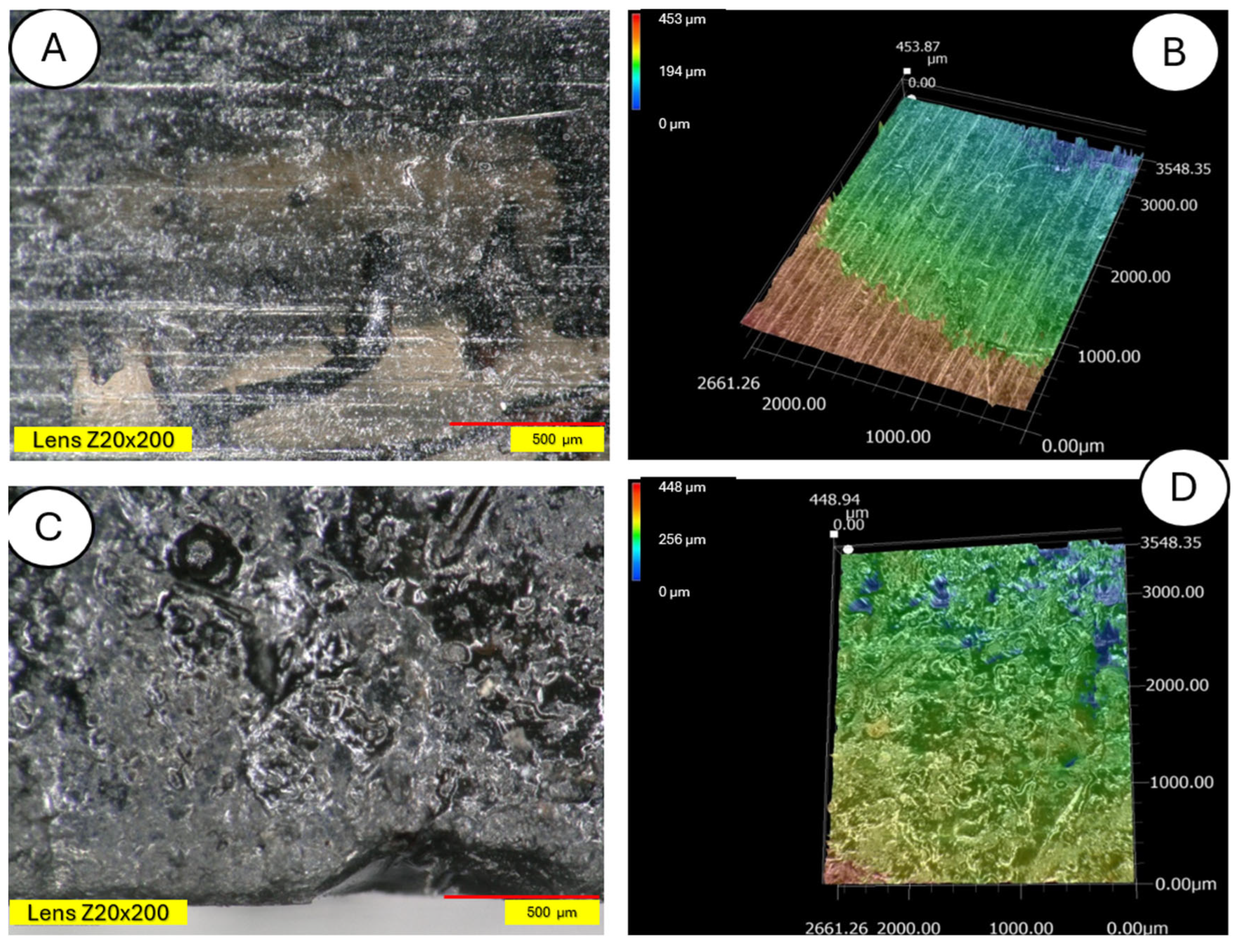

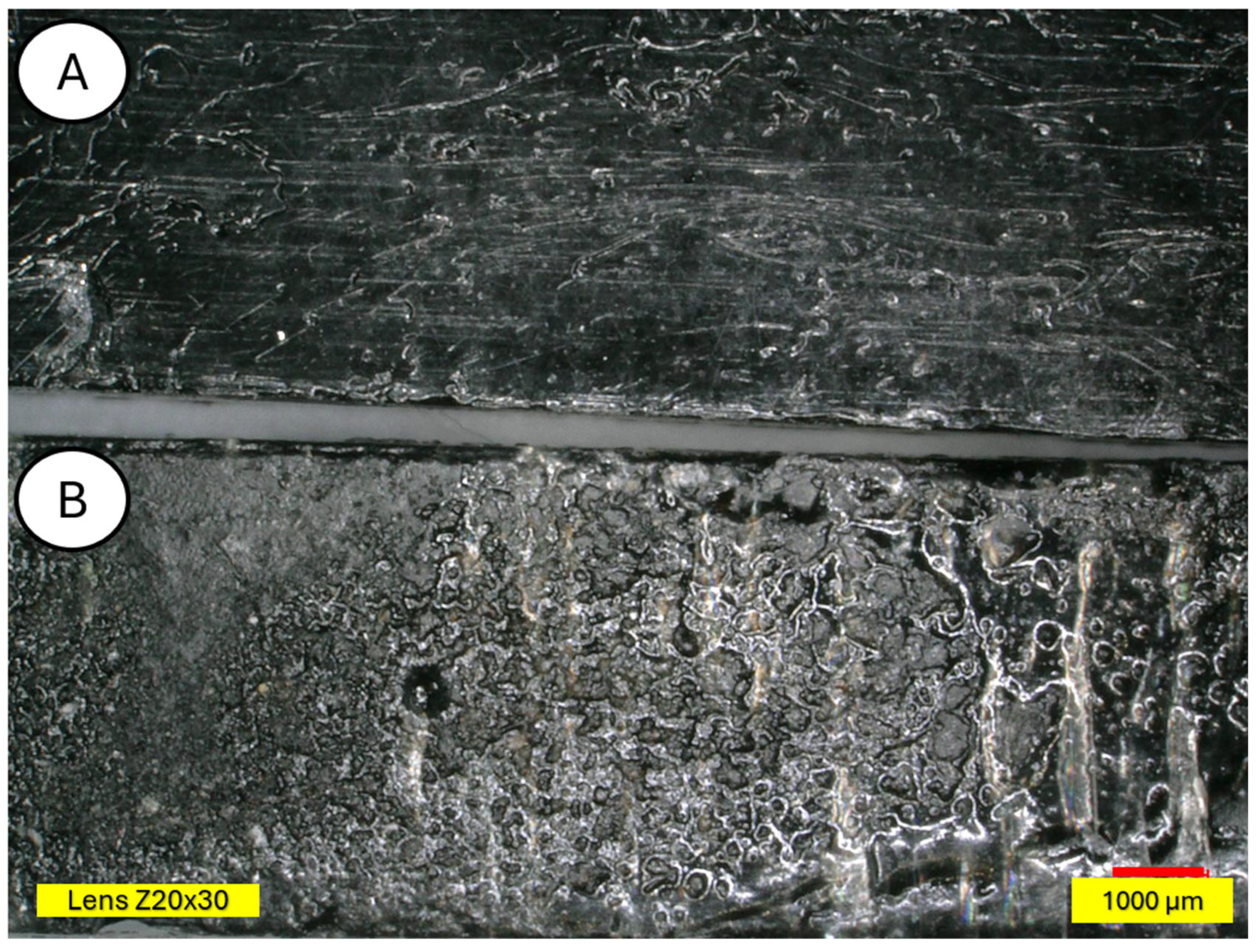

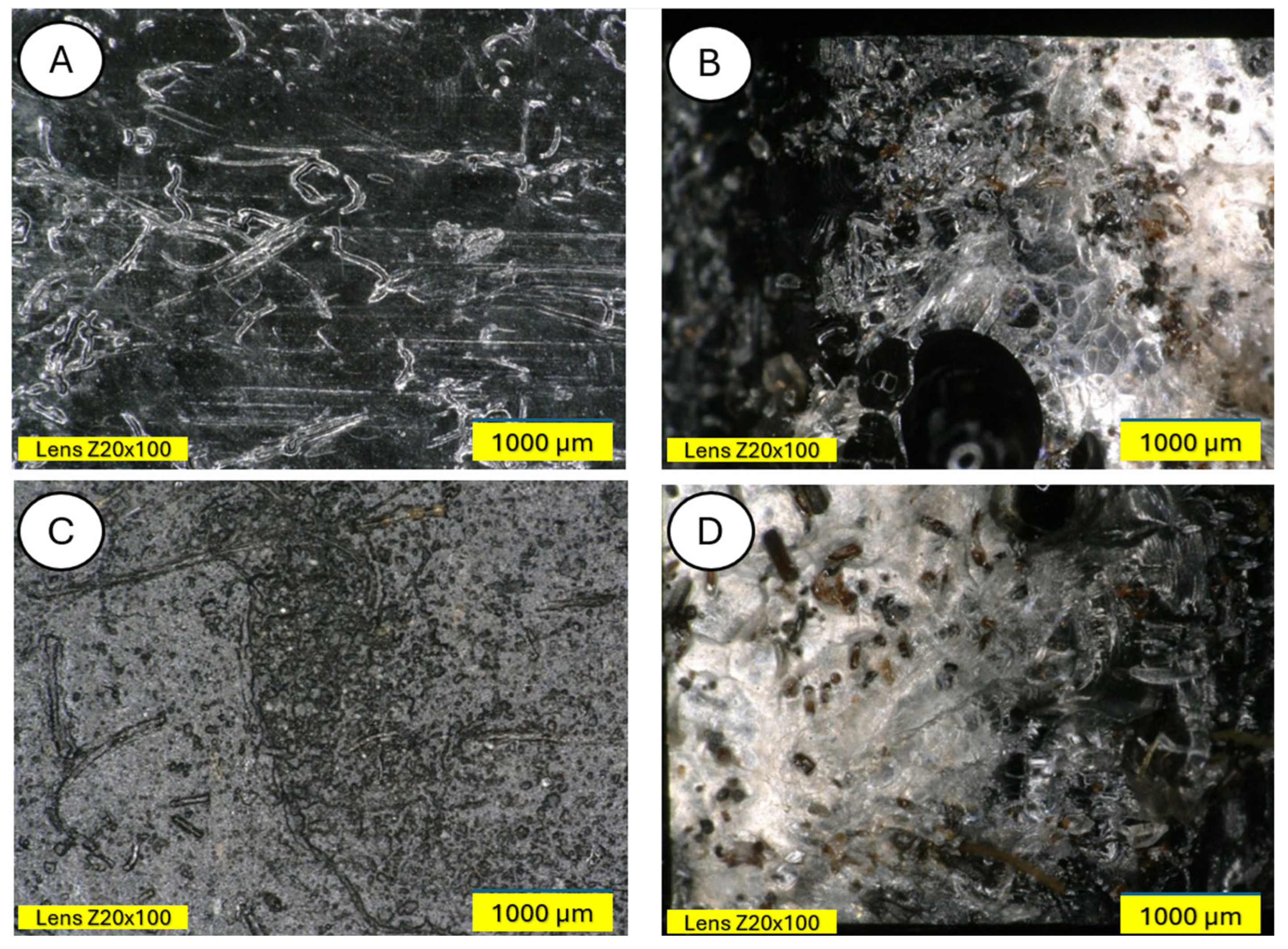

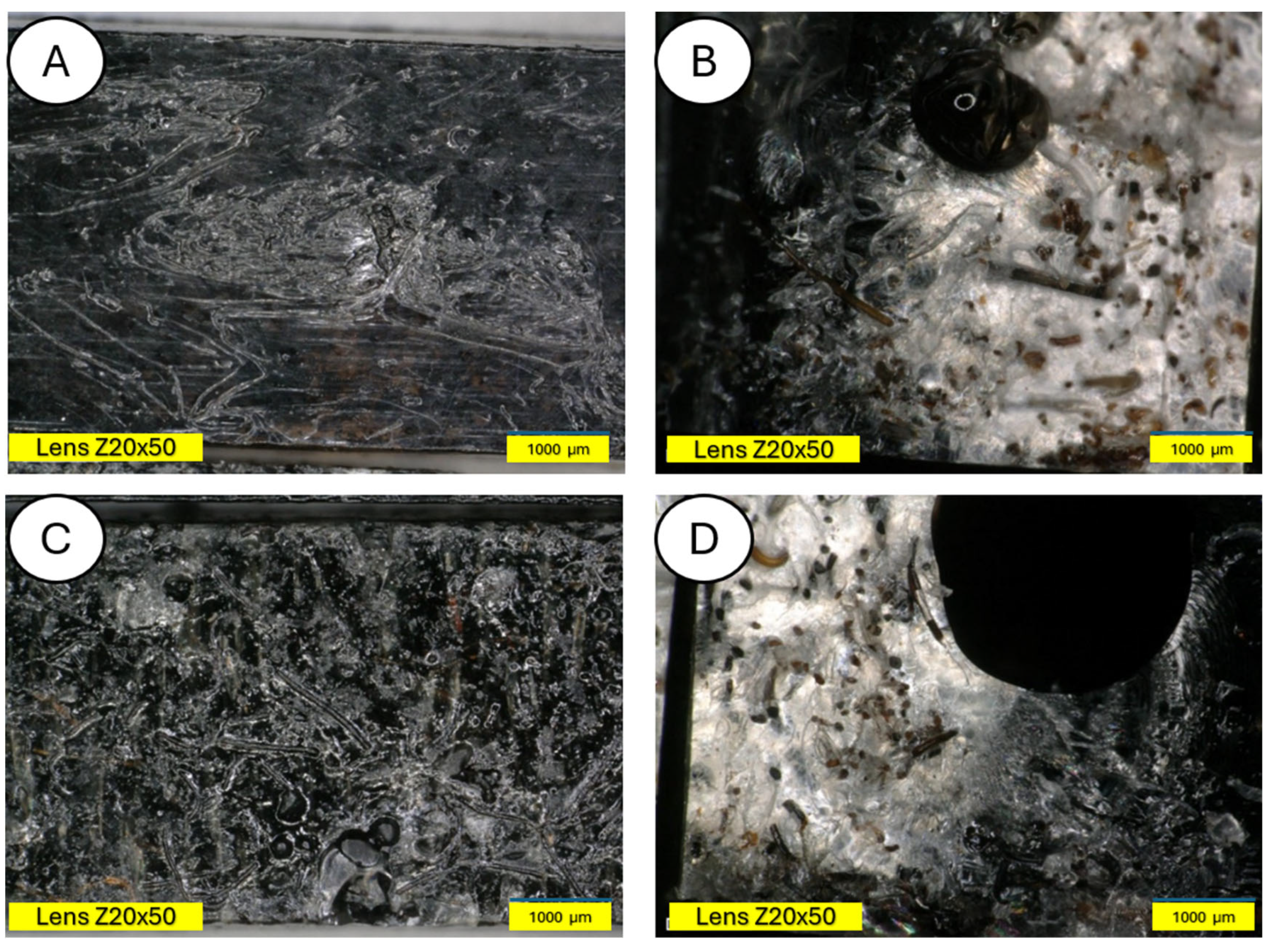

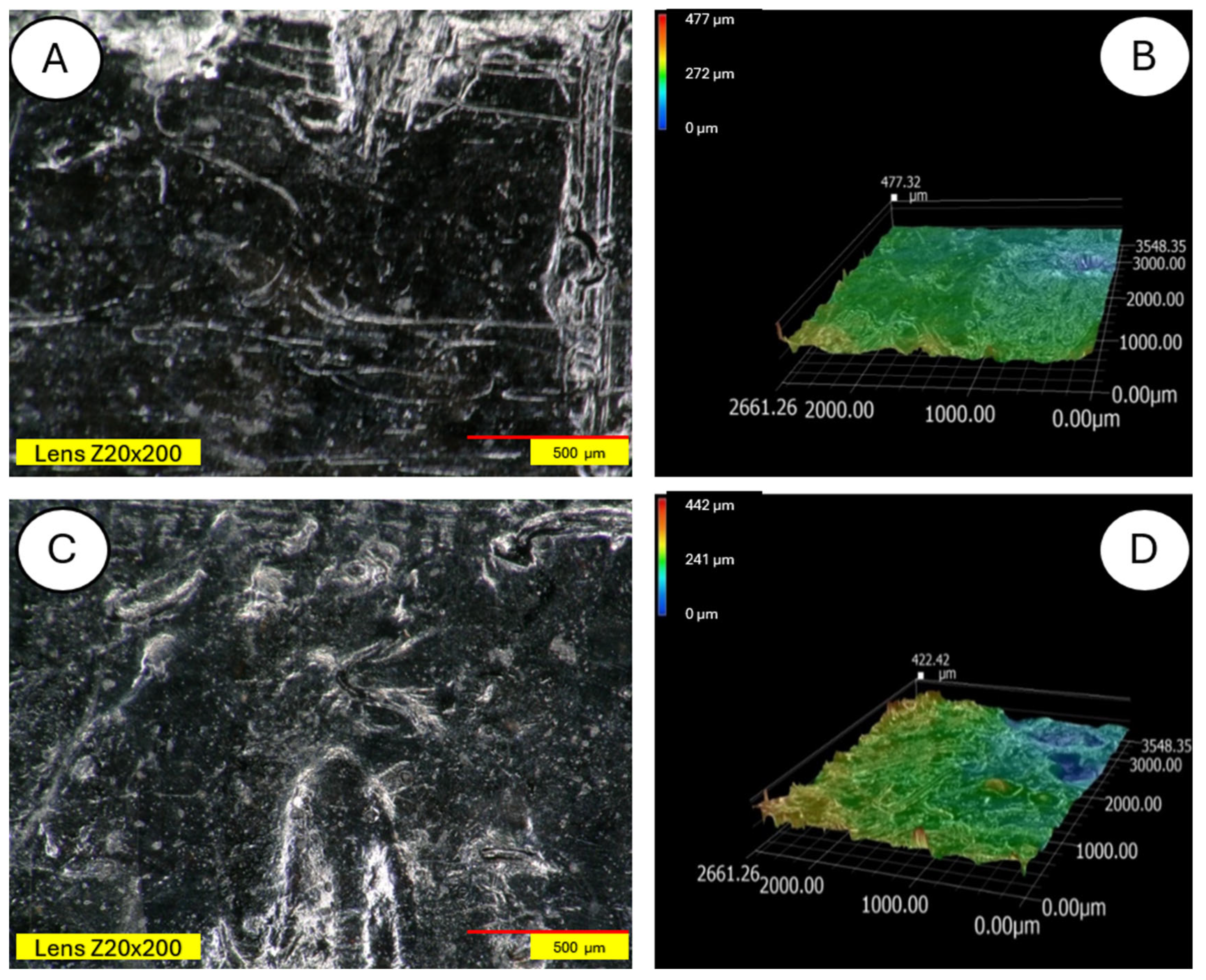

3.4. Results and Analysis of Microscopic Examinations

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cholewińska, P.; Michalak, M.; Wyrostek, A.; Czyż, K.; Konkol, D. Badanie impedancji, ciepłochronności i naprężenia zrywającego wełny jednolitej i mieszanej. Wiad. Zootech. 2018, 56, 50–55. [Google Scholar]

- Villavicencio, A.M.; Niżnikowski, R. Wykorzystanie pozaklasowego włókna alpak i wełny owczej do zastosowania w różnych sektorach gospodarki. Prz. Włók.-Włókno Odzież Skóra 2022, 6, 35–39. [Google Scholar] [CrossRef]

