Compressive Failure and Dual-Defect Coupling Effects of Open-Hole Composite Laminates with Drilling-Induced Delamination

Abstract

1. Introduction

2. Sample Preparation and Experiment

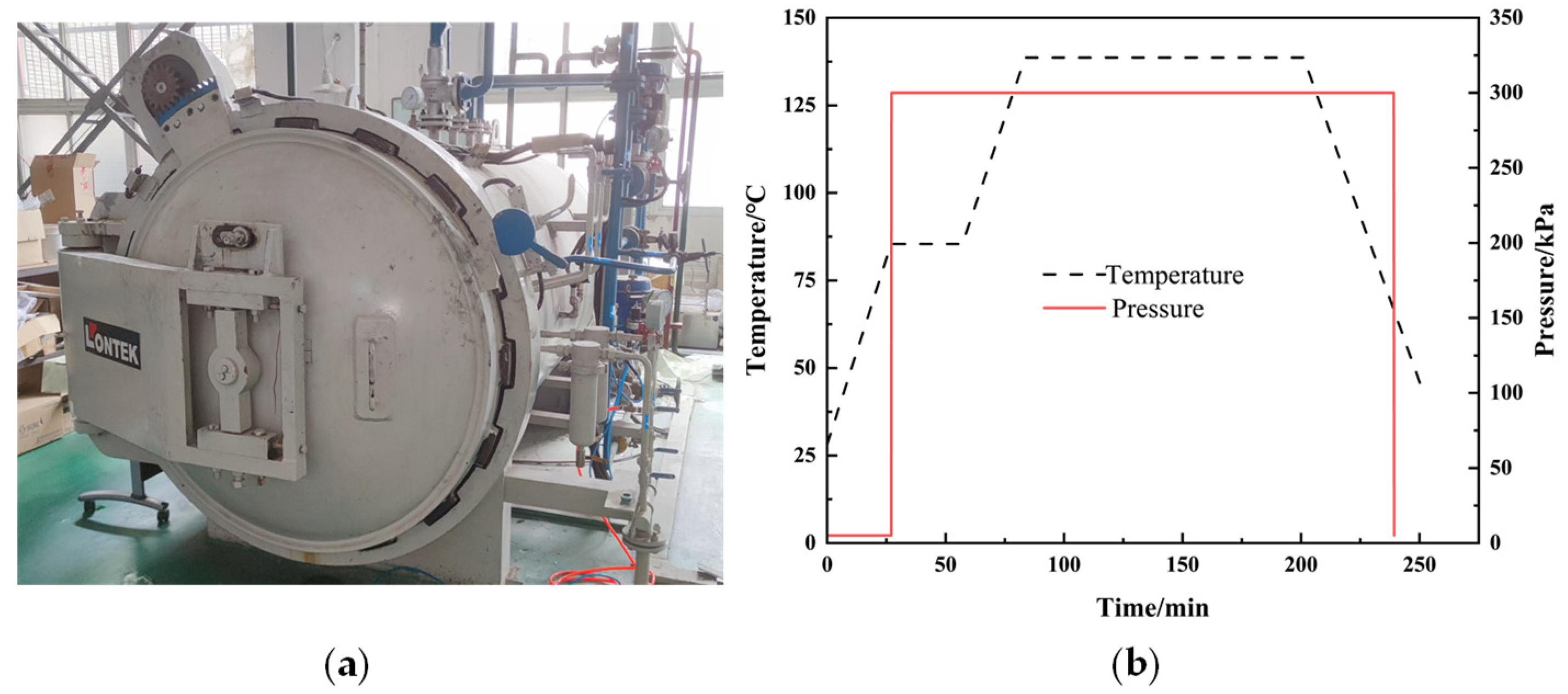

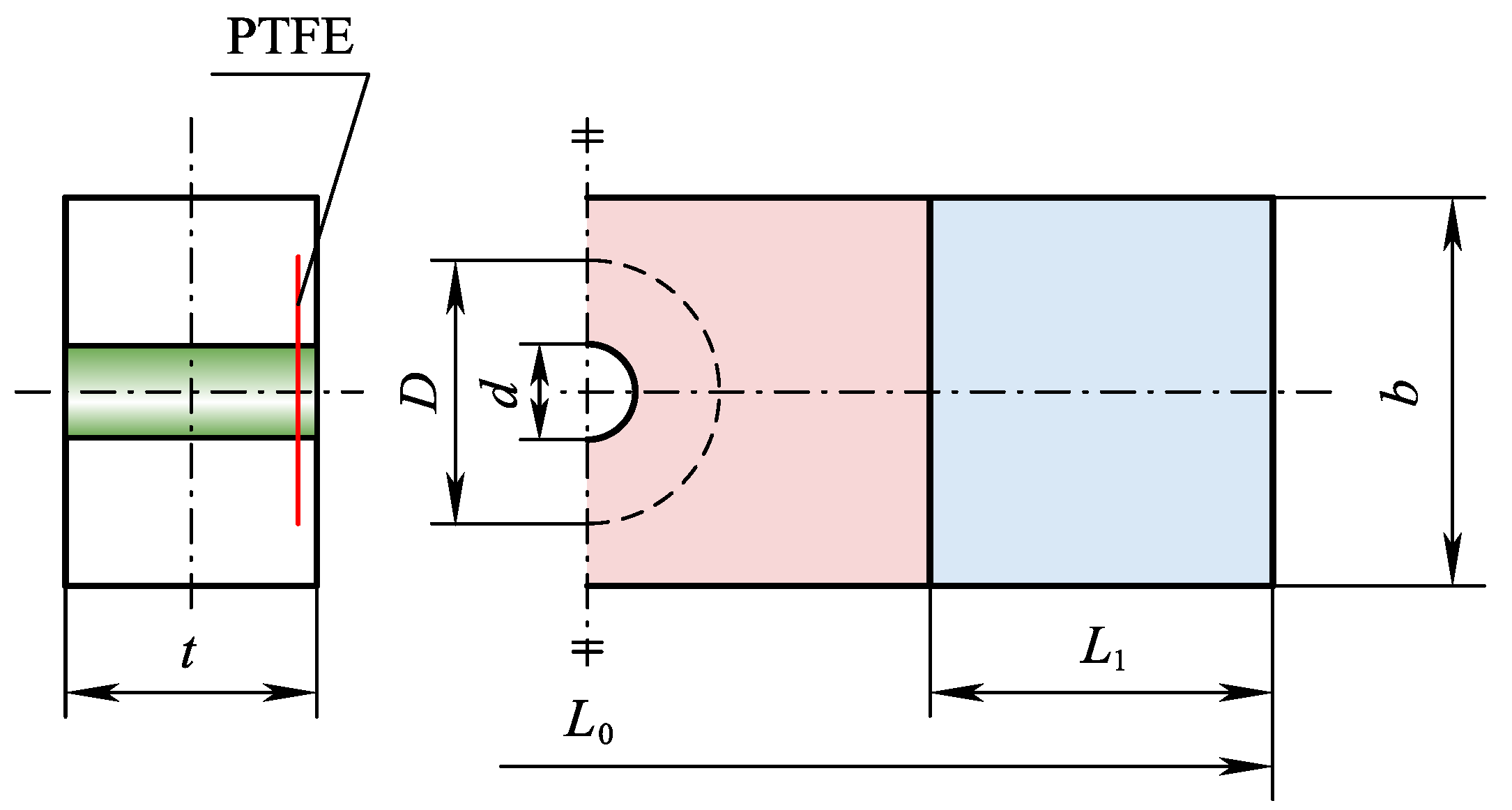

