Influence of Post-Weld Heat Treatment on the Performance of UHSS Joints

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Welding Procedure and Heat Treatment Conditions

2.3. Microstructural and Mechanical Characterization

3. Results and Discussion

3.1. Thermo-Calc Analysis

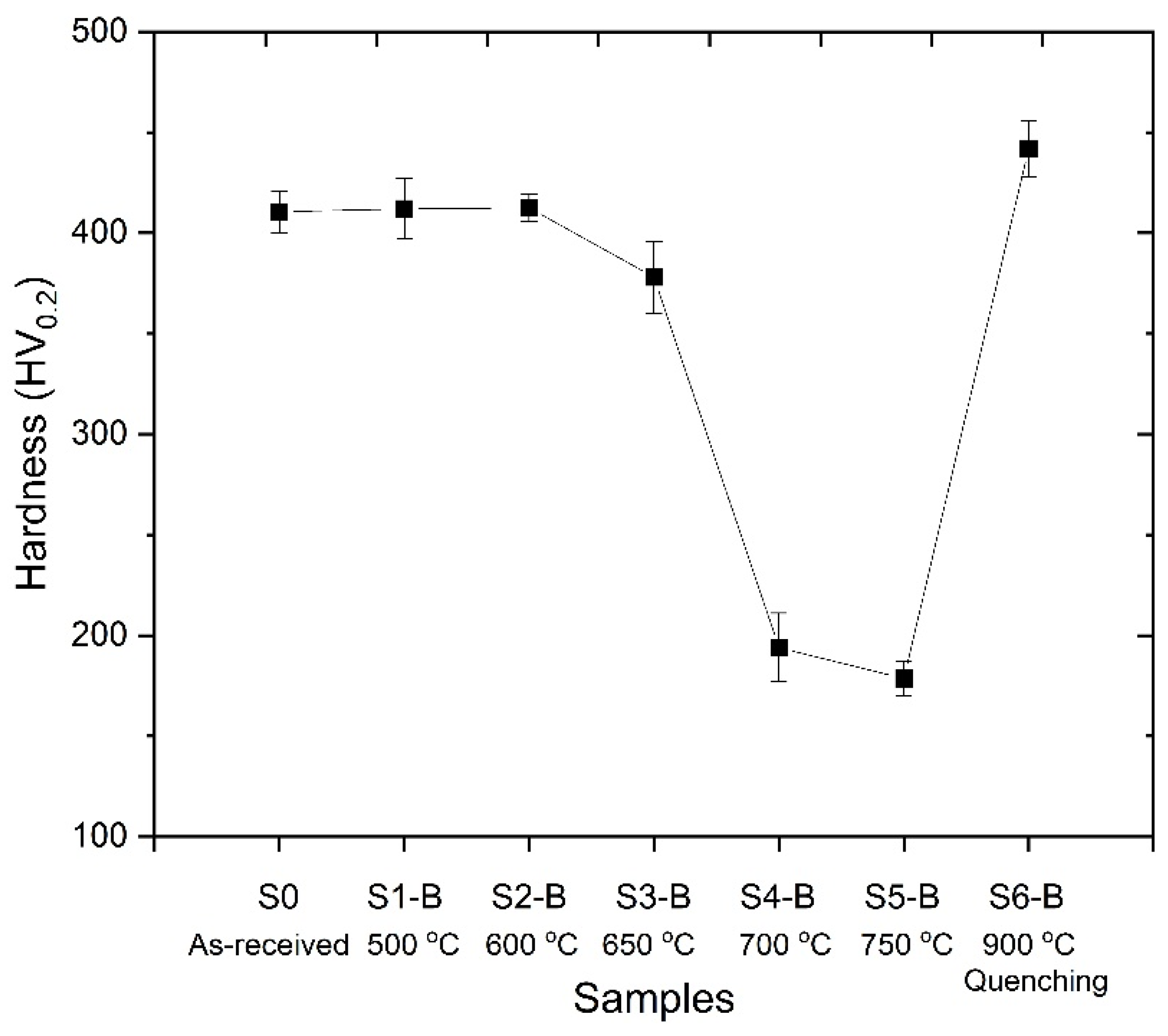

