Microstructure and Mechanical Properties of Functionally Graded Materials on a Ti-6Al-4V Titanium Alloy by Laser Cladding

Abstract

1. Introduction

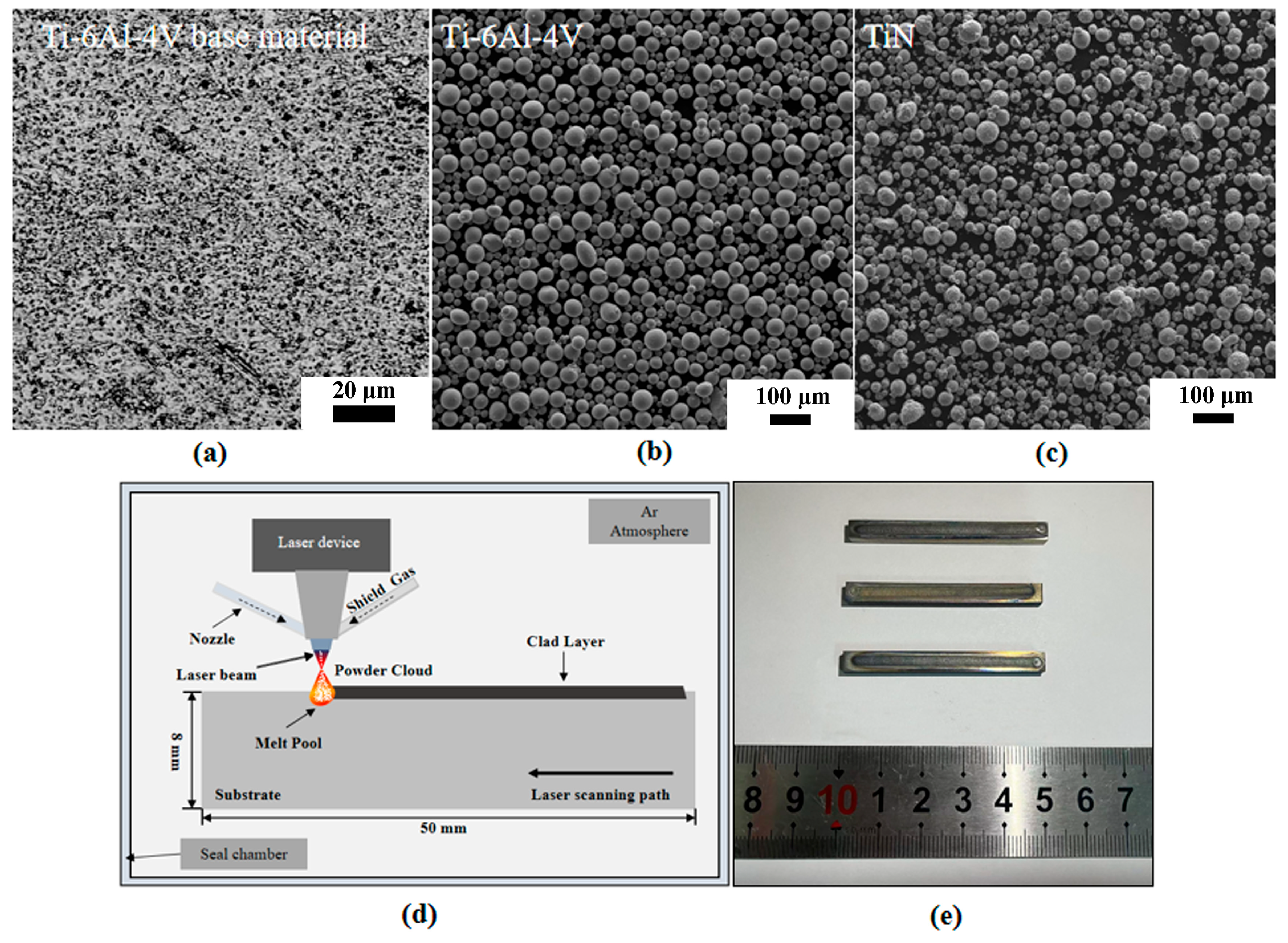

