Effects of w/b Ratio on Sodium Sulfate Crystallization Damage and Degradation Mechanisms in Semi-Immersed Alkali-Activated Slag Mortar

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of AAS Mortars

2.3. Experiment of the Semi-Immersion Form of AAS Sodium Sulphate Erosion

2.3.1. Surface Crystallization and Mass Change

2.3.2. Mechanical Property

2.3.3. Pore Structure Analysis

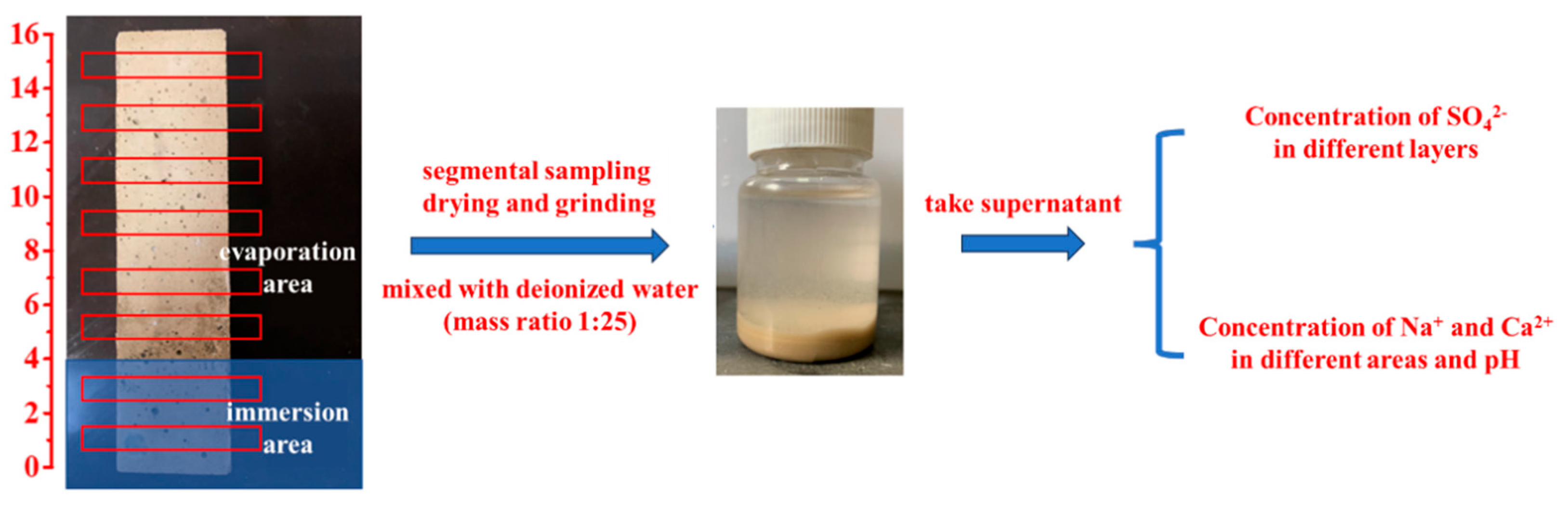

2.4. Erosion Resistance Mechanism of AAS

3. Results and Discussion

3.1. Macroscopic Performance Evolution Under Sulfate Attack

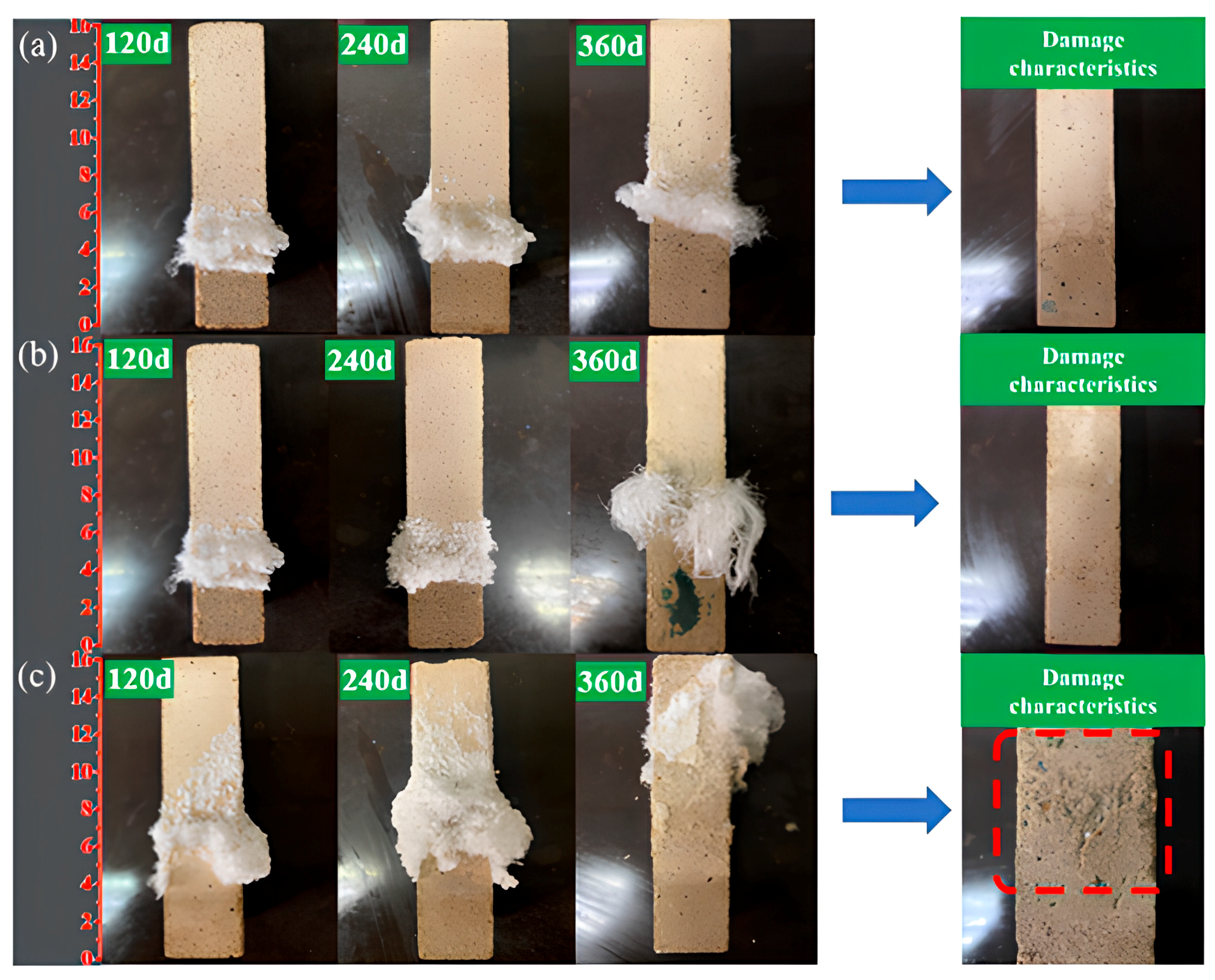

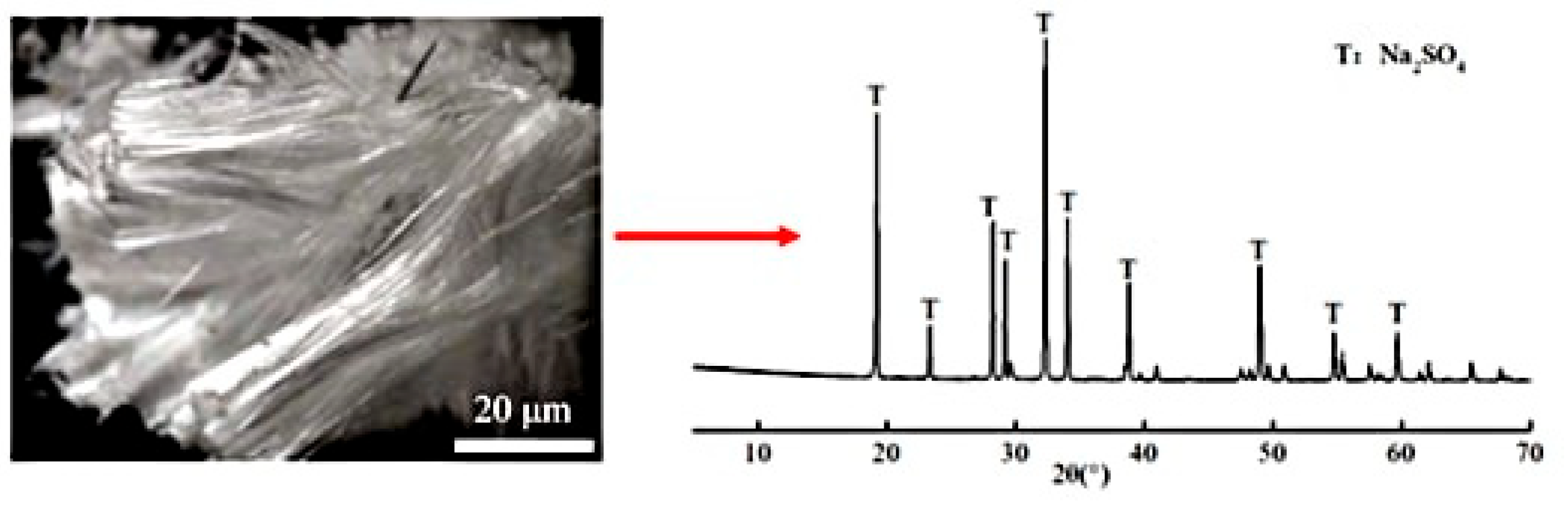

3.1.1. Surface Crystallization and Morphological Deterioration

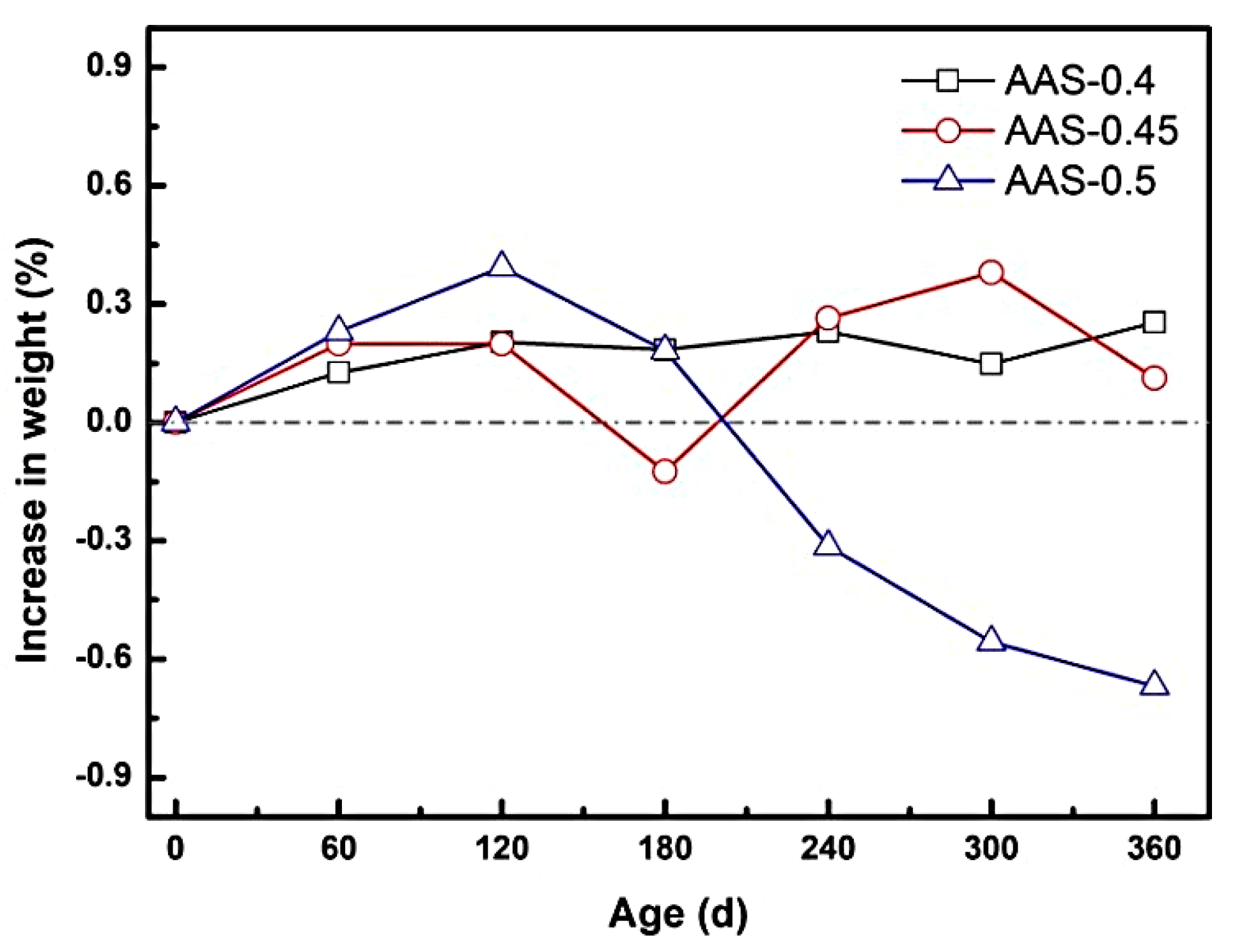

