Abstract

Cemented paste backfill (CPB) plays an important role in sustainable mining by providing structural support and reducing surface subsidence. While traditional destructive testing methods such as unconfined compressive strength (UCS) tests offer valuable understanding of material strength, they require a lot of resources, are time-consuming, and environmentally unfriendly. However, non-destructive testing (NDT) techniques such as ultrasonic pulse velocity (UPV), electrical resistivity (ER), and acoustic emission (AE) provide sustainable alternatives by preserving sample integrity, minimizing waste, and enabling real-time monitoring. This study systematically reviews and quantitatively compares the effectiveness of UPV, ER, and AE in predicting the strength of CPB. Meta-analysis of 30 peer-reviewed studies reveals that UPV and AE provide the most consistent and reliable correlations with UCS, with R2 values of 0.895 and 0.896, respectively, while ER shows more variability due to its sensitivity to environmental factors. Additionally, a synthetic model combining UPV, AE and ER demonstrates improved accuracy in predicting strength. This hybrid approach enhances predictions of material performance while supporting sustainability in mining and construction. Our research advocates for better testing practices and presents a promising direction for future infrastructure projects, where real-time, non-invasive monitoring can enhance material performance evaluation and optimize resource use.

1. Introduction

Cemented paste backfill (CPB) is a modern approach applied in sustainable mining practices, especially in the underground mines, to address the problems associated with mine tailings and to provide structural support for roadways or pavement materials. CPB is a composite material to fill voids, which also helps mitigate surface subsidence and improve ground conditions [1,2,3]. CPB must meet specific compressive strength requirements to ensure structural stability. Industry standards ASTM C39/C39M-24 [4] and practical guidelines mandate minimum strengths of >0.7 MPa for temporary structures and >1.5 MPa for long-term stability [5]. These thresholds ensure safe ground support and prevent subsidence risks.

The strength of CPB, pavement, and other concrete materials is often tested by methods that involve breaking the material samples. A well-known test for this is the unconfined compressive strength (UCS) test. Even though this test provides important information, it requires a lot of resources, produces waste, and takes a lot of time to complete. These drawbacks make it not very suitable for practices that aim to be environmentally friendly and sustainable [6,7]. Such limitations become particularly problematic when assessing backfill performance in active mining areas where real-time strength evaluation is crucial for safety.

As the mining industry strives to be more environmentally friendly, finding ways to check materials without causing damage is crucial. Methods such as ultrasonic pulse velocity (UPV), electrical resistivity (ER), and acoustic emission (AE) offer non-destructive solutions [8,9]. These techniques help maintain the integrity of samples, cut down on waste, and provide real-time insights into material properties. This shift promotes resource efficiency and helps us understand their sustainability, durability and strength prediction in various construction applications [10,11]. Although this study focuses on CPB, the NDT methods discussed, such as UPV, ER and AE are also widely applicable in assessing pavement materials, concrete and asphalt.

The properties of CPB have usually been assessed through destructive testing methods, such as UCS, triaxial tests, and tensile strength tests. While these methods provide accurate and reliable results, they are inherently limited by their destructive nature [12,13,14]. Destructive testing entails pulling out and destroying samples, which not only undermines the integrity of the backfill structure but also restricts the scalability and frequency of testing [15,16,17]. Furthermore, these methods are time consuming, labor-demanding and not very suitable for use in real time conditions [18,19].

Recent progress in NDT methods such as UPV, ER, and AE holds promise for CPB assessment. UPV is used to measure how quickly waves travel through materials, providing information about their density and elasticity [15,16]; ER examines electrical conductivity, which helps assess hydration levels and porosity [18]; and AE identifies tiny cracks that form under stress, offering early warnings of potential failures [19,20]. Individually, these methods address specific DT shortcomings: they preserve sample integrity, enable real-time monitoring, and reduce costs by up to 40% [21,22]. However, existing studies remain fragmented, with no systematic comparison of their reliability across diverse CPB compositions or environmental conditions [23,24]. For instance, while Yılmaz and Ercikdi [25] demonstrated UPV’s strong UCS correlation (R2 = 0.79–0.95) in silica-rich tailings, Wu et al. [26] noted ER’s susceptibility to moisture fluctuations—a gap this review bridges through meta-analysis.

This paper presents a systematic review of how three important NDT methods like UPV, ER, and AE perform in predicting the strength of CPB focusing on their sustainability aspects. It highlights the benefits of these methods, focusing on how they can be better for the environment and help reduce costs for the mining and construction sectors. We quantify the predictive power of UPV, ER, and AE for UCS through meta-analysis, elucidating method-specific strengths and limitations using 30 relevant studies.

2. Testing Methods Overview

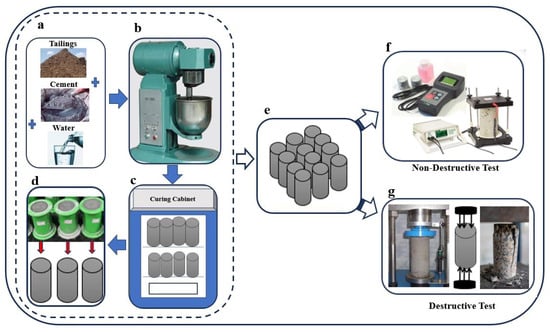

Figure 1 presents the sequence of steps followed in the CPB process to prepare the samples and subjected them to destructive and non-destructive assessment. In step (a), the raw materials—cement, water and tailings—are collected. In step (b), these substances are put into an automatic mixer to create a uniform paste mixture. Step (c) entails pouring the mix that has been prepared into cylindrical molds to make sure that it is uniform and compacted to the right level. The samples are then cured in a controlled surrounding (d) using a curing machine to provide the right temperature and humidity conditions. After curing (e), the hardened CPB samples will either or both undergo (f) NDT and (g) DT for mechanical assessments to determine their structural integrity and performance.

Figure 1.

Presents (a–d) Step by Step CPB preparation, (e) required sample for testing process, (f) non-destructive methods and (g) destructive testing method.

2.1. Overview of Destructive Testing Methods

Destructive testing (DT) methods are necessary for identifying the mechanical behavior of materials especially in construction and engineering fields. The approaches entail the use of forces on the materials up to failure, to determine important characteristics such as the load carrying capacity, toughness and the general performance. This methodology is well established and conforms with industry standards for the evaluation of structural materials and provides concise and quantifiable information on their performance during stressful conditions [27,28,29].

Among the DT methods, the UCS test is one of the most common for CPB, where a cylindrical sample of CPB is subjected to axial compression up to failure, and the stress–strain relationship is recorded to determine the maximum compressive stress that the material can tolerate [30,31,32]. This parameter is very important in determining the load carrying capacity and the structural integrity of CPB and therefore affects the safety and efficiency of mining operations. UCS test results are used in the optimization of CPB mix designs to ensure that the mixes developed are capable of meeting the required strength criteria for the various applications especially in underground mining where it is essential that the CPB has enough strength to support the surrounding rock masses [17,33].

Another important method of destructive testing is the triaxial test that receives mechanical properties of CPB under in situ-like conditions. This test applies a controlled stress to a cylindrical sample in three orthogonal directions, so as to determine shear strength and failure mechanisms. Complex loading conditions of mining environment are simulated by triaxial tests made on CPB to determine its behavior. While most CPB testing focuses on static loads, dynamic load studies like drop-weight or split-Hopkinson bar tests are emerging to simulate blast or seismic impacts [34,35]. These remain less common due to CPB’s primary role in static load-bearing. These tests outcomes reveal that with confining pressure, both peak and residual strengths rise, vital information for optimizing mix designs for geological stress resistance [36]. Triaxial tests are nevertheless costly and time consuming because they require specialized equipment and very precise sample preparation.

The Brazilian test, also known as the splitting tensile strength test, is another method employed to measure the tensile strength of brittle materials such as CPB. This test induces tensile stresses that lead to failure along the vertical plane by applying a compressive load diametrically across a cylindrical sample [37,38]. This test is especially significant for determining CPB resistance to cracking and failure that is critical for maintaining the stability and durability of structures in mining operations. However, like other destructive tests, it is limited in its ability to allow samples to be used for further analysis and may not accurately replicate field conditions because of differences in stress distribution [39,40,41].

Table 1 below highlights the fundamental differences between these three commons destructive (UCS, Triaxial and Brazilian) testing methods used to evaluate the mechanical properties of CPB and similar materials. The UCS test measures uniaxial compressive strength under zero confinement, providing a baseline for material performance. The Triaxial test incorporates confining pressure to simulate in situ stress conditions, yielding shear strength parameters critical for geotechnical applications. In contrast, the Brazilian test indirectly assesses tensile strength, a key property for predicting crack initiation in brittle CPB structures.

Table 1.

Comparison of destructive testing methods for CPB: key characteristics, measured properties, and applications of UCS, Triaxial and Brazilian tests.