2. Materials and Methods

3. Results

3.1. Microstructure

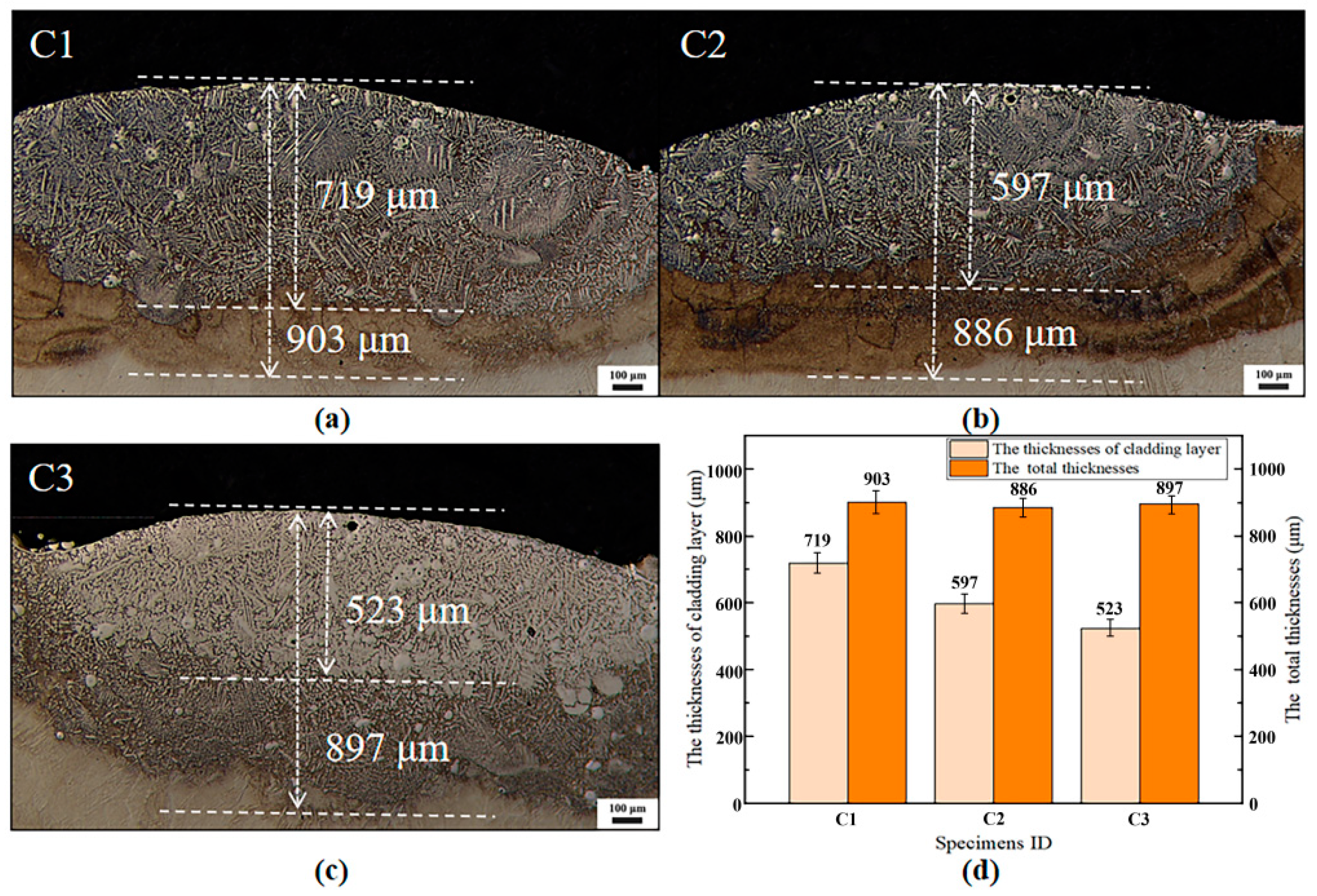

3.1.1. Optical Microscopy

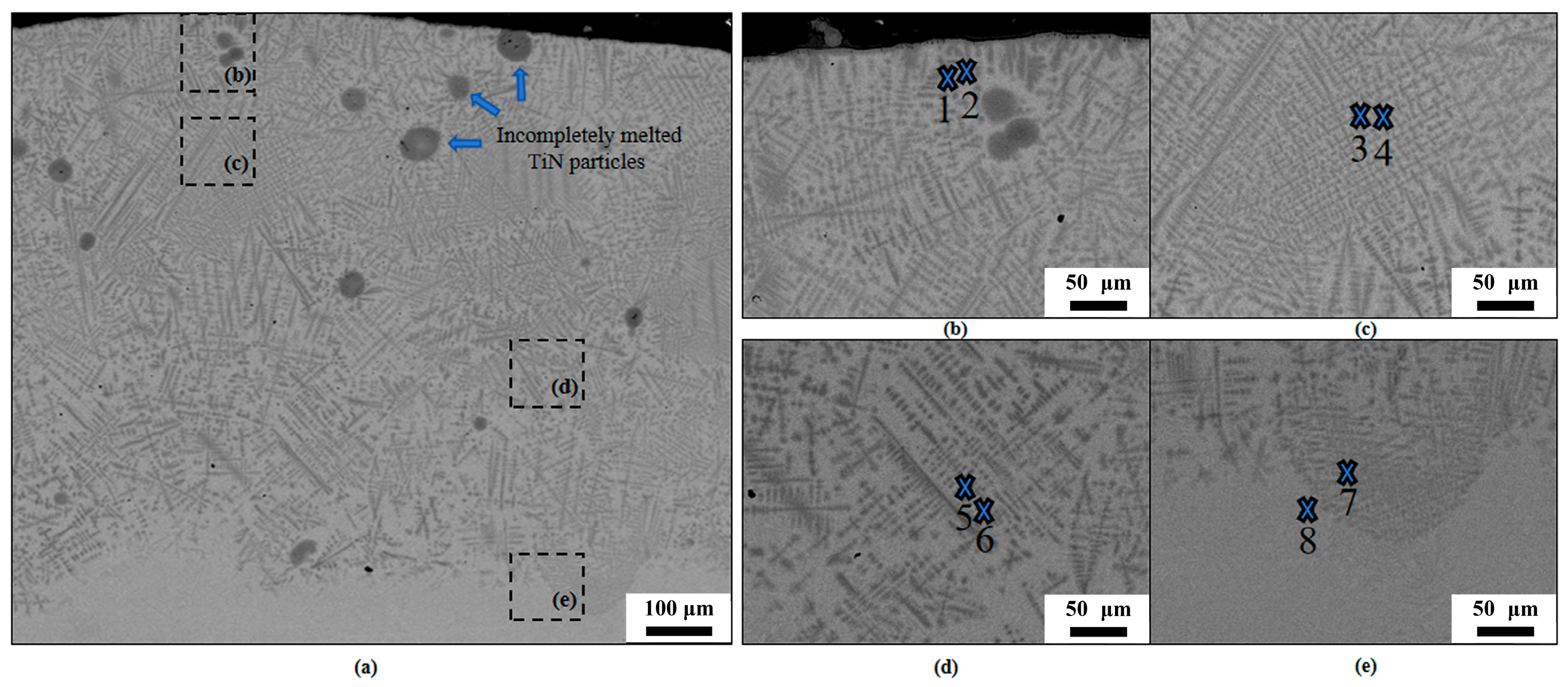