3.1.2. Mass Change and Spalling Behavior

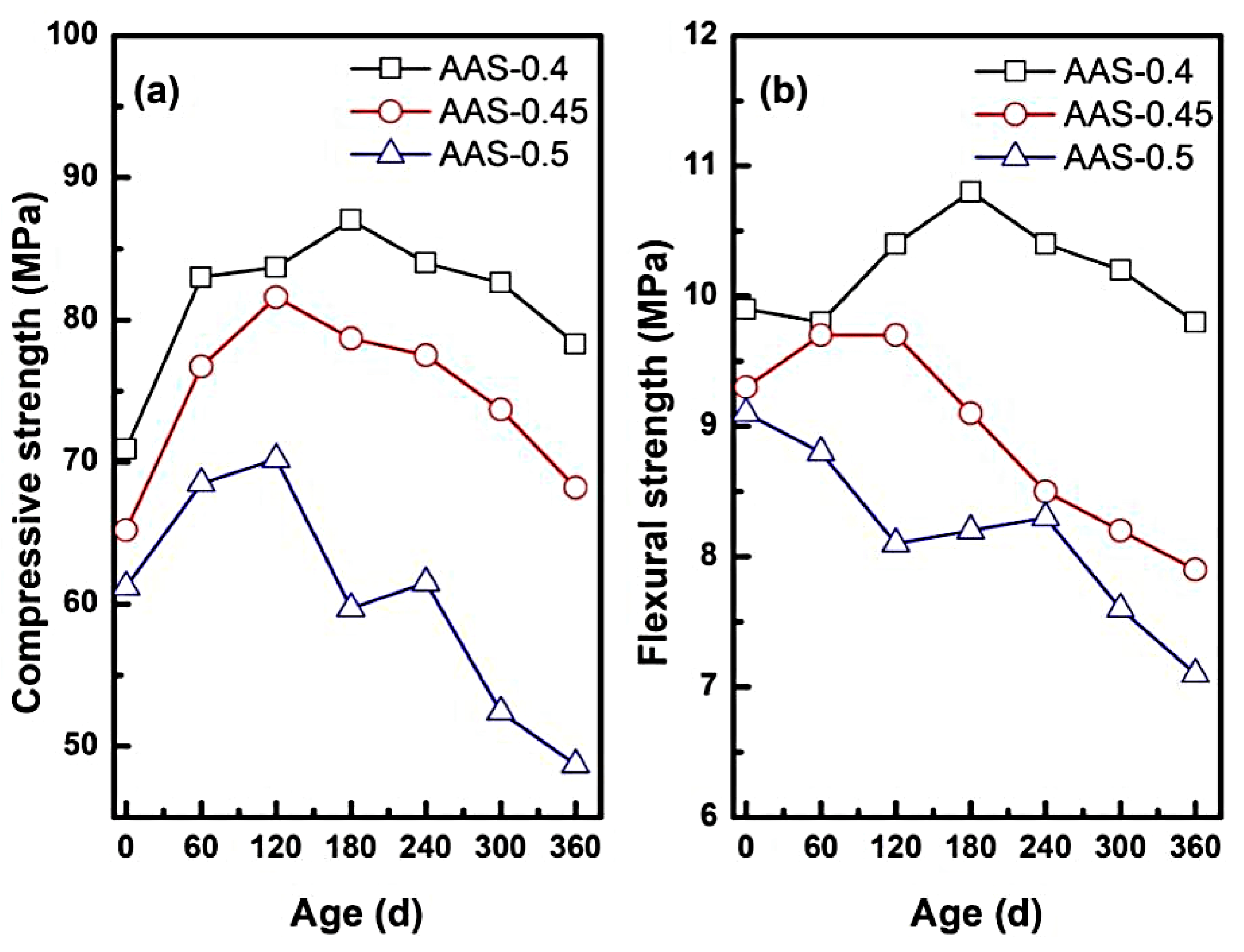

3.1.3. Mechanical Degradation: Compressive and Flexural Strength

3.1.4. Pore Structure Evolution and Water Absorption Dynamics

3.2. Mechanistic Insights into Sulfate-Induced Degradation

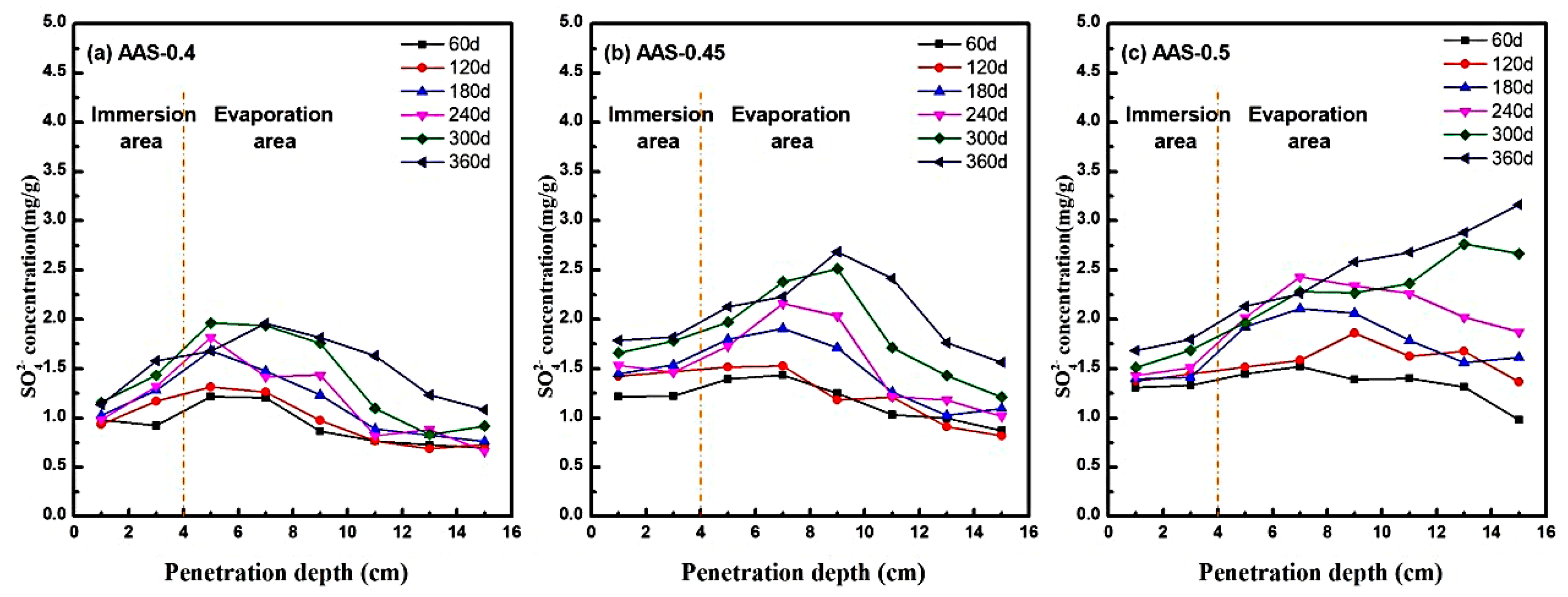

3.2.1. Analysis of SO42− Ion Migration Behavior

