Evaluation of Crack Resistance Performance of Semi-Flexible Pavement Materials

Abstract

1. Introduction

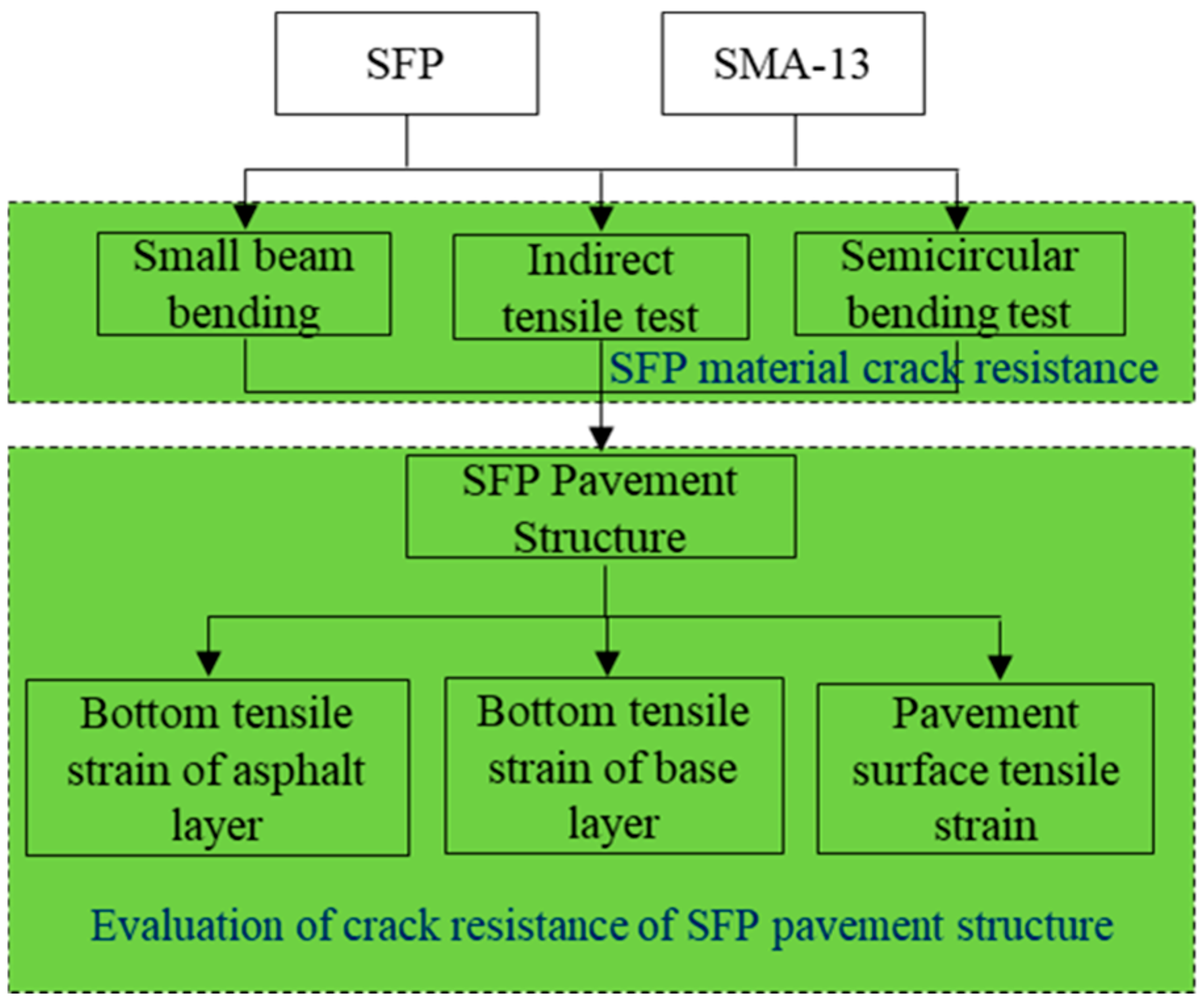

2. Research Objectives and Methods

- Assess the crack resistance of semi-flexible pavement (SFP) materials through low-temperature beam bending tests, semi-circular bending (SCB) tensile tests, and indirect tensile tests.

- Investigate the structural improvement effects of SFP on pavement crack resistance.

3. Materials and Tests

3.1. Materials

- (1)

- Asphalt binder

- (2)

- Aggregate

- (3)

- Porous asphalt mixture and SMA-13

- (4)

- Grouting materials and SFP

3.2. Tests

- (1)

- Low-temperature beam test

- (2)

- Indirect tensile test

- (3)

