1. Introduction

Internal combustion engines, as one of the most important power sources today, are widely used in automobiles, ships, aircraft, and other fields. However, with the increasingly severe global energy crisis and environmental pollution problems, the requirements for the performance of internal combustion engines are also constantly increasing. Pistons, as one of the most critical components in internal combustion engines, work under extremely harsh conditions, not only having to withstand the impact of high-temperature and high-pressure gas but also experiencing rapid reciprocating motion and heat exchange processes. These complex working conditions place extremely high demands on the material, structure, and cooling system of the piston. Hence, through thermal–mechanical coupling analysis, dynamic characteristics research, and structural optimization, the power performance and fuel economy of the engine are improved. In the meantime, the wear is effectively reduced, and the service life is prolonged.

With the rapid development of computer technology and numerical analysis methods, advanced technologies such as finite element analysis (FEA) and computational fluid dynamics have been widely used in piston design and optimization. Through FEA, the stress distribution, deformation, and temperature field characteristics of the piston under complex working conditions can be accurately simulated, providing a scientific basis for the structural optimization. By using modal analysis, the dynamic performance can be deeply understood, and potential resonance risks can be predicted, providing a basis for vibration avoidance design. However, the thermomechanical coupling analysis and optimization research of the piston still faces many challenges. The working process of the piston involves the coupling effect of multiple physical fields, such as the interaction of the temperature field, stress field, and fluid field, which makes the analysis process extremely complex. The optimization design needs to consider multiple objective functions and constraints, such as strength, stiffness, mass, cost, etc. Therefore, how to find the optimal solution among these conflicting objectives is a current research hotspot.

Nowadays, some progress has been made in the research on the performance optimization and failure mechanism of pistons under complex working conditions. Regarding the wear problem of the titanium alloy piston skirt, through the application of metallographic analysis, electron microscope scanning, and FEA (ABAQUS), it was revealed that the deformation caused by insufficient stiffness of the piston skirt was the main failure reason, and the wear failure problem was solved through structural parameter optimization [

1]. The experimental results show that the research on the thermal insulation performance of the composite adiabatic piston has achieved remarkable results. The results show that the application of the thermal insulation pad and air gap has a significant effect on improving the thermal insulation effect of piston. It has been proven that the finite element model has high-precision prediction performance [

2]. In the exploration of piston cooling and strength optimization, the design research of the internal cooling oil cavity reveals its complex influence on piston heat transfer and structural strength, and the orthogonal test design method effectively evaluates the optimization potential of factors such as oil cavity type and surface area [

3]. For high-strength diesel engine pistons, through SolidWorks modeling and FEA, the thermal stress, thermal deformation, and stress concentration areas of the piston under high-temperature and high-pressure environments are discussed in detail, providing a scientific basis for structural improvement [

4]. After thermal boundary condition analysis, temperature field simulation, and experimental verification, an innovative design scheme of aluminum skirt piston with steel top came into being. In this scheme, a composite heat-insulating piston with air gap and heat-insulating gasket was proposed to reduce the heat flow output in the piston ring groove area. Through structural optimization and adjustment, the contact stress distribution between the thermal insulation gasket and the piston top is greatly improved. These research results not only deepen the understanding of the performance and failure mechanism of diesel engine pistons but also point out the direction for future piston design and optimization [

5].

The thermal fatigue life and wear resistance of pistons, as key components, have become a research hotspot. Regarding the influence of uneven temperature distribution on the top surface during the intake process on fatigue life, researchers have successfully predicted the fatigue life through CFD simulation, FEA, and material testing and revealed the significant impact of intake cooling effects on its fatigue life [

6]. In addition, for the change in the thermal load of the piston with different working conditions, especially the characteristics of thermal stress and thermal strain under cold start and other working conditions, a detailed analysis has been carried out, providing a theoretical basis for the design of high-strength diesel engine pistons [

7]. Furthermore, in order to improve the wear resistance of the piston skirt, a bionic through-hole structure based on the bionic non-smooth theory was designed, as well as through FEA and bench tests. It significantly reduced skirt wear and optimized the oil film retention ability [

8].

The friction loss of the internal combustion engine piston–cylinder liner system, as a key factor affecting engine energy efficiency and emissions, has received widespread attention [

9,

10,

11]. To effectively reduce this loss, researchers have drawn inspiration from nature and applied the shell structure to the design of the piston skirt. Through orthogonal experimental design, combined with durability bench tests, the significant effect of the bionic structure in improving the wear resistance of the piston, reducing the frictional resistance, and improving the stability of the cylinder pressure has been confirmed. This research shows that the application of a shell stripe structure can reduce the wear of the piston skirt. It also optimizes the stress distribution and prolongs fatigue life. The working temperature is significantly reduced.

With the continuous progress of engine technology, heat loss and emission issues have become the key factors restricting the efficiency and lifespan of engines. To address this challenge, thermal ceramic coatings are regarded as an important means of improving engine performance due to their excellent heat insulation and wear resistance. In several studies, zirconium carbide ceramic coatings have been applied to the pistons and cylinders of V12 engines, and FEA reveals that they significantly reduce the heat flux and effectively block heat transfer, thereby improving engine efficiency and extending the lifespan of parts [

12]. With the increase in diesel engine power, pistons are faced with more severe thermal and mechanical loads, and their fatigue life has become the focus of design. With the help of advanced simulation tools such as ANSYS, researchers have deeply analyzed the thermomechanical coupling behavior of pistons under complex working conditions to ensure that the design meets the strength requirements, providing a theoretical basis for improving the overall performance of diesel engines [

13]. Through topology optimization and metal additive manufacturing technology, the innovative design of the compressor piston has been realized, significantly reducing the amount of materials used and improving efficiency, demonstrating the great potential of advanced manufacturing technology in improving the performance of turbo-machinery [

14]. In response to the mechanical failure problem of commercial vehicle diesel engines at high-temperature torque points, ceramic coating technology has once again demonstrated its application value. Studies on the effect of different thicknesses of ceramic coatings on the piston temperature distribution show that increasing the coating thickness can reduce temperature [

15].

Research on Al-Si alloy piston materials shows that through the optimization of extrusion casting and heat treatment processes, the thermal conductivity and strength of the materials can be significantly improved, providing new ideas for the selection and processing of piston materials [

16]. The research on aluminum–silicon (Al-Si) alloy piston materials has been continuously deepened, and especially significant progress has been made in the influence of alloying elements on thermal properties. By measuring the influence of the addition of different alloying elements (such as Cu and Ni) on key parameters such as the thermal diffusivity of Al-Si alloys, and combining experiments with finite element simulations, the important role of alloy composition on the surface temperature and overall thermal performance has been revealed. These studies indicate that reasonable control of the content of alloying elements can effectively adjust the heat resistance and high-temperature performance of piston materials, thereby improving the operating efficiency and reliability of the engine [

17].

The piston shape design, as one of the key factors that improve the performance of diesel engines, has also received widespread attention. By comparing and analyzing the characteristics of different piston shapes—such as flat, domed, cup-shaped, and bowl-shaped—in terms of thermal stress, temperature distribution, and total deformation, it is found that flat and domed pistons perform better in reducing thermal stress and total deformation [

18]. To further improve the reliability of diesel engine and prolong its service life, researchers have also optimized the piston geometry based on FEA. By comprehensively considering the influence of geometric parameters such as intake depth and exhaust valve groove on the temperature and stress, significant improvements in piston performance have been achieved using advanced optimization algorithms. These optimization measures can reduce the temperature and stress and verify the effectiveness of the algorithm and the feasibility of the optimization strategy [

19]. In the study of heat transfer and combustion processes in piston–cylinder assemblies, numerical simulation techniques play an important role. Numerical simulation based on FEA can analyze the thermal stress and heat loss of the piston at different temperatures [

20]. Especially for the analysis of static temperature field distribution and thermomechanical coupling stress, it reveals the main role of mechanical loads in piston stress and realizes the simultaneous reduction of piston mass and maximum thermomechanical coupling stress through multi-objective optimization design [

21].

Although the above studies have made significant progress in multiple aspects of piston performance improvement, there are still some problems that need to be solved urgently. Most of the existing studies focus on the optimization of a single performance of the piston or the solution of a specific failure mechanism, only focusing, for example, on the improvement of wear resistance, the improvement of insulation performance, or the reduction in thermal stress; there is a lack of comprehensive optimization research on multiple performances, such as piston stiffness, strength, and dynamic characteristics. However, in actual working conditions, the various performances of the piston are interrelated and interact with each other. The improvement of a single performance may harm other performances. Hence, the multi-objective collaborative optimization is required from the system level. Meanwhile, in terms of optimization design methods, although various optimization algorithms and experimental design methods have been applied to piston design, most studies have failed to fully combine sensitivity analysis with response surface models. Sensitivity analysis can reveal the degree of influence of each design variable on objective functions, helping to clarify the optimization focus. Response surface models can efficiently establish the relationship between design variables and objective function and provide a calculation model for optimization algorithms.

This study conducts a comprehensive optimization of the stiffness, strength, and dynamic characteristics of a piston. First, a high-precision finite element model of the piston is established based on ANSYS Workbench, and the boundary conditions are determined in combination with the actual working conditions for thermomechanical coupling analysis and dynamic characteristic analysis, providing accurate data support for the optimization design. Second, five geometric dimensions are selected as design variables, and multiple performance indicators, such as deformation, mass, temperature, and the first to third natural frequencies, are taken as optimization objectives. A response surface model is constructed through the design of the experiments method, and the model is fully verified and evaluated using the “Residuals vs. Run” plot and “Predicted vs. Actual” plot. Then, a sensitivity analysis is carried out to deeply analyze the influence of each variable on the system performance in combination with the response surface. Finally, advanced optimization algorithms such as the multi-objective genetic algorithm (MOGA) are used for multi-objective collaborative optimization to improve the comprehensive performance of the piston, providing a solution for promoting the further development of engine technology.

2. Finite Element Analysis of the Piston

2.1. Establishment of the Finite Element Model of the Piston

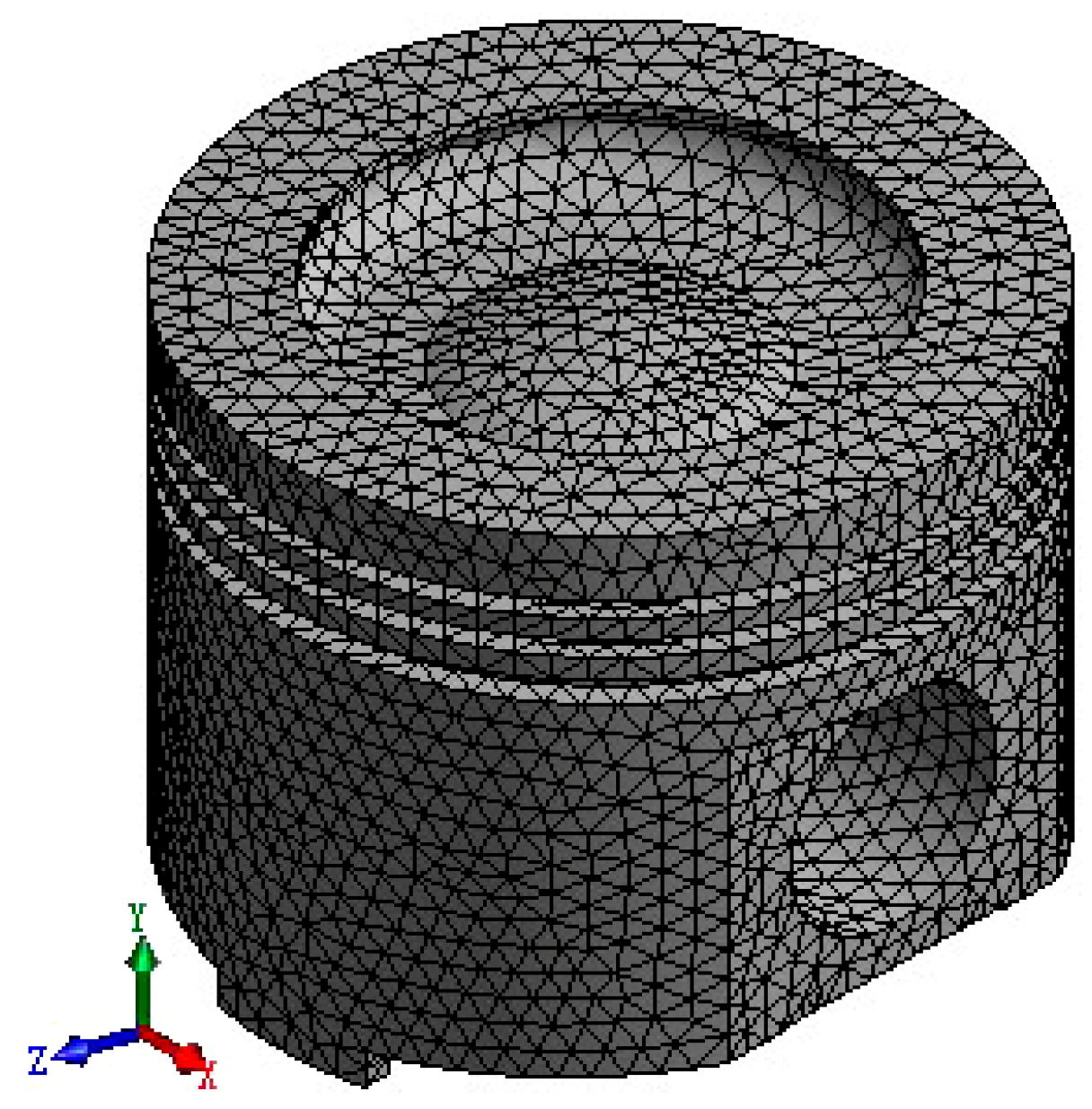

This paper adopts the seamless integration of three-dimensional (3D) modeling software SolidWorks (version: 2020) and ANSYS Workbench (version: 2020 R2) to achieve efficient sharing and conversion of design data. Through this process, the established 3D piston model is directly imported into the ANSYS Workbench environment. Therefore, the integrity and accuracy of the model are preserved, and the complexity of data transmission is greatly simplified. In ANSYS Workbench, a fine meshing strategy is implemented for this model, using 5 mm as the mesh reference size to ensure the balance between analysis accuracy and computational efficiency. The divided finite element model shows highly refined structural features, including 63,689 nodes and 39,770 mesh elements, with an average mesh quality of up to 0.80. This indicator verifies the excellent quality of the meshing and provides a guarantee for the accuracy of subsequent simulation analysis.

