Study on the Rheological Optimization and Multiscale Verification of the Asphalt Rejuvenator

Abstract

1. Introduction

2. Objectives of the Study

3. Materials and Methods

3.1. Introduction to the Preparation and Testing of Rejuvenated Asphalt Binders

3.1.1. Test Raw Materials

3.1.2. Preparation Method of Rejuvenated Asphalt Binder

3.1.3. Introduction to Test Methods for Asphalt Binder Scale

3.1.4. Basic Properties of Rejuvenator Raw Materials

3.2. Asphalt Mixture Preparation Process and Test Methods

3.2.1. Design of Asphalt Mixture Mass Ratio of Asphalt Binder and Aggregate

3.2.2. Asphalt Mixture Preparation Process

3.2.3. Test Methods for Road Performance of Asphalt Mixtures

3.3. A Block Diagram Containing the Experimental Research Program

4. Experimental Results and Discussion

4.1. Determination of Rejuvenator Formula

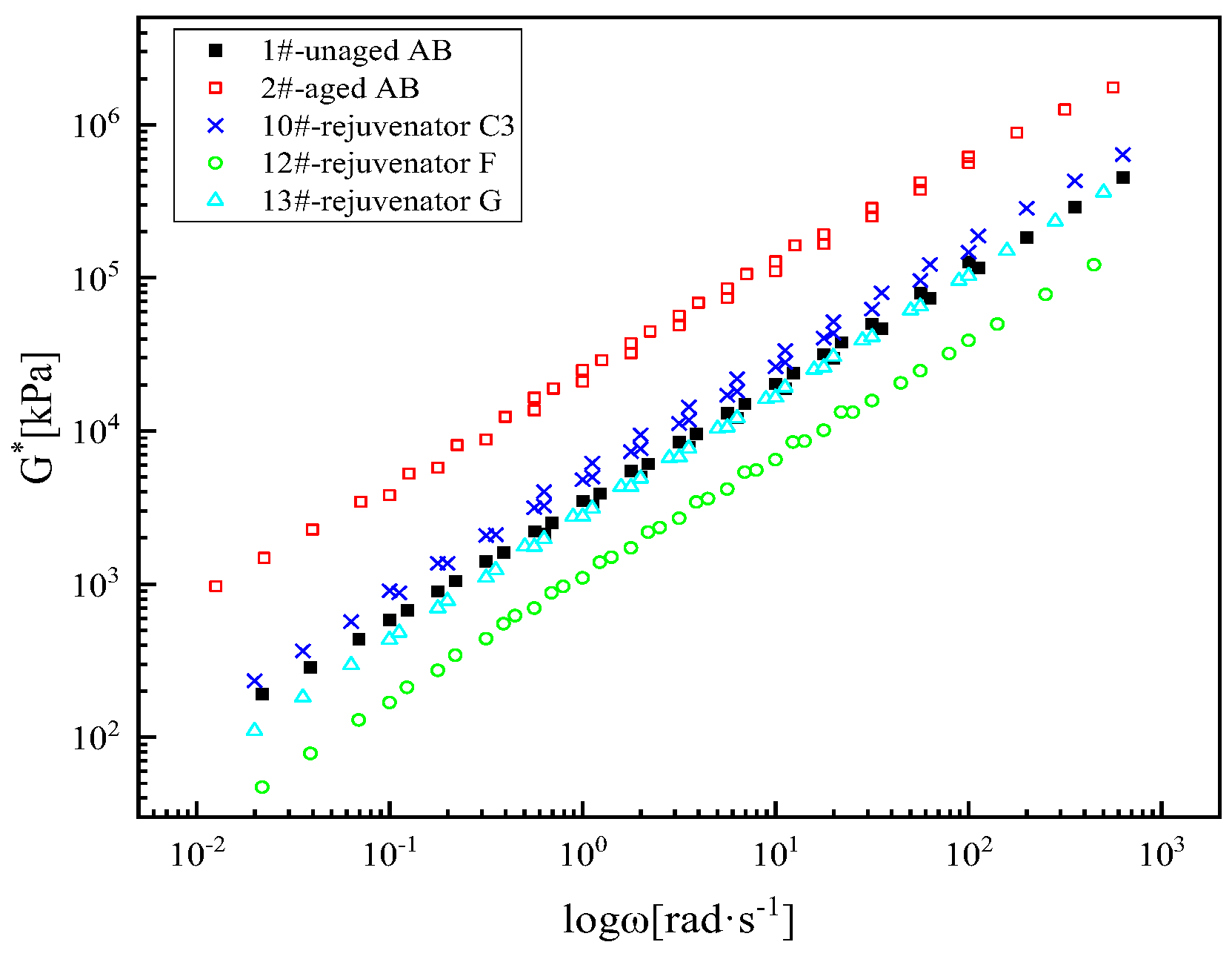

4.1.1. Base Oil Optimization

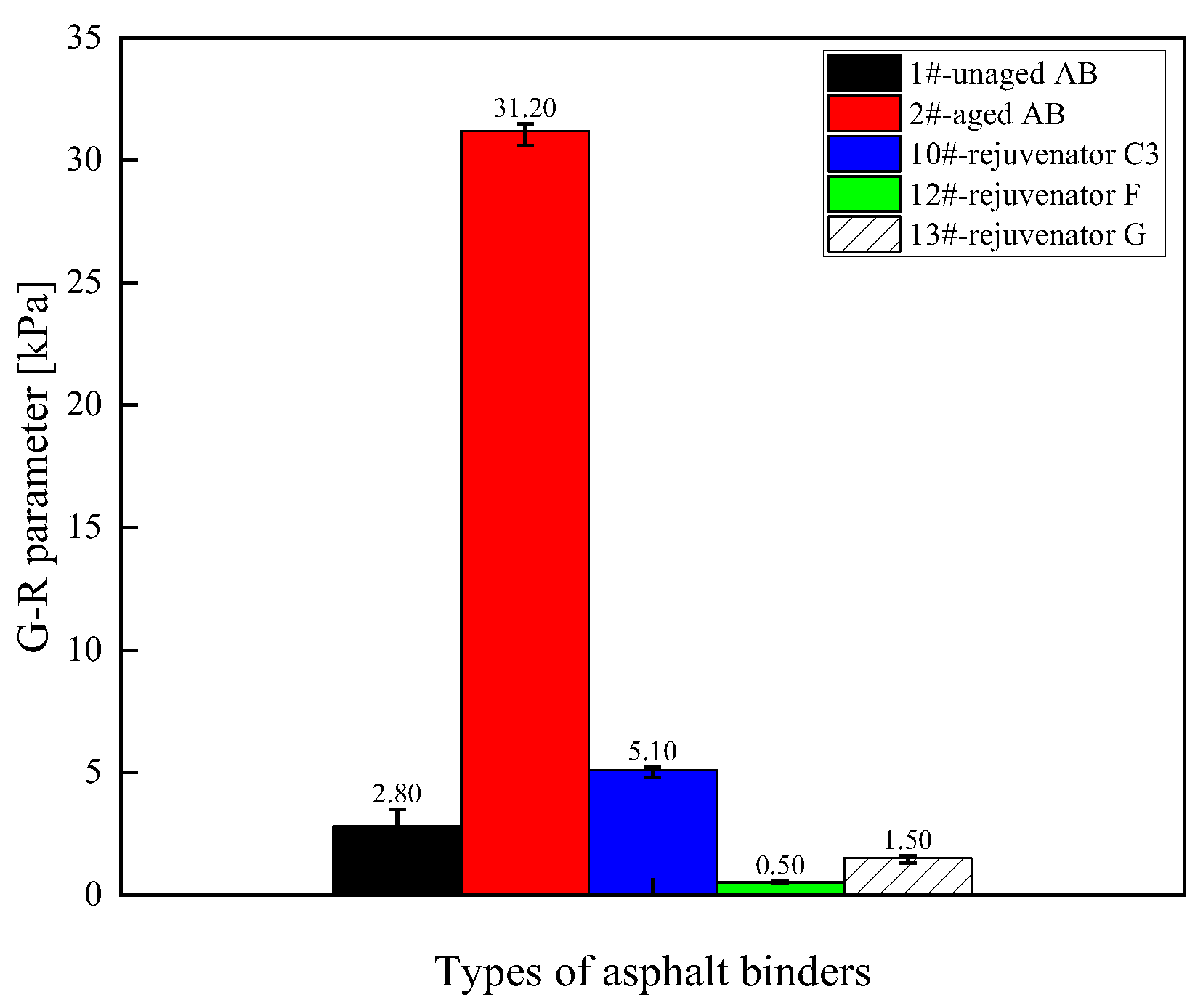

4.1.2. Formulation Optimization

4.1.3. Selection of Oil-like Materials of Aromatic Hydrocarbons

4.2. Study on the Effect of Different Rejuvenators on the Road Performance of Asphalt Mixtures

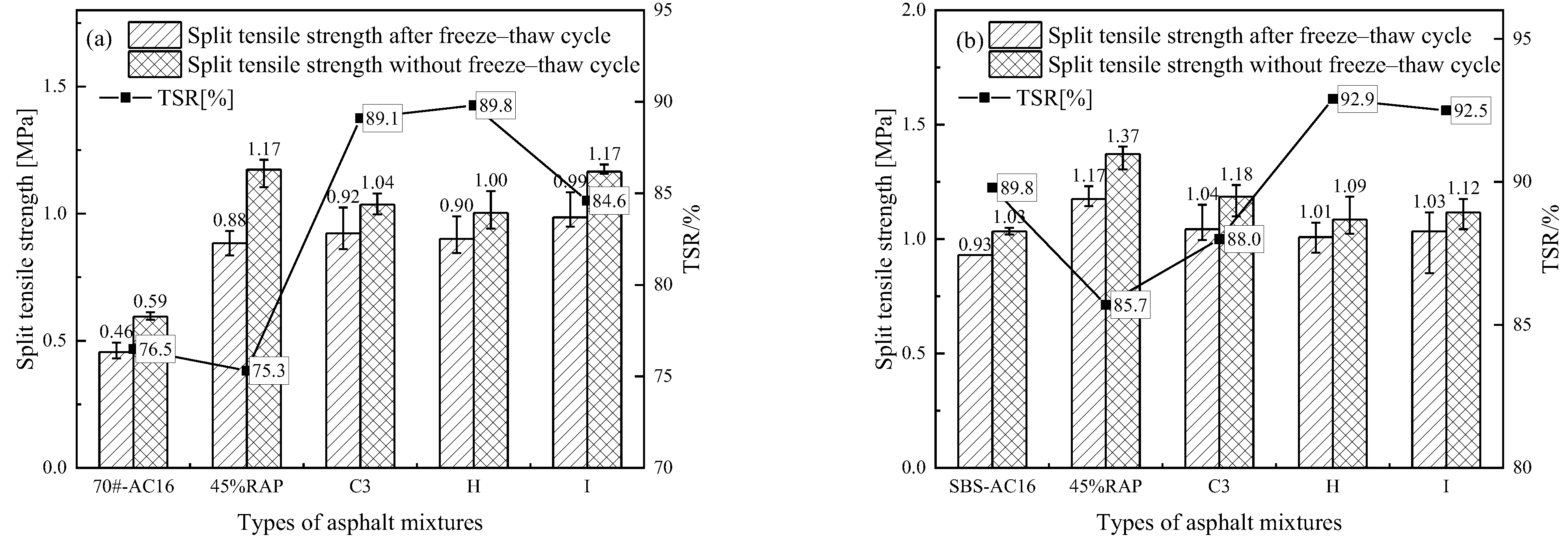

4.2.1. Water Stability Test Results

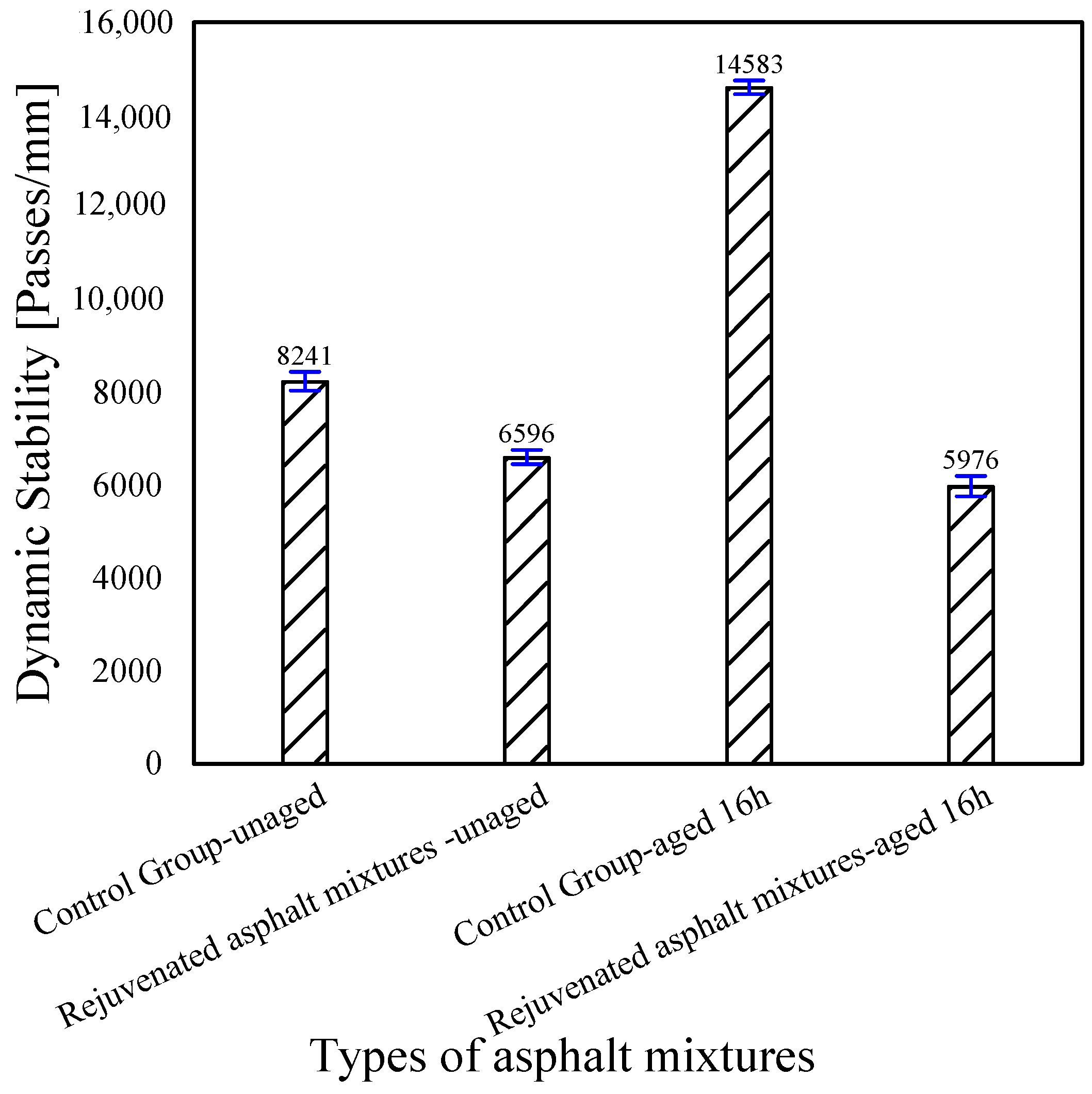

4.2.2. Analysis of High-Temperature Performance Test Results

4.2.3. Low-Temperature Performance Test Results

4.3. Paving of the Rejuvenator C3 Test Section

- (a)

- Control group (conventional SMA13 asphalt mixture);

- (b)

- SMA13 asphalt mixture with a rejuvenator;

