Effects of Deformation Parameters on Phase Transformation of B1500HS High-Strength Steel During the Non-Isothermal Deformation Process

Abstract

1. Introduction

2. Materials and Methods

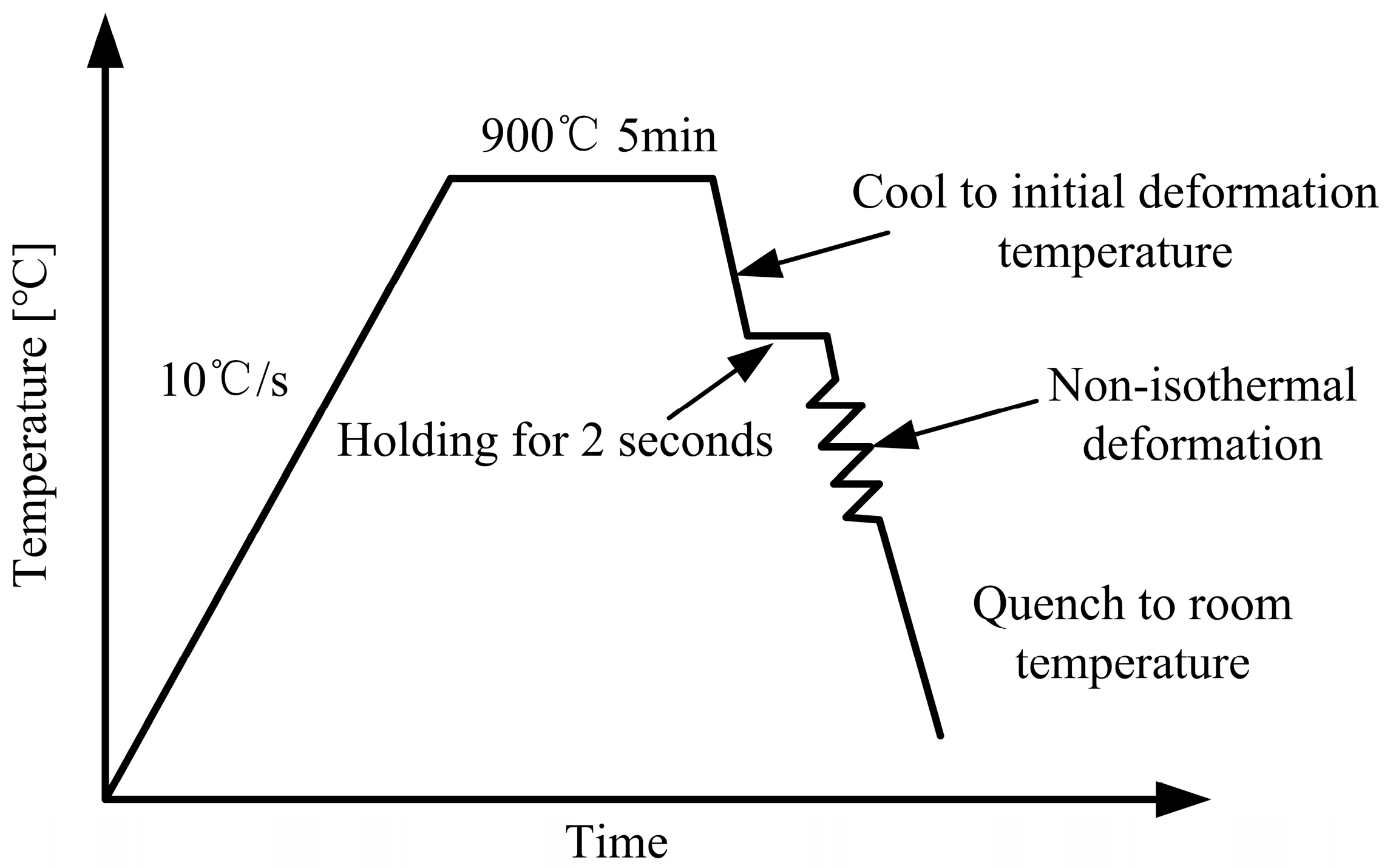

