Microstructure and Tensile Properties of Cu-Ti Composites Deposited by Cold Spray Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

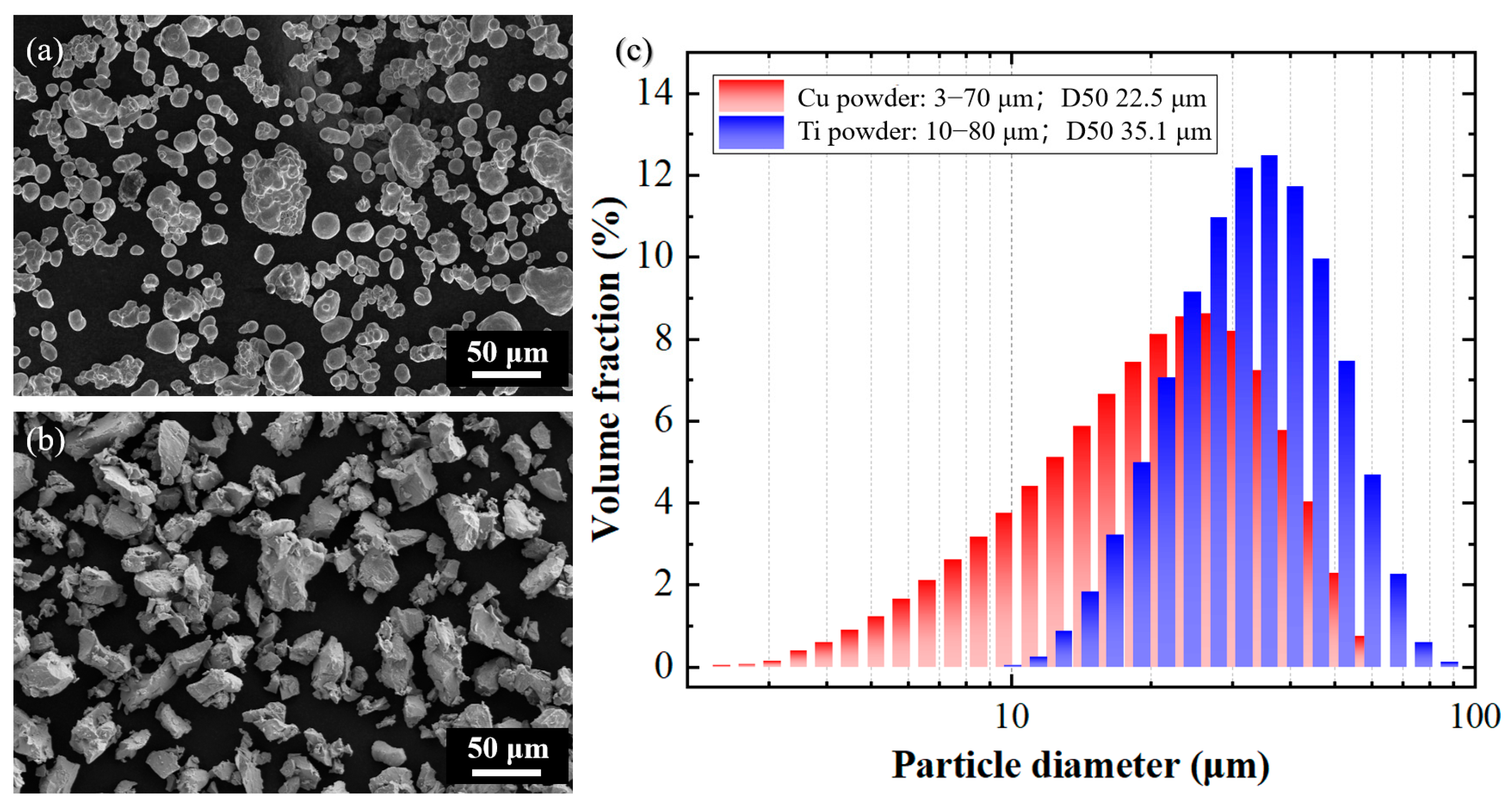

2.1. Preparation of Cu-Ti Composite Samples

2.2. Mechanical Property Testing and Microstructure Characterization

3. Results and Discussion

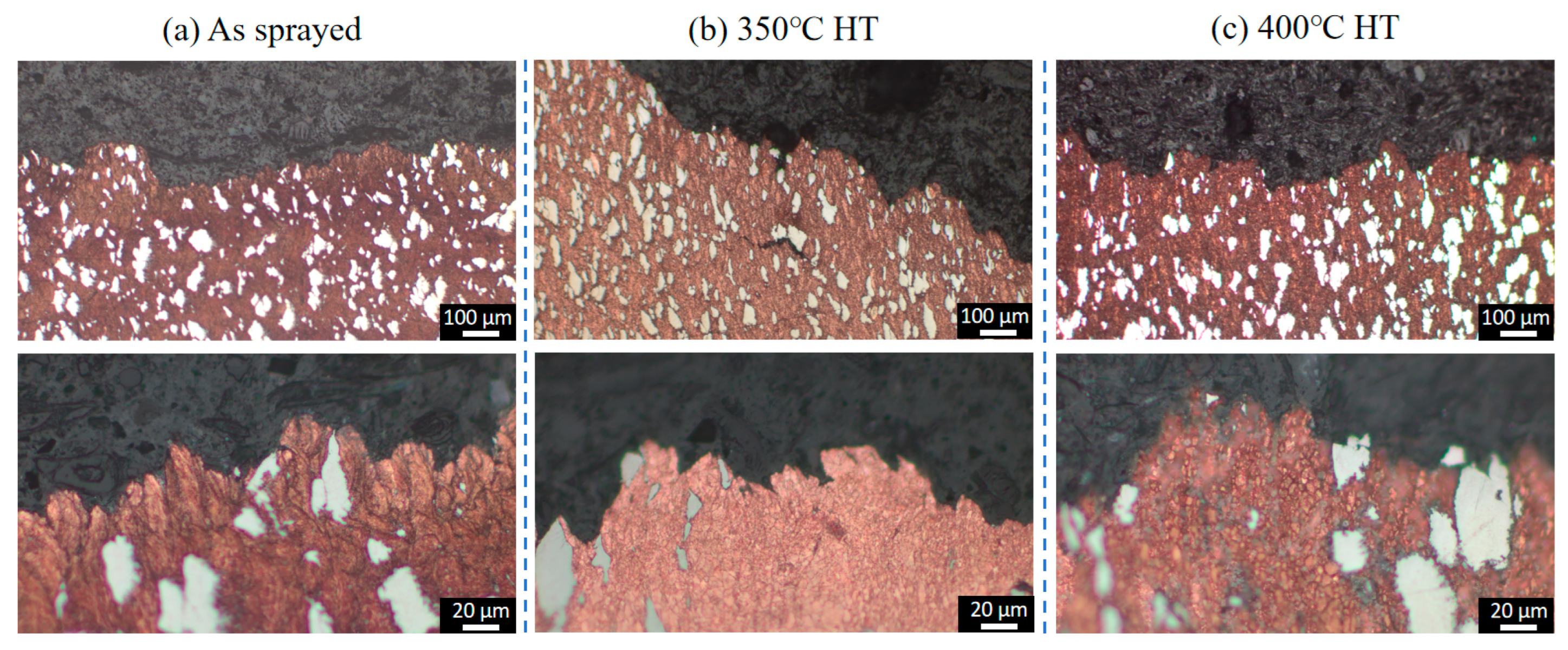

3.1. Microstructure

3.2. Hardness

3.3. Tensile Properties

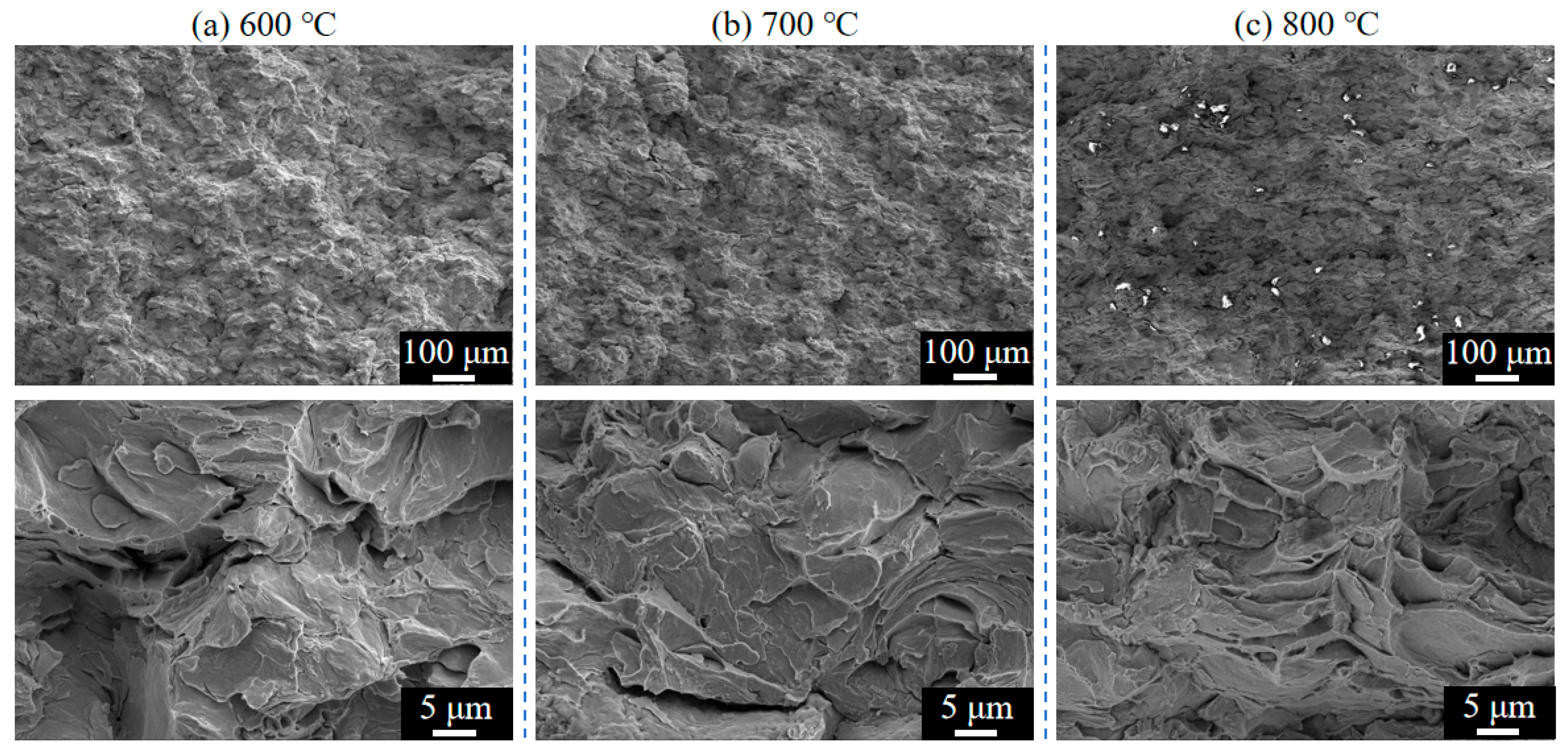

3.4. Analysis of Tensile Fracture Behavior

4. Conclusions

- (1)

- The cold-spray propellant gas temperature significantly regulates the properties of Cu-Ti deposits. As the temperature increases from 600 °C to 800 °C, the tensile strength of the deposits improves, reaching 338 MPa at 800 °C, which is attributed to the plastic deformation and work-hardening effect caused by high-speed particle impact. Post-heat treatment promotes copper matrix recrystallization, eliminates work hardening, and increases the elongation to 15% after 400 °C heat treatment.