- Szatkowski, P.; Tadla, A.; Flis, Z.; Szatkowska, M.; Suchorowiec, K.; Molik, E. The potential application of sheep wool as a component of composites. Rocz. Nauk. Pol. Towar. Zootech. 2021, 17, 1–8. [Google Scholar] [CrossRef]

- Simpson, W.S.; Crawshaw, G.H. Wool: Science and Technology; Woodhead Publishing Limited: Cambridge, UK; CRC Press LLC: Boca Raton, FL, USA, 2002. [Google Scholar]

- Niżnikowski, R. Hodowla i Użytkowanie Owiec; Wydawnictwo Wieś Jutra: Warsaw, Poland, 2011; pp. 196–205. [Google Scholar]

- Wasilewska, A.W.; Pietruszka, B.L. Materiały naturalne w ekobudownictwie. Przegląd Bud. 2017, 88, 50–53. [Google Scholar]

- Andrzejewska, A.; Topoliński, T. Polimery biodegradowalne do zastosowań biomedycznych. Postęp. Inż. Mech. 2015, 6, 5–12. [Google Scholar]

- Kim, N.K.; Lin, R.J.T.; Bhattacharyya, D. Effects of wool fibres, ammonium polyphosphate and polymer viscosity on the flammability and mechanical performance of PP/wool composites. Polym. Degrad. Stab. 2015, 119, 167–177. [Google Scholar] [CrossRef]

- Chandramohan, D.; Marimuthu, K. A review on natural fibers. Int. J. Res. Rev. Appl. Sci. 2011, 8, 194–206. [Google Scholar]

- Pach, J.; Mayer, P. Kompozyty polimerowe z roślinnymi włóknami naturalnymi na potrzeby współczesnej motoryzacji. Mechanik 2010, 83, 270–274. [Google Scholar]

- Ragaišienė, A.; Rusinavičiūtė, J.; Milašiene, D.; Ivanauskas, R. Comparison of Selected Chemical Properties of