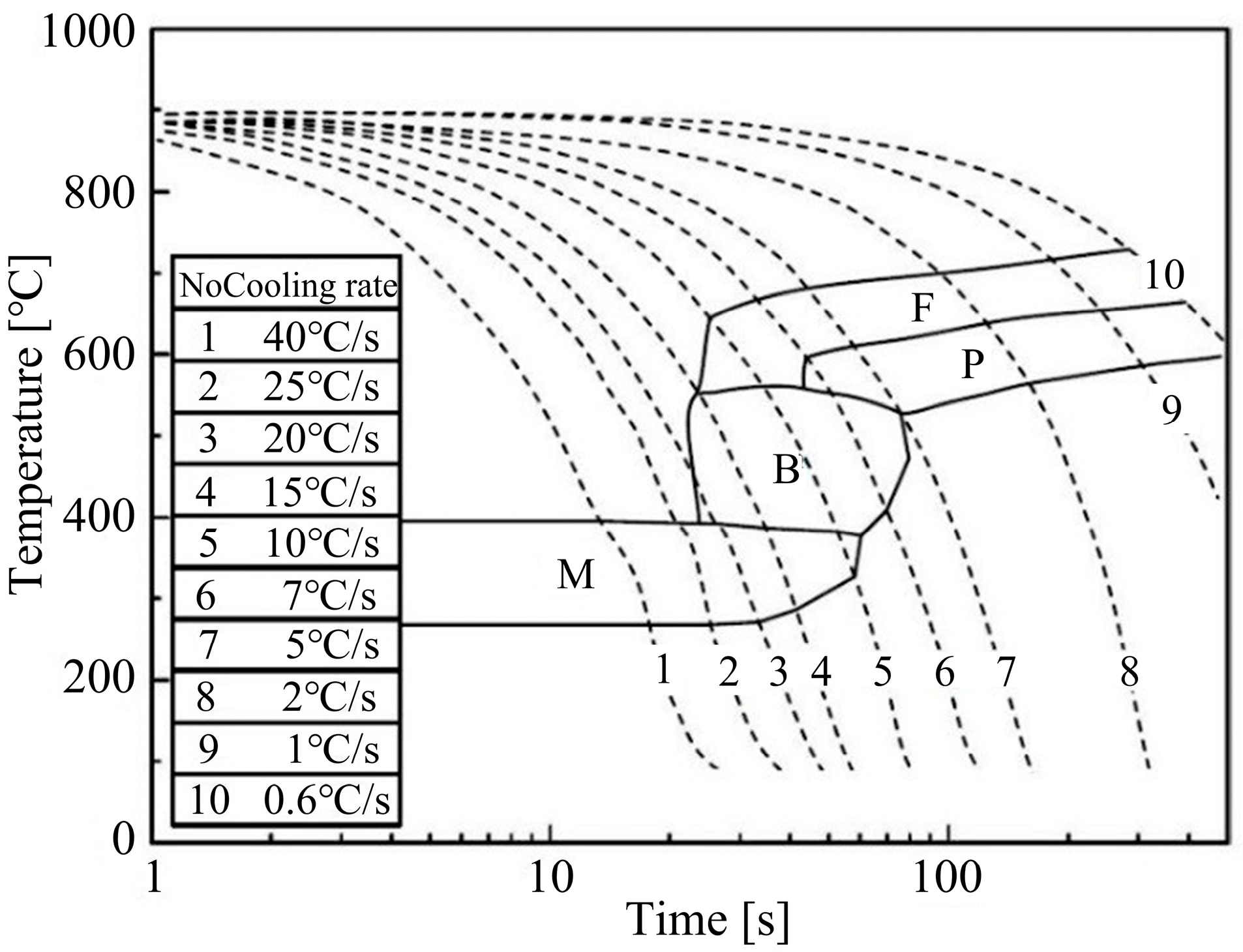

2.1. Non-Isothermal Deformation Test

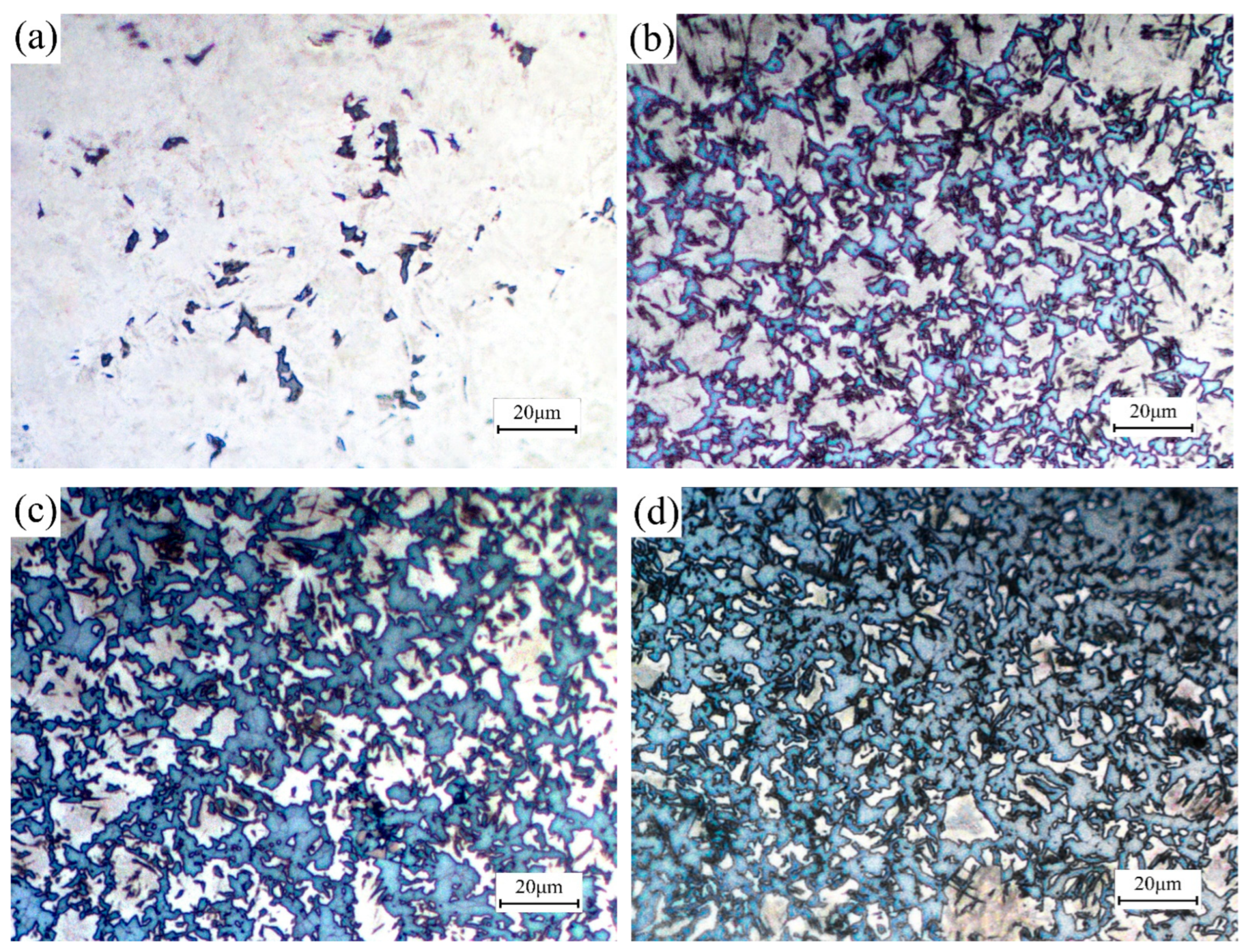

2.2. Microstructure

2.3. Hardness

3. Results and Discussion

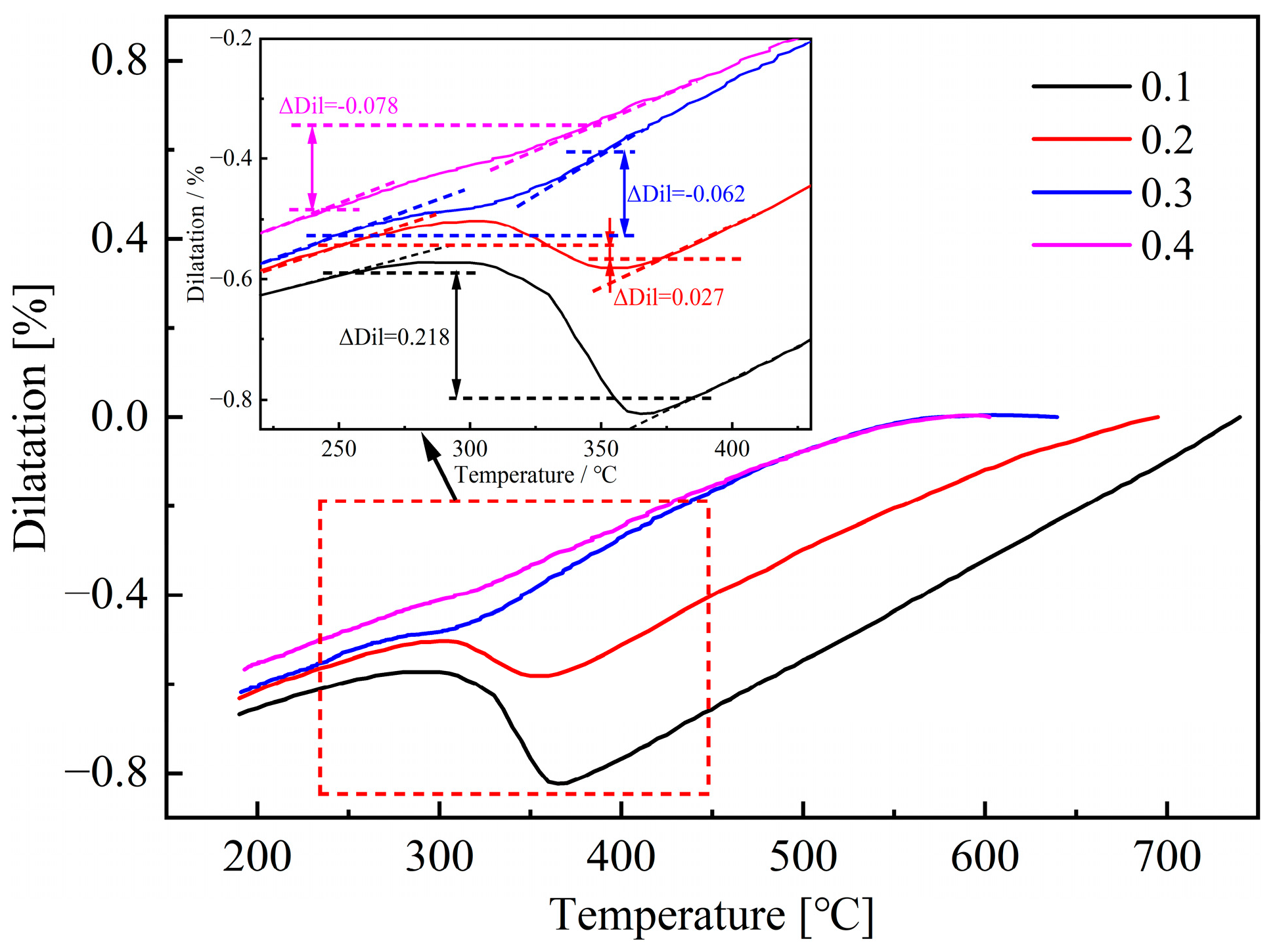