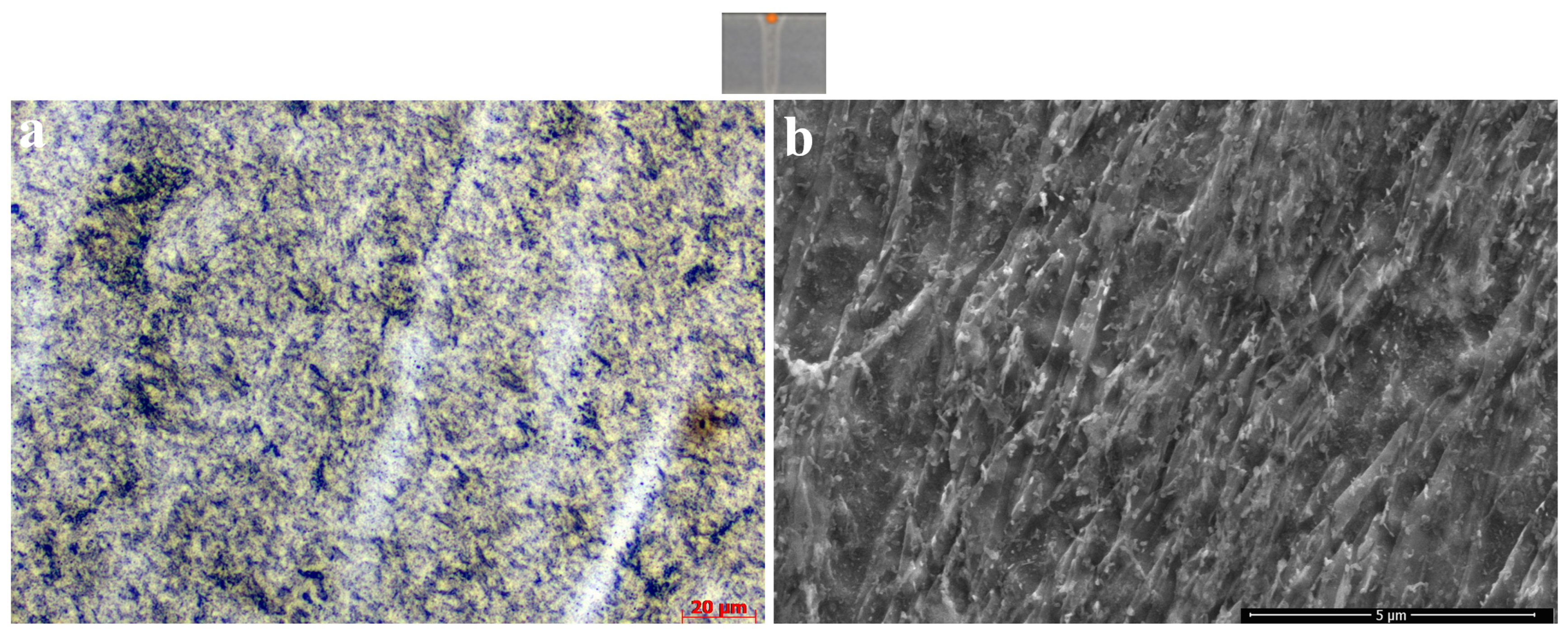

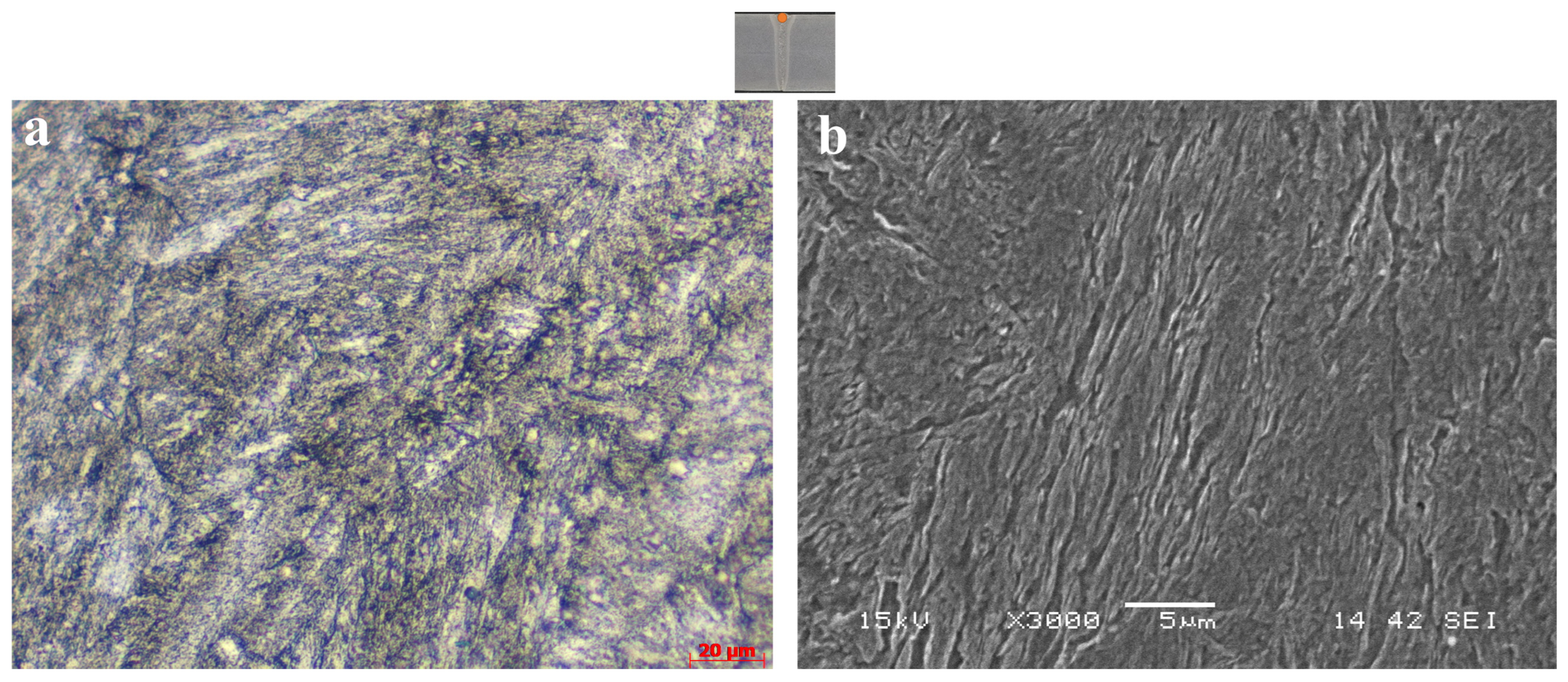

3.2. Characterization of the Base Material Before and After the Heat Treatment Process