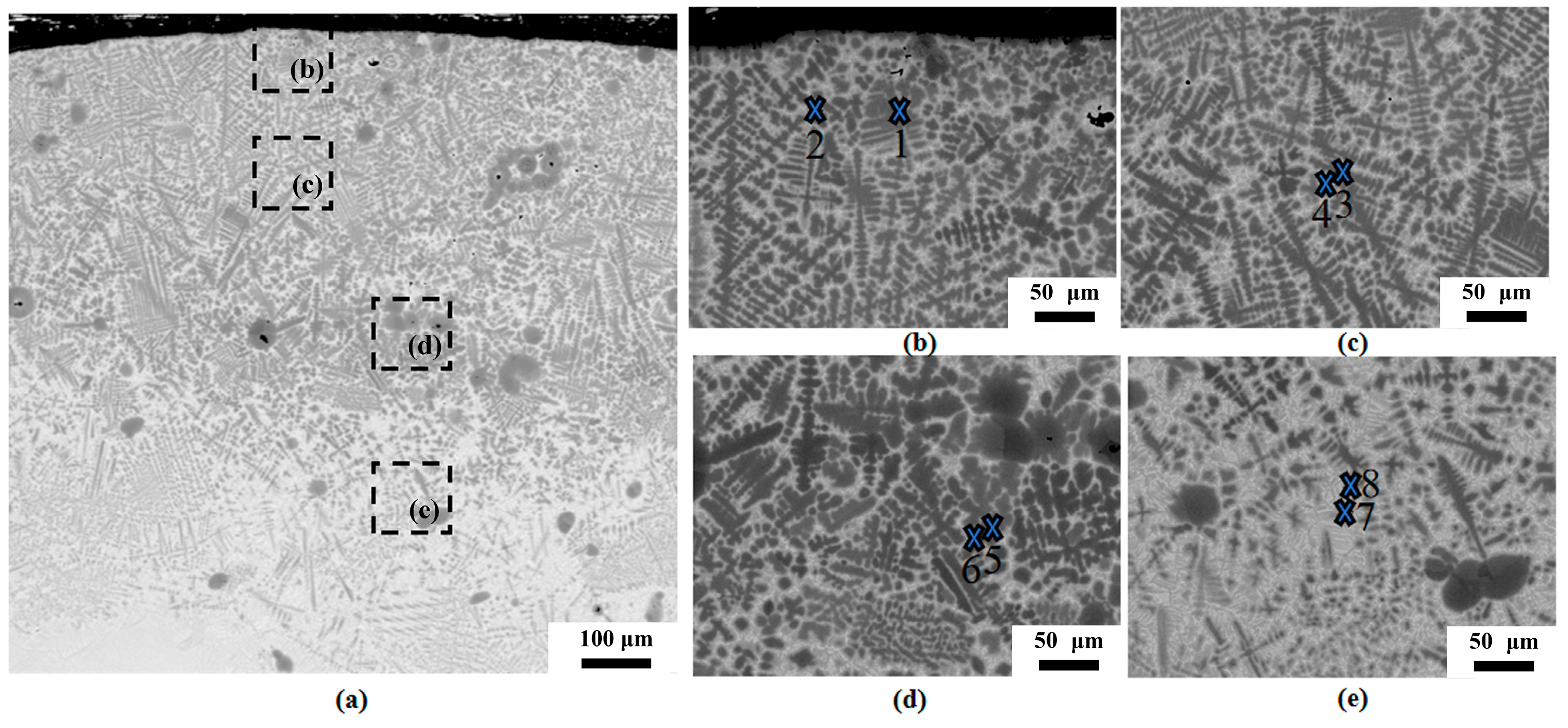

3.1.2. Scanning Electron Microscopy

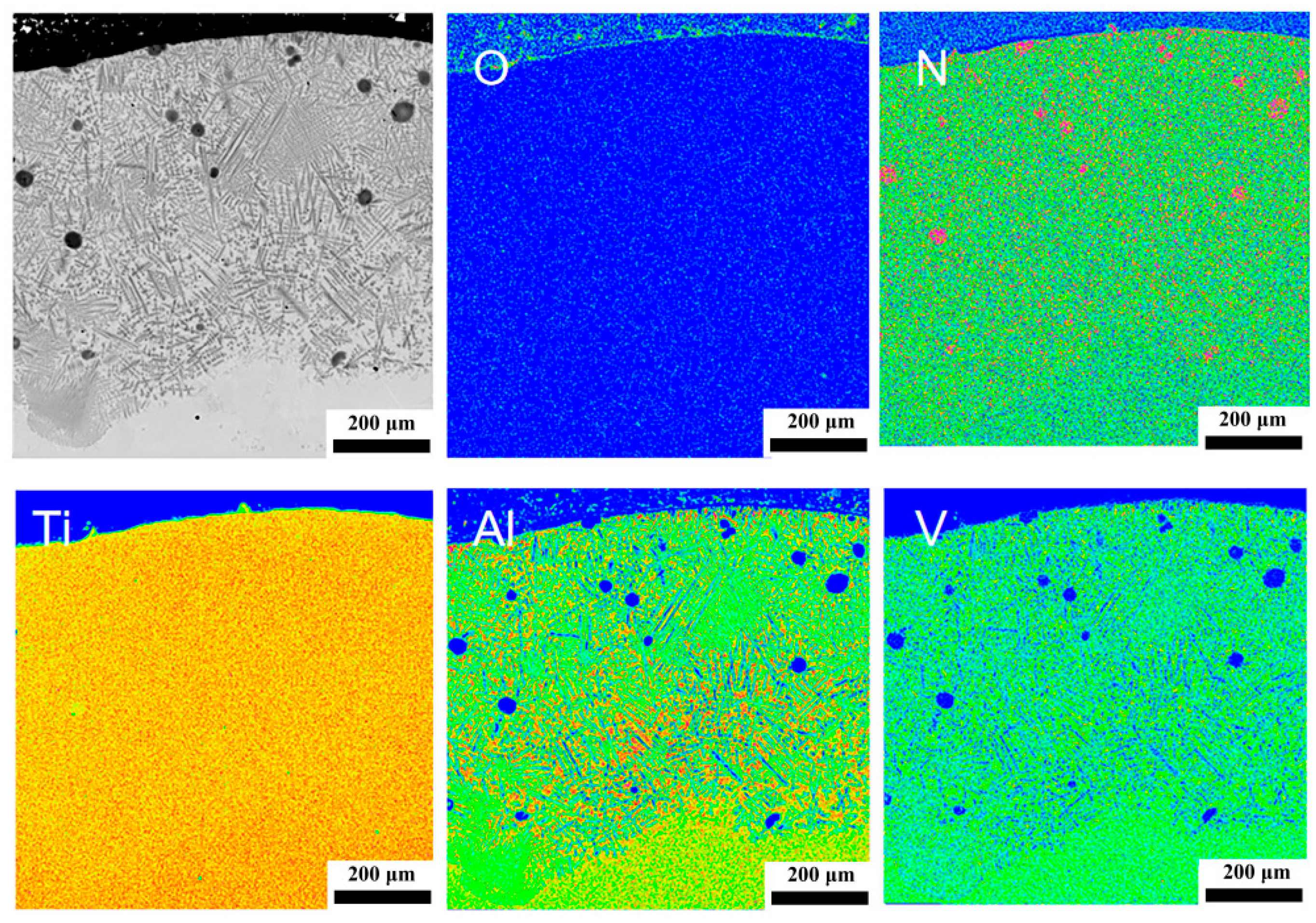

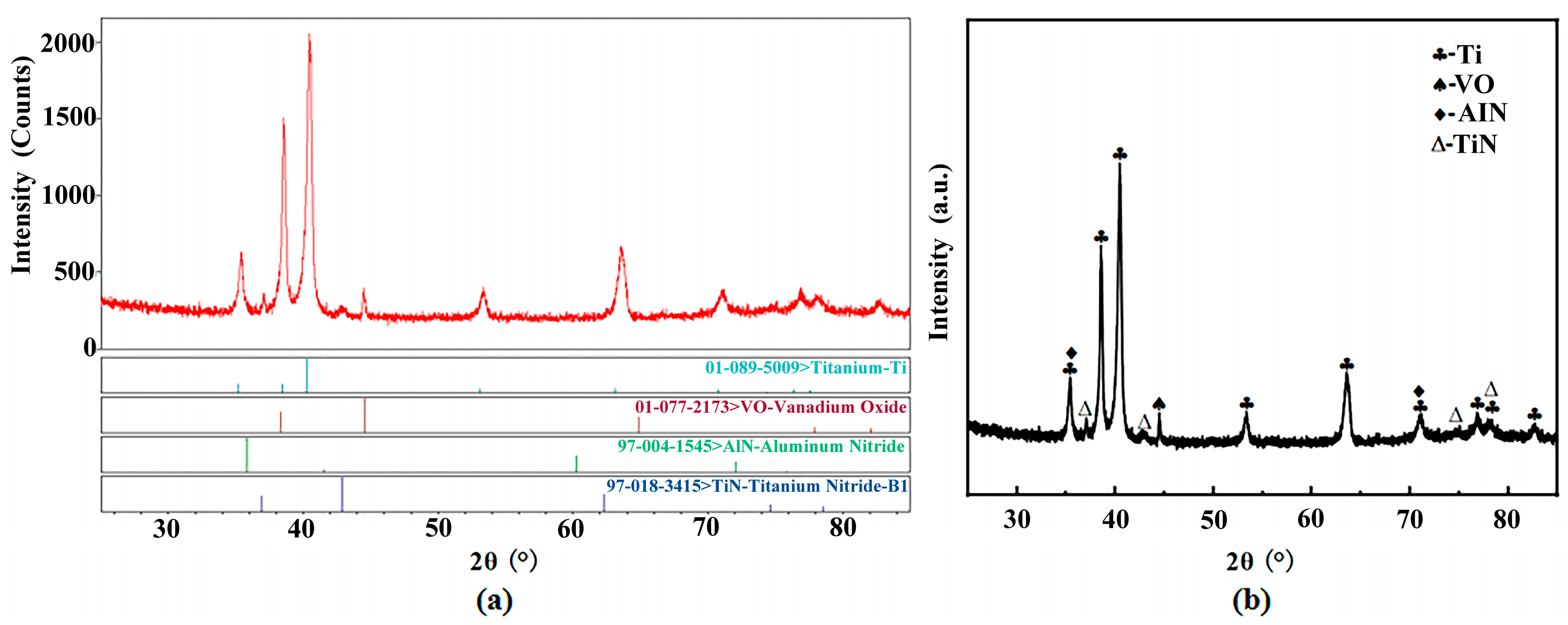