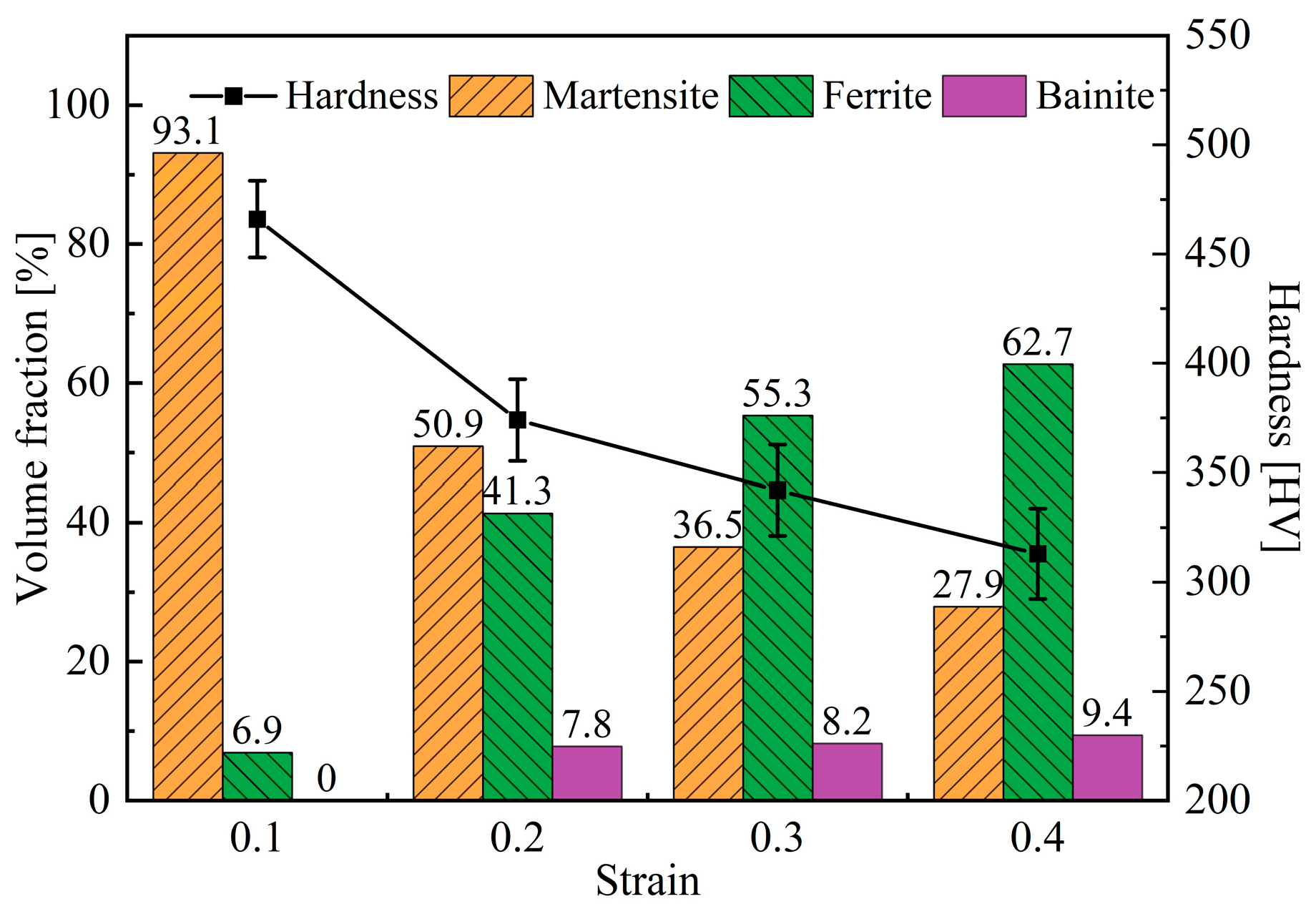

3.1. Effect of Strain

3.2. Effect of Initial Deformation Temperature

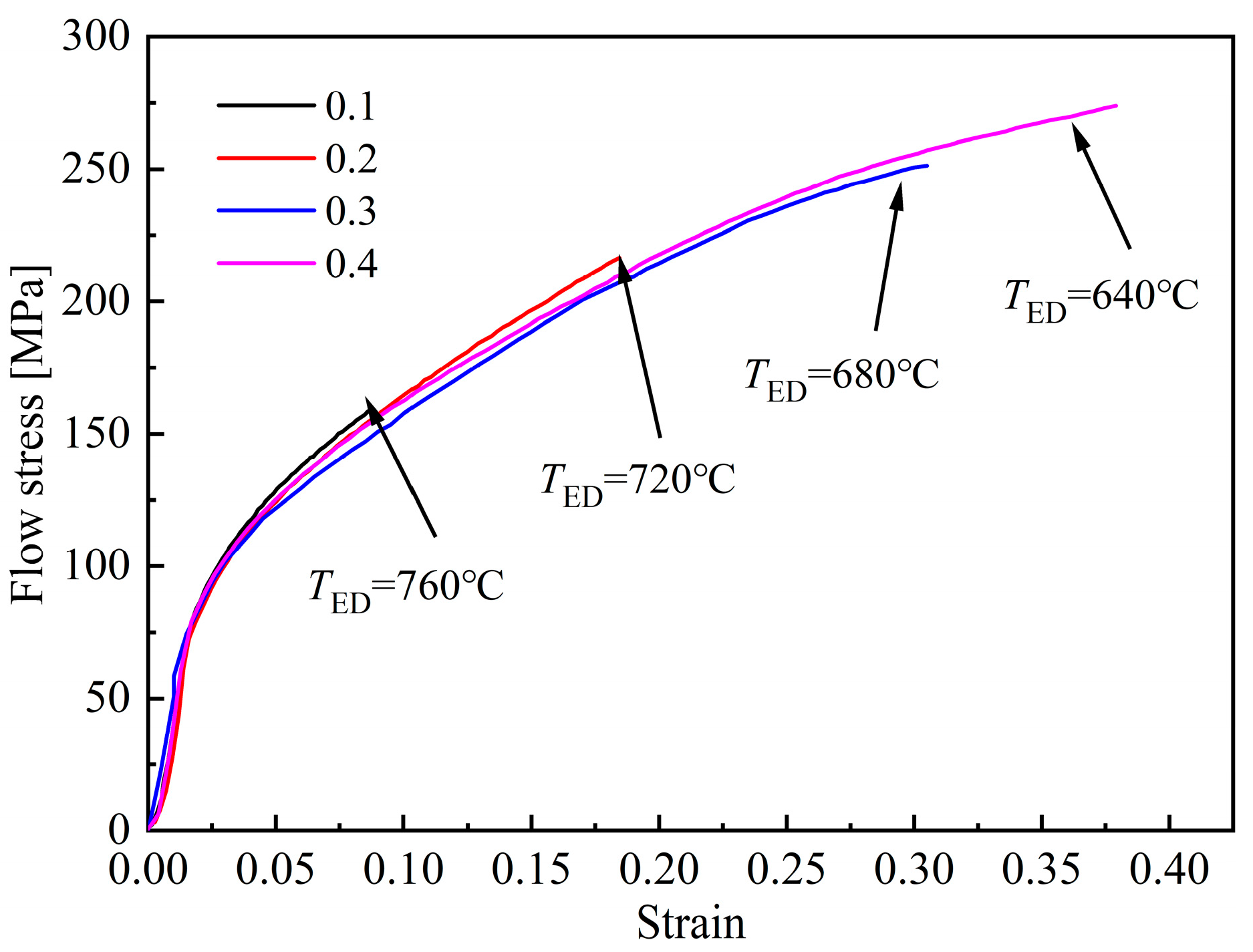

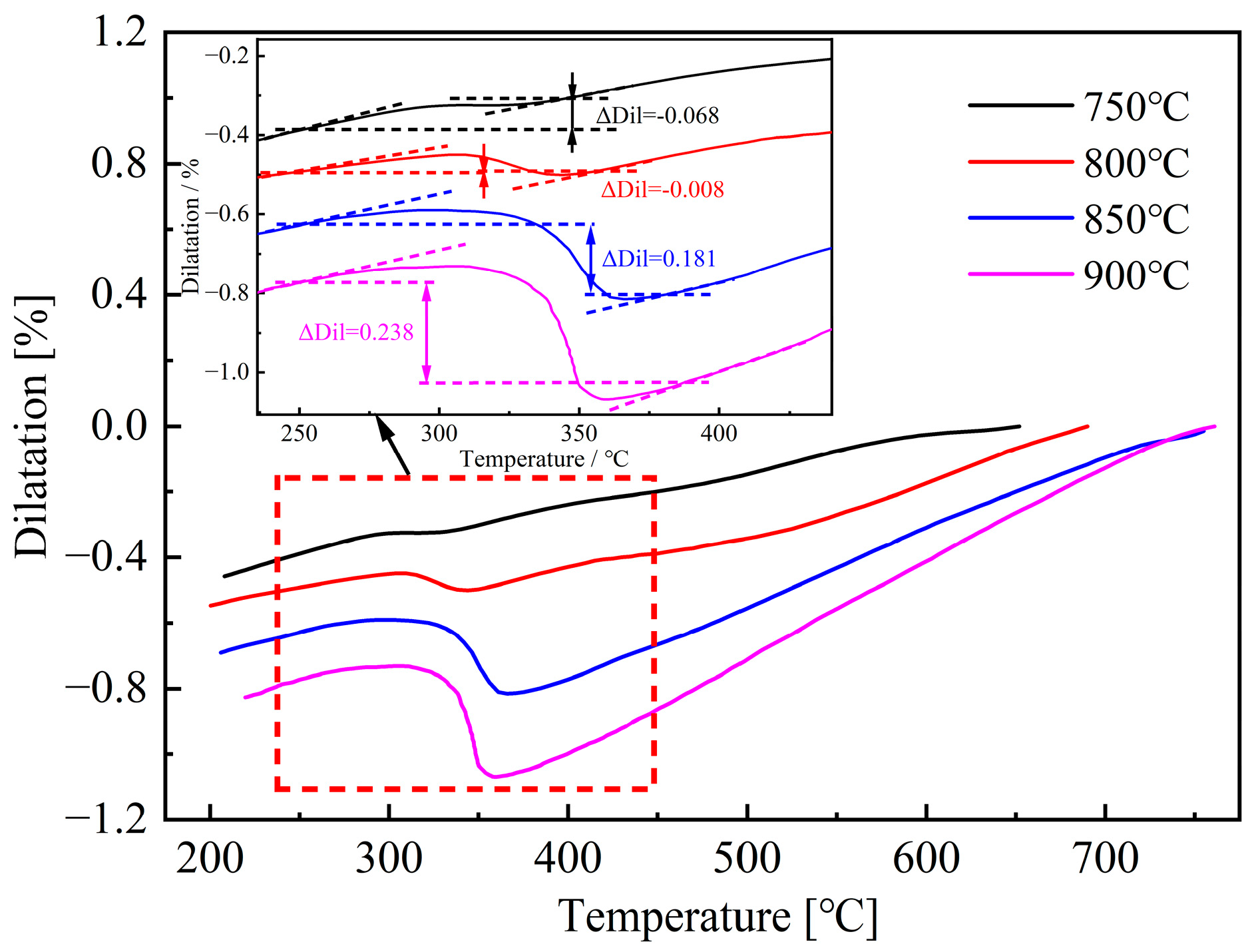

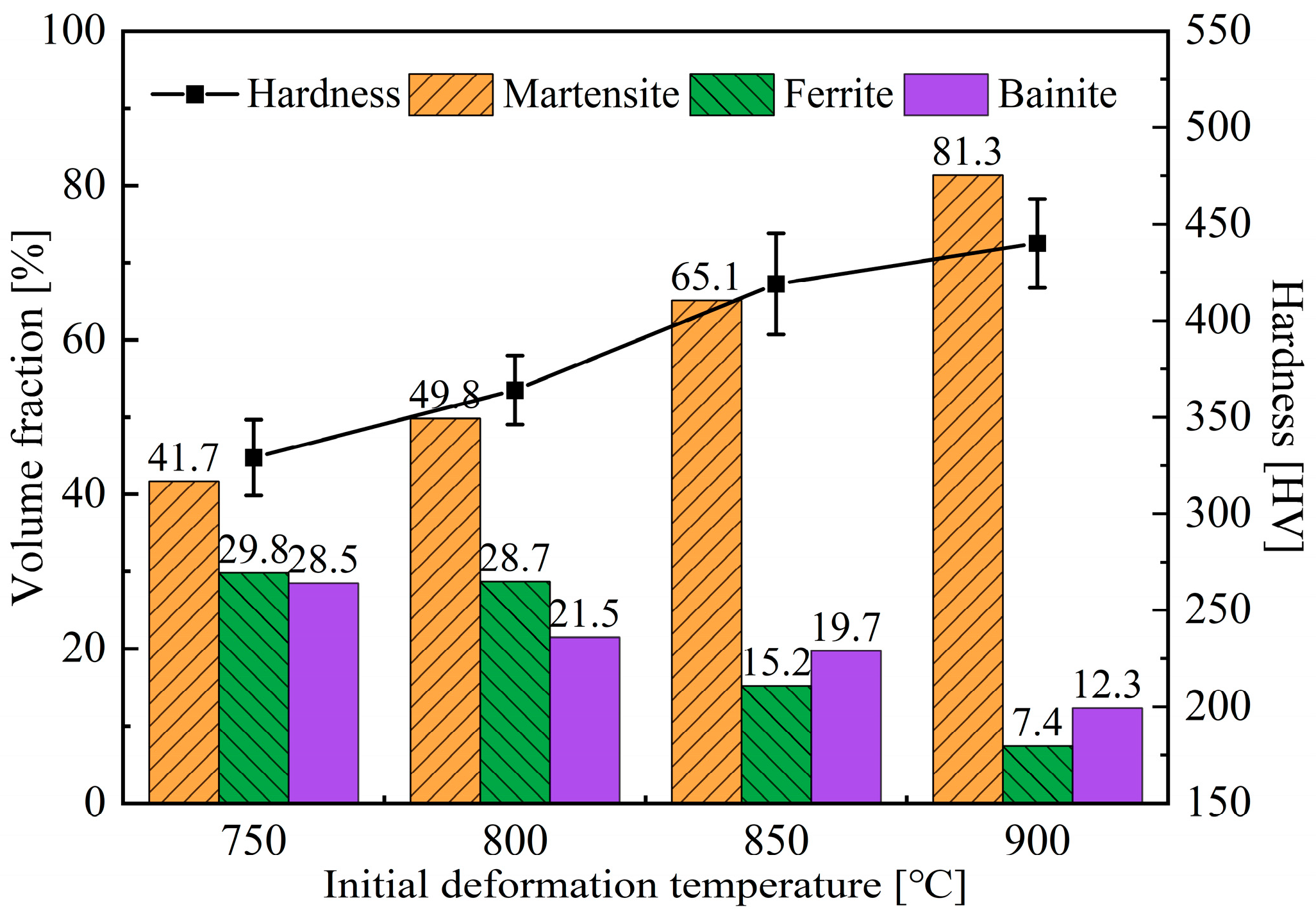

