Sustainable Soil–Cement Composites with Rice Husk Ash and Silica Fume: A Review of Performance and Environmental Benefits

Abstract

1. Introduction

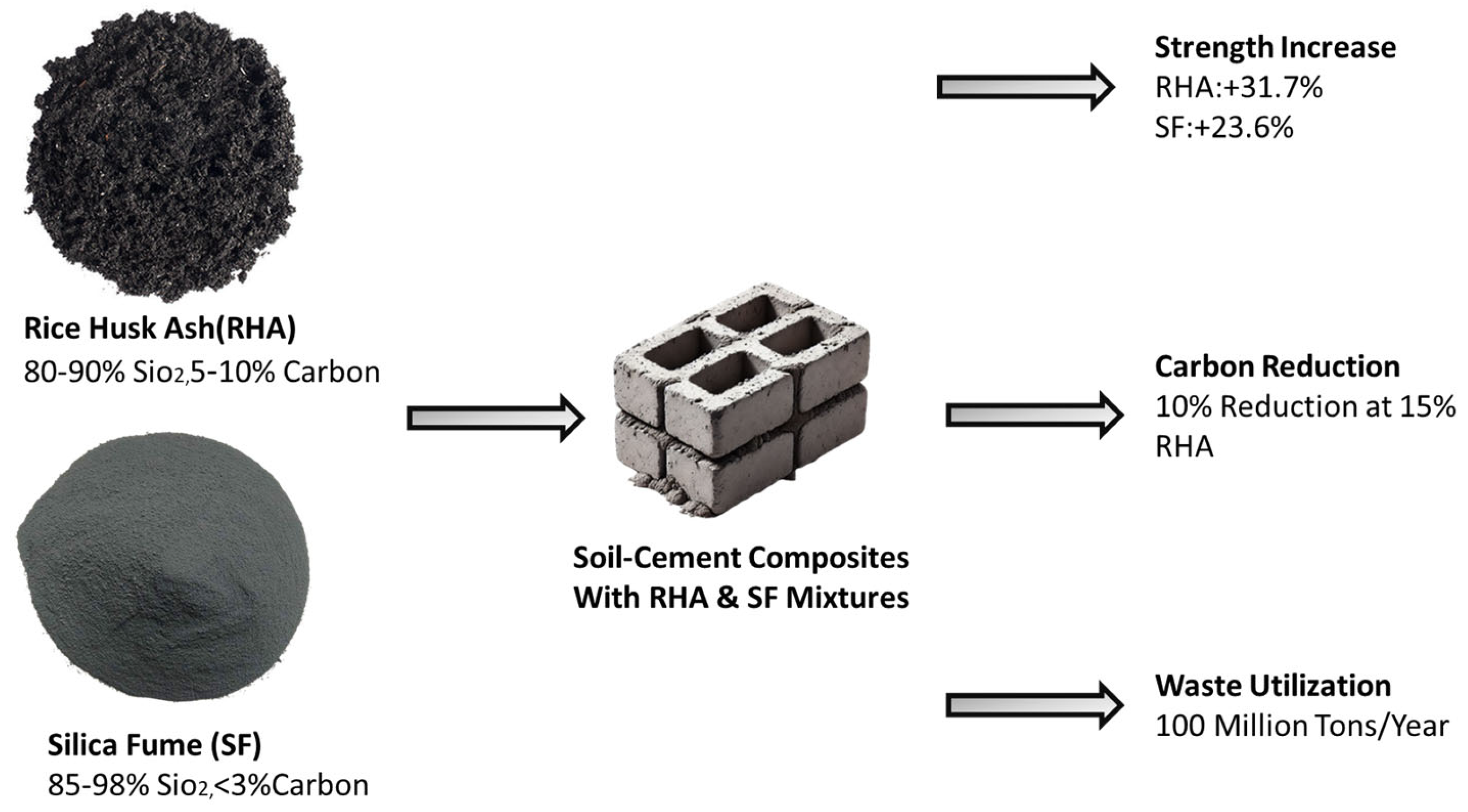

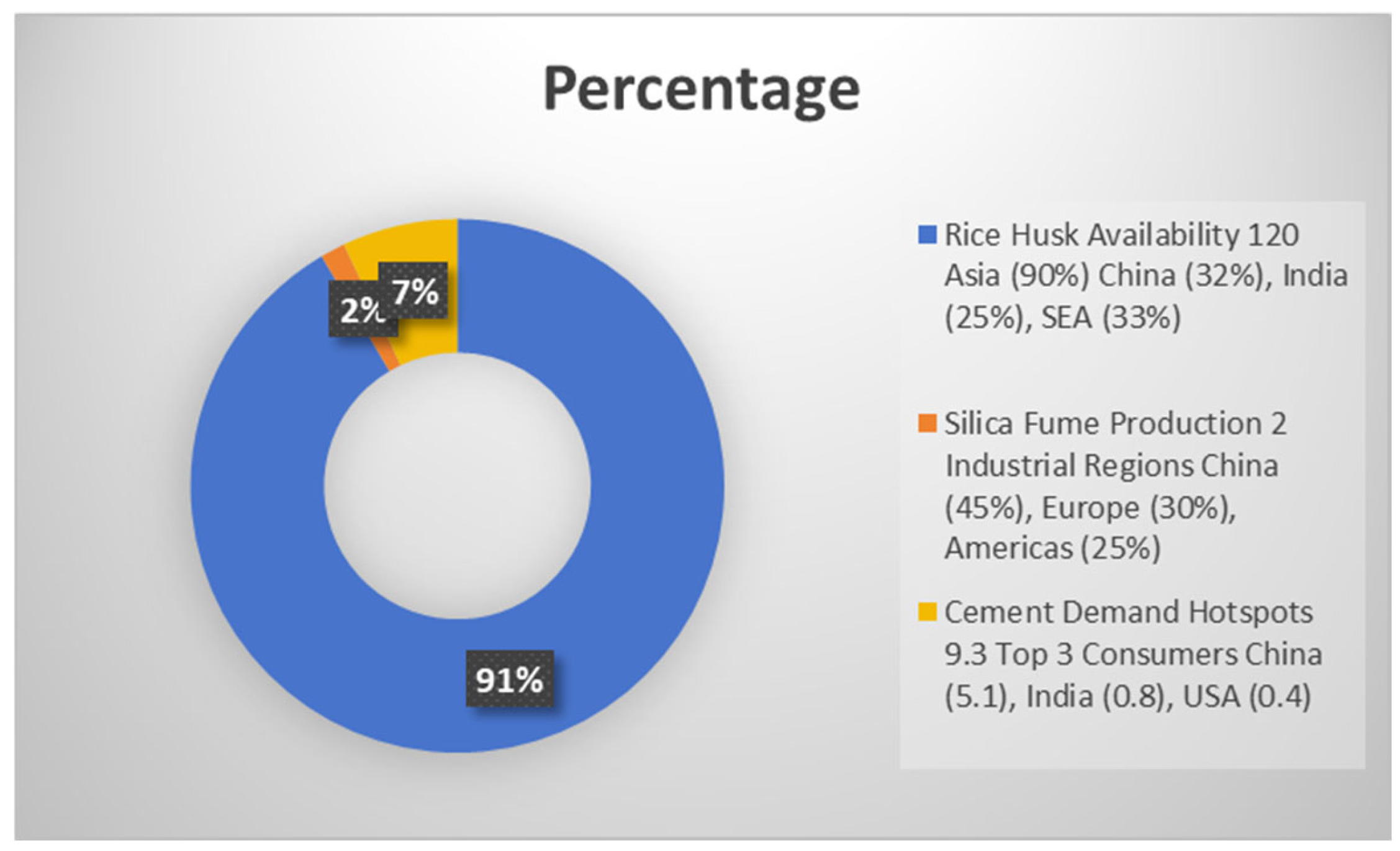

2. Characteristics of Rice Husk Ash and Silica Fume

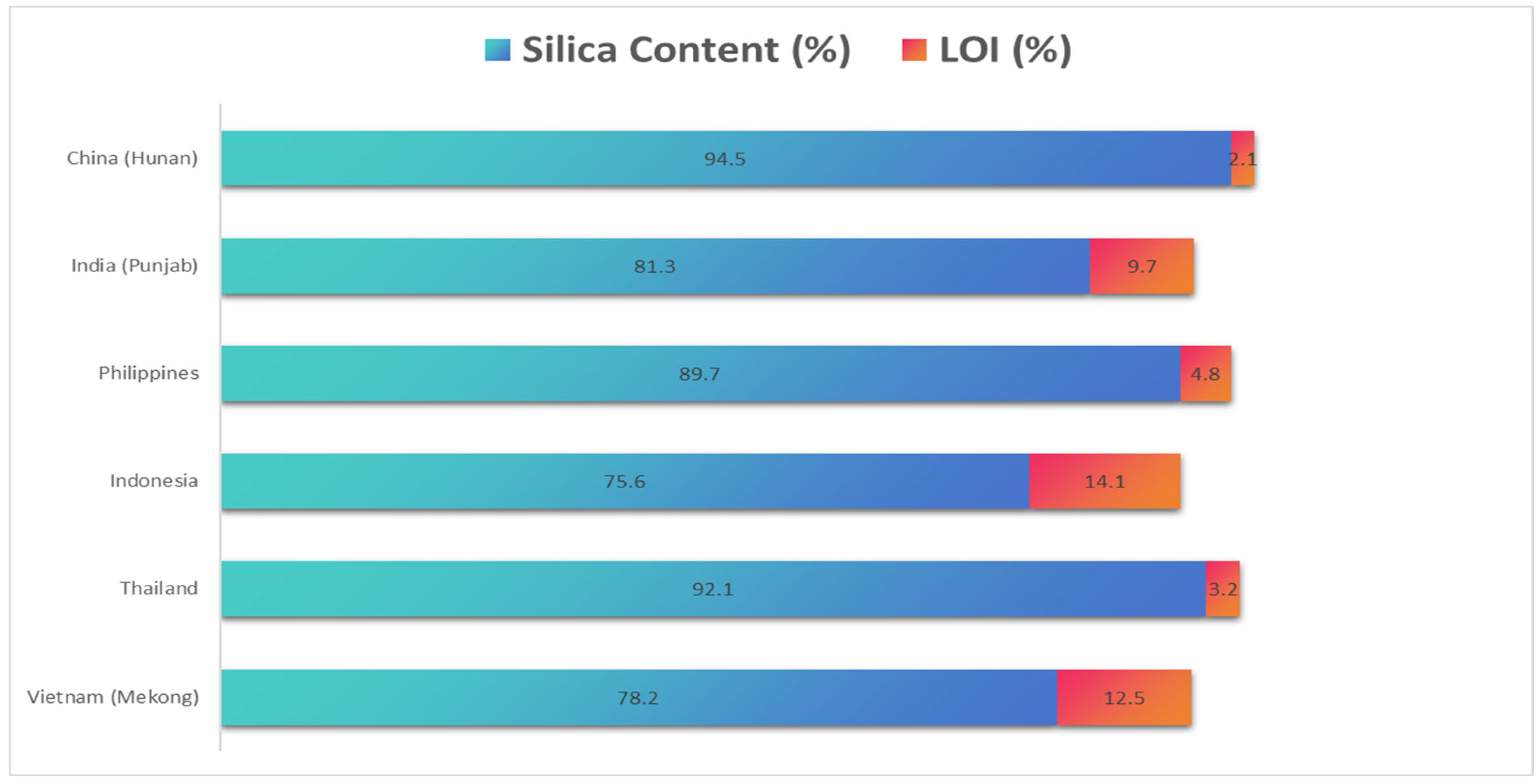

2.1. Chemical Composition

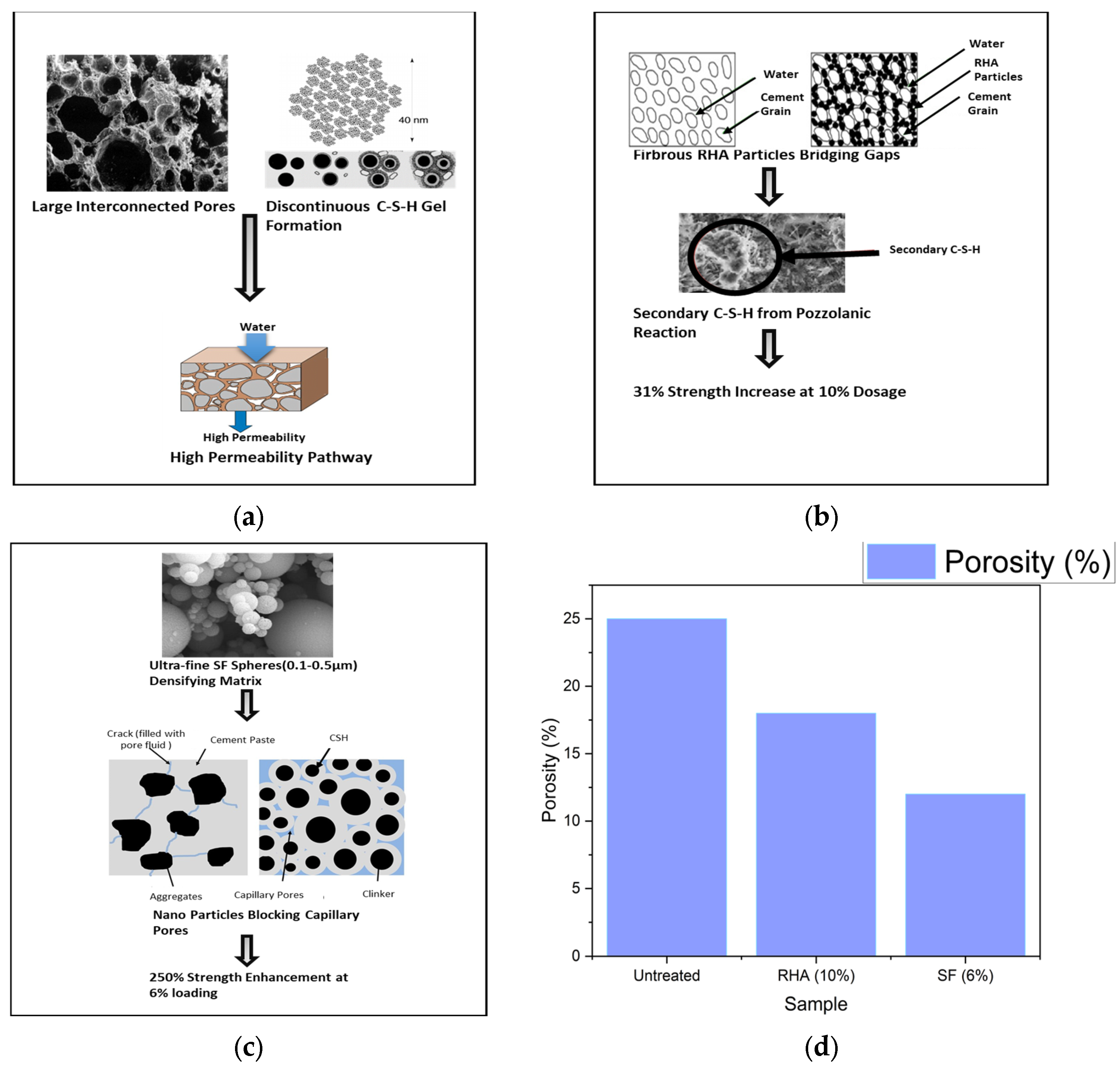

2.2. Mechanical Properties

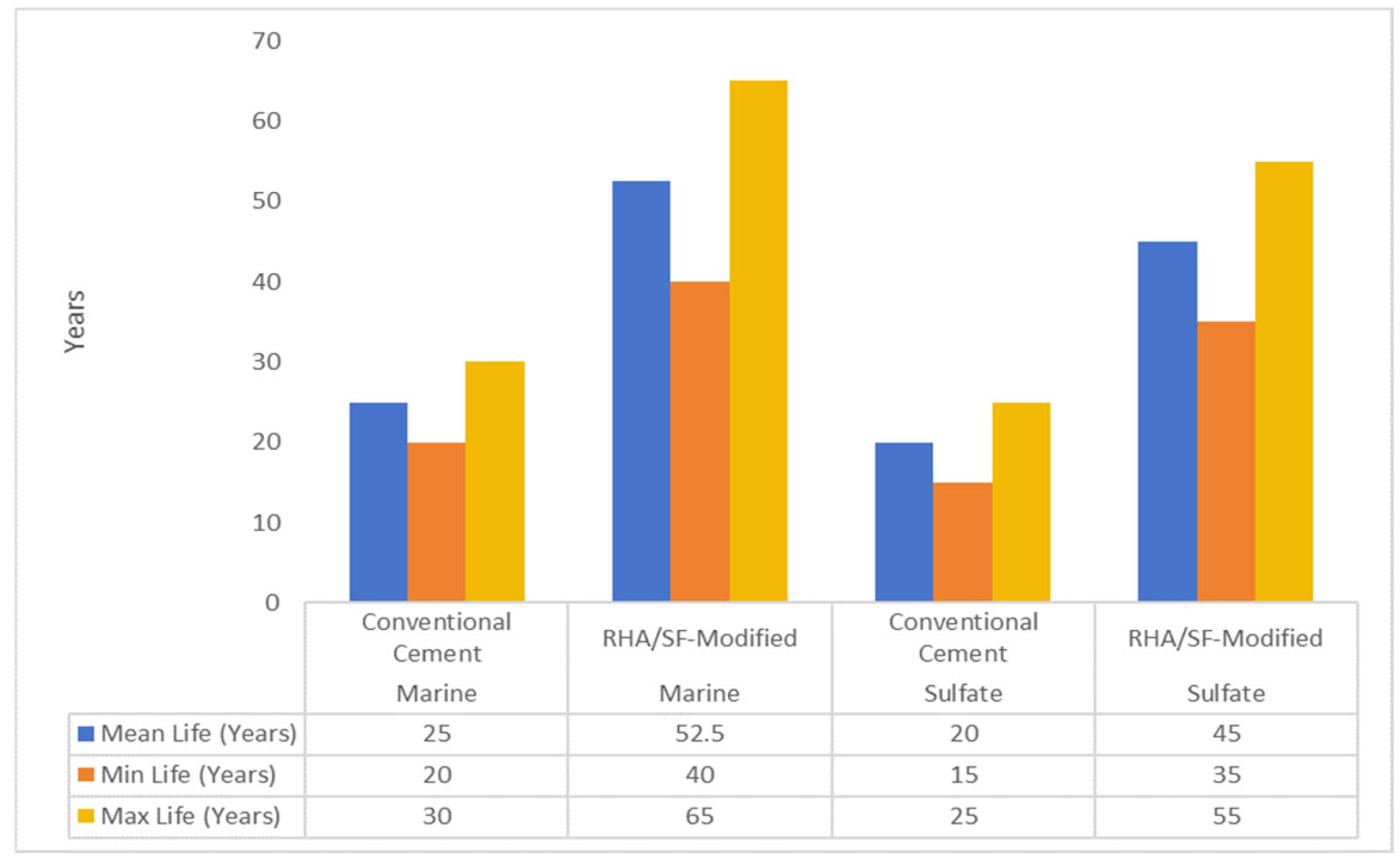

2.3. Durability Enhancement

3. Environmental Impact

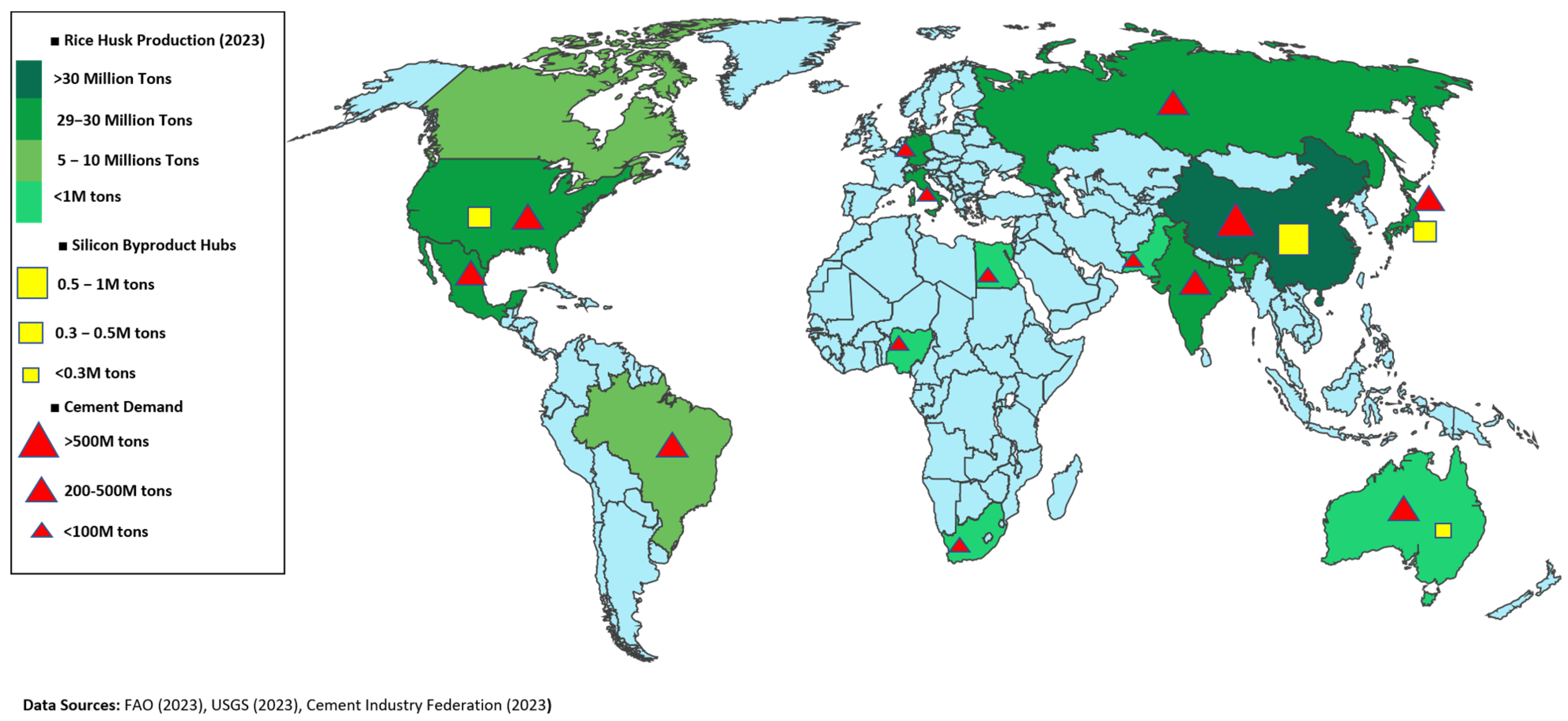

3.1. Waste Utilization and Circular Economy

3.2. Carbon Emissions Reduction

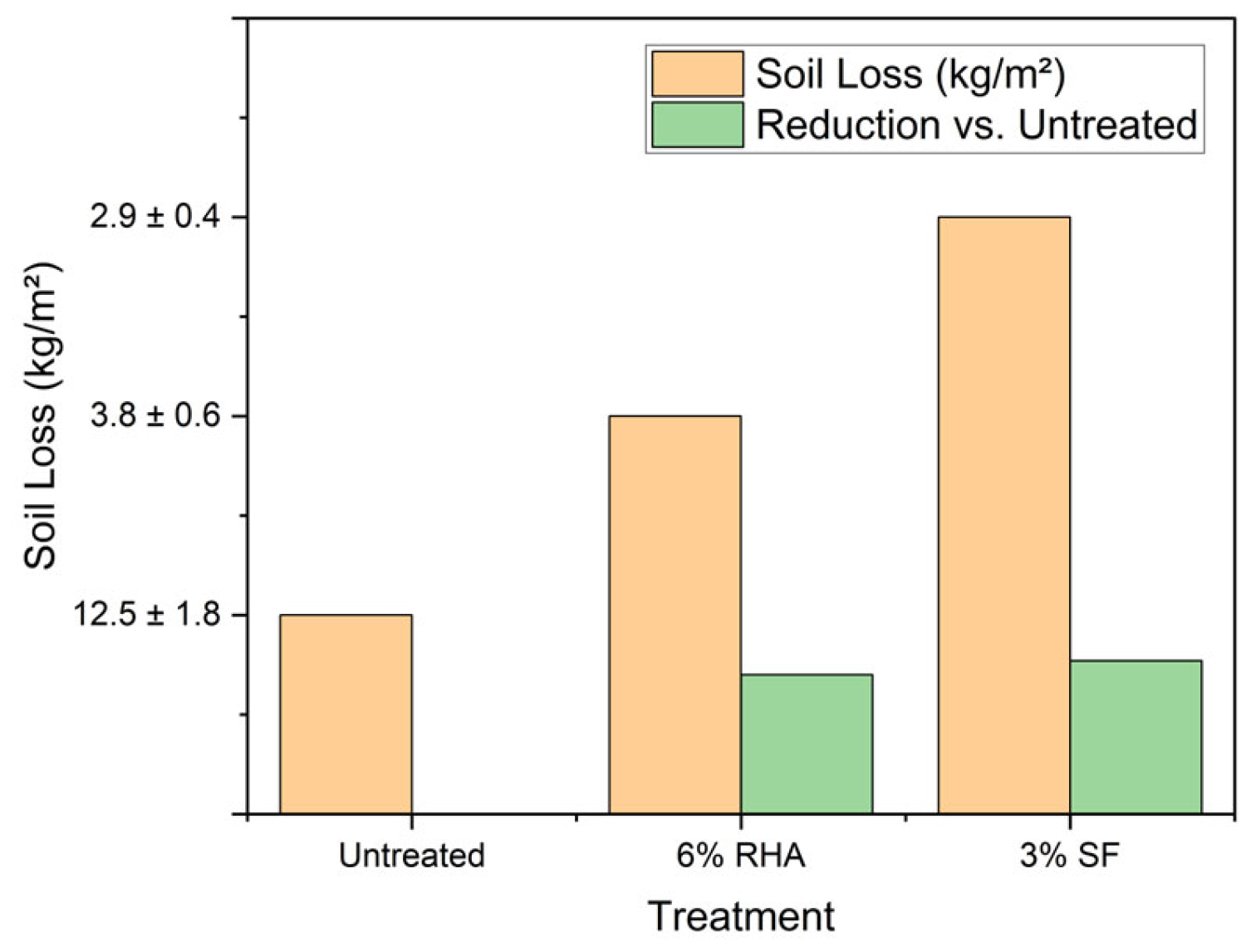

3.3. Improved Soil Properties and Erosion Control

4. Challenges and Future Directions

4.1. Material Variability and Quality Control

