Multiscale Geometric Characterization and Discrimination of Dermatoglyphs (Fingerprints) on Hardened Clay—A Novel Archaeological Application of the GelSight Max

Abstract

1. Introduction

1.1. Purpose and Scope of the Research

1.2. Fingerprint Structure and Documentation

1.3. Fingerprint Analysis on Archaeological Pottery: A Brief Summary

1.4. GelSight and Fingerprints

1.5. The GelSight Max Instrument

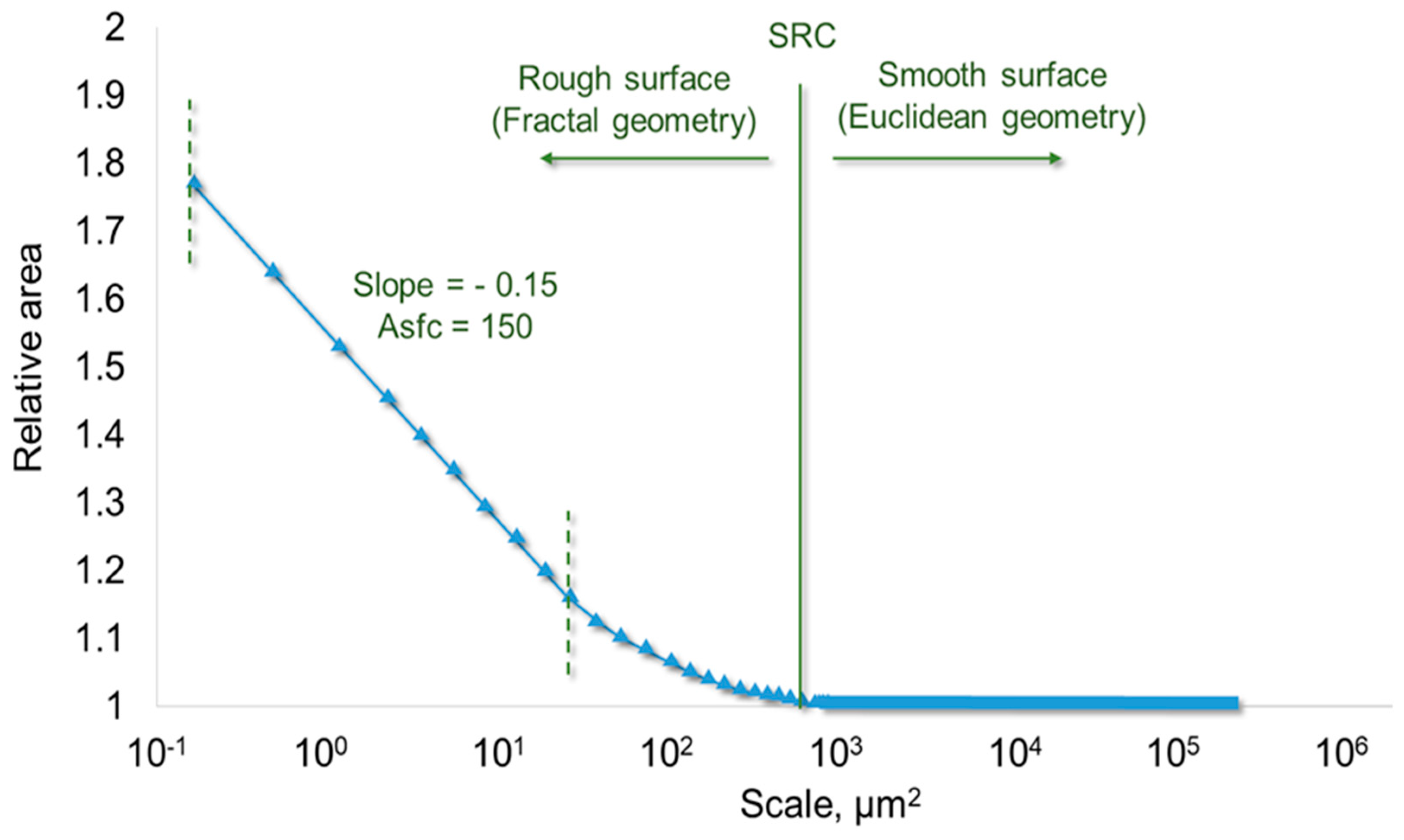

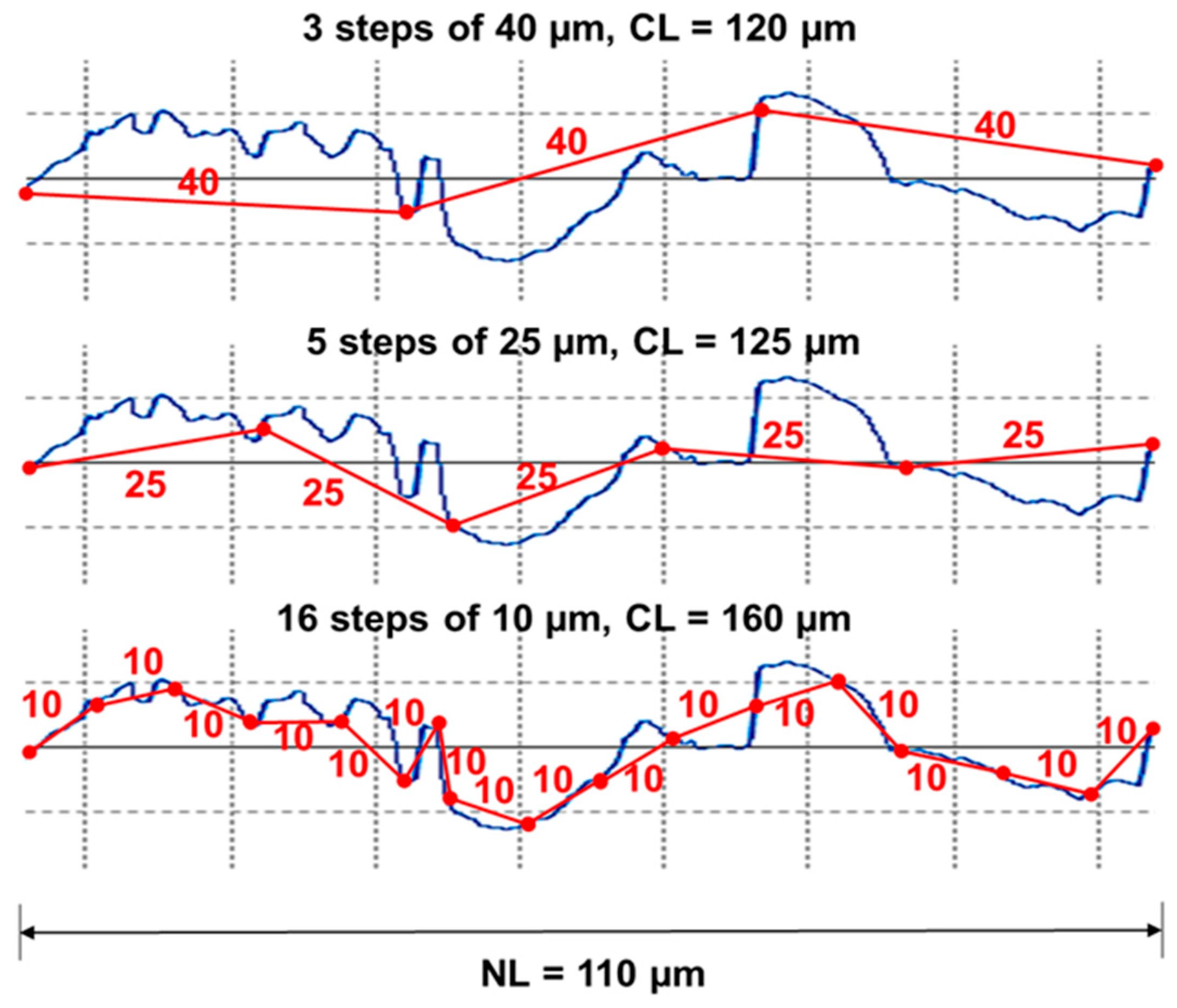

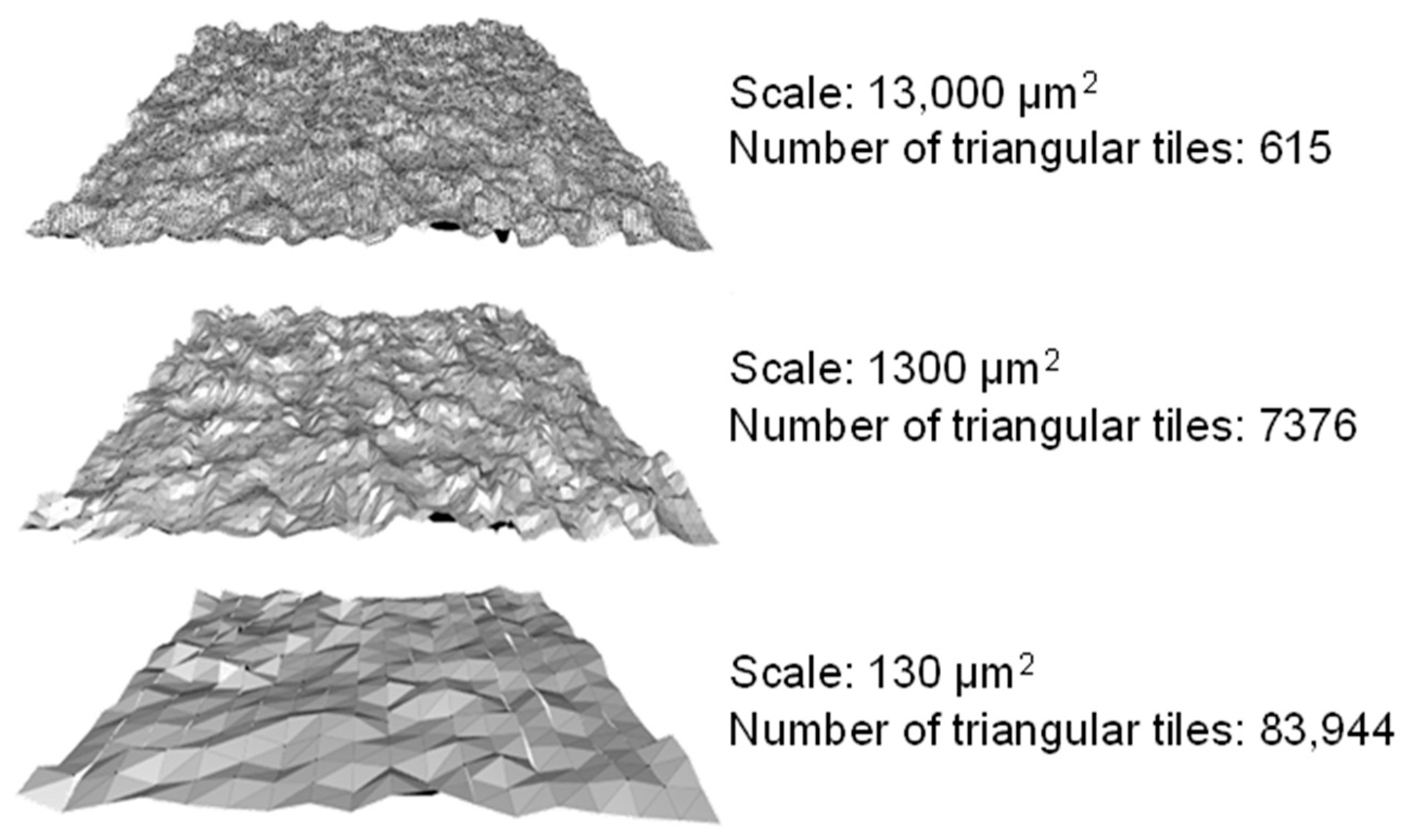

1.6. Scale-Sensitive Fractal Analysis

2. Materials and Methods

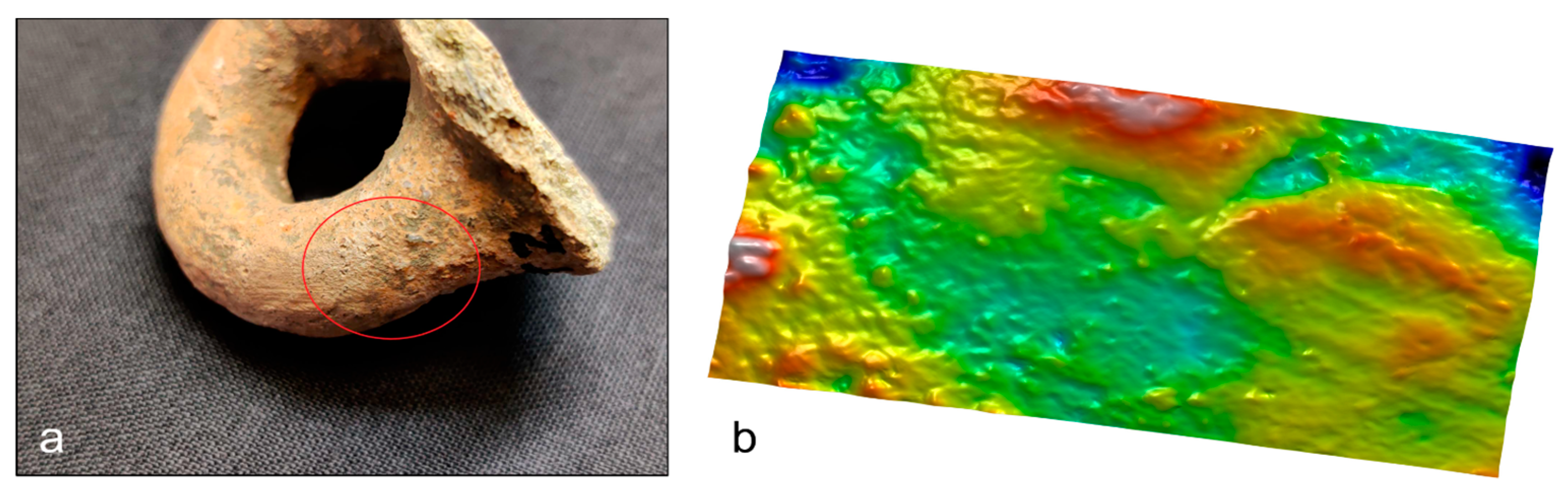

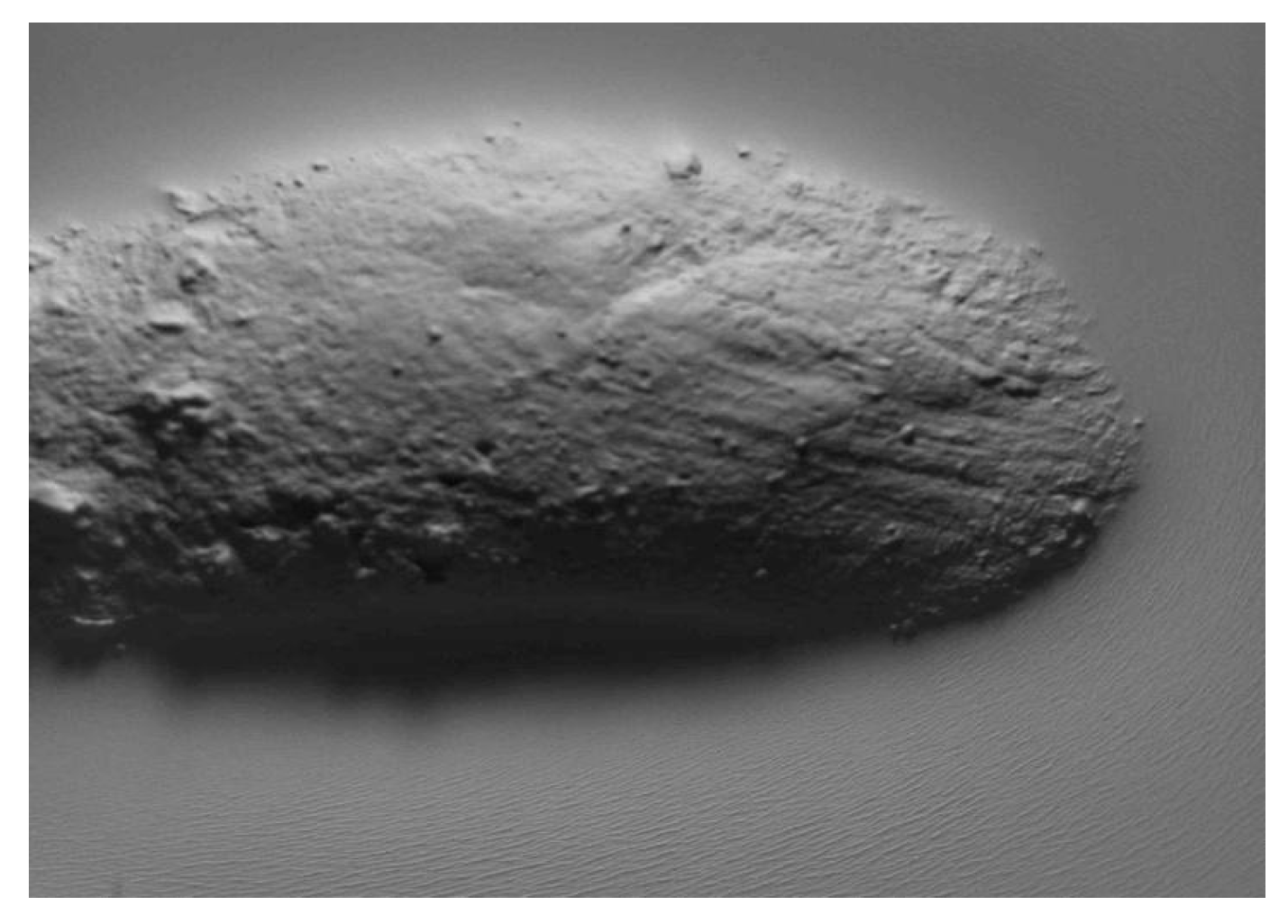

2.1. Materials

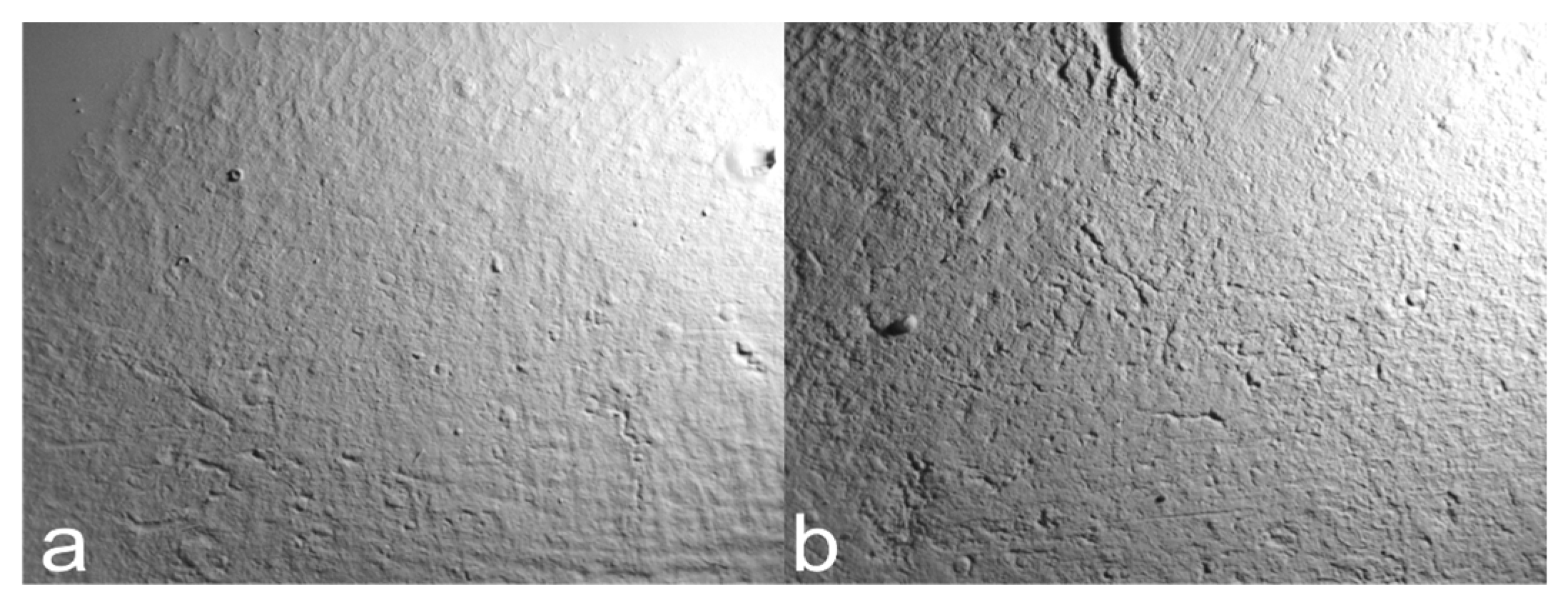

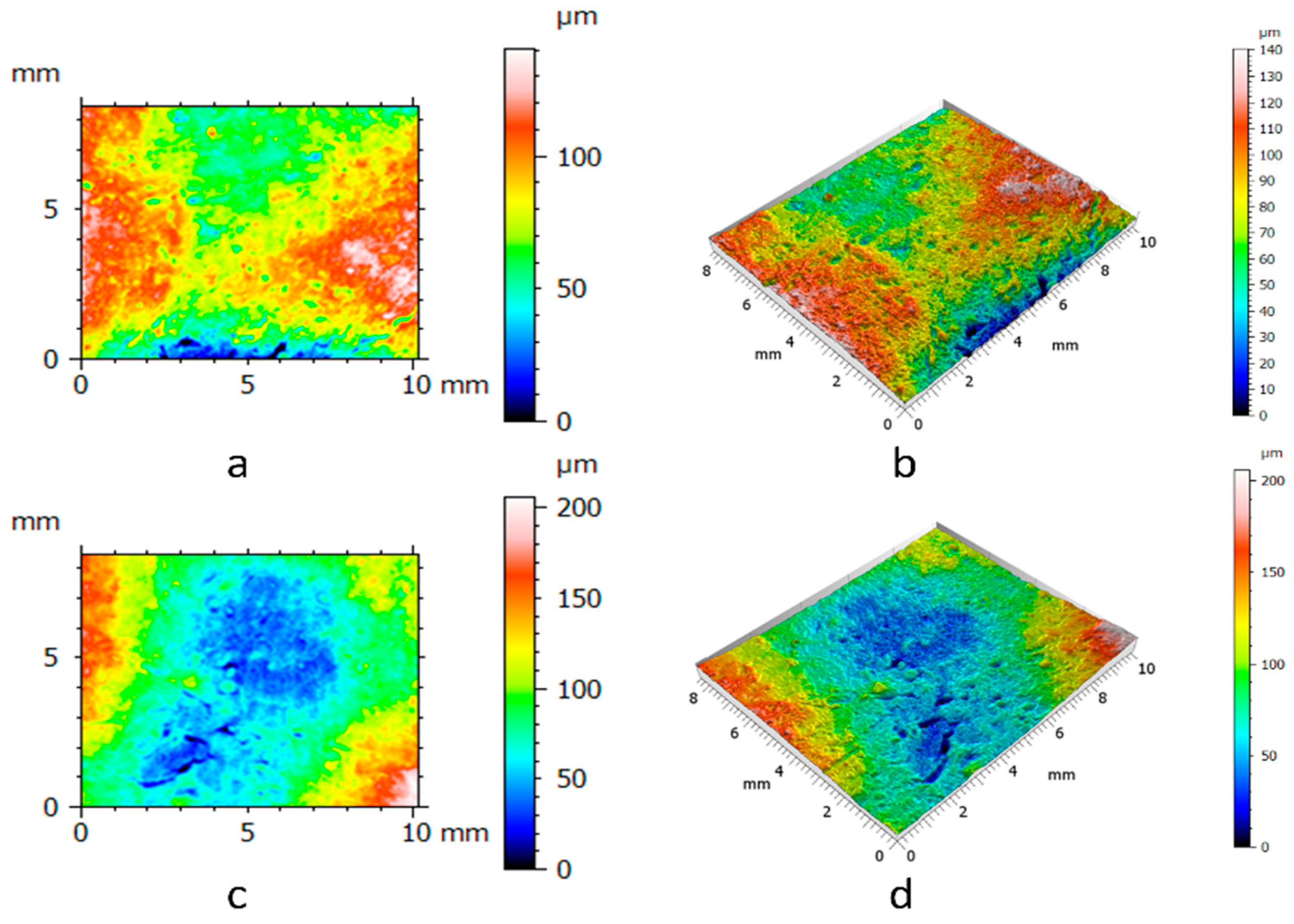

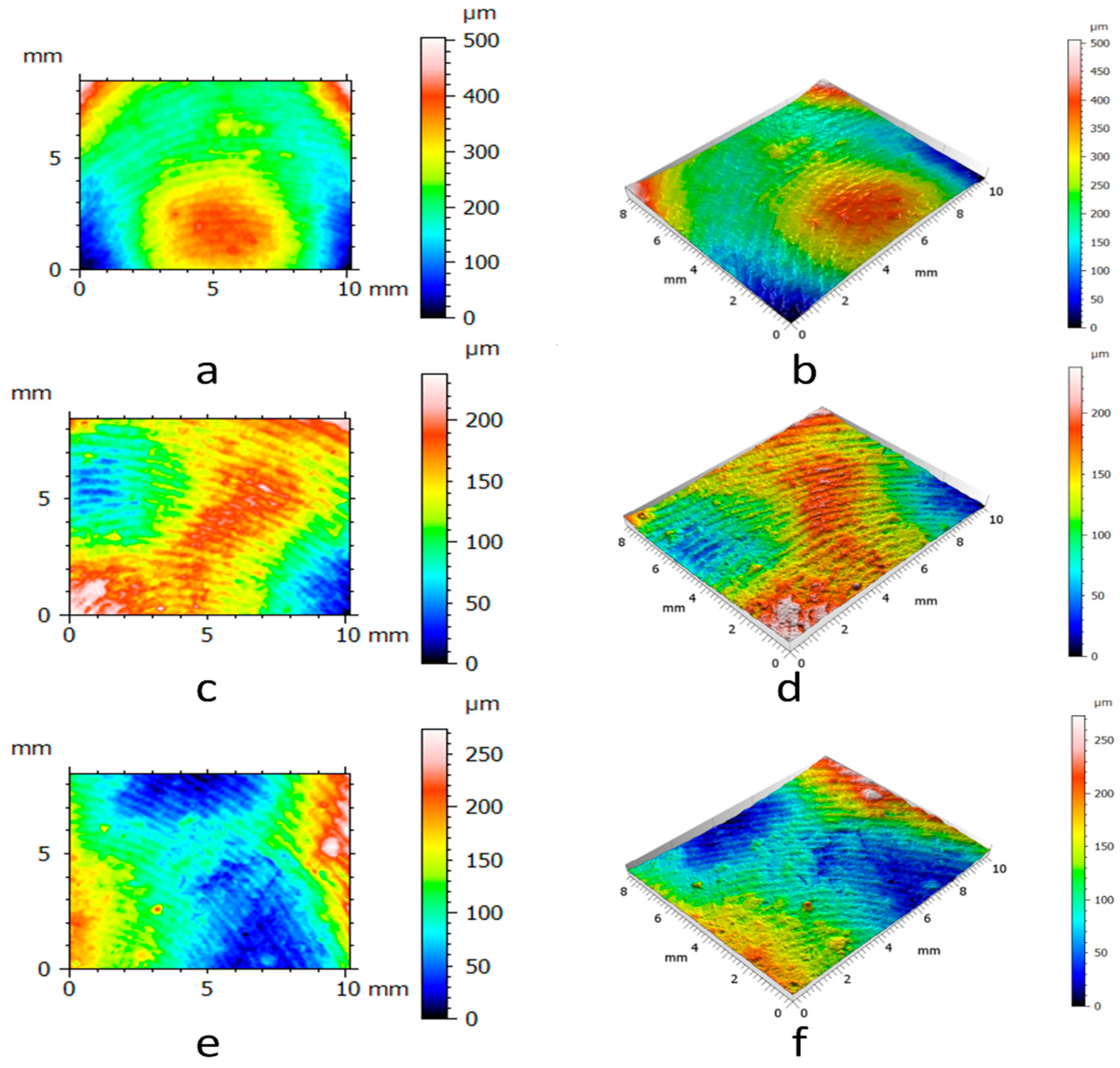