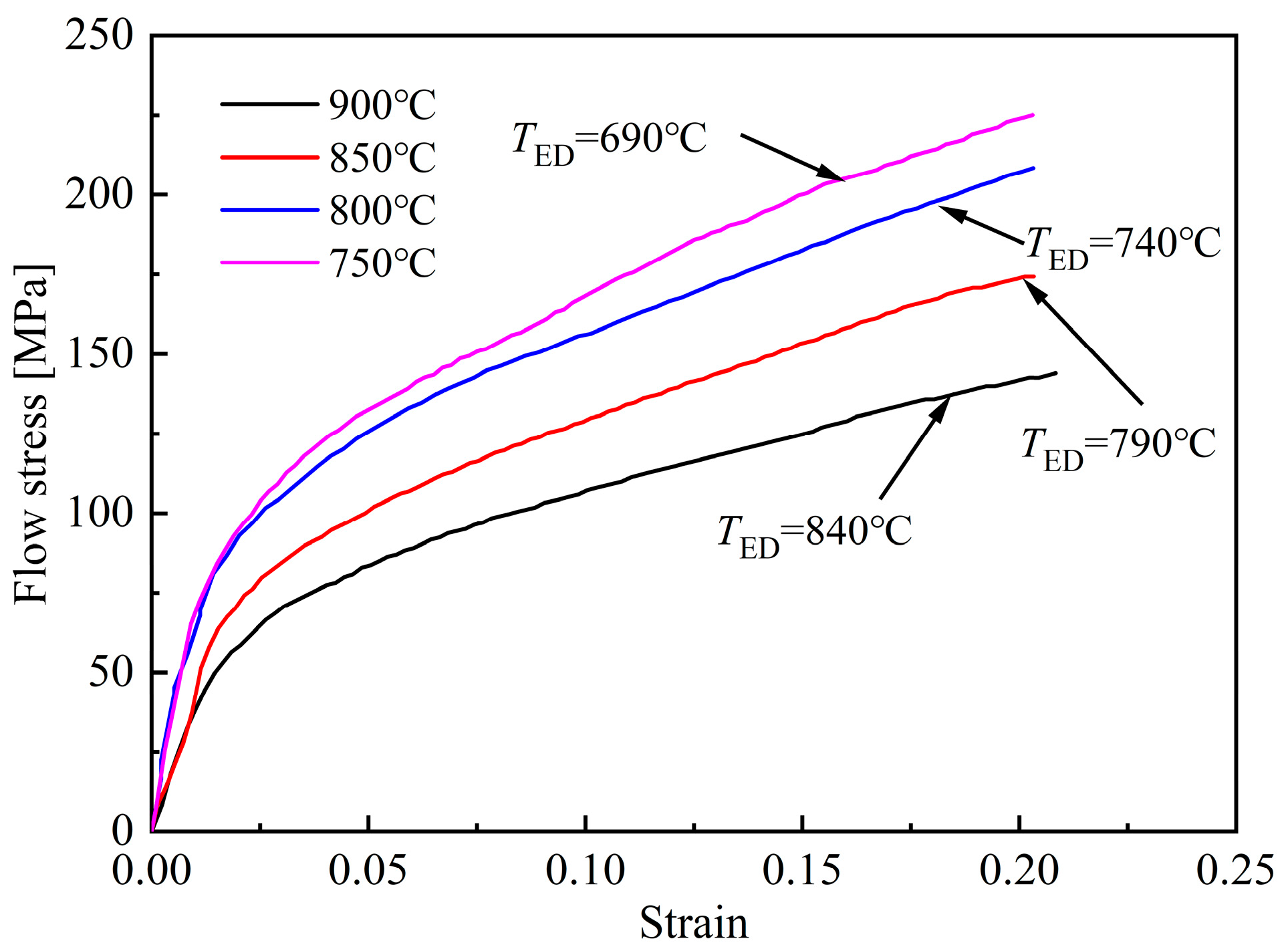

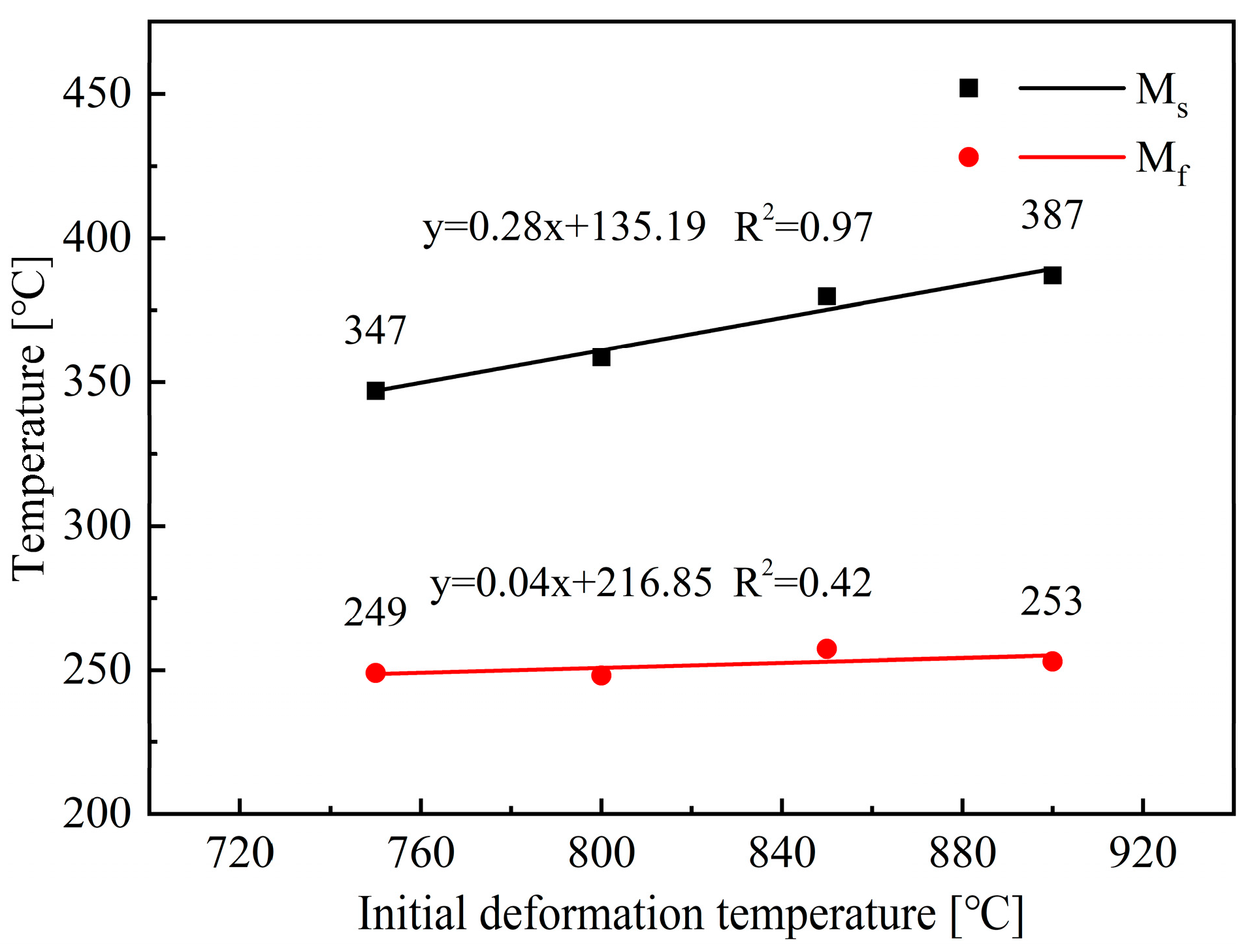

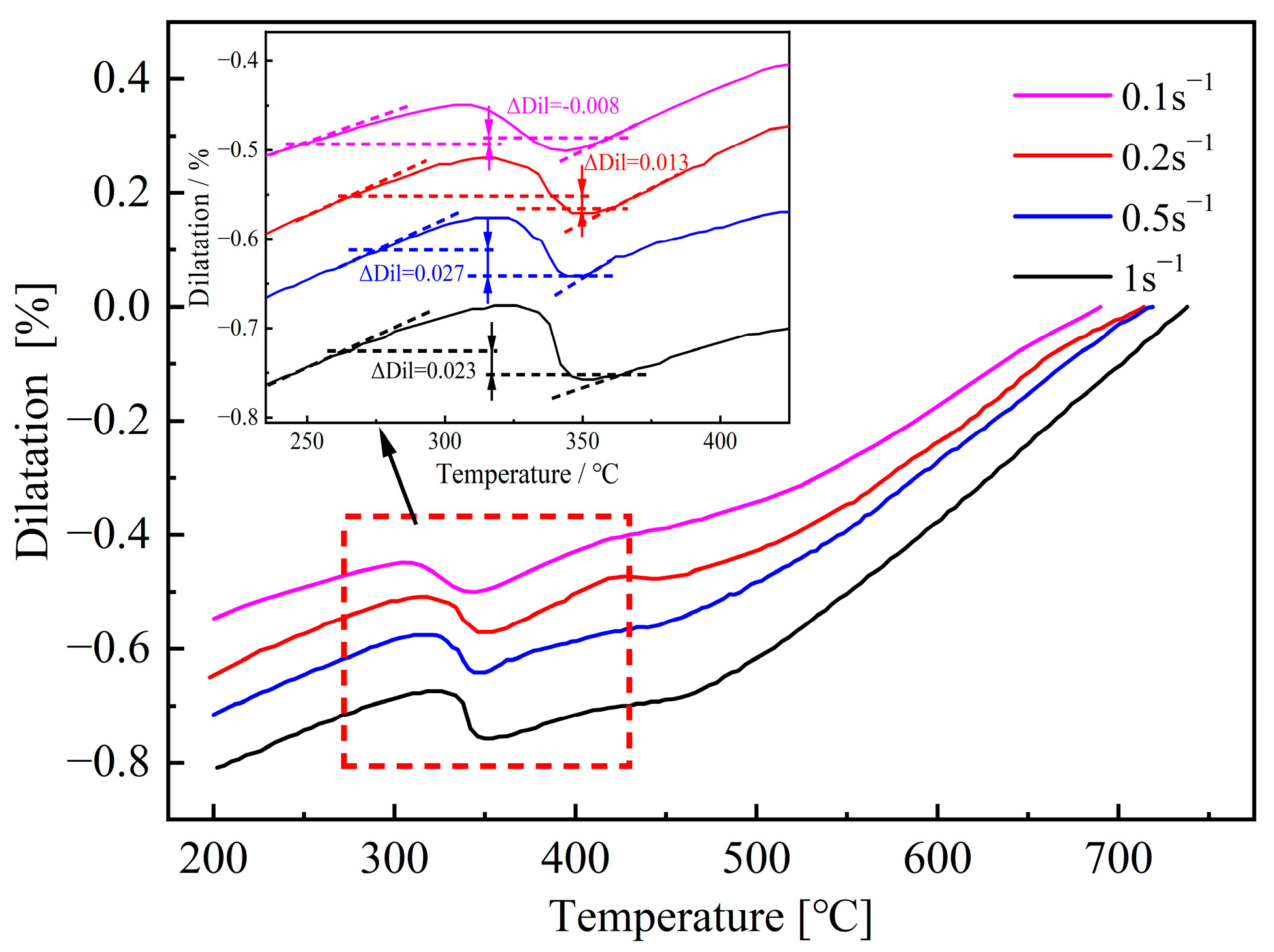

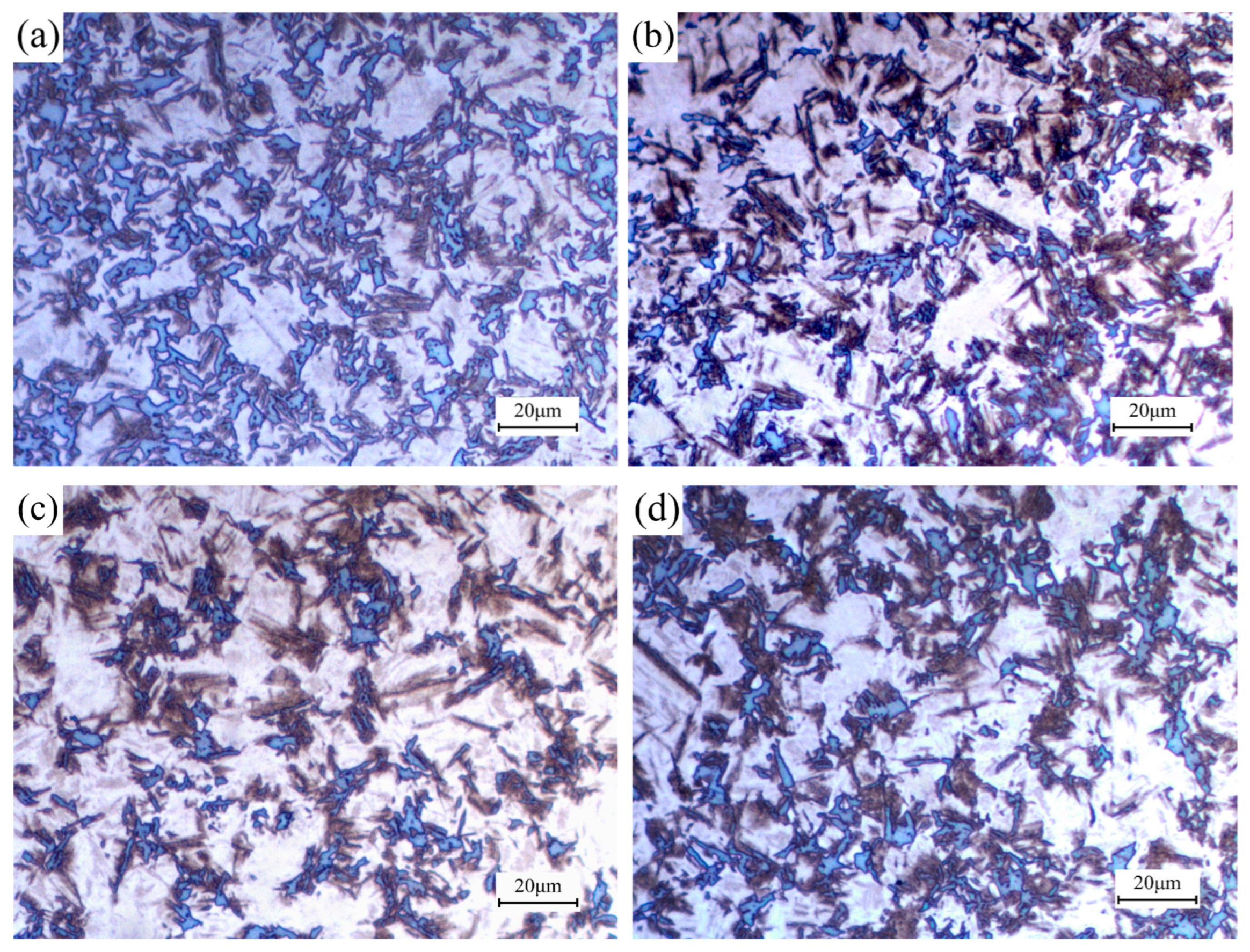

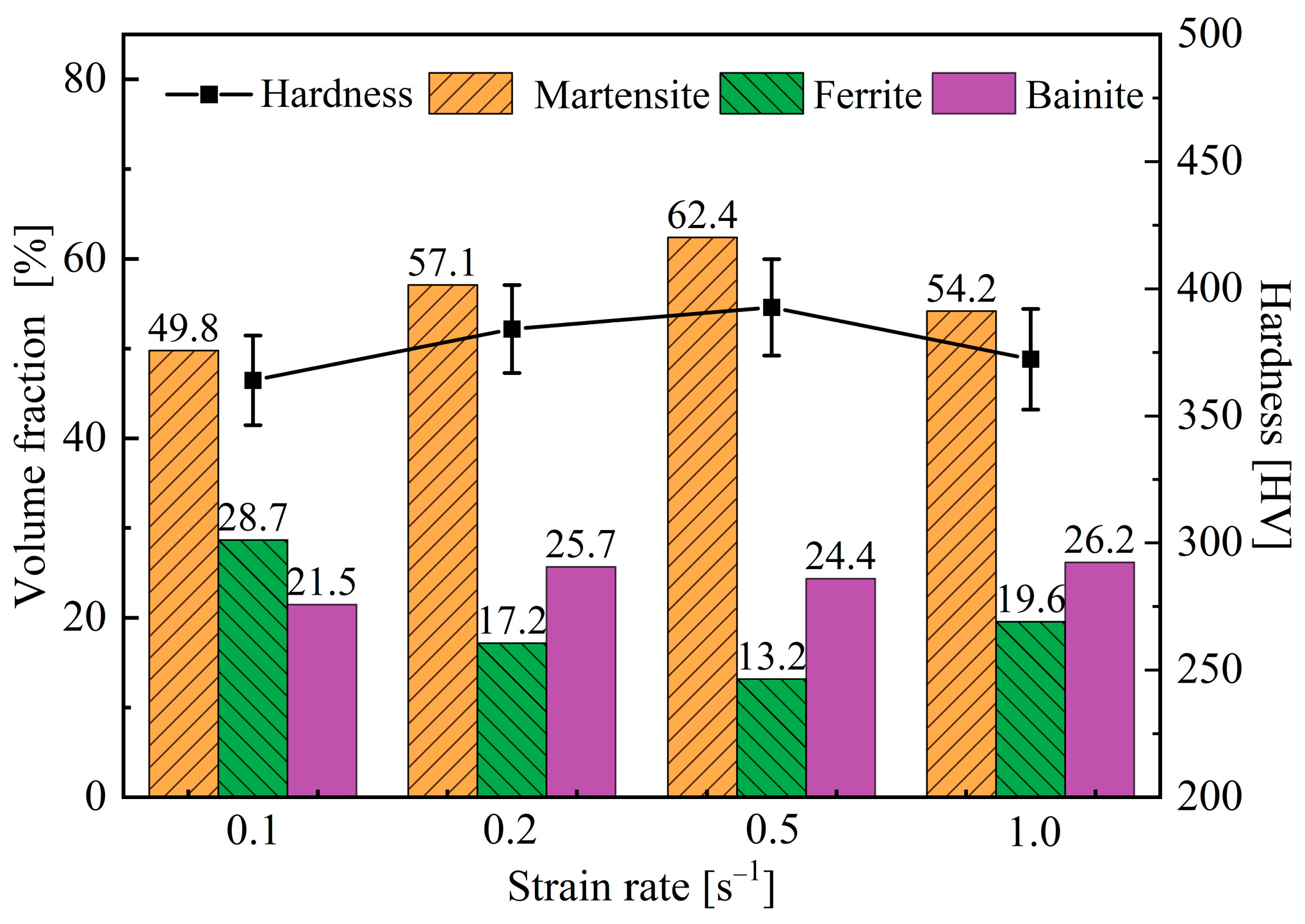