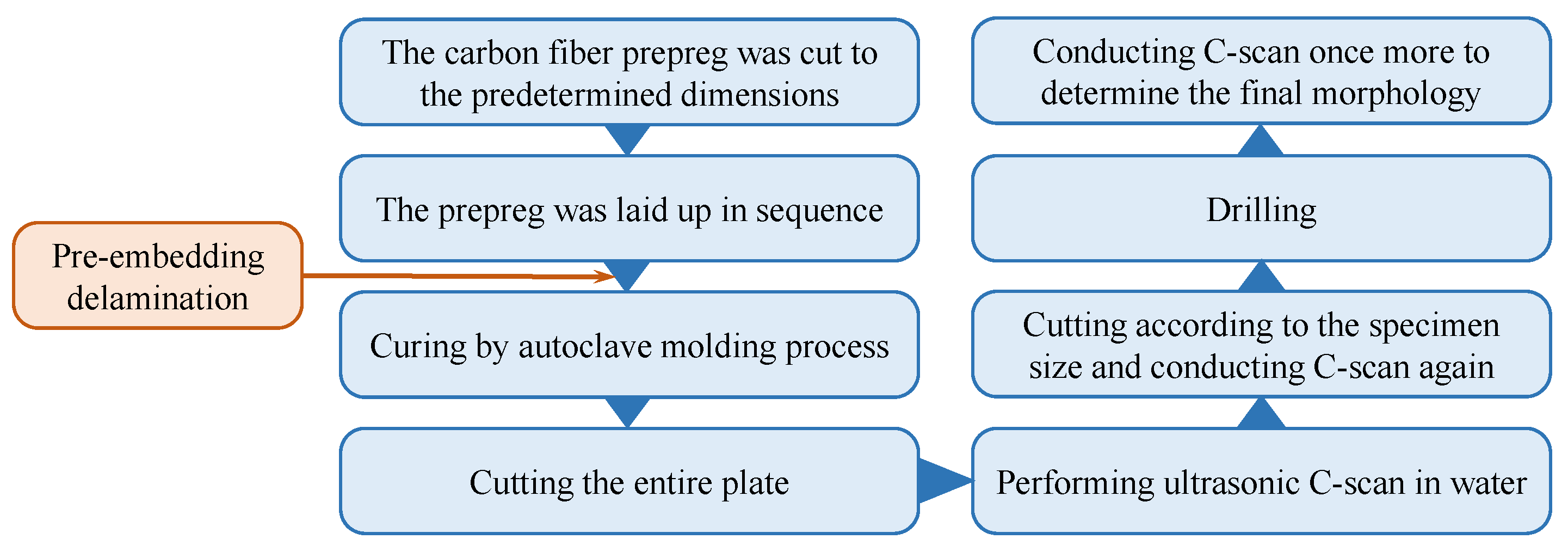

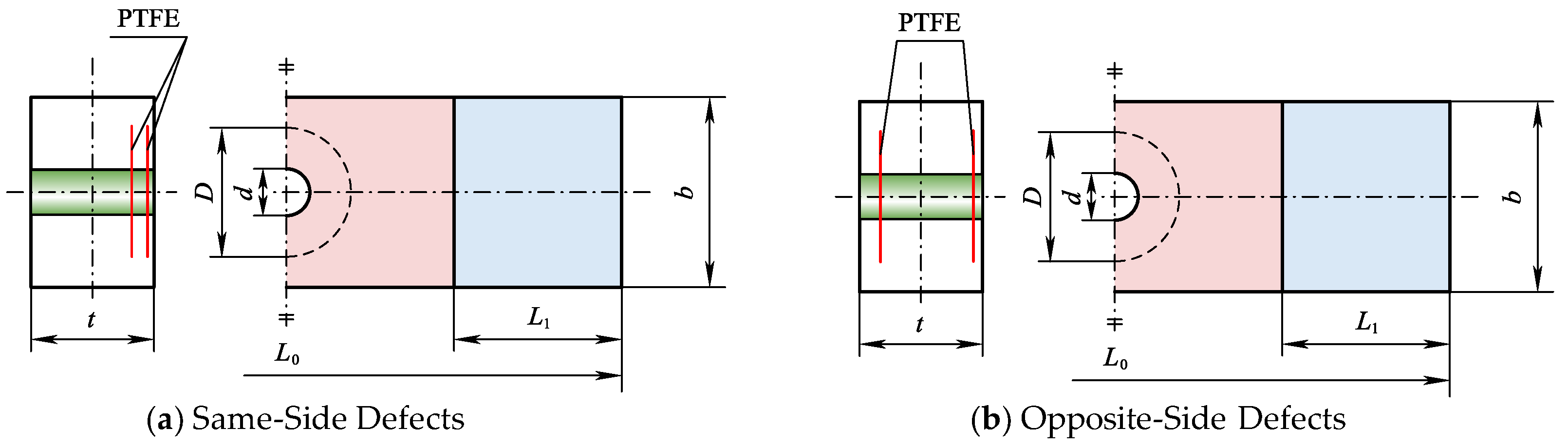

2.1. Sample Preparation

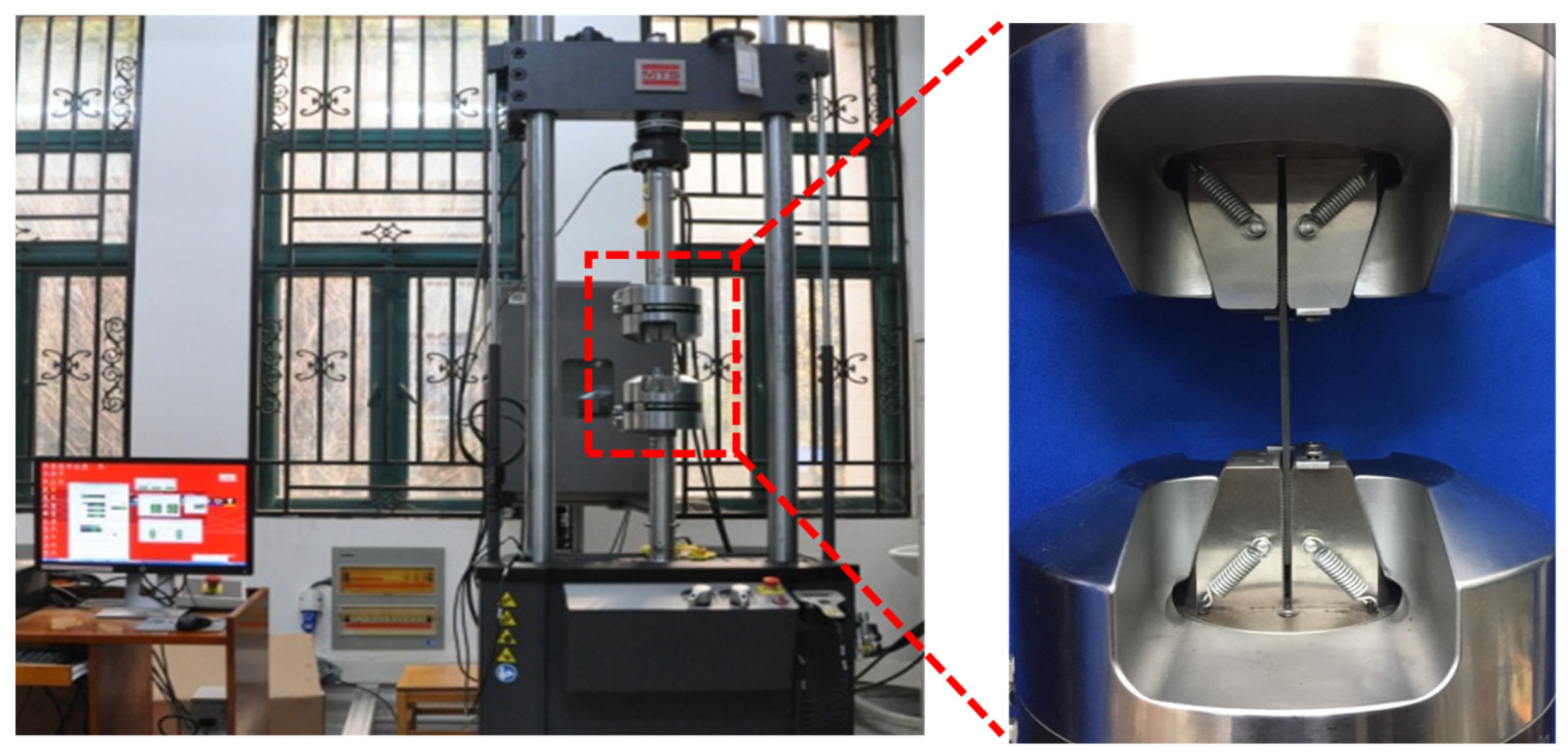

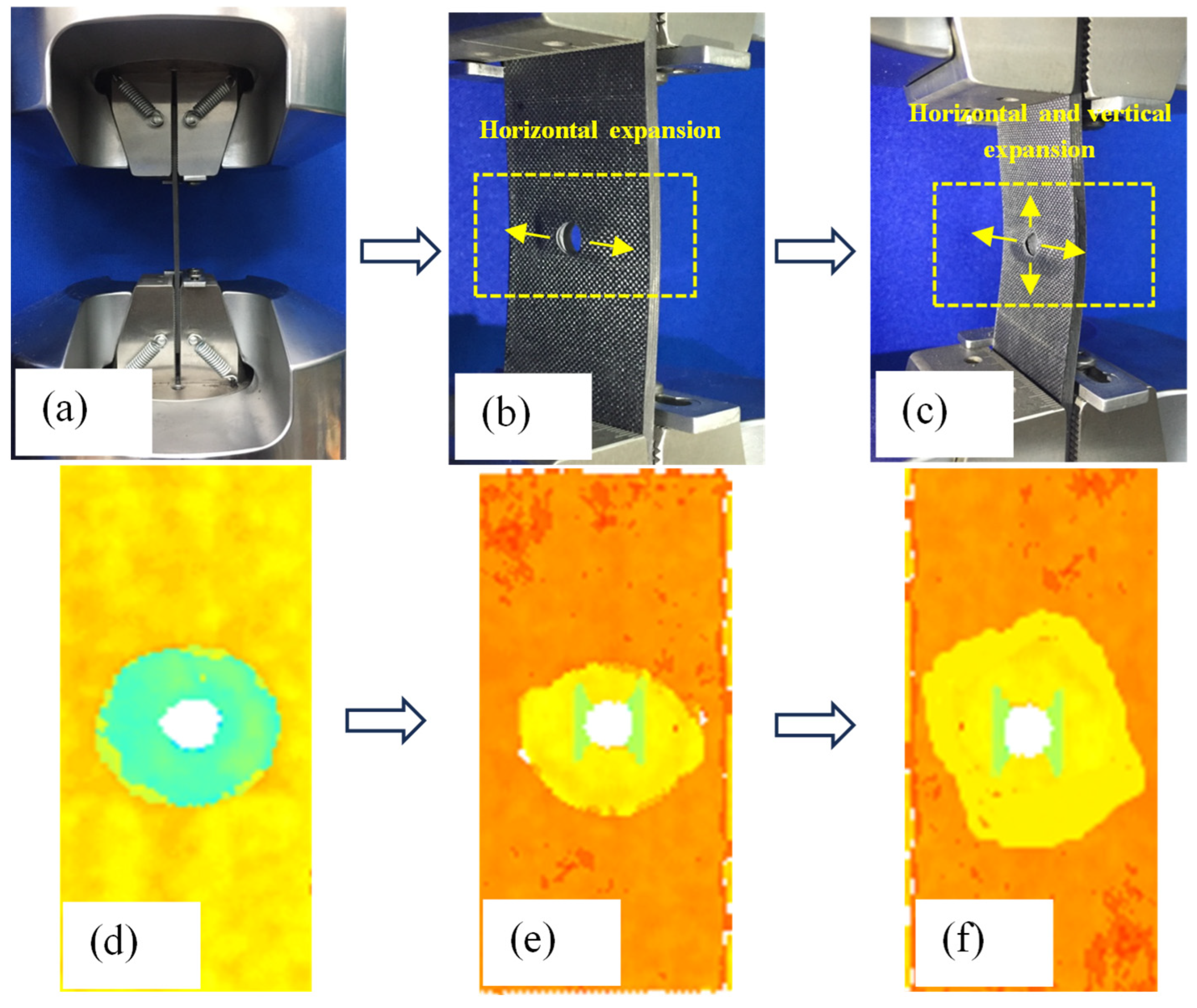

2.2. Compression Test Scheme

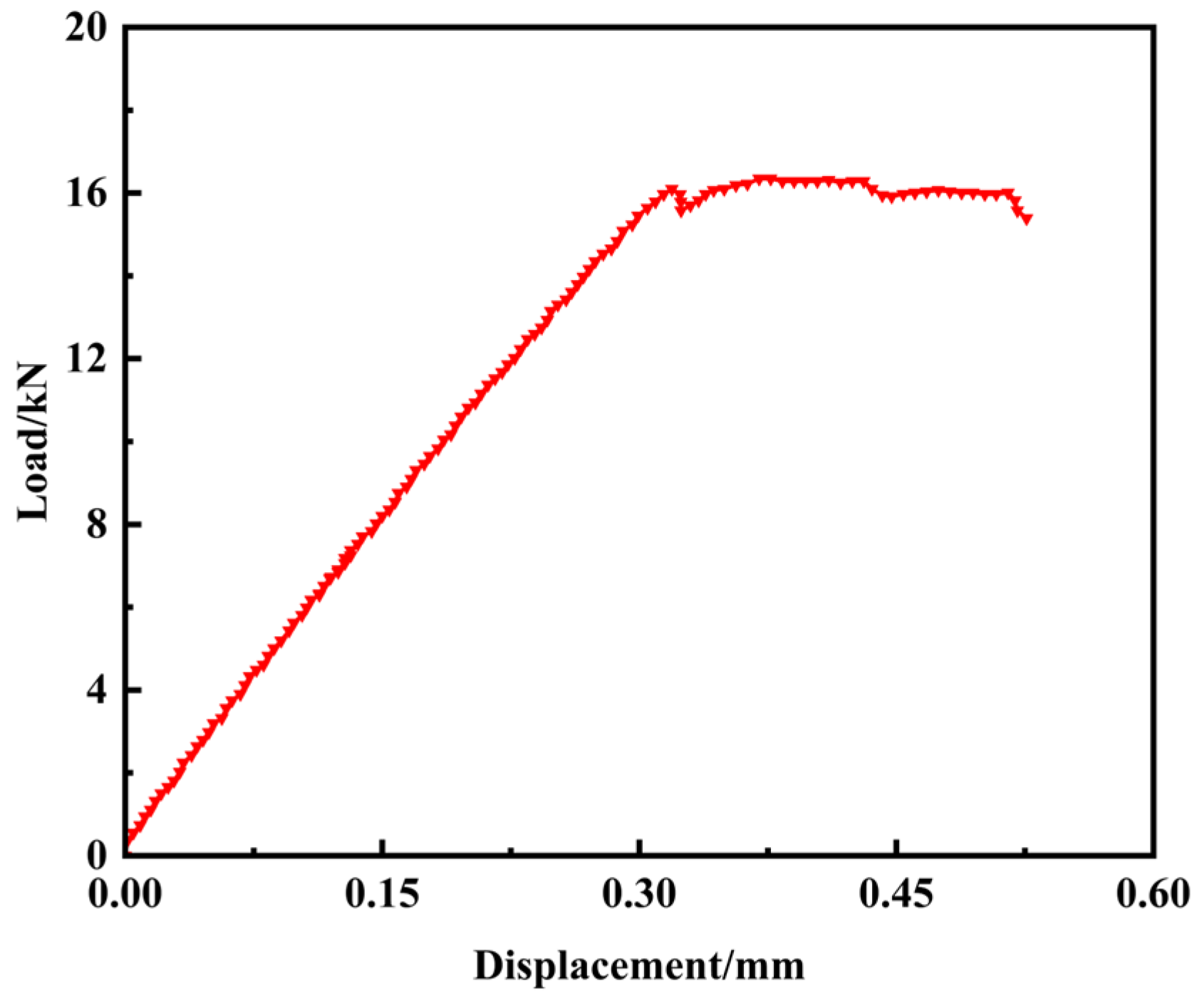

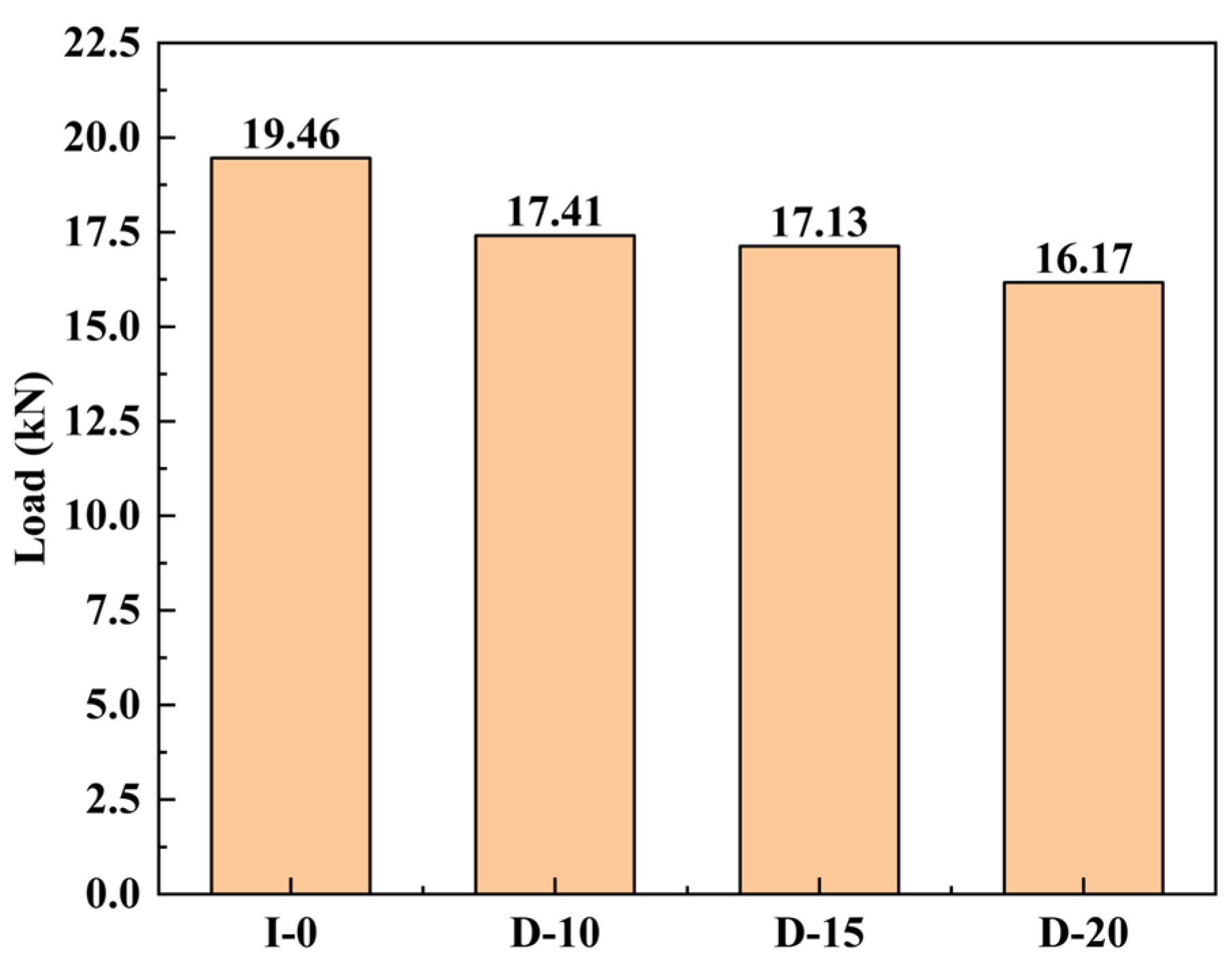