4.2. Optimal Dosage and Mix Design

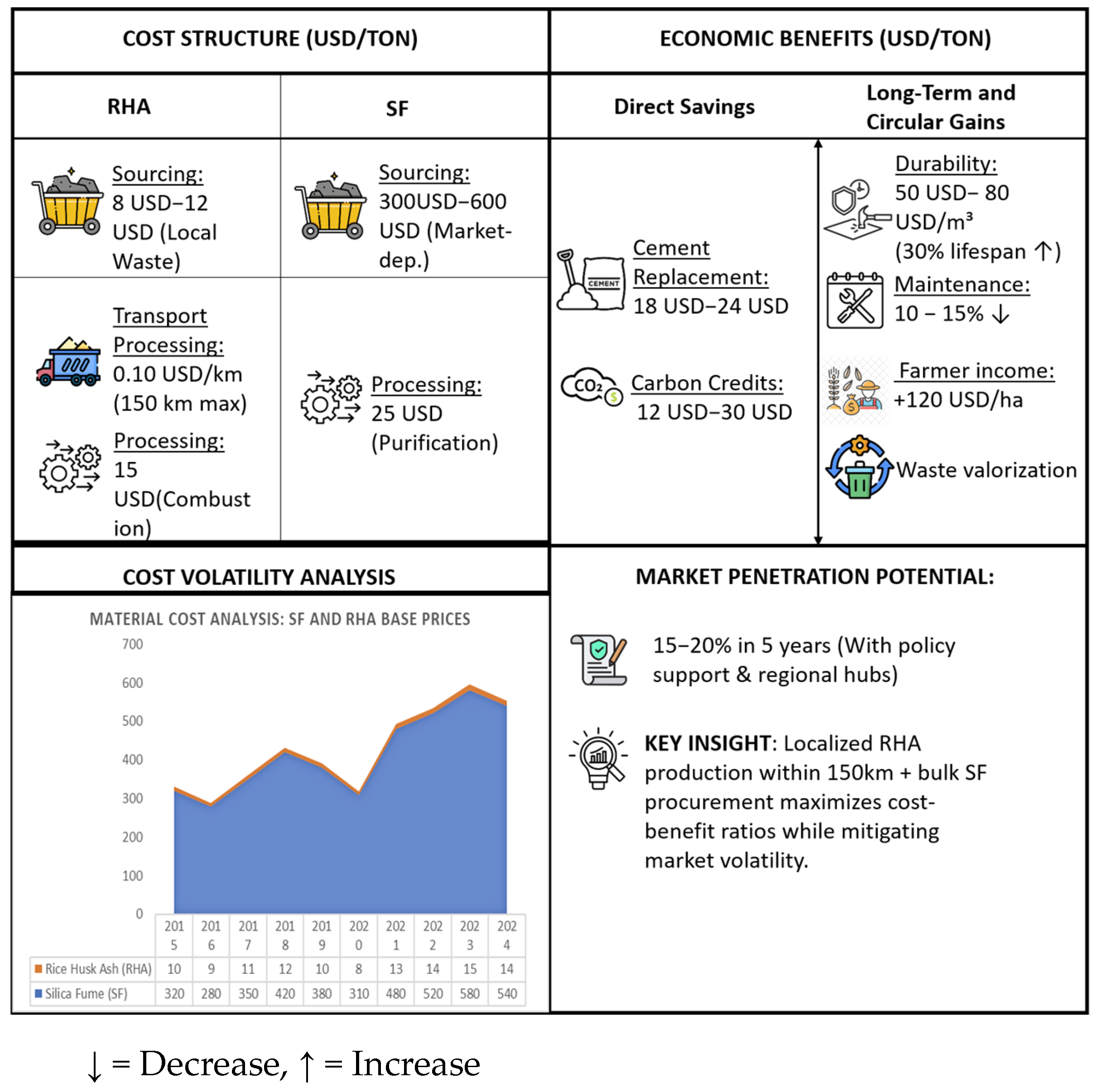

4.3. Economic and Regulatory Considerations

- 1.

- Regional Development Initiatives:

- Agricultural waste hubs for decentralized RHA production.

- Industrial symbiosis networks optimizing SF utilization [38].

- 2.

- Policy Interventions:

- 3.

- Stakeholder Collaboration:

- Farmer cooperatives establishing reliable RHA supply chains.

- Industry partnerships ensuring quality control.

- Workforce training programs for proper implementation [2].

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abbey, S.J.; Eyo, E.U.; Oti, J.; Amakye, S.Y.; Ngambi, S. Mechanical properties and microstructure of fibre-reinforced clay blended with by-product cementitious materials. Geosciences 2020, 10, 241. [Google Scholar] [CrossRef]