- (c)

- Control group + 16 h aging;

- (d)

- SMA13 asphalt mixture with a rejuvenator + 16 h aging.

4.3.1. Water Stability Test Results of Experimental Road

4.3.2. Analysis of High-Temperature Performance Test Results of Experimental Road

4.3.3. Low-Temperature Performance Test Results of Experimental Road

4.4. Economic Analysis of Regenerators

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Sample Number | Sample Name |

|---|---|

| 1# | Unaged SBS-modified asphalt binder |

| 2# | Aged SBS-modified asphalt binder |

| 3# | Aged SBS-modified asphalt binder + Rejuvenator A |

| 4# | Aged SBS-modified asphalt binder + Rejuvenator B |

| 5# | Aged SBS-modified asphalt binder + Rejuvenator C |

| 6# | Aged SBS-modified asphalt binder + Rejuvenator D |

| 7# | Aged SBS-modified asphalt binder + Rejuvenator E |

| 8# | Aged SBS-modified asphalt binder + Rejuvenator C1 |

| 9# | Aged SBS-modified asphalt binder + Rejuvenator C2 |

| 10# | Aged SBS-modified asphalt binder + Rejuvenator C3 |

| 11# | Aged SBS-modified asphalt binder + Rejuvenator C4 |

| 12# | Aged SBS-modified asphalt binder + Rejuvenator F |

| 13# | Aged SBS-modified asphalt binder + Rejuvenator G |

| The Type of Rejuvenator and Its Proportion to the Mass Fraction of the Asphalt Binder | Base Oil Type and Content | Plasticizer Content | Proportion of Modifier A |

|---|---|---|---|

| Rejuvenator A, 11.72% | Oil of the third vacuum stream oil 9% | 2.28% | 0.44% |

| Rejuvenator B, 11.72% | Oil of the fifth vacuum stream oil 9% | 2.28% | 0.44% |