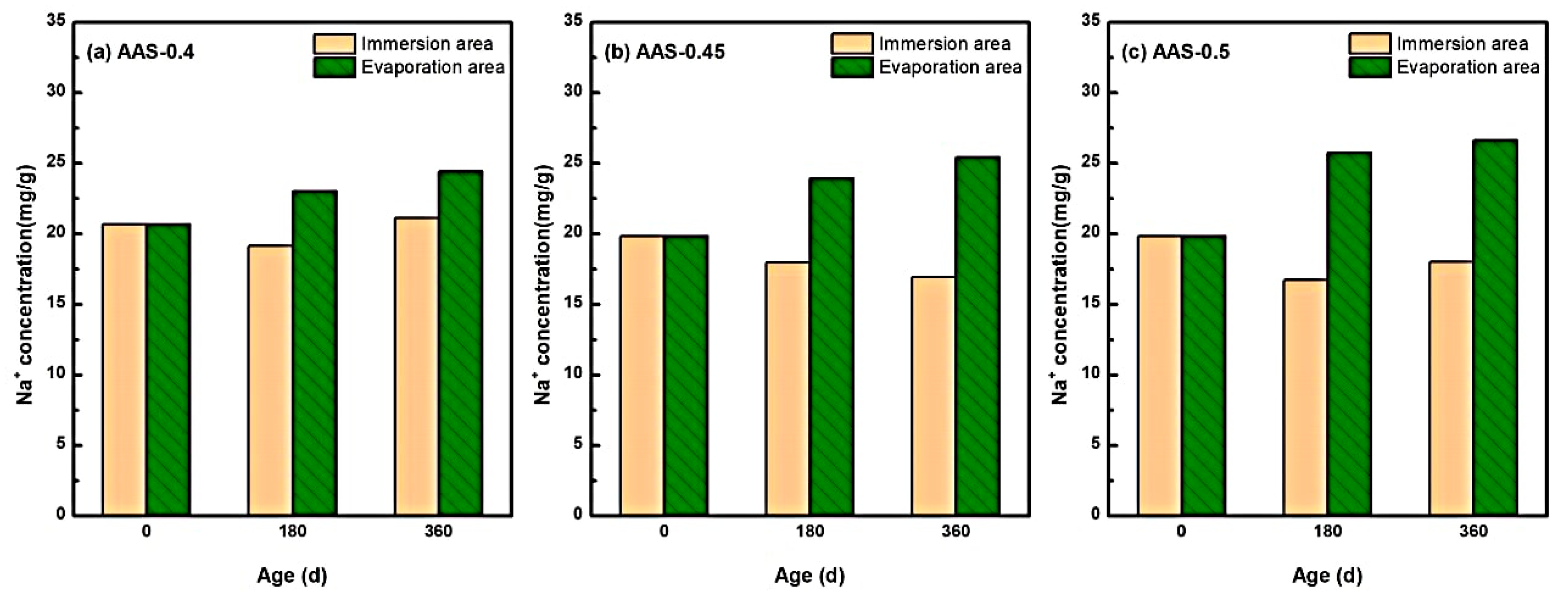

3.2.2. Na+ Ion Redistribution and Crystallization Influence

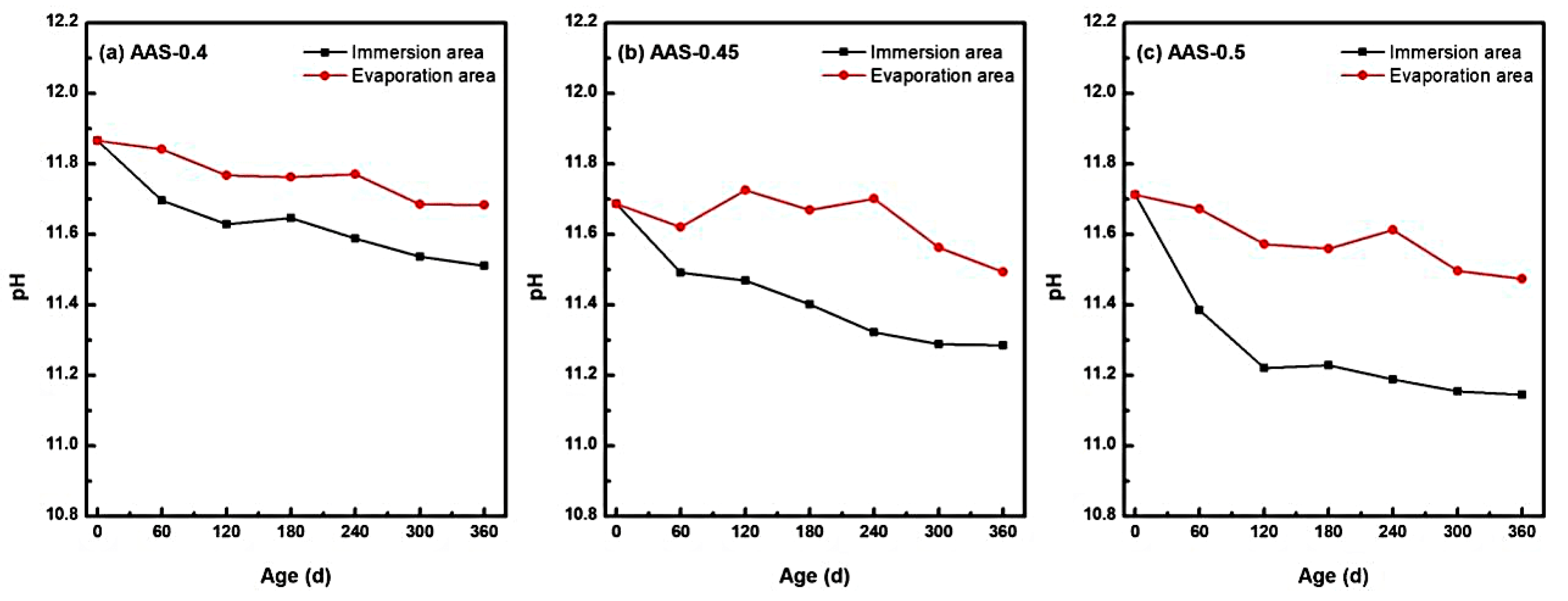

3.2.3. pH Evolution and Alkalinity Loss

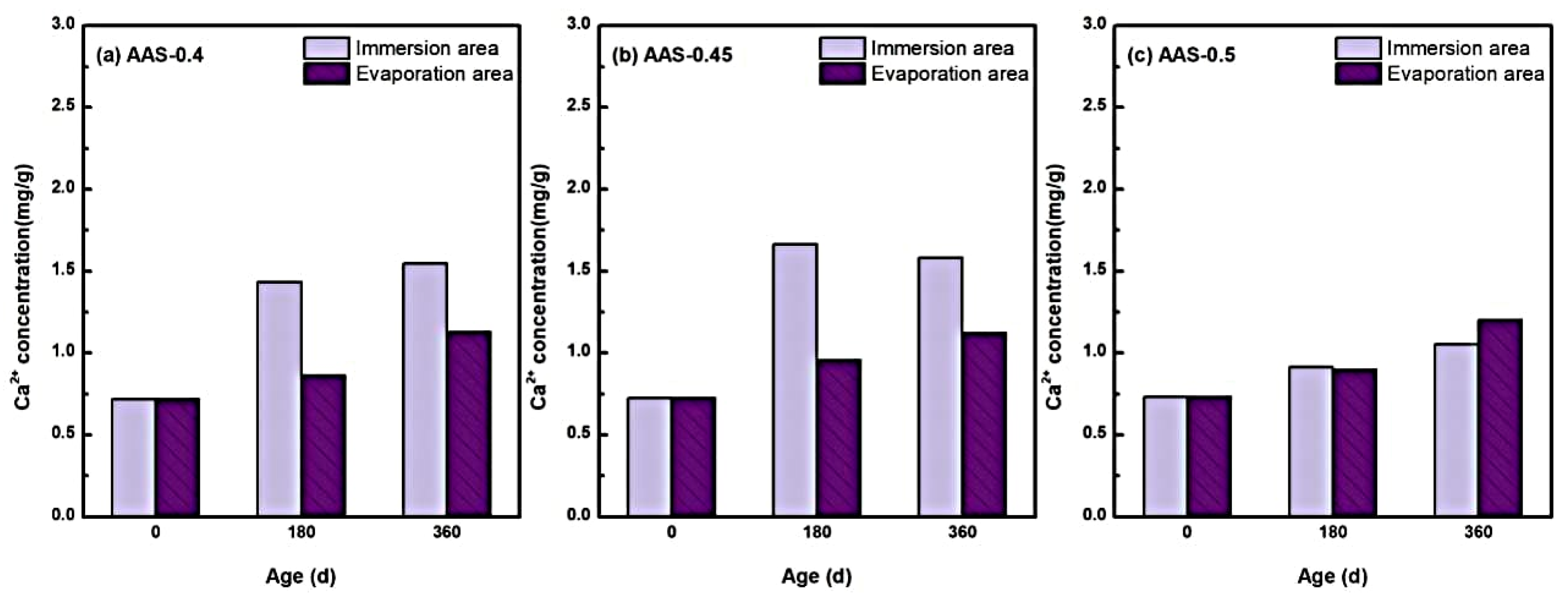

3.2.4. Decalcification and Free Ca2+ Release

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martins, M.C.; Langaro, E.A.; Macioski, G.; Medeiros, M.H.F. External ammonium sulfate attack in concrete: Analysis of the current methodology. Constr. Build. Mater. 2021, 277, 122252. [Google Scholar] [CrossRef]

- Ikumi, T.; Segura, I. Numerical assessment of external sulfate attack in concrete structures. A review. Cem. Concr. Res. 2019, 121, 91–105. [Google Scholar] [CrossRef]