Destructive testing methods provide valuable insights into the mechanical properties of CPB, but they suffer from inherent limitations, including sample destruction, time-consuming preparation, labor intensity, and limited scalability. Additionally, these methods cannot simulate real-world conditions, lack repeatability, require complex data interpretation and generate material waste [42,43]. As summarized in Table 1, these drawbacks have motivated researchers to adopt NDT methods such as UPV and ER testing as visualized in Figure 1 and Figure 2 which preserve sample integrity while offering real-time, scalable, and repeatable assessments of CPB properties without compromising structural capacity.

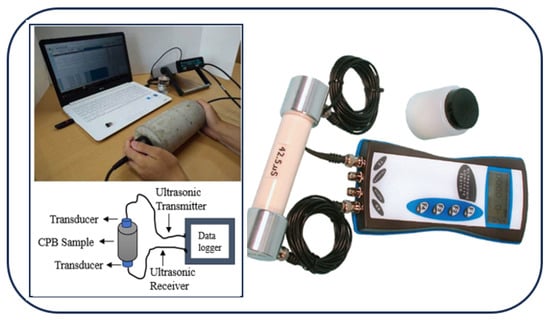

Figure 2.

Image showing UPV Testing Setup as NDT method for CPB sample. It includes an ultrasound transmitter, a transducer for the CPB sample, a data logger, and an ultrasound receiver.

2.2. Non-Destructive Testing Methods

- Ultrasonic Pulse Velocity (UPV) Testing

UPV testing is a non-destructive testing method that is applied widely for the assessment of the physical properties of materials such as CPB. It works by sending high frequency ultrasonic waves into a material and then measuring the velocity of the waves. The wave velocity is a function of material density, elasticity and compressive strength and thus enables the engineer to make property evaluations without having to destroy the sample. It gives information about the internal structure and integrity of CPB by analyzing the time taken by the waves to travel through the material and any changes in the amplitude or frequency of the waves [44,45].

The UPV testing setup, which is illustrated by Figure 2, utilizes an ultrasonic transmitter and a transducer that is responsible for generating and sending ultrasonic waves through the material under examination is referred to as the setup. These signals are sent through the material and are received by ultrasonic cables which are connected to a data display and logger unit for analysis. The facts about the integrity, homogeneity and possible flaws of the substance are obtained from the captured data [46,47]. This method is especially useful for quality control and monitoring in both laboratory and field conditions since it allows multiple evaluations of the same specimen or structure at different times [48,49].

UPV presents information online, which is very useful in making on-the-spot decisions and changes during construction or mining operations [50]. For these reasons, it is a suitable tool for examining the CPB at different levels, from material testing at the initial stage to monitoring during the service period. However, the precision of the results depends significantly on proper calibration, which needs reference samples with known properties. Another issue is that material heterogeneity, such as density variations, voids, and cracks, can influence the propagation of ultrasonic waves, resulting in irregular outcomes [51,52,53].

- Electrical Resistivity Testing

The principle of electrical resistivity testing is based on the fact that the resistivity of a material is a function of its physical properties. Thus, porosity and microstructure of the cement paste changes with the degree of hydration, which, in turn, affects the electrical resistivity. Lower resistivity is a characteristic of porous structures while higher resistivity is observed in more dense and better hydrated materials [54,55]. The setup for resistivity measurements is simple and can be used in the field and the laboratory. This method is also suitable for online control that enables online assessment of the curing process and the quality of CPB. This correlation highlights the importance of resistivity testing as an early warning tool in assessing the performance of CPB [56,57,58].

However, there are some demerits of using electrical resistivity testing. A major drawback is the sensitivity to moisture content; changes in moisture can lead to changes in resistivity which can make data analysis difficult [59]. The moisture content of CPB can be a major factor in the electrical properties of the mixture, and thus, proper control and measurement of the environmental conditions during testing is very essential [60]. Moreover, the analysis of resistivity data is quite complex and requires knowledge of the materials structure and hydration mechanism since resistivity by itself is not a full characterization of the material state [61,62].

- Acoustic Emission (AE)

The AE test is based on the detection of transient elastic waves emitted when energy is released from a material containing localized sources of energy such as microcracks and fractures [63,64]. CPB will be subjected to stress and the micro events generate acoustic signals that can be caught by sensitive sensors. The information derived from the analysis of these signals gives information on the damage mechanisms occurring inside the backfill material and the growth of cracks [65,66]. The AE is suitable for monitoring damage evolution in CPB and real time assessment of its stability is possible [67].

A major strength of AE is that it can provide real time monitoring of the propagation of cracks and failure mechanisms, which is very useful in the study of CPB behavior under load and failure prediction [27,68]. Moreover, AE can be employed for the discrimination of the initial hydration products in cement composites and therefore to determine the strength and durability of CPB [69]. Furthermore, AE is suitable for continuous monitoring of large areas, which is important for numerous applications of backfill in mining, where the conditions are usually dynamic [70].

However, there are some significant demerits of AE which cannot be ignored. The major restriction is that accurate capturing and analysis of acoustic signals need sensitive and high-quality equipment, and noise can be a problem [64]. It is important to separate the meaningful acoustic signals from the noise for accurate evaluation. Moreover, AE data analysis can be rather complicated, and the signals are not always straightforward to link to certain damage types. Therefore, the analysis of the data and the conclusions about the state of CPB made from it requires professional knowledge [71,72,73].

3. Methodology: Systematic Review and Meta-Analysis Protocol

3.1. Literature Search Strategy

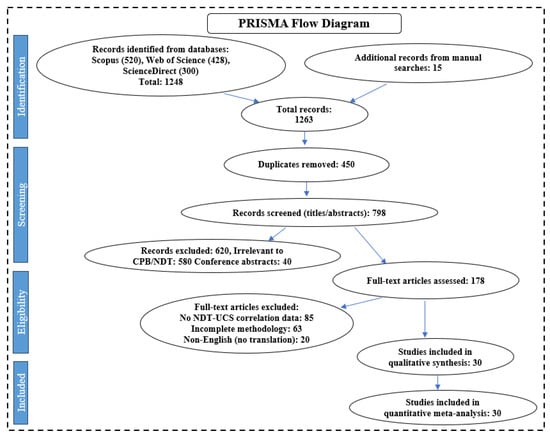

We explored five major research databases such as Scopus and Web of Science, depicted in Figure 3. Our search included terms like “cemented paste backfills” or “CPB”, “non-destructive testing” or “NDT”, as well as “ultrasonic”, “electrical resistivity”, “acoustic emission”, and “strength prediction” or “UCS correlation”. We focused on peer-reviewed studies from 2010 to 2025 that demonstrated clear quantitative links between NDT techniques like UPV, ER, or AE, and UCS. These studies needed to detail their CPB mix designs, including specifics about binder types and tailings compositions. They also had to provide statistical data, such as R2 data, to calculate effect sizes. We excluded studies solely using DT methods, focusing on non-cemented backfills, duplicates, conference summaries, or those lacking comprehensive methodological details.

Figure 3.

PRISMA flowchart illustrating the method used to search and select literature systematically. From the 1248 records identified, 30 studies were chosen for the meta-analysis.

3.2. Study Screening and Statistical Analysis

The PRISMA framework, as shown in Figure 3, was selected for its rigor in systematic reviews, minimizing selection bias via transparent screening stages. Initially, we identified 1248 records and eliminated 450 duplicates. Subsequently, 620 studies were dismissed, as their titles and abstracts did not pertain to CPB/NDT. Next, we assessed 178 studies in full to determine their relevance. Out of these, only 30 met all criteria. We prioritized studies with controlled experimental conditions, such as ASTM/ISO compliant curing protocols, included at least three samples per mix design, and provided clear error metrics like standard deviations. This thorough process ensured we included high-quality, reproducible data for meta-analysis using Python 3.9 (libraries: NumPy, pandas, scikit-learn, and Matplotlib) to assess data consistency through R2 values, and create forest plots to evaluate different NDT methods.

4. Comparison of Destructive and Non-Destructive Testing

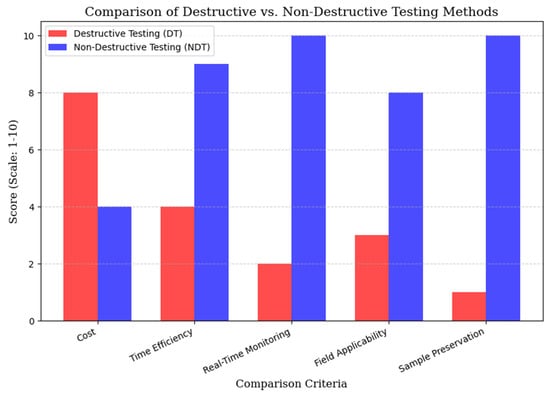

Table 2 and Figure 4 compare DT and NDT methods using qualitative scores (1–10 scale). While DT provides highly accurate strength data through destructive failure testing, it suffers from sample destruction, high costs, specialized equipment requirements, and slow turnaround—limiting its field applicability. In contrast, NDT techniques preserve sample integrity, enabling real-time monitoring and repeat assessments with moderate-to-high precision. Their cost-effectiveness, efficiency, and field adaptability make NDT particularly valuable for large-scale applications across mining, construction, and manufacturing sectors, where operational continuity is crucial. The quantitative comparison highlights NDT’s advantages in sustainability and scalability while acknowledging DT’s superior absolute accuracy for controlled laboratory conditions.