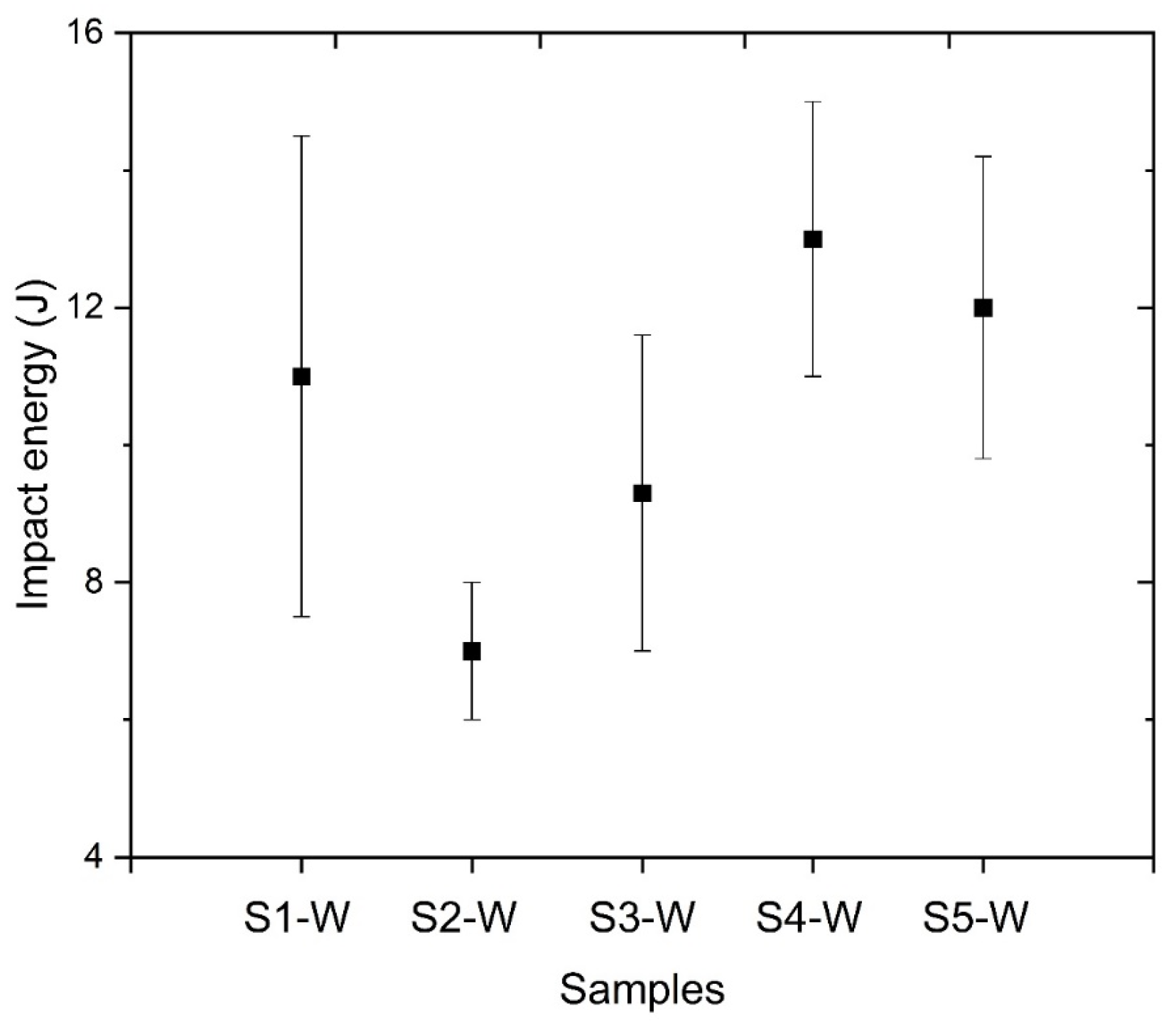

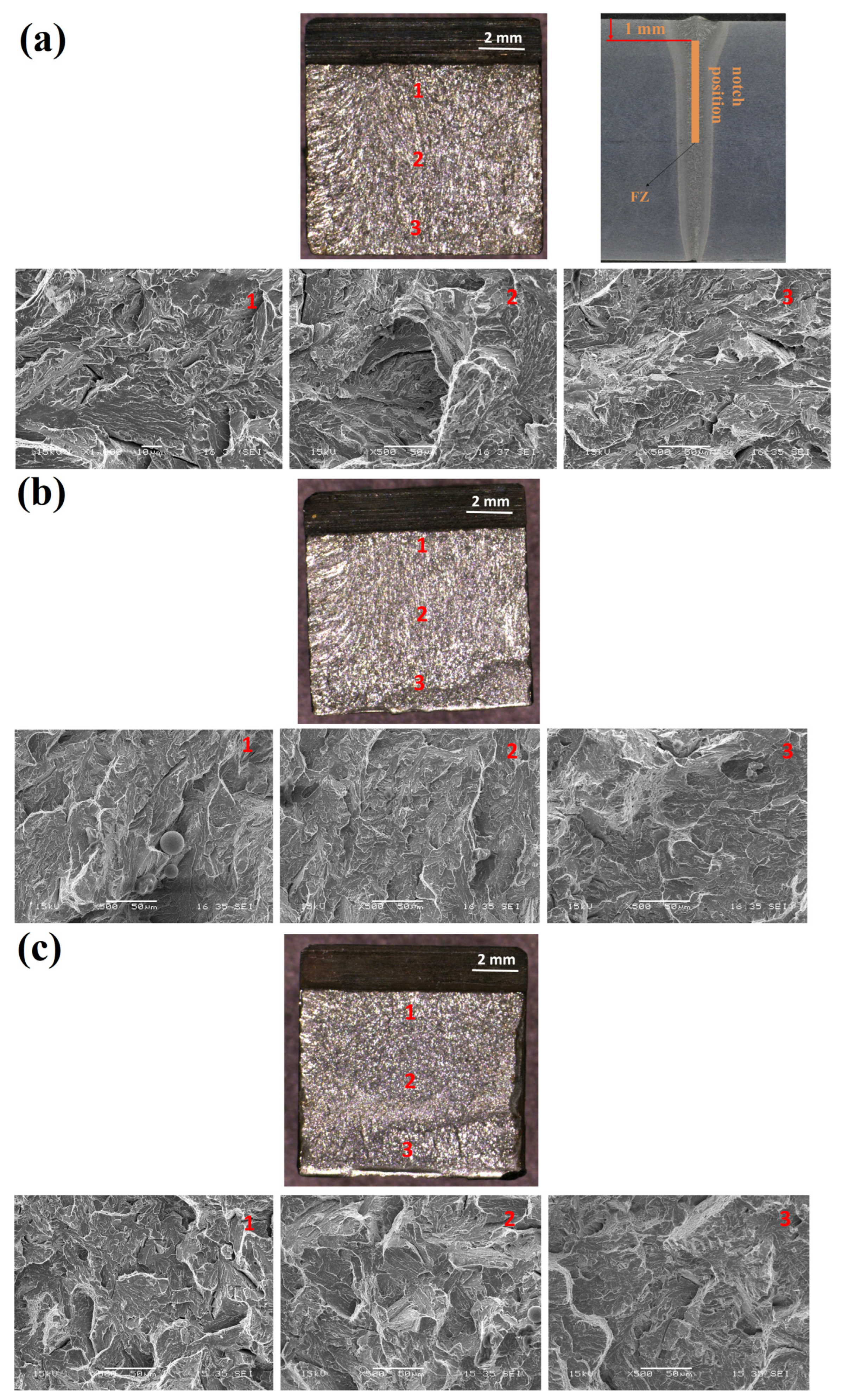

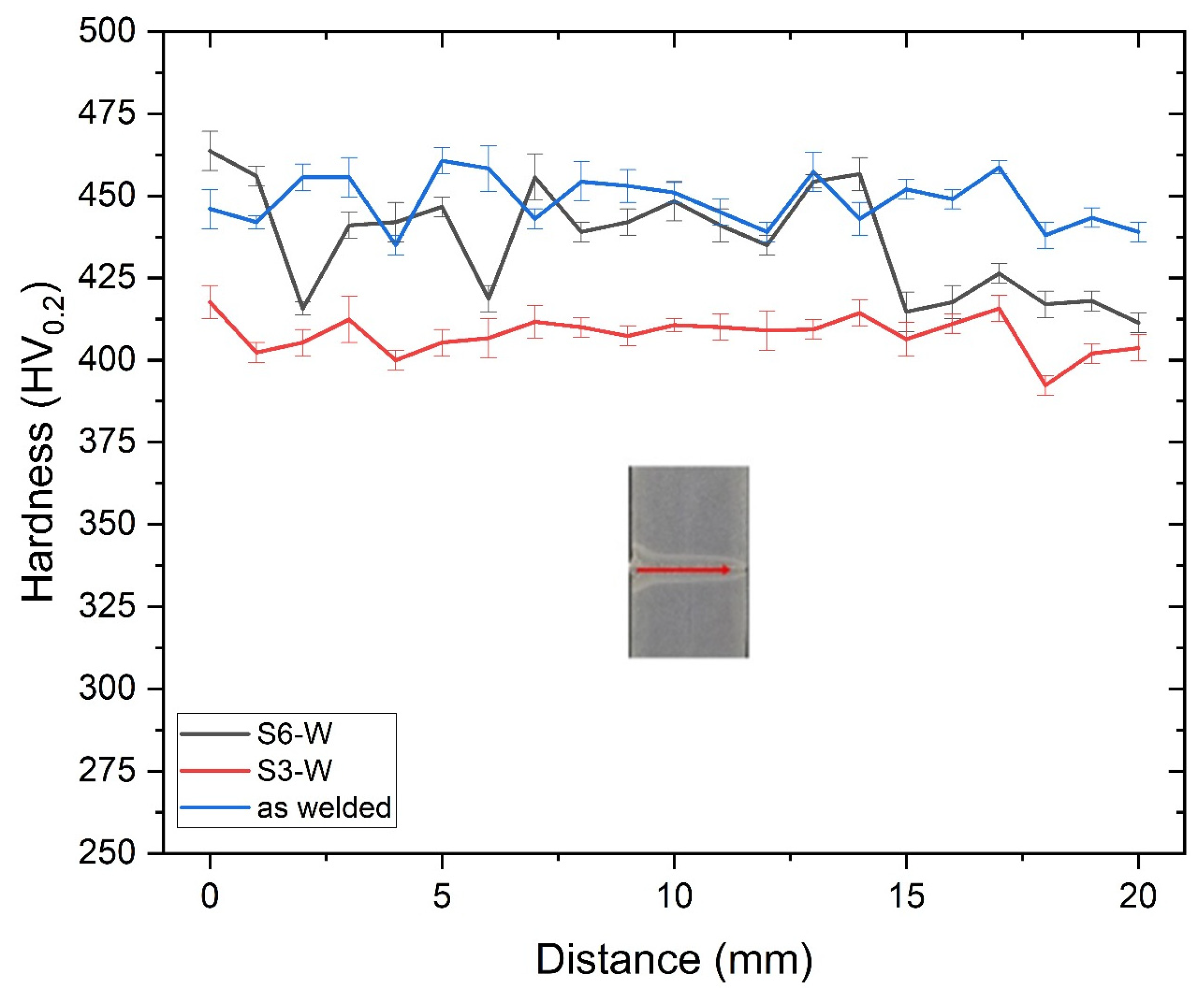

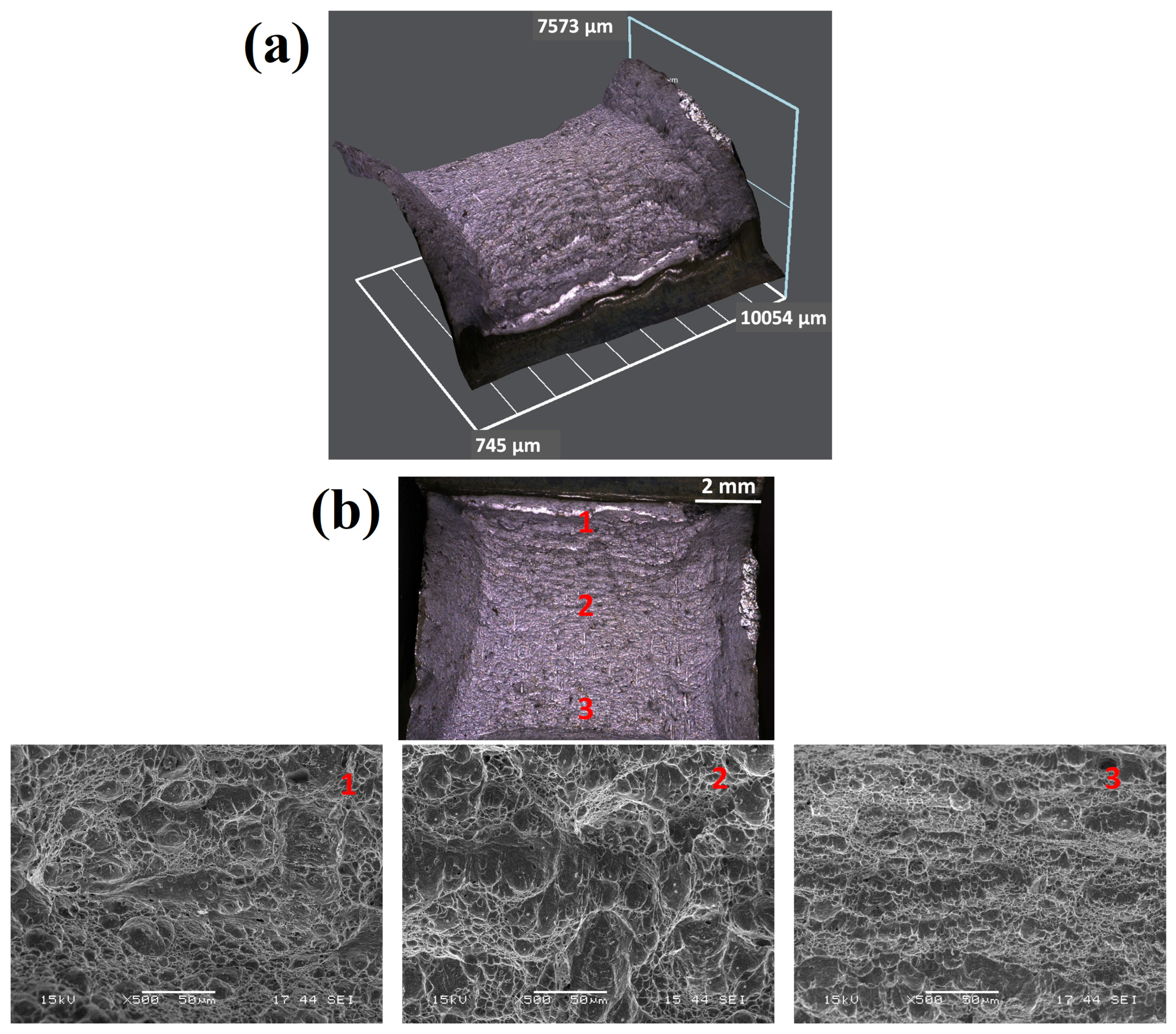

3.3. Characterization of the Weld Metal

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, J.B.; Luo, Y.L.; Su, L.; Lin, X.; Luo, Y.B.; Zhang, L. Low-temperature compression behaviour of square CFST columns using Q960 ultra-high strength steel. J. Constr. Steel Res. 2021, 183, 106727. [Google Scholar] [CrossRef]