- Tang, S.W.; Yao, Y.; Andrade, C.; Li, Z.J. Recent durability studies on concrete structure. Cem. Concr. Res. 2015, 78, 143–154. [Google Scholar] [CrossRef]

- Shen, C.; Tang, D.; Lyu, Z.; Yang, C.; Yu, L. Distribution of coarse aggregate and steel fibers in ultra-high performance concrete containing coarse aggregate (UHPC-CA) and their effect on the flexural performance. Constr. Build. Mater. 2024, 421, 135666. [Google Scholar] [CrossRef]

- Yang, B.; Hu, X.; Li, A.; Zhao, T.; Sun, Y.; Fu, H. Degradation mechanism of cast-in-situ concrete under long-term sulfate saline soil attack. Constr. Build. Mater. 2025, 478, 141401. [Google Scholar] [CrossRef]

- Sun, L.; Lan, S.; Wang, C. Durability and microstructural evolution of seawater sea-sand coral concrete under different exposure environments of sulfate attack. Constr. Build. Mater. 2025, 478, 141399. [Google Scholar] [CrossRef]

- Qin, S.; Zhang, M.; Zou, D.; Liu, T.; Li, Y. Mesoscale modeling of mechanical deterioration in sulfate-attacked concrete. Eng. Fract. Mech. 2025, 323, 04025154. [Google Scholar] [CrossRef]

- Banik, D.; He, R.; Lu, N.; Feng, Y. Mitigation mechanisms of alkali silica reaction through the incorporation of colloidal nanoSiO2 in accelerated mortar bar testing. Constr. Build. Mater. 2024, 422, 135834. [Google Scholar] [CrossRef]

- Gong, K.; White, C.E. Nanoscale Chemical Degradation Mechanisms of Sulfate Attack in Alkali-activated Slag. J. Phys. Chem. C 2018, 122, 5992–6004. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.-B. Sulfate attack on alkali-activated slag concrete. Cem. Concr. Res. 2002, 32, 211–216. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.; Yang, K.; Zhu, X.; Gevaudan, J.P.; Yang, C.; Basheer, M. The long-term failure mechanisms of alkali-activated slag mortar exposed to wet-dry cycles of sodium sulphate. Cem. Concr. Compos. 2021, 116, 103893. [Google Scholar] [CrossRef]

- Scherer, G.W. Stress from crystallization of salt. Cem. Concr. Res. 2004, 34, 1613–1624. [Google Scholar] [CrossRef]

- Li, Q.; Yang, K.; Yang, C. An alternative admixture to reduce sorptivity of alkali-activated slag cement by optimising pore structure and introducing hydrophobic film. Cem. Concr. Compos. 2019, 95, 183–192. [Google Scholar] [CrossRef]

- Zhu, X.; Li, Q.; Yang, K.; Mu, S.; Zhang, Z.; Magee, B.; Yang, C.; Basheer, M. Characterisation of temporal variations of alkali-activated slag cement property using microstructure features and electrical responses. Constr. Build. Mater. 2020, 261, 119884. [Google Scholar] [CrossRef]

- Puertas, F.; Fernández-Jiménez, A.; Blanco-Varela, M.T. Pore solution in alkali-activated slag cement pastes. Relation to the composition and structure of calcium silicate hydrate. Cem. Concr. Res. 2024, 34, 139–148. [Google Scholar] [CrossRef]

- Mierzwiński, D.; Walter, J. Autoclaving of alkali-activated materials. IOP Conf. Ser. Mater. Sci. Eng. 2019, 706, 012012. [Google Scholar] [CrossRef]

- Mierzwiński, D.; Korniejenko, K.; Łach, M.; Mikuła, J.; Krzywda, J. Effect of Coffee Grounds Addition on Efflorescence in Fly Ash-based Geopolymer. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012035. [Google Scholar] [CrossRef]

- Kuang, L.; Li, G.; Ma, W.; Liu, L.; Cui, X. Effect of metakaolin on the chloride diffusion properties of alkali-activated slag in an acidic environment. Appl. Clay Sci. 2024, 260, 107544. [Google Scholar] [CrossRef]

- Olatoyan, O.J.; Okeyinka, O.M.; Oluwafemi, B.; Oyewo, S.T.; Olayanju, O.K.; Kareem, M.A.; Adebanjo, A.U.; Salami, M.O. Investigation of tensile strength performance of green concrete incorporating steel slag. Hybrid Adv. 2024, 6, 100186. [Google Scholar] [CrossRef]

- Liu, J.; Yan, C.; Zhang, J.; Li, J.; Zhao, J.; Shen, X.; Cao, F.; Zhang, G.; Meng, X. Characteristics of AC impedance and pore structure in solid waste-based cementitious materials with different water-to-binder ratios. Constr. Build. Mater. 2025, 467, 140342. [Google Scholar] [CrossRef]

- Zheng, R.; Xia, J.; Liu, E.; Zhou, Q.; Wang, H. A high water-cement ratio aerated concrete using carbon dioxide as the foaming agent: Mix design, pore structure and hydration products. J. Build. Eng. 2025, 108, 112926. [Google Scholar] [CrossRef]

- GB/T 14684-2022; Sand for Construction. State Administration for Market Regulation: Beijing, China, 2022.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). State Administration for Market Regulation: Beijing, China, 2021.

- Wang, Y.; Jin, S.; Li, Y.; Zhao, B.; Chen, D.; Li, J.; Zhang, T.C. Polyvinyl alcohol fiber reinforced electrolytic manganese slag based geopolymer mortar: Mechanical properties and microstructure. Constr. Build. Mater. 2025, 477, 141390. [Google Scholar] [CrossRef]

- Wulandari, R.; Meysara; Emiliana; Sunarno; Heltina, D.; Khairat; Amri, A. Structural and physicomechanical properties of rice husk Ash-based geopolymer mortar with the addition of graphene nanosheets. Mater. Today Proc. 2023, 87, 70–78. [Google Scholar] [CrossRef]