Table 2.

A detailed comparison of DT and NDT methods focusing on how they perform in terms of resources conservation, material integrity preservation and cost-effectiveness.

Figure 4.

Bar chart comparing DT and NDT across key assessment criteria. It focuses on important factors like saving resources, reducing costs, and material integrity preservation.

4.1. Case Studies and Applications

Various NDT methods are used to assess the properties of CPB in both laboratory and field conditions. The following are 10 case studies for each NDT method, along with their effectiveness, challenges and implications for CPB assessment.

4.1.1. Ultrasonic Testing Method

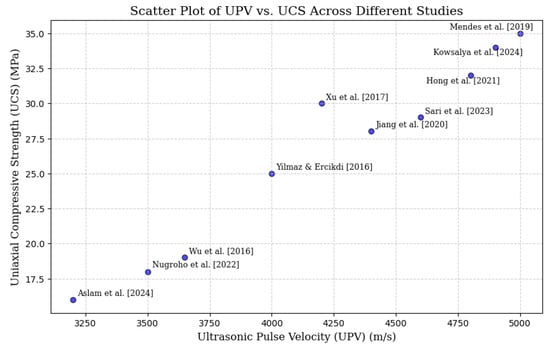

To enhance clarity and enable rapid visual comparison, Figure 5 and Figure 6 present the correlation studies between UPV and UCS from Table 3 in the form of scatter plots and trend graphs. This visual representation effectively illustrates the relationship between UPV and UCS across multiple studies, thus enabling an at-a-glance comparison of the NDT systems.

Figure 5.

Scatter plot graph showing the relationship between UPV and UCS across different studies [13,16,24,53,74,75,76,77,78,79].

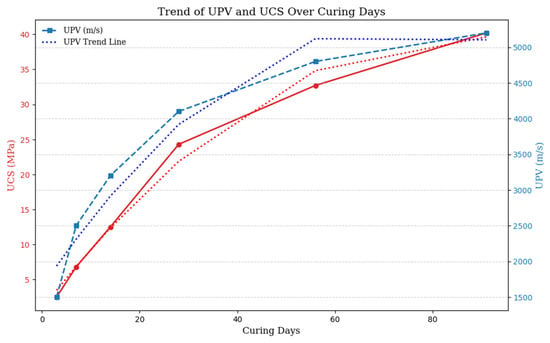

Figure 6.

This figure shows the evolution of UCS (MPa) and UPV (m/s) with curing days. The red dotted line represents the polynomial trend for UCS, while quadratic trend lines (dashed) are fitted for both UCS and UPV, highlighting their increase over time.

Table 3.

Comparison of UPV and UCS correlation studies, showing the effectiveness of UPV as a non-destructive alternative for UCS prediction across different material types.

Several research studies presented in Table 3 show that UPV can be used as a reliable, non-destructive alternative to UCS for the evaluation of cemented materials, concrete and paste backfill. Studies have revealed UPV-UCS correlations across curing periods and material compositions, confirming UPV ability to predict strength in CPB, cemented gangue backfill (CGB), and alkali-activated slag-based backfill [74,75,76]. It has been highlighted that UPV’s utility in assessing concrete quality, especially in silica fume (SF) and varied binder mixtures. In addition, studies have further validated UPV for sustainable lightweight and fly ash-based concretes by monitoring hydration, density, and porosity, respectively [77,78]. Therefore, UPV can provide a non-invasive and efficient real-time estimation of UCS for improving quality control in mining and construction.

The studies presented in Table 3 collectively define UPV as a strong candidate for predicting UCS in a variety of cementitious materials, such as CPB, gangue backfill (CGB), alkali activated slag based backfill, and concrete mixtures. The studies show high correlation coefficients (R2 > 0.85), which prove that UPV can be used to monitor the hydration process, material density and porosity. The study on sustainable materials (such as silica fume modified and lightweight concrete) also confirms the suitability of UPV for assessing different binders and curing conditions. As a non-destructive and online measurement method, UPV is shown to be applicable for practical use as an alternative to UCS testing in mining, construction, and material engineering.

4.1.2. Electrical Resistivity (ER) Testing

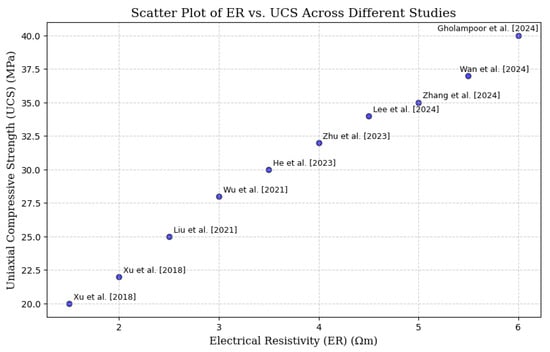

To improve readability and enable fast visualization of the data, Figure 7 and Figure 8 present the correlation studies between ER and UCS from Table 4 in a scatter plot with a trend line. This graphical representation effectively shows the connection between ER and UCS across multiple studies, facilitating a more straightforward comparison of the non-destructive testing (NDT) systems.

Figure 7.

Scatter plot graph showing the relationship between ER and UCS across different studies [25,60,80,81,82,83,84,85,86,87].

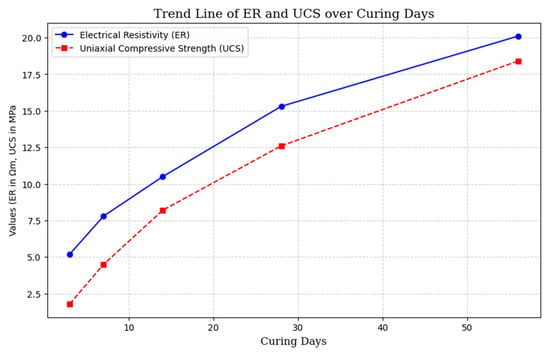

Figure 8.

Present trend line showing how ER and UCS change over curing periods.

Table 4.

Comparison of ER and UCS correlation studies, highlighting the sustainability benefits of ER in waste reduction, real-time monitoring, and cost-effective testing.

The Correlation Studies in Table 4 have proven ER to be a non-destructive alternative to UCS testing to determine the mechanical properties of CPB, concrete and other cementitious products. Figure 7 and Figure 8 visualize a good correlation between ER and UCS and that ER can be used to monitor hydration, porosity and microstructural evolution during curing periods. However, sample non-homogeneity, particularly in the case of air voids or uneven binder distributions, can significantly affect ER measurements by disrupting ionic conduction pathways, potentially leading to localized resistivity variations of up to 20% [86,87,88]. The results show that higher ER values are associated with higher UCS, and this is because of material densification and reduced permeability. Further work on hydration mechanisms, curing temperatures, and additives like calcium nitrite and slag also corroborates ER predictive role. As ER can monitor strength evolution in real-time without destroying specimens it emerges as a low-cost and time-saving alternative to UCS and finds its place in quality control in mining, geotechnical engineering and construction.

4.1.3. Acoustic Emission (AE) Monitoring

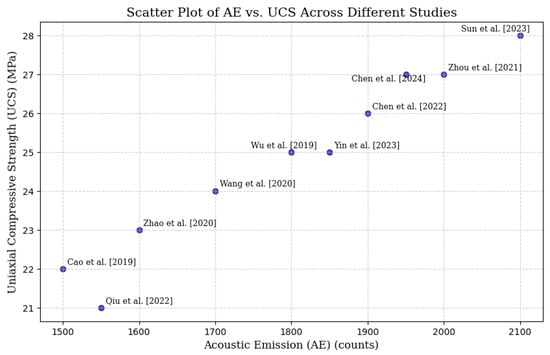

To enhance understanding and allow for quick data observation, Figure 9 and Figure 10 depict the correlation between AE and UCS, using data from Table 5. These figures include a scatter plot showing the relationship between AE and UCS across different studies and a trend line that clearly illustrates the relationships found in various studies. This visual format makes it easier to compare non-destructive testing (NDT) systems.

Figure 9.

Scatter plot graph showing the relationship between AE and UCS across different studies [88,89,90,91,92,93,94,95,96,97].

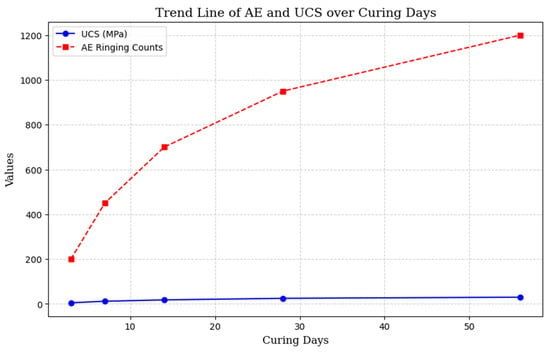

Figure 10.

Present trend line showing how AE and UCS change over curing periods.

Table 5.

Summary of AE monitoring studies correlating AE signals with UCS in CPB and other materials, highlighting AE as a reliable non-destructive method for tracking damage evolution and material failure.

