Interface Block and Microstructure Evolution in Ultrasonic Welding of Aluminum

Abstract

1. Introduction

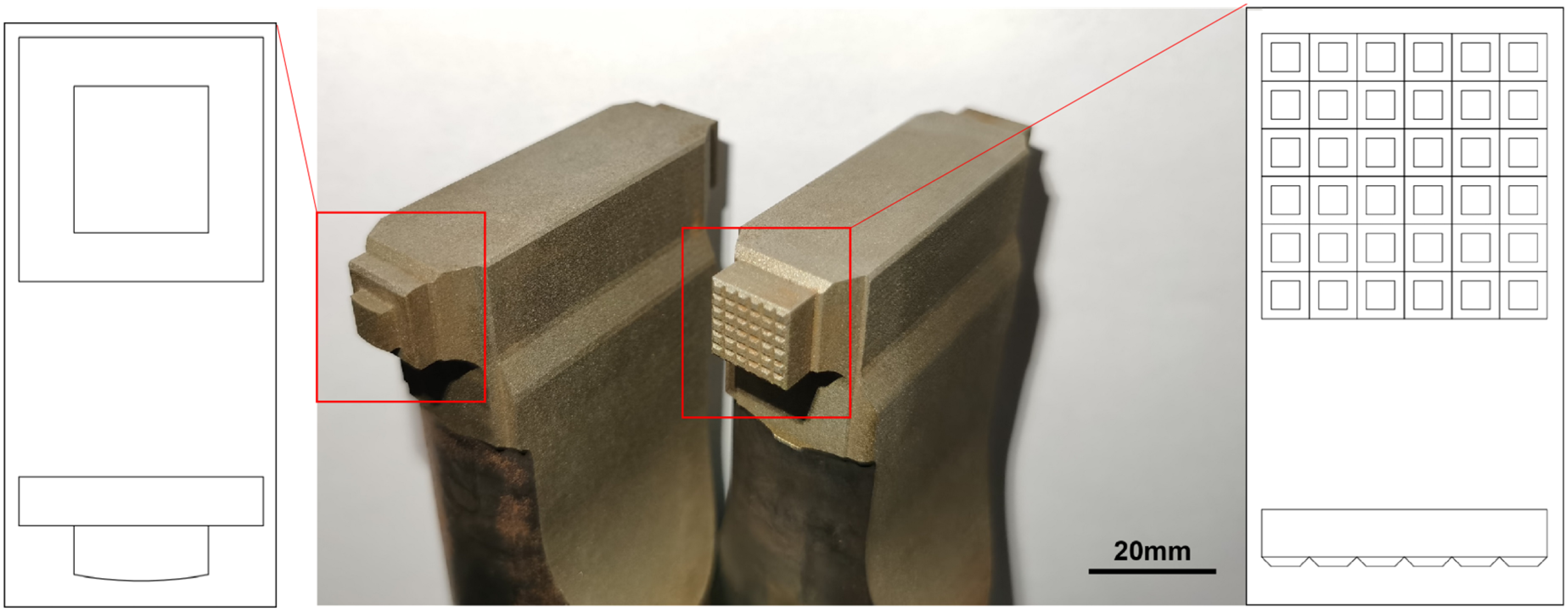

2. Materials and Methods

3. Results and Discussion