2.2. Surface Measurement and Analysis

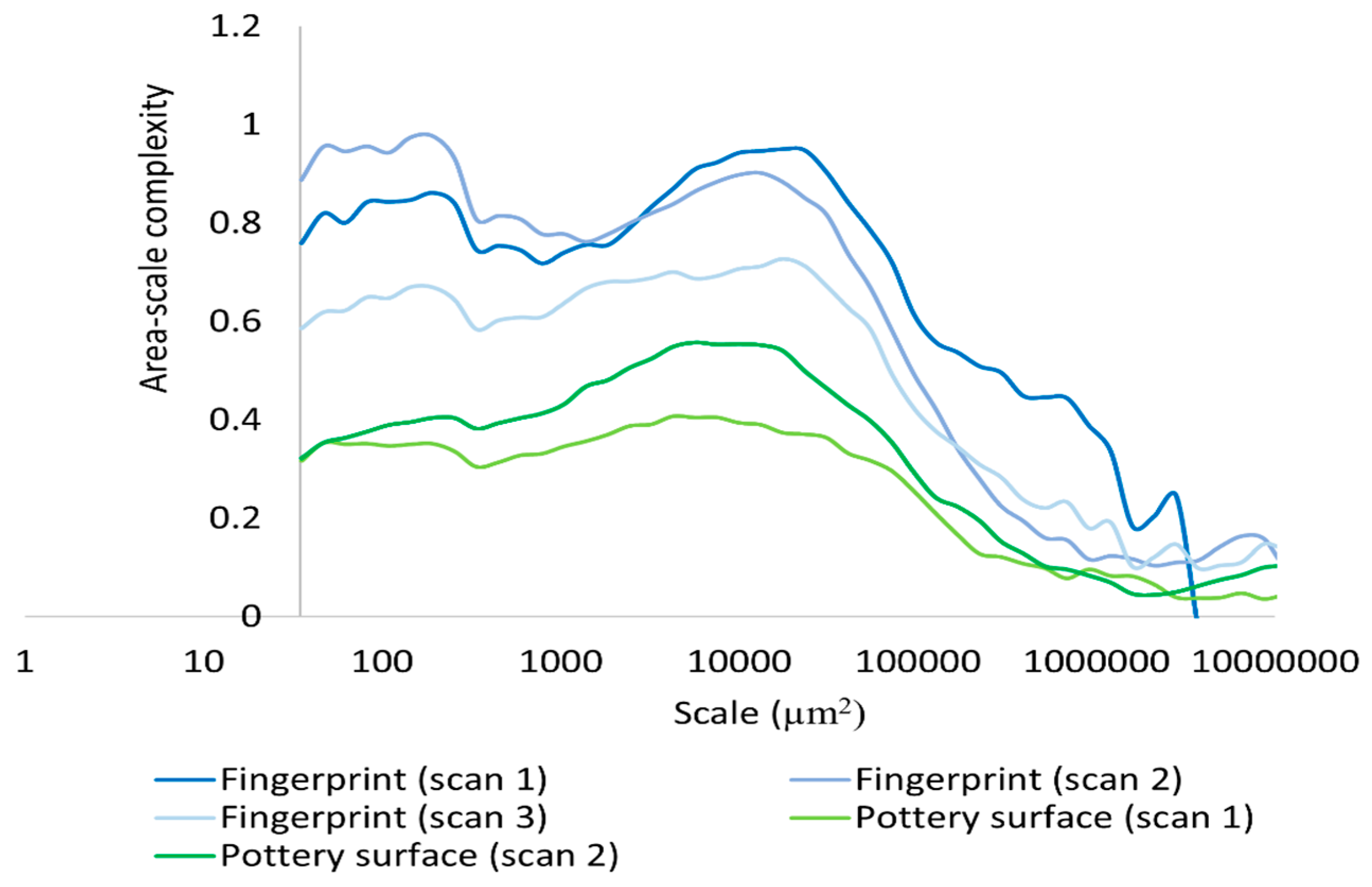

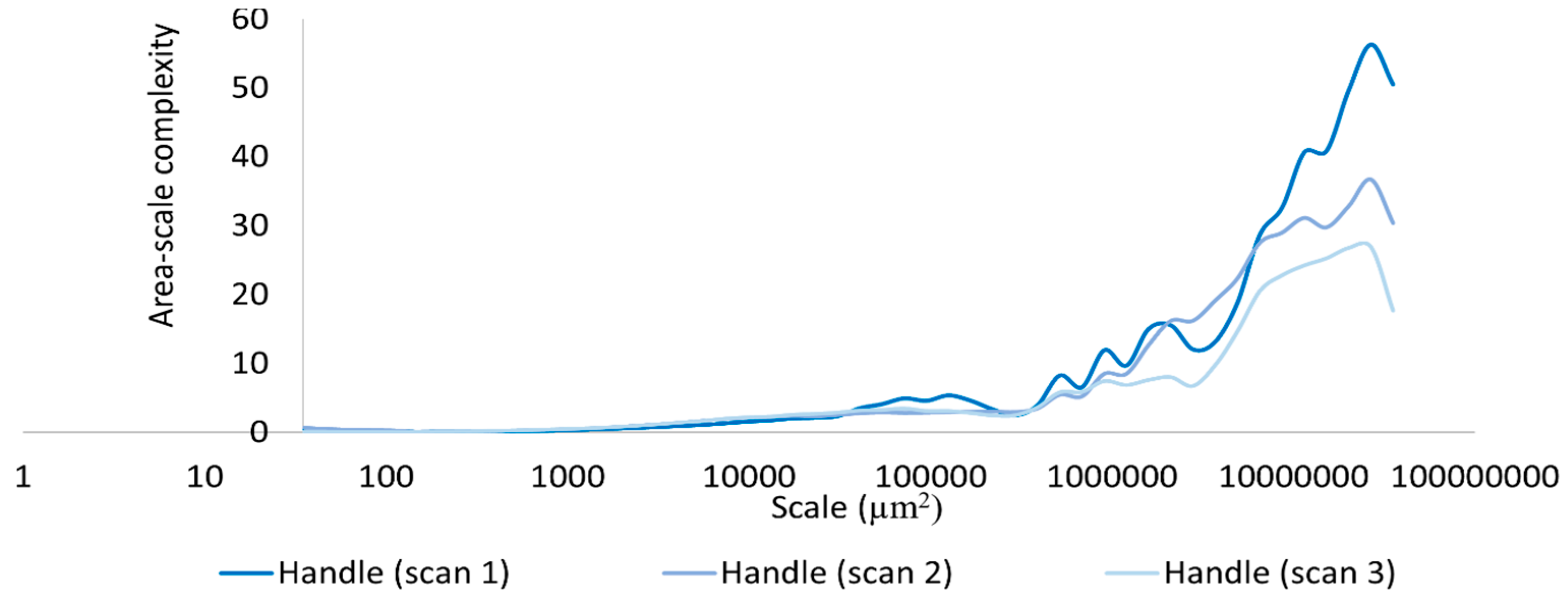

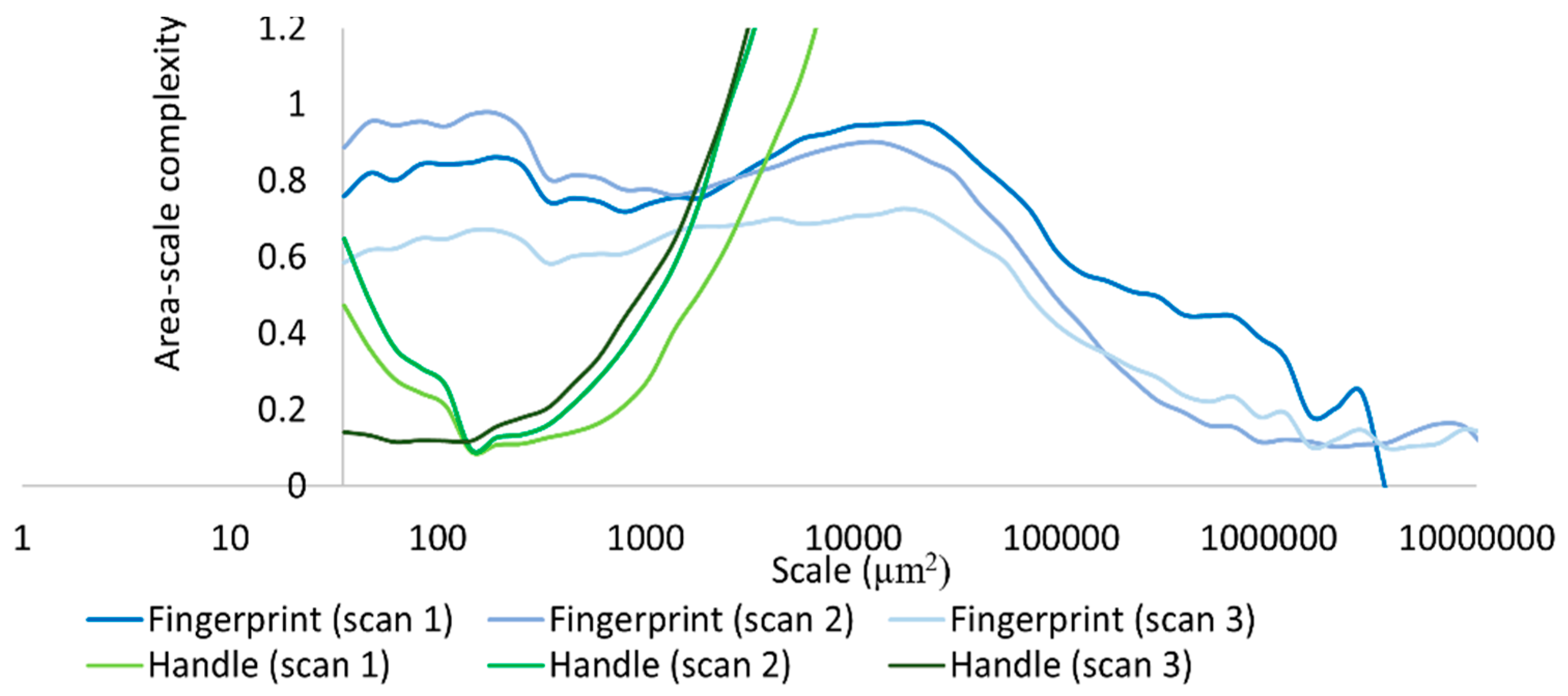

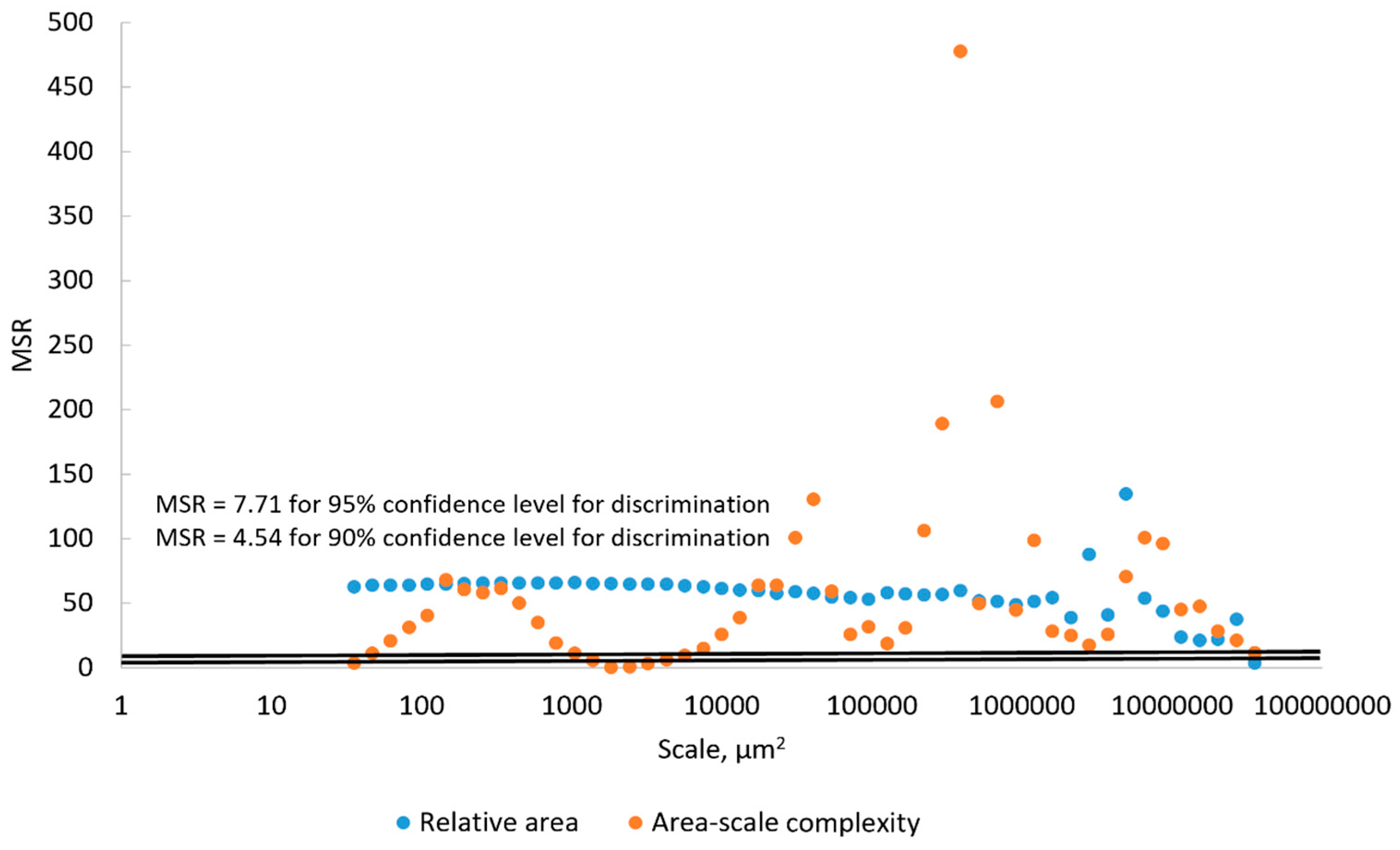

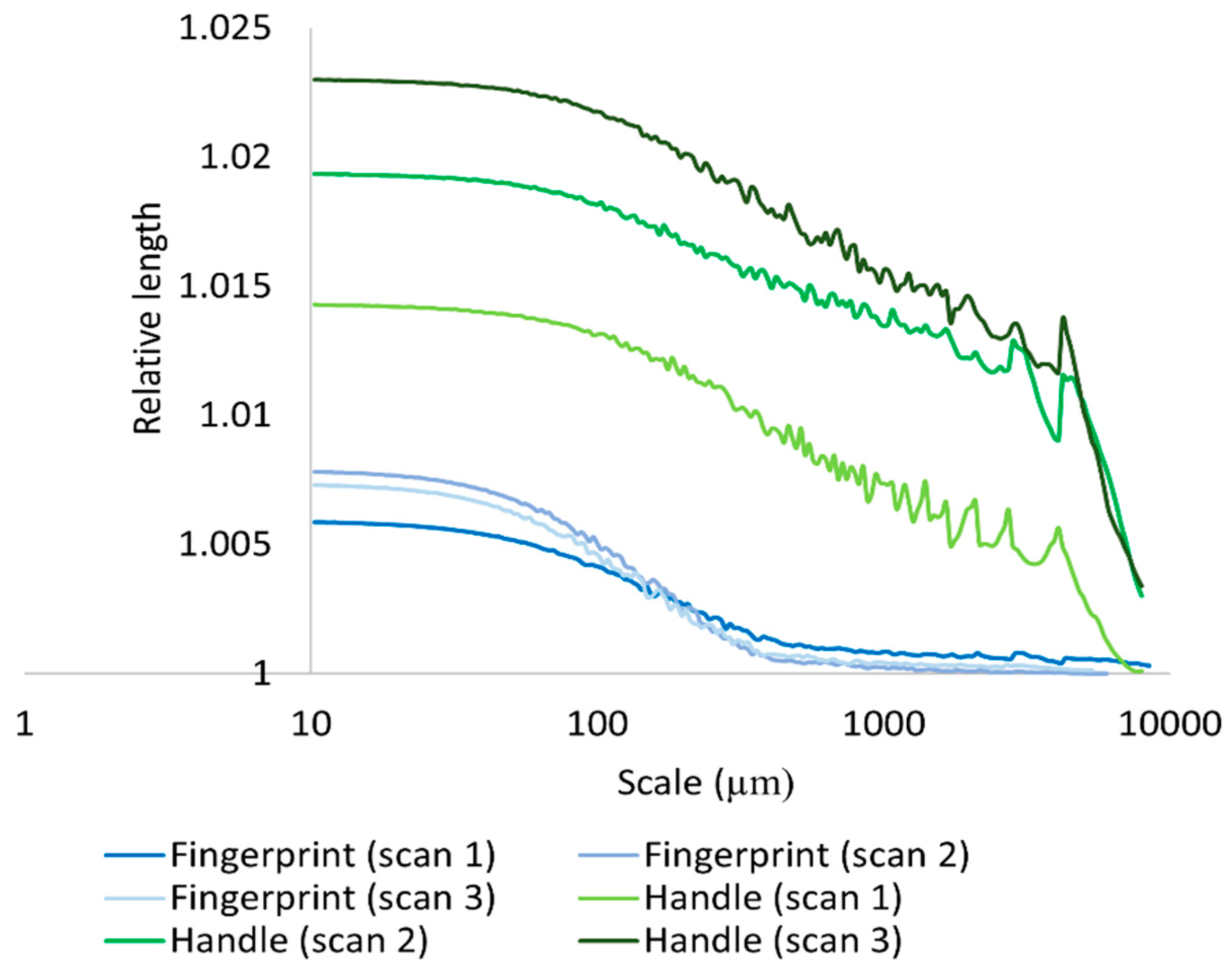

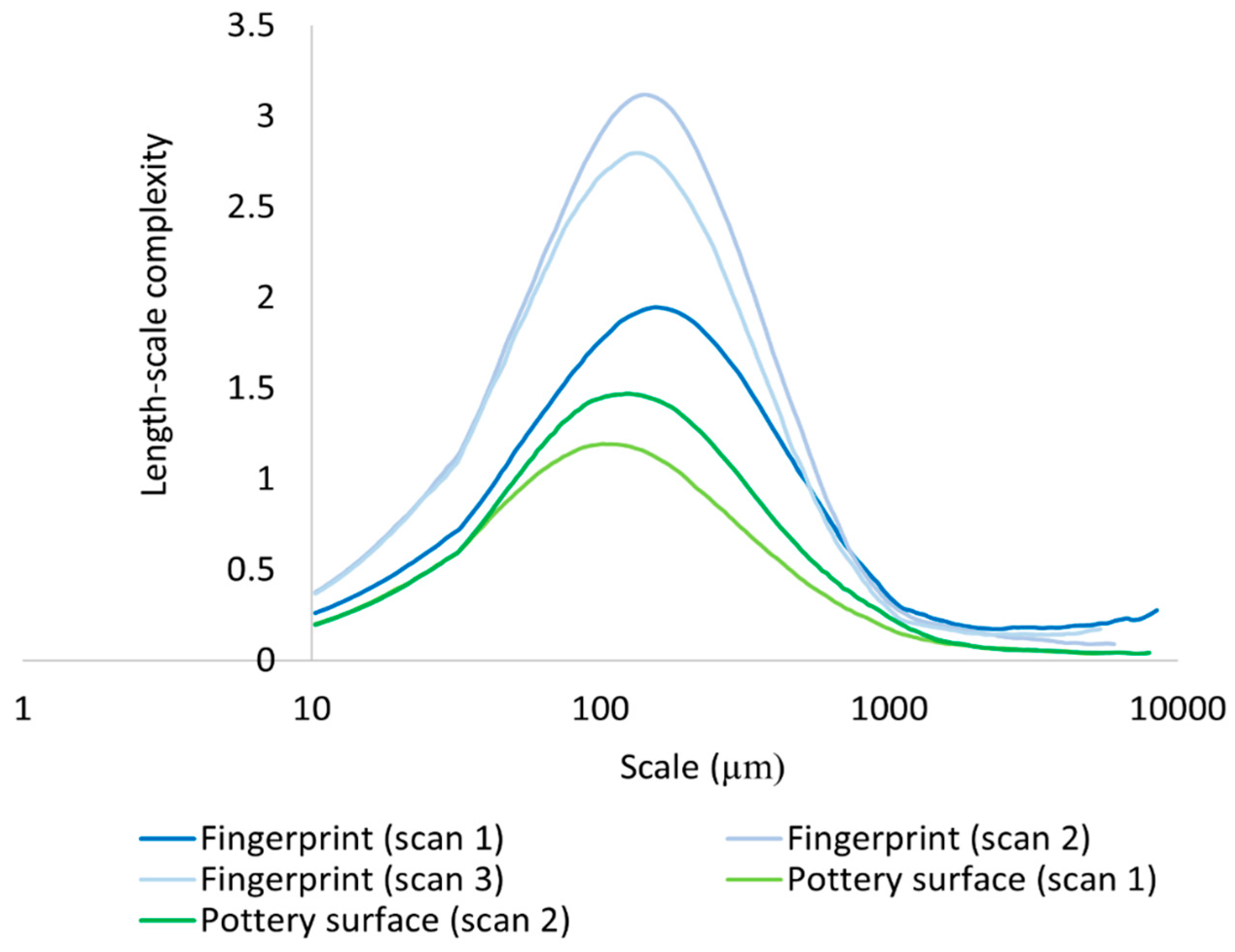

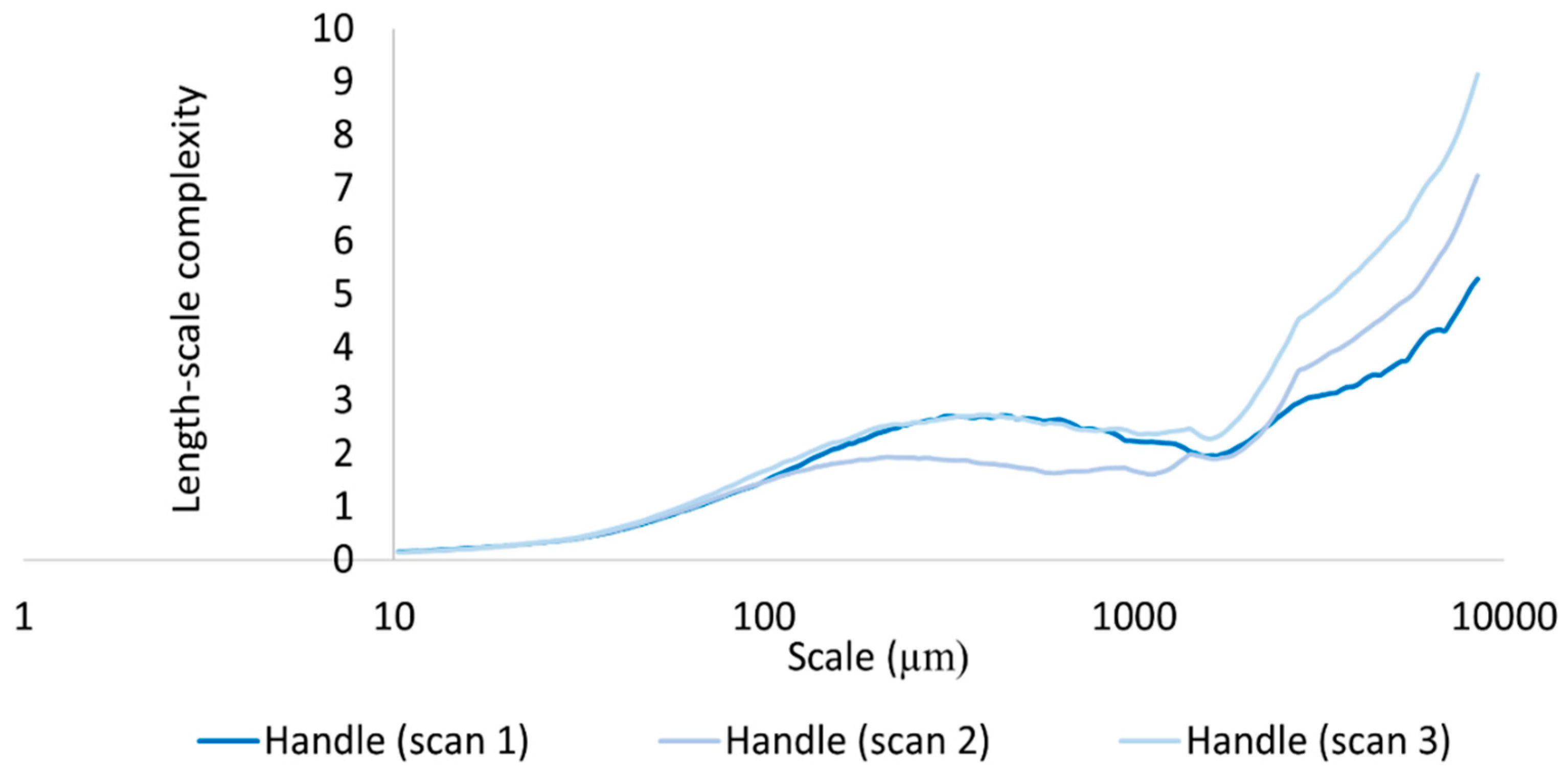

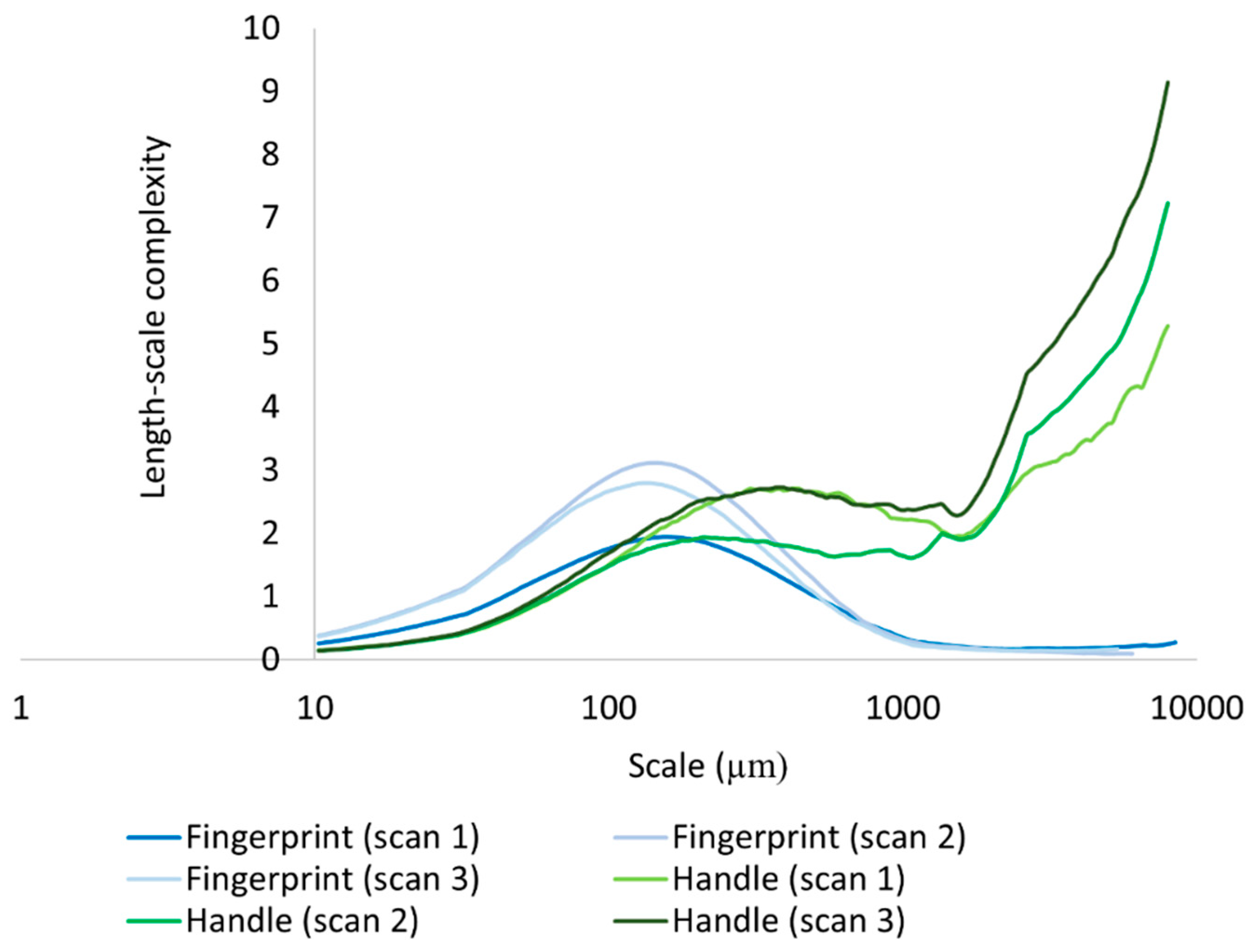

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yum, S.M.; Baek, I.K.; Hong, D.; Kim, J.; Jung, K.; Kim, S.; Eom, K.; Jang, J.; Kim, S.; Sattorov, M.; et al. Fingerprint ridges allow primates to regulate grip. Proc. Natl. Acad. Sci. USA 2020, 117, 31665–31673. [Google Scholar] [CrossRef] [PubMed]

- Caplan, R.M. How fingerprints came into use for personal identification. J. Am. Acad. Dermatol. 1990, 23, 109–114. [Google Scholar] [CrossRef]