3.2. Phase Analysis and Element Distribution

3.3. Mechanical Properties

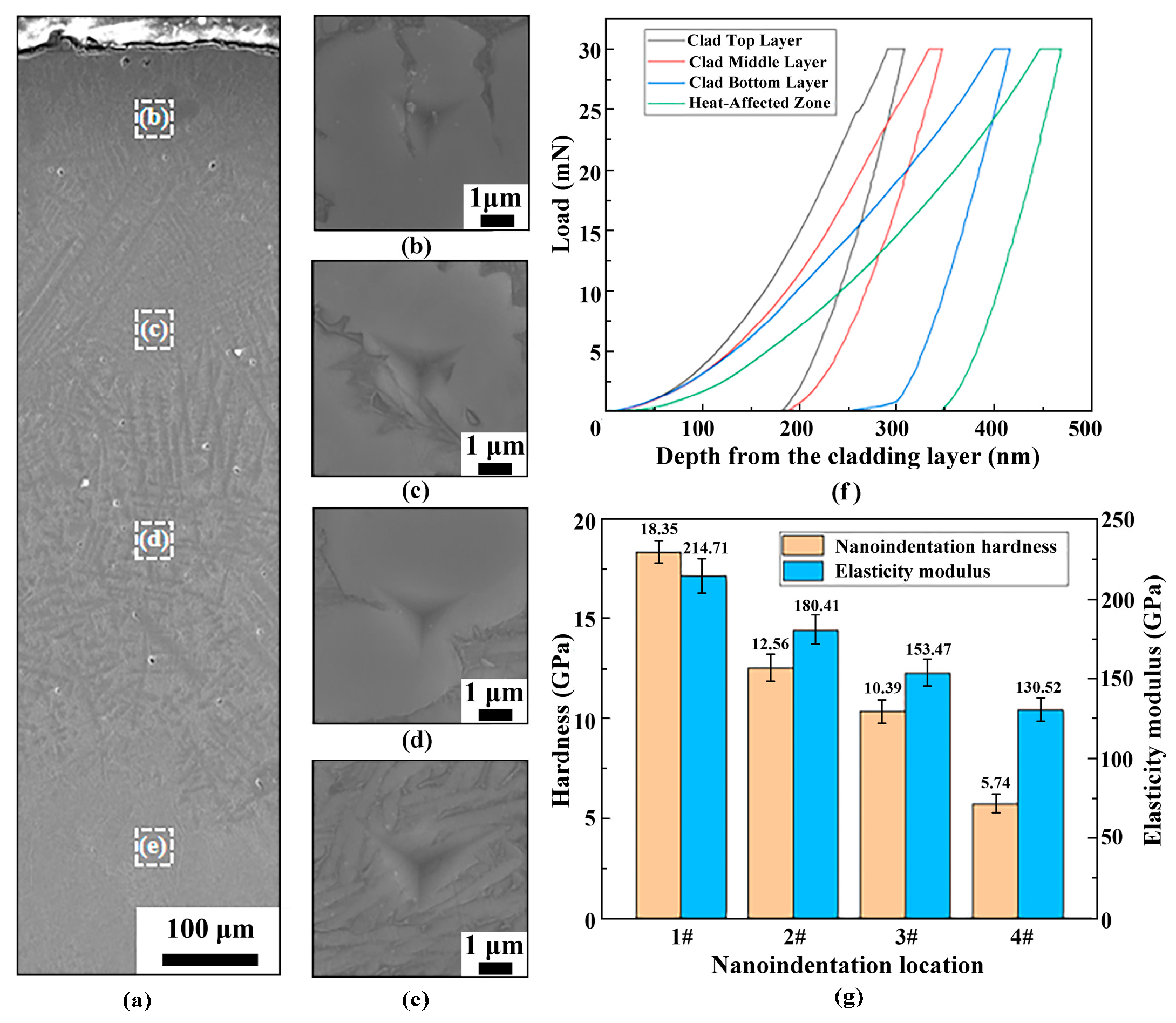

3.3.1. Nanoindentation Hardness and Elastic Modulus

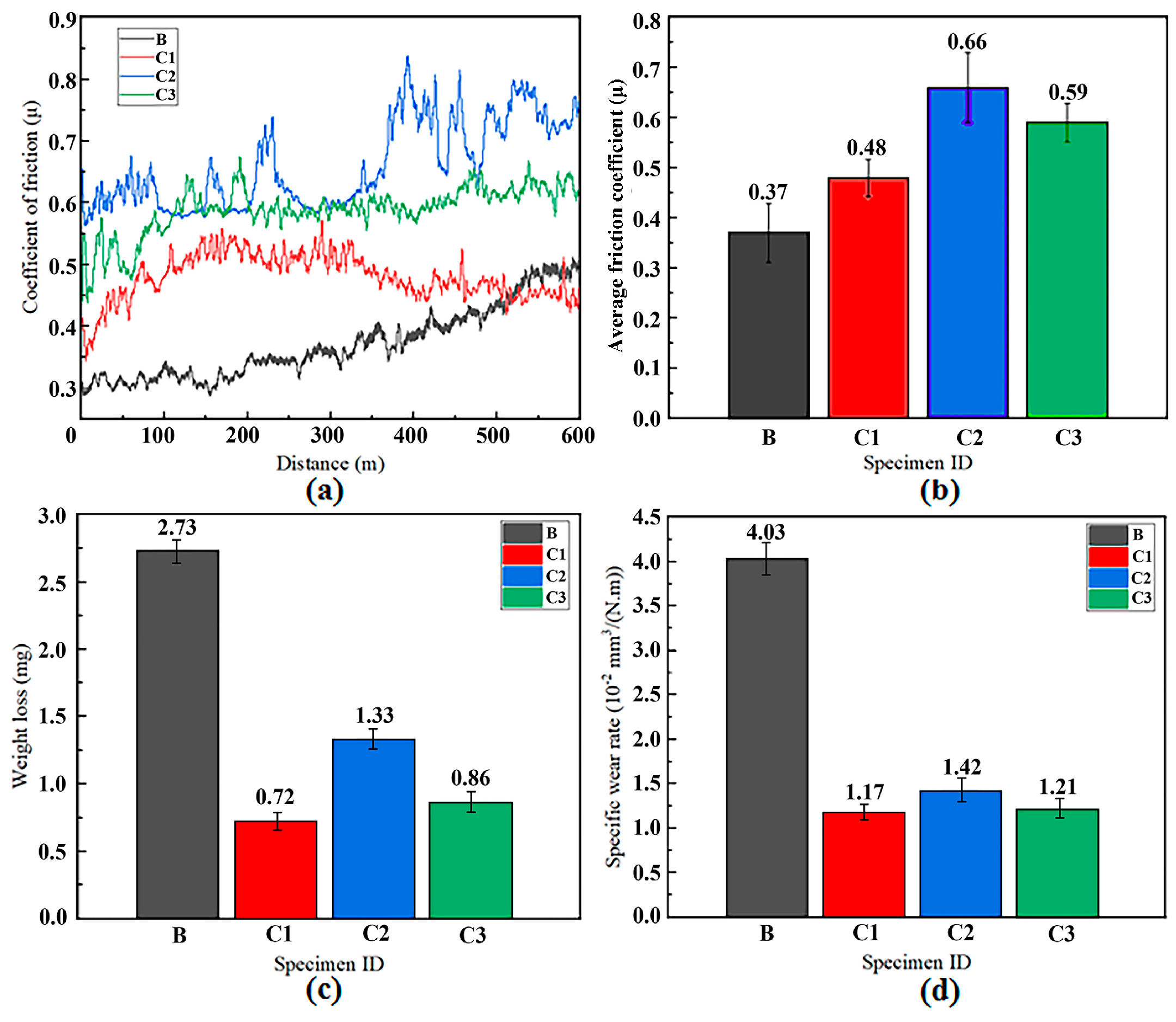