Fibres from Different Breeds of Dogs and German Blackface Sheep. Fibres Text. East. Eur. 2016, 24, 21–28. [Google Scholar] [CrossRef][Green Version]

- Thomason, J.L. Glass fibre sizing: A review. Compos. Part Appl. Sci. Manuf. 2019, 127, 105619. [Google Scholar] [CrossRef]

- Miedzianowska, J.; Masłowski, M.; Strzelec, K. Kompozyty polimerowe zawierające włókna roślinne—Czynniki wpływające na wytrzymałość mechaniczną. Technol. Jakość Wyr. 2018, 63, 45–54. [Google Scholar]

- Jayaraman, K. Manufacturing sisal–polypropylene composites with minimum fibre degradation. Compos. Sci. Technol. 2003, 63, 367–374. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Bharath, K.N.; Basavarajappa, S. Flammability Characteristics of Chemical Treated Woven Natural Fabric Reinforced Phenol Formaldehyde Composites. Procedia Mater. Sci. 2014, 5, 1880–1886. [Google Scholar] [CrossRef]

- Favero, C.; Giavazzi, F. Should the Euro Area Be Run as a Closed Economy. Am. Econ. Rev. 2008, 98, 138–145. [Google Scholar] [CrossRef][Green Version]

- Fantilli, A.P.; Sicardi, S.; Dotti, F. The use of wool as fiber-reinforcement in cement-based mortar. Constr. Build. Mater. 2017, 139, 562–569. [Google Scholar] [CrossRef]

- Stoica, M.; Marian Antohi, V.; Laura Zlati, M.; Stoica, D. The financial impact of replacing plastic packaging by biodegradable biopolymers—A smart solution for the food industry. J. Clean. Prod. 2020, 277, 124013. [Google Scholar] [CrossRef]