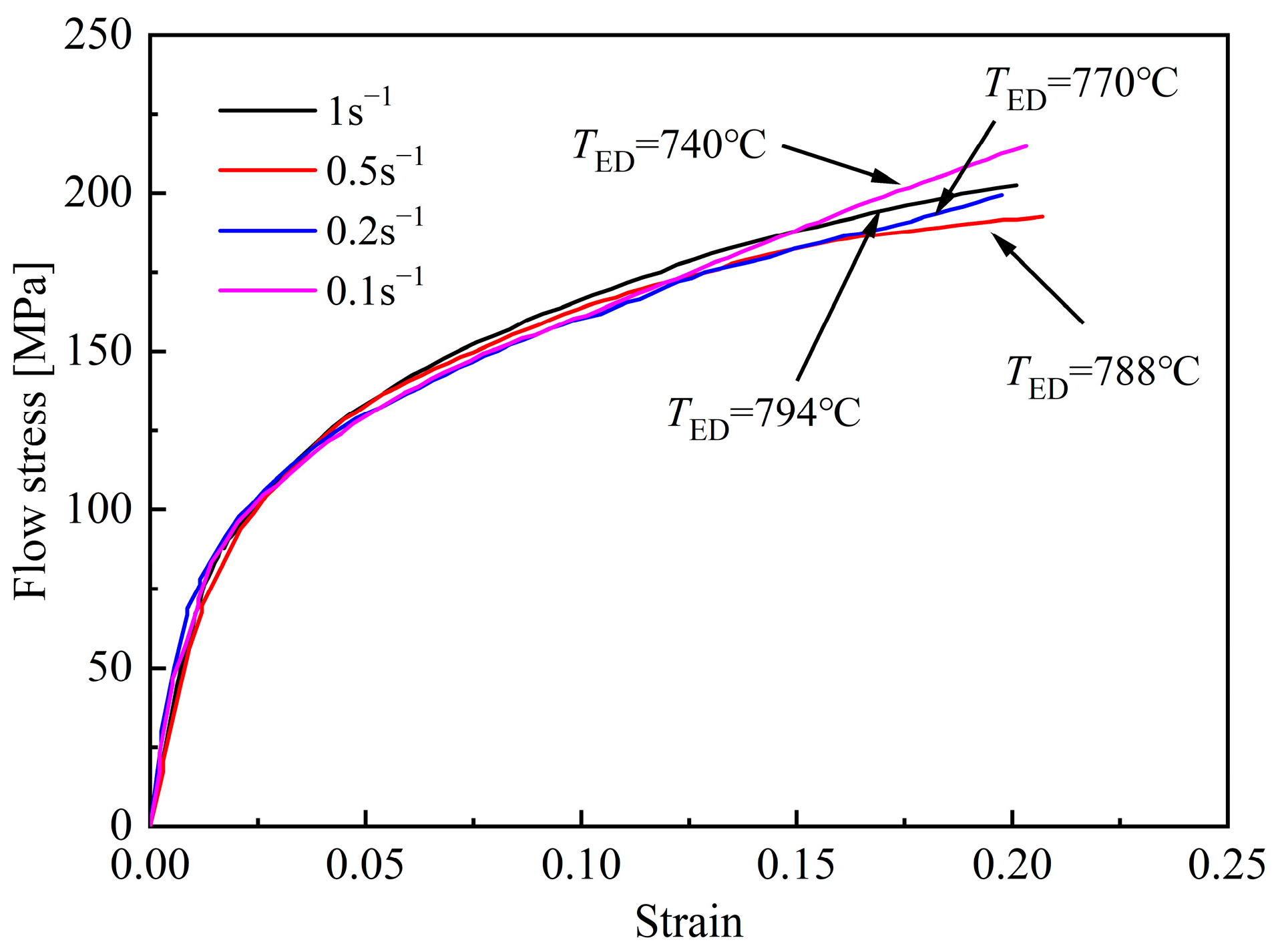

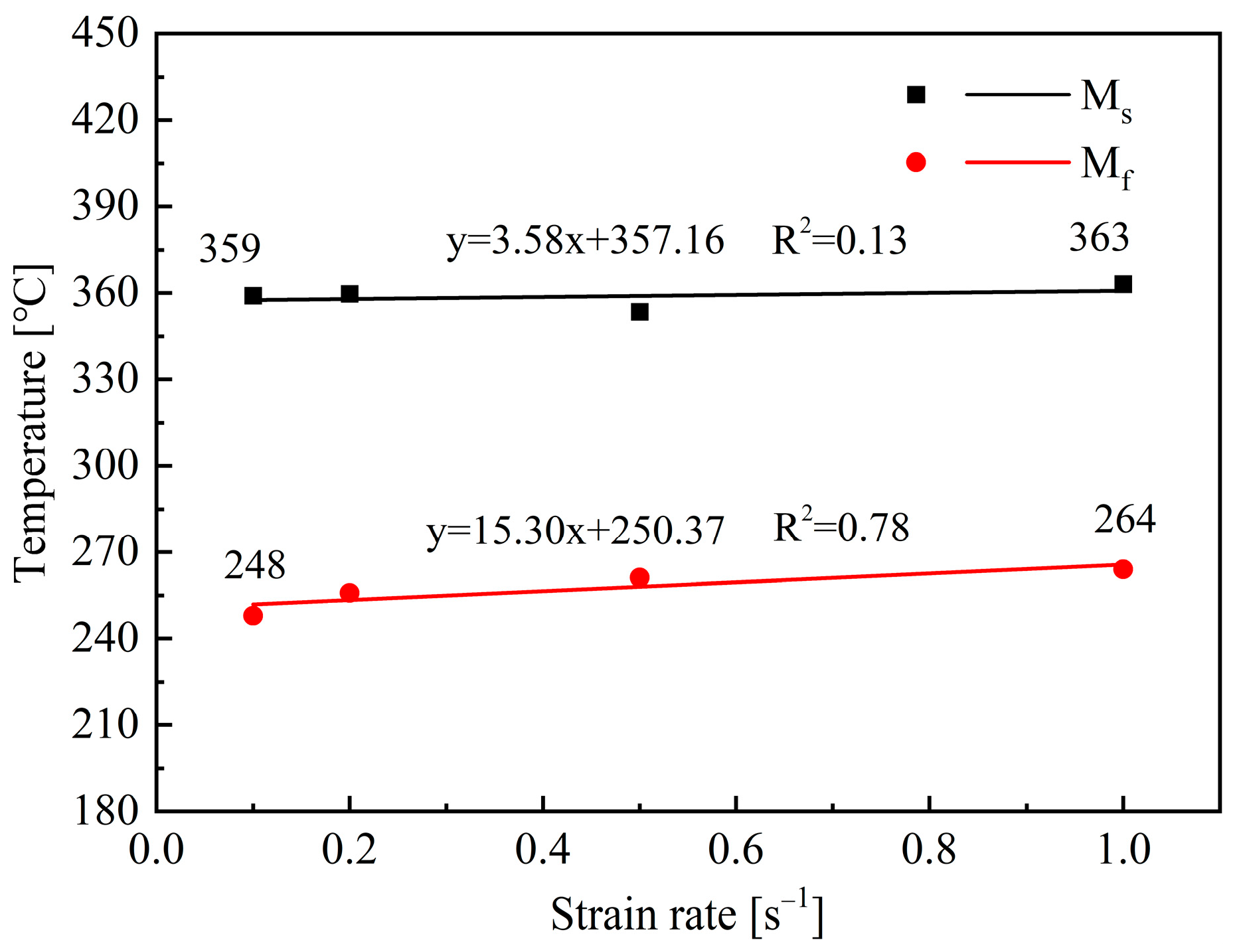

3.3. Effect of Strain Rate

4. Conclusions

- (1)

- The stored deformation energy introduced by non-isothermal deformation can promote the transformation of ferrite. Through the quantitative analysis of microstructure, as the strain increases and the initial deformation temperature decreases, more ferrite is present in the deformed specimen, which leads to the decrease in hardness.