| Rejuvenator C, 11.72% | 1# oil-like materials of aromatic hydrocarbons 9% | 2.28% | 0.44% |

| Rejuvenator D, 11.72% | Commodity rejuvenator I | ||

| Rejuvenator E, 11.72% | Roast duck oil 9% | 2.28% | 0.44% |

| Rejuvenator C1, 8.72% | 1# oil-like materials of aromatic hydrocarbons 6% | 2.28% | 0.44% |

| Rejuvenator C2, 7.22% | 1# oil-like materials of aromatic hydrocarbons 4.5% | 2.28% | 0.44% |

| Rejuvenator C3, 7.82% | 1# oil-like materials of aromatic hydrocarbons 6% | 1.52% | 0.3% |

| Rejuvenator C4, 6.32% | 1# oil-like materials of aromatic hydrocarbons 4.5% | 1.52% | 0.3% |

| Rejuvenator F, 7.82% | 2# oil-like materials of aromatic hydrocarbons 6% | 1.52% | 0.3% |

| Rejuvenator G, 7.82% | 3# oil-like materials of aromatic hydrocarbons 6% | 1.52% | 0.3% |

| Rejuvenator H, 7.82% | Commodity rejuvenator II | ||

| Rejuvenator I, 7.82% | Commodity rejuvenator III | ||

References

- Mohd Hasan, M.R.; You, Z. Estimation of cumulative energy demand and green house gas emissions of ethanol foamed WMA using life cycle assessment analysis. Constr. Build. Mater. 2015, 93, 1117–1124. [Google Scholar] [CrossRef]

- Guo, M.; Liang, M.; Du, X. Evaluation on Feasibility of Carbon Black and Hindered Amine Light Stabilizer as UV-Resistant Additives of Asphalt Binder. J. Test. Eval. 2023, 51, 3987–4003. [Google Scholar] [CrossRef]

- Guo, M.; Yin, X.; Du, X.; Tan, Y. Effect of aging, testing temperature and relative humidity on adhesion between asphalt binder and mineral aggregate. Constr. Build. Mater. 2023, 363, 129775. [Google Scholar] [CrossRef]

- Cong, P.; Luo, W.; Xu, P.; Zhao, H. Investigation on recycling of SBS modified asphalt binders containing fresh asphalt and rejuvenating agents. Constr. Build. Mater. 2015, 91, 225–231. [Google Scholar] [CrossRef]

- Chen, A.; Liu, G.; Zhao, Y.; Li, J.; Pan, Y.; Zhou, J. Research on the aging and rejuvenation mechanisms of asphalt using atomic force microscopy. Constr. Build. Mater. 2018, 167, 177–184. [Google Scholar] [CrossRef]

- Guo, N.; You, Z.; Zhao, Y.; Tan, Y. Performance of Warm Mix Asphalt with Recycled Asphalt Mixtures Considering the Effect of Rejuvenating Agent. J. Build. Mater. 2015, 18, 674–681. [Google Scholar]

- Xiao, F.; Su, N.; Yao, S.; Amirkhanian, S.; Wang, J. Performance grades, environmental and economic investigations of reclaimed asphalt pavement materials. J. Clean. Prod. 2019, 211, 1299–1312. [Google Scholar] [CrossRef]

- Roy, S.; Hossain, Z.; Baumgardner, G.; Zaman, M. Micro-mechanistic and Spectroscopic Analysis of RAP-Blended Asphalt Binders Rejuvenated with Waste Oils. Int. J. Pavement Res. Technol. 2023, 11, 1–18. [Google Scholar] [CrossRef]

- Cao, W.; Wang, C. Fatigue performance characterization and prediction of asphalt binders using the linear amplitude sweep based viscoelastic continuum damage approach. Int. J. Fatigue 2019, 119, 112–125. [Google Scholar] [CrossRef]

- Ma, W.; Huang, T.; Guo, S.; Yang, C.; Ding, Y.; Hu, C. Atomic force microscope study of the aging/rejuvenating effect on asphalt morphology and adhesion performance. Constr. Build. Mater. 2019, 205, 642–655. [Google Scholar] [CrossRef]

- Wang, Z.; Ding, H.; Ma, X.; Yang, W.; Ma, X. Predicting Dynamic Properties and Fatigue Performance of Aged and Regenerated Asphalt Using Time–Temperature–Aging and Time–Temperature–Regenerator Superposition Principles. Coatings 2024, 14, 1486. [Google Scholar] [CrossRef]