- Patrucco, A.; Zoccola, M.; Anceschi, A. Exploring the Potential Applications of Wool Fibers in Composite Materials: A Review. Polymers 2024, 16, 2360. [Google Scholar] [CrossRef]

- Szatkowski, P.; Tadla, A.; Flis, Z.; Szatkowska, M.; Suchorowiec, K.; Molik, E. Production of biodegradable packaging with sheep wool fibres for medical applications. Anim. Sci. Genet. 2022, 18, 57–67. [Google Scholar] [CrossRef]

- Jose, S.; George, J.S.; Jacob, T.A.; Vijayan, P.P.; Bhanu, A.V.A.; Nedumpillil, N.N.; Thomas, S. Nanosilica incorporated coarse wool-epoxy hybrid biocomposites with improved physico-mechanical properties. Front. Mater. 2023, 10, 1140602. [Google Scholar] [CrossRef]

- Rahaman, N.M.A.; Uddin, M.E.; Dey, T.K.; Jamal, M.; Sivanantham, G.; Islam, R. Biodegradable composite from discarded hair keratin and graphene oxide with improved mechanical, thermal and barrier properties: An eco-friendly solution to waste materials. Polym. Int. 2023, 72, 1186–1196. [Google Scholar] [CrossRef]

- Raghvendra, G.; Ojha, S.; Acharya, S.K.; Pal, S.K. Green Composites Based on Animal Fiber and Their Applications for a Sustainable Future. Polymers 2023, 15, 601. [Google Scholar] [CrossRef] [PubMed]

- Adamczyk, K.; Siwek, P.; Michałek, B. Exploring Advancements in Bio-Based Composites for Thermal Insulation: A Systematic Review. Sustainability 2025, 17, 1143. [Google Scholar] [CrossRef]

- Kowalczyk, A.; Majchrzak, E.; Pietrzyk, M. A Novel Biodegradable Technology for Wool Fabric Restoration and Cotton Color Retention Based on Shikimic Acid and L-Arginine. Textiles 2024, 4, 549–560. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, P.; Sharma, R. Investigation of Damping Properties of Natural Fiber-Reinforced Composites at Various Impact Energy Levels. Polymers 2024, 16, 3553. [Google Scholar] [CrossRef]

- Berechet, M.D.; Niculescu, O.; Deselnicu, D.C.; Georgescu, M. Short Review on Keratin Synthesis and Its Applications in Composite Materials. In Proceedings of the ICAMS 2024 Conference, Bucharest, Romania, 16–18 October 2024; pp. 45–52. [Google Scholar]

- EN ISO 527-1:2020; Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization (ISO): Geneva, Switzerland, 2020.

- Golubović, Z.; Bojović, B.; Kirin, S.; Milovanović, A.; Petrov, L.; Anđelković, B.; Sofrenić, I. Effect of Aging on Tensile and Chemical Properties of Polylactic Acid and Polylactic Acid-Like Polymer Materials for Additive Manufacturing. Polymers 2024, 16, 1035. [Google Scholar] [CrossRef]

- Brown, M.H.; Badzinski, T.D.; Pardoe, E.; Ehlebracht, M.; Maurer-Jones, M.A. UV Light Degradation of Polylactic Acid Kickstarts Enzymatic Hydrolysis. ACS Mater. Au 2024, 4, 92–98. [Google Scholar] [CrossRef]

- Cristea, M.; Ionita, D.; Iftime, M.M. Dynamic Mechanical Analysis Investigations of PLA-Based Renewable Materials: How Are They Useful? Materials 2020, 13, 5302. [Google Scholar] [CrossRef]

- Shi, Z.; Zou, C.; Zhou, F.; Zhao, J. Analysis of the Mechanical Properties and Damage Mechanism of Carbon Fiber/Epoxy Composites under UV Aging. Materials 2022, 15, 2919. [Google Scholar] [CrossRef]

- Ghasemian, R.; Barani, H.; Khazaei, F. Surface modification and performance of wool fibers after combined plasma and enzyme treatments. Sci. Rep. 2025, 15, 9079. [Google Scholar] [CrossRef]

- Siracusa, V.; Rocculi, P.; Romani, S.; Rosa, M.D. Biodegradable polymers for food packaging: A review. Trends Food Sci. Technol. 2008, 19, 634–643. [Google Scholar] [CrossRef]

- Zhang, M.; Biesold, G.M.; Choi, W.; Yu, J.; Deng, Y.; Silvestre, C. Recent advances in polymers and polymer composites for food packaging. Mater. Today. 2022, 53, 134–161. [Google Scholar] [CrossRef]