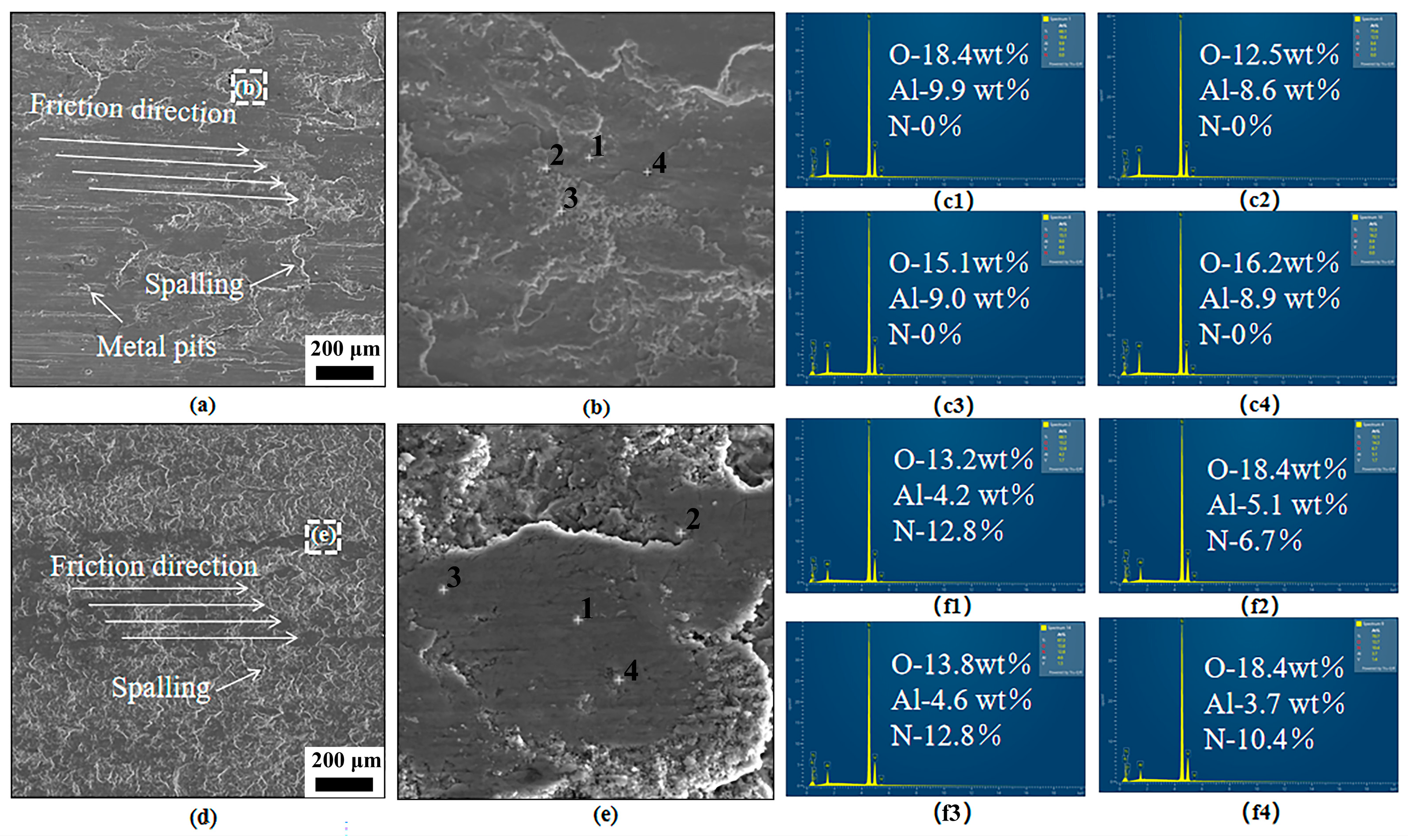

3.3.2. Wear Resistance

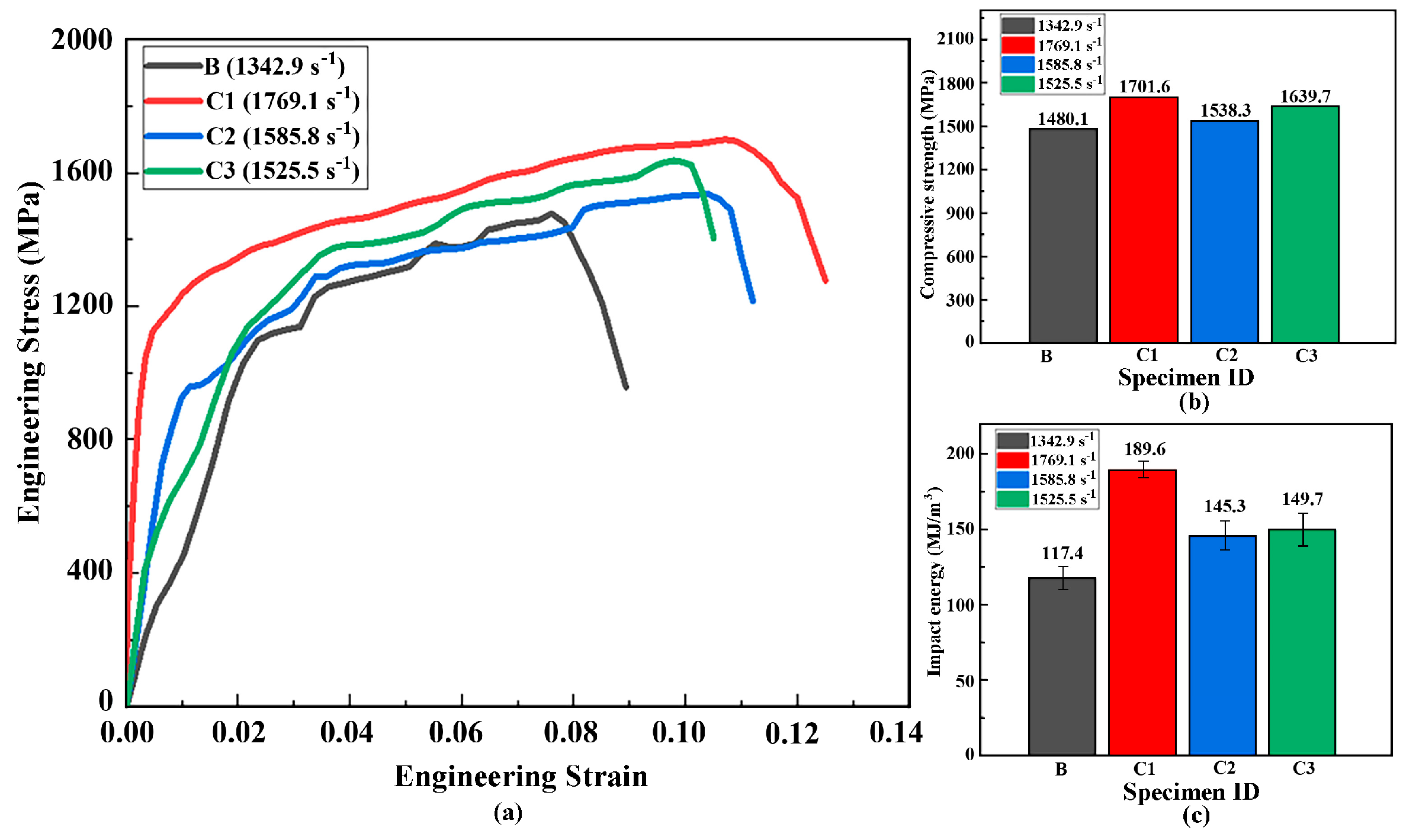

3.3.3. Impact Toughness

4. Discussion