- Chen, H.; Shi, M.; Ma, R.; Zhang, M. Advances in fingermark age determination techniques. Analyst 2021, 146, 33–47. [Google Scholar] [CrossRef] [PubMed]

- Cummins, H.; Midlo, C. Finger Prints, Palms and Soles: An Introduction to Dermatoglyphics; Dover Publications: New York, NY, USA, 1961. [Google Scholar]

- Feng, J.; Ouyang, Z.; Cai, A. Fingerprint matching using ridges. Pattern Recognit. 2006, 39, 2131–2140. [Google Scholar] [CrossRef]

- Peta, K.; Stemp, W.J.; Chen, R.; Love, G.; Brown, C.A. Multiscale characterizations of topographic measurements on lithic materials and microwear using a GelSight Max: Investigating potential archaeological applications. J. Archaeol. Sci. Rep. 2024, 57, 104637. [Google Scholar] [CrossRef]

- Chang, J.H.; Fan, K.C. Fingerprint ridge allocation in direct gray-scale domain. Pattern Recognit. 2001, 34, 1907–1925. [Google Scholar] [CrossRef]

- Choi, H.; Choi, K.; Kim, J. Fingerprint matching incorporating ridge features with minutiae. IEEE Trans. Inf. Forensics Secur. 2011, 6, 338–345. [Google Scholar] [CrossRef]

- Daluz, H.M. Fundamentals of Fingerprint Analysis, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar] [CrossRef]

- Kücken, M.; Newell, A.C. Fingerprint formation. J. Theor. Biol. 2005, 235, 71–83. [Google Scholar] [CrossRef]

- Berry, J.; Stoney, D.A. The history and development of fingerprinting. In Advances in Fingerprint Technology, 2nd ed.; Lee, H.C., Gaensslen, R.E., Eds.; CRC Press: Boca Raton, FL, USA, 2001; pp. 13–52. [Google Scholar]

- Kaushal, N.; Kaushal, P. Human identification and fingerprints: A review. J. Biomet. Biostat. 2011, 2, 1000123. [Google Scholar] [CrossRef]