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- Xue, L.; Ni, Z.; Zhou, Z.; Zhang, Z.; Xiong, H.; Wang, H.; Zhuge, X.; Liu, H. Effects of desulfurized gypsum on shrinkage behavior of alkali-activated slag (AAS) and hybrid alkali-activated cement (HAC). Case Stud. Constr. Mater. 2025, 22, e04320. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; Hamdan, S.; van Deventer, J.S.J. Microstructural changes in alkali activated fly ash/slag geopolymers with sulfate exposure. Mater. Struct. 2012, 46, 361–373. [Google Scholar] [CrossRef]

- Yin, K.; Luo, Z.; Liu, X.; Pan, H.; Zhi, T.; Feng, H.; Song, Y.; Su, Y. Preparation and application of Na2SiO3@EC microcapsules for self-healing alkali-activated slag. Constr. Build. Mater. 2023, 400, 132651. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, Y.X.; Khennane, A. Numerical modelling of degradation of cement-based materials under leaching and external sulfate attack. Comput. Struct. 2015, 158, 1–14. [Google Scholar] [CrossRef]

- Ran, B.; Li, K.; Fen-Chong, T.; Omikrine-Metalssi, O.; Dangla, P. Spalling rate of concretes subject to combined leaching and external sulfate attack. Cem. Concr. Res. 2022, 162, 106951. [Google Scholar] [CrossRef]

- Rashad, A.M.; Bai, Y.; Basheer, P.A.M.; Milestone, N.B.; Collier, N.C. Hydration and properties of sodium sulfate activated slag. Cem. Concr. Compos. 2013, 37, 20–29. [Google Scholar] [CrossRef]

- Guan, X.; Hou, X.; Hao, X.; Liu, Y.; Li, F.; Hou, P. Dynamic energy performance and pore structure of CGSC under sulfate attack: An SHPB-based study. Constr. Build. Mater. 2024, 457, 139457. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, F.; Deng, D.; Xie, Y.; Long, G.; Tang, X. Physical sulfate attack on concrete lining–A field case analysis. Case Stud. Constr. Mater. 2017, 6, 206–212. [Google Scholar] [CrossRef]

- Jia, Z.; Cao, R.; Xiong, Y.; Zhang, S.; Jia, L.; Zhang, Y.; Gao, Y. Understanding the deterioration of hydration products in alkali-activated slag/Portland cement exposure to sulfate attack. J. Build. Eng. 2024, 95, 110292. [Google Scholar] [CrossRef]

- Nguyen, T.N.; Phung, Q.T.; Jacques, D.; Neji, M.; Dauzeres, A.; Elsen, J.; Pontikes, Y. Microstructure, water permeability and micromechanical properties of alkali activated slag subjected to accelerated leaching. Mater. Des. 2024, 238, 112706. [Google Scholar] [CrossRef]

- Emminger, Y.H.; Ladner, L.; Ruiz-Agudo, C. Comparative study of the early stages of crystallization of calcium silicate hydrate (C-S-H) and calcium aluminate silicate hydrate (C-A-S-H). Cem. Concr. Res. 2025, 193, 107873. [Google Scholar] [CrossRef]

- Myers, R.J.; Bernal, S.A.; Provis, J.L. Phase diagrams for alkali-activated slag binders. Cem. Concr. Res. 2017, 95, 30–38. [Google Scholar] [CrossRef]

- Liu, Z.; Deng, D.; Schutter, G.D.; Yu, Z. Chemical sulfate attack performance of partially exposed cement and cement+fly ash paste. Constr. Build. Mater. 2012, 28, 230–237. [Google Scholar] [CrossRef]

- Gentilini, C.; Franzoni, E.; Bandini, S.; Nobile, L. Effect of salt crystallisation on the shear behaviour of masonry walls: An experimental study. Constr. Build. Mater. 2012, 37, 181–189. [Google Scholar] [CrossRef]

- Yan, S.; Liu, Y.; Liang, Y. A space fractal derivative crack model for characterizing chloride ions superdiffusion in concrete in the marine tidal zone. Constr. Build. Mater. 2024, 450, 138585. [Google Scholar] [CrossRef]

- Li, W.; Li, Y.; Liu, W.; Fan, M.; Zhang, X.; Han, X.; Jin, G.; Xu, C. Continuous separation of alkali and salt through pressure-concentration double driven diffusion dialysis and its mathematic model. Sep. Purif. Technol. 2021, 272, 118934. [Google Scholar] [CrossRef]

- Jiang, H.; Xu, Z.; Wang, X.; Qi, H.; Shan, D.; Guo, B.; Xu, J. Anisotropic capillary-driven evaporation performance on laser textured prismatic micropillars. Int. J. Heat Mass Transf. 2025, 246, 126972. [Google Scholar] [CrossRef]

- Song, S.; Jennings, H.M. Pore solution chemistry of alkali-activated ground granulated blast-furnace slag. Cem. Concr. Res. 1999, 29, 159–170. [Google Scholar] [CrossRef]

- Džunuzović, N.; Komljenović, M.; Nikolić, V.; Ivanović, T. External sulfate attack on alkali-activated fly ash-blast furnace slag composite. Constr. Build. Mater. 2017, 157, 737–747. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, K.; Zhang, D.; Zhang, J.; Jiao, Y.; Fang, C.; Tang, W.; Zhao, Z. Durability of geopolymer cementitious materials synergistically stimulated by Ca2+ and Na+. Case Stud. Constr. Mater. 2024, 21, e03514. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Fu, S.Y.; Wei, K.; Liu, X.; Chen, Y.K.; Wang, R.K.; Yu, R. Clarify the impact of chloride ion migration in different concentration fields on the hydration and microstructure characteristics of ultra-low water/binder ratio cement-based composites under submerged conditions. Cem. Concr. Compos. 2025, 160, 106014. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, Z.; Dong, E.; Fan, D.; Yu, R. Impact of freezing conditions on the characteristics of ultra-low water binder ratio cementitious composites (ULCC): Towards to hydration mechanism and molecular migration model. Constr. Build. Mater. 2024, 435, 136878. [Google Scholar] [CrossRef]

- Ying, J.; Deng, C.; Qian, S.; Chen, B. Effect of water-to-binder ratio on chloride ion diffusion in concrete under continuous biaxial compression. Constr. Build. Mater. 2024, 416, 135308. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly ash-based geopolymer: Clean production, properties and applications. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar] [CrossRef]