- Abera, H.; Jebamalai Raj, S. Assessment of concrete with silica fume as partial cement replacement. Int. J. Adv. Res. Innov. Ideas Educ. 2021, 7, 2395–4396. [Google Scholar]

- Abohamer, H.; Elseifi, M.A.; Mayeux, C.; Cooper, S.B., III; Cooper, S., Jr. Effects of asphalt binder additives and industrial fillers on the mechanical and functional properties of open graded friction course. Transp. Res. Rec. 2023, 2679, 831–845. [Google Scholar] [CrossRef]

- Ahmed, Z.; Somani, S.B. Construction of sustainable roads using the mixture of alkali-activated rice husk ash and fly ash. Suranaree J. Sci. Technol. 2024, 31, 010280. [Google Scholar] [CrossRef]

- Alhaji, M.M.; Alhassan, M.; Adejumo, T.W.; Dogo, A.I. Microstructural investigation and strength properties of clay stabilized with cement, rice husk ash, and promoter. J. Technol. 2020, 82, 14353. [Google Scholar] [CrossRef]

- Amin, M.N.; Rehman, K.U.; Shahzada, K.; Khan, K.; Wahab, N.; Alabdullah, A.A. Mechanical and microstructure performance and global warming potential of blended concrete containing rice husk ash and silica fume. Constr. Build. Mater. 2022, 346, 128470. [Google Scholar] [CrossRef]

- Bazuhair, R.W. Laboratory evaluation of the effect of rice husk fiber on soil properties and behaviors. J. Umm Al-Qura Univ. Eng. Archit. 2023, 14, 166–171. [Google Scholar] [CrossRef]

- Chen, Q.; Xie, K.; Tao, G.; Nimbalkar, S.; Peng, P.; Rong, H. Laboratory investigation of microstructure, strength, and durability of cemented soil with Nano-SiO₂ and basalt fibers in freshwater and seawater environments. Constr. Build. Mater. 2023, 392, 132008. [Google Scholar] [CrossRef]

- Chen, R.; Congress, S.S.C.; Cai, G.; Duan, W.; Liu, S. Sustainable utilization of biomass waste-rice husk ash as a new solidified material of soil in geotechnical engineering: A review. Constr. Build. Mater. 2021, 292, 123219. [Google Scholar] [CrossRef]

- Cheng, G.; Zhu, H.-H.; Wen, Y.-N.; Shi, B.; Gao, L. Experimental investigation of consolidation properties of nano-bentonite mixed clayey soil. Sustainability 2020, 12, 459. [Google Scholar] [CrossRef]

- Chmielewska, I.; Gosk, W. Sustainable soil stabilization: The use of waste materials to improve the engineering properties of soft soils. Inżynieria Bezpieczeństwa Obiektów Antropogenicznych 2022, 3, 34–41. [Google Scholar] [CrossRef]