- Jing, W.; Ding, S.; Wang, L.; Lu, W.; Ge, D. Performance evaluation of styreneic methyl copolymer regenerated SBS-modified asphalt and its mixture with high content RAP. Case Stud. Constr. Mat. 2023, 19, e2657. [Google Scholar] [CrossRef]

- Mogawer, W.; Bennert, T.; Daniel, J.S.; Bonaquist, R.; Austerman, A.; Booshehrian, A. Performance characteristics of plant produced high RAP mixtures. Road Mater. Pavement Des. 2012, 13, 183–208. [Google Scholar] [CrossRef]

- Ma, H.; Guo, F.; Han, J.; Zhi, P. Analysis of Rheological Properties and Regeneration Mechanism of Recycled Styrene–Butadiene–Styrene Block Copolymer (SBS) Modified Asphalt Binder Using Different Rejuvenators. Materials 2024, 17, 4258. [Google Scholar] [CrossRef]

- Zhang, R.; You, Z.; Ji, J.; Shi, Q.; Suo, Z. A Review of Characteristics of Bio-Oils and Their Utilization as Additives of Asphalts. Molecules 2021, 26, 5049. [Google Scholar] [CrossRef]

- Qin, Y.; Dong, R.; Li, Y. Characterization of light components in rubber-oil mixtures reclaimed asphalt and their effect on the self-healing performance of asphalt. Constr. Build. Mater. 2024, 444, 137866. [Google Scholar] [CrossRef]

- Xu, S.; Sun, D.; Zhang, X. Study of Aging Asphalt Recovery Using Peanut Oil Residue as a Biomass Regenerator. J. Transp. Eng. Part B Pavements 2024, 1, 151. [Google Scholar] [CrossRef]

- Guo, M.; Liang, M.; Sreeram, A.; Bhasin, A.; Luo, D. Characterisation of rejuvenation of various modified asphalt binders based on simplified chromatographic techniques. Int. J. Pavement Eng. 2022, 23, 4333–4343. [Google Scholar] [CrossRef]

- Guo, M.; Liu, H.; Jiao, Y.; Mo, L.; Tan, Y.; Wang, D.; Liang, M. Effect of WMA-RAP technology on pavement performance of asphalt mixture: A state-of-the-art review. J. Clean. Prod. 2020, 266, 121704. [Google Scholar] [CrossRef]

- Guo, M.; Zhang, R.; Du, X.; Liu, P. A State-of-the-Art Review on the Functionality of Ultra-Thin Overlays Towards a Future Low Carbon Road Maintenance. Engineering 2024, 32, 82–98. [Google Scholar] [CrossRef]

- Roy, S.; Hossain, Z. Effects of Aging on Multiscale Mechanistic Properties of Asphalt Binders. Int. J. Pavement Res. Technol. 2023, 18, 78–90. [Google Scholar] [CrossRef]

- Xu, B.; Ding, R.; Yang, Z.; Sun, Y.; Zhang, J.; Lu, K.; Cao, D.; Gao, A. Investigation on performance of mineral-oil-based rejuvenating agent for aged high viscosity modified asphalt of porous asphalt pavement. J. Clean. Prod. 2023, 395, 136285. [Google Scholar] [CrossRef]

- Yan, Y.; Hernando, D.; Roque, R. A solvent free method to characterize the effect of recycled asphalt shingles on virgin asphalt binder. J. Clean. Prod. 2019, 208, 795–805. [Google Scholar] [CrossRef]

- Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Ran, Y. Study on Performance and Mechanism of Multiplerecycled SBS Modified Asphalt. Master’s Thesis, South China University of Technology, Guangzhou, China, 2018. [Google Scholar]

- Ding, Y. Research on Aging and Recycling Performance of SBS Modified Asphalt. Master’s Thesis, China University of Petroleum, Beijing, China, 2017. [Google Scholar]

- Yi, J.; Wang, Y.; Pei, Z.; Xu, M.; Feng, D. Mechanisms and research progress on biological rejuvenators for regenerating aged asphalt: Review and discussion. J. Clean. Prod. 2023, 422, 138622. [Google Scholar] [CrossRef]

- Enfrin, M.; Gowda, A.; Giustozzi, F. Low-cost chemical modification of refined used cooking oil to produce long-lasting bio-asphalt pavements. Resour. Conserv. Recycl. 2024, 204, 107493. [Google Scholar] [CrossRef]