- Liu, M.; Suo, S.; Wu, J.; Gan, Y.; Hanaor, D.A.; Chen, C.Q. Tailoring porous media for controllable capillary flow. J. Colloid Interface Sci. 2019, 539, 379–387. [Google Scholar] [CrossRef]

- Zhang, M.; Zou, D.; Qin, S.; Zhang, X.; Liu, T. Decoupling chemical and physical sulfate attack on OPC and L.SAC concrete under wet-dry cycles. J. Build. Eng. 2025, 99, 111637. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.; Liao, H.; Zou, D.; Liu, T. Deterioration mechanism of OPC mortar under combined chemical and physical sulfate attack in partial immersion. Constr. Build. Mater. 2025, 475, 141187. [Google Scholar] [CrossRef]

- Ohno, M.; Maekawa, K. Fully coupled physicochemical-mechanical modeling of sulfate attack-induced expansion in cement-based materials. Cem. Concr. Compos. 2025, 161, 106076. [Google Scholar] [CrossRef]

- Rashad, A.M.; Mokhtar, M.M.; El-Nashar, M.H.; Mohamed, R.A.-E. Waste marble powder emerges as a promising material choice to enhance the properties of alkali-activated slag cement. Sustain. Chem. Pharm. 2025, 43, 101864. [Google Scholar] [CrossRef]

- Liu, L.; Chen, X.; Pang, K.; Neupane, A.; Xie, L.; Shen, D. Degradation of alkali-activated slag pastes exposed to high-concentration chloride, sulfate and magnesium multi-salt solutions. Constr. Build. Mater. 2025, 464, 140182. [Google Scholar] [CrossRef]

- Abdalqader, A.; Jin, F.; Al-Tabbaa, A. Performance of magnesia-modified sodium carbonate-activated slag/fly ash concrete. Cem. Concr. Compos. 2019, 103, 160–174. [Google Scholar] [CrossRef]

- Chen, P. Alkali-activated slag material. In High-Volume Mineral Admixtures in Cementitious Binders; Woodhead Publishing: Sawston, UK, 2025; pp. 167–194. [Google Scholar]

- Park, J.; Wang, L. The Structure and Properties of Silicate Slags. In Treatise Process Metall; Elsevier: Amsterdam, The Netherlands, 2024; pp. 113–200. [Google Scholar]

- Sun, B.; Ye, G.; de Schutter, G. A review: Reaction mechanism and strength of slag and fly ash-based alkali-activated materials. Constr. Build. Mater. 2022, 326, 126843. [Google Scholar] [CrossRef]

- Ferrante, F.; Bertini, M.; Ferlito, C.; Lisuzzo, L.; Lazzara, G.; Duca, D. A computational and experimental investigation of halloysite silicic surface modifications after alkaline treatment. Appl. Clay Sci. 2023, 232, 106813. [Google Scholar] [CrossRef]

| Compositions | SiO2 | CaO | Al2O3 | MnO | Na2O | MgO | Fe2O3 | K2O | LOI |

|---|---|---|---|---|---|---|---|---|---|

| Content | 27.91 | 43.91 | 13.44 | 0.39 | 0.35 | 7.53 | 0.60 | 0.37 | 0.61 |

| Parameter | AAS-0.4 | AAS-0.45 | AAS-0.5 | Standard/Note |

|---|---|---|---|---|

| w/b ratio | 0.40 | 0.45 | 0.50 | |

| Na2O content | 4% | 4% | 4% | Slag mass basis |

| Binder:sand ratio | 1:3 | 1:3 | 1:3 | By mass |

| Activator SiO2:Na2O | 1.5 | 1.5 | 1.5 | Molar ratio |

| Curing conditions | 20 ± 2 °C, >95% RH for 28 d | GB/T 17671-2021 [23] | ||

| Property | AAS-0.4 | AAS-0.45 | AAS-0.5 | Test Method |

|---|---|---|---|---|

| Mass change (%) | +0.25 | +0.13 | −0.67 | Equation (1) |

| Compressive. strength loss (%) | −10.0 | −16.4 | −30.6 | GB/T 17671-2021 |

| Flexural strength loss (%) | −0.10 | −15.05 | −26.38 | |

| Open porosity (%) | 7.72 | 10.24 | 12.08 | ASTM C642 |

| SO42− at 15 cm * (mg/g) | 1.10 | 1.55 | 3.20 | UV spectrophotometry |

| Na+ mobility index * (%) | +19.03 | +28.16 | +34.26 | ICP-OES |

| Free Ca2+ # (mg/g) | 1.548 | 1.550 | 1.112 | |

| pH value change # (%) | −3.06 | −3.47 | −4.85 | pH meter |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Qiu, Y.; Liu, P.; Ye, J.; Yin, K.; Yu, L.; Yang, C. Effects of w/b Ratio on Sodium Sulfate Crystallization Damage and Degradation Mechanisms in Semi-Immersed Alkali-Activated Slag Mortar. Materials 2025, 18, 2988. https://doi.org/10.3390/ma18132988

Zhou Z, Qiu Y, Liu P, Ye J, Yin K, Yu L, Yang C. Effects of w/b Ratio on Sodium Sulfate Crystallization Damage and Degradation Mechanisms in Semi-Immersed Alkali-Activated Slag Mortar. Materials. 2025; 18(13):2988. https://doi.org/10.3390/ma18132988

Chicago/Turabian StyleZhou, Zhenwei, Yuetao Qiu, Peng Liu, Jianxiong Ye, Kunpeng Yin, Linwen Yu, and Changhui Yang. 2025. "Effects of w/b Ratio on Sodium Sulfate Crystallization Damage and Degradation Mechanisms in Semi-Immersed Alkali-Activated Slag Mortar" Materials 18, no. 13: 2988. https://doi.org/10.3390/ma18132988

APA StyleZhou, Z., Qiu, Y., Liu, P., Ye, J., Yin, K., Yu, L., & Yang, C. (2025). Effects of w/b Ratio on Sodium Sulfate Crystallization Damage and Degradation Mechanisms in Semi-Immersed Alkali-Activated Slag Mortar. Materials, 18(13), 2988. https://doi.org/10.3390/ma18132988