AE monitoring has been established as a reliable non-destructive alternative to the conventional UCS testing for determining the mechanical properties and failure behavior of CPB and other related materials. The AE parameters such as ring count and strength rate have a good correlation with stress–strain conduct and can capture the crack growth and failure process [88,89]. In addition, the AE is capable of monitoring real-time crack propagation and changes in structural integrity under different stress conditions [90,91]. Thus, AE can be used to assess the mechanical properties and failure behavior of CPB.

Furthermore, studies confirmed the validity of using AE for the estimation of UCS by studying micro-crack evolution [92,93], where some studies continued to extend the application of AE to shear failure analysis and gangue-based CPB [94,95]. Yin et al. [96] brought forward a new AE-based index for determining instability, and Chen et al. [97] highlighted the complementary application of AE in conjunction with UCS to depict the mechanical behavior of CPB. Hence, from several studies, it can be concluded that AE monitoring is a viable, online, and non-invasive technique for determining the strength, deformation, and failure of CPB or other cemented backfill with minimum dependence on destructive testing.

5. Comparative and Meta-Analysis of NDT Methods for UCS Prediction

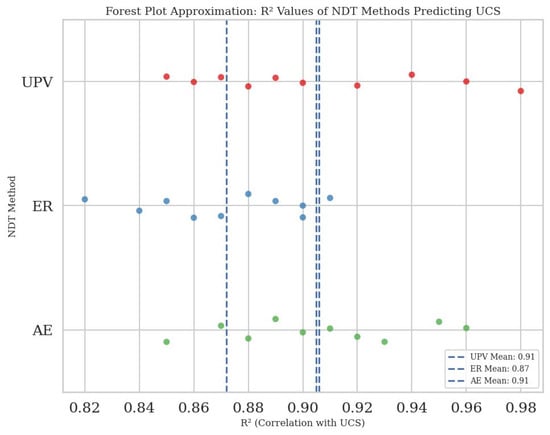

To quantitatively compare the performance of NDT methods in predicting the UCS of CPB, a meta-analysis was conducted using data from 30 peer-reviewed studies. The correlation coefficients (R2) between each method and UCS were extracted then visualized through a forest plot as shown in Figure 11.

Figure 11.

Forest plot of R2 values between NDT methods and UCS across 30 studies. This figure compares the R² values of NDT methods: UPV (green), AE (red), and ER (blue) in predicting UCS. Each point represents a study’s R², with dashed lines showing the mean R² for each method. AE shows the highest average R² value among the methods.

The results indicate that the UPV and AE methods are very dependable and consistent. They have high average R2 values of 0.895 and 0.896, meaning they are quite accurate. These methods show little variation across different studies, which makes them robust for predicting UCS with various CPB mixes. Notably, UCS thresholds are important in high-stress environments (e.g., deep mines with σ3 > 5 MPa) or weak host rocks like coal where CPB must prevent roof collapse or pillar failure. Tailings composition (sulfidic vs. siliceous) further dictates UCS targets, underscoring the need for reliable NDT correlations under diverse geotechnical conditions. On the other hand, the ER method has a slightly lower average R2 of 0.872 and displays more variation, with R2 values ranging from 0.82 to 0.91. This is mostly because ER is sensitive to external conditions like moisture and temperature.

These findings suggest that all three methods are effective for assessing CPB strength without causing damage. However, UPV and AE are particularly reliable and practical in different environments. AE is excellent for detecting early signs of cracking and failure, while UPV is best for monitoring hydration and material becoming denser. The variability in ER performance highlights the importance of controlling environmental factors when using this method.

The strong correlation between these methods supports the use of hybrid systems. Combining UPV with AE or ER could improve real-time prediction, early warnings, and monitoring the health of structures in mining areas. To compare these non-destructive testing (NDT) methods, we examined correlation coefficients, error margins, and sensitivity ranges from various studies. This section provides numerical benchmarks for UPV, ER, and AE in predicting UCS, offering a more data-focused evaluation based on prior findings from sources like [24,74], and [92].

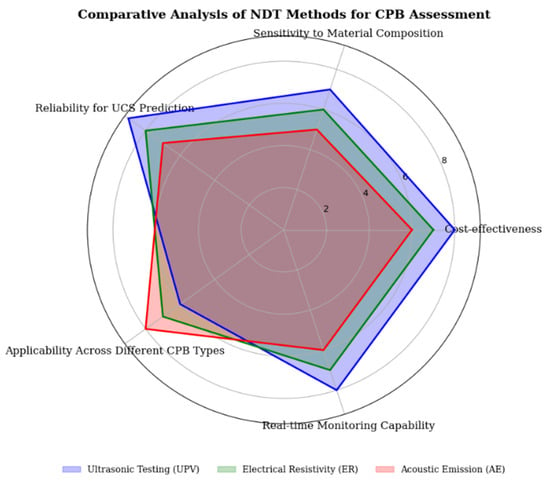

A systematic comparison of NDT methods for CPB assessment is provided in Table 6 above; however, the information is represented visually in Figure 12 using Radar chart which makes the information easily understandable and easier to analyze. It can be used effectively to compare UPV, ER and AE against a number of critical factors and show their strengths and weaknesses. This graphical approach is a comprehensive comparison tool that can be used to easily determine the most appropriate NDT method for a given application.

Table 6.

Summary of meta-analysis results for NDT methods (UPV, ER, and AE) based on R2 correlation with UCS, showing the predictive strength and variability of each method.

Figure 12.

Radar Chart showing the comparative performance of UPV, ER, and AE across five critical parameters. Higher values indicate better performance in each category. Data extracted from multiple case studies (2020–2024) assessing NDT methods for CPB evaluation.

The UPV method has a high correlation with UCS (R2 = 0.85–0.95) and is therefore a very accurate non-destructive tool for estimating strength. However, the ±5% error margin, which is caused by voids, density variations, and material heterogeneity, needs to be calibrated for different CPB mixtures [41,72]. In a similar manner, ER testing is a moderate to strong UCS correlation (R2 = 0.78–0.92) and is suitable for hydration and microstructural monitoring [81]. However, accuracy is ±10% and it is sensitive to moisture, which means that it needs to be applied in controlled conditions or with correction factors [86]. Acoustic Emission (AE) monitoring, which correlates well with UCS (R2 = 0.80–0.96), can detect 85–96% of crack events before failure, providing up to 48 h of predictive lead time [92,94]. However, AE accuracy depends on sensor placement, signal noise filtering, and crack initiation conditions, requiring advanced processing techniques for enhanced reliability.

The fundamental differences in performance are from their underlying physics: UPV measures wave velocity through solids, ER tracks ionic conductivity in pore solutions, and AE records stress induced acoustic waves. The strengths of these techniques are complementary, and it is conceivable that hybrid methods that incorporate aspects of UPV, ER, and AE could represent a more holistic framework for the assessment of CPB.

6. Simulation-Based Validation of a Hybrid NDT Approach

To support the comparative meta-analysis of existing NDT techniques, a simulation-based assessment was conducted to evaluate the predictive strength of a hybrid NDT model that integrates UPV, AE and ER for UCS estimation. Due to the scarcity of publicly available datasets containing all three NDT parameters together, a synthetic dataset had to be developed. This dataset is like the real world in terms of material conditions and the way measurements can vary, providing a controlled environment to explore the behavior of CPB under hybrid NDT monitoring.

6.1. Synthetic Data Generation

A total of 100 synthetic samples were created using possible value ranges found in the literature, as projected in Table 7. The UPV values were designed with a normal distribution, averaging 3.2 km/s with a small variation in ±0.3. This represents how sound waves typically move through compacted CPB. AE values were generated using a gamma distribution to reflect the skewed nature of acoustic emissions during crack initiation and progression. ER values were developed using a uniform distribution, meaning they were evenly distributed between 50 and 120 ohm-m. This range matches the differences in moisture and small pores in the materials used to fill backfilled spaces.

Table 7.

A summary of the synthetic data generated for the studies (see Supplementary Materials for full dataset).

The UCS is a simple linear equation made with three predictors, as shown in Equation (1). To mimic the unpredictability of real-world situations, it includes random variations to capture the uncertainties we often experience:

where ε is a Gaussian noise term with mean 0 and standard deviation 5 MPa.

UCS = 10 ⋅ UPV + 0.8 ⋅ AE − 0.05 ⋅ ER + ε

6.2. Model Training and Evaluation

Models were trained using Python’s scikit-learn (v1.2) with an 80/20 split, balancing computational efficiency and robust validation (sufficient test samples). This ratio aligns with ML best practices for small-to-medium datasets [3,36], avoiding overfitting while preserving statistical power. Linear regression (LR) and random forest (RF) models were selected in order to evaluate how well the models works. These models used three input features—UPV, AE, and ER—to predict UCS, the target variable. We split the dataset, using 80% for training the models and 20% for testing to make sure the results are reliable. The performance results for these models can be found in Table 8, which provides a clear comparison of how each model did in making predictions.

Table 8.

LR and RF model performance across different NDT input configurations for UCS prediction.

