Microstructure and Property Evolution of Pure Copper Under Asynchronous Rolling

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructural Evolution

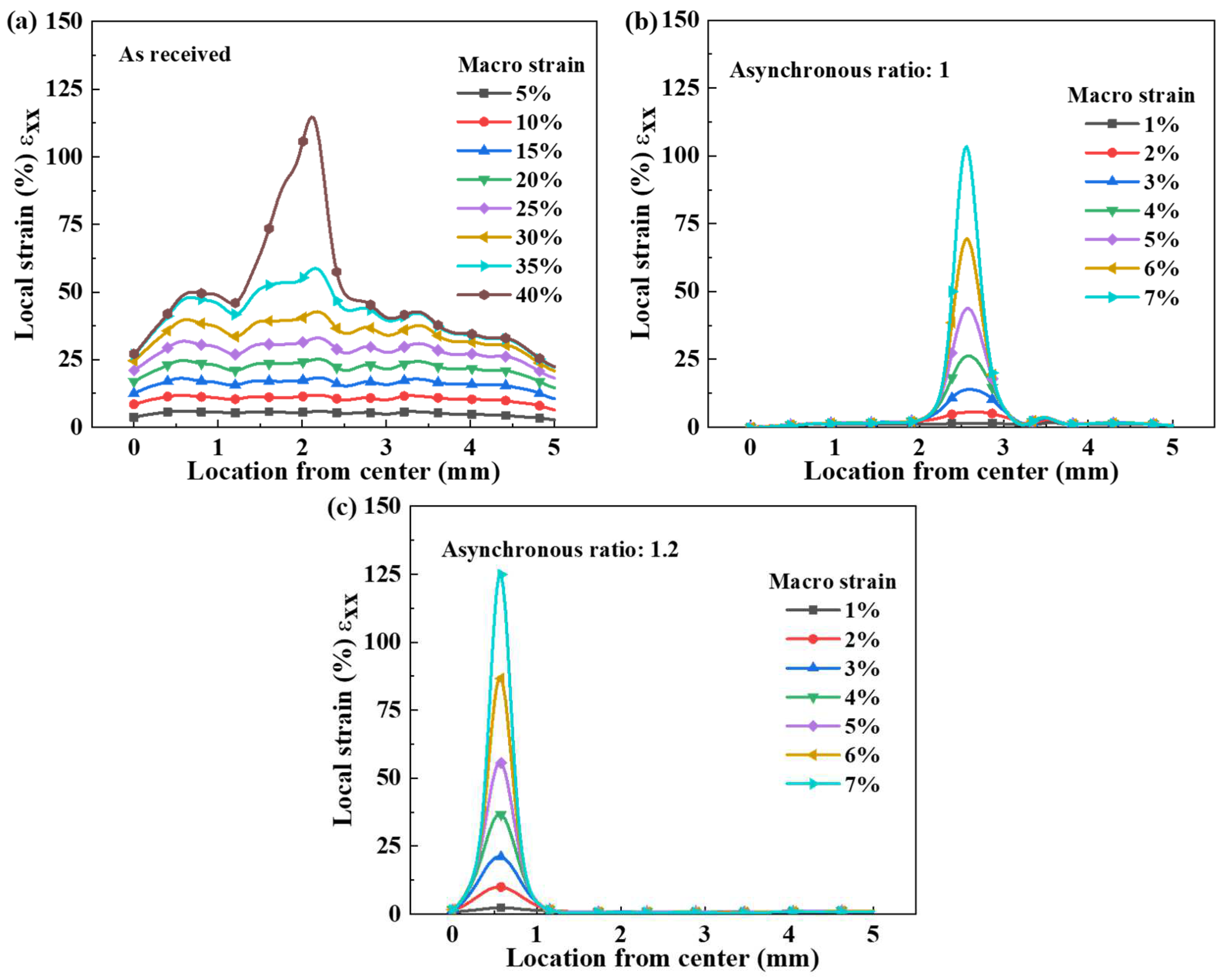

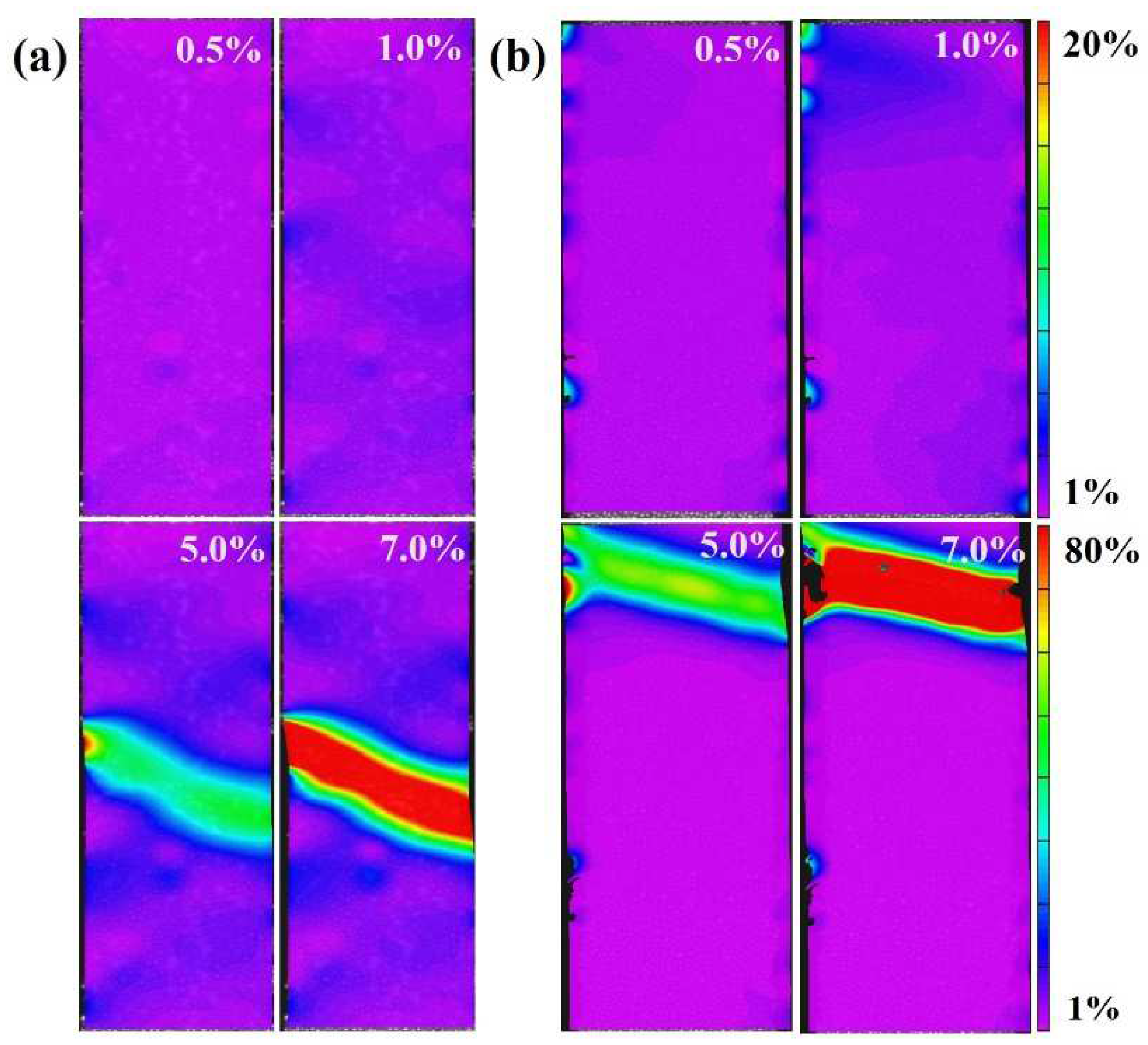

3.2. Strain Distribution

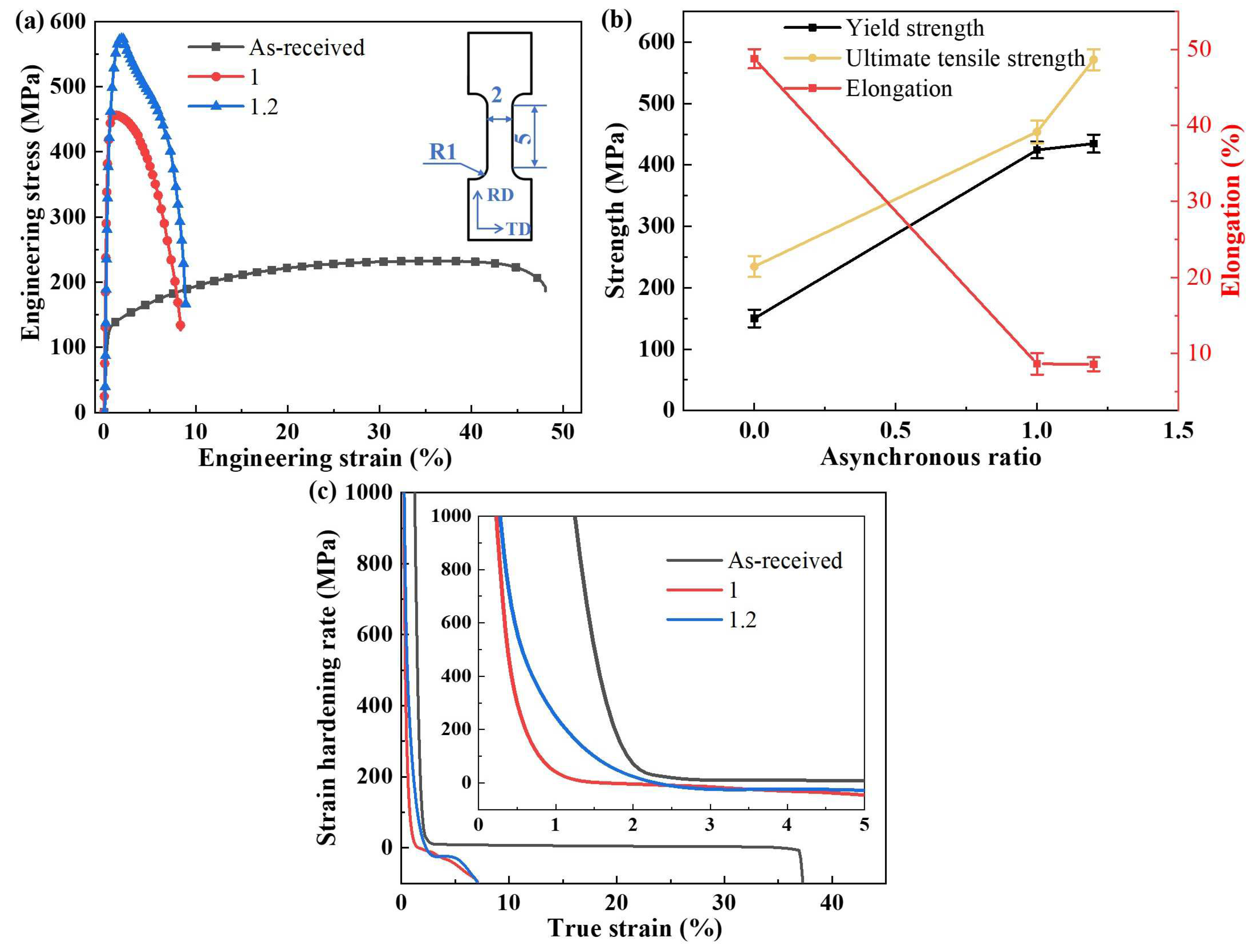

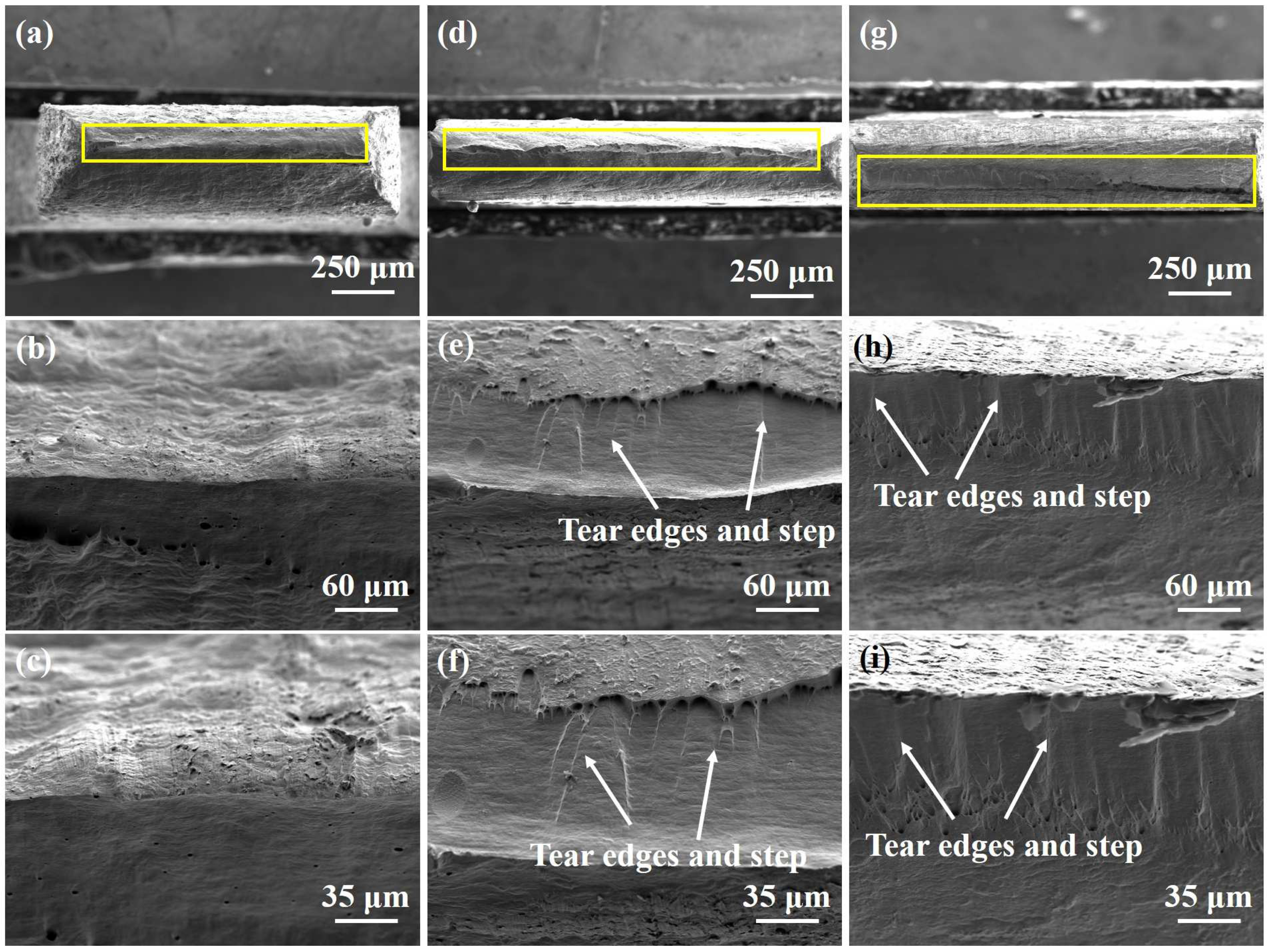

3.3. Tensile Properties

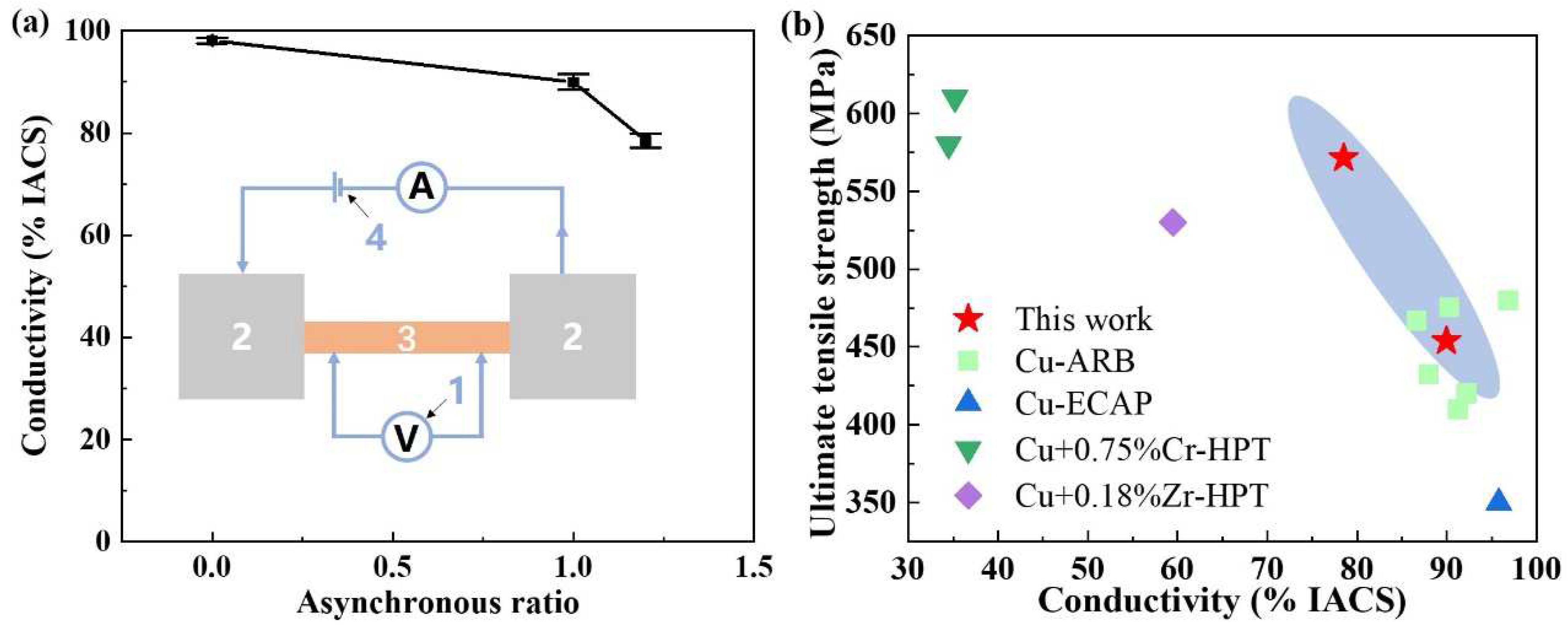

3.4. Electrical Properties

4. Conclusions

- The asynchronous rolling process substantially improves the YS and UTS of pure copper. Specifically, at an asynchronous ratio of 1.2, the YS and UTS increased by 189.7% and 143.5%, respectively. However, the