- Madej, K.; Jachym, R. Welding of High Strength Toughened Structural Steel S960QL. Biul. Inst. Spaw. 2017, 2017, 6–16. [Google Scholar] [CrossRef] [PubMed]

- Nishimura, R.; Ma, N.; Liu, Y.; Li, W.; Yasuki, T. Measurement and analysis of welding deformation and residual stress in CMT welded lap joints of 1180 MPa steel sheets. J. Manuf. Process. 2021, 72, 515–528. [Google Scholar] [CrossRef]

- Schaupp, T.; Schroepfer, D.; Kromm, A.; Kannengiesser, T. Welding residual stresses in 960 MPa grade QT and TMCP high-strength steels. J. Manuf. Process. 2017, 27, 226–232. [Google Scholar] [CrossRef]

- Schaupp, T.; Schroepfer, D.; Kromm, A.; Kannengiesser, T. Welding Residual Stress Distribution of Quenched and Tempered and Thermo-Mechanically Hot Rolled High Strength Steels. Adv. Mater. Res. 2014, 996, 457–462. [Google Scholar] [CrossRef]

- Dzioba, I.; Pala, T. Influence of LWE on strength of welded joints of HSS S960-Experimental and numerical analysis. Materials 2020, 13, 747. [Google Scholar] [CrossRef]

- Esterl, R.; Sonnleitner, M.; Weißensteiner, I.; Hartl, K.; Schnitzer, R. Influence of quenching conditions on texture and mechanical properties of ultra-high-strength steels. J. Mater. Sci. 2019, 54, 12875–12886. [Google Scholar] [CrossRef]

- Laitila, J.; Larkiola, J. Effect of enhanced cooling on mechanical properties of a multipass welded martensitic steel. Weld. World 2019, 63, 637–646. [Google Scholar] [CrossRef]

- Tümer, M.; Pixner, F.; Vallant, R.; Domitner, J.; Enzinger, N. Mechanical and microstructural properties of S1100 UHSS welds obtained by EBW and MAG welding. Weld. World 2022, 66, 1199–1211. [Google Scholar] [CrossRef]

- Tümer, M.; Pixner, F.; Enzinger, N. Residual Stresses, Microstructure, and Mechanical Properties of Electron Beam Welded Thick S1100 Steel. J. Mater. Eng. Perform. 2022, 31, 2136–2146. [Google Scholar] [CrossRef]

- Sisodia, R.P.S.; Gáspár, M.; Hodúlová, E. Effect of beam oscillation and focusing on the electron beam welded 1100M high strength structural steel joint. J. Phys. Conf. Ser. 2023, 2443, 012008. [Google Scholar] [CrossRef]

- Tümer, M.; Schneider-Bröskamp, C.; Enzinger, N. Fusion welding of ultra-high strength structural steels—A review. J. Manuf. Process. 2022, 82, 203–229. [Google Scholar] [CrossRef]

- Sisodia, R.P.S.; Gáspár, M. An Approach to Assessing S960QL Steel Welded Joints Using EBW and GMAW. Metals 2022, 12, 678. [Google Scholar] [CrossRef]

- Steimbreger, C.; Gubeljak, N.; Vuherer, T.; Enzinger, N.; Ernst, W.; Chapetti, M. Effect of welding processes on the fatigue behaviour of ultra-high strength steel butt-welded joints. Eng. Fract. Mech. 2022, 275, 108845. [Google Scholar] [CrossRef]

- voestalpine Grobblech GmbH. High-Strength and Ultra-High-Strength Heavy Plates; voestalpine Grobblech GmbH: Linz, Austria, 2024; pp. 5–9. [Google Scholar]

- DIN EN ISO 6892-1; Metallic materials—Tensile Testing—Part 1: Method to Test at Room Temperature. ISO: Geneva, Switzerland, 2016.

- DIN EN ISO 148-1; Metallic Materials—Charpy Pendulum Impact Test—Part 1. ISO: Geneva, Switzerland, 2011.

- DIN EN ISO 9016; Destructive Tests on Welds in Metallic Materials—Impact Tests—Test Specimen Location, Notch Orientation and Examination. ISO: Geneva, Switzerland, 2012.