Figure 1 shows the piston model after grid division.

2.2. Physical Properties of Piston Materials

For the piston studied in this paper, the material selected is aluminum alloy (6061), which takes into account the needs of lightweight, high strength, and good thermal conductivity.

Table 1 and

Table 2 list, in detail, the thermophysical property parameters of this aluminum alloy material, including, but not limited to, key indicators such as density, elastic modulus, and thermal conductivity coefficient. The accurate input of these data lays a solid foundation for the subsequent thermal steady-state analysis, ensuring that the simulation results can truly reflect the thermal behavior characteristics of the piston in the working state.

2.3. Thermal Load Analysis of the Piston

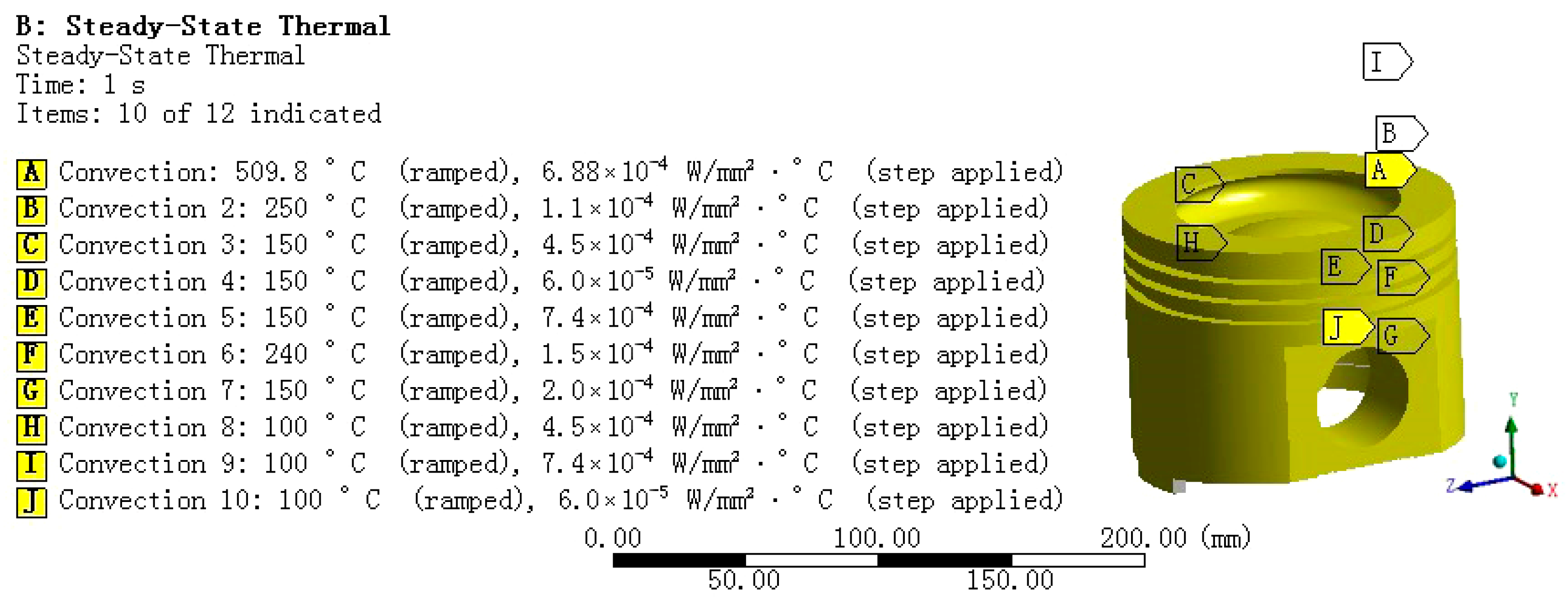

In the thermal load analysis, first, we import the piston geometric model, add the corresponding material properties, and then perform mesh generation. In the mesh generation stage, an appropriate mesh strategy is adopted to refine the key areas to capture the subtle changes in heat transfer. Then, according to the actual situation, combined with the heat transfer coefficient at the surface temperature of each part of the piston, a complete thermal analysis boundary is constructed via empirical formula, as shown in

Table 3 [

22].

In the specific operation, to accurately find the setting position of adding convection coefficient, we input the convection coefficient values corresponding to each part of the piston in

Table 3 one by one, as shown in the

Figure 2. After the convection coefficient is set, the system will perform thermal analysis and calculation on the piston according to these parameters, thus obtaining key information such as the temperature distribution of the piston in the steady thermal environment.

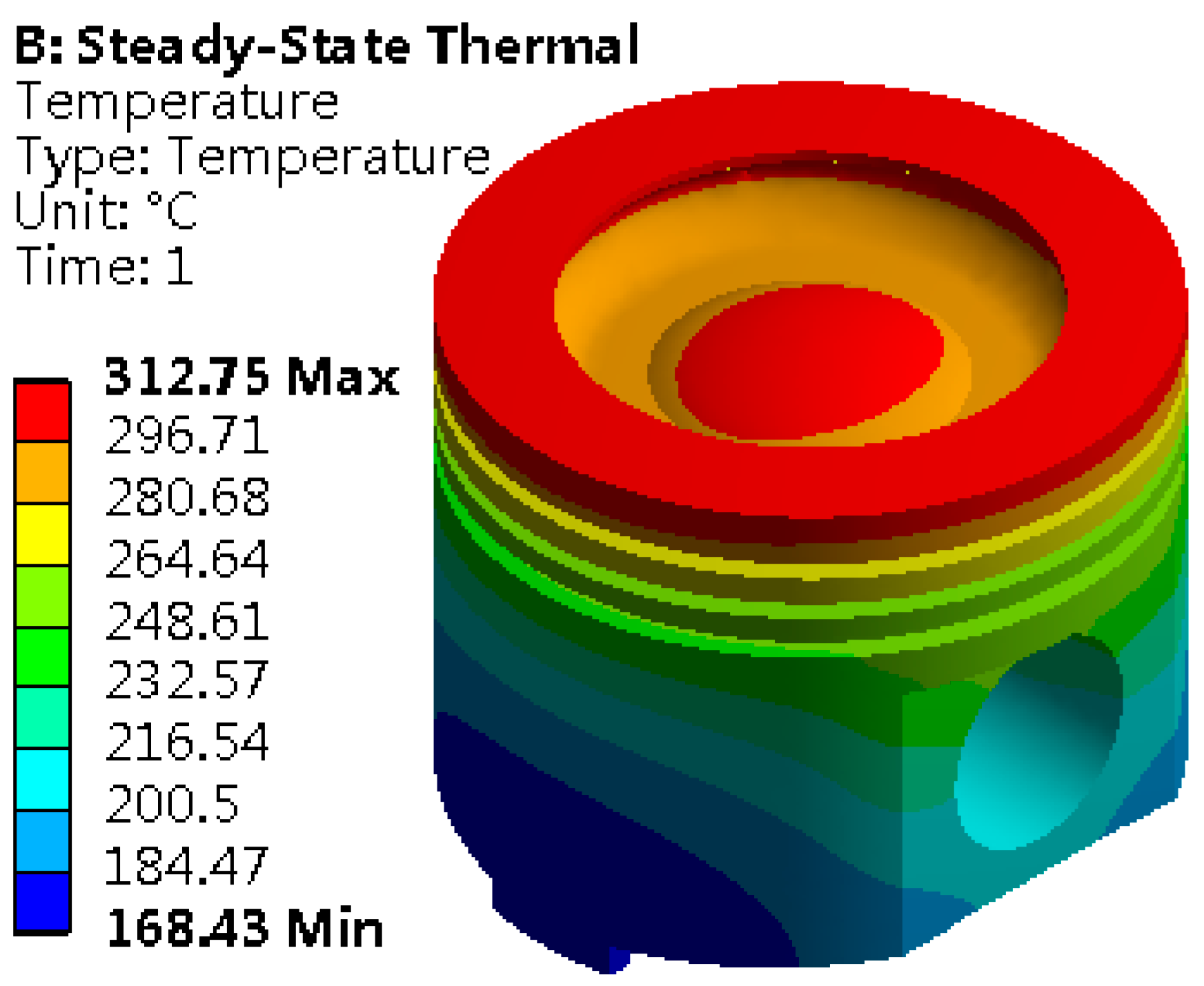

Set the solution options, focusing on the core indicator of the temperature field distribution. Finally, the solution program is executed, and the temperature field distribution map is obtained, as shown in

Figure 3. It reveals the temperature gradient and heat transfer path inside the piston, providing solid data support for subsequent thermal design and optimization.

The distribution map of the piston temperature field clearly reveals the spatial difference of its thermal state, with the highest temperature reaching 312.75 °C and the lowest temperature at 168.43 °C. It displays a significant temperature gradient from top to bottom. This temperature change is particularly obvious in the piston combustion chamber and the top edge area. The top edge bears the heat radiation and convection heat transfer of high-temperature gas, and the lubrication condition is limited, so it becomes the concentrated area of heat load. As the core area of gas combustion, the combustion chamber continuously receives the heat transfer of high-temperature gas, which causes the temperature in this area to climb to 312.75 °C. On the other hand, the piston skirt can effectively take away heat because they are far away from the high-temperature gas heat source, so the temperature is maintained at a low level and the skirt temperature is stable at 168.43 °C. This temperature distribution law is highly consistent with the design concept of “top heat absorption–skirt heat dissipation” of the piston. From the heat conduction path, heat is absorbed from the top of the piston and transferred to the skirt, which further accelerates the heat dissipation and forms a top-down temperature gradient. It not only verifies the accuracy of theoretical analysis but also truly restores the heat conduction and heat dissipation characteristics under actual working conditions. Meanwhile, the maximum temperature at the top, 509.8 °C, listed in

Table 3, was input as a boundary condition into the simulation model, representing the external heat source temperature applied to the top of the piston during the thermal analysis process. The temperature distribution of 312.75 °C, shown in

Figure 3, is the actual temperature achieved at the top of the piston after thermal steady state analysis, reflecting the true temperature situation of the model under steady-state conditions.