- (2)

- Fracture microanalysis reveals that a high propellant gas temperature enhances the deposits’ cohesive strength. Subsurface cracking was observed beneath fracture surfaces in specimens prepared at 600 °C and 700 °C, while absent in 800 °C specimens, highlighting the advantage of higher propellant gas temperatures in improving cohesive bonding strength.

- (3)

- The optimized process combination (800 °C propellant gas + 400 °C heat treatment) achieves synergistic property optimization. The deposit exhibits a tensile strength of 270 MPa and an elongation of 15%, providing key process references for the application of cold-sprayed Cu-Ti composites in the engineering field.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nemani, A.V.; Ghaffari, M.; Bokati, K.S.; Valizade, N.; Afshari, E.; Nasiri, A. Advancements in additive manufacturing for copper-based alloys and composites: A comprehensive review. J. Manuf. Mater. Process. 2024, 8, 54. [Google Scholar]

- Jiang, Q.; Zhang, P.; Yu, Z.; Shi, H.; Wu, D.; Yan, H.; Ye, X.; Lu, Q.; Tian, Y. A review on additive manufacturing of pure copper. Coatings 2021, 11, 740. [Google Scholar] [CrossRef]

- Khandpur, M.S.; Giubilini, A.; Iuliano, L.; Minetola, P. On the Use of Green and Blue Laser Sources for Powder Bed Fusion: State of the Art Review for Additive Manufacturing of Copper and Its Alloys. Metals 2024, 14, 1464. [Google Scholar] [CrossRef]

- Suman, P.; Bannaravuri, P.K.; Baburao, G.; Kandavalli, S.R.; Alam, S.; ShanthiRaju, M.; Pulisheru, K.S. Integrity on properties of Cu-based composites with the addition of reinforcement: A review. Mater. Today Proc. 2021, 47, 6609–6613. [Google Scholar] [CrossRef]