- Acree, M.A. Is there a gender difference in fingerprint ridge density? Forensic Sci. Int. 1999, 102, 35–44. [Google Scholar] [CrossRef]

- Cadd, S.; Islam, M.; Manson, P.; Bleay, S. Fingerprint composition and aging: A literature review. Sci. Justice 2015, 55, 219–238. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez-Redomero, E.; Alonso, C.; Romero, E.; Galera, V. Variability of fingerprint ridge density in a sample of Spanish Caucasians and its application to sex determination. Forensic Sci. Int. 2008, 180, 17–22. [Google Scholar] [CrossRef] [PubMed]

- Králík, M.; Novotný, V. Epidermal ridge breadth: An indicator of age and sex in paleodermatoglyphs. Var. Evol. 2003, 11, 5–30. [Google Scholar]

- Mundorff, A.Z.; Bartelink, E.J.; Murad, T.A. Sexual dimorphism in finger ridge breadth measurements: A tool for sex estimation from fingerprints. J. Forensic Sci. 2014, 59, 891–897. [Google Scholar] [CrossRef]

- Nayak, V.C.; Rastogi, P.; Kanchan, T.; Yoganarasimha, K.; Kumar, G.P.; Menezes, R.G. Sex differences from fingerprint ridge density in Chinese and Malaysian population. Forensic Sci. Int. 2010, 197, 67–69. [Google Scholar] [CrossRef]

- Rife, D.C. Finger prints as criteria of ethnic relationship. Am. J. Hum. Genet. 1953, 11, 189–202. [Google Scholar] [CrossRef]

- Sánchez-Andrés, A.; Barea, J.A.; Rivaldería, N.; Alonso-Rodríguez, C.; Gutiérrez-Redomero, E. Impact of aging on fingerprint ridge density: Anthropometry and forensic implications in sex inference. Sci. Justice 2018, 58, 323–334. [Google Scholar] [CrossRef]