elongation decreased, indicating a trade-off between strength and ductility due to increased work hardening.

- DIC analysis revealed that asynchronous rolling introduces strain localization early in the tensile deformation process. The degree of strain concentration increases with the asynchronous ratio, contributing to a reduction in uniform plastic deformation.

- The conductivity of pure copper decreases with the increase in asynchronous ratio, which is primarily due to the increase in defect density resulting from asynchronous rolling. The electrical conductivity decreased by 19.96% when the asynchronous ratio was 1.2.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eivani, A.R.; Shojaei, A.; Park, N.; Jafarian, H.R. Fabrication of Cu-Cug Nanocomposites with Enhanced Mechanical Strength and Reduced Electrical Resistivity. J. Mater. Res. Technol. 2021, 11, 650–666. [Google Scholar] [CrossRef]

- Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T.; Hong, R.G. Ultra-Fine Grained Bulk Aluminum Produced by Accumulative Roll-Bonding (Arb) Process. Scr. Mater. 1998, 39, 1221–1227. [Google Scholar] [CrossRef]

- Wan, H.; Leung, N.; Algharaibeh, S.; Sui, T.; Liu, Q.; Peng, H.; Su, B. Cost-Effective Fabrication of Bio-Inspired Nacre-Like Composite Materials with High Strength and Toughness. Compos. Part B Eng. 2020, 202, 108414. [Google Scholar] [CrossRef]