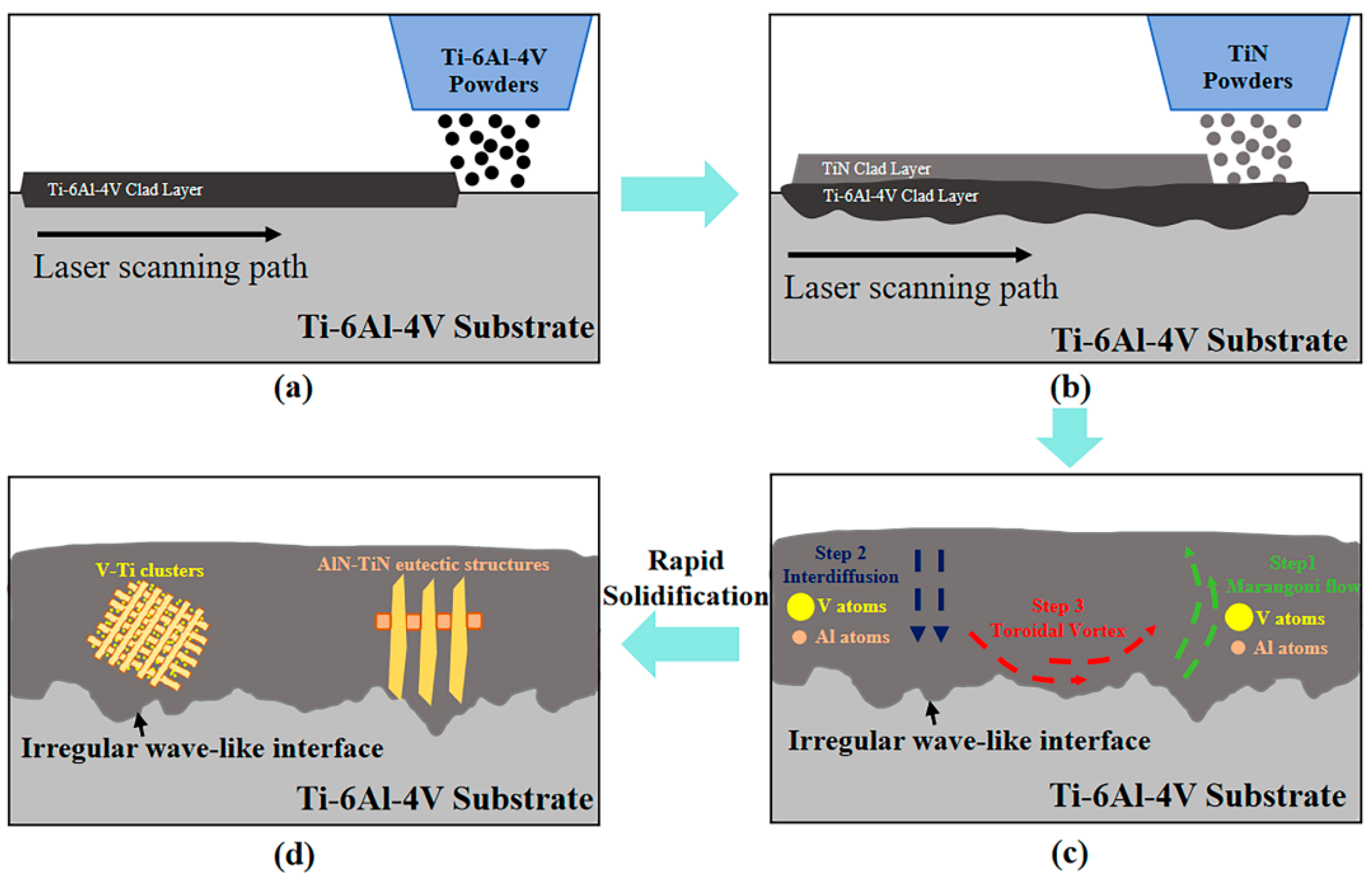

4.1. Rapid Solidification in the FGMs

- (1)

- Metastable phase formation and interface strengthening

- (2)

- Grain refinement and defect regulation

- (3)