Table 8’s results show that LR model consistently outperforms RF model when using single-input features especially with AE, while RF struggles to capture patterns with limited inputs. However, RF performance improves with hybrid inputs, particularly with the full combination (UPV + AE + ER), where it achieves its best R2 of 0.320. Although LR still shows slightly higher accuracy overall, the results highlight RF potential in capturing complex, non-linear relationships when multiple NDT features are integrated.

To maintain clarity and avoid redundancy in figure presentation, only the best-performing hybrid configuration is visualized. Among the three possible two-feature combinations (UPV + AE, UPV + ER, AE + ER), the UPV + AE model demonstrated the highest predictive performance with respect to R2 and mean absolute error (MAE). As such, it serves as a representative case to illustrate the improvement achievable through partial feature integration, while ensuring the manuscript remains concise and focused.

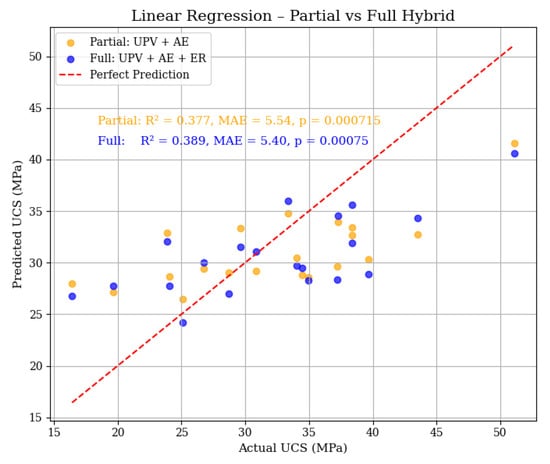

As shown in Figure 13, both partial and full models demonstrate moderate alignment with actual UCS, but the full hybrid model (blue markers) yields a marginal improvement over the partial hybrid model (orange markers). Specifically, the full hybrid configuration achieves an R2 of 0.389 and MAE of 5.40 MPa, and a significant p-value of 0.00075, compared to the partial model R2 of 0.377 and MAE of 5.54 MPa, and p-value of 0.000715. Although the improvement might seem small, it shows the benefit of including ER in predicting UCS. This is important when small improvements can lead to more reliable assessments of structures. Such enhancements are especially valuable for CPB and similar materials. The results demonstrate that even with straightforward methods, using various types of data can improve the accuracy of strength evaluations.

Figure 13.

Actual versus predicted UCS using LR models trained on partial (UPV + AE) and full (UPV + AE + ER) hybrid inputs. The red dashed line represents perfect prediction (y = x). Annotated within the plot are the R2, MAE, and p-values from an auxiliary LR analysis confirming statistical significance. The inclusion of ER improves prediction accuracy modestly.

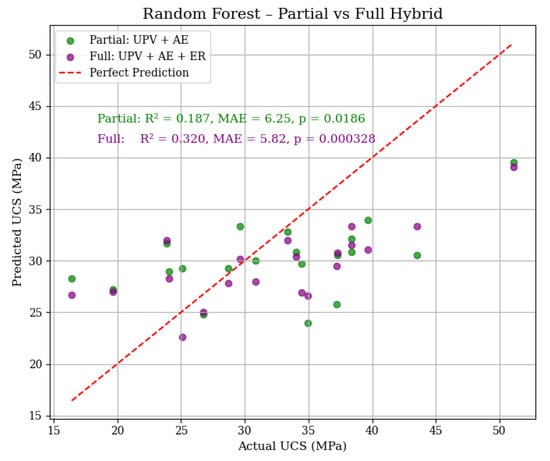

As shown in Figure 14, the full hybrid model (purple markers) clearly shows better clustering along the perfect prediction line, with an R2 of 0.320 and MAE of 5.82 MPa, and a significant p-value of 0.000328, compared to the partial model R2 of 0.187 and MAE of 6.25 MPa, and p-value of 0.0186. This performance improvement confirms the value of incorporating ER alongside UPV and AE, especially in ML frameworks capable of capturing non-linear feature interactions. Unlike LR, where adding ER had marginal impact, RF capitalizes more effectively on the diversity of input data. These findings support the conclusion that a full hybrid NDT approach enhances model generalization and prediction accuracy, offering practical benefits for reliable UCS assessment in cement-based materials.

Figure 14.

Actual versus predicted UCS using RF models with partial (UPV + AE) and full (UPV + AE + ER) hybrid inputs. The red dashed line indicates the ideal prediction line. R2, MAE, and p-values are annotated within the plot, showing that the full hybrid model significantly improves prediction accuracy compared to the partial hybrid configuration. These results highlight the advantage of incorporating multiple NDT parameters for more reliable UCS estimation.

6.3. Residual and Feature Analysis

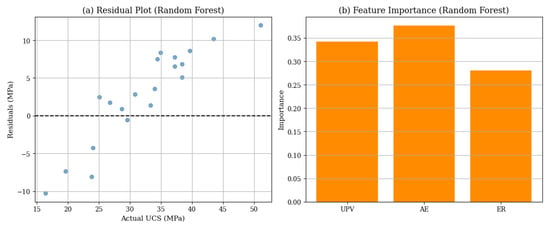

Figure 15 offers a deeper understanding of how the RF model operates with hybrid NDT inputs. The residual plot (a) shows that prediction errors are spread around the zero line, indicating that the model performs well without obvious bias or underfitting issues. The feature importance plot (b), reveals that AE and UPV are the most significant for the model predictions, while ER contributes less but is still helpful. This means that combining all three NDT methods improves the model’s accuracy, but AE and UPV have more influence in predicting UCS. These perceptions confirm the usefulness of the hybrid method and help professionals decide which NDT variables are most important when data is limited.

Figure 15.

RF model results using hybrid NDT inputs (UPV, AE, ER), with (a) showing the residual plot and moderate prediction errors around the zero line, and (b) showing the feature importance plot identifying AE and UPV as dominant predictors of UCS.

6.4. Discussion and Broader Relevance

The simulation demonstrates that combining different NDT methods, such as UPV, AE, and ER results in more accurate predictions than relying on any single method. This combined approach is effective not only for CPB conditions but also for other cement and pavement materials. UPV and AE are commonly used in road diagnostics to detect issues like compaction problems and fatigue cracking. ER helps identify moisture-related damage. Thus, the hybrid NDT model offers a reliable way to assess the strength of structures without causing harm. It can be applied in smart road systems, quality assurance and asset management, making it a valuable tool for future infrastructure projects. To enhance this model further, future work should involve testing it with real-world data to ensure its effectiveness and applicability.

7. Conclusions

This study reviewed and benchmarked the effectiveness of UPV, AE, and ER as NDT for estimating the compressive strength of CPB and similar cementitious systems. Thirty peer-reviewed studies were analyzed, selecting ten for each method and conducting meta-analyses to quantitatively compare their performance using reported R2 values. The findings reveal that UPV proved to be the most dependable for predicting strength in different mixtures and at different curing times. AE and ER were also useful but less consistent. Each method provides unique insights into material properties, such as density, presence of cracks, and moisture content.

To better understand how a hybrid diagnostic strategy could be more effective, a synthetic simulation dataset was created using data from all three NDT techniques. Researchers developed linear regression and random forest models to predict material strength more accurately. The hybrid model which utilized the combined dataset outperformed the models that relied on just one NDT input. It achieved an R2 value of 0.389 and MAE of 5.40 MPa. Analyzing the errors showed that the hybrid model was better at reducing both bias and prediction mistakes.

Additionally, when looking at which features were most important, it became clear that UPV, AE, and ER each played a key role in enhancing the model performance. Although this simulation was designed around CPB conditions, the proposed hybrid framework is transferable to pavement and asphalt materials, where similar NDT techniques are used to examine compaction quality, fatigue cracking and subsurface moisture damage. The model is useful for both underground and surface materials, making it a valuable tool for sustainable and non-invasive checking in infrastructure projects.

This study presents a two-pronged approach combining systematic review and simulation modeling to link current NDT methods with ways to predict future conditions. Demonstrating the hybrid NDT approach is an important step toward using advanced tools for quality checks, maintenance planning, and developing modern infrastructure systems. Future work should focus on gathering real-world data for this method, testing the models in actual field conditions and exploring how these methods can work together with new sensors and IoT technologies for ongoing monitoring.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/ma18122888/s1, Synthetic NDT and UCS Data.