- Cao, X.; Quan, Y.; Deng, M.; Tang, B.; Kong, L. Progress and Perspective of Bio-asphalt Preparation, Structural Characterization, and Rheological Properties. Energy Fuel 2024, 38, 1657–1675. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Z.; Xiang, Q.; Qin, W.; Yi, J. Research on the influence of RAP and aged asphalt on the performance of plant-mixed hot recycled asphalt mixture and blended asphalt. Case Stud. Constr. Mater. 2021, 15, 722. [Google Scholar] [CrossRef]

- Al-Qadi, I.L. Reclaimed asphalt pavement—A literature review. Crack. Asph. Concr. Pavements 2007, 07, 001. [Google Scholar]

- Baghaee Moghaddam, T.; Baaj, H. The use of rejuvenating agents in production of recycled hot mix asphalt: A systematic review. Constr. Build. Mater. 2016, 114, 805–816. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. Evaluation of Rejuvenator’s Effectiveness with Conventional Mix Testing for 100% Reclaimed Asphalt Pavement Mixtures. Transp. Res. Rec. J. Transp. Res. Board 2013, 2370, 17–25. [Google Scholar] [CrossRef]

- Raouf, M.A.; Williams, R.C. Temperature and Shear Susceptibility of a Nonpetroleum Binder as a Pavement Material. Transp. Res. Rec. J. Transp. Res. Board 2010, 2180, 9–18. [Google Scholar] [CrossRef]

- Yang, X.; Mills-Beale, J.; You, Z. Chemical characterization and oxidative aging of bio-asphalt and its compatibility with petroleum asphalt. J. Clean. Prod. 2017, 142, 1837–1847. [Google Scholar] [CrossRef]

- Zeng, M.; Pan, H.; Zhao, Y.; Tian, W. Evaluation of asphalt binder containing castor oil-based bioasphalt using conventional tests. Constr. Build. Mater. 2016, 126, 537–543. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- JTG F40-2004; Technical Specification for Construction of Highway Asphalt Pavements. Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- Rowe, G.M.; Sharrock, M.J. Alternate Shift Factor Relationship for Describing Temperature Dependency of Viscoelastic Behavior of Asphalt Materials. Transp. Res. Rec. J. Transp. Res. Board 2011, 2207, 125–135. [Google Scholar] [CrossRef]

- Yusoff, N.I.M.; Jakarni, F.M.; Nguyen, V.H.; Hainin, M.R.; Airey, G.D. Modelling the rheological properties of bituminous binders using mathematical equations. Constr. Build. Mater. 2013, 40, 174–188. [Google Scholar] [CrossRef]

- Ruan, Y.; Davison, R.R.; Glover, C.J. An Investigation of Asphalt Durability: Relationships Between Ductility and Rheological Properties for Unmodified Asphalts. Pet. Sci. Technol. 2003, 21, 231–254. [Google Scholar] [CrossRef]

- Sui, C.; Farrar, M.J.; Harnsberger, P.M.; Tuminello, W.H.; Turner, T.F. New Low-Temperature Performance-Grading Method. Transp. Res. Rec. 2011, 2207, 43–48. [Google Scholar] [CrossRef]

- Sui, C.; Farrar, M.J.; Tuminello, W.H.; Turner, T.F. New Technique for Measuring Low-Temperature Properties of Asphalt Binders with Small Amounts of Material. Transp. Res. Rec. 2010, 2179, 23–28. [Google Scholar] [CrossRef]

- Guo, M.; Yao, X.; Du, X. Low temperature cracking behavior of asphalt binders and mixtures: A review. J. Road Eng. 2023, 3, 350–369. [Google Scholar] [CrossRef]

- Guo, M.; Liang, M.; Liu, H.; Du, X. Optimization and validation of waste bio-oil based high-performance rejuvenator for rejuvenating aged bitumen. Mater. Struct. 2023, 56, 1–16. [Google Scholar] [CrossRef]

- Li, C.; Ma, F.; Fu, Z.; Dai, J.; Wen, Y.; Shi, K. Using Cereclor plasticizer to modify the virgin asphalt binder: A case of rheological properties improvement. Constr. Build. Mater. 2022, 318, 126039. [Google Scholar] [CrossRef]

- Cao, W.; Li, X. The Rejuvenating Potential of Plasticizers on Oxidatively Aged Asphalts: Rheological and Molecular Dynamics Perspectives. Polymers 2022, 14, 4624. [Google Scholar] [CrossRef] [PubMed]