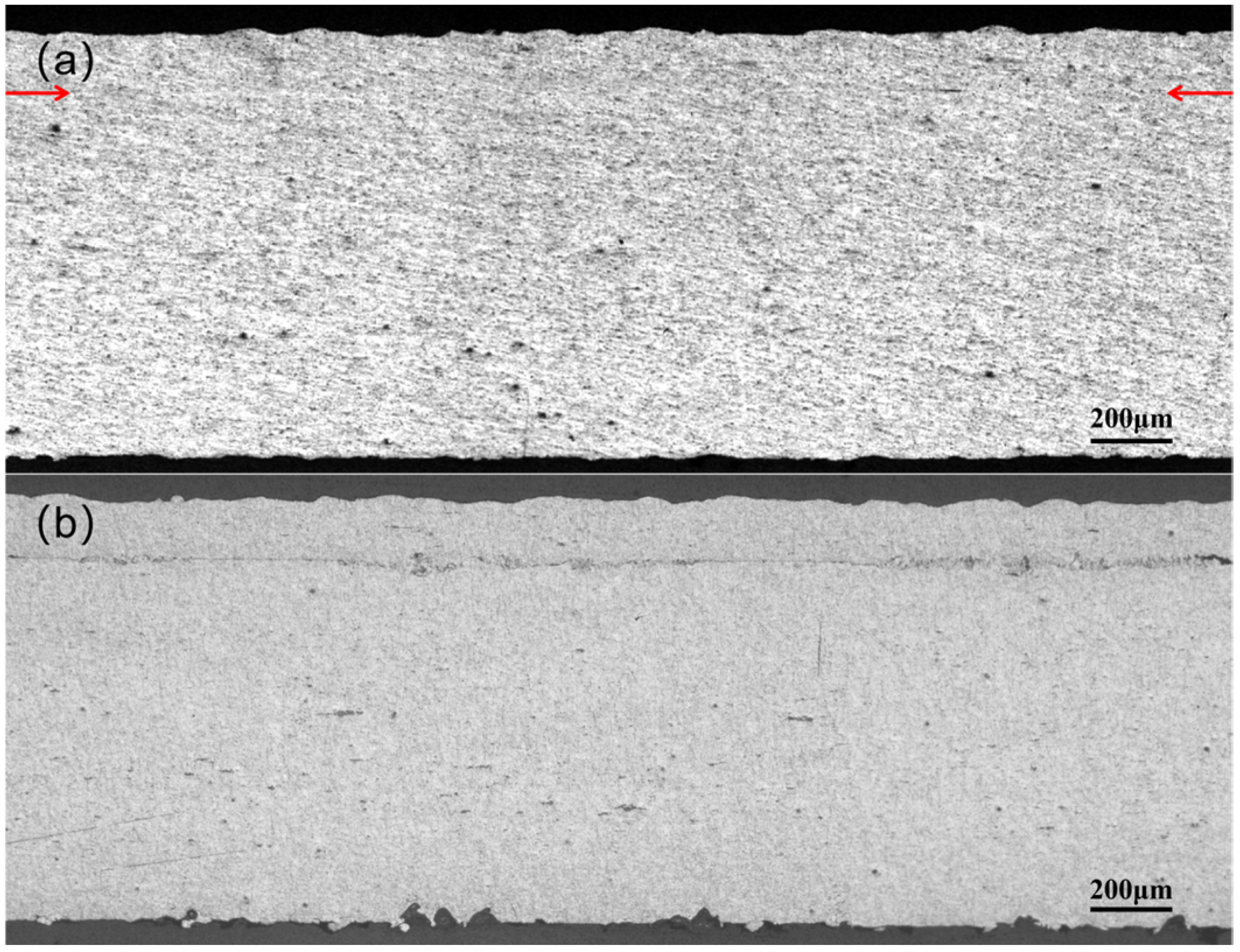

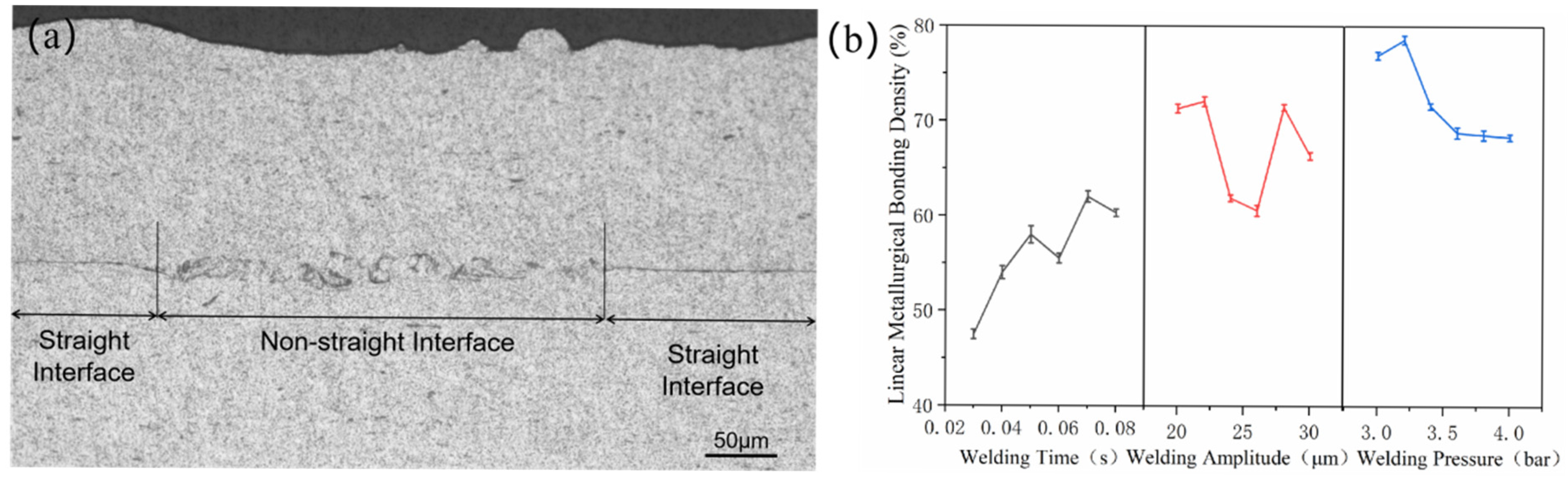

3.1. Microstructure of the Interface

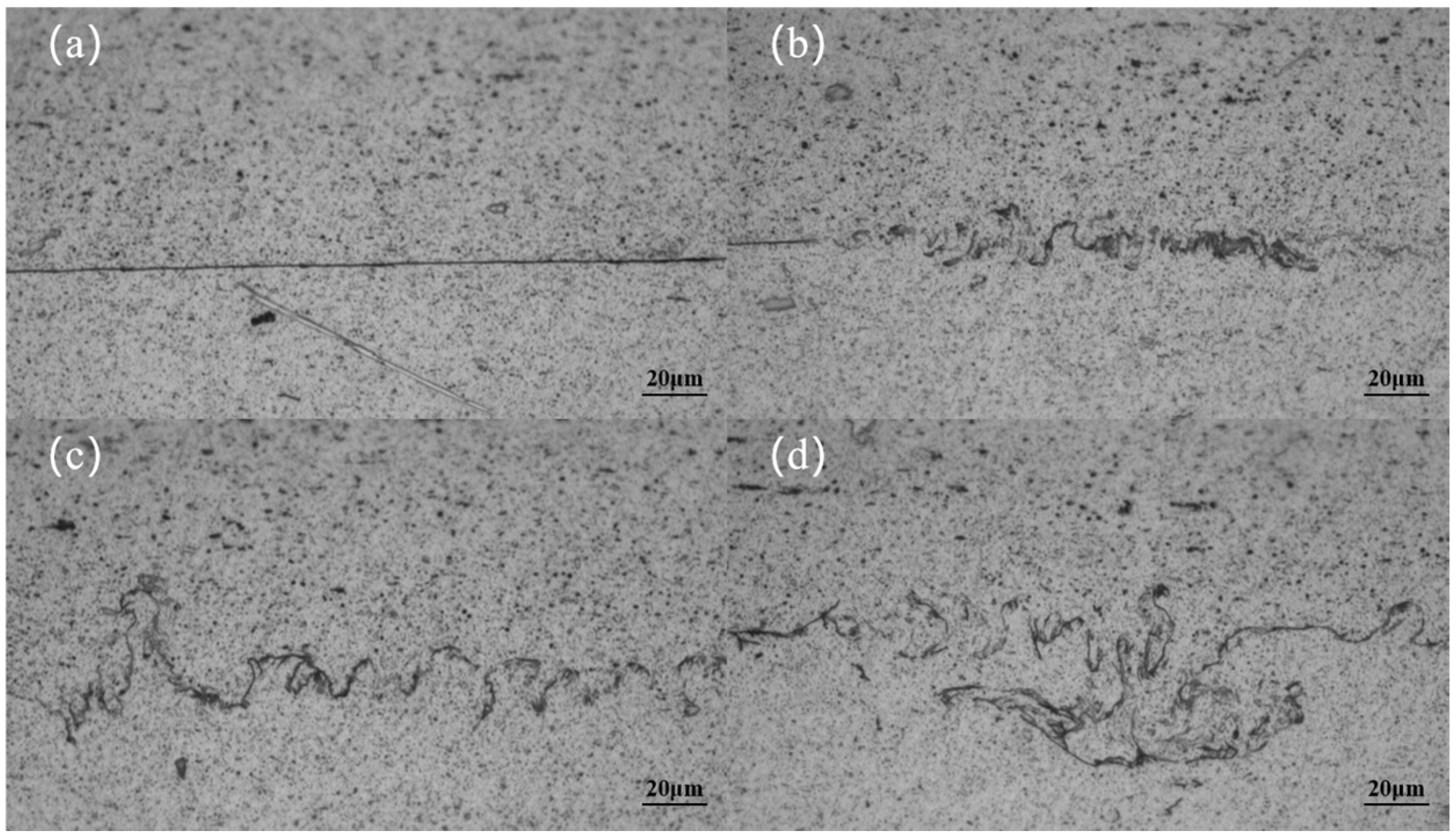

3.2. Microstructure Evolution of the Interface