- Tiza, T.M.; Singh, S.K.; Kumar, L.; Shettar, M.P.; Singh, S.P. Assessing the potentials of Bamboo and sheep wool fiber as sustainable construction materials: A review. Mater. Today Proc. 2021, 47, 4484–4489. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Suwanmanee, U.; Leejarkpai, T.; Rudeekit, Y.; Mungcharoen, T. Life cycle energy consumption and greenhouse gas emissions of polylactic acid (PLA) and polystyrene (PS) trays. Agric. Nat. Resour. 2010, 44, 703–716. [Google Scholar]

- Alyousef, R.; Alabduljabbar, H.; Mohammadhosseini, H.; Mohamed, A.M.; Siddika, A.; Alrshoudi, F. Utilization of sheep wool as potential fibrous materials in the production of concrete composites. J. Build. Eng. 2020, 30, 101216. [Google Scholar] [CrossRef]

- Jóźwiak-Niedźwiedzka, D.; Fantilli, A.P. Wool-Reinforced Cement Based Composites. Materials 2020, 13, 3590. [Google Scholar] [CrossRef]

- Statuto, D.; Bochicchio, M.; Sica, C.; Picuno, P. Experimental development of clay bricks reinforced with agricultural by-products. In Proceedings of the ATAE2018 Symposium, Opatija, Croatia, 27 February–1 March 2018. [Google Scholar]

- Fiore, V.; Di Bella, G.; Valenza, A. Effect of Sheep Wool Fibers on Thermal Insulation and Mechanical Properties of Cement-Based Composites. J. Nat. Fibers 2020, 17, 1532–1543. [Google Scholar] [CrossRef]

- Sharma, S.C.; Sahoo, A.; Chand, R. Potential use of waste wool in agriculture: An overview. Indian J. Small Rumin. 2019, 25, 1. [Google Scholar] [CrossRef]

- Barone, J.R.; Schmidt, W.F. Polyethylene reinforced with keratin fibers obtained from chicken feathers. Compos. Sci. Technol. 2005, 65, 173–181. [Google Scholar] [CrossRef]

- Ferreira, D.; Cruz, J.; Fangueiro, R. Surface modification of natural fibers in polymer composites. In Green Composites for Automotive Applications; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

| Material | Density [kg m−3] | Thermal Conductivity [W m−1 K−1] |

|---|---|---|

| Polyamide 6 fiber | 1140 | 0.25 |

| PET fiber | 1390 | 0.14 |

| PP fiber | 910 | 0.12 |

| PE fiber | 920 | 0.34 |

| PVC fiber | 1360 | 0.16 |

| Water | 100 | 0.58 |

| Wool felt | 320 | 0.047 |

| Wool fibers | 1300 | 0.1924 |

| Air | 1.29 | 0.024 |

| Fibers | Strength [MPa] | Elongation at Break [%] | Elastic Modulus [MPa] |

|---|---|---|---|

| Cotton | 264–654 | 3.0–7.0 | 4980–10,920 |

| Wool | 120–174 | 25–35 | 2340–3420 |

| Silk | 252–528 | 20–25 | 7320–11,220 |

| Flax | 300–900 | 2.7–3.2 | 24,000 |

| Jute | 342–672 | 1.7–1.8 | 43,800 |

| Sisal | 444–552 | 2.0–2.5 | - |

| Ramie | 348–816 | 3.6–3.8 | 53,400 |

| Glass fibers | 4800 | 1.8–3.2 | 86,000 |

| Sample Name and Wool Concentration | Sample Name After Aging Process and Wool Concentration |

|---|---|

| Pure PLA | Pure PLA after UV |

| PLA/pure wool 5%, 15% | PLA/pure wool 5%, 15% after UV |

| PLA/acid wool 5%, 15% | PLA/acid wool 5%, 15% after UV |

| PLA/Fe wool 5%, 15% | PLA/Fe wool 5%, 15% after UV |

| PLA/tar 5%, 15% | PLA/tar 5%, 15% after UV |

| Sample | Glass Transition [°C] | Glass Transition Temperature Difference [%] | Storage Modulus at 0 °C [MPa] | Storage Modulus Difference at 0 °C [%] | Storage Modulus at 50 °C [MPa] | Storage Modulus Difference at 50 °C [%] |

|---|---|---|---|---|---|---|

| Pure PLA | 60.22 | - | 16,212.4 | - | 13,460.4 | - |

| Pure PLA after UV | 61.37 | 1.15 | 12,669.7 | −21.85 | 9191.1 | −31.72 |

| PLA/pure wool 15% | 64.13 | 3.91 | 15,245.8 | −5.96 | 16,429.3 | 22.06 |

| PLA/pure wool 15% after UV | 61.28 | 1.06 | 24,957.0 | 53.94 | 17,965.0 | 33.47 |

| PLA/acid wool 15% | 64.69 | 4.47 | 13,834.1 | −14.67 | 15,801.9 | 17.40 |

| PLA/acid wool 15% after UV | 66.10 | 5.88 | 18,727.8 | 15.52 | 16,941.5 | 25.86 |