- Sharma, S.; Shrestha, R.; Krishan, K.; Kanchan, T. Sex estimation from fingerprint ridge density. A Rev. literature. Acta Biomed. 2021, 2, e2021366. [Google Scholar] [CrossRef]

- Walton, A.; Moret, S.; Barash, M.; Gunn, P. The frequency of fingerprint patterns separated by ethnicity and sex in a general population from Sydney, Australia. Aust. J. Forensic Sci. 2019, 51 (Suppl. 1), S162–S167. [Google Scholar] [CrossRef]

- Åström, P.; Eriksson, S.-A. Fingerprints and Archaeology; Studies in Mediterranean Archaeology 28; Paul Åströms Förlag: Göteborg, Sweden, 1980. [Google Scholar]

- Kamp, K.A.; Timmerman, N.; Lind, G.; Graybill, J.; Natowsky, I. Discovering childhood: Using fingerprints to find children in the archaeological record. Am. Antiq. 1999, 64, 309–315. [Google Scholar] [CrossRef]

- Fowler, K.D.; Walker, E.; Greenfield, H.J.; Ross, J.; Maeir, A.M. The identity of potters in early states: Determining the age and sex of fingerprints on Early Bronze Age pottery from Tell eṣ-Ṣâfi/Gath, Israel. J. Archaeol. Method Theory 2019, 26, 1470–1512. [Google Scholar] [CrossRef]

- Fowler, K.D.; Ross, J.; Walker, E.; Barritt-Cleary, C.; Greenfield, H.J.; Maeir, A.M. Fingerprint evidence for the division of labour and learning pottery-making at Early Bronze Age Tell eṣ-Ṣâfi/Gath, Israel. PLoS ONE 2020, 15, e0231046. [Google Scholar] [CrossRef]

- Faux-Campbell, J.L. Fingerprinting the Past: A Paleodermatoglyphic Examination of Figurine Production at Teotihuacan, Mexico. Ph.D. Thesis, Department of Anthropology, State University of New York, Buffalo, NY, USA, 2018. [Google Scholar]

- Faulds, H. On the skin-furrows of the hand. Nature 1880, 22, 605. [Google Scholar] [CrossRef]

- Cummins, H. Ancient finger prints in clay. J. Crim. Law Criminol. 1941, 32, 468–481. [Google Scholar] [CrossRef]

- Branigan, K.; Papadatos, Y.; Wynn, D. Fingerprints on Early Minoan pottery: A pilot study. Annu. Br. Sch. Athens 2002, 97, 49–53. [Google Scholar] [CrossRef]

- Stinson, S.L. Household Ritual, Gender, and Figurines in the Hohokam Regional System. Ph.D. Thesis, Department of Anthropology, University of Arizona, Tucson, AZ, USA, 2004. [Google Scholar]

- Králík, M.; Nejman, L. Fingerprints on artifacts and historical items: Examples and comments. J. Anc. Fingerpr. 2007, 1, 4–15. [Google Scholar]

- Sanders, A. Fingerprints, sex, state, and the organization of the Tell Leilan ceramic industry. J. Archaeol. Sci. 2015, 57, 223–238. [Google Scholar] [CrossRef]

- Lichtenberger, A.; Moran, K.L. Ancient fingerprints from Beit Nattif: Studying Late Roman clay impressions on oil lamps and figurines. Antiquity 2018, 92, e3. [Google Scholar] [CrossRef]

- Kantner, J.; McKinney, D.; Pierson, M.; Wester, S. Reconstructing sexual divisions of labor from fingerprints on Ancestral Puebloan pottery. Proc. Natl. Acad. Sci. USA 2019, 116, 12220–12225. [Google Scholar] [CrossRef]

- Dyowe Roig, A.E.; Estebaranz-Sánchez, F.; Martínez, L.M.; Molist Montaña, M. Analysis of fingerprints on a PPNB figurine from the Tell Halula site, Syria. Archaeol. Anthropol. Sci. 2023, 15, 40. [Google Scholar] [CrossRef]

- Hruby, J. Appendix C: The fingerprints on pottery. In Midea: The Megaron Complex and Shrine Area. Excavations on the Lower Terraces 1994–1997; Walberg, G., Ed.; Prehistory Monographs 20; INSTAP Academic Press: Philadelphia, PA, USA, 2007; pp. 481–482. [Google Scholar]

- Burchill, A.T.; Sanders, A.; Morgan, T.J.H. Inferring the age and sex of ancient potters from fingerprint ridge densities: A data-driven, Bayesian mixture modelling approach. MethodsX 2023, 11, e102292. [Google Scholar] [CrossRef] [PubMed]

- Sanders, A.; Burchill, A. Mean ridge breadth and ridge density tell the same story for ancient fingerprints: A critique of the “Age-Sex Identification Matrix” method of demographic reconstruction. J. Archaeol. Sci. 2024, 169, e106036. [Google Scholar] [CrossRef]

- Sanders, A.; Lumsden, S.; Burchill, A.Y.; Mouamar, G. Transformations in the roles of men, women, and children in the ceramic industry at Early Bronze Age Hama, Syria and contemporary sites. J. Anthropol. Archaeol. 2023, 70, e101501. [Google Scholar] [CrossRef]

- Beatty, B.L.; Kahan, S.; Bas, B.; Zou, B.; Werpachowski, N. Contrasting results of surface metrology techniques for three-dimensional human fingerprints. arXiv 2024, arXiv:2410.12648. [Google Scholar] [CrossRef]

- Johnson, M.K.; Adelson, E.H. Retrographic sensing for the measurement of surface texture and shape. In Proceedings of the 2009 IEEE Conference on Computer Vision and Pattern Recognition, Miami, FL, USA, 20–25 June 2009; pp. 1070–1077. [Google Scholar] [CrossRef]

- Johnson, M.K.; Cole, F.; Raj, A.; Adelson, E.H. Microgeometry capture using an elastomeric sensor. ACM Trans. Graph. 2011, 30, 1–8. [Google Scholar] [CrossRef]

- Li, R.; Adelson, E. Sensing and recognizing surface textures using a Gelsight sensor. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Portland, OR, USA, 23–28 June 2013; Volume 31, pp. 1241–1247. Available online: https://www.cv-foundation.org/openaccess/content_cvpr_2013/html/Li_Sensing_and_Recognizing_2013_CVPR_paper.html (accessed on 1 May 2025).

- Yuan, W.; Dong, S.; Adelson, E.H. Gelsight: High-resolution robot tactile sensors for estimating geometry and force. Sensors 2017, 17, e2762. [Google Scholar] [CrossRef]

- Stemp, W.J.; Watson, A.; Evans, A.A. Surface analysis of stone and bone tools. Surf. Topogr. Metrol. Prop. 2016, 4, e013001. [Google Scholar] [CrossRef]

- Campbell, R.M. Quantitatively distinguishing between bone surface modifications using confocal microscopy and scale–sensitive fractal analysis. Master’s Thesis, Department of Anthropology and Geography, Colorado State University, Fort Collins, CO, USA, 2023. [Google Scholar]

- Key, A.J.M.; Stemp, W.J.; Morozov, M.; Proffitt, T.; de la Torre, I. Is loading a significantly influential factor in the development of lithic microwear? An experimental test using LSCM on basalt from Olduvai Gorge. J. Archaeol. Method Theory 2015, 22, 1193–1214. [Google Scholar] [CrossRef]

- Key, A.; Bartkowiak, T.; Macdonald, D.A.; Mietlinski, P.; Gapinski, B.; de la Torre, I.; Stemp, W.J. Quantifying edge sharpness on stone flakes: Comparing mechanical and micro-geometric definitions across multiple raw materials from Olduvai Gorge (Tanzania). J. Archaeol. Method Theory 2024, 31, 51–74. [Google Scholar] [CrossRef]

- Macdonald, D.A.; Bartkowiak, T.; Stemp, W.J. 3D multiscale curvature analysis of tool edges as an indicator of cereal harvesting intensity. J. Archaeol. Sci. Rep. 2020, 33, 102523. [Google Scholar] [CrossRef]

- Macdonald, D.A.; Bartkowiak, T.; Mendak, M.; Stemp, W.J.; Key, A.; de la Torre, I.; Wieczorowski, M. Revisiting lithic edge characterization with microCT: Multiscale study of edge curvature, re-entrant features, and profile geometry on Olduvai Gorge quartzite flakes. Archaeol. Anthropol. Sci. 2022, 14, e33. [Google Scholar] [CrossRef]

- Macdonald, D.A.; Martisius, N.L.; Stemp, W.J.; Brown, C.A.; Guthrie, L.; Gleason, M.A. Quantification of microwear on experimental shell tools: First results using focus variation microscopy, surface roughness, and multiscale geometric analyses. J. Archaeol. Sci. Rep. 2025, 62, e104986. [Google Scholar] [CrossRef]

- Martisius, N.L. Accessing the ephemeral using multiscale 3D microscopy of bone microwear. J. Archaeol. Sci. Rep. 2022, 45, e103634. [Google Scholar] [CrossRef]

- Pedergnana, A.; Calandra, I.; Evans, A.A.; Bob, K.; Hildebrandt, A.; Ollé, A. Polish is quantitatively different on quartzite flakes used on different worked materials. PLoS ONE 2020, 15, e0243295. [Google Scholar] [CrossRef] [PubMed]

- Pontzer, H.; Scott, J.R.; Lordkipanidze, D.; Ungar, P.S. Dental microwear texture analysis and diet in the Dmanisi hominins. J. Hum. Evol. 2011, 61, 683–687. [Google Scholar] [CrossRef]

- Schmidt, C.W.; El Zaatari, S.; Van Sessen, R. Dental microwear texture analysis in bioarchaeology. In Dental Wear in Evolutionary and Biocultural Contexts; Schmidt, C.W., Watson, J.T., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 143–168. [Google Scholar] [CrossRef]

- Schmidt, C.W.; Ungar, P.S. Dental microwear analysis: Wear we are going, wear we have been. In A companion to biological anthropology; Larsen, C.S., Ed.; Wiley: Hoboken, NJ, USA, 2023; pp. 572–586. [Google Scholar] [CrossRef]

- Scott, R.S.; Ungar, P.S.; Bergstrom, T.S.; Brown, C.A.; Grine, F.E.; Teaford, M.F.; Walker, A. Dental microwear texture analysis shows within-species diet variability in fossil hominins. Nature 2005, 436, 693–695. [Google Scholar] [CrossRef]

- Stemp, W.J. A review of quantification of lithic use-wear using laser profilometry: A method based on metrology and fractal analysis. J. Archaeol. Sci. 2014, 48, 15–25. [Google Scholar] [CrossRef]