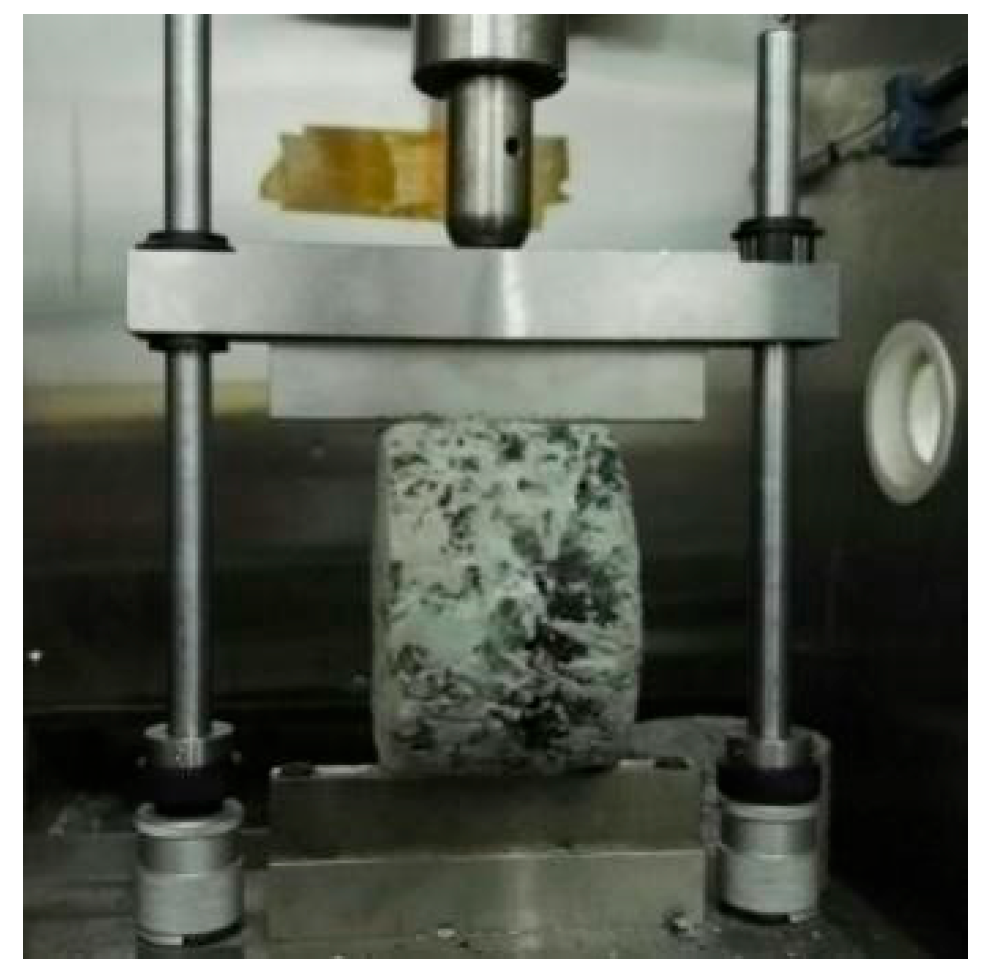

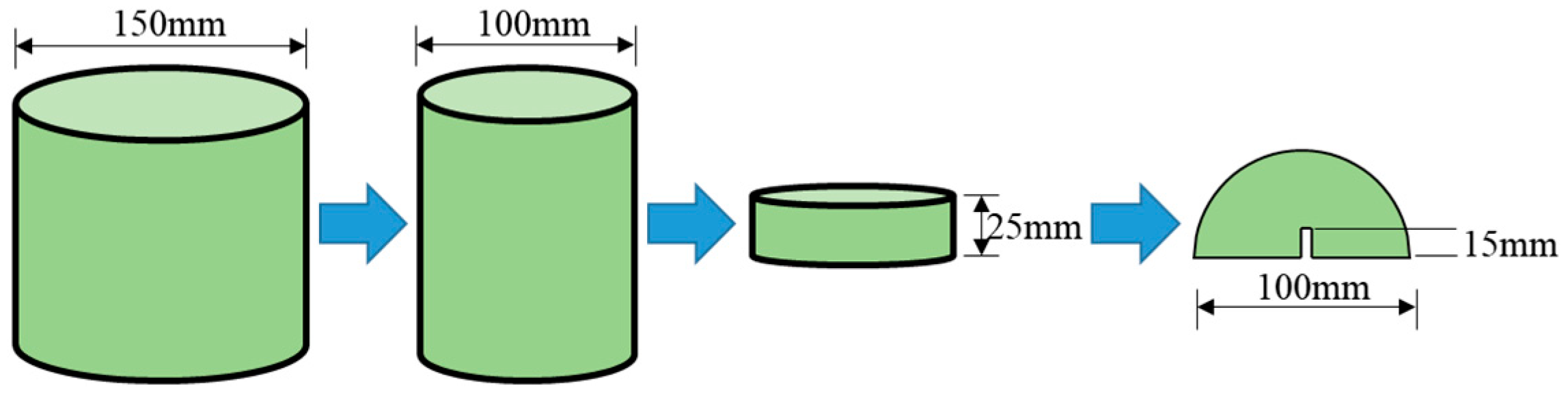

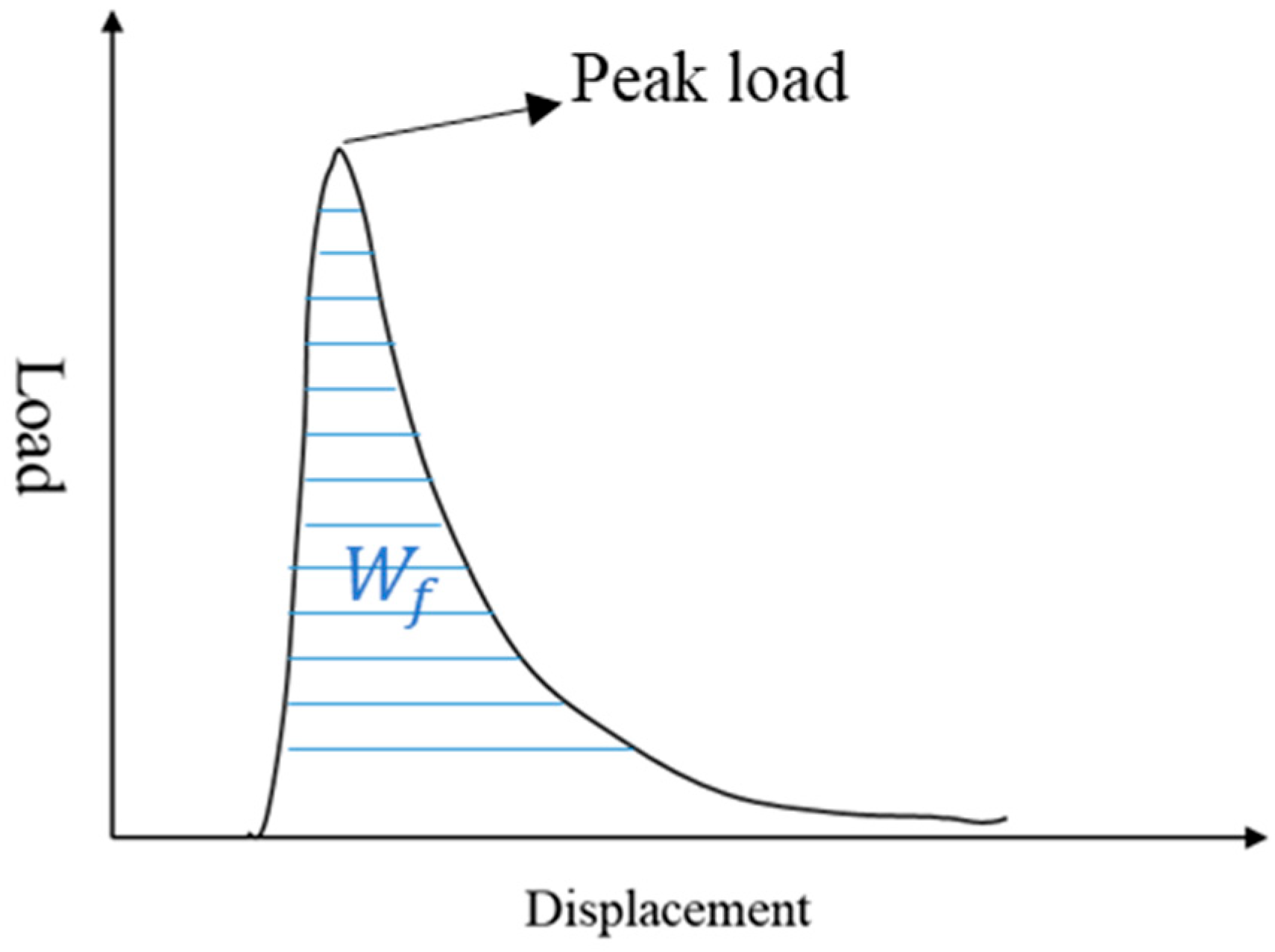

- Semi-circular bending (SCB) tensile test

- (4)

- Dynamic Modulus Testing

- (5)