2.3. Compression Test Result

3. Numerical Simulation of Open-Hole Composite Laminates with Delamination Defects

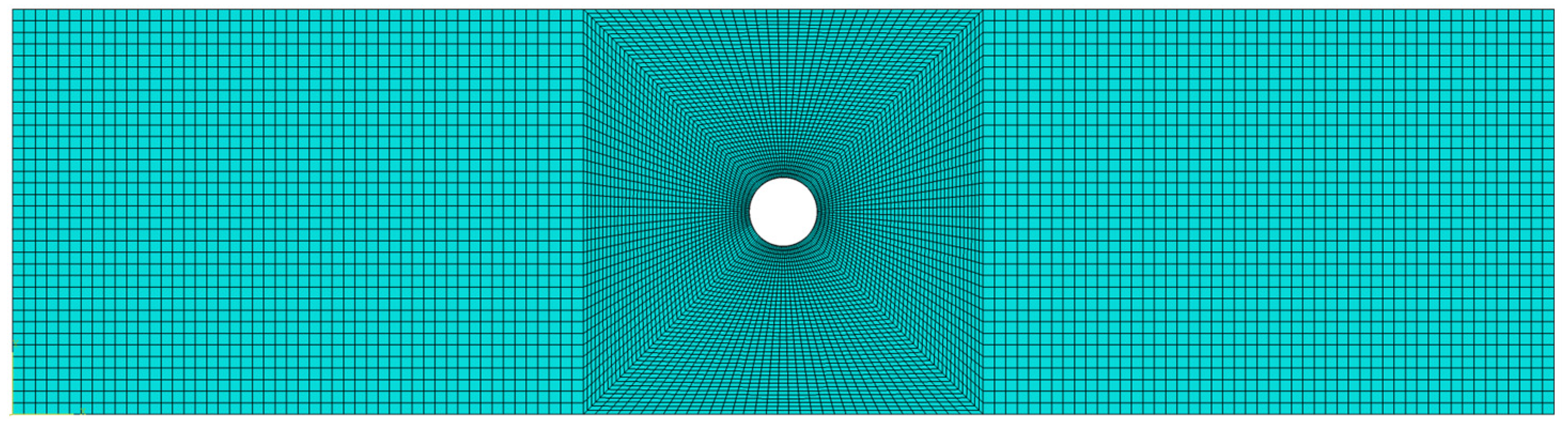

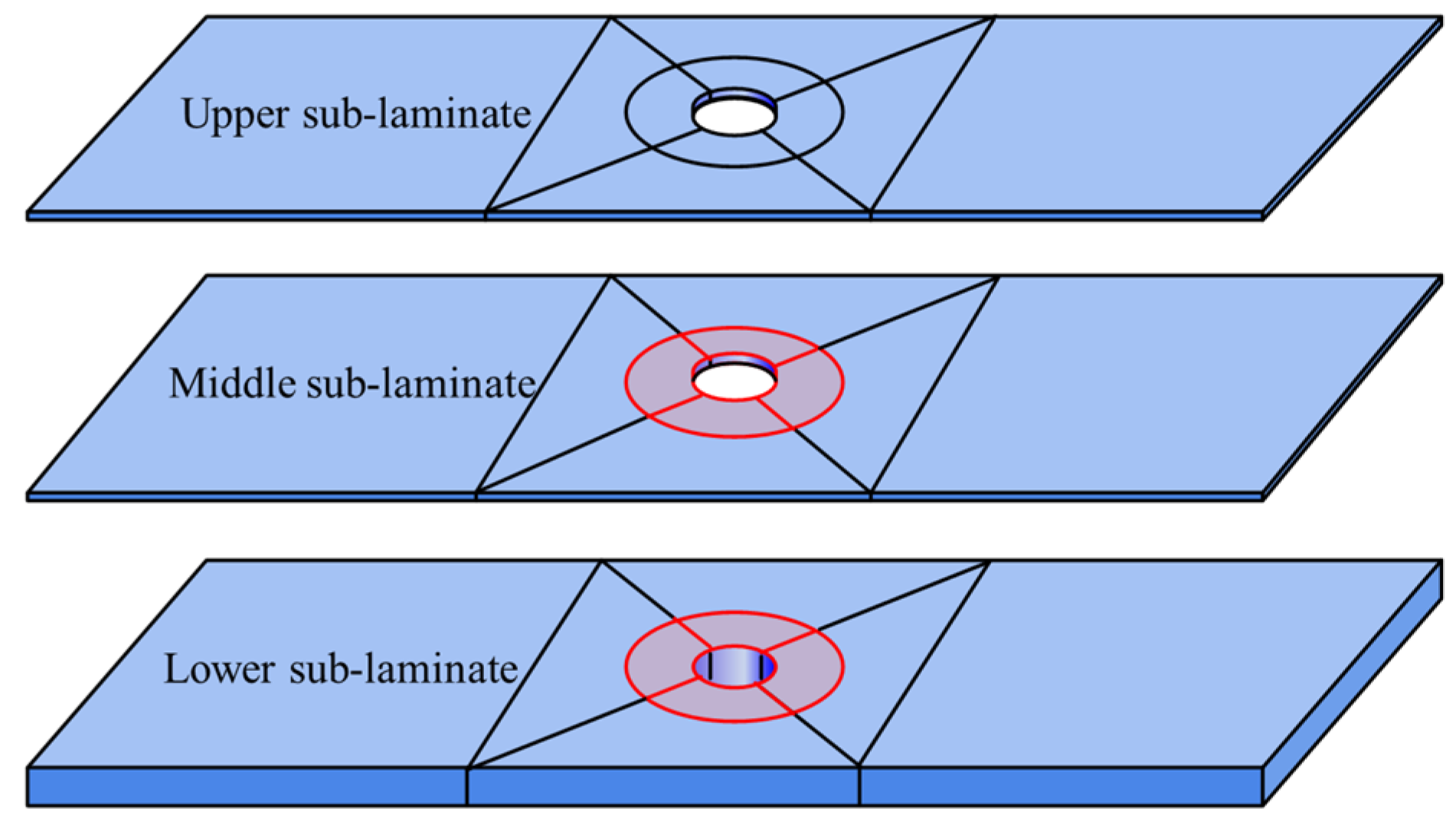

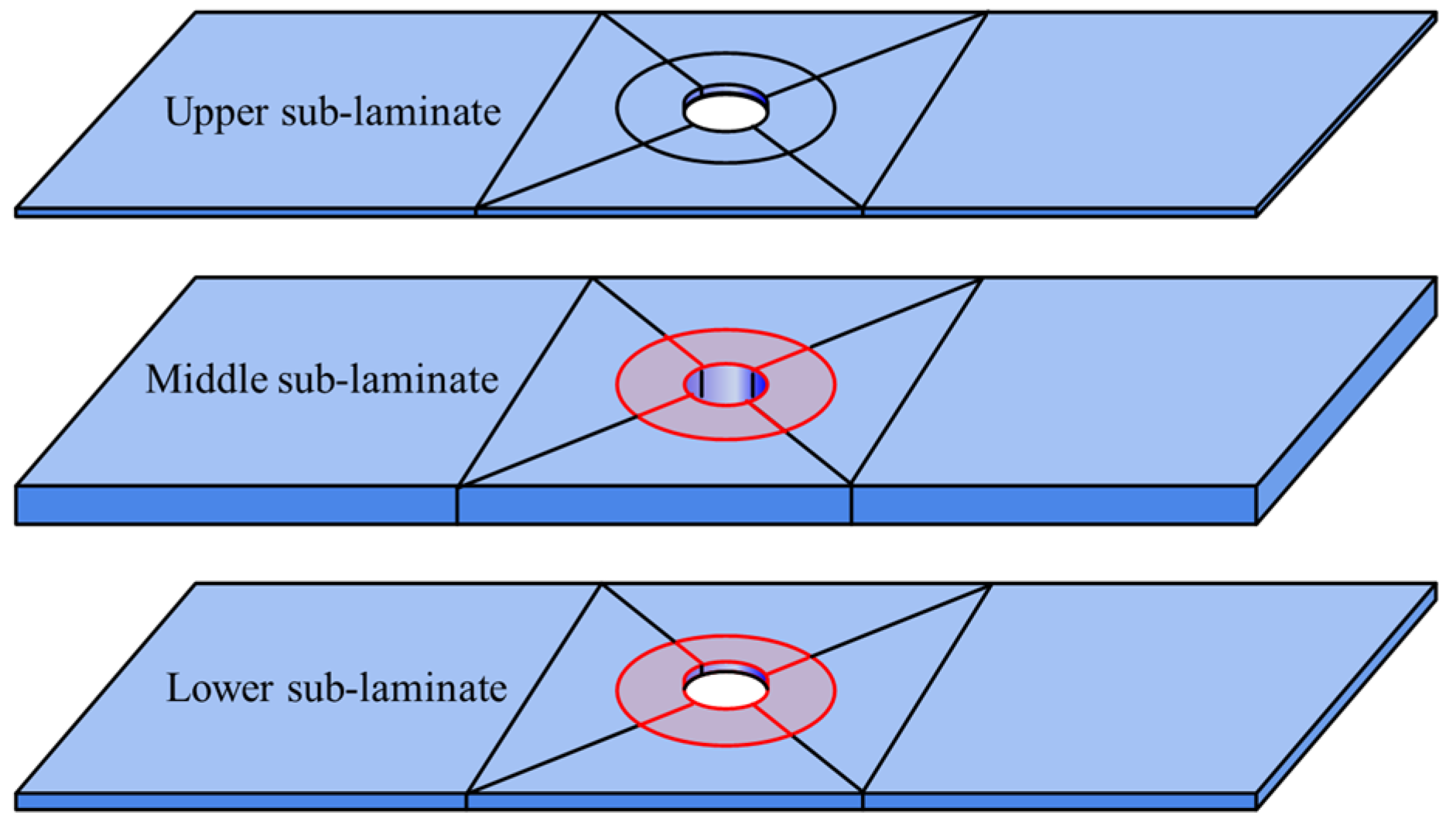