Author Contributions

Conceptualization, S.B.A., Q.C., E.Y. and D.W.; methodology, S.B.A., Q.C. and E.Y.; software, S.B.A. and Q.C.; validation, S.B.A., Q.C. and D.W.; formal analysis, S.B.A., Q.C., E.Y. and D.W.; investigation, Q.C., E.Y. and D.W.; resources, S.B.A., Q.C., E.Y. and D.W.; data curation, S.B.A., Q.C., E.Y. and D.W.; writing—original draft preparation, S.B.A. and Q.C.; writing—review and editing, E.Y. and D.W.; visualization, S.B.A., Q.C., E.Y. and D.W.; supervision, Q.C.; project administration, Q.C. and S.B.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was made possible through funding from the National Natural Science Foundation of China (Grants 52274151 and 52474165), for which the authors express their sincere appreciation.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| AAS | Alkali-Activated Slag |

| AE | Acoustic Emission |

| CPB | Cemented Paste Backfill |

| ER | Electrical Resistivity |

| LR | Linear Regression |

| NDT | Non-Destructive Testing |

| RF | Random Forest |

| R2 | Coefficient of Determination |

| UCS | Uniaxial Compressive Strength/Unconfined Compressive Strength |

| UPV | Ultrasonic Pulse Velocity |

| DT | Destructive Testing |

| MAE | Mean Absolute Error |

| ASTM | American Society for Testing and Materials |

| ISO | International Organization for Standardization |

| SF | Silica Fume |

| WPA | Waste Pumice Aggregate |

| FAC | Fly Ash Cenosphere |

| NER | Normalized Electrical Resistivity |

| ICPB | Improved Cemented Paste Backfill |

| DS | Dredged Sediment |

| IoT | Internet of Things |

References

- He, W.; Zhao, K.; Zheng, C.; Li, S.; Shi, W. Strength development monitoring of cemented paste backfill using guided waves. Sensors 2021, 21, 8499. [Google Scholar] [CrossRef] [PubMed]

- Pan, A.; Grabinsky, M. Direct Tensile Measurement for Cemented Paste Backfill. Minerals 2023, 13, 1218. [Google Scholar] [CrossRef]

- Qi, C.; Zhang, Q.; Chen, Q.; Fourie, A. A strength prediction model using artificial intelligence for recycling waste tailings as cemented paste backfill. J. Clean. Prod. 2018, 183, 566–578. [Google Scholar] [CrossRef]

- ASTM C39/C39M-24; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2024.

- Chen, Q.; Zhu, L.; Wang, Y.; Chen, J.; Qi, C. The carbon uptake and mechanical property of cemented paste backfill carbonation curing for low concentration of CO2. Sci. Total. Environ. 2022, 852, 158516. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, D.; Dai, B.; Chen, Q. Guidance and review: Advancing mining technology for enhanced production and supply of strategic minerals in China. Green. Smart Min. Eng. 2024, 1, 2–11. [Google Scholar] [CrossRef]

- Joel, S. Compressive strength of concrete using fly ash and rice husk ash: A review. Civ. Eng. J. 2020, 6, 1400–1410. [Google Scholar]

- Kashem, A.; Karim, R.; Alharthai, M.; Das, P.; Datta, S.D. Compressive strength prediction of sustainable concrete incorporating rice husk ash (RHA) using hybrid machine learning algorithms and parametric analyses. Case Stud. Constr. Mater. 2024, 20, e03030. [Google Scholar] [CrossRef]

- Teymen, A.; Mengüç, E.C. Comparative evaluation of different statistical tools for the prediction of uniaxial compressive strength of rocks. Int. J. Min. Sci. Technol. 2020, 30, 785–797. [Google Scholar] [CrossRef]

- Biswal, U.S.; Pasla, D.; Mishra, M.; Singh, M.K. Experimental investigation and comparative machine learning prediction of the compressive strength of recycled aggregate concrete incorporated with fly ash, GGBS, and metakaolin. Innov. Infrastruct. Solut. 2022, 7, 242. [Google Scholar] [CrossRef]

- Ren, Q.; Han, S.; Wang, G.; Li, M. Prediction of rock compressive strength using machine learning algorithms based on spectrum analysis of geological hammer. Geotech. Geol. Eng. 2019, 37, 475–489. [Google Scholar] [CrossRef]

- Yesiloglu-Gultekin, N.; Sezer, E.; Gokceoglu, C. Prediction of uniaxial compressive strength of granitic rocks by various nonlinear tools and comparison of their performances. Int. J. Rock. Mech. Min. Sci. Géoméch. Abstr. 2013, 62, 113–122. [Google Scholar] [CrossRef]

- Sari, M.; Karasu, S.; Yilmaz, E.; Kasap, T. Exploring the link between ultrasonic and strength behavior of cementitious mine backfill by considering pore structure. Constr. Build. Mater. 2023, 370, 130588. [Google Scholar] [CrossRef]

- Al-Bakri, A.Y.; Ahmed, H.M.; Hefni, M.A. Experimental Investigation of Recycling Cement Kiln Dust (CKD) as a Co-Binder Material in Cemented Paste Backfill (CPB) Made with Copper Tailings. Minerals 2024, 14, 750. [Google Scholar] [CrossRef]

- Sovják, R.; Vogel, F.; Beckmann, B. Triaxial compressive strength of ultra high performance concrete. Acta Polytech. 2013, 53, 901–905. [Google Scholar] [CrossRef]

- Jiang, H.; Li, Y.; Liu, J.; Yilmaz, E.; Han, J.; Sun, Q. Relationship between ultrasonic pulse velocity and uniaxial compressive strength for cemented paste backfill with alkali-activated slag. Nondestruct. Test. Eval. 2020, 35, 359–377. [Google Scholar] [CrossRef]

- ASTM G57-06; Standard Test Method for Field Measurement of Soil Resistivity Using the Wenner Four-Electrode Method. ASTM International: West Conshohocken, PA, USA, 2006.

- Irianto, N.A.I.; Anwar, B.A.M.K.; Anuar, I.Z.K. The assessment of standard concrete under damage and undamage condition using non-destructive test (NDT) method. Multidiscip. Appl. Res. Innov. 2023, 4, 54–60. [Google Scholar]

- Citra, Z.; Apdeni, R.; Wibowo, P.D.; Malinda, Y.; Herol, H.; Wibisono, A. Testing of Concrete Structures with Non-Destructive Test Method (NDT) Using Ultrasonic Pulse Velocity (UPV) at the Building on the Ancol Beach. CIVED 2024, 11, 217–225. [Google Scholar] [CrossRef]

- Cao, S.; Xue, G.; Yilmaz, E. Flexural behavior of fiber reinforced cemented tailings backfill under three-point bending. IEEE Access 2019, 7, 139317–139328. [Google Scholar] [CrossRef]

- Quan, W.; Fall, M. Temperature-driven crack self-healing and performance recovery in cemented tailings materials. Case Stud. Constr. Mater. 2024, 21, e04105. [Google Scholar] [CrossRef]

- Fall, M.; Nasir, O. Mechanical behaviour of the interface between cemented tailings backfill and retaining structures under shear loads. Geotech. Geol. Eng. 2010, 28, 779–790. [Google Scholar] [CrossRef]

- Zhao, X.; Fourie, A.; Qi, C.-C. Mechanics and safety issues in tailing-based backfill: A review. Int. J. Miner. Met. Mater. 2020, 27, 1165–1178. [Google Scholar] [CrossRef]

- Yılmaz, T.; Ercikdi, B. Predicting the uniaxial compressive strength of cemented paste backfill from ultrasonic pulse velocity test. Nondestruct. Test. Eval. 2016, 31, 247–266. [Google Scholar] [CrossRef]

- Wu, W.; Zhang, Y.; Xu, W. Measuring Ultrasonic and Electrical Properties of Early-Age Cemented Tailings Backfill. Minerals 2023, 13, 135. [Google Scholar] [CrossRef]

- Pérez, J.A.V.; Guzmán, E.M.A.; Molina, W.M.; Sánchez, M.A.; Moreno, I.T.; Chávez-García, H.L. Evaluation of the electrical resistivity, ultrasonic pulse velocity and mechanical properties in portland cement pastes type II. Key Eng. Mater. 2020, 841, 198–202. [Google Scholar] [CrossRef]

- ISO 679; Methods of Testing Cements-Determination of Strength. International Organization for Standardization: Geneva, Switzerland, 2009.

- Kot, P.; Yeboah, D.; Muradov, M.; Hashim, K.; Gkantou, M.; Kamaris, G.S. Recent advancements in non-destructive testing techniques for structural health monitoring. Appl. Sci. 2021, 11, 2750. [Google Scholar] [CrossRef]

- Tejedor, B.; Lucchi, E.; Bienvenido-Huertas, D.; Nardi, I. Non-destructive techniques (NDT) for the diagnosis of heritage buildings: Traditional procedures and futures perspectives. Energy Build. 2022, 263, 112029. [Google Scholar] [CrossRef]

- Fall, M.; Saa, E.; Benzaazoua, M. Mix proportioning of underground cemented tailings backfill. Tunn. Undergr. Space Technol. 2008, 23, 80–90. [Google Scholar] [CrossRef]

- Tang, R.; Xin, J.; Li, L.; Ning, J.; Shao, X.; Zhao, B.; Tian, C.; Li, C.; Xu, B. Experimental study on the effect of fly ash with ammonium salt content on the properties of cemented paste backfill. Constr. Build. Mater. 2023, 369, 130513. [Google Scholar] [CrossRef]

- Qiu, J.; Xing, J.; Sun, X.; Li, S.; Yang, L. Strength characteristics and failure mechanism of cemented super-fine unclassified tailings backfill. Minerals 2017, 7, 58. [Google Scholar] [CrossRef]

- Heidari, M.; Kargarian, S.; Khanlari, G.R.; Kaveh, M.T. Predicting the uniaxial compressive and tensile strengths of gypsum rock by point load testing. Rock. Mech. Rock. Eng. 2012, 45, 265–273. [Google Scholar] [CrossRef]