2.4. Thermal–Mechanical Coupling Analysis of the Piston

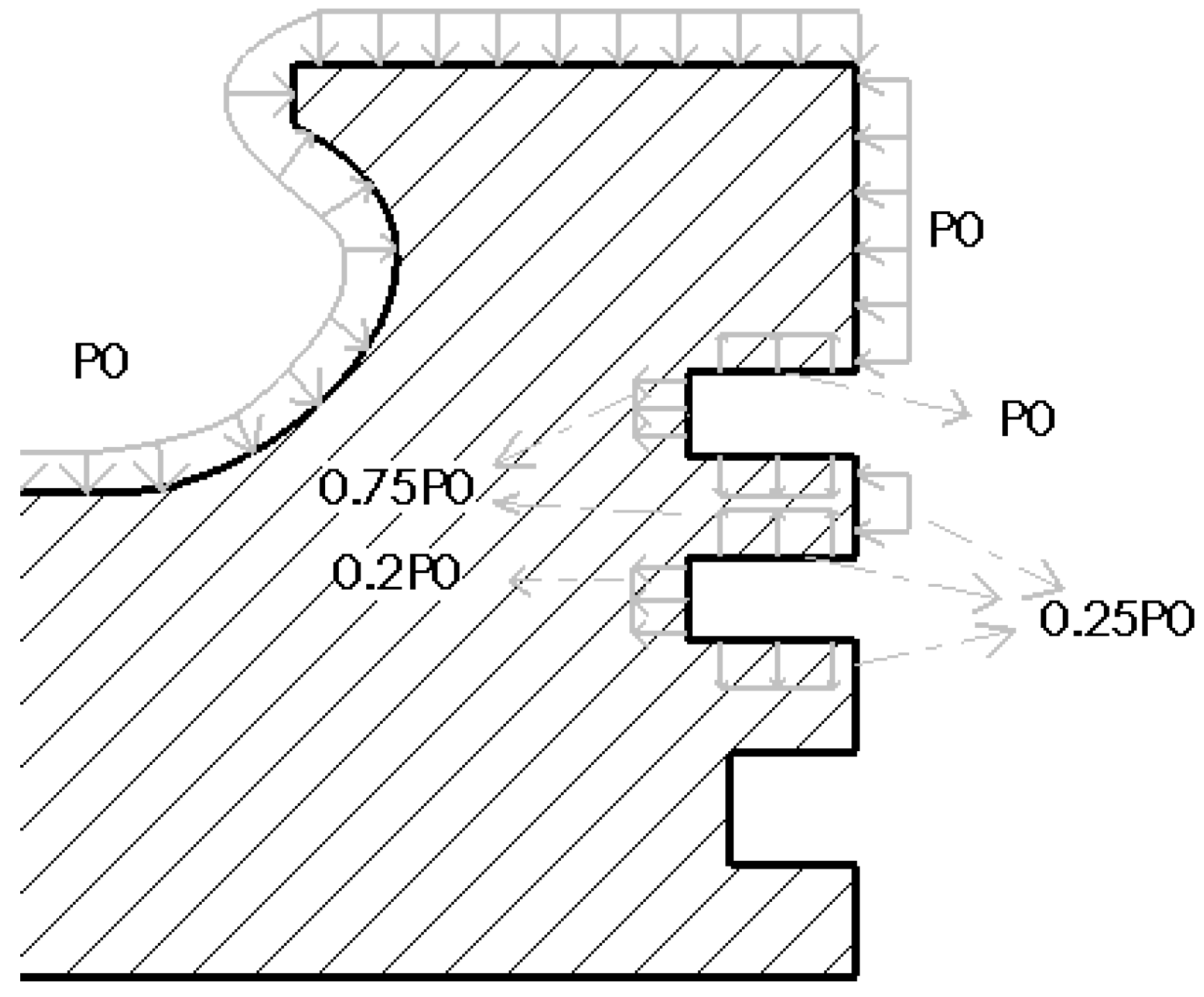

When the piston is subjected to gas pressure, its pressure distribution shows a significant gradient change, gradually decaying from the top to the skirt of the piston. Specifically, the pressure distribution can be finely divided into several key areas for in-depth analysis. The top surface of the piston, as the direct surface of gas pressure, bears the maximum pressure load. Next is the firepower bank area, located below the top surface, where although the pressure is reduced, it is still at a relatively high level, posing an important test of the piston strength. Then there is the three-ring area, where the pressure is further reduced, but it is still a key influencing area for the piston’s sealing and lubrication performance. Finally, the remaining parts can be regarded as negligible areas due to the relatively small pressure.

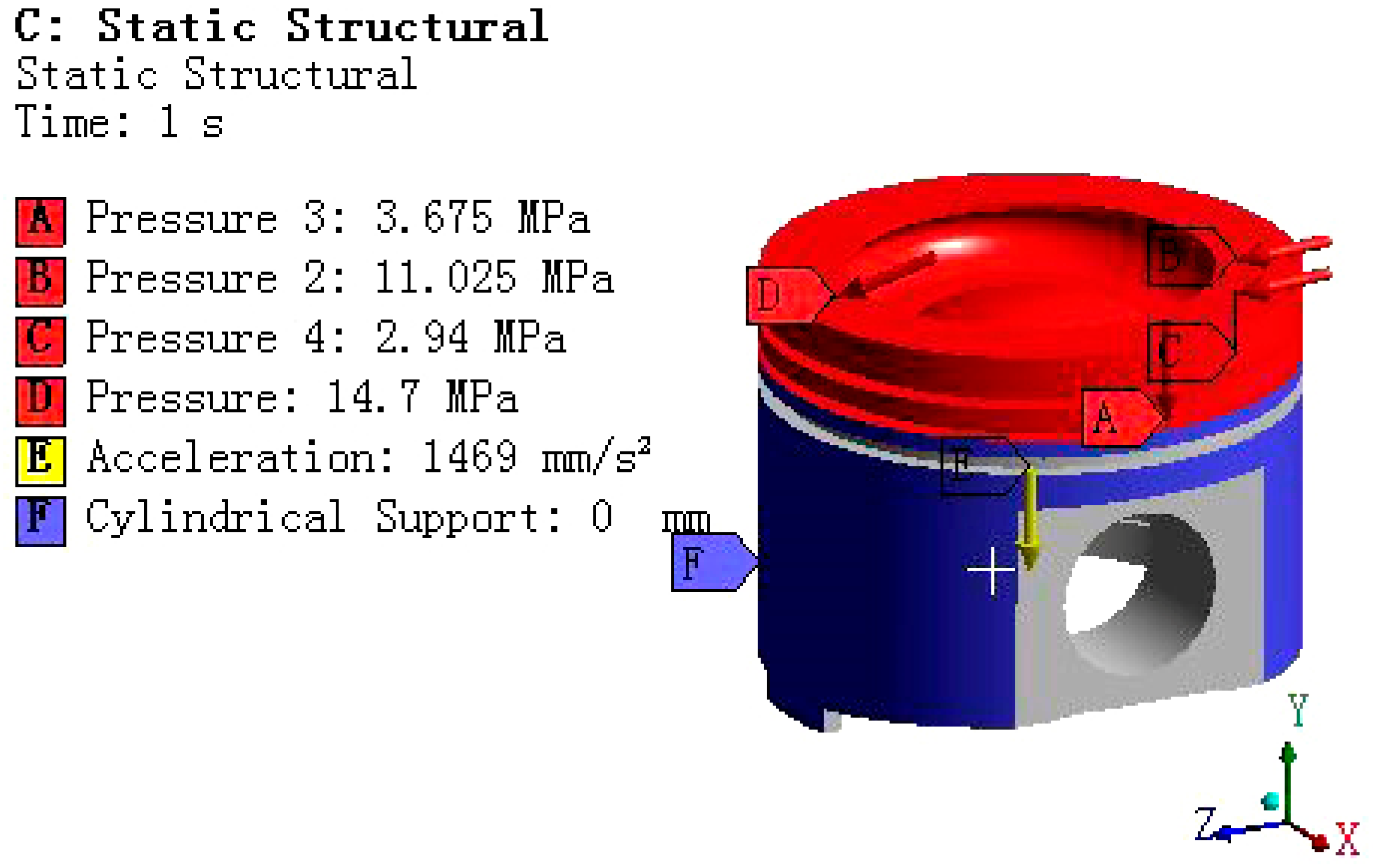

Figure 4 depicts this pressure distribution characteristic in detail, providing a data basis for the mechanical analysis.

In the thermal mechanical coupling analysis of pistons, the main external loads considered are combustion gas pressure and reciprocating inertial force. Among them, the reciprocating inertial force reaches its maximum value when the piston is located at the top and bottom dead center positions. This article simulates it by applying a downward acceleration load, which is 1469 mm/s2.

The gas pressure load is applied according to the pressure distribution shown in

Figure 4, and the specific settings are as follows.

① Surface pressure load (discretized according to the dynamic pressure curve in

Figure 4).

The top surface of the piston and the upper side of the first ring groove: P0 = 14.7 MPa.

The inner diameter surface of the first ring groove is 0.75 P0 = 11.025 MPa.

The lower side of the first ring groove and the upper side of the second ring groove: 0.25 P0 = 3.675 MPa.

The inner diameter surface of the second ring groove is 0.2 P0 = 2.94 MPa.

② Inertial load

Apply a global downward acceleration of α = 1469 mm/s2 (simulating the maximum inertial force at the top dead center).

③ Piston pin connection constraint

Establish a cylindrical joint between the center of the piston pin hole and the fixed reference point. Designate the inner surface of the pin hole as the reference surface for moving parts (allowing rotation around the pin axis).

④ Auxiliary coordinate system

Establish a cylindrical coordinate system based on the piston top surface.

⑤ Piston skirt constraint

Apply cylindrical support to the outer surface. Fixed radial degrees of freedom (Radial DOF), releasing axial/circumferential degrees of freedom.

The piston model with complete boundary conditions (including gas pressure, inertial load, cylindrical support, and cylindrical pair) is shown in the following

Figure 5.

In addition, although this article did not directly model the interaction between the piston ring and the cylinder liner in the model, the indirect effects of the piston ring on the piston heat conduction path, contact pressure distribution, and friction behavior have been considered through the above boundary condition settings. In the subsequent structural dynamics analysis, these boundary conditions will help to more accurately reflect the thermal mechanical response of the piston under actual operating conditions.

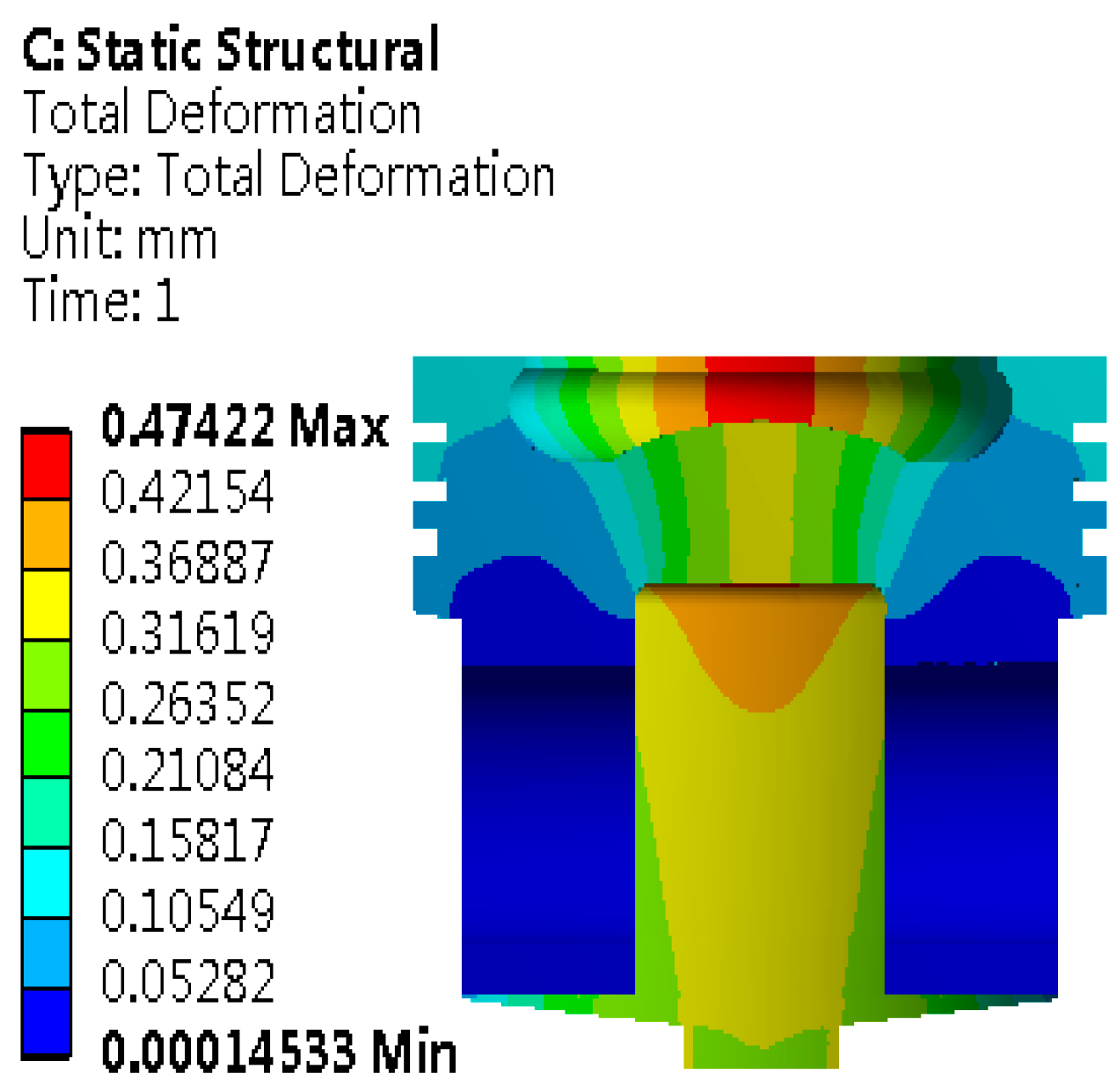

Based on theoretical analysis and adding reasonable boundary conditions. The simulation calculation is carried out. After a series of rigorous calculations and simulations, the piston deformation distribution map as shown in

Figure 6 is obtained. The map visually displays the mechanical response of the piston under specific working conditions.

As shown in

Figure 6, the maximum deformation reaches 0.47422 mm, and the deformation is mainly concentrated in the top area of the piston. The piston head is the core area that bears the heat load of gas. Even if the maximum deformation is considered, the piston design can still ensure the effective sealing performance between the cylinder liner and the piston. Therefore, the piston is always in a stable working state, and cylinder pulling failure caused by its deformation is effectively avoided. In the actual working environment, this design ensures the dynamic balance between the piston and the cylinder liner, preventing friction and wear caused by too small a gap and avoiding the problem of reduced sealing performance due to too large a gap, laying the foundation for the continuous and efficient operation of the piston. Therefore, the piston can effectively resist the deformation effect caused by the thermal load, ensuring that the engine is not disturbed by this factor and maintaining its normal operating state.