- Hassan, S.; Gupta, M. Development of a novel magnesium–copper based composite with improved mechanical properties. Mater. Res. Bull. 2002, 37, 377–389. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Y.; Wu, H.; Yang, S.; Jie, X. Structure and corrosion behavior of cold-sprayed Cu/Ni composite coating post-treated by ultrasonic shot peening. SN Appl. Sci. 2020, 2, 201. [Google Scholar] [CrossRef]

- Wu, X.-K.; Zhou, X.-L.; Cui, H.; Zheng, X.; Zhang, J.-S. Deposition behavior and characteristics of cold-sprayed Cu-Cr composite deposits. J. Therm. Spray Technol. 2012, 21, 792–799. [Google Scholar] [CrossRef]

- Rajkovic, V.; Bozic, D.; Stasic, J.; Wang, H.; Jovanovic, M.T. Processing, characterization and properties of copper-based composites strengthened by low amount of alumina particles. Powder Technol. 2014, 268, 392–400. [Google Scholar] [CrossRef]

- Deng, N.; Tang, J.; Xiong, T.; Li, J.; Zhou, Z. Fabrication and characterization of WCu composite coatings with different W contents by cold spraying. Surf. Coat. Technol. 2019, 368, 8–14. [Google Scholar] [CrossRef]

- Tian, J.; Xu, K.; Hu, J.; Zhang, S.; Cao, G.; Shao, G. Durable self-polishing antifouling Cu-Ti coating by a micron-scale Cu/Ti laminated microstructure design. J. Mater. Sci. Technol. 2021, 79, 62–74. [Google Scholar] [CrossRef]

- Hu, Q.; Liu, H.; Gao, F.; Yang, X.; Li, J.; Liu, R.; Liu, Z.; Wang, D. Investigation on blood compatibility of Cu/Ti metal coating prepared via various bias voltages and copper content. Metals 2022, 12, 435. [Google Scholar] [CrossRef]

- Tian, J.-J.; Wang, K.; Xu, K.-W.; Luo, X.-T.; Shao, G.-S.; Li, C.-J. Effect of coating composition on the micro-galvanic dissolution behavior and antifouling performance of plasma-sprayed laminated-structured CuTi composite coating. Surf. Coat. Technol. 2021, 410, 126963. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H. A comprehensive review on sustainable cold spray additive manufacturing: State of the art, challenges and future challenges. J. Clean. Prod. 2021, 310, 127606. [Google Scholar] [CrossRef]

- Sun, W.; Chu, X.; Lan, H.; Huang, R.; Huang, J.; Xie, Y.; Huang, J.; Huang, G. Current implementation status of cold spray technology: A short review. J. Therm. Spray Technol. 2022, 31, 848–865. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Li, P.; Guo, W.; Ma, G.; Wang, H. Copper-Based Composite Coatings by Solid-State Cold Spray Deposition: A Review. Coatings 2023, 13, 479. [Google Scholar] [CrossRef]

- Rokni, M.; Nutt, S.; Widener, C.; Champagne, V.; Hrabe, R. Review of relationship between particle deformation, coating microstructure, and properties in high-pressure cold spray. J. Therm. Spray Technol. 2017, 26, 1308–1355. [Google Scholar] [CrossRef]

- Ralls, A.M.; Kasar, A.K.; Daroonparvar, M.; Siddaiah, A.; Kumar, P.; Kay, C.M.; Misra, M.; Menezes, P.L. Effect of Gas Propellant Temperature on the Microstructure, Friction, and Wear Resistance of High-Pressure Cold Sprayed Zr702 Coatings on Al6061 Alloy. Coatings 2022, 12, 263. [Google Scholar] [CrossRef]

- Daroonparvar, M.; Kasar, A.K.; Farooq Khan, M.U.; Menezes, P.L.; Kay, C.M.; Misra, M.; Gupta, R.K. Improvement of Wear, Pitting Corrosion Resistance and Repassivation Ability of Mg-Based Alloys Using High Pressure Cold Sprayed (HPCS) Commercially Pure-Titanium Coatings. Coatings 2021, 11, 57. [Google Scholar] [CrossRef]

- Yin, S.; Cavaliere, P.; Aldwell, B.; Jenkins, R.; Liao, H.; Li, W.; Lupoi, R. Cold spray additive manufacturing and repair: Fundamentals and applications. Addit. Manuf. 2018, 21, 628–650. [Google Scholar] [CrossRef]