- Dahlia, P.; Dasar, A. Strength performance of concrete using rice husk ash (RHA) as supplementary cementitious material (SCM). Civ. Eng. Forum 2022, 8, 261–276. [Google Scholar] [CrossRef]

- Dong, X.; Wang, M.; Song, M.; Hou, N. Engineering properties and microscopic mechanisms of composite-cemented soil as backfill of ultra-deep and ultra-narrow foundation trenches. Appl. Sci. 2023, 13, 1952. [Google Scholar] [CrossRef]

- Du, C.; Yang, G.; Zhang, T.; Yang, Q. Multiscale study of the influence of promoters on low-plasticity clay stabilized with cement-based composites. Constr. Build. Mater. 2019, 213, 537–548. [Google Scholar] [CrossRef]

- Duong, N.T.; Tran, K.Q.; Satomi, T.; Takahashi, H. Effects of agricultural by-product on mechanical properties of cemented waste soil. J. Clean. Prod. 2022, 365, 132814. [Google Scholar] [CrossRef]

- Endale, S.A.; Taffese, W.Z.; Vo, D.-H.; Yehualaw, M.D. Rice husk ash in concrete. Sustainability 2023, 15, 137. [Google Scholar] [CrossRef]

- Falahnejad, M.; Mahdikhani, M. Investigating the effect of natural pozzolans on mechanical properties of roller compacted concrete. J. Struct. Eng. Geo-Tech. 2020, 10, 45–54. [Google Scholar]

- Ganta, M.; Ramesh, B.; Jyosyula, S.K.R. Rice husk ash as a potential supplementary cementitious material in concrete solution towards sustainable construction. Innov. Infrastruct. Solut. 2022, 7, 148. [Google Scholar] [CrossRef]

- Guo, H. Performance evaluation of sustainable concrete using silica fume and demolished brick waste aggregate. Sustain. Constr. Mater. 2023, 49, 571–581. [Google Scholar] [CrossRef]

- He, Y.; Gu, F.; Xu, C.; Chen, J. Influence of iron/aluminum oxides and aggregates on plant available water with different amendments in red soils. J. Soil Water Conserv. 2019, 74, 145–159. [Google Scholar] [CrossRef]

- Igibah, C.E.; Amu, O.O.; Agashua, L.O.; Ugochukwu, E.T. Improving the soil properties by adding rice husk ash (RHA) and ordinary Portland cement (OPC): An experimental analysis. Arch. Curr. Res. Int. 2022, 22, 30281. [Google Scholar] [CrossRef]

- Jaiswal, V.; Avesh, M.; Gautam, A.; Sharma, M.; Yadav, B. Towards sustainable soil stabilization: A review of innovative techniques. J. Sustain. Constr. 2024, 3, 24–32. [Google Scholar] [CrossRef]

- Jiang, N.; Wang, C.; Wang, Z.; Li, B.; Liu, Y.-A. Strength characteristics and microstructure of cement stabilized soft soil admixed with silica fume. Materials 2021, 14, 1929. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Huang, Z.; Ma, F.; Luo, X. Analysis of strength development and soil-water characteristics of rice husk ash-lime stabilized soft soil. Materials 2019, 12, 3873. [Google Scholar] [CrossRef]

- Kani, E.N.; Rafiean, A.H.; Tavakolzadeh, M.; Ghaffar, S.H. Performance enhancement of cementitious soil stabilizers using incorporated nanosilica. Results Eng. 2022, 16, 100713. [Google Scholar] [CrossRef]

- Kumar, R.S.; Vijayan, D.S.; Mubarak Manzoor, P.A.; Subinjith, N.; Santhosh, S. Effect of silica fume on strength of glass fiber incorporated concrete. AIP Conf. Proc. 2020, 2271, 030020. [Google Scholar] [CrossRef]

- Lai, H.-J.; Cui, M.-J.; Wu, S.-F.; Yang, Y.; Chu, J. Retarding effect of concentration of cementation solution on biocementation of soil. Acta Geotech. 2021, 16, 3457–3469. [Google Scholar] [CrossRef]

- Li, X.; Qin, D.; Hu, Y.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A systematic review of waste materials in cement-based composites for construction applications. J. Build. Eng. 2022, 45, 103447. [Google Scholar] [CrossRef]

- Lu, L.; Ma, Q.; Hu, J.; Li, Q. Mechanical properties, curing mechanism, and microscopic experimental study of polypropylene fiber coordinated fly ash modified cement–silty soil. Materials 2021, 14, 5441. [Google Scholar] [CrossRef]

- Ma, J.; Su, Y.; Liu, Y.; Tao, X. Strength and microfabric of expansive soil improved with rice husk ash and lime. Adv. Civ. Eng. 2020, 2020, 9646205. [Google Scholar] [CrossRef]

- Natarajan, S.; Jeelani, S.H.; Sunagar, P.; Magade, S.; Salvi, S.S.; Bhattacharya, S. Investigating conventional concrete using rice husk ash (RHA) as a substitute for finer aggregate. J. Phys. 2022, 2272, 012030. [Google Scholar] [CrossRef]

- Yin, G.-J.; Wen, X.-D.; Miao, L.; Cui, D.; Zuo, X.-B.; Tang, Y.-J. A review on the transport-chemo-mechanical behavior in concrete under external sulfate attack. Coatings 2023, 13, 174. [Google Scholar] [CrossRef]

- Ou, K.-L.; Hou, P.-J.; Huang, B.-H.; Chou, H.-H.; Yang, T.-S.; Huang, C.-F.; Ueno, T. Bone healing and regeneration potential in rabbit cortical defects using an innovative bioceramic bone graft substitute. Appl. Sci. 2020, 12, 446. [Google Scholar] [CrossRef]

- Pradhan, S.S.; Mishra, U.; Biswal, S.K. Influence of RHA on strength and durability properties of alkali activated concrete. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Pushpakumara, B.H.J.; Mendis, W.S.W. Suitability of rice husk ash (RHA) with lime as a soil stabilizer in geotechnical applications. Int. J. Geo-Eng. 2020, 13, 169. [Google Scholar] [CrossRef]

- Raheem, A.A.; Anifowose, M.A. Effect of ash fineness and content on consistency and setting time of RHA blended cement. Mater. Today Proc. 2023, 86, 18–23. [Google Scholar] [CrossRef]

- Raman, R.S.; Lavanya, C.; Revathi, V.; Nijhawan, G.; Yadav, D.K.; Mohammad, Q.; Sethi, V.A. Optimization of RHA and cement proportion for soil stabilization. E3S Web of Conf. 2024, 529, 01015. [Google Scholar] [CrossRef]

- Sachdeva, N.; Shrivastava, N. Sustainable use of solid waste as additives in soil stabilization: A state-of-art review. Evergreen 2023, 10, 2536–2558. [Google Scholar] [CrossRef]

- Sharma, M.; Kumar, A. Soil stabilization using rice husk ash and coir fibre. Int. J. Innov. Res. Eng. Manag. 2022, 9, 13. [Google Scholar] [CrossRef]

- ASTM C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. National Standard of the People’s Republic of China: Beijing, China, 2022.