2.5. Modal Analysis of the Piston

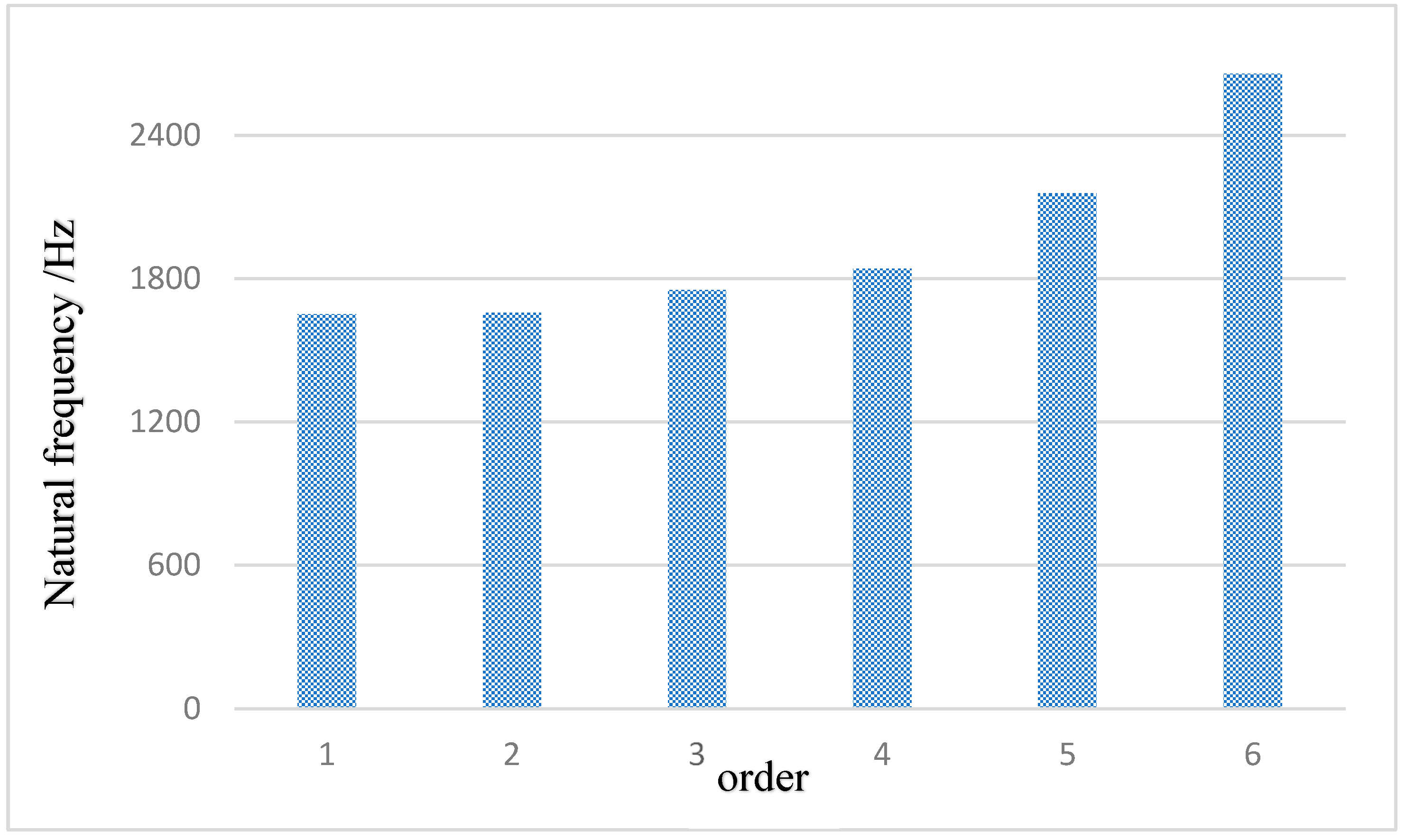

Modal analysis, as a key means to study the dynamic characteristics of structures in the state of free vibration, aims to research the natural frequencies and modal shapes. In the structural design of pistons, this analysis link is particularly important as it directly relates to the vibration performance and operational stability of the piston. By using ANSYS software (version: 2020 R2), the first- to sixth-order natural frequencies were obtained, as shown in

Figure 7. It displays the vibration patterns of the piston at different orders, providing data support for the in-depth understanding of the dynamic response characteristics of the piston, optimizing structural design, and preventing resonance phenomena. It is an indispensable part of piston performance evaluation and optimization design.

The first- to sixth-order natural frequencies of the piston are shown in

Table 4 below.

This study conducts a detailed modal analysis of the piston, aiming to accurately solve its natural frequencies and corresponding vibration modes at each order. This analysis not only provides a scientific basis for the dynamic performance evaluation of the piston but also prevents fatigue fracture problems caused by resonance during the piston’s working process by identifying potential resonance risks. Therefore, it focuses on the in-depth analysis of the first to sixth orders of vibration modes. The natural frequency distribution of the piston presents certain characteristics, in which the high-order frequencies are significantly higher than 1651.6 Hz, while the low-order natural frequencies are densely distributed in a narrow range from 1651.6 Hz to 2656.8 Hz. Based on the conclusion of the modal analysis, it is of great significance for the subsequent optimization design of the piston structure, aiming to reduce the possibility of resonance and ensure the long-term stable operation.

2.6. Harmonic Response Analysis of the Piston

Harmonic response analysis, also known as sweep frequency analysis, is a key means to evaluate the steady-state response of linear structures under periodic external forces. This analysis focuses on the forced vibration characteristics of the structure, aiming to accurately define its vibration frequency range and response mode. Through this method, it is possible to effectively capture and reflect the resonance phenomenon and potential fatigue risks of the structure at specific frequencies, providing a scientific basis for optimizing design and safe operation. In practical operations, the modal superposition method, as the core technology of harmonic response analysis, is widely used in the calculation process. In this method, the modal shapes of each order of the structure are weighted and superimposed according to the corresponding coefficients. This method is used to evaluate the overall dynamic response of the structure under different frequency excitations so as to improve the accuracy of analysis and make the calculation results closer to the actual situation. It also significantly enhances the understandability and interpretability of the results.

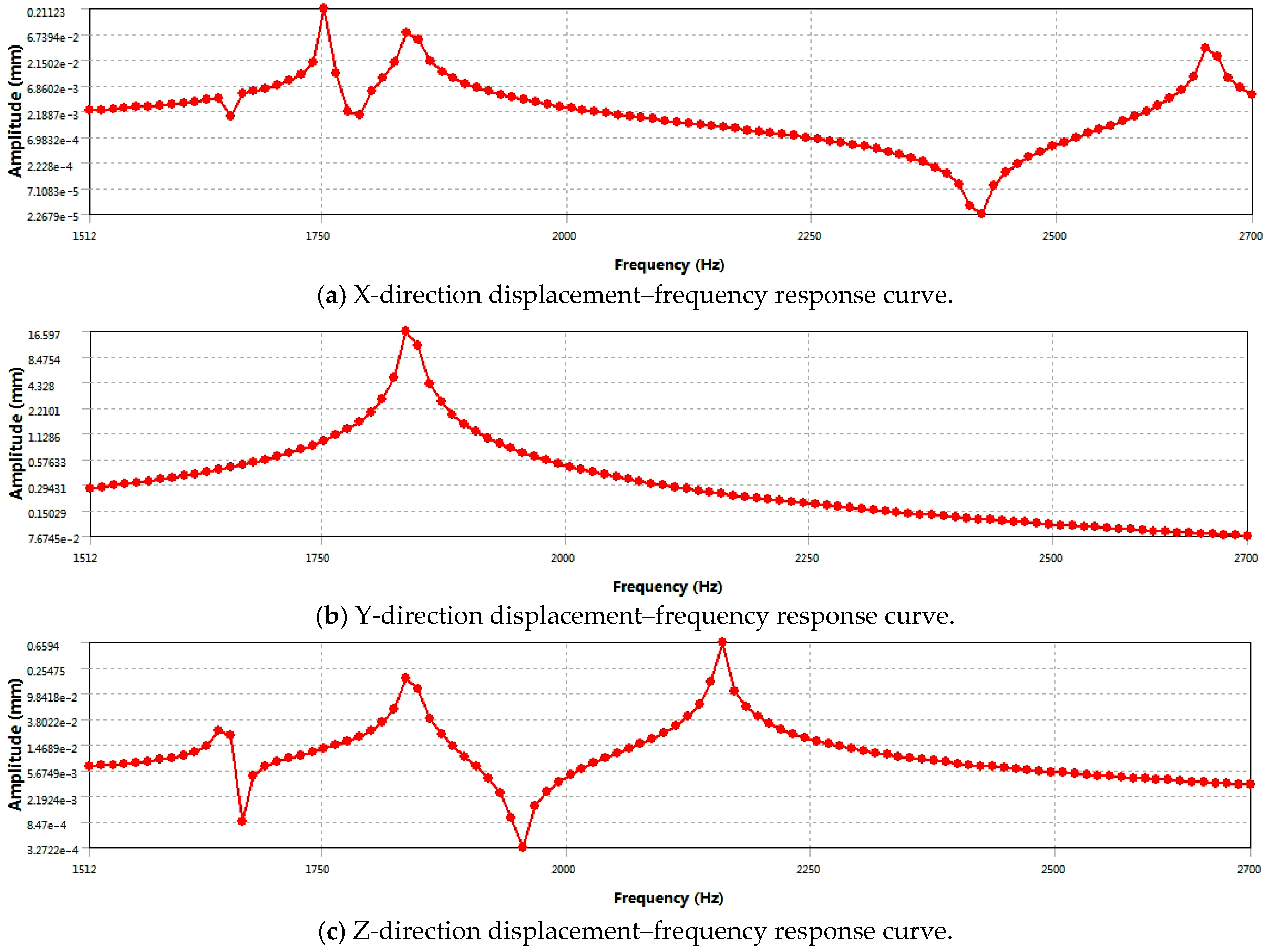

To deeply explore the dynamic characteristics of the piston, this study takes modal analysis as the theoretical basis and adopts the modal superposition method to analyze the harmonic response of the piston. To simulate the actual working condition, the piston pin is fixed, and the first to sixth modes are extracted via the Block Lanczos method, focusing on the modal characteristics in the frequency band of 1500–2700 Hz. A pressure load of 14.7 MPa in the -Y direction was applied to the piston top surface, the maximum scanning frequency was set at 2700 Hz, and a fine frequency interval of 100 Hz was adopted. Based on the first to sixth natural frequencies obtained by modal analysis, the displacement–frequency response curves in the X, Y, and Z directions were drawn, as shown in

Figure 8. These curves demonstrate the displacement response law of the piston under different frequency excitations, providing important data support for predicting the resonance behavior, evaluating the structural strength, and optimizing the design scheme.

The results of harmonic response analysis provide key data support for the dynamic performance analysis of the piston.

Figure 8a reveals the displacement behavior of the piston in the X direction, showing that at a specific frequency of 1752 Hz, the displacement response reaches a peak and then gradually decays, indicating that the vibration of the piston is the most intense at this frequency.

Figure 8b shows that there is a peak displacement of 16.6 mm near the resonance frequency of 1840 Hz, which represents the maximum relative displacement component achieved by the piston at this excitation frequency. This displacement reflects the vibration amplitude of the piston in the Y-axis direction caused by excitation and is an important indicator of structural dynamic response.

Figure 8c shows the vibration characteristics of the piston in the Z direction. At the frequency of 2160 Hz, the vibration displacement reaches its maximum and then decreases gradually. It shows that the resonance frequency in the Z direction is different from the first two.

Based on the results of harmonic response analysis, the piston geometry studied in this paper presents remarkable vibration characteristics under dynamic load. In the spatial rectangular coordinate system, three characteristic resonance frequencies of 1752 Hz (X direction), 1836 Hz (Y direction), and 2160 Hz (Z direction) are detected, respectively. Therefore, based on the above analysis of dynamic response characteristics, although the resonance frequency characteristics (1752 Hz/1836 Hz/2160 Hz) revealed in this study are only applicable to the specific piston geometry studied in this paper, the harmonic response analysis method based on modal analysis results can provide a universal technical path for the evaluation of vibration characteristics of similar reciprocating components. It is suggested that the above characteristic frequency range should be strictly avoided in the design of engine operating conditions and the control of the piston excitation source in order to prevent the risk of fatigue failure caused by co-vibration stress. For piston components with similar topological structure characteristics or service conditions, the whole process analysis framework of “geometric modeling-modal analysis-frequency response prediction” constructed in this study can be used for reference to carry out targeted structural dynamics optimization design.