- Jafari, M.; Shahsavari, M.; Grabinsky, M. Drained triaxial compressive shear response of cemented paste backfill (CPB). Rock. Mech. Rock. Eng. 2021, 54, 3309–3325. [Google Scholar] [CrossRef]

- Nie, X.; Ren, M.; Jing, H.; Wu, J.; Deng, T.; Wang, Q.; Zhang, Q.; Yin, Q. Investigating mechanical properties of cemented gangue backfill materials subjected to static-dynamic combined loads. Constr. Build. Mater. 2023, 400, 132674. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, G.; Na, Q.; Wu, A.; Cao, C.; Wang, L.; Wang, Z. Experimental research and numerical simulation of the multi-field performance of cemented paste backfill: Review and future perspectives. Int. J. Miner. Met. Mater. 2023, 30, 193–208. [Google Scholar] [CrossRef]

- Sun, W.; Wu, S. A study of crack initiation and source mechanism in the Brazilian test based on moment tensor. Eng. Fract. Mech. 2021, 246, 107622. [Google Scholar] [CrossRef]

- Tang, G.; Guo, L.J.; Yang, X.; Liu, G. Determination of the relationship between direct tensile test and Brazilian splitting test of cemented tailings backfill. In Paste 2023: Proceedings of the 25th International Conference on Paste, Thickened and Filtered Tailings; University of Alberta, Edmonton, and Australian Centre for Geomechanics: Perth, Australia, 2023. [Google Scholar]

- Komurlu, E.; Kesimal, A.; Demir, S. Experimental and numerical analyses on determination of indirect (splitting) tensile strength of cemented paste backfill materials under different loading apparatus. Géoméch. Eng. 2016, 10, 775–791. [Google Scholar] [CrossRef]

- Kaklis, K.; Agioutantis, Z.G.; Mavrigiannakis, S.P.; Nomikos, P.P. A multi-stage triaxial test for cemented paste backfill. In ARMA US Rock Mechanics/Geomechanics Symposium; ARMA: Seattle, Washington, 2018. [Google Scholar]

- García, V.J.; Zúñiga-Suárez, A.R.; Villalta-Granda, L.J.; Márquez, C.O.; Zuñiga-Torres, B.C. Brazilian test of concrete specimens subjected to different loading geometries: Review and new insights. Int. J. Concr. Struct. Mater. 2017, 11, 343–363. [Google Scholar] [CrossRef]

- Srivastava, A.; Singh, S.K.; Sharma, C.S. Correlation between ultrasonic pulse velocity (UPV) and compressive strength of coal bottom ash mortar. J. Inst. Eng. (India) Ser. A 2021, 102, 421–433. [Google Scholar] [CrossRef]

- Widodo, S.; Nugroho, M.S.; Mahardika, H.; Ma’ARif, F. Correlation of ultrasonic pulse velocity with porosity and compressive strength of mortar with limestone for building quality assessment. UKaRsT 2022, 6, 190–202. [Google Scholar] [CrossRef]

- Jiang, H.; Qiu, J.; Liu, S.; Yi, H.; Yilmaz, E. Ultrasonic evaluation of strength properties of cemented paste backfill: Effects of mineral admixture and curing temperature. Ultrasonics 2020, 100, 105983. [Google Scholar] [CrossRef]

- Xu, X.; Sun, X.; Yao, W.; Wu, P.; Liu, N.; Guo, Z.; Qiu, J. Strength and ultrasonic characteristics of cemented paste backfill incorporating foaming agent. Minerals 2021, 11, 681. [Google Scholar] [CrossRef]

- Qiu, J.; Jiang, H.; Zhao, Y.; Guo, Z.; Yang, L. Effect of tailings fineness on flow, strength, ultrasonic and microstructure characteristics of cemented paste backfill. Constr. Build. Mater. 2020, 263, 120645. [Google Scholar] [CrossRef]

- Diez d’Aux, M. Ultrasonic Wave Measurement Through Cement Paste Backfill. Master’s Thesis, University of Toronto, Toronto, ON, Canada, 2008. [Google Scholar]

- Rehman, S.K.U.; Jameel, M.; Memon, S.A.; Ibrahim, Z. Nondestructive test methods for concrete bridges: A review. Constr. Build. Mater. 2016, 107, 58–86. [Google Scholar] [CrossRef]

- Wang, Z.; Ji, X.; Guo, H.; Wang, J.; Zhang, H.; Zhang, H.; Zhang, T.; Huo, J.; Shao, T.; Yu, P.; et al. Principles, properties and applications of smart conductive cement-based composites: A state-of-the-art review. Constr. Build. Mater. 2023, 408, 133569. [Google Scholar] [CrossRef]

- Zárate, D.M.; Cárdenas, F.; Forero, E.F.; Peña, F.O. Strength of concrete through ultrasonic pulse velocity and uniaxial compressive strength. Int. J. Technol. 2022, 13, 103–114. [Google Scholar] [CrossRef]

- IS 516:2018; Hardened Concrete—Methods of Test. Bureau of Indian Standards (BIS): New Delhi, India, 2018.

- IS 13311:1992; Method of Non-Destructive Testing of Concrete-Part 1: Ultrasonic Pulse Velocity Testing. Bureau of Indian Standards (BIS): New Delhi, India, 1992.

- Kowsalya, M.; Nachiar, S.; Anandh, S. Correlation Between Compressive Strength and Ultrasonic Pulse Velocity (UPV) of Fly ash Cenosphere Concrete. Eng. J. 2024, 28, 41–49. [Google Scholar] [CrossRef]

- Lang, L.; Liu, N.; Chen, B. Investigation on the strength, durability and swelling of cement-solidified dredged sludge admixed fly ash and nano-SiO2. Eur. J. Environ. Civ. Eng. 2022, 26, 2913–2933. [Google Scholar] [CrossRef]

- Wan, Y.; Xue, J.; Li, J.; Hui, X.; He, X.; Feng, D.; Liu, X.; Wang, S. Performance of green binder developed from flue gas desulfurization gypsum incorporating Portland cement and large-volume fly ash. Constr. Build. Mater. 2022, 348, 128679. [Google Scholar] [CrossRef]

- Fall, M.; Ouellet, S.; Benzaazoua, M. Experimental characterization of the influence of tailings fineness and density on the quality of cemented paste backfill. Miner. Eng. 2005, 18, 41–44. [Google Scholar] [CrossRef]

- Saedi, A.; Jamshidi-Zanjani, A.; Darban, A.K. A review on different methods of activating tailings to improve their cementitious property as cemented paste and reusability. J. Environ. Manag. 2020, 270, 110881. [Google Scholar] [CrossRef]

- Zhang, H.; Hu, W.; Xia, K.; Chen, S.; Ye, L.L.; Li, H. Study on mechanical behavior of inclined cemented tailings composite backfill (CTCB) under uniaxial compression. Constr. Build. Mater. 2024, 439, 137410. [Google Scholar] [CrossRef]

- Tu, B.; Liu, L.; He, H.; Ding, X.; Yang, Q. Comparative Analysis of Uniaxial and Triaxial Compression Characteristics of Cement Tailings Backfill. Min. Met. Explor. 2025, 42, 335–345. [Google Scholar] [CrossRef]

- Xu, W.; Tian, X.; Wan, C. Prediction of mechanical performance of cemented paste backfill by the electrical resistivity measurement. J. Test. Eval. 2018, 46, 2450–2458. [Google Scholar] [CrossRef]

- Fang, K.; Haruna, S.; Zhang, J.; Cui, L.; Li, M. Cost optimization of cemented paste backfill: State-of-the-art review and future perspectives. Miner. Eng. 2023, 204, 108414. [Google Scholar] [CrossRef]

- Dahlin, T.; Olsson, P.; Hedblom, P.; Rejkjær, S.; Lumetzberger, M. Novel electrode design for non-destructive resistivity measurement on material in geotechnical standard sample cylinders. In Proceedings of the NSG2023 29th European Meeting of Environmental and Engineering Geophysics, Edinburgh, UK, 3–7 September 2023; European Association of Geoscientists & Engineers: Utrecht, The Netherlands, 2023. [Google Scholar]

- Carrasco, Á.; Leaman, F.; Méndez, F.; Vicuña, C.M. Short review of the use of acoustic emissions for detection and monitoring of cracks. Acoust. Aust. 2021, 49, 273–280. [Google Scholar] [CrossRef]

- Wang, B.; Kang, M.; Li, Q.; Yang, L.; Shu, X. Mechanical behavior, acoustic emission and principal strain field evolution properties of layered cemented paste backfill under unconfined compression. Constr. Build. Mater. 2024, 415, 135111. [Google Scholar] [CrossRef]

- Yin, S.; Liu, X.; Wang, H.; Wu, A.; Wang, Y.; Shao, Y. A systematic review of paste technology in metal mines for cleaner production in China. J. Clean. Prod. 2020, 247, 119590. [Google Scholar] [CrossRef]