3.1. Numerical Model of Open-Hole Laminates with Delamination Defects

3.2. Cohesive Model

3.3. Damage Criterion

3.4. Numerical Analysis Results of Open-Hole Composite Laminates with Delamination Defects

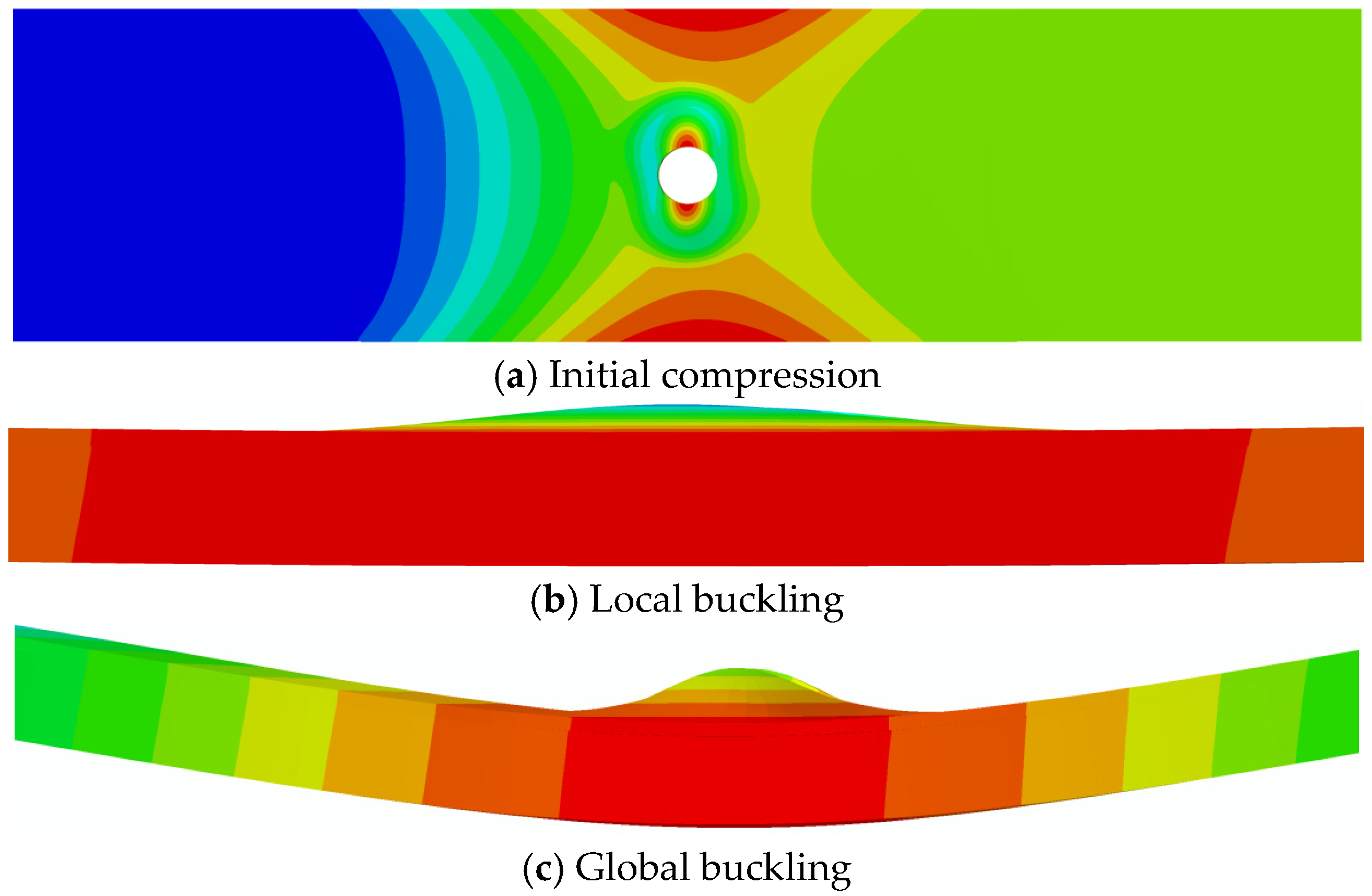

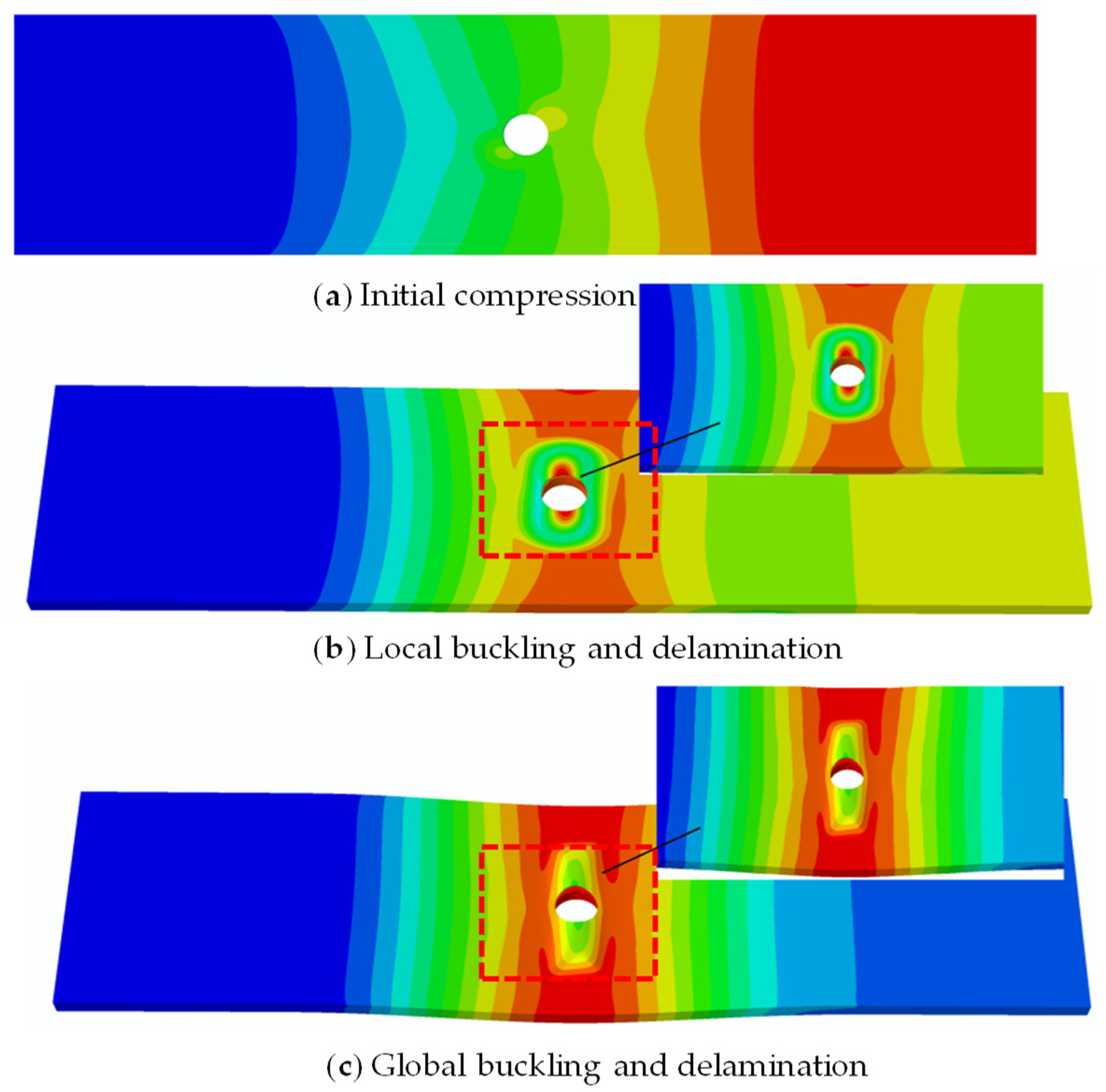