- Wang, F.; Ding, C.; Yang, Z.; Zhang, H.; Ding, Z.; Li, H.; Xu, J.; Shan, D.; Guo, B. Microstructure Evolution and Mechanical Properties of Alcocrfeni2.1 Eutectic High-Entropy Alloys Processed by High-Pressure Torsion. Materials 2024, 17, 2954. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, P.; Zhou, W.; Luo, H.; Li, Z. Microstructure and Properties of Plain-Weave Carbon Fabric Reinforced Ceramic Composites Containing Cu-Si Alloy. Compos. Part B Eng. 2018, 145, 129–135. [Google Scholar] [CrossRef]

- Ding, C.; Xu, J.; Shan, D.; Guo, B.; Langdon, T.G. Sustainable Fabrication of Cu/Nb Composites with Continuous Laminated Structure to Achieve Ultrahigh Strength and Excellent Electrical Conductivity. Compos. Part B Eng. 2021, 211, 108662. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel Ultra-High Straining Process for Bulk Materials—Development of the Accumulative Roll-Bonding (Arb) Process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Jiang, P.; Liu, D.; Zou, H.; Liu, J.; Wu, W.; Pan, H.; Wang, Z.; Zhang, Y.; Dai, G. Effect of Multi-Path Asynchronous Rolling Process On Microstructure and Mechanical Properties of Zk60 Magnesium Alloy. Materials 2024, 17, 1647. [Google Scholar] [CrossRef]