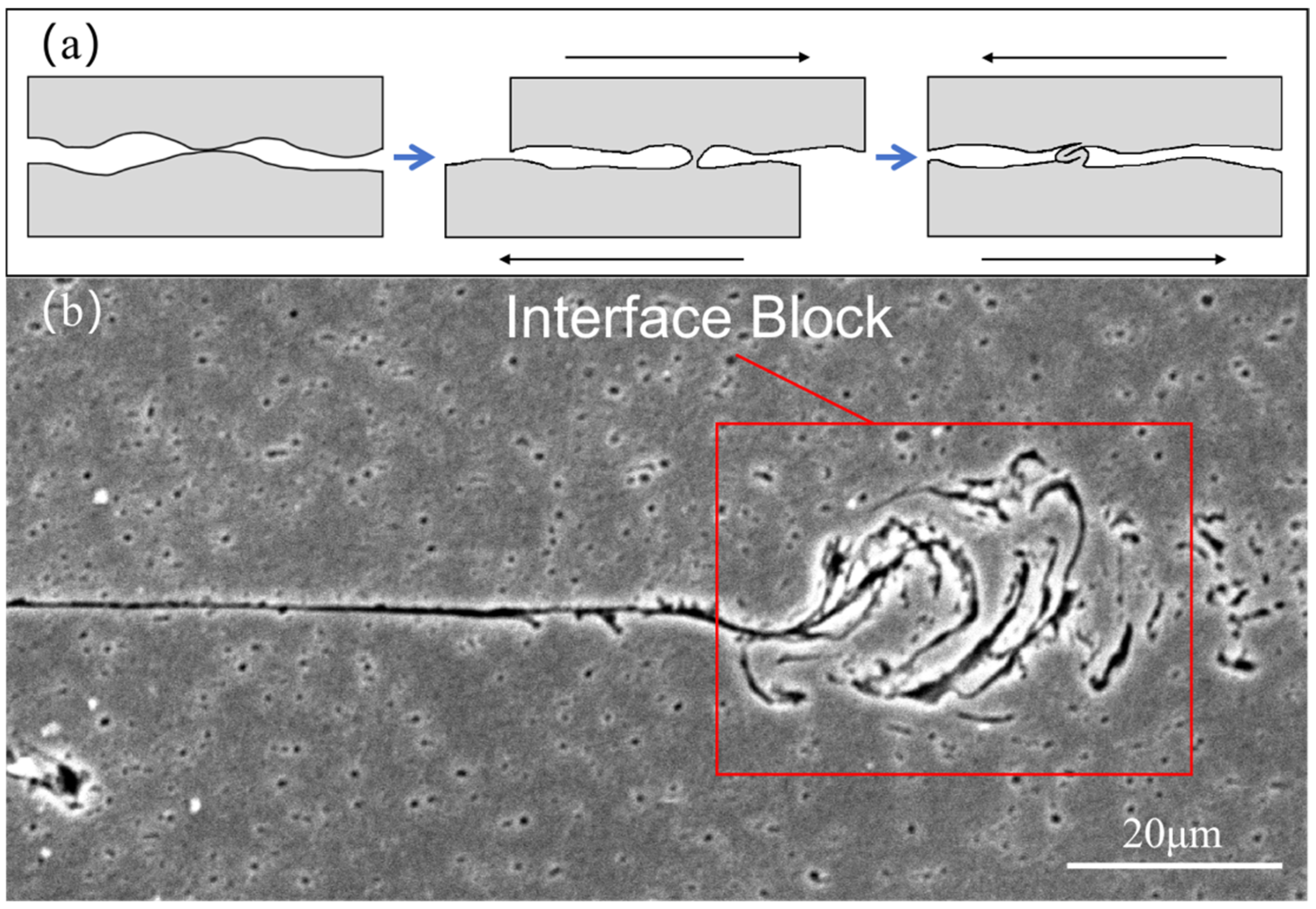

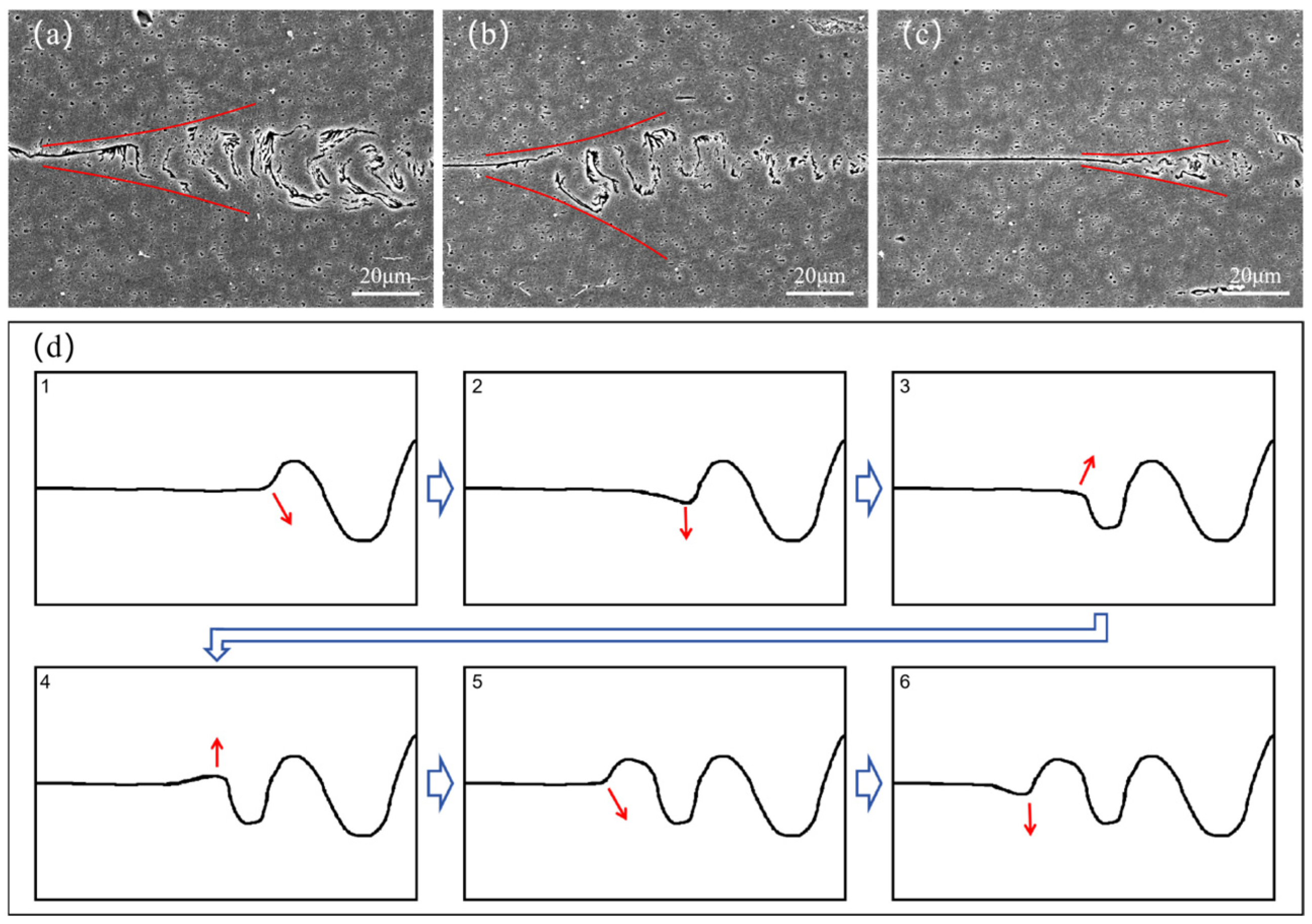

3.3. Bonding Mechanism and Plastic Flow

4. Conclusions

- The interface undergoes recrystallization after intense plastic deformation, resulting in a good metallurgical bonding. The LMD of the interface is found to be positively correlated with welding time and negatively correlated with welding pressure, while the effect of welding amplitude is complex.