- ASTM C1012; Standard Test Method for Length Change of Hydraulic-Cement Mortars Exposed to a Sulfate Solution. National Standard of the People’s Republic of China: Beijing, China, 2024.

| Component/Property | RHA | SF |

|---|---|---|

| Major Oxides | ||

| SiO2 (Silica) | 80–93% | 85–99% |

| Carbon (Unburnt Residue) | 5–15% (depends on combustion) | <3% (high-purity SF) |

| K2O (Potassium Oxide) | 1–5% | <0.5% |

| CaO (Calcium Oxide) | 0.5–3% | 0.1–1% |

| Minor Oxides | ||

| Al2O3 (Alumina) | 0.5–2% | 0.2–1.5% |

| Fe2O3 (Iron Oxide) | 0.3–1.5% | 0.1–1% |

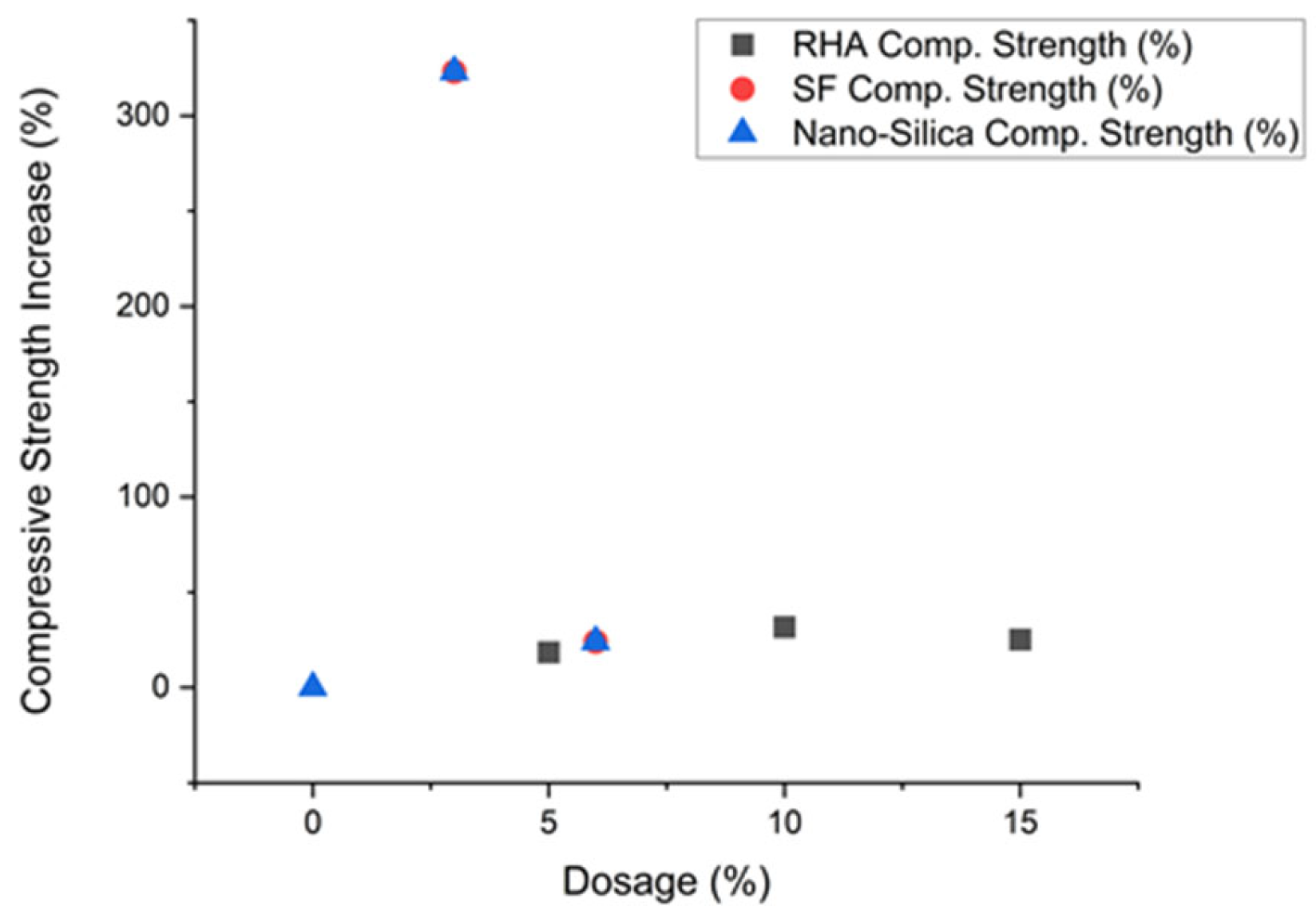

| Property | RHA Performance | SF Performance | Nano-Silica Performance | Key Findings |

|---|---|---|---|---|

| Optimal Dosage | 10% | 2–6% | 1–3% | SF shows higher efficiency at lower dosages |

| Compressive Strength | +31.7% at 10% | +250% at 6% | +323% at 3% | Nano-silica > SF > RHA in strength gain |

| Tensile Strength | Improved (fibrous nature) | Improved (pore filling) | - | RHA enhances crack resistance |

| Modulus of Elasticity | Increased | Increased | - | Better stiffness for high-stress applications |

| Mechanism | Fibrous structure absorbs energy | Ultra-fine particles fill voids | Nanoparticles nucleate C-S-H | SF acts faster, RHA provides long-term benefits |

| Property | Mechanism | Improvement (%) | Optimal Dosage |

|---|---|---|---|

| Water Permeability | SF refines capillary pores (0.1–0.5 μm) | ↓ 40–50% | SF: 7–10% |

| Water Absorption | RHA pozzolanic products clog pores | ↓ 30–35% (90 days) | RHA: 10–15% |

| Chloride Diffusion | SF densifies matrix, reduces pore connectivity | ↓ 50% (5 years, marine) | SF: 7–12% |

| Sulfate Resistance | RHA–SF reduces Ca(OH)2, limits sulfate ingress | Expansion ↓ 60–70% | RHA: 15% + SF: 7% |

| Acid Resistance | Modified C-S-H stability (pH 2–4) | Service life ↑ 3× | RHA: 10% + SF: 5% |

| Freeze–Thaw Resistance | Pore refinement reduces ice formation | Cycles to failure ↑ 3–4× | SF: 8–10% |

| Carbonation Depth | Reduced porosity limits CO2 ingress | ↓ 30–40% | RHA: 10–15% |

| Chloride-Induced Corrosion | Synergistic RHA–SF reduces Cl− mobility | Corrosion delay ↑ 5–8× | RHA: 15% + SF: 7% |

| Mechanism | Performance Metric | Conventional Cement | RHA/SF System | Reduction |

|---|---|---|---|---|

| Production Emissions | CO2 per kg of material | 0.89 kg | 0.18 kg (RHA) | 80% |