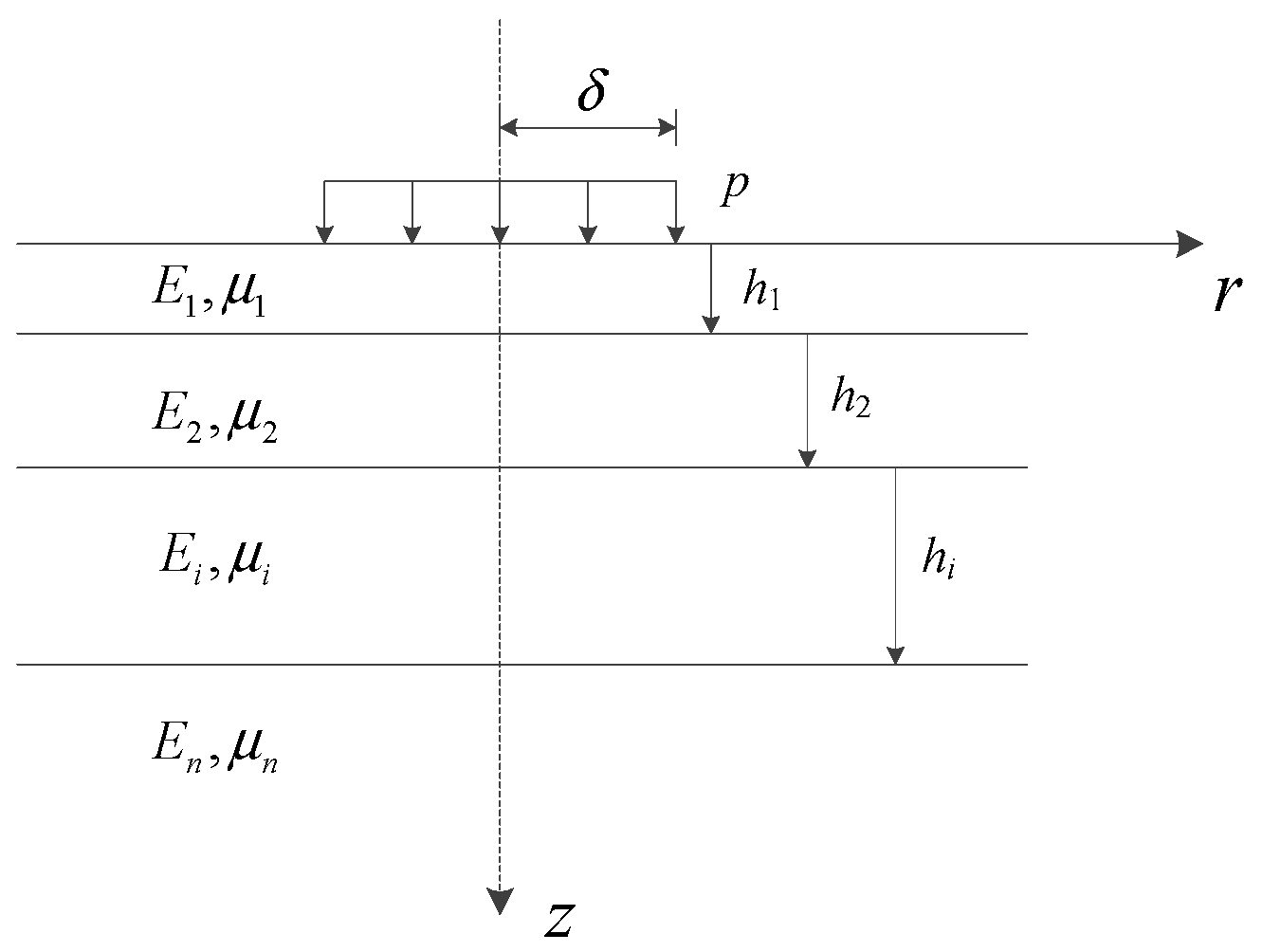

- Analytical Methodology

4. SFP Material Crack Resistance

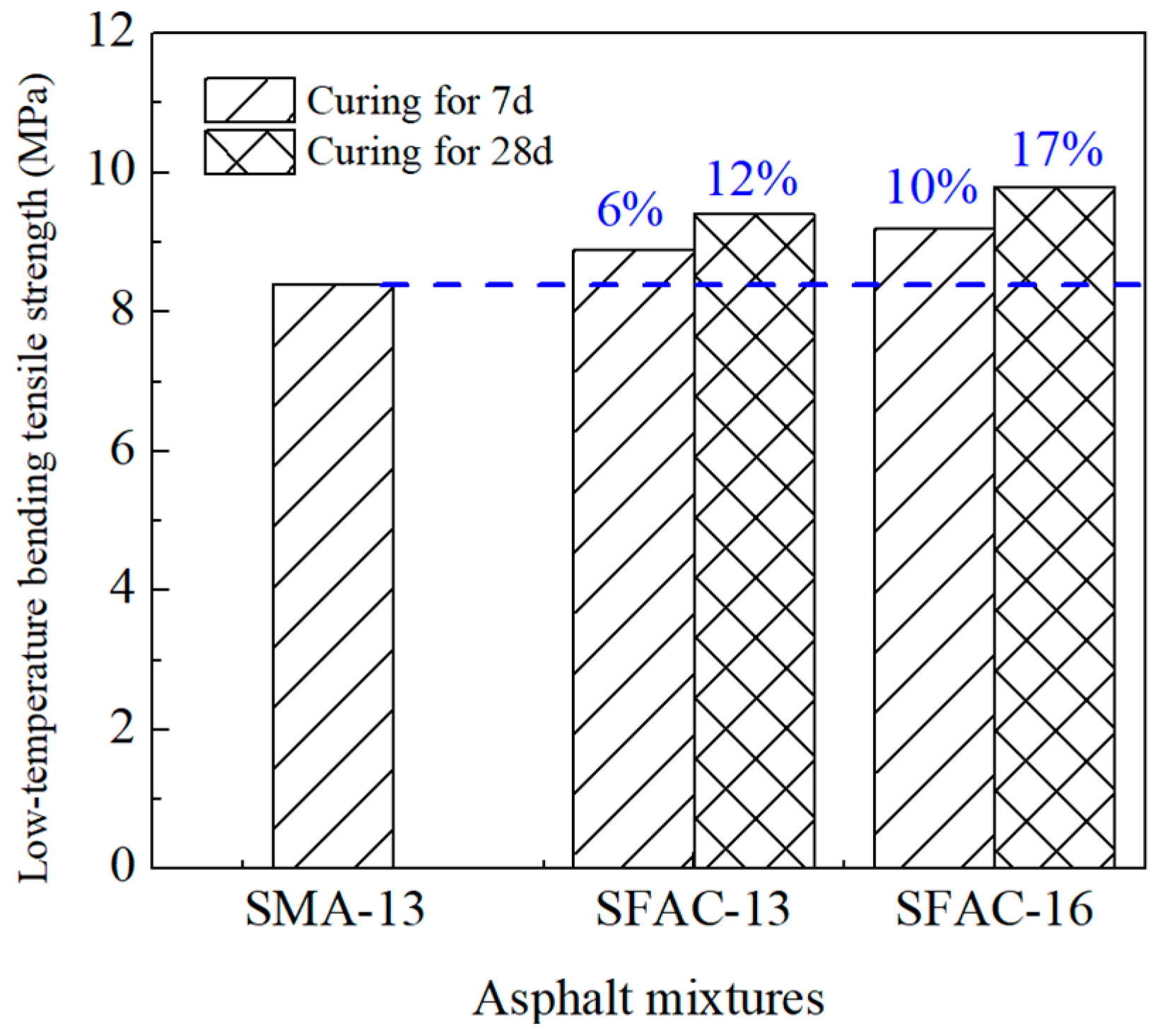

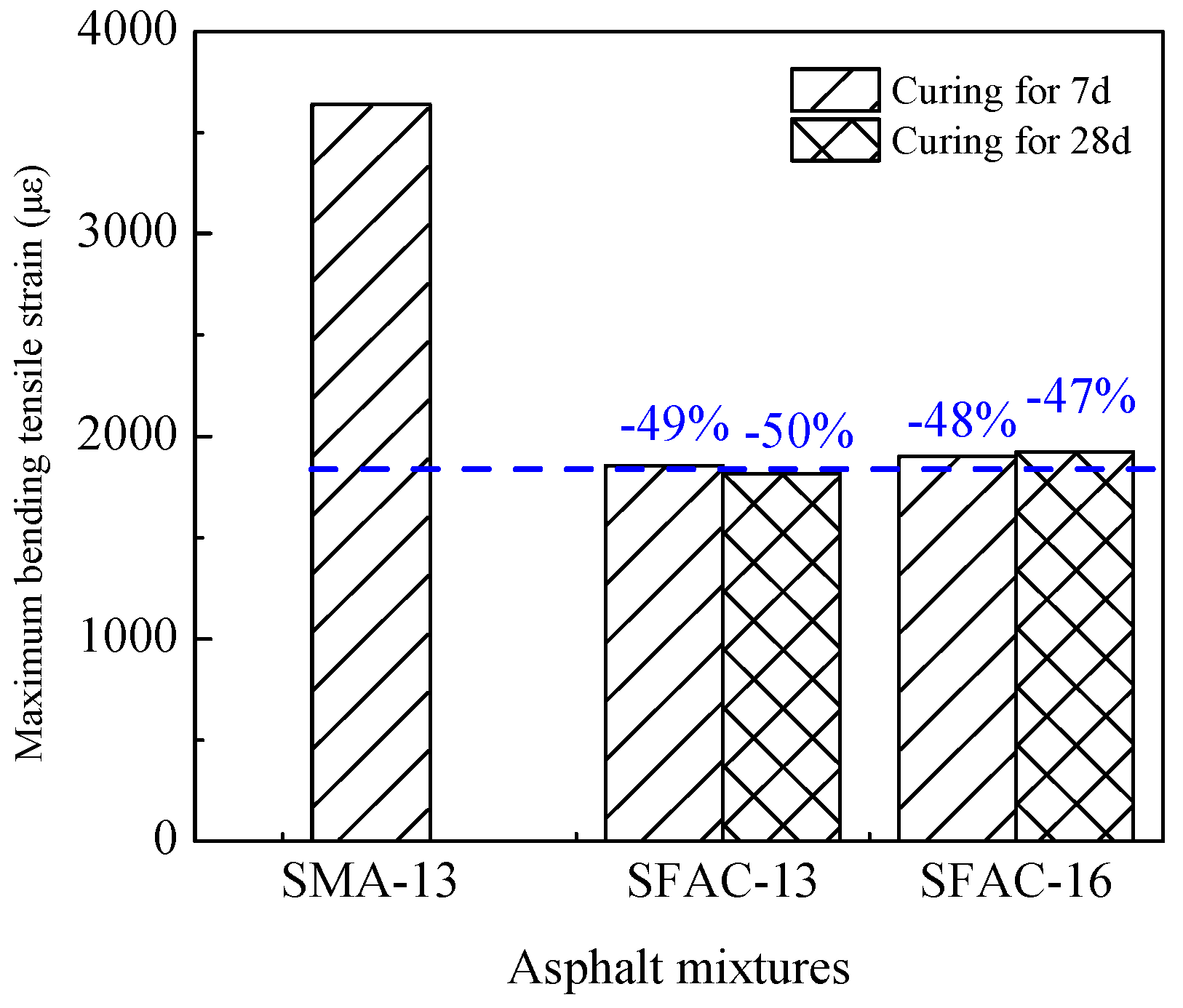

4.1. Low-Temperature Beam Test Result

4.2. Indirect Tensile Test Result

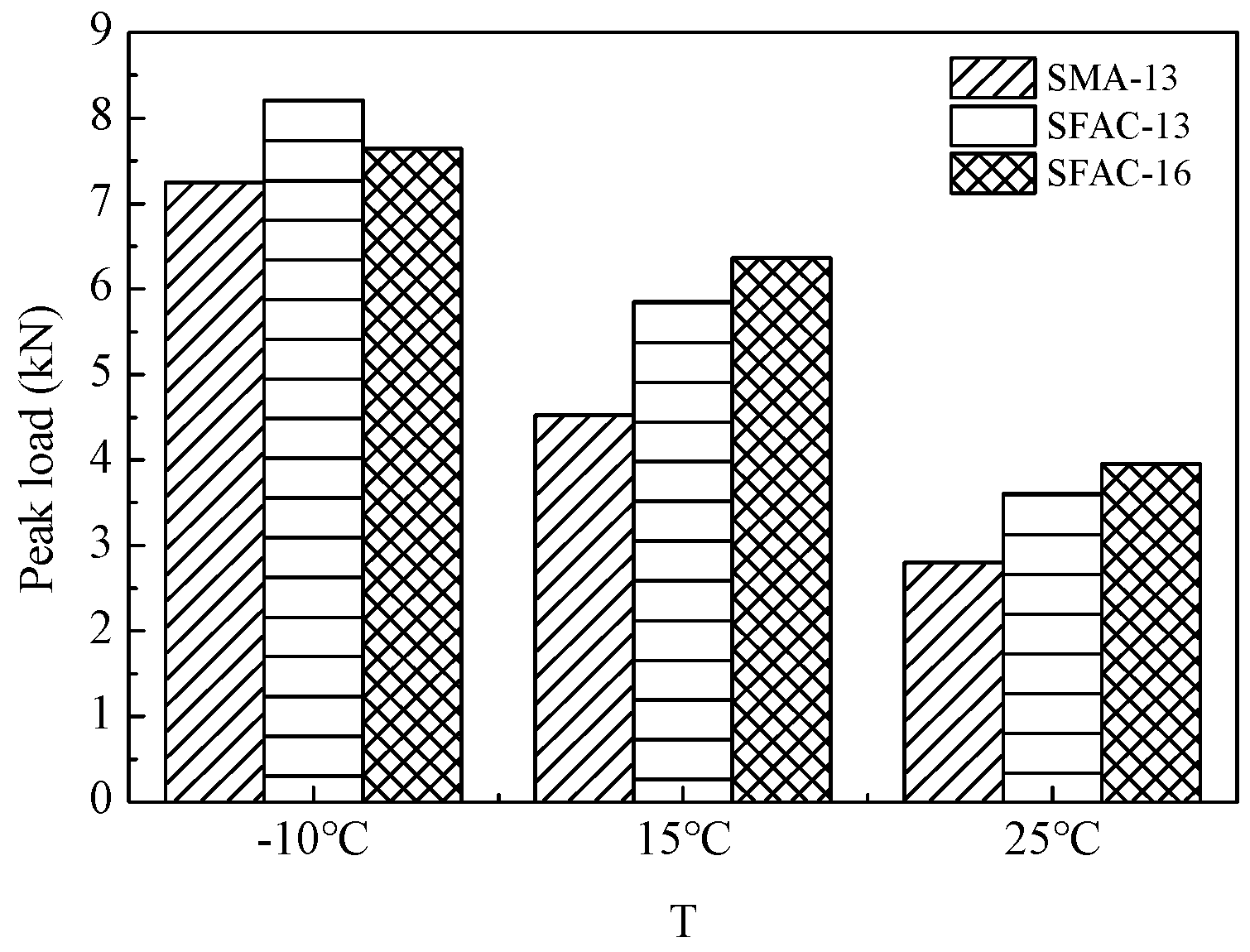

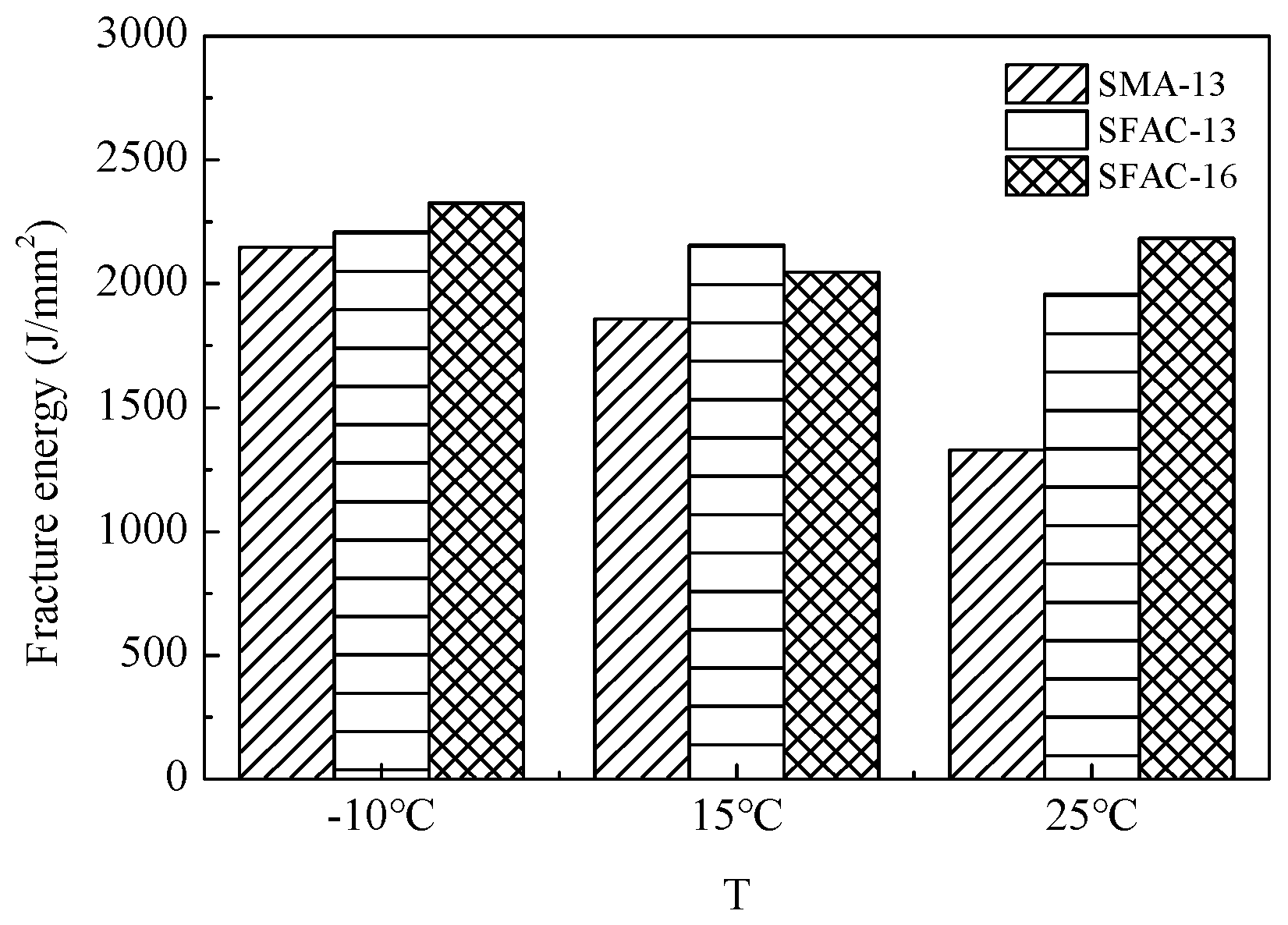

4.3. Semi-Circular Bending (SCB) Tensile Test Result

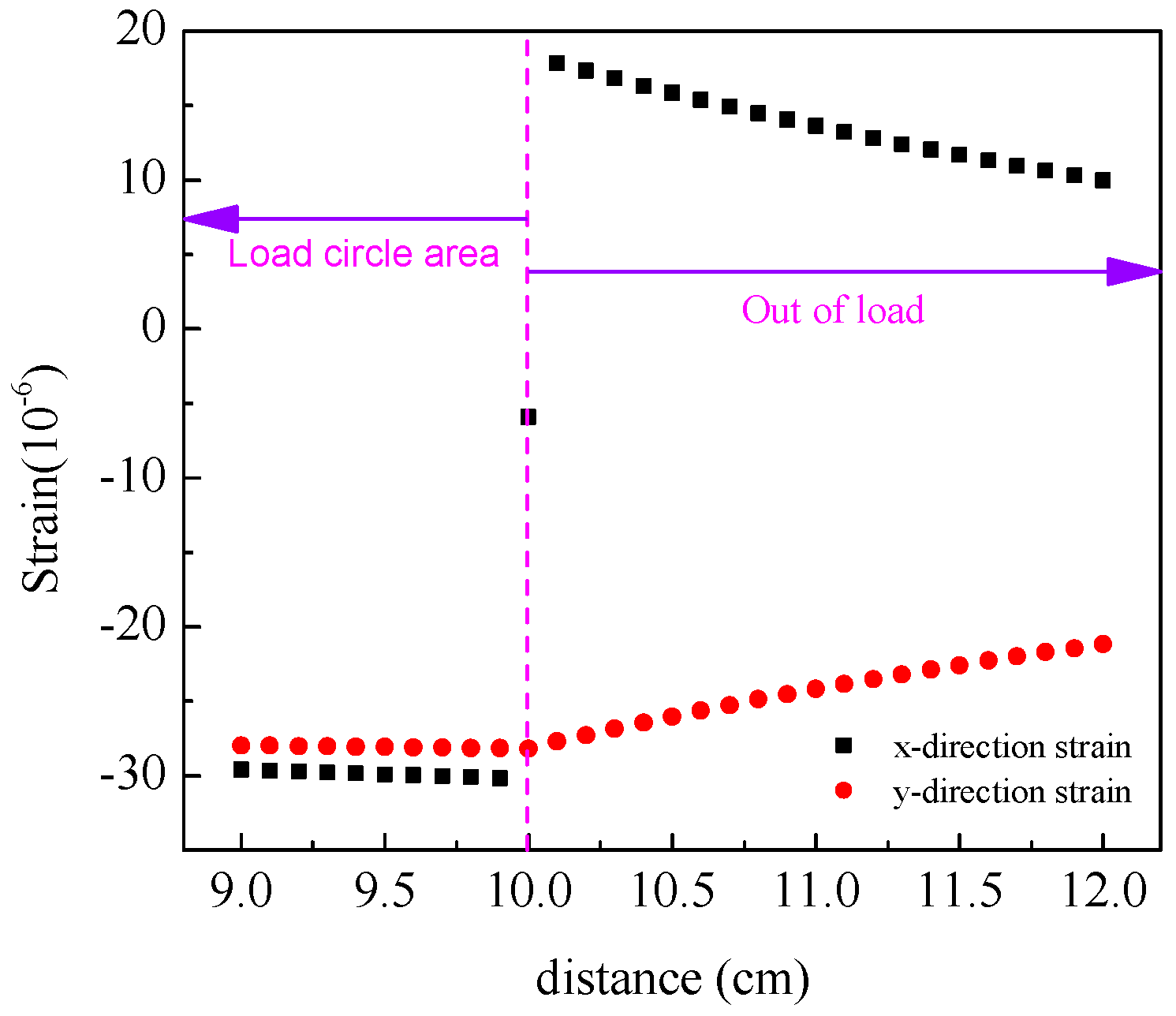

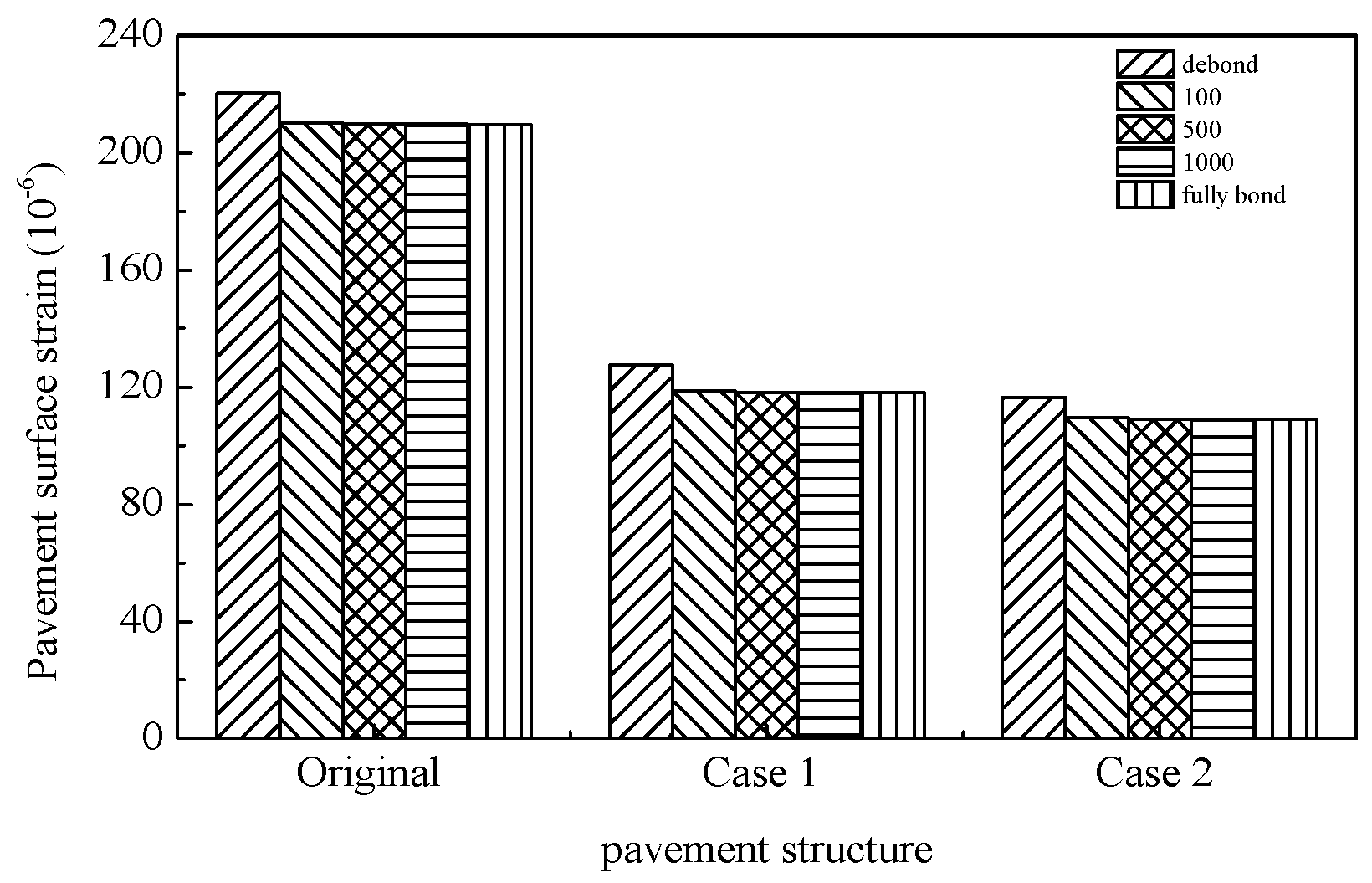