- ISO 6507-1; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. ISO: Geneva, Switzerland, 2018.

- Rehrl, J.; Mraczek, K.; Pichler, A.; Werner, E. The impact of Nb, Ti, Zr, B, V, and mo on the hydrogen diffusion in four different AHSS/UHSS microstructures. Steel Res. Int. 2014, 85, 336–346. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Chandiran, E.; Dong, H.K.; Kamikawa, N.; Miyamoto, G.; Furuhara, T. Current Understanding of Microstructure and Properties of Micro-Alloyed Low Carbon Steels Strengthened by Interphase Precipitation of Nano-Sized Alloy Carbides: A Review. JOM 2021, 73, 3214–3227. [Google Scholar] [CrossRef]

- Yin, R.; Liu, D.; Chen, J.; Wang, J. Investigation of Microstructure and Properties of Ultra-High Strength Steel in Aero-Engine Components following Heat Treatment and Deformation Processes. Metals 2023, 13, 1353. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Liu, B.; Wei, D. Synergistic enhancement of strength and ductility of cobalt-free maraging steel via nanometer-scaled microstructures. Mater. Sci. Eng. A 2022, 842, 143099. [Google Scholar] [CrossRef]

- Li, J.; Zhan, D.; Jiang, Z.; Zhang, H.; Yang, Y.; Zhang, Y. Progress on improving strength-toughness of ultra-high strength martensitic steels for aerospace applications: A review. J. Mater. Res. Technol. 2023, 23, 172–190. [Google Scholar] [CrossRef]

- Lee, S.; Kim, S.; Hwang, B.; Lee, B.S.; Lee, C.G. Effect of carbide distribution on the fracture toughness in the transition temperature region of an SA 508 steel. Acta Mater. 2002, 50, 4755–4762. [Google Scholar] [CrossRef]

- Shanmugam, S.; Ramisetti, N.K.; Misra, R.D.K.; Hartmann, J.; Jansto, S.G. Microstructure and high strength-toughness combination of a new 700 MPa Nb-microalloyed pipeline steel. Mater. Sci. Eng. A 2008, 478, 26–37. [Google Scholar] [CrossRef]

- Maruschak, P.; Konovalenko, I.; Sorochak, A. Methods for evaluating fracture patterns of polycrystalline materials based on the parameter analysis of ductile separation dimples: A review. Eng. Fail. Anal. 2023, 153, 107587. [Google Scholar] [CrossRef]

- Mondiere, A.; Déneux, V.; Binot, N.; Delagnes, D. Controlling the MC and M2C carbide precipitation in Ferrium® M54® steel to achieve optimum ultimate tensile strength/fracture toughness balance. Mater. Charact. 2018, 140, 103–112. [Google Scholar] [CrossRef]

- voestalpine Steel Division. Alform x-Treme; voestalpine Steel Division: Linz, Austria, 2023; pp. 1–3. [Google Scholar]

| Sample Code | Temperature | Heating Rate (°C/min) | Holding Time (min) | Cooling | |

|---|---|---|---|---|---|

| Base Metal | Weld Metal | ||||

| S1-B | S1-W | 500 | 15 | 120 | Free cooling in furnace |

| S2-B | S2-W | 600 | |||

| S3-B | S3-W | 650 | |||

| S4-B | S4-W | 700 | |||

| S5-B | S5-W | 750 | |||

| S6-B | S6-W | 900 | 30 | 5 | Quenching |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tümer, M.; Kısasöz, A.; Pixner, F.; Enzinger, N. Influence of Post-Weld Heat Treatment on the Performance of UHSS Joints. Materials 2025, 18, 2792. https://doi.org/10.3390/ma18122792

Tümer M, Kısasöz A, Pixner F, Enzinger N. Influence of Post-Weld Heat Treatment on the Performance of UHSS Joints. Materials. 2025; 18(12):2792. https://doi.org/10.3390/ma18122792

Chicago/Turabian StyleTümer, Mustafa, Alptekin Kısasöz, Florian Pixner, and Norbert Enzinger. 2025. "Influence of Post-Weld Heat Treatment on the Performance of UHSS Joints" Materials 18, no. 12: 2792. https://doi.org/10.3390/ma18122792

APA StyleTümer, M., Kısasöz, A., Pixner, F., & Enzinger, N. (2025). Influence of Post-Weld Heat Treatment on the Performance of UHSS Joints. Materials, 18(12), 2792. https://doi.org/10.3390/ma18122792