- Zou, H.; Zhou, W.; Liu, D.; Jiang, P. Microstructures Evolution and Enhanced Performance of Zk60 Magnesium Alloys Manufactured by Multi-Path Asynchronous Warm Rolling. J. Alloys Metall. Syst. 2025, 10, 100180. [Google Scholar] [CrossRef]

- Wang, G.; Liu, L.; Meng, Y.; Bai, G.; Gu, Q. Real-Time Integrated Path Tracking Control Using Input Dimensionality-Reducing and Asynchronous Sampling Methods. J. Frankl. Inst. 2024, 361, 106690. [Google Scholar] [CrossRef]

- Wang, D.; Jing, Y.; Gao, Y.; Li, J.; Shi, Y.; Misra, R.D.K. Enhanced Mechanical Properties of Az91 Magnesium Alloy by Asynchronously Large-Strain High-Efficiency Rolling with Bimodal Grain Structure. J. Mater. Res. Technol. 2023, 27, 4430–4439. [Google Scholar] [CrossRef]

- Hu, H.; Li, J.; Wang, J.; Zhang, T. Research On Mechanical Properties and Electromagnetic Shielding Effectiveness in Mg-8Li-2Y-Zn/Al Multilayered Composites Fabricated by Asymmetric Accumulative Roll Bonding. J. Alloys Compd. 2023, 939, 168793. [Google Scholar] [CrossRef]

- Li, H.; Ding, C.; Ding, Z.; Zhang, H.; Wang, F.; Chen, Y.; Bao, J.; Xu, J.; Guo, B.; Shan, D. Mechanical Properties and Fracture Behavior of Laminated Heterostructured Composites Under Different Current Densities. Rare Met. Mater. Eng. 2024, 53, 2713–2717. [Google Scholar]

- Lu, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh Strength and High Electrical Conductivity in Copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef]

- Xu, J.; Li, J.; Shan, D.; Guo, B. Microstructural Evolution and Micro/Meso-Deformation Behavior in Pure Copper Processed by Equal-Channel Angular Pressing. Mater. Sci. Eng. A 2016, 664, 114–125. [Google Scholar] [CrossRef]

- Gu, T.; Medy, J.R.; Volpi, F.; Castelnau, O.; Forest, S.; Hervé-Luanco, E.; Lecouturier, F.; Proudhon, H.; Renault, P.O.; Thilly, L. Multiscale Modeling of the Anisotropic Electrical Conductivity of Architectured and Nanostructured Cu-Nb Composite Wires and Experimental Comparison. Acta Mater. 2017, 141, 131–141. [Google Scholar] [CrossRef]

- Chen, J.; Hu, X.; Liu, X. Softening Effect On Fracture Stress of Pure Copper Processed by Asynchronous Foil Rolling. Materials 2019, 12, 2319. [Google Scholar] [CrossRef]

- Xu, L.; Yu, K.; Wang, L.; Quan, S.; Kong, L.; Yang, H.; Zhang, X.; Peng, Y.; Wang, Y. Microstructure and Mechanical Properties of Pure Copper Plate Processed by Novel Dynamic Offsets and Shear Force Adjustment Rolling. J. Mater. Res. Technol. 2024, 29, 558–570. [Google Scholar] [CrossRef]

- Wang, J.; Xu, R.; Wang, S.; Qian, T.; Shi, Q. Formation Mechanism and Organizational Controlling of Ultra-Fine-Grain Copper Processed by Asymmetrical Accumulative Rolling-Bond and Annealing. Trans. Nonferrous Met. Soc. China 2012, 22, 2672–2678. [Google Scholar] [CrossRef]

- Ding, C.; Xu, J.; Li, X.; Shan, D.; Guo, B.; Langdon, T.G. Microstructural Evolution and Mechanical Behavior of Cu/Nb Multilayer Composites Processed by Accumulative Roll Bonding. Adv. Eng. Mater. 2020, 22, 1900702. [Google Scholar] [CrossRef]