| Clinker Replacement | Typical replacement level | 0% | 15–25% (RHA) 5–10% (SF) | 20–35% |

| Durability | Chloride permeability reduction | Baseline | 30–50% ↓ | — |

| Sulfate attack resistance improvement | Baseline | 40–60% ↑ | — | |

| Life-Cycle Savings | Emissions per year of service | 100% | 75–85% | 15–25% |

| Curing Energy | Temperature reduction | 0 °C | 20–30 °C ↓ | — |

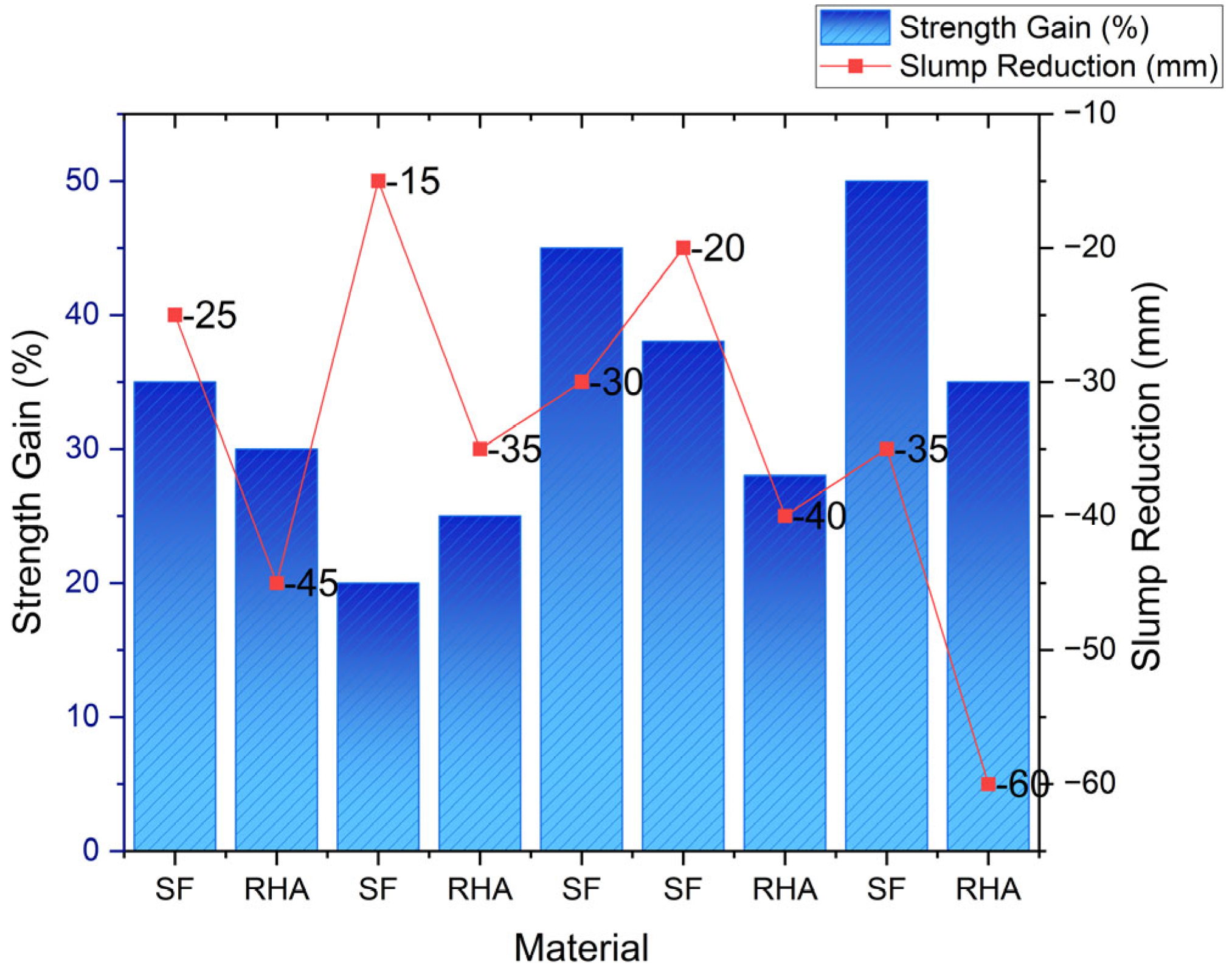

| Application | Material | Optimal Dosage (% Cement Mass) | Strength Gain (Mpa) | Workability Impact | Key Considerations |

|---|---|---|---|---|---|

| High-strength concrete | SF | 5–8% | 29.55 | ΔSlump = −20–30 mm | Use PCE superplasticizers (0.8–1.2% dosage) |

| RHA | 10–12% | 24.65 | ΔSlump = −40–50 mm | Pre-wet RHA to reduce water demand | |

| Mass concrete | SF | 3–5% | 14.75 | ΔSlump = −10–20 mm | Controls thermal cracking |

| RHA | 7–10% | 19.7 | ΔSlump = −30–40 mm | Enhances long-term durability | |

| Shotcrete | SF | 6–9% | 34.5 | ΔSlump = −25–35 mm | Requires set accelerators |

| RHA | Not recommended | - | - | High absorption causes rebound losses | |

| Precast elements | SF | 4–6% | 24.6 | ΔSlump = −15–25 mm | Enables early demolding |

| RHA | 8–10% | 19.7 | ΔSlump = −35–45 mm | Combine with 2% nano-silica for faster setting | |

| Marine/chloride exposure | SF | 7–10% | 39.45 | ΔSlump = −30–40 mm | Critical for chloride binding |

| RHA | 12–15% | 29.6 | ΔSlump = −50–70 mm | Synergistic with SF (1:2 ratio optimal) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, X.; Rahman, M.M.; Sun, Y.; Zhao, Y.; Wang, J. Sustainable Soil–Cement Composites with Rice Husk Ash and Silica Fume: A Review of Performance and Environmental Benefits. Materials 2025, 18, 2880. https://doi.org/10.3390/ma18122880

Yin X, Rahman MM, Sun Y, Zhao Y, Wang J. Sustainable Soil–Cement Composites with Rice Husk Ash and Silica Fume: A Review of Performance and Environmental Benefits. Materials. 2025; 18(12):2880. https://doi.org/10.3390/ma18122880

Chicago/Turabian StyleYin, Xiaosan, Md Mashiur Rahman, Yuzhou Sun, Yi Zhao, and Jian Wang. 2025. "Sustainable Soil–Cement Composites with Rice Husk Ash and Silica Fume: A Review of Performance and Environmental Benefits" Materials 18, no. 12: 2880. https://doi.org/10.3390/ma18122880

APA StyleYin, X., Rahman, M. M., Sun, Y., Zhao, Y., & Wang, J. (2025). Sustainable Soil–Cement Composites with Rice Husk Ash and Silica Fume: A Review of Performance and Environmental Benefits. Materials, 18(12), 2880. https://doi.org/10.3390/ma18122880