Effect of Filler Type, Content, and Silanization on the Flexural Strength, Elastic Modulus, Shore D Hardness, and Two-Body Wear of PAEK Compounds

Abstract

1. Introduction

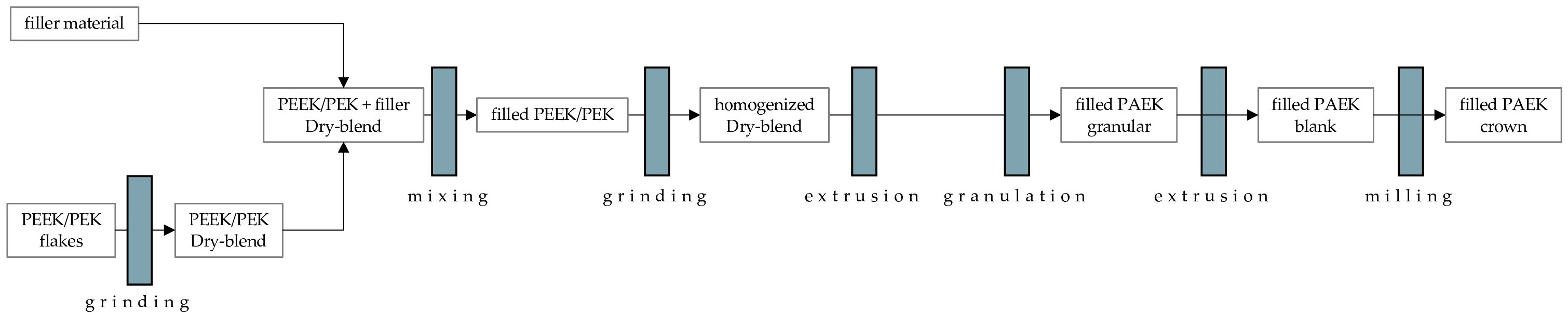

2. Materials and Methods