- Serrano-Munoz, I.; Fernández, R.; Saliwan-Neumann, R.; González-Doncel, G.; Bruno, G. Dislocation Structures After Creep in an Al-3.85 %Mg Alloy Studied Using Ebsd-Kam Technique. Mater. Lett. 2023, 337, 133978. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, C.; Zeng, H.; Liu, X.; Song, X.; Zhang, Z.; Liu, S.; Li, J. Mechanical Response and Microstructure Evolution of Ta1 Titanium Under Normal Ultrasonic Vibration Processing. Materials 2025, 18, 1712. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Wu, G. Deformation Behavior of Ti2AlC Particles in Aluminum Matrix Composites Characterized by Electron Backscatter Diffraction. Mater. Lett. 2025, 385, 138171. [Google Scholar] [CrossRef]

- Fang, Z.; Wang, L.; Yu, F.; He, Y.; Wang, Z. Mechanism of Fatigue-Life Extension Due to Dynamic Strain Aging in Low-Carbon Steel at High Temperature. Materials 2024, 17, 4660. [Google Scholar] [CrossRef]

- Wang, H.; Ma, J.; Yuan, M.; Liang, G.; Pei, X.; Miao, Y.; Li, M. Microstructure, Deformation Behaviors and Gnd Density Evolution of Ti-Al Laminated Composites Under the Incremental Compression Test. Mater. Today Commun. 2022, 33, 104605. [Google Scholar] [CrossRef]

- Yang, Z.; Bao, J.; Ding, C.; Son, S.; Ning, Z.; Xu, J.; Shan, D.; Guo, B.; Kim, H.S. Electroplasticity in the Al0.6Cocrfenimn High Entropy Alloy Subjected to Electrically-Assisted Uniaxial Tension. J. Mater. Sci. Technol. 2023, 148, 209–221. [Google Scholar] [CrossRef]

- Hu, H.; Zhang, T.; Wang, J.; Li, J. Microstructure, Mechanical Properties, and Electrical Conductivity of Mg-8Li-2Y-Zn/Al Multilayered Composites Fabricated by Cross Asynchronous Accumulative Roll Bonding. RSC Adv. 2022, 12, 3125–31214. [Google Scholar] [CrossRef]

- Li, J.; Ding, C.; Chen, W.; Shan, D.; Guo, B.; Xu, J. Strain Localization and Ductile Fracture Mechanism of Micro/Mesoscale Deformation in Ultrafine-Grained Pure Copper. Mater. Des. 2023, 229, 111873. [Google Scholar] [CrossRef]

- Dobatkin, S.V.; Shangina, D.V.; Bochvar, N.R.; Janeček, M. Effect of Deformation Schedules and Initial States On Structure and Properties of Cu–0.18% Zr Alloy After High-Pressure Torsion and Heating. Mater. Sci. Eng. A 2014, 598, 288–292. [Google Scholar] [CrossRef]

- Dobatkin, S.V.; Gubicza, J.; Shangina, D.V.; Bochvar, N.R.; Tabachkova, N.Y. High Strength and Good Electrical Conductivity in Cu–Cr Alloys Processed by Severe Plastic Deformation. Mater. Lett. 2015, 153, 5–9. [Google Scholar] [CrossRef]

- Higuera-Cobos, O.F.; Cabrera, J.M. Mechanical, Microstructural and Electrical Evolution of Commercially Pure Copper Processed by Equal Channel Angular Extrusion. Mater. Sci. Eng. A 2013, 571, 103–114. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, S.; Bai, L.; Zhang, P.; Zhu, Q. Microstructure and Property Evolution of Pure Copper Under Asynchronous Rolling. Materials 2025, 18, 2776. https://doi.org/10.3390/ma18122776

Jiang S, Bai L, Zhang P, Zhu Q. Microstructure and Property Evolution of Pure Copper Under Asynchronous Rolling. Materials. 2025; 18(12):2776. https://doi.org/10.3390/ma18122776

Chicago/Turabian StyleJiang, Shan, Long Bai, Pin Zhang, and Qiang Zhu. 2025. "Microstructure and Property Evolution of Pure Copper Under Asynchronous Rolling" Materials 18, no. 12: 2776. https://doi.org/10.3390/ma18122776

APA StyleJiang, S., Bai, L., Zhang, P., & Zhu, Q. (2025). Microstructure and Property Evolution of Pure Copper Under Asynchronous Rolling. Materials, 18(12), 2776. https://doi.org/10.3390/ma18122776