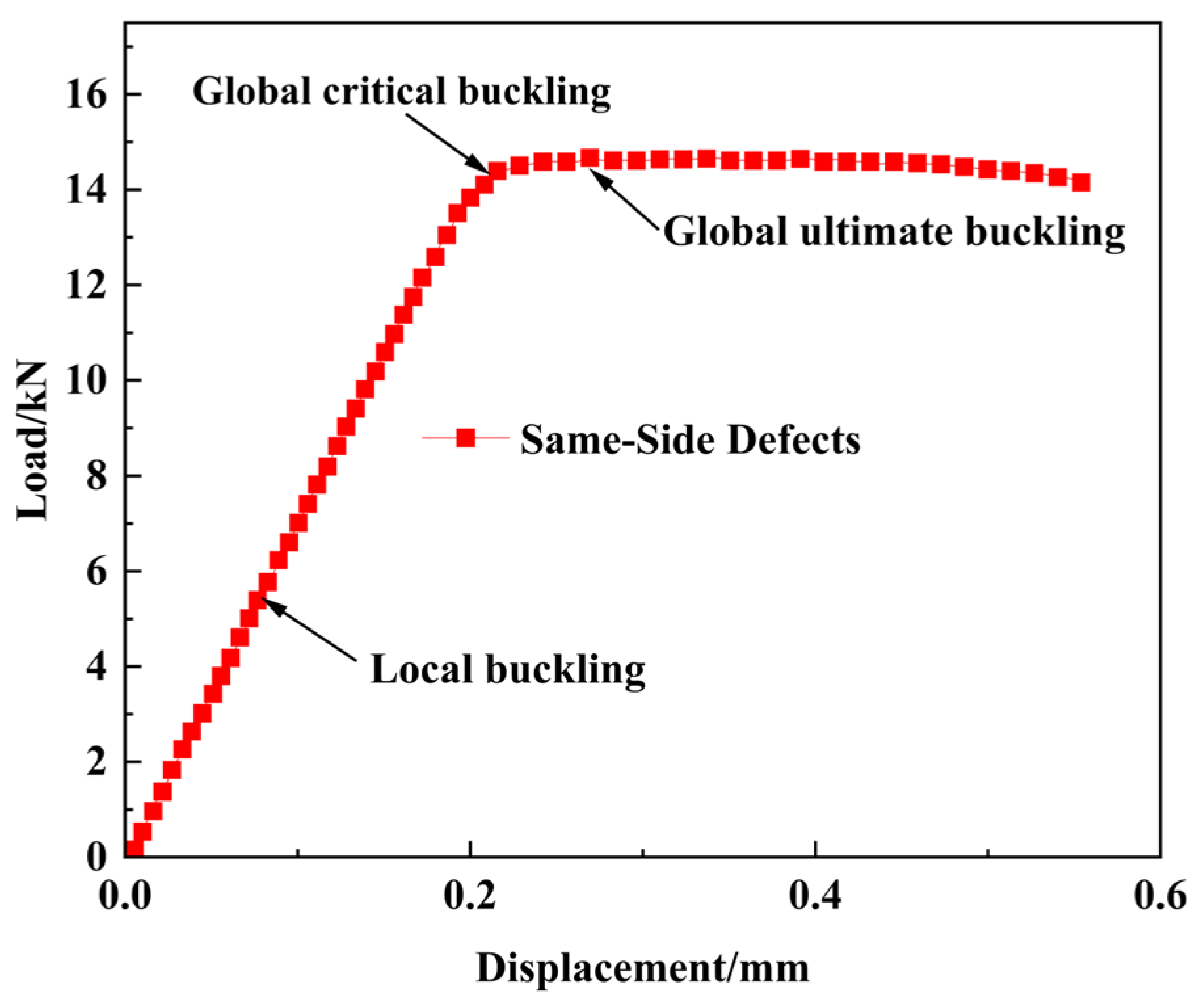

3.4.1. Analysis of Compressive Buckling Simulation Results

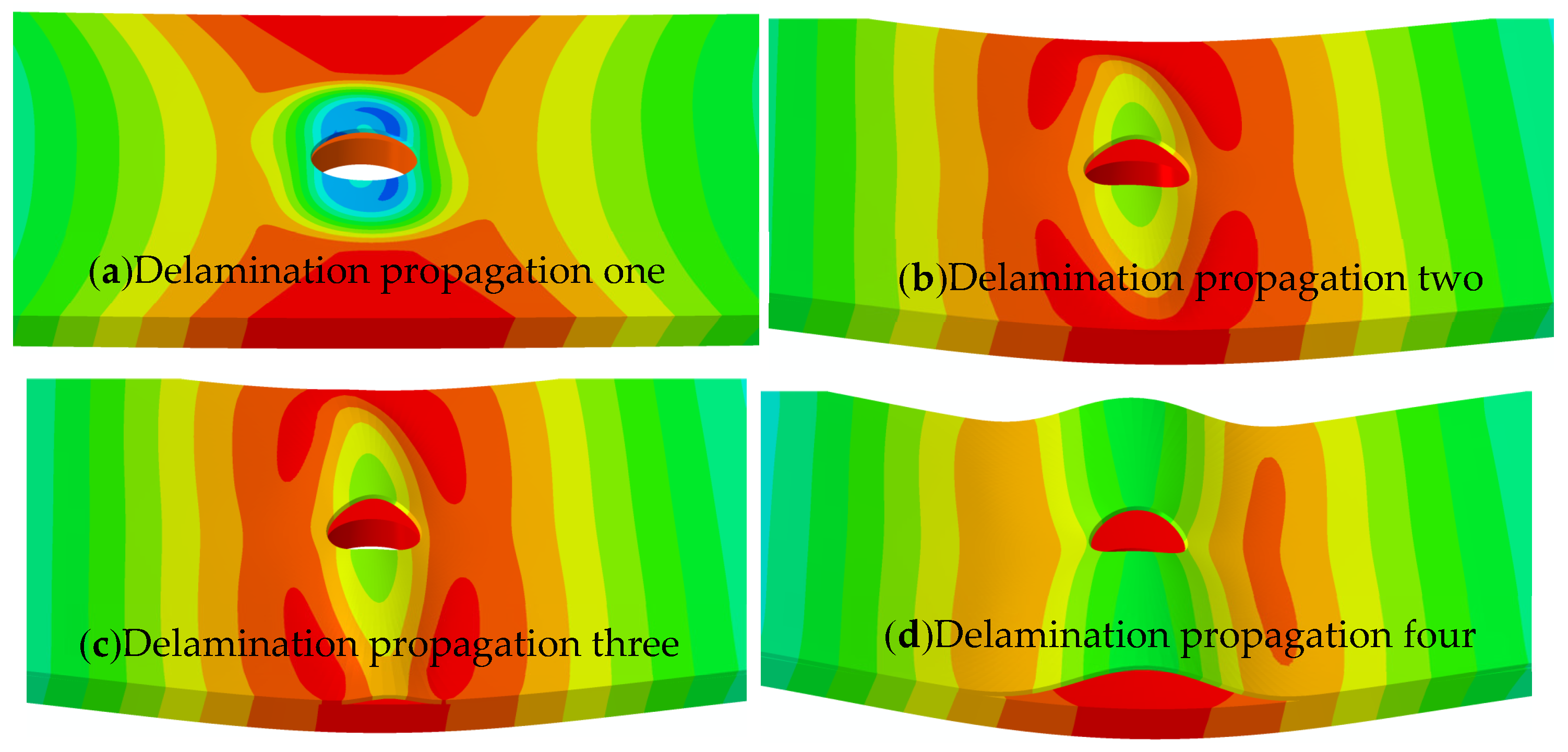

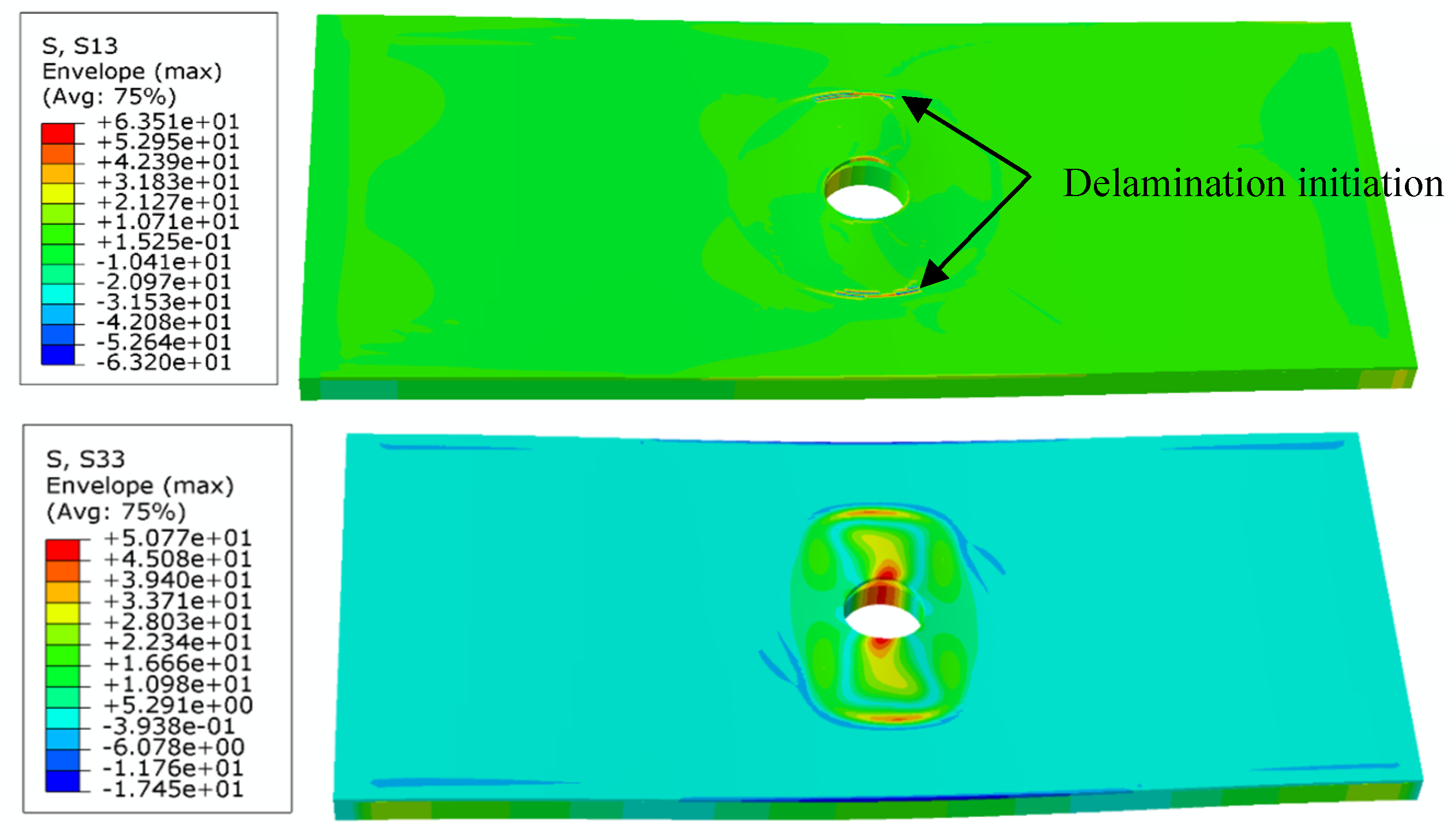

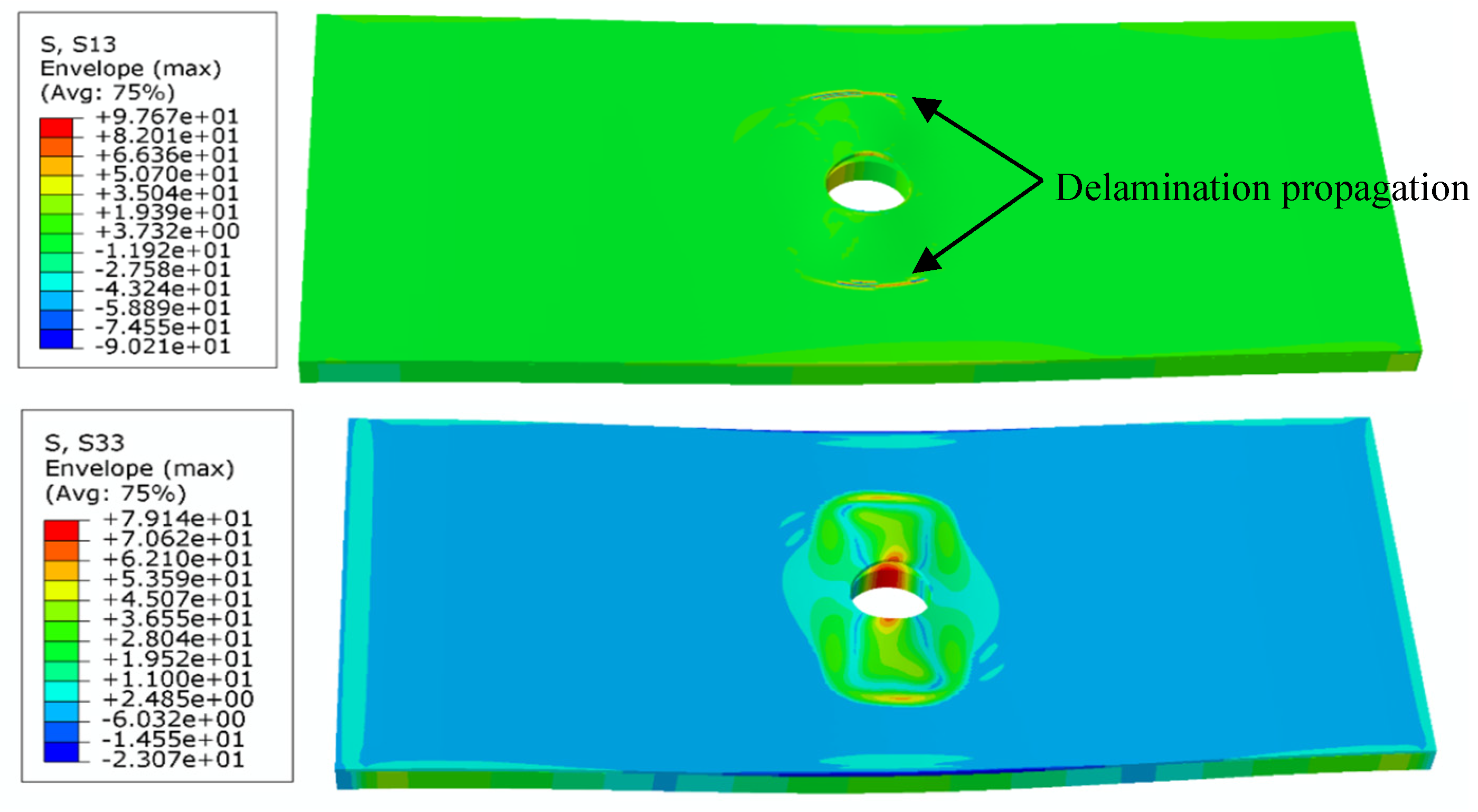

3.4.2. Analysis of Compressive Delamination Propagation Simulation Results