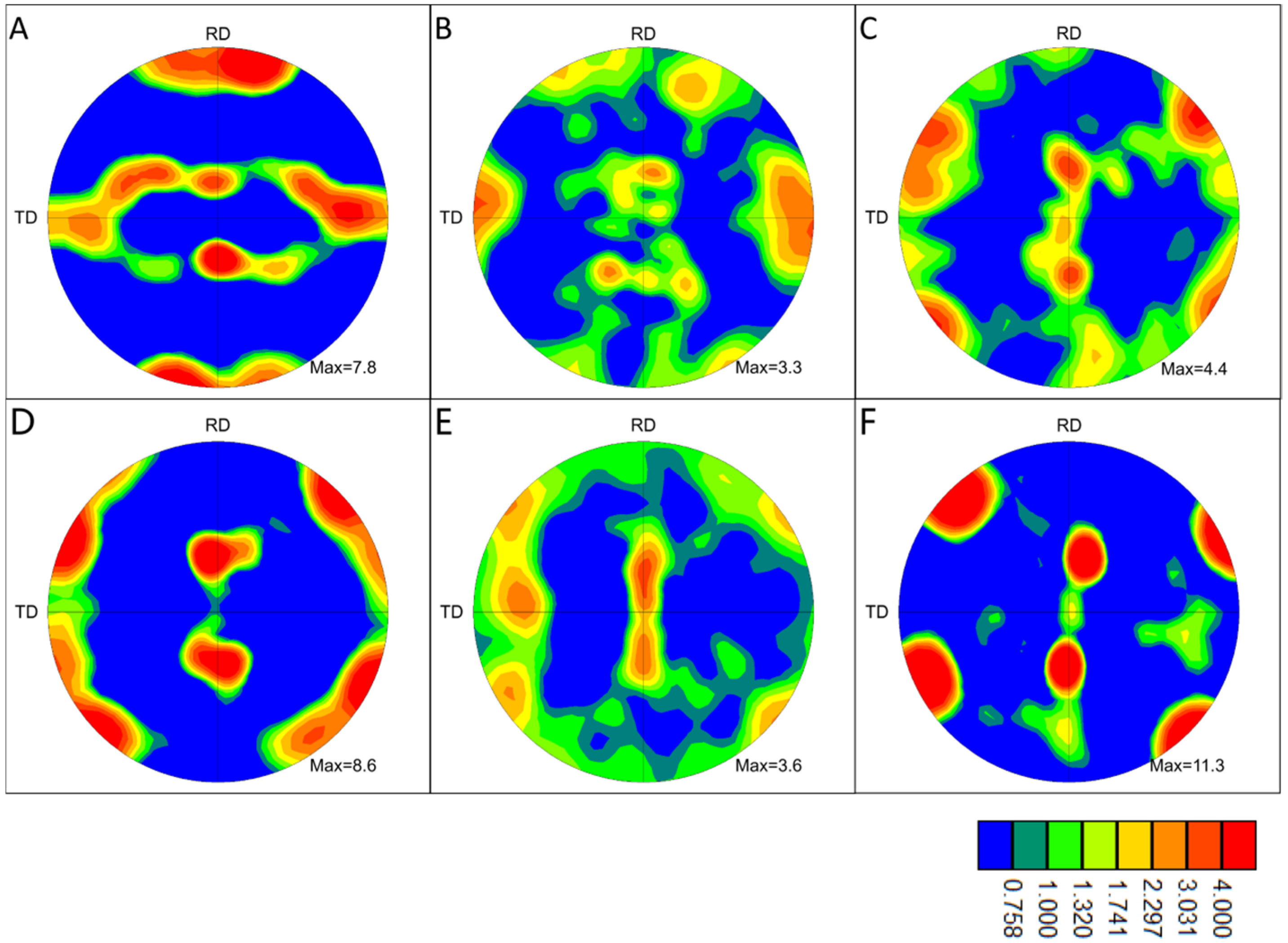

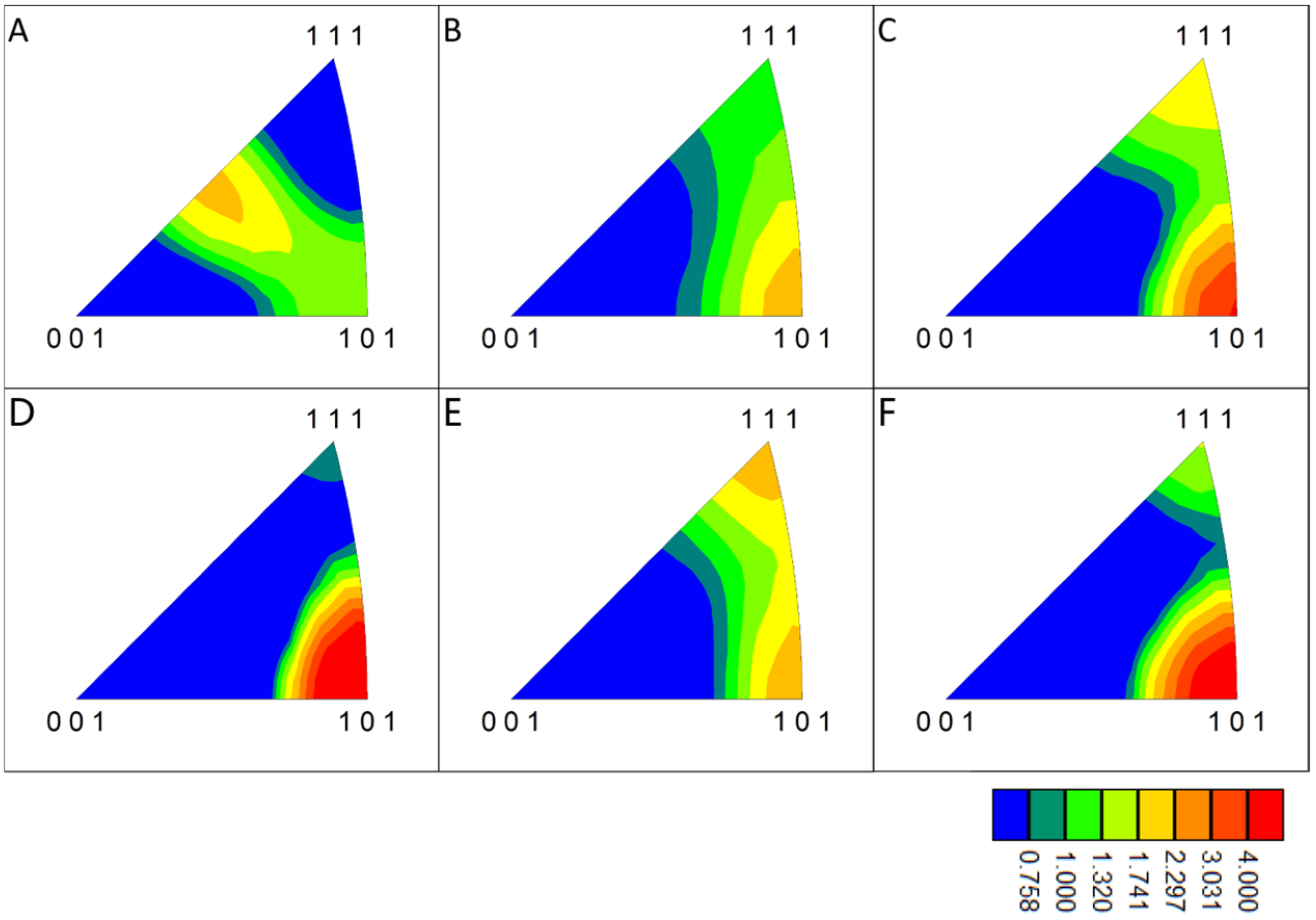

- The microstructure evolution of the weld interface was clarified. The material at the interface recrystallizes after intense plastic deformation and forms a recrystallization texture. After repeated deformation, the recrystallization texture develops into a new texture different from that in the original material. That is, it evolves in the order of original texture, recrystallization, recrystallized texture, and new texture.