3. Optimization Design of the Piston

3.1. Mathematical Model and ANOVA

The quadratic response surface optimization mathematical model is an optimization method based on the multivariate quadratic regression equation in statistics to fit the complex functional relationship between design variables and objective functions. It achieves the purpose of reducing the amount of calculation and improving the optimization efficiency by constructing a simplified quadratic polynomial model to replace the highly complex input-output relationship in the actual system. The quadratic response surface model is based on the multiple linear regression method and determines the unknown coefficients in the polynomial by the least squares estimation method. This model represents the system’s response (i.e., output variable or objective function) as a quadratic polynomial function of the design variables (i.e., input parameters).

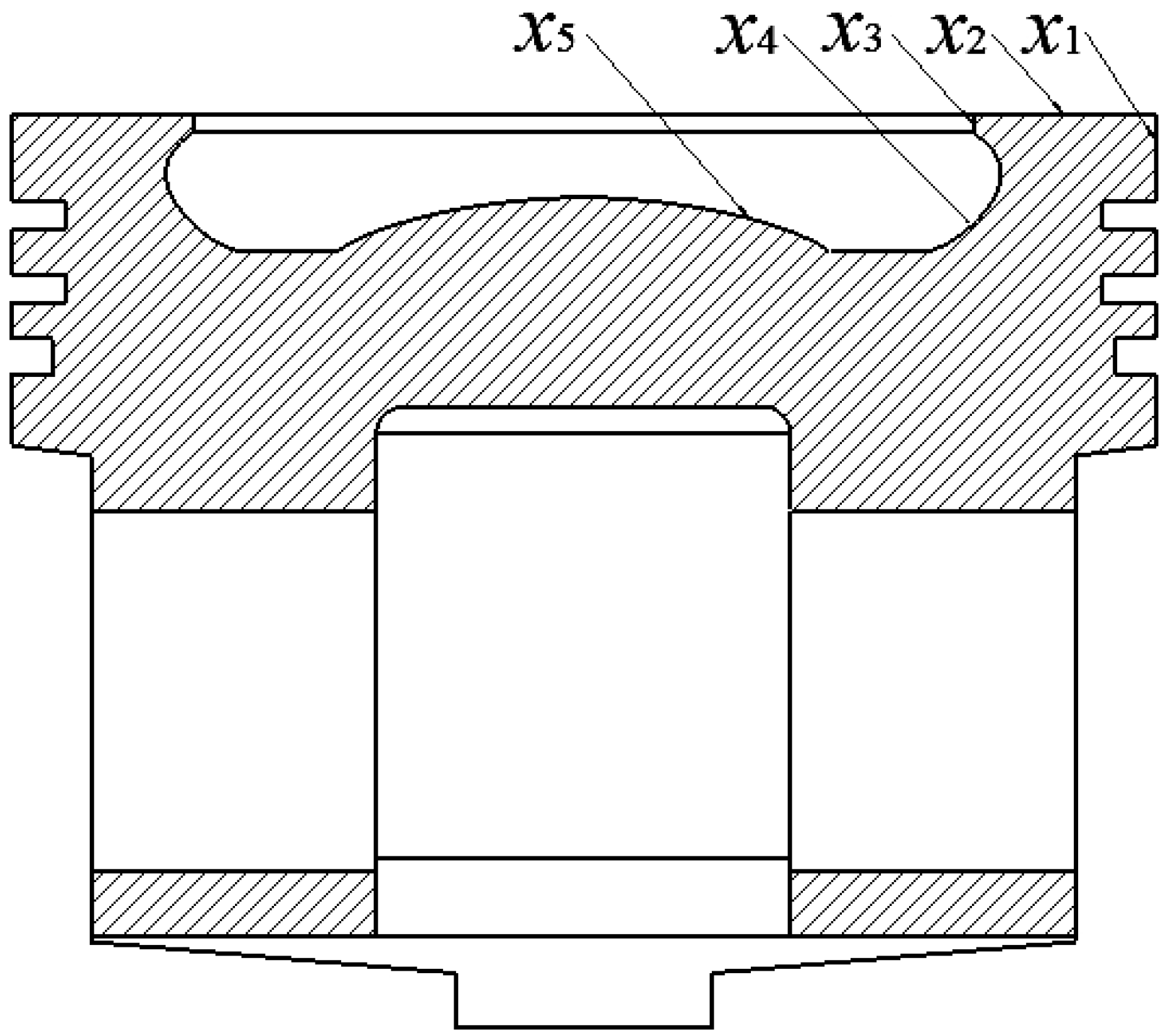

When optimizing the design of the piston, selecting and defining the optimization variables is a crucial first step. To achieve the optimization of piston performance, five geometry dimensions were selected as design variables:

x1 is the height of the fire land;

x2 is the top surface width;

x3 is the top surface thickness;

x4 is radius of top surface transition arc 2; and

x5 is radius of top surface transition arc 1. The selection of these parameters is based on their significant impact on the working performance of the piston, such as sealing, heat load capacity, mechanical strength, and durability.

Table 5 details the initial value ranges of these design variables.

Figure 9 shows the geometric structure of the piston and marks the specific locations of these geometric dimensions. By adjusting the values of these design variables, this study aims to explore the potential for improving piston performance without increasing additional material costs or manufacturing complexity.

The response surface analysis was conducted on the designed sample points by using Design-Expert software (version: 8.0.6). First, the sample points were accurately input into the system, and then the software automatically processed and generated detailed calculation expressions. This process not only simplifies the complex data processing flow but also ensures the accuracy of the analysis results. Subsequently, through the built-in variance analysis function, the software comprehensively evaluated the significance of the regression model equation, and the results showed that the model fitting effect was excellent, providing a solid statistical basis for subsequent in-depth analysis. It is particularly worth noting that Design-Expert visually displays the regression equation with encoded independent variables as the core, which profoundly reveals the intrinsic relationship between design variables and performance goals.

For the quadratic polynomial response surface model of n design variables, as shown in Equation (1).

In the formula, y is the objective function.

β0, βi, βij, and βii (i < j) are undetermined coefficients of the polynomial.

β0 is a constant term.

βi is the linear effect of the design variable xi.

βij is the linear interaction effect between design variables xi and xj.

βii is the quadratic effect of the design variable xi.

n is the number of design variables.

Generally, the quadratic response surface modeling has a 95% possibility. Due to the large number of design variables of the moving crossbeam, the quadratic response surface is directly used for modeling, and all quadratic terms, linear terms, and interactions between various factors are considered. In the quadratic regression analysis, the backward method (Backward) is used to delete the design variables and interactions that have no significant impact. Through the above analysis, the final established quadratic response surface models are shown in Equations (2)–(7).

The final equation of mass is fitted by the quadratic response surface model, as shown in

y1.

The final equation of the temperature fitted by the quadratic response surface model, as shown in

y2.

The final equation of the deformation is fitted by the quadratic response surface model, as shown in

y3.

The final equation of the first frequency is fitted by the quadratic response surface model, as shown in

y4.

The final equation of the second frequency is fitted by the quadratic response surface model, as shown in

y5.

The final equation of the third frequency is fitted by the quadratic response surface model, as shown in

y6.

To evaluate the fitting ability of the quadratic response surface model to the output response, the F-value, P-value, Std. Dev (standard deviation), Mean (mean), Mean Square (mean square), Sum of Squares and Residual of the model are given, respectively. At the same time, the determination coefficient

R2, the adjusted determination coefficient

Ra2, and the prediction determination coefficient

Rpred2 are used for evaluation. The calculation methods of the determination coefficient

R2 and the adjusted determination coefficient

Ra2 are given in Equations (8) and (9).

The evaluation value table of the fitting degree of the response surface model is shown in

Table 6.

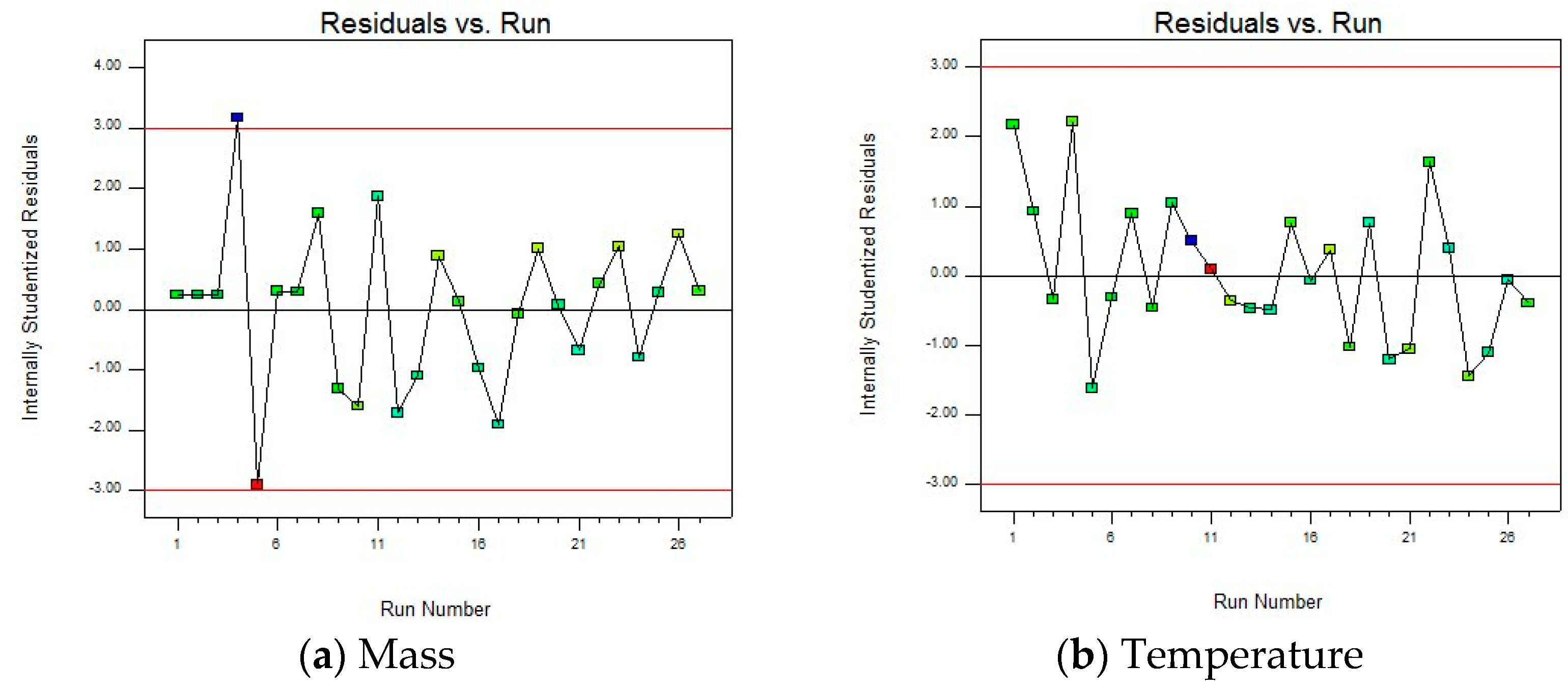

To study the rationality of the fitted model, the sufficiency of model fitting, and to identify potential data problems, the “Residuals vs. Run” plot is given, as shown in

Figure 10.

There are no obvious trends, periodicities, etc., in the residual and run sequence number plot, and there are no upward, downward, or periodic change trends with the increase in the run sequence number, indicating that the model fitting effect is good and can better capture the patterns in the data. However, there are also two abnormal data points in the figure that are far from the zero value line (generally considered that the absolute value of the internal studentized residual is greater than 3, as shown by the red line in the figure), namely, 4 and 5 in the run sequence. Therefore, when optimizing the model in the subsequent steps, the outliers should be corrected or removed to improve the accuracy and reliability.