| PLA/Fe wool 15% | 62.12 | 1.90 | 13,397.5 | −17.36 | 12,893.4 | −4.21 |

| PLA/Fe wool 15% after UV | 63.73 | 3.51 | 15,221.1 | −6.11 | 13,609.7 | 1.11 |

| PLA/tar 15% | 63.73 | 3.51 | 14,564.0 | −10.17 | 13,698.3 | 1.77 |

| PLA/tar 15% after UV | 61.23 | 1.01 | 20,586.4 | 26.98 | 15,537.2 | 15.43 |

| Sample | Young’s Modulus [MPa] | Standard Deviation of Young’s Modulus [MPa] | Strength [MPa] | Standard Deviation of Strength [MPa] | Strain [%] | Standard Deviation of Strain [%] | Work of Destruction [N × mm] | Standard Deviation of Destruction Work [N × mm] |

|---|---|---|---|---|---|---|---|---|

| Pure PLA | 2180 | 1086 | 97.7 | 2.1 | 7.2 | 0.7 | 781.30 | 91.63 |

| Pure PLA after UV | 2377 | 191 | 21.6 | 17.4 | 1.8 | 0.6 | 40.31 | 14.36 |

| PLA/pure wool 15% | 3717 | 263 | 38.4 | 31.0 | 1.6 | 1.2 | 78.28 | 102.86 |

| PLA/pure wool 15% after UV | 3030 | 384 | 39.2 | 19.4 | 2.4 | 0.5 | 102.65 | 50.65 |

| PLA/acid wool 15% | 3650 | 98 | 66.4 | 14.6 | 3.1 | 0.6 | 214.86 | 87.67 |

| PLA/acid wool 15% after UV | 2887 | 284 | 38.0 | 24.5 | 2.6 | 0.3 | 120.59 | 20.10 |

| PLA/Fe wool 15% | 3750 | 115 | 60.4 | 24.6 | 2.3 | 1.1 | 147.64 | 122.56 |

| PLA/Fe wool 15% after UV | 3090 | 380 | 46.1 | 13.7 | 2.4 | 0.2 | 106.61 | 22.64 |

| PLA/tar 15% | 3667 | 68 | 81.0 | 28.6 | 2.6 | 1.3 | 176.04 | 130.62 |

| PLA/tar 15% after UV | 3197 | 301 | 51.2 | 22.5 | 2.8 | 0.4 | 154.11 | 45.72 |

| Dry Weight of Sample, m1 [g] | Wet Sample Weight, m2 [g] | m1/(m1m2) [-] | Density [g/cm3] | |

|---|---|---|---|---|

| Pure PLA | 1.482 | 0.275 | 1.228 | 1.224 |

| Pure PLA after UV | 1.406 | 0.249 | 1.215 | 1.212 |

| PLA/pure wool 15% | 1.276 | 0.205 | 1.191 | 1.188 |

| PLA/pure wool 15% after UV | 1.34 | 0.201 | 1.176 | 1.173 |

| PLA/acid wool 15% | 1.48 | 0.161 | 1.122 | 1.119 |

| PLA/acid wool 15% after UV | 1.45 | 0.188 | 1.149 | 1.146 |

| PLA/Fe wool 15% | 0.996 | 0.169 | 1.204 | 1.201 |

| PLA/Fe wool 15% after UV | 1.4 | 0.171 | 1.139 | 1.136 |

| PLA/tar 15% | 1.381 | 0.27 | 1.243 | 1.239 |

| PLA/tar 15% after UV | 1.055 | 0.242 | 1.298 | 1.294 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szatkowski, P. The Influence of Various Chemical Modifications of Sheep Wool Fibers on the Long-Term Mechanical Properties of Sheep Wool/PLA Biocomposites. Materials 2025, 18, 3056. https://doi.org/10.3390/ma18133056

Szatkowski P. The Influence of Various Chemical Modifications of Sheep Wool Fibers on the Long-Term Mechanical Properties of Sheep Wool/PLA Biocomposites. Materials. 2025; 18(13):3056. https://doi.org/10.3390/ma18133056

Chicago/Turabian StyleSzatkowski, Piotr. 2025. "The Influence of Various Chemical Modifications of Sheep Wool Fibers on the Long-Term Mechanical Properties of Sheep Wool/PLA Biocomposites" Materials 18, no. 13: 3056. https://doi.org/10.3390/ma18133056

APA StyleSzatkowski, P. (2025). The Influence of Various Chemical Modifications of Sheep Wool Fibers on the Long-Term Mechanical Properties of Sheep Wool/PLA Biocomposites. Materials, 18(13), 3056. https://doi.org/10.3390/ma18133056