- A mechanism of an interface block promoting the formation of metallurgical bonding at the interface is proposed. The obstruction of surface deformation by the interface block results in the formation of a non-straight interface. Following a series of microstructural evolutions, a metallurgical bonded interface is formed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abbas, Z.; Zhao, L.; Deng, J.; Wang, S.; Hong, W. Advances in ultrasonic welding of lightweight alloys: A review. High Temp. Mater. Process. 2023, 42, 20220298. [Google Scholar] [CrossRef]

- Kicukov, E.; Gursel, A. Ultrasonic welding of dissimilar materials: A review. Period. Eng. Nat. Sci. (PEN) 2015, 3, 28–36. [Google Scholar] [CrossRef]

- Friel, R.J.; Harris, R.A. Ultrasonic Additive Manufacturing—A Hybrid Production Process for Novel Functional Products. Procedia CIRP 2013, 6, 35–40. [Google Scholar] [CrossRef]

- Hehr, A.; Norfolk, M. A comprehensive review of ultrasonic additive manufacturing. Rapid Prototyp. J. 2019, 26, 445–458. [Google Scholar] [CrossRef]

- Sridharan, N.; Wolcott, P.; Dapino, M.; Babu, S.S. Microstructure and texture evolution in aluminum and commercially pure titanium dissimilar welds fabricated using ultrasonic additive manufacturing. Scr. Mater. 2016, 117, 1–5. [Google Scholar] [CrossRef]

- Wolcott, P.J.; Sridharan, N.; Babu, S.S.; Miriyev, A.; Frage, N.; Dapino, M.J. Characterisation of Al–Ti dissimilar material joints fabricated using ultrasonic additive manufacturing. Sci. Technol. Weld. Join. 2016, 21, 114–123. [Google Scholar] [CrossRef]

- Deng, Z.; Gingerich, M.B.; Han, T.; Dapino, M.J. Yttria-stabilized zirconia-aluminum matrix composites via ultrasonic additive manufacturing. Compos. Part B Eng. 2018, 151, 215–221. [Google Scholar] [CrossRef]

- James, S.; Dang, C. Investigation of shear failure load in ultrasonic additive manufacturing of 3D CFRP/Ti structures. J. Manuf. Process. 2020, 56, 1317–1321. [Google Scholar] [CrossRef]

- Chen, X.; Hehr, A.; Dapino, M.J.; Anderson, P.M. Deformation Mechanisms in NiTi-Al Composites Fabricated by Ultrasonic Additive Manufacturing. Shape Mem. Superelast. 2015, 1, 294–309. [Google Scholar] [CrossRef]

- McMickell, M.B.; Hahnlen, R.; Farinholt, K.M.; Dapino, M.J. Active metal-matrix composites with embedded smart materials by ultrasonic additive manufacturing. In Proceedings of the Industrial and Commercial Applications of Smart Structures Technologies, San Diego, CA, USA, 8–9 March 2010. [Google Scholar]

- Hehr, A.; Norfolk, M.; Wenning, J.; Sheridan, J.; Leser, P.; Leser, P.; Newman, J.A. Integrating Fiber Optic Strain Sensors into Metal Using Ultrasonic Additive Manufacturing. JOM 2017, 70, 315–320. [Google Scholar] [CrossRef]

- Hyer, H.C.; Sweeney, D.C.; Petrie, C.M. Functional fiber-optic sensors embedded in stainless steel components using ultrasonic additive manufacturing for distributed temperature and strain measurements. Addit. Manuf. 2022, 52, 102681. [Google Scholar] [CrossRef]

- Bournias-Varotsis, A.; Friel, R.J.; Harris, R.A.; Engstrøm, D.S. Ultrasonic Additive Manufacturing as a form-then-bond process for embedding electronic circuitry into a metal matrix. J. Manuf. Process. 2018, 32, 664–675. [Google Scholar] [CrossRef]

- Li, J.; Monaghan, T.; Nguyen, T.T.; Kay, R.W.; Friel, R.J.; Harris, R.A. Multifunctional metal matrix composites with embedded printed electrical materials fabricated by ultrasonic additive manufacturing. Compos. Part B Eng. 2017, 113, 342–354. [Google Scholar] [CrossRef]

- Bournias-Varotsis, A.; Wang, S.; Hutt, D.; Engstrøm, D.S. The Effect of Ultrasonic Additive Manufacturing on Integrated Printed Electronic Conductors. Electron. Mater. Lett. 2018, 14, 413–425. [Google Scholar] [CrossRef]

- Han, T.; Kuo, C.-H.; Sridharan, N.; Headings, L.M.; Babu, S.S.; Dapino, M.J. Effect of weld power and interfacial temperature on mechanical strength and microstructure of carbon steel 4130 fabricated by ultrasonic additive manufacturing. Manuf. Lett. 2020, 25, 64–69. [Google Scholar] [CrossRef]

- Liao, J.-C.; Chung, Y.-T.; Huang, J.-R.; Wong, P.-C.; Lin, J.-Y. Influence of weld size on energy input and interfacial strength during dissimilar ultrasonic welding of stainless steel to titanium. J. Mater. Process. Technol. 2025, 337, 118727. [Google Scholar] [CrossRef]

- Dehoff, R.R.; Babu, S.S. Characterization of interfacial microstructures in 3003 aluminum alloy blocks fabricated by ultrasonic additive manufacturing. Acta Mater. 2010, 58, 4305–4315. [Google Scholar] [CrossRef]