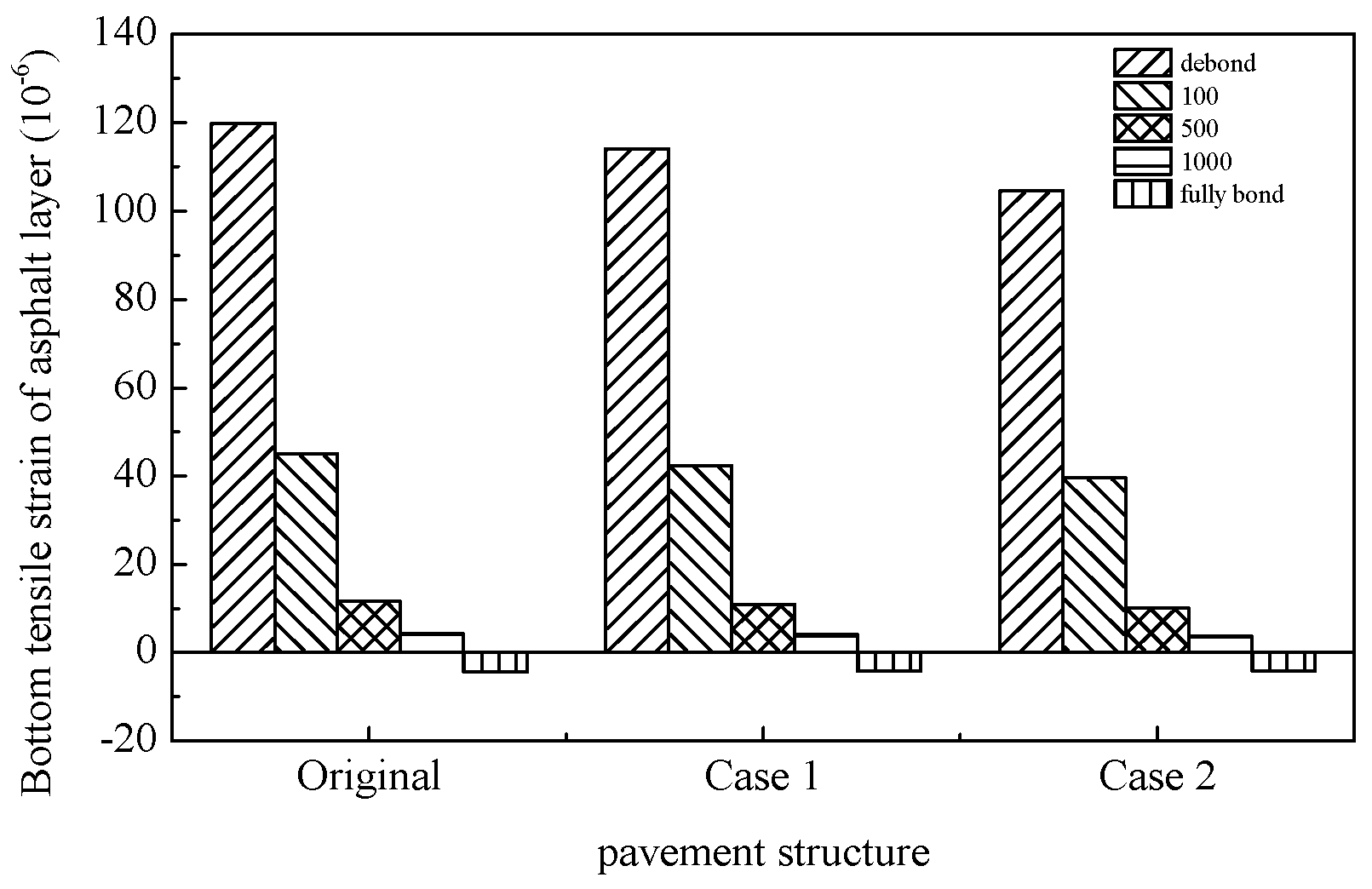

5. SFP Pavement Structure Crack Resistance

6. Conclusions

- (1)

- A comparative analysis of low-temperature flexural tensile strength, indirect tensile strength, and fracture energy between the SFP materials and SMA-13 reveals that the SFP materials exhibit superior crack resistance at ambient and elevated temperatures. However, at low temperatures, while the SFP materials demonstrate comparable flexural strength and fracture energy to SMA-13, their significantly reduced flexural tensile strain indicates limitations in low-temperature ductility. These results suggest that low-temperature flexural tensile strain alone cannot holistically assess the low-temperature crack resistance of SFP materials.

- (2)

- Compromised interlayer bonding between the surface and base layers substantially exacerbates fatigue cracking at the asphalt layer base and semi-rigid base layer yet exerts minimal influence on surface-initiated cracking mechanisms.