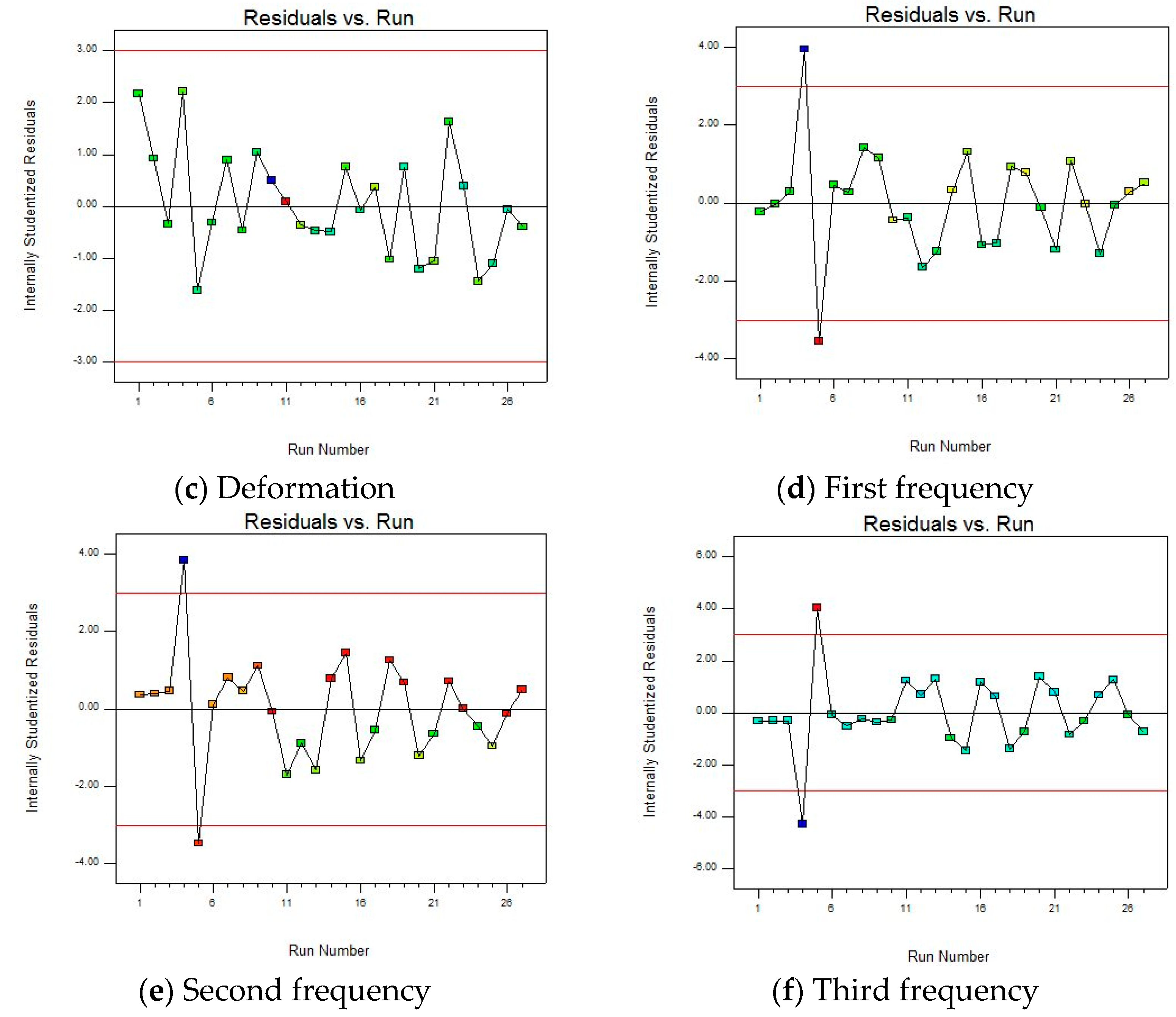

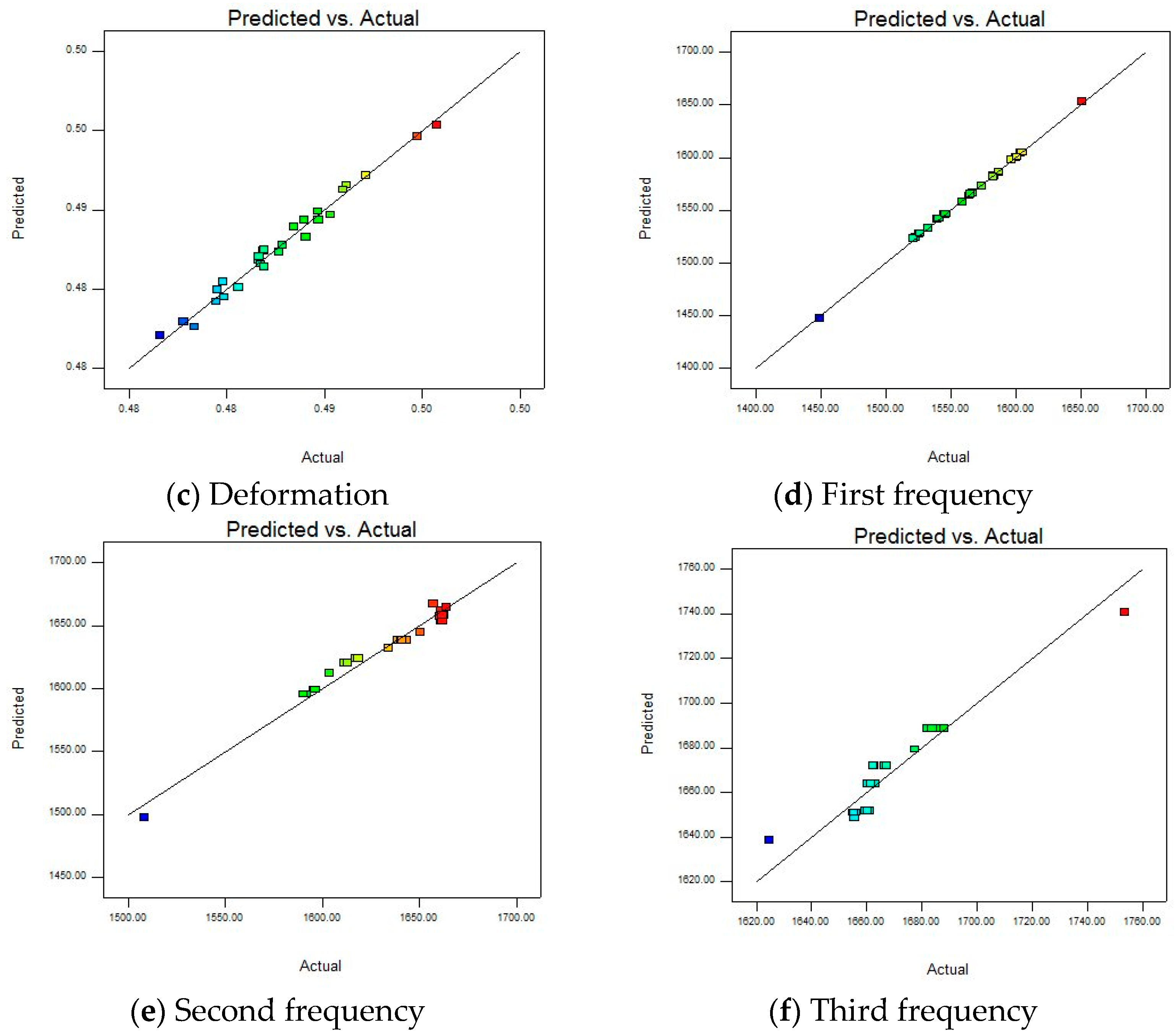

To further evaluate the fitting accuracy and predictive ability of the model on the experimental data, a “Predicted vs. Actual” diagram is presented, as shown in

Figure 11. Studying whether the data points are distributed around the diagonal, it is apparent that the model can accurately capture the experimental patterns. This visual comparison can quickly identify whether the model is over-fitting or under-fitting, providing direction for subsequent optimization.

Most of the data points are relatively concentrated near the straight line, indicating that the predicted values of the model and the actual values are relatively close, and the model can fit the actual situation to a certain extent, which is a relatively ideal state. At the same time, there are individual points (such as blue and red points) that deviate far from the straight line. Combined with the residual and run sequence number diagram, outliers need to be corrected or eliminated to improve the accuracy and reliability of the model.

3.2. Sensitivity Analysis

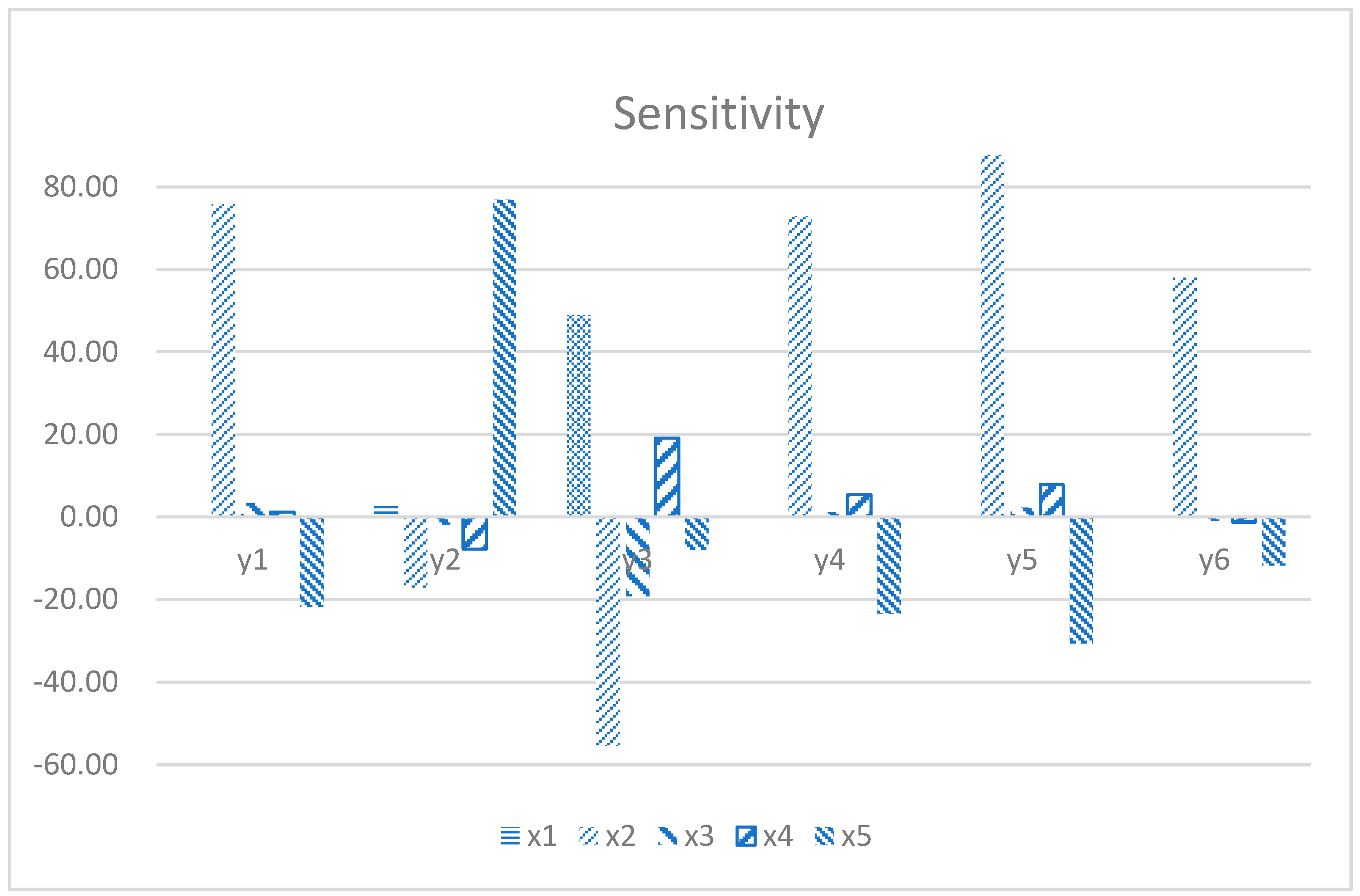

Sensitivity analysis, as a core analytical method, aims to precisely quantify the sensitivity of the output of a mathematical model or system to changes in its input parameters. This method delves into how the system state or output changes in response to fine-tuning system parameters and external conditions, thereby revealing which parameters have the most significant impact on system performance. Based on the results of a detailed design of experiments (DOE), by analyzing the generated design points, this study successfully plotted the sensitivity histogram of the five geometry dimensions as shown in

Figure 12. It directly shows the contribution of each parameter to the model output change and provides valuable insight for decision-makers and researchers, enabling them to focus on those parameters that have the greatest impact on the model performance. Based on these sensitivity analysis results, targeted model optimization strategies can be implemented to significantly improve the prediction accuracy of the model.

In the analysis results presented in

Figure 11, the significant impact of multiple key parameters of piston design on its performance indicators can be clearly observed.

x2 and

x5 are crucial in optimizing piston performance. First, these two parameters have a significant impact on

y1, indicating that in lightweight design, precisely regulating the top surface width and the size of the transition arc is an effective way to reduce piston mass.

x2 and

x5 have the same important impact on

y2. By optimizing these parameters, the heat load distribution of the piston during operation can be effectively adjusted, thereby reducing the piston temperature, extending the service life of the material, and improving the overall thermal efficiency of the engine. The mechanical response characteristics of the piston are also jointly regulated by multiple design parameters. Specifically,

x1,

x2,

x3, and

x4 jointly act on

y3. In terms of dynamic characteristics, the changes in

x2 and

x5 show significant effects on

y4,

y5, and

y6. The increase in natural frequency helps to enhance the vibration resistance of the piston, reduce the risk of failure caused by resonance, and ensure the smoothness and reliability of engine operation. Through reasonable combination and collocation of these parameters, the deformation of piston can be reduced. In this way, the structural strength of the piston is effectively enhanced, and the risk of fatigue failure caused by stress concentration phenomenon is significantly reduced. Thereby effectively improving its durability and reliability. The sensitivity analysis results reveal the internal relationship between piston design parameters and key performance indexes. At the same time, it points out the direction for the subsequent optimization design. By reasonably changing the parameters

x1 to

x5, the piston temperature can be reduced, and the dynamic characteristics can be optimized.

3.3. Results and Discussion

Based on sensitivity analysis results, the response surface methodology is used to construct a complex mathematical model between the objective function (such as mass y1, temperature y2, and maximum deformation y3, etc.) and the design variables (x1, x3, x3, x4, and x5). This model aims to accurately describe the nonlinear relationship between parameters and provide strong theoretical support for optimization design.