- JTG/T 5521-2019; Technical Specifications for Highway Asphalt Pavement Recycling. Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- Blankenship, P.B.; Anderson, M.A.; King, G.N. A Laboratory and Field Investigation to Develop Test Procedures for Predicting Non-load Associated Cracking of Airfield HMA Pavements. Airfield Asphalt Pavement Technology Program 2010, 06-01. AMEC Project No. 09-119-00948. Available online: https://www.eng.auburn.edu/research/centers/ncat/files/aaptp/Report.Final.06-01 (accessed on 15 June 2025).

| Test Items | Unit | Standard Value | Pen.70 Measured Value | SBS Measured Value |

|---|---|---|---|---|

| Penetration (25 °C, 5 s, 100 g) | 0.1 mm | 60~80 | 75 | 70 |

| Ductility (10 °C is used for Pen.70 VAB, 5 °C is used for SBS-modified asphalt binder) | cm | binder | >100 | 38 |

| Softening point | °C | 46 | 48.0 | 75.5 |

| Flash point | °C | 260 | 263 | 278 |

| Oil-like Materials of Aromatic Hydrocarbons | Plasticizer | Modifier A | |

|---|---|---|---|

| Density (25 °C g·cm−3) | 1.045 | 1.02 | 0.97 |

| Kinematic viscosity (mm2/s 100 °C) | 23 | - | - |

| Flashpoint/°C | 230 | 218 | 210 |

| Boiling point/°C | 386 | - | |

| Aromatics content/% (weight percentage) | 86.3 | - | - |

| Performance | Index | A | B | C | D | E | C1 | C2 | C3 | C4 | F | G |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Complex modulus | G* at 10 rad/s | 96.19 | 97.20 | 100.93 | 110.73 | 101.59 | 99.62 | 102.21 | 93.38 | 81.46 | 115.26 | 104.11 |

| High-temperature rutting properties | Jnr at 3.2 kPa | 1384.05 | 1379.74 | 1862.50 | 2819.40 | 1819.40 | 1099.57 | 914.22 | 616.81 | 539.22 | 4608.19 | 1539.22 |

| Medium-temperature fatigue performance | G–R parameter | 98.24 | 98.24 | 103.52 | 105.63 | 98.59 | 102.46 | 95.42 | 91.90 | 81.34 | 108.10 | 104.58 |

| Cracking resistance at low temperatures | −18 °C, m value | 146.51 | 139.53 | 147.67 | 215.12 | 134.88 | 140.70 | 131.40 | 97.67 | 97.67 | 303.49 | 160.47 |

| −18 °C, S value | 271.11 | 212.12 | 208.58 | 377.51 | 258.59 | 211.06 | 207.72 | 211.74 | 202.36 | 377.99 | 231.65 |

| Number | Test Items | Unit | Technical Indicators | Test Results | Result Determination |

|---|---|---|---|---|---|

| 1 | Viscosity (60 °C) | mm2/s | 50–175 | 96.43 | Qualified |

| 2 | Flash point | °C | 230 | Qualified | |

| 3 | Content of saturated fragrance | % | 12.45 | Qualified | |

| 4 | Content of sweet fragrance | % | Actual measurement records | 59.73 | Measured value |

| 5 | Viscosity ratio before and after the thin film oven test | -- | 0.55 | Qualified | |

| 6 | Mass changes before and after the thin film oven test | % | 0.85 | Qualified | |

| 7 | Density (15 °C) | g/cm3 | Actual measurement records | 1.06 | Measured value |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, S.; Wang, Z.; Yao, X.; Guo, M.; Zhang, H.; Chen, H.; Zhang, F. Study on the Rheological Optimization and Multiscale Verification of the Asphalt Rejuvenator. Materials 2025, 18, 2925. https://doi.org/10.3390/ma18132925

Song S, Wang Z, Yao X, Guo M, Zhang H, Chen H, Zhang F. Study on the Rheological Optimization and Multiscale Verification of the Asphalt Rejuvenator. Materials. 2025; 18(13):2925. https://doi.org/10.3390/ma18132925

Chicago/Turabian StyleSong, Shanglin, Zhen Wang, Xiupeng Yao, Meng Guo, Haihong Zhang, Hongbin Chen, and Fukui Zhang. 2025. "Study on the Rheological Optimization and Multiscale Verification of the Asphalt Rejuvenator" Materials 18, no. 13: 2925. https://doi.org/10.3390/ma18132925

APA StyleSong, S., Wang, Z., Yao, X., Guo, M., Zhang, H., Chen, H., & Zhang, F. (2025). Study on the Rheological Optimization and Multiscale Verification of the Asphalt Rejuvenator. Materials, 18(13), 2925. https://doi.org/10.3390/ma18132925