- Fujii, H.T.; Sriraman, M.R.; Babu, S.S. Quantitative Evaluation of Bulk and Interface Microstructures in Al-3003 Alloy Builds Made by Very High Power Ultrasonic Additive Manufacturing. Metall. Mater. Trans. A 2011, 42, 4045–4055. [Google Scholar] [CrossRef]

- Zhang, C.; Li, H.; Liu, Q.; Huang, C.; Zhou, K. Ultrasonic Welding of Aluminum to Steel: A Review. Metals 2022, 13, 29. [Google Scholar] [CrossRef]

- Sriraman, M.R.; Babu, S.S.; Short, M. Bonding characteristics during very high power ultrasonic additive manufacturing of copper. Scr. Mater. 2010, 62, 560–563. [Google Scholar] [CrossRef]

- Li, Z.; Wu, S.; Li, H. Advances in Experimentation and Numerical Modeling of Aluminum and Copper Ultrasonic Welding. Micromachines 2025, 16, 263. [Google Scholar] [CrossRef] [PubMed]

- Ni, Z.; Ma, J.; Nazarov, A.A.; Yuan, Z.; Wang, X.; Ao, S.; Ji, H.; Guo, P.; Qin, J. Improving the weldability and mechanical property of ultrasonic spot welding of Cu sheets through a surface gradient structure. J. Mater. Res. Technol. 2025, 36, 2652–2668. [Google Scholar] [CrossRef]

- Wu, W.; Jiang, J.; Li, G.; Fuh, J.Y.H.; Jiang, H.; Gou, P.; Zhang, L.; Liu, W.; Zhao, J. Ultrasonic additive manufacturing of bulk Ni-based metallic glass. J. Non-Cryst. Solids 2019, 506, 1–5. [Google Scholar] [CrossRef]

- Li, G.; Zhao, J.; Fuh, J.Y.H.; Wu, W.; Jiang, J.; Wang, T.; Chang, S. Experiments on the Ultrasonic Bonding Additive Manufacturing of Metallic Glass and Crystalline Metal Composite. Materials 2019, 12, 2975. [Google Scholar] [CrossRef]

- Massey, C.P.; Havrilak, C.J.; Gussev, M.N.; Terrani, K.A.; Nelson, A.T. Ultrasonic additive manufacturing of zirconium: Pilot results. Mater. Lett. 2021, 302, 130330. [Google Scholar] [CrossRef]

- Patel, V.K.; Bhole, S.D.; Chen, D.L. Influence of ultrasonic spot welding on microstructure in a magnesium alloy. Scr. Mater. 2011, 65, 911–914. [Google Scholar] [CrossRef]

- Qi, H.; Ye, F.; Lu, H. Visualization of plastic flow in metal ultrasonic welding by adding interlayer. J. Manuf. Process. 2022, 83, 571–575. [Google Scholar] [CrossRef]

- Fujii, H.T.; Shimizu, S.; Sato, Y.S.; Kokawa, H. High-strain-rate deformation in ultrasonic additive manufacturing. Scr. Mater. 2017, 135, 125–129. [Google Scholar] [CrossRef]

- Shimizu, S.; Fujii, H.T.; Sato, Y.S.; Kokawa, H.; Sriraman, M.R.; Babu, S.S. Mechanism of weld formation during very-high-power ultrasonic additive manufacturing of Al alloy 6061. Acta Mater. 2014, 74, 234–243. [Google Scholar] [CrossRef]

| Welding Pressure | Welding Amplitude | Welding Time | |

|---|---|---|---|

| Group 1 | 3–4 bar | 20 μm | 0.05 s |

| Group 2 | 4 bar | 20–30 μm | 0.05 s |

| Group 3 | 4 bar | 20 μm | 0.03–0.08 s |

| Average Grain Size (μm) | Maximum Grain Size (μm) | Standard Deviation (μm) | |

|---|---|---|---|

| Area A | 1.38 | 8.61 | 0.66 |

| Area B | 1.22 | 2.44 | 0.35 |

| Area C | 1.22 | 2.59 | 0.39 |

| Area D | 1.37 | 5.24 | 0.65 |

| Area E | 1.30 | 3.00 | 0.45 |

| Area F | 1.49 | 6.57 | 0.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, H.; Ye, F.; Wang, Y.; Sun, K. Interface Block and Microstructure Evolution in Ultrasonic Welding of Aluminum. Materials 2025, 18, 2853. https://doi.org/10.3390/ma18122853

Qi H, Ye F, Wang Y, Sun K. Interface Block and Microstructure Evolution in Ultrasonic Welding of Aluminum. Materials. 2025; 18(12):2853. https://doi.org/10.3390/ma18122853

Chicago/Turabian StyleQi, Hang, Fuxing Ye, Yingfan Wang, and Kaiqi Sun. 2025. "Interface Block and Microstructure Evolution in Ultrasonic Welding of Aluminum" Materials 18, no. 12: 2853. https://doi.org/10.3390/ma18122853

APA StyleQi, H., Ye, F., Wang, Y., & Sun, K. (2025). Interface Block and Microstructure Evolution in Ultrasonic Welding of Aluminum. Materials, 18(12), 2853. https://doi.org/10.3390/ma18122853