- Calla, E.; McCartney, D.; Shipway, P. Effect of deposition conditions on the properties and annealing behavior of cold-sprayed copper. J. Therm. Spray Technol. 2006, 15, 255–262. [Google Scholar] [CrossRef]

- Grigoriev, S.; Okunkova, A.; Sova, A.; Bertrand, P.; Smurov, I. Cold spraying: From process fundamentals towards advanced applications. Surf. Coat. Technol. 2015, 268, 77–84. [Google Scholar] [CrossRef]

- Assadi, H.; Schmidt, T.; Richter, H.; Kliemann, J.-O.; Binder, K.; Gärtner, F.; Klassen, T.; Kreye, H. On parameter selection in cold spraying. J. Therm. Spray Technol. 2011, 20, 1161–1176. [Google Scholar] [CrossRef]

- Schmidt, T.; Assadi, H.; Gärtner, F.; Richter, H.; Stoltenhoff, T.; Kreye, H.; Klassen, T. From particle acceleration to impact and bonding in cold spraying. J. Therm. Spray Technol. 2009, 18, 794–808. [Google Scholar] [CrossRef]

- Venkatesh, L.; Chavan, N.M.; Sundararajan, G. The influence of powder particle velocity and microstructure on the properties of cold sprayed copper coatings. J. Therm. Spray Technol. 2011, 20, 1009–1021. [Google Scholar] [CrossRef]

- Huang, R.; Sone, M.; Ma, W.; Fukanuma, H. The effects of heat treatment on the mechanical properties of cold-sprayed coatings. Surf. Coat. Technol. 2015, 261, 278–288. [Google Scholar] [CrossRef]

- Chen, C.; Xie, Y.; Yin, S.; Li, W.; Luo, X.; Xie, X.; Zhao, R.; Deng, C.; Wang, J.; Liao, H. Ductile and high strength Cu fabricated by solid-state cold spray additive manufacturing. J. Mater. Sci. Technol. 2023, 134, 234–243. [Google Scholar] [CrossRef]

- Li, W.-Y.; Li, C.-J.; Liao, H. Effect of annealing treatment on the microstructure and properties of cold-sprayed Cu coating. J. Therm. Spray Technol. 2006, 15, 206–211. [Google Scholar] [CrossRef]

- Yu, B.; Tam, J.; Li, W.; Cho, H.; Legoux, J.-G.; Poirier, D.; Giallonardo, J.; Erb, U. Microstructural and bulk properties evolution of cold-sprayed copper coatings after low temperature annealing. Materialia 2019, 7, 100356. [Google Scholar] [CrossRef]

- Boyle, C.H.; Meguid, S.A. Mechanical performance of integrally bonded copper coatings for the long term disposal of used nuclear fuel. Nucl. Eng. Des. 2015, 293, 403–412. [Google Scholar] [CrossRef]

- Sandström, R.; Hallgren, J.; Burman, G. Stress Strain Flow Curves for Cu-OFP; Svensk Kärnbränslehantering AB: Stockholm, Sweden, 2009. [Google Scholar]

- Liu, Z.; Wang, H.; Haché, M.J.; Chu, X.; Irissou, E.; Zou, Y. Prediction of heterogeneous microstructural evolution in cold sprayed copper coatings using local Zener-Hollomon parameter and strain. Acta Mater. 2020, 193, 191–201. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, J.; Huang, J.; Li, H.; Zhang, K.; Lan, H.; Xin, H.; Huang, R. Microstructure and Tensile Properties of Cu-Ti Composites Deposited by Cold Spray Additive Manufacturing. Materials 2025, 18, 2787. https://doi.org/10.3390/ma18122787

Cheng J, Huang J, Li H, Zhang K, Lan H, Xin H, Huang R. Microstructure and Tensile Properties of Cu-Ti Composites Deposited by Cold Spray Additive Manufacturing. Materials. 2025; 18(12):2787. https://doi.org/10.3390/ma18122787

Chicago/Turabian StyleCheng, Jia, Jibo Huang, Haifan Li, Kejie Zhang, Haiming Lan, Hongmin Xin, and Renzhong Huang. 2025. "Microstructure and Tensile Properties of Cu-Ti Composites Deposited by Cold Spray Additive Manufacturing" Materials 18, no. 12: 2787. https://doi.org/10.3390/ma18122787

APA StyleCheng, J., Huang, J., Li, H., Zhang, K., Lan, H., Xin, H., & Huang, R. (2025). Microstructure and Tensile Properties of Cu-Ti Composites Deposited by Cold Spray Additive Manufacturing. Materials, 18(12), 2787. https://doi.org/10.3390/ma18122787