4. Dual-Defect Coupling Effects of Open-Hole Composite Laminates

4.1. Same-Side Defect Coupling Effects on Compressive Failure of Open-Hole Composite Laminates

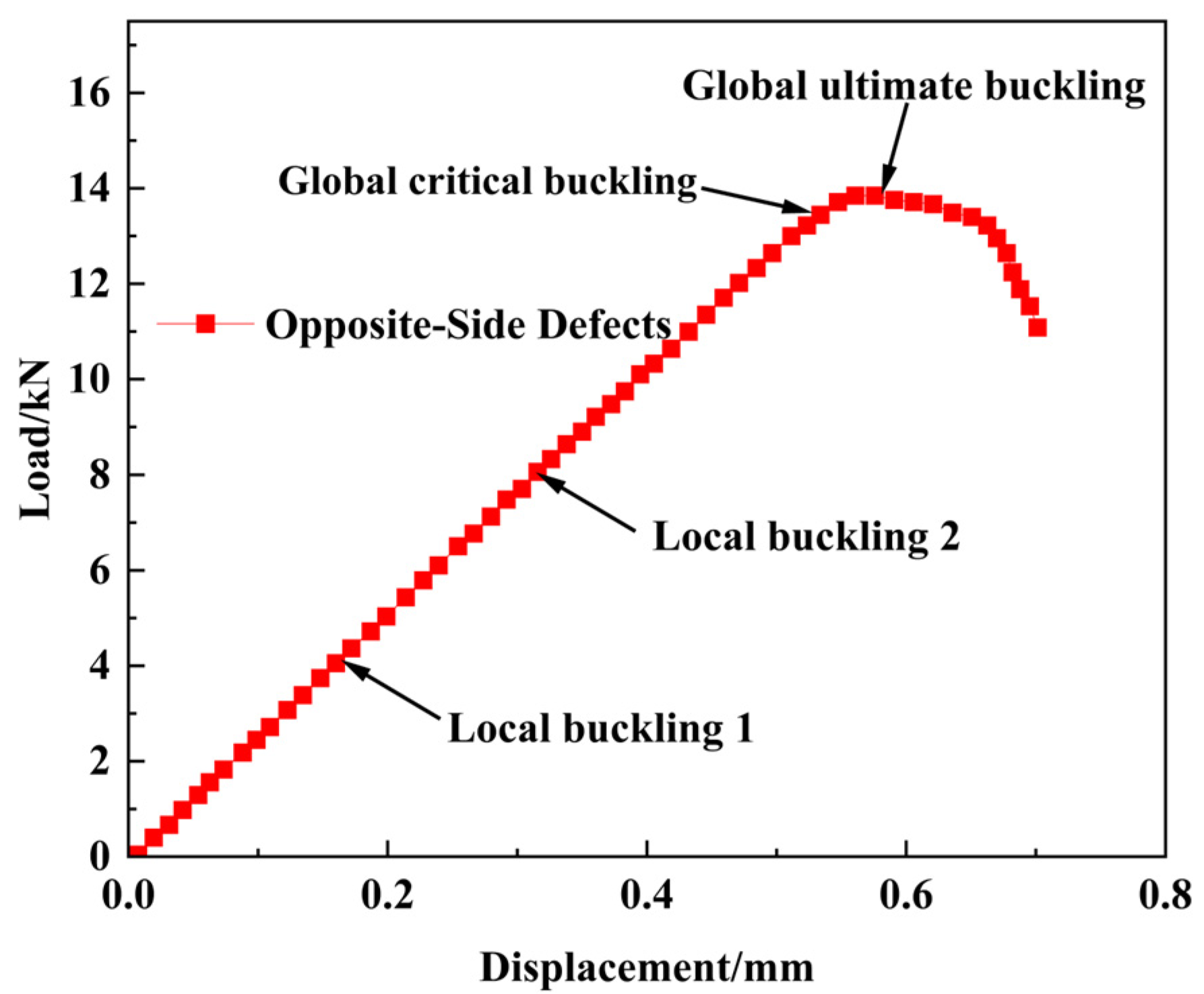

4.2. Opposite-Side Defect Coupling Effects on Compressive Failure of Open-Hole Composite Laminates

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, L.B.; Gong, Y.; Zhang, J.Y. A survey on delamination growth behavior in fiber reinforced compo-site laminates. Acta Aeronaut. Astronaut. Sin. 2019, 39, 10-7527. [Google Scholar]