- (3)

- The implementation of semi-flexible materials as surface layers effectively enhances pavement surface crack resistance but demonstrates negligible improvement in fatigue cracking resistance for both the asphalt layers and semi-rigid base layers.

- (4)

- Double-layer SFP configurations exhibit comparable surface crack resistance to single-layer SFP systems. Strategic application recommendations are proposed. Single-layer SFP materials are advised for road sections with moderate rutting severity (e.g., intersections and long longitudinal slopes). Double-layer SFP materials are recommended for high-stress zones experiencing concurrent severe rutting and surface cracking (e.g., heavy-duty traffic lanes).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, S.; Yang, X.; Zhong, K.; Yin, J. Open-graded asphalt concrete grouted by latex modified cement mortar. Road Mater. Pavement Des. 2020, 21, 61–77. [Google Scholar] [CrossRef]

- Cihackova, P.; Hyzl, P.; Stehlik, D.; Dasek, O.; Šernas, O.; Vaitkus, A. Performance characteristics of the open-graded asphalt concrete filled with a special cement grout. Balt. J. Road Bridge Eng. 2015, 10, 316–324. [Google Scholar] [CrossRef]

- Mayer, J.; Thau, M. Jointless pavements for heavy-duty airport application: The semi-flexible approach. In Advancing Airfield Pavements; American Society of Civil Engineers: Reston, VA, USA, 2001; pp. 87–100. [Google Scholar]

- Hassani, A.; Taghipoor, M.; Karimi, M.M. A state of the art of semi-flexible pavements: Introduction, design, and performance. Constr. Build. Mater. 2020, 253, 119196. [Google Scholar] [CrossRef]

- Dhandapani, B.P.; Mullapudi, R.S. Design and performance characteristics of cement grouted bituminous mixtures-a review. Constr. Build. Mater. 2023, 369, 130586. [Google Scholar] [CrossRef]

- Khan, M.I.; Sutanto, M.H.; Yusoff, N.I.M.; Zoorob, S.E.; Rafiq, W.; Ali, M.; Fediuk, R.; Vatin, N.I. Cementitious grouts for semi-flexible pavement surfaces—A review. Materials 2022, 15, 5466. [Google Scholar] [CrossRef]

- Asim, M.; Ahmad, M.; Alam, M.; Ullah, S.; Iqbal, M.J.; Ali, S. Prediction of Rutting in Flexible Pavements Using Finite Element Method. Civil Eng. J. 2021, 7, 1310–1326. [Google Scholar] [CrossRef]

- Zarei, S.; Alae, M.; Ouyang, J.; Zhao, Y. Rutting and Surface-Initiated Cracking Mechanisms of Semi-Flexible Pavements with Cement Asphalt Emulsion Pastes. Int. J. Pavement Eng. 2022, 24, 2024187. [Google Scholar] [CrossRef]

- Deng, C.; Huang, C.; Hong, J.; Zhao, T.; Zhang, D. The Study of Super-Early-Strength Semi-Flexible Pavement Used in Municipal Road. J. Highw. Eng. 2016, 41, 116–119. [Google Scholar]

- Husain, N.M.; Mahmud, H.B.; Karim, M.R.; Hamid, N. Effects of Aggregate Gradations on Properties of Grouted Macadam Composite Pavement. In Proceedings of the 2010 2nd International Conference on Chemical, Biological and Environmental Engineering, Cairo, Egypt, 2–4 November 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 128–131. [Google Scholar]

- Liu, F.; Zheng, M.; Ye, Y. Formulation and properties of a newly developed powder geopolymer grouting material. Constr. Build. Mater. 2020, 258, 120304. [Google Scholar] [CrossRef]

- Xiang, J.; Liu, L.; Cui, X.; He, Y.; Zheng, G.; Shi, C. Effect of limestone on rheological, shrinkage and mechanical properties of alkali—Activated slag/fly ash grouting materials. Constr. Build. Mater. 2018, 191, 1285–1292. [Google Scholar] [CrossRef]

- Xiang, J.; Liu, L.; Cui, X.; He, Y.; Zheng, G.; Shi, C. Effect of Fuller-fine sand on rheological, drying shrinkage, and microstructural properties of metakaolin-based geopolymer grouting materials. Cem. Concr. Compos. 2019, 104, 103381. [Google Scholar] [CrossRef]

- Zhao, W.; Yang, Q. Study on the Applicability of Asphalt Concrete Skeleton in the Semi-Flexible Pavement. Constr. Build. Mater. 2022, 327, 126923. [Google Scholar] [CrossRef]

- Wang, D.; Liang, X.; Jiang, C.; Pan, Y. Impact Analysis of Carboxyl Latex on the Performance of Semi-Flexible Pavement Using Warm-Mix Technology. Constr. Build. Mater. 2018, 179, 566–575. [Google Scholar] [CrossRef]

- Koting, S.; Mahmud, H.; Karim, M.R. Influence of Superplasticizer Type and Dosage on the Workability and Strength of Cementitious Grout for Semi-Flexible Pavement Application. Proc. East. Asia Soc. Transp. Stud. 2007, 6, 280. [Google Scholar]

- Zhang, J.; Cai, J.; Pei, J.; Li, R.; Chen, X. Formulation and performance comparison of grouting materials for semi-flexible pavement. Constr. Build. Mater. 2016, 115, 582–592. [Google Scholar] [CrossRef]

- Wang, Y.J.; Guo, C.Y.; Tian, Y.F.; Wang, J.J. Design of Mix Proportion of Cement Mortar with High-Performance Composite Semi-Flexible Pavement. Adv. Mater. Res. 2013, 641, 342–345. [Google Scholar] [CrossRef]

- Cai, X.; Zhang, J.; Zhang, H.; Yao, Z.; Chen, X.; Yang, J. Identification of Microstructural Characteristics in Semi-Flexible Pavement Material Using Micromechanics and Nano-Techniques. Constr. Build. Mater. 2020, 246, 118426. [Google Scholar] [CrossRef]

- Khan, M.I.; Sutanto, M.H.; Khan, K.; Iqbal, M.; Napiah, M.B.; Zoorob, S.E.; Klemeš, J.J.; Bokhari, A.; Rafiq, W. Effective Use of Recycled Waste PET in Cementitious Grouts for Developing Sustainable Semi-Flexible Pavement Surfacing Using Artificial Neural Network (ANN). J. Clean. Prod. 2022, 340, 130840. [Google Scholar] [CrossRef]

- Davoodi, A.; Esfahani, M.A.; Bayat, M.; Mohammadyan-Yasouj, S.E.; Rahman, A. Influence of Nano-Silica Modified Rubber Mortar and EVA Modified Porous Asphalt on the Performance Improvement of Modified Semi-Flexible Pavement. Constr. Build. Mater. 2022, 337, 127573. [Google Scholar] [CrossRef]

- Pei, J.; Cai, J.; Zou, D.; Zhang, J.; Li, R.; Chen, X.; Jin, L. Design and Performance Validation of High-Performance Cement Paste as a Grouting Material for Semi-Flexible Pavement. Constr. Build. Mater. 2016, 126, 206–217. [Google Scholar] [CrossRef]

- Bharath, G.; Shukla, M.; Nagabushana, M.N.; Chandra, S.; Shaw, A. Laboratory and Field Evaluation of Cement Grouted Bituminous Mixes. Road Mater. Pavement Des. 2020, 21, 1694–1712. [Google Scholar]

- Yang, B.; Weng, X. The Influence on the Durability of Semi-Flexible Airport Pavement Materials to Cyclic Wheel Load Test. Constr. Build. Mater. 2015, 98, 171–175. [Google Scholar] [CrossRef]

- Ling, T.Q.; Zhao, Z.J.; Xiong, C.H.; Dong, Y.Y.; Liu, Y.Y.; Dong, Q. The Application of Semi-Flexible Pavement on Heavy Traffic Roads. Int. J. Pavement Res. Technol. 2009, 2, 211–217. [Google Scholar]

- Xiong, Z.; Gong, M.; Hong, J.; Deng, C. The Influential Factors of Semi-Flexible Pavement Cracking Performance. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2022, 37, 953–962. [Google Scholar] [CrossRef]

- Gong, M.; Xiong, Z.; Chen, H.; Deng, C.; Chen, X.; Yang, J.; Zhu, H.; Hong, J. Evaluation on the Cracking Resistance of Semi-Flexible Pavement Mixture by Laboratory Research and Field Validation. Constr. Build. Mater. 2019, 207, 387–395. [Google Scholar] [CrossRef]

- Yang, Q.; Zhao, W. Research on the Crack Resistance of Semi-Flexible Pavement Based on Bonding and Rheological Properties of Asphalt. Constr. Build. Mater. 2022, 356, 129093. [Google Scholar] [CrossRef]

- Zarei, S.; Ouyang, J.; Zhao, Y. Evaluation of Fatigue Life of Semi-Flexible Pavement with Cement Asphalt Emulsion Pastes. Constr. Build. Mater. 2022, 349, 128797. [Google Scholar] [CrossRef]

- T/CECS G:D51-01-2019; Technical Specifications for Road Poured Semi-Flexible Pavement. China Architecture Building Press: Beijing, China, 2019.