Since the response surface model used in this paper involves five design variables and six objective functions, it will take a lot of space to list all model expressions completely, and not all models have significant engineering analysis value. Therefore, the response surface models selected are all developed around the scenes where there is a significant correlation between the design variables and the objective functions. In the meantime, combined with the results of sensitivity analysis, the variable combinations that show strong parameter sensitivity in mathematics are screened out together, and the shape of response surface is presented intuitively.

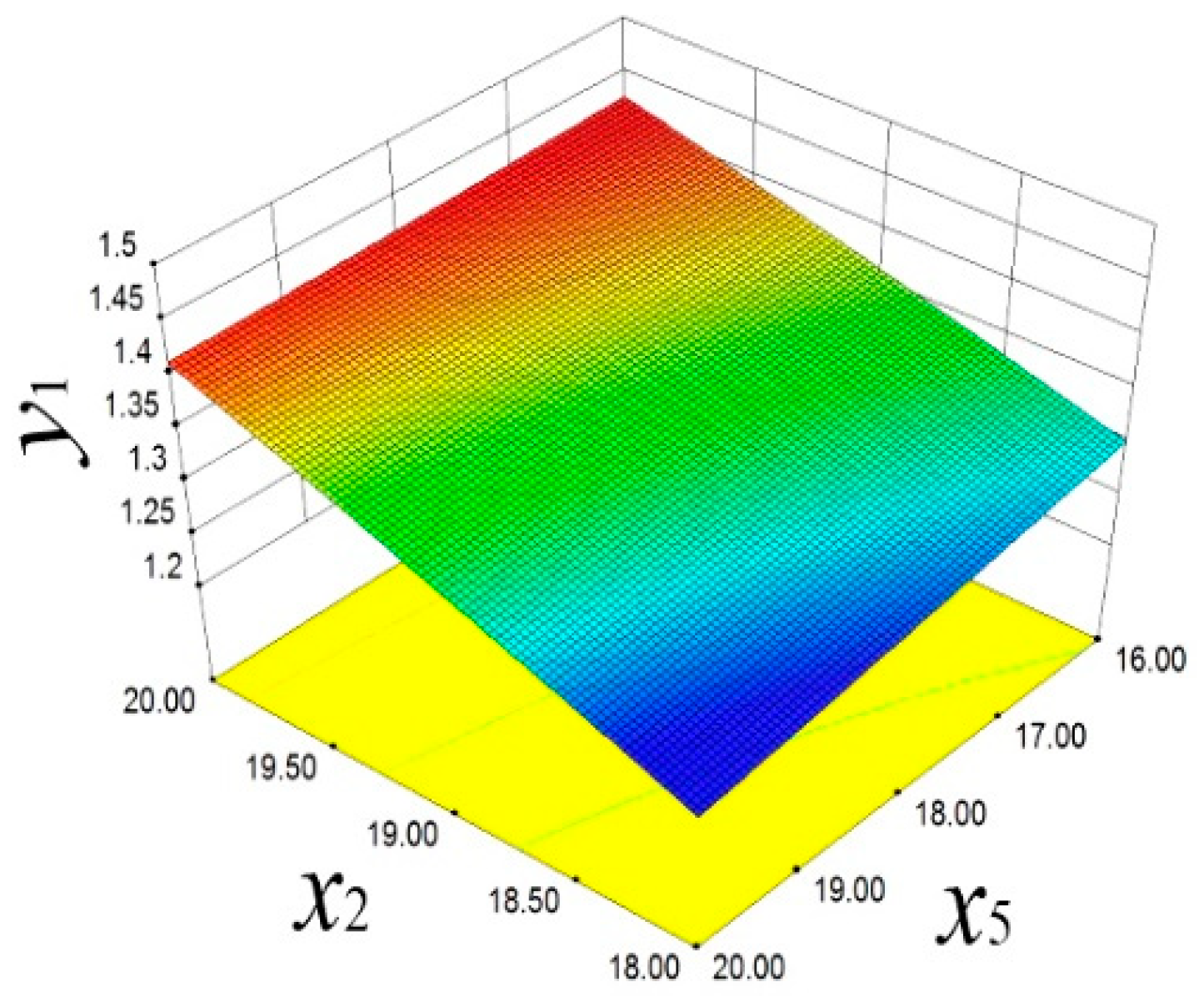

As shown in

Figure 13, the response surface model reveals a positive correlation between

x2 and

y1. With the increase in

x2,

y1 significantly increases. The decrease in

x5 also has a similar effect on

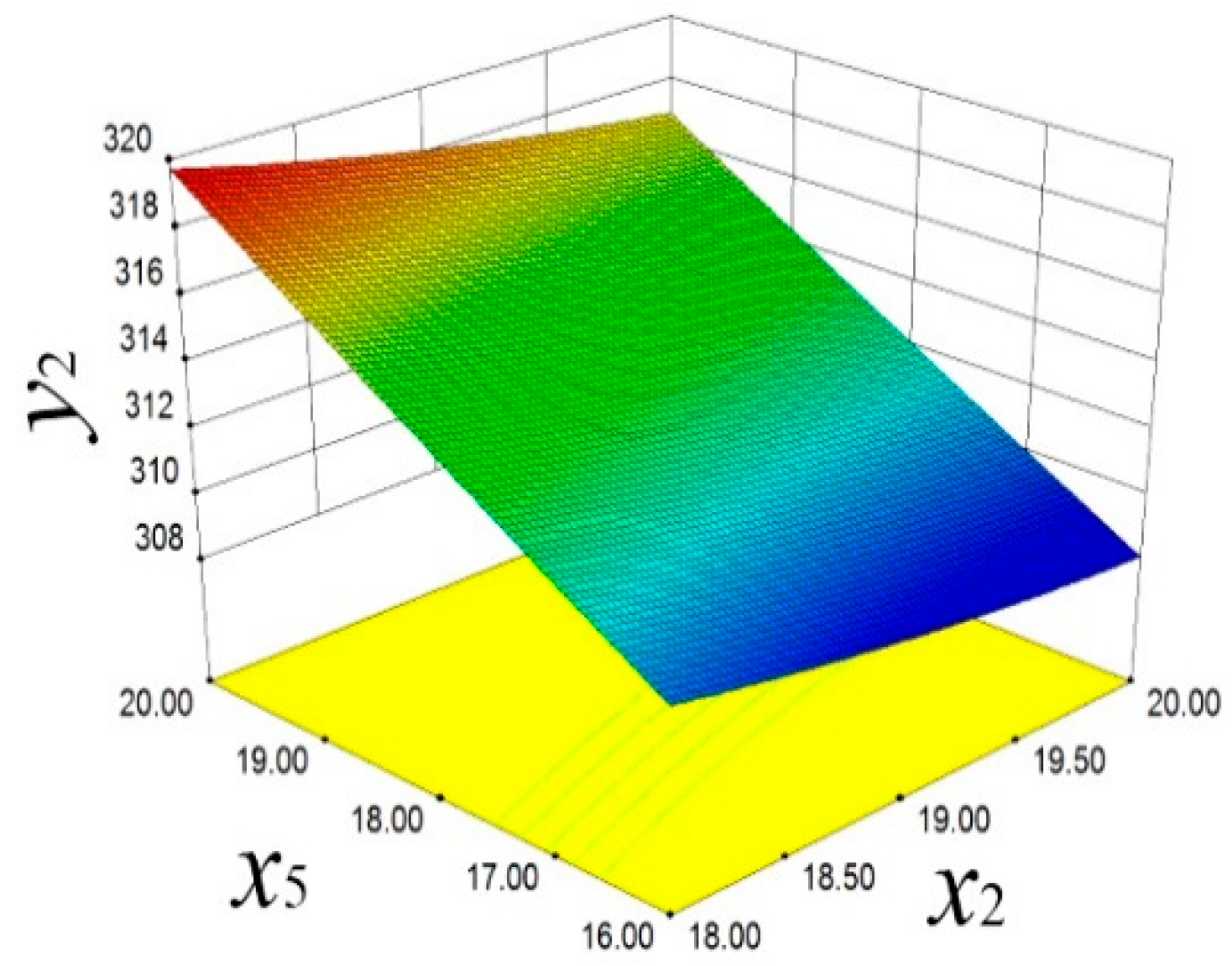

y1, indicating that these two parameters have significant sensitivity in controlling the piston mass. As shown in

Figure 14, the reverse regulation effect of

x2 and

x5 on the piston temperature

y2 is demonstrated. When

x2 decreases and

x5 increases,

y2 shows an upward trend. This finding reveals the important role of design variables in regulating the distribution of piston thermal load, providing a scientific basis for optimizing the thermal management strategy.

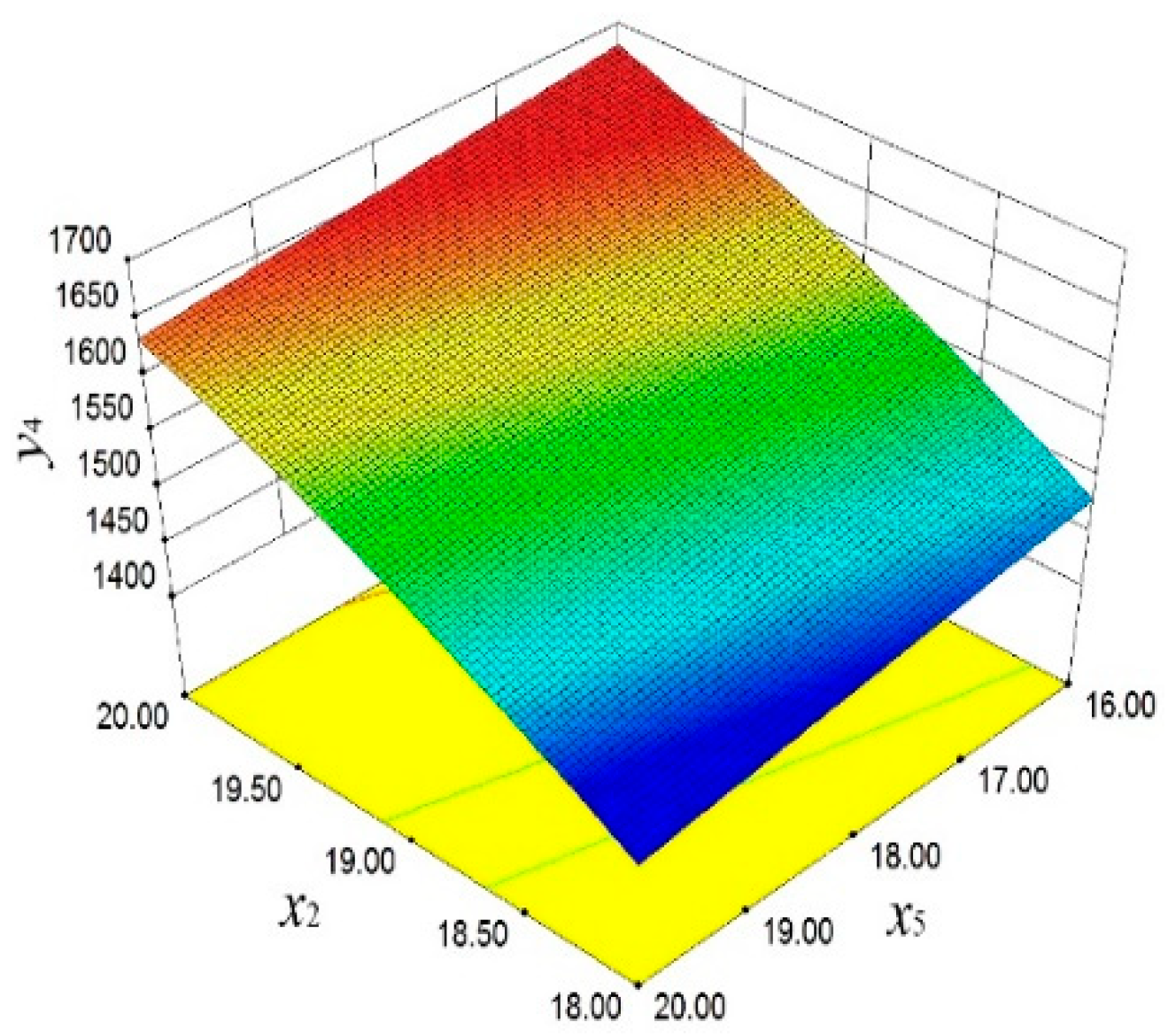

In

Figure 15, the significant influence of

x2 and

x5 on

y4 is demonstrated. With the increase in

x2 and the decrease in

x5,

y4 shows an upward trend. This finding emphasizes the importance of these two design parameters in improving the dynamic stability of the piston.