- Stemp, W.J.; Chung, S. Discrimination of surface wear on obsidian tools using LSCM and RelA: Pilot study results. Scanning 2011, 33, 279–293. [Google Scholar] [CrossRef]

- Stemp, W.J.; Childs, B.E.; Vionnet, S.; Brown, C.A. Quantification and discrimination of lithic use-wear: Surface profile measurements and length-scale fractal analysis. Archaeometry 2009, 51, 366–382. [Google Scholar] [CrossRef]

- Stemp, W.J.; Lerner, H.J.; Kristant, E.H. Quantifying microwear on experimental Mistassini quartzite scrapers: Preliminary results of exploratory research using LSCM and scale-sensitive fractal analysis. Scanning 2013, 35, 28–39. [Google Scholar] [CrossRef]

- Stemp, W.J.; Andruskiewicz, M.D.; Gleason, M.A.; Rashid, Y.H. Experiments in ancient Maya blood-letting: Quantification of surface wear on obsidian blades. Archaeol. Anthropol. Sci. 2015, 7, 423–439. [Google Scholar] [CrossRef]

- Stemp, W.J.; Stemp, M. UBM laser profilometry and lithic use-wear analysis: A variable length scale investigation of surface topography. J. Archaeol. Sci. 2001, 28, 81–88. [Google Scholar] [CrossRef]

- Stemp, W.J.; Stemp, M. Documenting stages of polish development on experimental stone tools: Surface characterization by fractal geometry using UBM laser profilometry. J. Archaeol. Sci. 2003, 30, 287–296. [Google Scholar] [CrossRef]

- Ungar, P.S.; Brown, C.A.; Bergstrom, T.S.; Walker, A. Quantification of dental microwear by tandem scanning confocal microscopy and scale-sensitive fractal analyses. Scanning 2003, 25, 185–193. [Google Scholar] [CrossRef]

- Ungar, P.S.; Grine, F.E.; Teaford, M.F. Dental microwear and diet of the Plio-Pleistocene hominin Paranthropus boisei. PLoS ONE 2008, 3, e2044. [Google Scholar] [CrossRef]

- Ungar, P.S.; Krueger, K.L.; Blumenschine, R.J.; Njau, J.; Scott, R.S. Dental microwear texture analysis of hominins recovered by the Olduvai Landscape Paleoanthropology Project, 1995–2007. J. Hum. Evol. 2012, 63, 429–437. [Google Scholar] [CrossRef]

- Watson, A.S.; Gleason, M.A. A comparative assessment of texture analysis techniques applied to bone tool use-wear. Surf. Topogr. Metrol. Prop. 2016, 4, e024002. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. Fractals: Form, Chance and Dimension; W.H. Freeman: San Francisco, CA, USA, 1977. [Google Scholar]

- Mandelbrot, B.B. The Fractal Geometry of Nature; W.H. Freeman: San Francisco, CA, USA, 1982. [Google Scholar]

- Brown, C.A.; Hansen, H.N.; Jiang, X.J.; Blateyron, F.; Berglund, J.; Senin, N.; Bartkowiak, T.; Dixon, B.; Le Goïc, G.; Quinsat, Y.; et al. Multiscale analyses and characterizations of surface topographies. CIRP Ann. 2018, 67, 839–862. [Google Scholar] [CrossRef]

- Stemp, W.J.; Lerner, H.J.; Kristant, E.H. Testing area-scale fractal complexity (Asfc) and laser scanning confocal microscopy (LSCM) to document and discriminate microwear on experimental quartzite scrapers. Archaeometry 2018, 60, 660–677. [Google Scholar] [CrossRef]

- ASME B46.1; Surface Texture (Surface Roughness, Waviness and Lay). American Society of Mechanical Engineers: New York, NY, USA, 2019.

- ISO 25178–2; Geometrical Product Specifications (GPS)—Surface Texture: Aerial—Part 2: Terms, Definitions, and Surface Texture Parameters. ISO: Geneva, Switzerland, 2012. Available online: https://www.iso.org/obp/ui/#iso:std:iso:25178:-2:ed-1:v1:en (accessed on 1 May 2025).

- Brown, C.A. Fractal-related multiscale geometric characterisation of topographies. In Characterisation of Areal Surface Texture; Leach, R., Ed.; Springer: Cham, Switzerland, 2024; pp. 151–180. [Google Scholar] [CrossRef]

- Peta, K.; Love, G.; Brown, C.A. Comparing repeatability and reproducibility of topographic measurement types directly using linear regression analyses of measured heights. Precis. Eng. 2024, 88, 192–203. [Google Scholar] [CrossRef]

- Stemp, W.J. Ghosts in the room and elephants in the machine: Data acquisition in surface texture analysis of stone tools. Lithic Technol. 2023, 48, 291–306. [Google Scholar] [CrossRef]

- Abad, A.C.; Ranasinghe, A. Visuotactile sensors with emphasis on gelsight sensor: A review. IEEE Sens. J. 2020, 20, 7628–7638. [Google Scholar] [CrossRef]

| Height Parameters | Descriptions (Units of Measurement) |

|---|---|

| Sa | Arithmetical mean height (µm) |

| Sp | Maximum peak height (µm) |

| Sq | Root mean square of height (µm) |

| Sku | Kurtosis–sharpness of roughness profile |

| Ssk | Skewness–degree of bias of roughness shape (asperity) |

| Sv | Maximum pit depth (µm) |

| Sz | Maximum height of scale-limited surface (µm) |

| Hybrid parameters | Descriptions (units of measurement) |

| Sdq | Root mean square gradient |

| Sdr | Developed interfacial area ratio (%) |

| Multiscale geometric parameters | Descriptions (units of measurement) |

| Das | Fractal dimension |

| Asfc | Area-scale complexity (µm2) |

| Lsfc | Length-scale complexity (µm) |

| RL | Relative length (µm) |

| Srel | Relative area (µm2) |

| Parameter | Value and Unit of Measurement |

|---|---|

| Field of view | 14.6 mm × 8.3 mm |

| Surface roughness range | 0.2–20 μm |

| x-y plane accuracy | 3 μm + 0.2% |

| z-axis/height (1–50 μm) accuracy | 0.3 μm + 4% |

| Capture speed | 0.5 ms |

| Hardened Clay—no fingerprint (experimental) | GelSight Max scan designation |

| Block 1 | Pottery surface (scan 1) |

| Block 2 | Pottery surface (scan 2) |

| Hardened clay—fingerprint (experimental) | GelSight Max scan designation |

| Individual 1—right thumbprint 1 | Fingerprint (scan 1) |

| Individual 2—right thumbprint 1a | Fingerprint (scan 2) |

| Individual 2—right thumbprint 1b | Fingerprint (scan 3) |

| Pottery handle fragment—fingerprint (archaeological) | GelSight Max scan designation |

| Pottery handle fragment 1—print 1a | Handle (scan 1) |

| Pottery handle fragment 1—print 1b | Handle (scan 2) |

| Pottery handle fragment 1—print 1c | Handle (scan 3) |

| Pottery Surface (Scan 1) Pottery Surface (Scan 2) | Fingerprint (Scan 1) Fingerprint (Scan 2) Fingerprint (Scan 3) | Handle (Scan 1) Handle (Scan 2) Handle (Scan 3) | |

|---|---|---|---|

| Sa (µm) [StDev] | 22.627 [5.907] | 46.678 [15.296] | 464.167 [30.059] |

| Sq (µm) [StDev] | 28.038 [7.832] | 58.135 [20.524] | 548.299 [38.113] |

| Ssk [StDev] | 0.305 [0.714] | 0.167 [0.477] | −0.637 [0.136] |

| Sku [StDev] | 3.110 [0.255] | 2.823 [0.230] | 2.278 [0.184] |

| Sp (µm) [StDev] | 92.205 [46.280] | 185.407 [84.956] | 753.868 [13.088] |

| Sv (µm) [StDev] | 80.950 [0.141] | 153.617 [67.920] | 1324.887 [112.948] |

| Sz (µm) [StDev] | 173.155 [46.266] | 339.023 [145.537] | 2078.756 [115.536] |

| Sdq [StDev] | 0.125 [0.007] | 0.153 [0.006] | 0.493 [0.057] |

| Sdr (%) [StDev] | 0.805 [0.078] | 1.170 [0.053] | 10.743 [2.152] |

| Pottery Surface (Scan 1) Pottery Surface (Scan 2) | Fingerprint (Scan 1) Fingerprint (Scan 2) Fingerprint (Scan 3) | Handle (Scan 1) Handle (Scan 2) Handle (Scan 3) | |

|---|---|---|---|

| R2 [StDev] | 0.9985 [0.0006] | 0.9863 [0.0221] | 0.9206 [0.1173] |

| Das [StDev] | 2.0009 [0.0002] | 2.0018 [0.0003] | 2.0501 [0.0647] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peta, K.; Stemp, W.J.; Stocking, T.; Chen, R.; Love, G.; Gleason, M.A.; Houk, B.A.; Brown, C.A. Multiscale Geometric Characterization and Discrimination of Dermatoglyphs (Fingerprints) on Hardened Clay—A Novel Archaeological Application of the GelSight Max. Materials 2025, 18, 2939. https://doi.org/10.3390/ma18132939

Peta K, Stemp WJ, Stocking T, Chen R, Love G, Gleason MA, Houk BA, Brown CA. Multiscale Geometric Characterization and Discrimination of Dermatoglyphs (Fingerprints) on Hardened Clay—A Novel Archaeological Application of the GelSight Max. Materials. 2025; 18(13):2939. https://doi.org/10.3390/ma18132939

Chicago/Turabian StylePeta, Katarzyna, W. James Stemp, Tera Stocking, Richard Chen, George Love, Matthew A. Gleason, Brett A. Houk, and Christopher A. Brown. 2025. "Multiscale Geometric Characterization and Discrimination of Dermatoglyphs (Fingerprints) on Hardened Clay—A Novel Archaeological Application of the GelSight Max" Materials 18, no. 13: 2939. https://doi.org/10.3390/ma18132939

APA StylePeta, K., Stemp, W. J., Stocking, T., Chen, R., Love, G., Gleason, M. A., Houk, B. A., & Brown, C. A. (2025). Multiscale Geometric Characterization and Discrimination of Dermatoglyphs (Fingerprints) on Hardened Clay—A Novel Archaeological Application of the GelSight Max. Materials, 18(13), 2939. https://doi.org/10.3390/ma18132939