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. China Communications Press: Beijing, China, 2004.

- Walubita, L.F.; Jamison, B.P.; Das, G.; Scullion, T.; Martin, A.E.; Rand, D.; Mikhail, M. Search for a Laboratory Test to Evaluate Crack Resistance of Hot-Mix Asphalt. Transp. Res. Rec. J. Transp. Res. Board 2011, 2210, 73–80. [Google Scholar] [CrossRef]

- Pszczola, M.; Jaczewski, M.; Rys, D.; Jaskula, P.; Szydlowski, C. Evaluation of Asphalt Mixture Low-Temperature Performance in Bending Beam Creep Test. Materials 2018, 11, 100. [Google Scholar] [CrossRef]

- Lee, S.I.; Faruk, A.N.; Walubita, L.F. Comparison of fracture cracking parameters from monotonic loading tests: Indirect tension and monotonic overlay tester tests. Transp. Res. Rec. 2016, 2576, 19–27. [Google Scholar] [CrossRef]

- ASTM D6931-23; Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2023.

- Chong, K.P.; Kuruppu, M.D. New Specimen for Fracture Toughness Determination for Rock and Other Materials. Int. J. Fract. 1984, 26, R59–R62. [Google Scholar] [CrossRef]

- Somé, S.C.; Feeser, A.; Pavoine, A. Numerical and Experimental Investigation of Mode I Cracking of Asphalt Concrete Using Semi-Circular Bending Test. Constr. Build. Mater. 2018, 169, 34–46. [Google Scholar] [CrossRef]

- Jiang, J.; Ni, F.; Dong, Q.; Wu, F.; Dai, Y. Research on the Fatigue Equation of Asphalt Mixtures Based on Actual Stress Ratio Using Semi-Circular Bending Test. Constr. Build. Mater. 2018, 158, 996–1002. [Google Scholar] [CrossRef]

- Ni, F.; Yu, B.; Gu, X.; Xu, K. Characterization of Fatigue Damage of Hot Mix Asphalt Based on Residual Strength. J. Mater. Civ. Eng. 2017, 29, 04017075. [Google Scholar] [CrossRef]

- ASTM E1820-23; Standard Test Method for Measurement of Fracture Toughness. ASTM International: West Conshohocken, PA, USA, 2023.

- Jablonski, B.; Regehr, J.; Rempel, G. Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures: Final Report Part Design Analysis; National Cooperative Highway Research Program: Washington, DC, USA, 2001. [Google Scholar]

- Walubita, L.F.; Zhang, J.; Das, G.; Hu, X.; Mushota, C.; Alvarez, A.E.; Scullion, T. Hot-Mix Asphalt Permanent Deformation Evaluated by Hamburg Wheel Tracking, Dynamic Modulus, and Repeated Load Tests. Transp. Res. Rec. J. Transp. Res. Board 2012, 2296, 46–56. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. Specifications for Design of Highway Asphalt Pavement; China Communications Press: Beijing, China, 2017. [Google Scholar]

- Chen, S.; Wang, D.; Yi, J.; Feng, D. Analytical Calculations for Asphalt Pavement Considering Interlayer Performance. J. Transp. Eng. Part B Pavements 2022, 148, 04022022. [Google Scholar] [CrossRef]

- Ling, S.; Chen, Z.; Sun, D.; Ni, H.; Deng, Y.; Sun, Y. Optimal Design of Pouring Semi-Flexible Pavement via Laboratory Test, Numerical Research, and Field Validation. Transp. Res. Rec. 2022, 2676, 479–495. [Google Scholar] [CrossRef]

- Spadoni, S.; Graziani, A.; Canestrari, F. Laboratory and Field Investigation of Grouted Macadam for Semi-Flexible Pavements. Case Stud. Constr. Mater. 2022, 16, e00853. [Google Scholar]

- Zhao, Y.; Alae, M.; Fu, G. Investigation of Mechanisms of Top-Down Fatigue Cracking of Asphalt Pavement. Road Mater. Pavement Des. 2018, 19, 1436–1447. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, L.; Sun, L. Investigation of Top-Down Cracking Performance of In-Situ Asphalt Mixtures Based on Accelerated Pavement Testing and Laboratory Tests. Constr. Build. Mater. 2018, 179, 277–284. [Google Scholar] [CrossRef]

- Huang, K.; Onifade, I.; Birgisson, B. Calibration of Mechanics-Based Pavement Predictive Framework for Top-Down Cracking Performance of Flexible Pavement Considering Wheel Wander Effect. Constr. Build. Mater. 2021, 306, 124792. [Google Scholar] [CrossRef]

- Alae, M.; Zhao, Y.; Zarei, S.; Fu, G.; Cao, D. Effects of Layer Interface Conditions on Top-Down Fatigue Cracking of Asphalt Pavements. Int. J. Pavement Eng. 2020, 21, 280–288. [Google Scholar] [CrossRef]

| Technical Index | Requirements |

|---|---|

| Mobility (s) | 10~14 |

| Shrinkage rate of 7 d (%) | <0.3 |

| Bleeding ratio (3 h) | <3 |

| Compressive strength of 7 d (MPa) | 10~30 |

| Flexural strength 7 d (MPa) | >2 |

| Asphalt | SBS Asphalt | |

|---|---|---|

| Penetration, 0.1 mm | 30 °C | 97.7 |

| 25 °C | 74.1 | |

| 15 °C | 26.2 | |

| Ductility (cm) | 55.2 (5 °C) | |

| Softening point (°C) | 87.5 | |

| Properties | Unit | Sieve Size (mm) | Mineral Powder | |||||

|---|---|---|---|---|---|---|---|---|

| 16~19 | 13.2~16 | 9.5~13.2 | 4.75~9.5 | 2.36~4.75 | 0~2.36 | |||

| Apparent density | g/cm3 | 2.954 | 2.942 | 2.935 | 2.857 | 2.845 | 2.847 | 2.686 |

| Bulk density | g/cm3 | 2.862 | 2.875 | 2.863 | 2.824 | 2.758 | — | — |

| Water absorption | /% | 1.14 | 1.45 | 1.23 | 1.75 | 1.23 | — | — |

| Types of Mixtures | Sieve Passing Rate (%) | Optimum Asphalt Content (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | ||

| SFAC-13 | 100 | 100 | 95 | 53.5 | 12 | 10 | 8.5 | 8 | 6.5 | 6 | 4 | 3.36 |

| SFAC-16 | 100 | 95 | 85 | 50 | 15 | 12 | 9 | 8 | 7 | 5 | 4 | 3.31 |

| SMA-13 | 100 | 100 | 97 | 59.5 | 26.5 | 21.3 | 17.9 | 14.7 | 12.4 | 11.2 | 9.6 | 5.8 |

| Test Items | Water Cement Ratio | Fluidity (s) | Flexural Strength (MPa) | Compressive Strength (MPa) | ||

|---|---|---|---|---|---|---|

| 4 h | 7 d | 4 h | 7 d | |||

| GM | 0.40 | 12.9 | 2.3 | 5.8 | 18 | 29 |

| Asphalt Mixtures | Low-Temperature Bending Tensile Strength (MPa) | Maximum Bending Tensile Strain (10−6) | Bending Modulus (MPa) |

|---|---|---|---|

| SMA-13 | 8.4 | 3642 | 2306 |

| SFAC-13 (7 d) | 8.9 | 1856 | 4795 |

| SFAC-13 (28 d) | 9.4 | 1816 | 5176 |

| SFAC-16 (7 d) | 9.2 | 1902 | 4837 |

| SFAC-16 (28 d) | 9.8 | 1923 | 5096 |

| Temperatures | SMA-13 | SFAC-13 | SFAC-16 | ||

|---|---|---|---|---|---|

| 7 d | 28 d | 7 d | 28 d | ||

| 15 °C | 1.52 | 1.79 | 1.92 | 1.91 | 2.05 |

| 50 °C | 0.15 | 0.47 | 0.59 | 0.52 | 0.62 |

| Temperature (°C) | Parameter | SMA-13 | SFAC-13 | SFAC-16 |

|---|---|---|---|---|

| −10 | Peak load (kN) | 7.25 | 8.21 | 7.65 |

| Flexural tensile strength (MPa) | 7.22 | 8.17 | 7.61 | |

| Fracture energy (J/mm2) | 2147 | 2209 | 2325 | |

| 15 | Peak load (kN) | 4.52 | 5.85 | 6.37 |

| Flexural tensile strength (MPa) | 4.50 | 5.82 | 6.34 | |

| Fracture energy (J/mm2) | 1857 | 2156 | 2048 | |

| 25 | Peak load (kN) | 2.80 | 3.63 | 3.95 |

| Flexural tensile strength (MPa) | 2.79 | 3.61 | 3.93 | |

| Fracture energy (J/mm2) | 1328 | 1956 | 2185 |

| Asphalt Mixtures | Dynamic Modulus (MPa) | |||

|---|---|---|---|---|

| 5 °C | 20 °C | 35 °C | 50 °C | |

| SFAC-13 | 24,128 | 14,782 | 4862 | 2003 |

| SFAC-16 | 24,892 | 16,254 | 5642 | 2244 |

| SMA-13 | 15,062 | 10,333 | 2602 | 1144 |

| AC-16 | 16,736 | 10,180 | 3182 | 1090 |

| AC-20 | 16,611 | 10,418 | 2831 | 1195 |

| Materials | Thickness (cm) | Modulus (MPa) | Poisson’s Ratio |

|---|---|---|---|

| SMA-13 | 5 | Determined by temperature | 0.25 |

| AC-16 | 6 | Determined by temperature | 0.25 |

| AC-20 | 7 | Determined by temperature | 0.25 |

| Cement-stabilized macadam | 20 | 16,000 | 0.25 |

| Cement-stabilized macadam | 16 | 8500 | 0.25 |

| Graded aggregate | 15 | 320 | 0.3 |

| Subgrade | — | 70 | 0.35 |

| Mechanical Response | Pavement Structure | Interlayer Bonding Condition (MPa/cm) | ||||