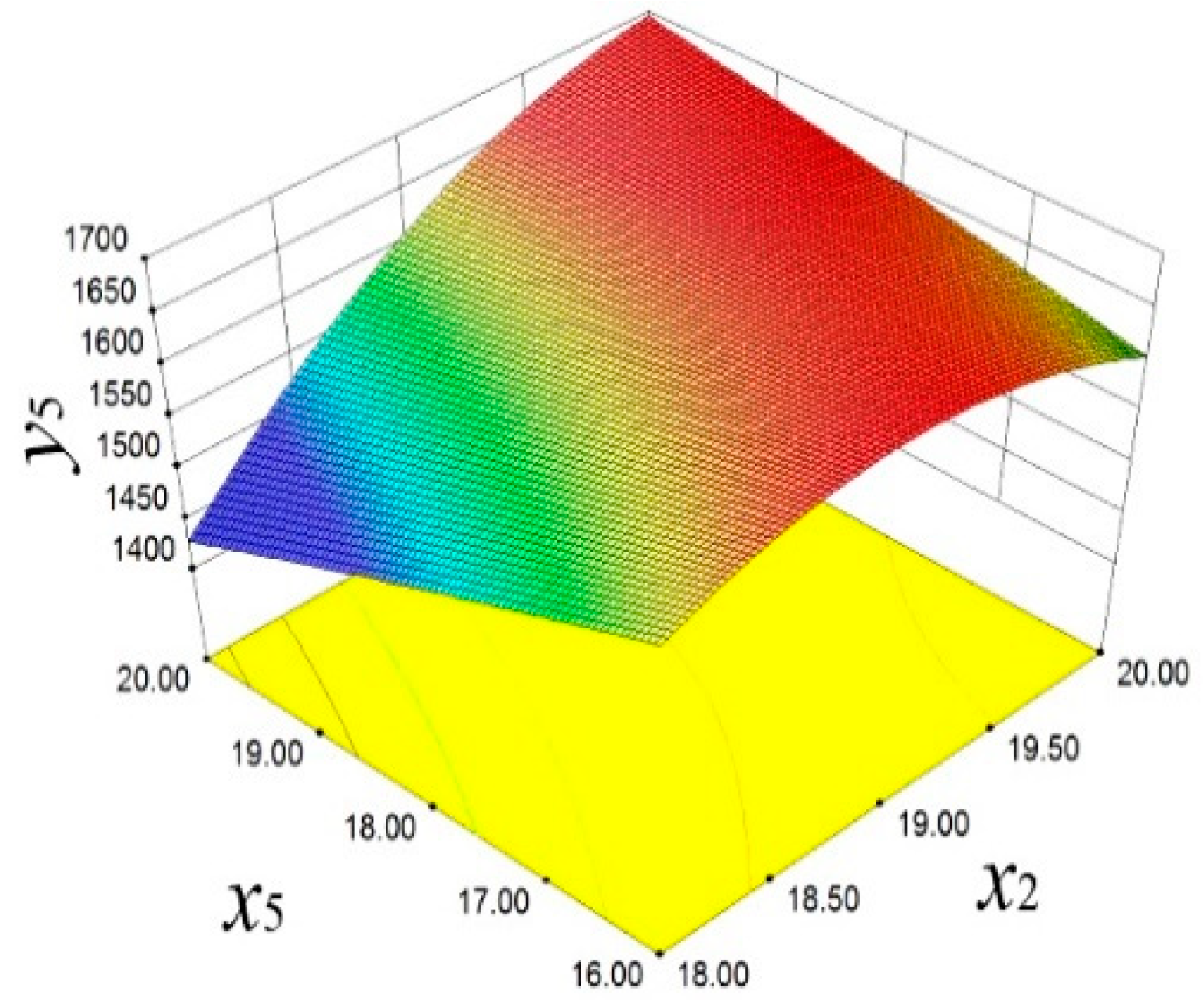

Figure 16 reveals the positive effect of

x2 and

x5 on

y5. With the increase in

x2 and the decrease in

x5,

y5 also increases.

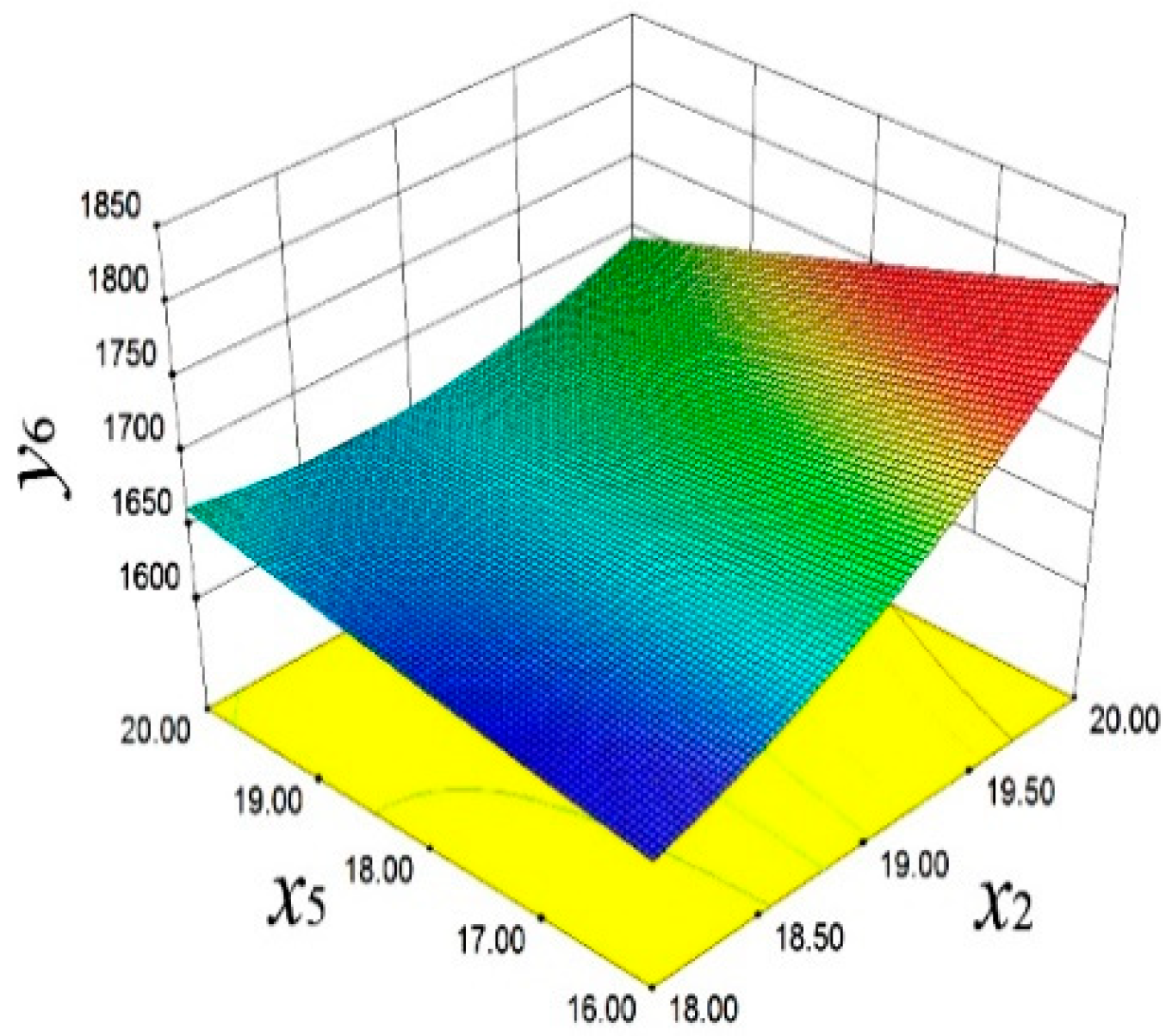

In

Figure 17, the influence of

x2 and

x5 on

y6 is demonstrated. Specifically, with the increase in

x2 and

x5,

y6 significantly increases. This finding reveals the crucial role of design variables in adjusting the high-order vibration characteristics, providing a perspective for improving the smooth operation of the engine. As shown in

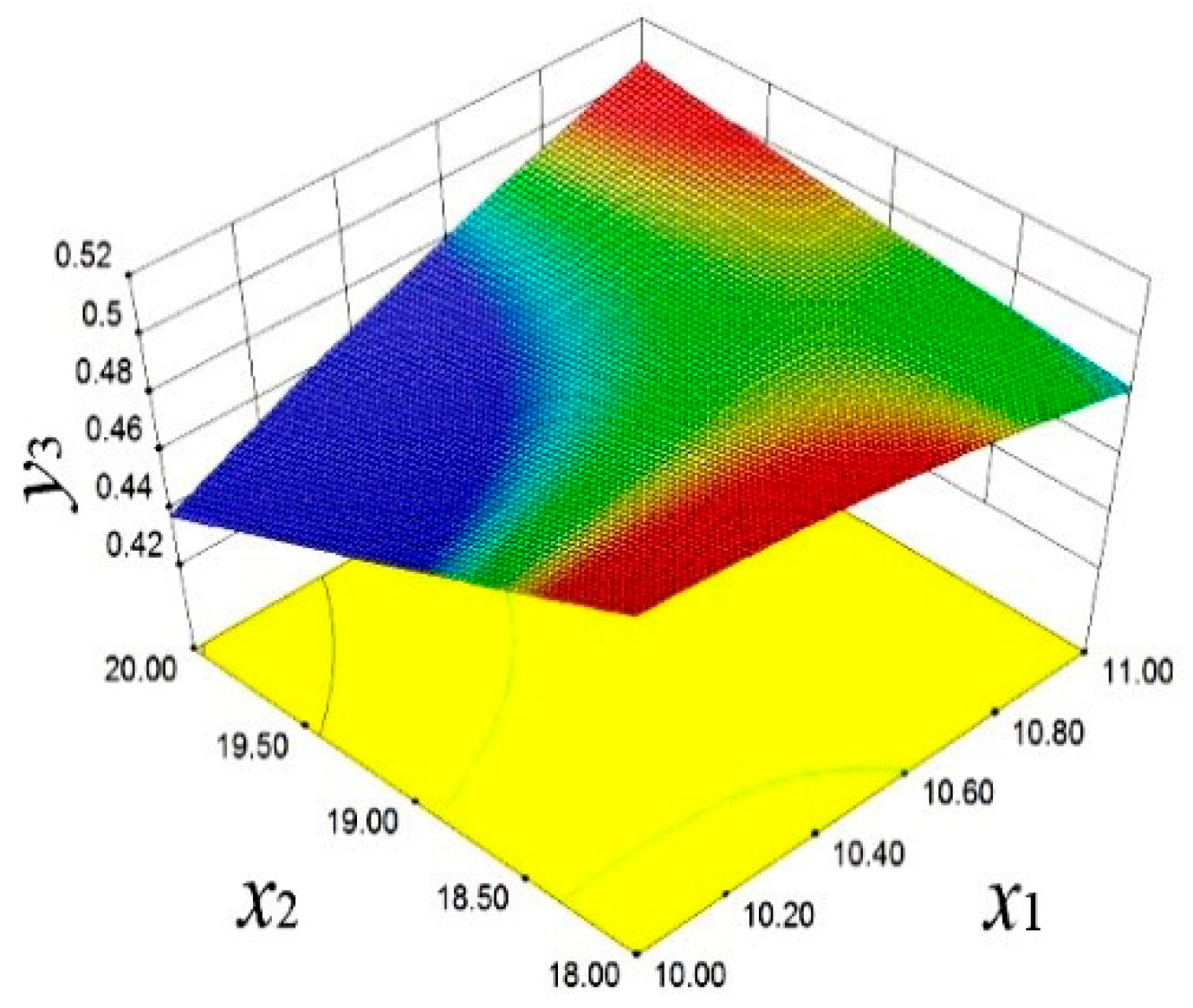

Figure 18,

y3 is affected by x

2 and

x1. When

x2 and

x1 decrease,

y3 significantly increases.

This complex relationship indicates that in optimizing the piston structure to reduce deformation and improve stiffness, the synergistic effect of multiple design parameters needs to be considered to achieve the best design effect.

The results explores the balance between mass, temperature, deformation, and the first to third frequencies, achieving a significant improvement in its overall performance without increasing mass. Then, the MOGA, screening, and RSM were, respectively, used to conduct a comprehensive and in-depth optimization. Through numerical calculations, the results of different optimization algorithms are given, as shown in

Table 7.

After elaborate experiments and in-depth analysis, the MOGA variation algorithm was finally selected as the optimal solution for implementation. The optimized results show that on the premise of relatively stable mass and deformation, a significant reduction in temperature has been achieved. The working temperature of the piston has been effectively reduced from the initial 312.75 °C to 308.07 °C. This improvement not only extends the service life of the component but also enhances the thermal efficiency of the overall system. In terms of dynamic characteristics, the optimized piston shows better dynamic characteristics. The first, second, and third frequencies are increased from 1651.60 Hz, 1656.70 Hz, and 1665.70 Hz to 1671.80 Hz, 1665.70 Hz, and 1776.50 Hz, respectively. The first to third frequencies are improved. The dynamic stability and vibration resistance of the piston are further enhanced.

To sum up, the optimization method proposed in this paper reduces the working temperature, improves its natural frequency and overall dynamic performance, and achieves the expected goal of multi-objective optimization design. The research results provide a method for the optimal design of the piston and even internal combustion engine parts.