- He, Z.; Ju, F.; Wang, T.; Ning, P.; Xiao, M.; Wang, D. Acoustic emission investigation of coal gangue cementitious composites under effects on fiber type. Case Stud. Constr. Mater. 2022, 17, e01567. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, J.; Hu, X.; Han, K.; Zhang, Z.; Jiang, F. Action mechanism of rice husk ash and the effect on main performances of cement-based materials: A review. Constr. Build. Mater. 2021, 288, 123068. [Google Scholar] [CrossRef]

- Li, D.; Wang, D.; Kong, X.; Wang, E.; Ali, M. Mechanical behaviors and acoustic emission fractal characteristics of coal specimens with a pre-existing flaw of various inclinations under uniaxial compression. Int. J. Rock. Mech. Min. Sci. 2019, 116, 38–51. [Google Scholar] [CrossRef]

- Song, X.; Shi, J.; Yang, F.; Yalçınkaya, Ç.; Zhao, W.; Yu, X. Progressive damage process and destabilization precursor recognition of sulfate tailing-cemented paste backfill based on acoustic emission. Powder Technol. 2023, 430, 119047. [Google Scholar] [CrossRef]

- Yang, L.; Zhu, W.; Hou, C.; Liu, X.; Yan, B.; Li, L. Monitoring the failure process of cemented paste backfill at different curing times by using a digital image correlation technique. Constr. Build. Mater. 2022, 346, 128487. [Google Scholar] [CrossRef]

- Chai, M.; Li, Y.; Zhang, Z.; Duan, Q.; Gao, Z.; Chen, R. An approach for identifying corrosion damage from acoustic emission signals using ensemble empirical mode decomposition and linear discriminant analysis. Meas. Sci. Technol. 2022, 33, 065018. [Google Scholar] [CrossRef]

- Jing, G.; Zhao, Y.; Lacidogna, G.; Montanari, P.M.; Gao, Y. Noise reduction based on improved variational mode decomposition for acoustic emission signal of coal failure. Appl. Sci. 2023, 13, 9140. [Google Scholar] [CrossRef]

- Godin, N.; Fantozzi, G.; Reynaud, P. Challenges and limitations in the identification of acoustic emission signature of damage mechanisms in composites materials. Appl. Sci. 2018, 8, 1267. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, Y.; Liu, Y. Mechanical performance and ultrasonic properties of cemented gangue backfill with admixture of fly ash. Ultrasonics 2016, 64, 89–96. [Google Scholar] [CrossRef]

- Xu, S.; Li, Y.; Li, K.; Suorineni, F.T. Evaluation of the strength and ultrasonic properties of foam-cemented paste backfill. Int. J. Min. Reclam. Environ. 2017, 31, 544–557. [Google Scholar] [CrossRef]

- Mendes, S.E.S.; Pereira, E.; Pereira, E.; Cremonez, C.; Oliveira, R.L.N.; Medeiros-Junior, R.A. Mixture design of concrete using ultrasonic pulse velocity. Int. J. Civ. Eng. 2019, 18, 113–122. [Google Scholar] [CrossRef]

- Nugroho, M.S.; Widodo, S.; Suryadwanti, N.; Rachmi, D.; Fajriani, Q.; Setiawan, W.; Ma’ARif, F. The effect of mortar mixture variations on the compressive strength and ultrasonic pulse velocity. INERSIA Lnformasi Dan. Ekspose Has. Ris. Tek. Sipil Dan. Arsit. 2022, 18, 225–234. [Google Scholar] [CrossRef]

- Hong, G.; Kim, Y.-J.; Chin, W.-J.; Choi, S.; Oh, S.; Song, C. Correlation between the compressive strength and ultrasonic pulse velocity of cement mortars blended with silica fume: An analysis of microstructure and hydration kinetics. Materials 2021, 14, 2476. [Google Scholar] [CrossRef]

- Aslam, H.M.S.; Khan, M.A.; Latif, A.; Rehman, A.U.; Hussain, S.; Noshin, S.; Yasin, M.; Onyelowe, K.C. Evaluating the mechanical and durability properties of sustainable lightweight concrete incorporating the various proportions of waste pumice aggregate. Results Eng. 2024, 24, 103496. [Google Scholar] [CrossRef]

- Xu, W.; Tian, X.; Cao, P. Assessment of hydration process and mechanical properties of cemented paste backfill by electrical resistivity measurement. Nondestruct. Test. Eval. 2018, 33, 198–212. [Google Scholar] [CrossRef]

- Liu, L.; Guo, L.; Song, K.-I.; Huan, C.; Yang, Q.; Yang, P.; Zhang, B. Study on hydration reaction and structure evolution of cemented paste backfill in early-age based on resistivity and hydration heat. Constr. Build. Mater. 2021, 272, 121827. [Google Scholar] [CrossRef]

- He, Z.; Ning, P.; Xiao, M.; Ju, F.; Zhou, C. An experimental investigation on the compaction characteristic of coal waste rock backfilling material using electrical resistivity method. Environ. Earth Sci. 2021, 80, 450. [Google Scholar] [CrossRef]

- Zhu, C.; Pu, Y.; Qi, C.; Yang, P.; Chen, J.; Liu, L.; Chen, Q. Effect of ice addition on the properties and microstructure of cemented paste backfill at early-age. J. Build. Eng. 2023, 71, 106439. [Google Scholar] [CrossRef]

- Lee, D.; Tutumluer, E.; Kim, D.-J.; Lee, J.-S.; Byun, Y.-H. Evaluation of electrical resistivity of cement-based materials using time domain reflectometry. Measurement 2024, 236, 115166. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, T.; Song, W.; Tan, Y.; Fu, J.; Taheri, A. Hydration mechanism and mechanical-thermal correlation of cemented paste backfill under different curing temperatures. J. Build. Eng. 2024, 85, 108691. [Google Scholar] [CrossRef]

- Wan, L.; Yu, M.; Wu, E.; Zhao, Y. The Effects of Calcium Nitrite on the Mechanical Properties and Microstructure of Early-Age Frozen Cement Paste. Materials 2024, 17, 2461. [Google Scholar] [CrossRef]

- Gholampoor, M.; Dahlin, T.; Hedblom, P.; Lumetzberger, M. Correlation between electrical resistivity and compressive strength of stabilized dredged sediment for early quality control. Transp. Eng. 2024, 18, 100280. [Google Scholar] [CrossRef]

- Cao, S.; Song, W.; Xue, G.; Yilmaz, E. Assessment of acoustic emission and triaxial mechanical properties of rock-cemented tailings matrix composites. Adv. Mater. Sci. Eng. 2019, 2019, 6742392. [Google Scholar] [CrossRef]

- Wu, J.; Chen, Z.; Han, G.; Feng, M.; Ni, X. Experimental investigation on mechanical properties of cemented paste backfill under different gradations of aggregate particles and types and contents of cementing materials. Adv. Mater. Sci. Eng. 2019, 2019, 9456861. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Song, W.; Fu, J.; Wang, Y. Mechanical behavior, acoustic emission properties and damage evolution of cemented paste backfill considering structural feature. Constr. Build. Mater. 2020, 261, 119958. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, J.; Zhu, S.; Zhou, Y.; Yu, X.; Wang, Q. Acoustic emission investigation of cemented paste backfill prepared with tantalum–niobium tailings. Constr. Build. Mater. 2020, 237, 117523. [Google Scholar] [CrossRef]

- Zhou, Y.; Yan, Y.; Wang, J.; Zhu, S.; Guo, Z.; Zhao, K.; Yu, X. On acoustic emission characteristics, initiation crack intensity, and damage evolution of cement-paste backfill under uniaxial compression. Constr. Build. Mater. 2021, 269, 121261. [Google Scholar] [CrossRef]

- Qiu, H.; Kang, W.; Huan, C.; Liu, L.; Hou, D.; Zhang, F. Experimental study on acoustic emission characteristics of cemented rock-tailings backfill. Constr. Build. Mater. 2022, 315, 125278. [Google Scholar] [CrossRef]

- Chen, T.; Guo, L.; Yan, Y.; He, Z.; Zhao, K.; Zhou, Y. Mechanical properties and acoustic emission response of cemented tailings backfill under variable angle shear. Constr. Build. Mater. 2022, 343, 128114. [Google Scholar] [CrossRef]

- Sun, K.; Wang, C.; Feng, W.; He, M.; Zhang, J.; Li, M.; Li, F. Mechanical properties and damage evolution characteristics based on the acoustic emission of gangue and high-water-content materials based cemented paste backfill. Constr. Build. Mater. 2023, 395, 132324. [Google Scholar] [CrossRef]

- Yin, S.; Li, G.; Chen, X.; Zhou, Y. A new acoustic emission characteristic parameter can be utilized to evaluate the failure of cemented paste backfill and rock combination. Constr. Build. Mater. 2023, 392, 132017. [Google Scholar] [CrossRef]

- Chen, G.; Ye, Y.; Fu, F.; Hu, N.; Zhang, Z.; Yao, N. Experimental study on mechanical strength and acoustic emission characteristics of waste rock cemented backfill. Bull. Eng. Geol. Environ. 2024, 83, 133. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).