- Solute trapping and cluster pinning

4.2. Interface Morphology of the FGMs

4.3. Microstructure Mechanisms for the FGMs

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Seo, S.; Park, J. Annealing Heat Treatment for Homogenizing the Microstructure and Mechanical Properties of Electron-Beam-Welded Thick Plate of Ti-6Al-4V Alloy. Materials 2023, 16, 7423. [Google Scholar] [CrossRef] [PubMed]

- Marin, E.; Lanzutti, A. Biomedical Applications of Titanium Alloys: A Comprehensive Review. Materials 2024, 17, 114. [Google Scholar] [CrossRef]

- Bai, H.; Zhong, L.; Kang, L.; Liu, J.; Zhuang, W.; Lv, Z.; Xu, Y. A Review on Wear-Resistant Coating with High Hardness and High Toughness on the Surface of Titanium Alloy. J. Alloys Compd. 2021, 882, 160645. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, L.; Yang, X.; Zhang, T.; Sun, R. Optimization of Microstructure and Properties of Composite Coatings by Laser Cladding on Titanium Alloy. Ceram. Int. 2021, 47, 2230–2243. [Google Scholar] [CrossRef]

- Xu, S.; Han, K.; Wang, H.; Xi, Y.; Wang, L.; Dong, X. The influence of adding B4C and CeO2 on the mechanical properties of laser cladding nickel-based coatings on the surface of TC4 titanium alloy. Materials 2024, 17, 3823. [Google Scholar] [CrossRef] [PubMed]

- Aizawa, T.; Yoshino, T.; Suzuki, Y.; Shiratori, T. Anti-Galling Cold, Dry Forging of Pure Titanium by Plasma-Carburized AISI420J2 Dies. Appl. Sci. 2021, 11, 595. [Google Scholar] [CrossRef]

- Meng, X.; Sun, Z.; Chu, X.; Guo, Y.; Chang, H.; Wang, Y. Microstructural Evolution and Wear Properties of In Situ (TiB + TiC)-Reinforced Ti6Al4V Matrix Composite Coating by Laser Melting Deposition. Mater. Charact. 2023, 205, 113192. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, M.; Fan, Z.; Huang, S.; Huang, H. Laser Deposition of Wear-Resistant Titanium Oxynitride/Titanium Composite Coatings on Ti-6Al-4V Alloy. Appl. Surf. Sci. 2020, 531, 147212. [Google Scholar] [CrossRef]

- Wei, G.; Tan, M.; Attarilar, S.; Li, J.; Uglov, V.V.; Wang, B.; Liu, J.; Lu, L.; Wang, L. An Overview of Surface Modification: A Way Toward Fabrication of Nascent Biomedical Ti–6Al–4V Alloys. J. Mater. Res. Technol. 2023, 24, 5896–5921. [Google Scholar] [CrossRef]

- Rong, G.; Li, Z.; Yao, K.; Chen, Y.; Sun, Y.; Li, J.; Ning, H. Preparation and Properties of Cu/Cu-Sn Alloy Cladding Layers on Titanium Alloy by Laser Cladding. J. Alloys Compd. 2025, 1020, 179547. [Google Scholar] [CrossRef]

- Gao, W.; Wang, S.; Hu, K.; Jiang, X.; Yu, H.; Sun, D. Effect of Laser Cladding Speed on Microstructure and Properties of Titanium Alloy Coating on Low Carbon Steel. Surf. Coat. Technol. 2022, 451, 129029. [Google Scholar] [CrossRef]

- Ren, Z.Y.; Hu, Y.L.; Tong, Y.; Cai, Z.H.; Liu, J.; Wang, H.D.; Liao, J.Z.; Xu, S.; Li, L.K. Wear-resistant NbMoTaWTi high entropy alloy coating prepared by laser cladding on TC4 titanium alloy. Tribol. Int. 2023, 182, 108366. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, C.; Xie, W.; Wu, D.; Du, B.; Zhang, X.; Wen, M.; Ma, R.; Li, R.; Jiao, J.; et al. Research Progress of Laser Cladding on the Surface of Titanium and Its Alloys. Materials 2023, 16, 3250. [Google Scholar] [CrossRef] [PubMed]

- Jia, W.; Song, X.; Zhu, Y.; Jiang, D.; Liu, M.; Ji, Y.; Wang, Y. Microstructural and performance analysis of (TiAl)95−xCu5Nix coatings prepared via laser surface cladding on Ti–6Al–4V substrates. Materials 2024, 17, 5036. [Google Scholar] [CrossRef]

- Yu, J.; Ho, H.; Chen, J. Effect of Ti Content on the Microstructure and Mechanical Properties of Laser Clad Ti/B4C/Dr40-Based Composite Coatings on Shaft Parts Surface. Ceram. Int. 2022, 48, 13551–13562. [Google Scholar] [CrossRef]

- Poloczek, T.; Lont, A.; Górka, J. The Structure and Properties of Laser-Cladded Inconel 625/TiC Composite Coatings. Materials 2023, 16, 1265. [Google Scholar] [CrossRef]

- Xu, J.; Liang, W.; Miao, Q.; Liu, R.; Zang, K.; Yu, J.; Wen, J.; Wang, Y. New Lightweight High-Entropy Alloy Coatings: Design Concept, Experimental Characterization, and High-Temperature Oxidation Behaviors. Surf. Coat. Technol. 2024, 491, 131154. [Google Scholar] [CrossRef]

- Liu, P.; Si, W.; Zhang, D.; Dai, S.; Jiang, B.; Shu, D.; Wu, L.; Zhang, C.; Zhang, M. Microstructure and Friction Properties of CoCrFeMnNiTix High-Entropy Alloy Coating by Laser Cladding. Materials 2022, 15, 4669. [Google Scholar] [CrossRef]

- Hu, K.; Tian, Y.; Jiang, X.; Yu, H.; Sun, D. Microstructure regulation and performance of titanium alloy coating with Ni interlayer on the surface of mild steel by laser cladding. Surf. Coat. Technol. 2024, 487, 130939. [Google Scholar] [CrossRef]

- Tyagi, S.A.; Manjaiah, M. Laser Additive Manufacturing of Titanium-Based Functionally Graded Materials: A Review. J. Mater. Eng. Perform. 2022, 31, 6131–6148. [Google Scholar] [CrossRef]

- Kulkarni, A.; Krenn, M.; Ansell, T. Microstructural Evolution and Tribological Performance of Functionally Graded Al-µB4C/BNNP Coatings Produced via Cold Spray. Therm. Spray Technol. 2025, 34, 1736–1746. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. On the formation of AlSi10Mg single tracks and layers in selective laser melting: Microstructure and nano-mechanical properties. J. Mater. Process. Technol. 2016, 230, 88–98. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Lei, X.; Lin, N.; Yuan, S.; Lei, C.; Nouri, M.; Liu, Z.; Yu, Y.; Zeng, Q.; Ma, G.; Li, D.; et al. Combining laser surface texturing and double glow plasma surface chromizing to improve tribological performance of Ti6Al4V alloy. Surf. Coat. Technol. 2024, 478, 130418. [Google Scholar] [CrossRef]