|---|---|---|---|---|---|---|

| Debond | 100 | 500 | 1000 | Fully Bond | ||

| Pavement surface tensile strain | Original | 7.9 | 8.2 | 8.8 | 9.1 | 9.3 |

| Case 1 | 3.1 | 3.4 | 3.9 | 4.1 | 4.4 | |

| Case 2 | 2.6 | 3.2 | 3.8 | 3.9 | 4.2 | |

| Tensile strain at the bottom of asphalt layer | Original | 19.8 | 12.8 | 8.6 | 7.1 | 4.4 |

| Case 1 | 19.3 | 12.5 | 8.5 | 7.0 | 4.5 | |

| Case 2 | 18.7 | 12.23 | 8.4 | 7.0 | 4.6 | |

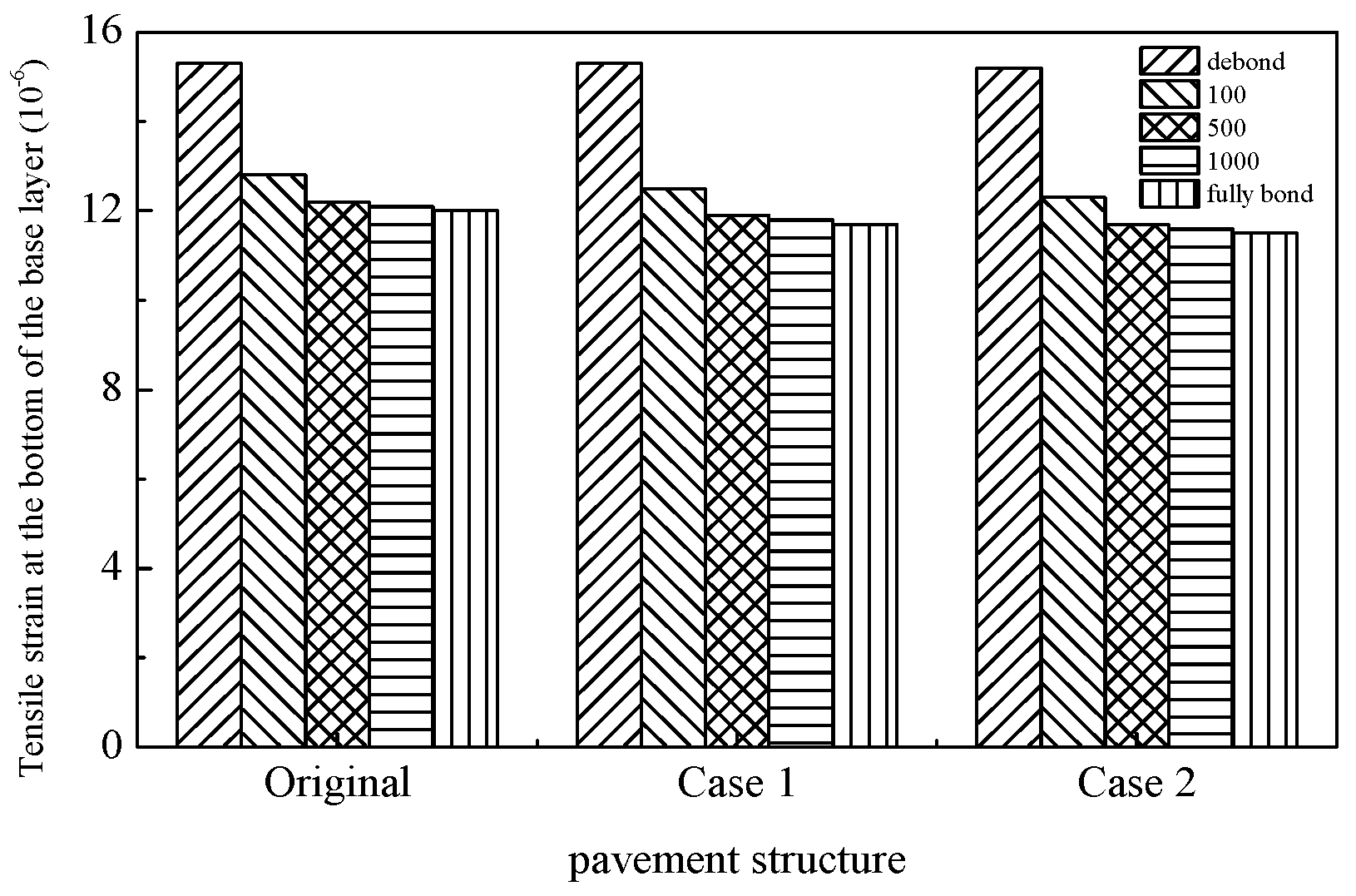

| Tensile strain at the bottom of the base layer | Original | 13.2 | 10.1 | 8.7 | 8.4 | 7.9 |

| Case 1 | 12.8 | 9.6 | 8.3 | 7.9 | 7.5 | |

| Case 2 | 12.6 | 9.5 | 8.1 | 7.8 | 7.3 | |

| Mechanical Response | Pavement Structure | Interlayer Bonding Condition (MPa/cm) | ||||

|---|---|---|---|---|---|---|

| Debond | 100 | 500 | 1000 | Fully Bond | ||

| Pavement surface tensile strain | Original | 16.6 | 15.6 | 15.9 | 16.1 | 16.3 |

| Case 1 | 10.2 | 9.4 | 9.7 | 9.8 | 10.0 | |

| Case 2 | 9.3 | 8.8 | 9.3 | 9.4 | 9.7 | |

| Tensile strain at the bottom of asphalt layer | Original | 24.1 | 14.9 | 8.5 | 6.2 | 1.9 |

| Case 1 | 23.7 | 14.6 | 8.4 | 6.2 | 2.1 | |

| Case 2 | 22.9 | 14.3 | 8.4 | 6.2 | 2.3 | |

| Tensile strain at the bottom of the base layer | Original | 13.6 | 10.5 | 9.11 | 8.7 | 8.3 |

| Case 1 | 13.4 | 10.1 | 8.8 | 8.4 | 7.9 | |

| Case 2 | 13.2 | 9.9 | 8.5 | 8.2 | 7.7 | |

| Mechanical Response | Pavement Structure | Interlayer Bonding Condition (MPa/cm) | ||||

|---|---|---|---|---|---|---|

| Debond | 100 | 500 | 1000 | Fully Bond | ||

| Pavement surface tensile strain | Original | 220.4 | 210.2 | 209.7 | 209.7 | 209.6 |

| Case 1 | 127.6 | 118.7 | 118.3 | 118.3 | 118.3 | |

| Case 2 | 116.61 | 109.4 | 109.2 | 109.2 | 109.2 | |

| Tensile strain at the bottom of asphalt layer | Original | 119.8 | 45.0 | 11.6 | 4.3 | −4.4 |

| Case 1 | 114.1 | 42.4 | 10.9 | 4.0 | −4.2 | |

| Case 2 | 104.5 | 39.6 | 10.1 | 3.7 | −4.1 | |

| Tensile strain at the bottom of the base layer | Original | 15.3 | 12.8 | 12.2 | 12.1 | 12.0 |

| Case 1 | 15.3 | 12.5 | 11.9 | 11.8 | 11.7 | |

| Case 2 | 15.2 | 12.3 | 11.7 | 11.6 | 11.5 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Zheng, J.; Wu, X.; Li, L. Evaluation of Crack Resistance Performance of Semi-Flexible Pavement Materials. Materials 2025, 18, 2796. https://doi.org/10.3390/ma18122796

Chen S, Zheng J, Wu X, Li L. Evaluation of Crack Resistance Performance of Semi-Flexible Pavement Materials. Materials. 2025; 18(12):2796. https://doi.org/10.3390/ma18122796

Chicago/Turabian StyleChen, Songqiang, Jianfei Zheng, Xi Wu, and Lufan Li. 2025. "Evaluation of Crack Resistance Performance of Semi-Flexible Pavement Materials" Materials 18, no. 12: 2796. https://doi.org/10.3390/ma18122796

APA StyleChen, S., Zheng, J., Wu, X., & Li, L. (2025). Evaluation of Crack Resistance Performance of Semi-Flexible Pavement Materials. Materials, 18(12), 2796. https://doi.org/10.3390/ma18122796