- (2)

- The effect of strain rate on ferrite phase transformation is not a single trend. When the strain rate increases from 0.1 to 0.5 s−1, the enhancement of TED leads to the decrease in deformation resistance, which reduces the promoting effect on ferrite transformation, resulting in the decrease of ferrite content. Afterwards, the increase in strain rate plays a dominant role in the variation of deformation resistance, and the increase of strain rate can promote the formation of ferrite.

- (3)

- The variation of deformation parameters can also cause the fluctuation of bainite content. The increase of strain and the decrease of initial deformation temperature can also enhance the content of bainite in the deformed specimens, but the effect is weaker than that on ferrite. The reason is that the non-isothermal deformation can not only promote the nucleation process of bainite but also have an inhibitory effect on the growth of it. Under the combined influence of the two opposite effects, the volume fraction of bainite does not change significantly.

- (4)

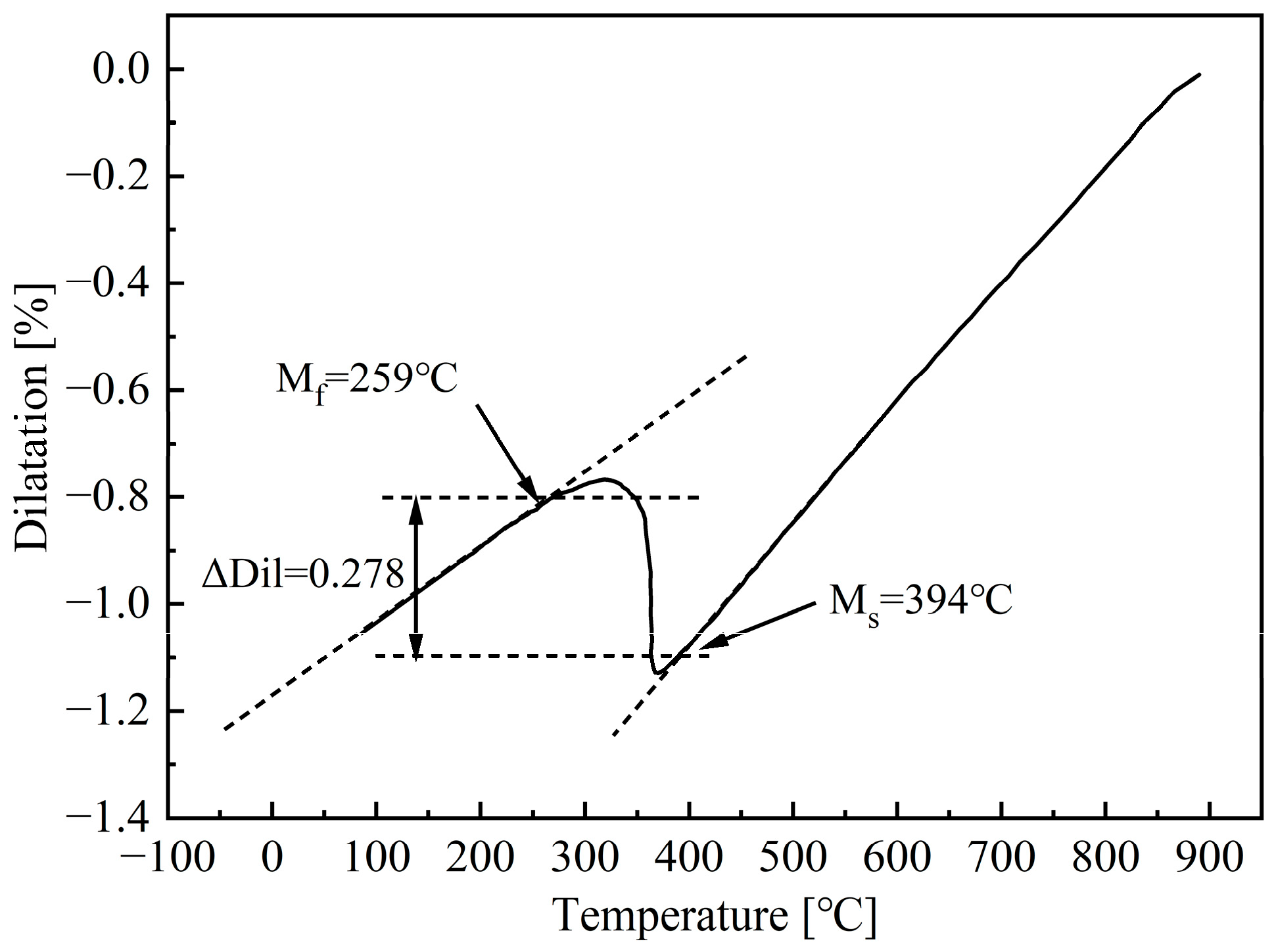

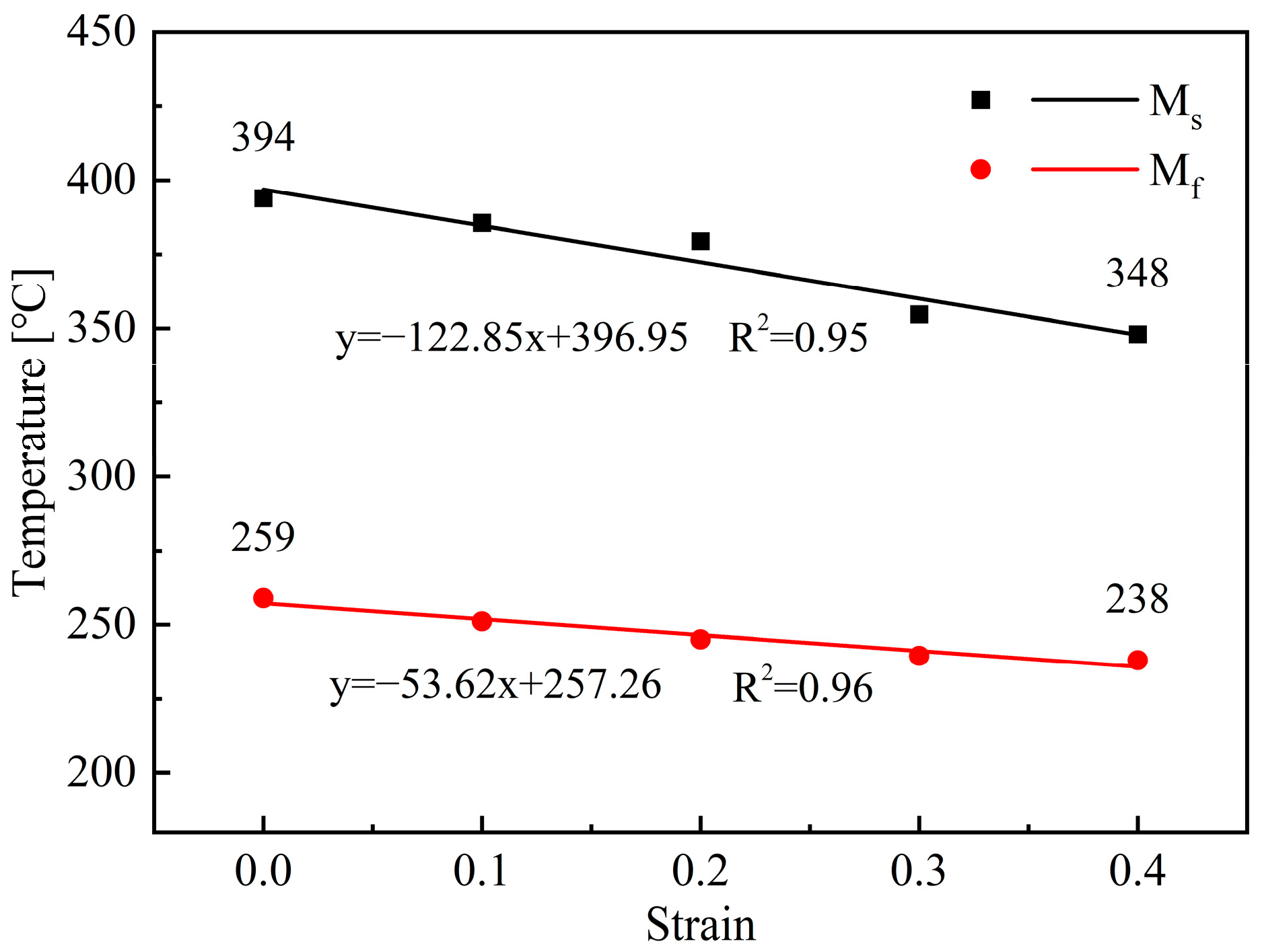

- Non-isothermal deformation can improve the stability of austenite, thus reducing the Ms temperature of B1500HS high-strength steel. With the increase of strain and decrease of initial deformation temperature, lower Ms temperature can be obtained. Meanwhile, the variation of strain rate has no significant impact on Ms temperature. Compared to the Ms temperature, the parameters mentioned above have less impact on the Mf.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Ms | martensite start temperature |

| Mf | martensite finish temperature |

| ΔDil | change in dilatation caused by martensite transformation |

| austenite dislocation energy per unit mole | |

| shear elastic modulus | |

| density of dislocation | |

| Burgers vector | |

| molar volume of austenite | |

| M | Taylor factor |

| α | material constant |

| flow stress | |

| interfacial energy | |

| chemical driving force | |

| critical nucleation energy | |

| nucleation rate | |

| proportionality constant | |

| diffusion activation energy of Fe atoms in austenite | |

| Boltzmann constant | |

| TED | ending temperature of deformation |

References

- Couto, C.P.; Revilla, R.I.; Colosio, M.A.; Costa, I.; Rossi, J.L. Electrochemical Behaviour of 22MnB5 Steel Coated with Hot-Dip Al-Si before and after Hot-Stamping Process Investigated by Means of Scanning Kelvin Probe Microscopy. Corros. Sci. 2020, 174, 108811. [Google Scholar] [CrossRef]