- Liang, J.; Liu, Y.; Yang, S.; Yin, X.; Chen, S.; Liu, C. Microstructure and wear resistance of laser cladding Ti-Al-Ni-Si composite coatings. Surf. Coat. Technol. 2022, 445, 128727. [Google Scholar] [CrossRef]

- Liu, Q.; Chu, S.; Zhang, X.; Wang, Y.; Zhao, H.; Zhou, B.; Wang, H.; Wu, G.; Mao, B. Laser shock processing of titanium alloys: A critical review on the microstructure evolution and enhanced engineering performance. J. Mater. Sci. Technol. 2024, 209, 262–291. [Google Scholar] [CrossRef]

- Tanaka, K.; Yamaguchi, T. Direct observation of bubble generation processes inside a molten pool during laser cladding. Surf. Coat. Technol. 2022, 447, 128831. [Google Scholar] [CrossRef]

- Li, M.; Ma, R.; Ren, Y.; Chang, S.; Li, L. New insights on dislocation forming mechanism of nickel-based superalloy fabricated by laser powder bed fusion. J. Mater. Res. Technol. 2024, 30, 4303–4309. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, R.; Liu, Y.; Zhang, L. Understanding melt pool characteristics in laser powder bed fusion: An overview of single- and multi-track melt pools for process optimization. Adv. Powder Mater. 2023, 2, 100137. [Google Scholar] [CrossRef]

- Liu, C.; Rao, J.; Sun, Z.; Lu, W.; Best, J.P.; Li, X.; Xia, W.; Gong, Y.; Wei, Y.; Zhang, B.; et al. Near-theoretical strength and deformation stabilization achieved via grain boundary segregation and nano-clustering of solutes. Nat Commun 2024, 15, 9283. [Google Scholar] [CrossRef]

- Reddy, K.M.; Guo, D.; Song, S.; Cheng, C.; Han, J.; Wang, X.; An, Q.; Chen, M. Dislocation-mediated shear amorphization in boron carbide. Sci. Adv. 2021, 7, eabc6714. [Google Scholar] [CrossRef] [PubMed]

- Qiu, C.; Punke, M.; Tian, Y.; Han, Y.; Wang, S.; Su, Y.; Salvalaglio, M.; Pan, X.; Srolovitz, D.J.; Han, J. Grain boundaries are Brownian ratchets. Science 2024, 385, 980–985. [Google Scholar] [CrossRef] [PubMed]

- Shu, L.; Wu, H.; Heng, Z.; Li, J.; Cang, X. Optimization, Microstructure, and Properties of Ti-6Al-4 V Coatings Fabricated by Laser Cladding. J. Mater. Eng Perform. 2023, 32, 7946–7959. [Google Scholar] [CrossRef]

- Omar, M.F.; Akil, H.M.; Ahmad, Z.A.; Mazuki, A.A.M.; Yokoyama, T. Dynamic properties of pultruded natural fibre reinforced composites using Split Hopkinson Pressure Bar technique. Mater. Des. 2010, 31, 4209–4218. [Google Scholar] [CrossRef]

| Specimen ID | Laser Power (W) | Powder for the Mid-Layer | Laser Power (W) | Powder for the Outer Layer |

|---|---|---|---|---|

| C1 | 1200 | Ti-6Al-4V | 1200 | TiN |

| C2 | 1400 | Ti-6Al-4V | 1200 | TiN |

| C3 | 1200 | TiN | 1200 | TiN |

| Data | O (wt%) | Ti (wt%) | Al (wt%) | V (wt%) | N (wt%) | |

|---|---|---|---|---|---|---|

| 1 | C1-1 | 2.57 | 83.482 | 0.814 | 1.34 | 12.309 |

| 2 | C1-2 | 0.52 | 78.601 | 8.809 | 7.044 | 3.424 |

| 3 | C1-3 | 0.49 | 85.596 | 0.398 | 1.249 | 13.873 |

| 4 | C1-4 | 0.964 | 80.938 | 7.232 | 6.654 | 3.818 |

| 5 | C1-5 | 1.275 | 84.838 | 0.619 | 1.271 | 12.969 |

| 6 | C1-6 | 0.213 | 82.381 | 7.068 | 5.436 | 5.734 |

| 7 | C1-7 | 0.652 | 85.212 | 0.813 | 1.258 | 12.65 |

| 8 | C1-8 | 0.435 | 84.801 | 5.521 | 4.086 | 5.221 |

| Data | O (wt%) | Ti (wt%) | Al (wt%) | V (wt%) | N (wt%) | |

|---|---|---|---|---|---|---|

| 1 | C3-1 | 2.345 | 82.906 | 0.114 | 1.161 | 16.021 |

| 2 | C3-2 | 0 | 80.156 | 6.897 | 5.061 | 4.714 |

| 3 | C3-3 | 0 | 83.172 | 0.118 | 1.092 | 15.372 |

| 4 | C3-4 | 0.603 | 81.475 | 6.725 | 5.829 | 3.88 |

| 5 | C3-5 | 0 | 83.238 | 0.125 | 1.111 | 16.423 |

| 6 | C3-6 | 1.142 | 82.601 | 6.749 | 5.821 | 6.535 |

| 7 | C3-7 | 0.286 | 83.829 | 5.807 | 3.915 | 6.704 |

| 8 | C3-8 | 0.455 | 84.12 | 5.689 | 5.68 | 4.012 |

| Optimal Wear-Resistant Specimen in Respective Studies | Wear Resistance Improvement |

|---|---|

| C1 FGM coating | 344% |

| (TiAl)95-xCu5Nix coatings [14] | 47% |

| Al-µB4C/BNNP Coatings [21] | 214% |

| NbMoTaWTi high entropy alloy coating [12] | 122% |

| TC4-LST + Cr coating [24] | 227% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Huang, X.; Wang, G.; Zhang, X.; Zhou, K.; Wang, B. Microstructure and Mechanical Properties of Functionally Graded Materials on a Ti-6Al-4V Titanium Alloy by Laser Cladding. Materials 2025, 18, 3032. https://doi.org/10.3390/ma18133032

Liu L, Huang X, Wang G, Zhang X, Zhou K, Wang B. Microstructure and Mechanical Properties of Functionally Graded Materials on a Ti-6Al-4V Titanium Alloy by Laser Cladding. Materials. 2025; 18(13):3032. https://doi.org/10.3390/ma18133032

Chicago/Turabian StyleLiu, Lanyi, Xiaoyang Huang, Guocheng Wang, Xiaoyong Zhang, Kechao Zhou, and Bingfeng Wang. 2025. "Microstructure and Mechanical Properties of Functionally Graded Materials on a Ti-6Al-4V Titanium Alloy by Laser Cladding" Materials 18, no. 13: 3032. https://doi.org/10.3390/ma18133032

APA StyleLiu, L., Huang, X., Wang, G., Zhang, X., Zhou, K., & Wang, B. (2025). Microstructure and Mechanical Properties of Functionally Graded Materials on a Ti-6Al-4V Titanium Alloy by Laser Cladding. Materials, 18(13), 3032. https://doi.org/10.3390/ma18133032