- Versaci, M.; Laganà, F.; Morabito, F.C.; Palumbo, A.; Angiulli, G. Adaptation of an Eddy Current Model for Characterizing Subsurface Defects in CFRP Plates Using FEM Analysis Based on Energy Functional. Mathematics 2024, 12, 2854. [Google Scholar] [CrossRef]

- Han, W.; Hu, K.; Shi, Q.; Zhu, F. Damage evolution analysis of open-hole tensile laminated composites using a progress damage model verified by AE and DIC. Compos. Struct. 2020, 247, 112452. [Google Scholar] [CrossRef]

- Yang, H.; Yang, Z.; Yang, L.; San, Y.N.; Lin, K.X.; Wu, Z.J. Progress in ultrasonic testing and imaging method for damage of carbon fiber composites. Acta Mater. Compos. Sin. 2023, 40, 4295–4317. [Google Scholar]

- Tafreshi, A.; Oswald, T. Global buckling behaviour and local damage propagation in composite plates with embedded delaminations. Int. J. Press. Vessel. Pip. 2003, 80, 9–20. [Google Scholar] [CrossRef]

- Auersch, L.; Schmid, G. A torque and thrust prediction model for drilling of composite materials. Compos. Part A Appl. Sci. Manuf. 2005, 36, 83–93. [Google Scholar]

- Wang, X.J.; Xia, J.K.; Ji, Y.D.; Cao, D.; Hu, H.; Li, S. Effect of tension damage on structures residual compression strength of open-hole composite laminates. Acta Mater. Compos. Sin. 2024, 41, 2111–2125. [Google Scholar]

- Duan, Q.F.; Li, S.X.; Song, P.H.; Cheng, W.; Cao, D.F.; Hu, H.X. Effect of drilling-induced delamination on buckling behavior of open hole composite laminate specimens under compressive loading. Strength Mater. 2019, 51, 624–632. [Google Scholar] [CrossRef]

- Li, X.N.; Wang, Y.S.; Zhou, X.F. Status of numerical simulation methods for delamination damage of composite laminates. Acta Mater. Compos. Sin. 2021, 38, 1076–1086. [Google Scholar]

- Du, H.Y.; Xi, X.B.; Meng, L.H.; Dong, X.L. Finite element analysis of post-buckled delamination of composite laminate with preliminary debond subjected to static and fatigue loads. Compos. Sci. Eng. 2018, 06, 39–43. [Google Scholar]

- Olsson, R. Analytical prediction of large mass impact damage in composite laminates. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1207–1215. [Google Scholar] [CrossRef]

- Karimi, N.Z.; Heidary, H.; Fotouhi, M.; Minak, G. Experimental analysis of GFRP laminates subjected to compression after drilling. Compos. Struct. 2017, 169, 144–152. [Google Scholar] [CrossRef]

- Zhuo, Y.; Guan, Z.D.; Zhou, R.; Tan, R.M. Experimental study on progressive damage of composite laminates by compression. Acta Mater. Compos. Sin. 2015, 32, 1762–1768. [Google Scholar]

- Zitoune, R.; Crouzeix, L.; Collombet, F.; Tamine, T.; Grunevald, Y.-H. Behaviour of composite plates with drilled and moulded hole under tensile load. Compos. Struct. 2011, 93, 2384–2391. [Google Scholar] [CrossRef]

- Rhead, A.T.; Butler, R.; Hunt, G.W. Compressive Strength of Composite Laminates with Delamination-Induced Interaction of Panel and Sublaminate Buckling modes. Compos. Struct. 2017, 171, 326–334. [Google Scholar] [CrossRef]

- Nilsson, K.-F.; Asp, L.; Alpman, J.; Nystedt, L. Delamination buckling and growth for delaminations at different depths in a slen.Delamination buckling and growth for delaminations at different depths in a slender composite panel. Int. J. Solids Struct. 2001, 38, 3039–3071. [Google Scholar] [CrossRef]

- Cui, Y.Y.; Chen, P.H. Prediction of Tensile Failure Behavior of Open-Hole Composite Plates Based on Deep Learning. J. Nanjing Univ. Aeronaut. Astronaut. 2024, 56, 468–477. [Google Scholar]

- Liu, Z.; Yan, L.; Wu, Z.; Zhou, J.; Wei, H.; Zhang, S.; Ren, X. Progressive damage analysis and experiments of open-hole composite laminates subjected to compression loads. Eng. Fail. Anal. 2023, 151, 107379. [Google Scholar] [CrossRef]

- Wysmulski, P. Analysis of the Effect of an Open Hole on the Buckling of a Compressed Composite Plate. Materials 2024, 17, 1081. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M—17; ASTM Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D6641/D6641M—16; ASTM Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D3518/D3518M—18; ASTM Standard Test Method for In-Plane Shear Response of Polymer Matrix Composite Materials by Tensile Test of a ±45 Laminate. ASTM International: West Conshohocken, PA, USA, 2018.

- Ismail, S.O.; Ojo, S.O.; Dhakal, H.N. Thermo-mechanical modelling of FRP cross-ply composite laminates drilling: Delamination damage analysis. Compos. Part B Eng. 2017, 108, 45–52. [Google Scholar] [CrossRef]

- Liu, P.; Gu, Z.; Peng, X.; Zheng, J. Finite element analysis of the influence of cohesive law parameters on the multiple delamination behaviors of composites under compression. Compos. Struct. 2015, 131, 975–986. [Google Scholar] [CrossRef]

- Turon, A.; Camanho, P.; Costa, J.; Renart, J. Accurate simulation of delamination growth under mixed-mode loading using cohesive elements: Definition of interlaminar strengths and elastic stiffness. Compos. Struct. 2010, 92, 1857–1864. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Li, Q.Y. Finite element progressive damage analysis of carbon fabric reinforced wood laminates. J. Shenyang Univ. Technol. 2017, 39, 22–27. [Google Scholar]

- Suemasu, H.; Gozu, K.; Hayashi, K.; Ishikawa, T. Compressive buckling of rectangular composite plates with a free-edge delamination. Aiaa J. 2015, 33, 312–319. [Google Scholar] [CrossRef]

- Gong, W.; Chen, J.; Patterson, E.A. Buckling and delamination growth behaviour of delaminated composite panels subject to four-point bending. Compos. Struct. 2016, 138, 122–133. [Google Scholar] [CrossRef]

- Guo, Q.R.; Song, Y.L.; Xu, J.X.; Lv, W.H. Study on uniaxial tensile progressive damage of composite laminates with a hole. J. Mech. Strength 2024, 46, 1243–1252. [Google Scholar]

| Parameter | Characteristic | Value |

|---|---|---|

| Longitudinal elastic modulus/MPa | E11 | 144,700 |

| Transverse elastic modulus/MPa | E22 = E33 | 9650 |

| In-plane modulus/MPa | G12 = G13 | 5800 |

| Out-of-plane modulus/MPa | G23 | 4800 |

| Poisson’s ratio | υ12 = υ13 | 0.3 |

| Poisson’s ratio | υ23 | 0.45 |

| Strain energy release rate/Jm−2 | GIC | 75 |

| Strain energy release rate/Jm−2 | GIIC | 547 |

| Fracture mode I intensity/MPa | TI | 61 |

| Fracture mode II intensity/MPa | TII | 68 |

| Interface stiffness/Nmm−3 | KP | 106 |

| B-K criterion power parameter | 1.45 |

| Type | Experimental Result (kN) | Numerical Simulation Result (kN) | Error |

|---|---|---|---|

| Intact-0 | 19.46 | 19.71 | 1.28% |

| Damage-10 | 17.41 | 15.71 | 9.76% |

| Damage-15 | 17.13 | 15.45 | 9.81% |

| Damage-20 | 16.17 | 15.20 | 6.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, R.; Liu, Y.; Nie, X.; Xiao, Q.; Liang, J.; Cao, D. Compressive Failure and Dual-Defect Coupling Effects of Open-Hole Composite Laminates with Drilling-Induced Delamination. Materials 2025, 18, 2790. https://doi.org/10.3390/ma18122790

Zhu R, Liu Y, Nie X, Xiao Q, Liang J, Cao D. Compressive Failure and Dual-Defect Coupling Effects of Open-Hole Composite Laminates with Drilling-Induced Delamination. Materials. 2025; 18(12):2790. https://doi.org/10.3390/ma18122790

Chicago/Turabian StyleZhu, Rui, Yonghui Liu, Xingyue Nie, Qingqing Xiao, Jingpu Liang, and Dongfeng Cao. 2025. "Compressive Failure and Dual-Defect Coupling Effects of Open-Hole Composite Laminates with Drilling-Induced Delamination" Materials 18, no. 12: 2790. https://doi.org/10.3390/ma18122790

APA StyleZhu, R., Liu, Y., Nie, X., Xiao, Q., Liang, J., & Cao, D. (2025). Compressive Failure and Dual-Defect Coupling Effects of Open-Hole Composite Laminates with Drilling-Induced Delamination. Materials, 18(12), 2790. https://doi.org/10.3390/ma18122790