- Ganapathy, M.; Li, N.; Lin, J.; Abspoel, M.; Bhattacharjee, D. A Novel Grip Design for High-Accuracy Thermo-Mechanical Tensile Testing of Boron Steel under Hot Stamping Conditions. Exp. Mech. 2018, 58, 243–258. [Google Scholar] [CrossRef]

- Chokshi, P.; Dashwood, R.; Hughse, D.J. Artificial Neural Network (ANN) Based Microstructural Prediction Model for 22MnB5 Boron Steel During Tailored Hot Stamping. Comput. Struct. 2017, 190, 162–172. [Google Scholar] [CrossRef]

- Bok, H.H.; Lee, M.G.; Pavlina, E.J.; Barlat, F.; Kim, H.D. Comparative Study of the Prediction of Microstructure and Mechanical Properties for a Hot-Stamped B-Pillar Reinforcing Part. Int. J. Mech. Sci. 2011, 53, 744–752. [Google Scholar] [CrossRef]

- Kim, H.Y.; Park, J.K.; Lee, M.G. Phase Transformation-Based Finite Element Modeling to Predict Strength and Deformation of Press-Hardened Tubular Automotive Part. Int J. Adv. Manuf. Technol. 2014, 70, 1787–1801. [Google Scholar] [CrossRef]

- Kusumi, K.; Yamamoto, S.; Ushioda, K. Mechanism for Excellent Shape Fixability in Hot Stamping Process. Mater. Trans. 2020, 61, 2121–2127. [Google Scholar] [CrossRef]

- Cai, T.J.; Lei, C.X.; Yang, W.Y.; Fu, H.Y.; Xing, Z.W. Role of the Mandrel in the Variable Curvature Local-Induction-Heating Bending Process of B1500HS Thin-Walled Rectangular Tubes. Int. J. Adv. Manuf. Technol. 2021, 114, 625–640. [Google Scholar] [CrossRef]

- He, X.; Qin, Y.Q.; Jiang, W.X. Effect of Welding Parameters on Microstructure and Mechanical Properties of Laser Welded Al-Si Coated 22MnB5 Hot Stamping Steel. J. Mater. Process. Technol. 2019, 270, 285–292. [Google Scholar] [CrossRef]

- Li, Y.F.; Li, S.H.; Chen, Y.; Han, G.F. Constitutive Parameters Identification Based on DIC Assisted Thermo-Mechanical Tensile Test for Hot Stamping of Boron Steel. J. Mater. Process. Technol. 2019, 271, 429–443. [Google Scholar] [CrossRef]

- Li, M.Y.; Yao, D.; Yang, L.; Wang, H.R.; Guan, Y.P. Kinetic Analysis of Austenite Transformation for B1500HS High-Strength Steel During Continuous Heating. Int. J. Miner. Metall. Mater. 2020, 27, 1508–1516. [Google Scholar] [CrossRef]

- Zhu, B.; Chen, Z.X.; Hu, F.K.; Dai, X.B.; Wang, L.; Zhang, Y.S. Feature Extraction and Microstructural Classification of Hot Stamping Ultra-High Strength Steel by Machine Learning. JOM 2022, 74, 3466–3477. [Google Scholar] [CrossRef]

- Salari, S.; Saeed-Akbari, A.; Naderi, M.; Bleck, W. Martensitic Transformation Behavior of B-Bearing Steel During Isothermal Deformation. Steel. Res. Int. 2012, 83, 733–742. [Google Scholar] [CrossRef]

- Shi, Z.M.; Liu, K.; Wang, M.Q.; Shi, J.; Dong, H.; Pu, J.; Chi, B.; Zhang, Y.S.; Jian, L. Effect of Non-Isothermal Deformation of Austenite on Phase Transformation and Microstructure of 22SiMn2TiB Steel. Mater. Sci. Eng. A. 2012, 535, 290–296. [Google Scholar] [CrossRef]

- Li, H.P.; He, L.F.; Yang, X.D.; Zhao, G.Q. Effect of Deformation and Cooling on the Phase Transformation of Martensite for B1500HS Boron Steel. Int. J. Mech. Eng. 2016, 52, 67–74. [Google Scholar] [CrossRef]

- Li, Y.F.; Chen, Y.; Li, S.H. Phase Transformation Testing and Modeling for Hot Stamping of Boron Steel Considering the Effect of the Prior Austenite Deformation. Mater. Sci. Eng. A 2021, 821, 141447. [Google Scholar] [CrossRef]

- Naderi, M.; Saeed-Akbari, A.; Bleck, W. The Effects of Non-Isothermal Deformation on Martensitic Transformation in 22MnB5 Steel. Mater. Sci. Eng. A 2008, 487, 445–455. [Google Scholar] [CrossRef]

- Abbasi, M.; Naderi, M.; Saeed-Akbari, A. Isothermal Versus Non-Isothermal Hot Compression Process: A Comparative Study on Phase Transformations and Structure-Property Relationships. Mater. Des. 2013, 45, 1–5. [Google Scholar] [CrossRef]

- Abbasi, M.; Saeed-Akbari, A.; Naderi, M. The Effect of Strain Rate and Deformation Temperature on the Characteristics of Isothermally Hot Compressed Boron-Alloyed Steel. Mater. Sci. Eng. A 2012, 538, 356–363. [Google Scholar] [CrossRef]

- Cai, X.W.; Chen, X.Y.; Zhou, Q.; Yang, X.F.; Jiang, R.G. Color Metallographic Quantitative Analysis Method of TRIP Steel Microstructure. Heat. Treat. Met. 2014, 39, 139–143. [Google Scholar] [CrossRef]

- Da Costa, F.H.; Fukugauchi, C.S.; Marcelo, D.S.P. Metallographic Analysis of a TRIP 800 Steel Using Digital Image Processing. Mater. Sci. Forum. 2014, 805, 236–241. [Google Scholar] [CrossRef]

- Li, M.Y.; Duan, Y.C.; Yao, D.; Guan, Y.P.; Yang, L. Constitutive Model and Flow Behavior of B1500HS High-Strength Steel During the Hot Deformation Process. Metals 2019, 10, 64. [Google Scholar] [CrossRef]

- Dong, H.; Sun, X. Deformation Induced Ferrite Transformation. Curr. Opin. Solid State Mater. Sci. 2009, 9, 269–276. [Google Scholar] [CrossRef]

- Xu, M.; Mi, Z.L.; Li, H.; Tang, D.; Jiang, H.T. Constitutive Model Based on Dislocation Density Theory for Hot Deformation Behavior of Ultra-High Strength Dual Phase Steel DP1000. Chin. J. Mater. Res. 2017, 31, 576–584. [Google Scholar] [CrossRef]

- Xu, Z.Y. Effect of stress on bainitic transformation in steel. Acta Metall. Sinica 2004, 40, 113–119. [Google Scholar] [CrossRef]

- Luo, Q.; Chen, H.C.; Chen, W.; Wang, C.C.; Xu, W.; Li, Q. Thermodynamic Prediction of Martensitic Transformation Temperature in Fe-Ni-C System. Scr. Mater. 2020, 187, 413–417. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Mo | B | Ti | V | S | P |

|---|---|---|---|---|---|---|---|---|---|

| 0.23 | 0.25 | 1.35 | 0.19 | 0.04 | 0.003 | 0.03 | 0.004 | 0.006 | 0.015 |

| No. | Amount of Strain | Strain Rate [s−1] | Cooling Rate [°C/s] | Initial Deformation Temperature [°C] |

|---|---|---|---|---|

| 1 | 0.1, 0.2, 0.3, 0.4 | 0.1 | 40 | 800 |

| 2 | 0.2 | 0.1 | 30 | 750, 800, 850, 900 |

| 3 | 0.2 | 0.1, 0.2, 0.5, 1.0 | 30 | 800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Yao, D.; Li, B.; Yue, S.; Chen, Z.; Ren, E.; Wang, N.; Yang, C. Effects of Deformation Parameters on Phase Transformation of B1500HS High-Strength Steel During the Non-Isothermal Deformation Process. Materials 2025, 18, 2843. https://doi.org/10.3390/ma18122843

Li M, Yao D, Li B, Yue S, Chen Z, Ren E, Wang N, Yang C. Effects of Deformation Parameters on Phase Transformation of B1500HS High-Strength Steel During the Non-Isothermal Deformation Process. Materials. 2025; 18(12):2843. https://doi.org/10.3390/ma18122843

Chicago/Turabian StyleLi, Muyu, Dan Yao, Bin Li, Suilu Yue, Zhiyong Chen, Erzhou Ren, Ningning Wang, and Chong Yang. 2025. "Effects of Deformation Parameters on Phase Transformation of B1500HS High-Strength Steel During the Non-Isothermal Deformation Process" Materials 18, no. 12: 2843. https://doi.org/10.3390/ma18122843

APA StyleLi, M., Yao, D., Li, B., Yue, S., Chen, Z., Ren, E., Wang, N., & Yang, C. (2025). Effects of Deformation Parameters on Phase Transformation of B1500HS High-Strength Steel During the Non-Isothermal Deformation Process. Materials, 18(12), 2843. https://doi.org/10.3390/ma18122843