3. Results

3.1. Effect of Filler Type on FX, Em, and SDH

3.2. Effect of Filler Content on FX, Em, and SDH

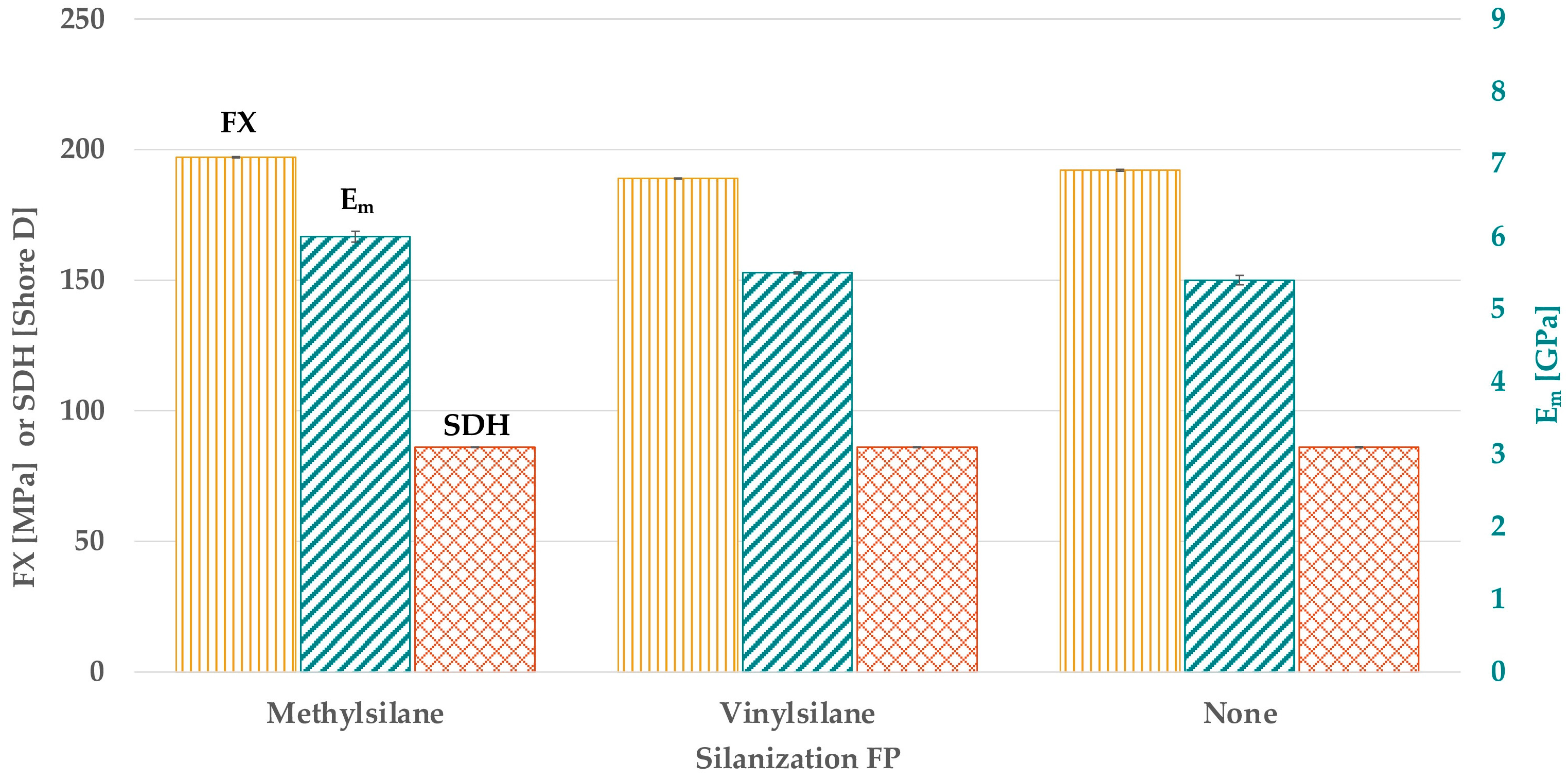

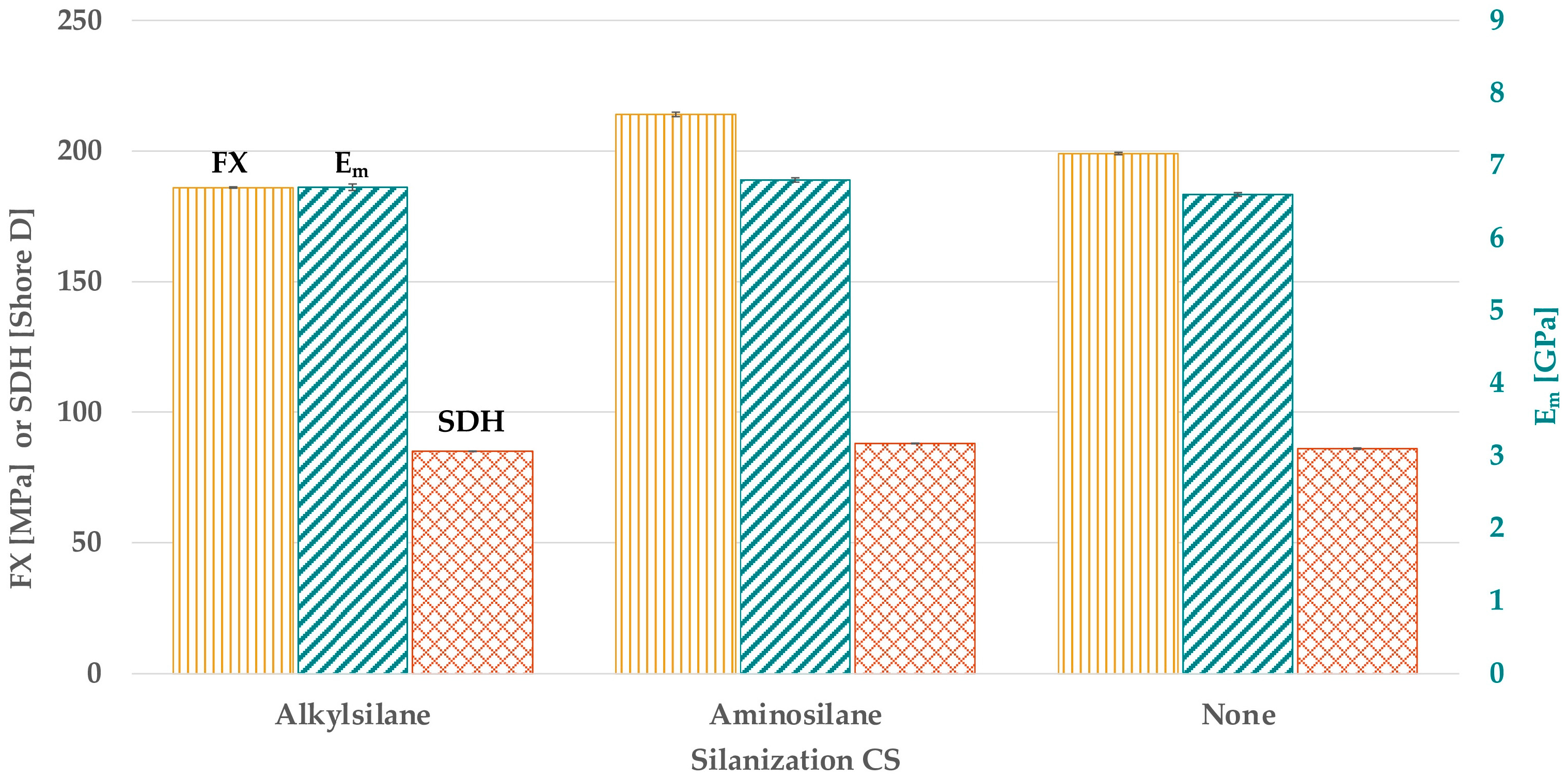

3.3. Effect of Filler Silanization on FX, Em, and SDH

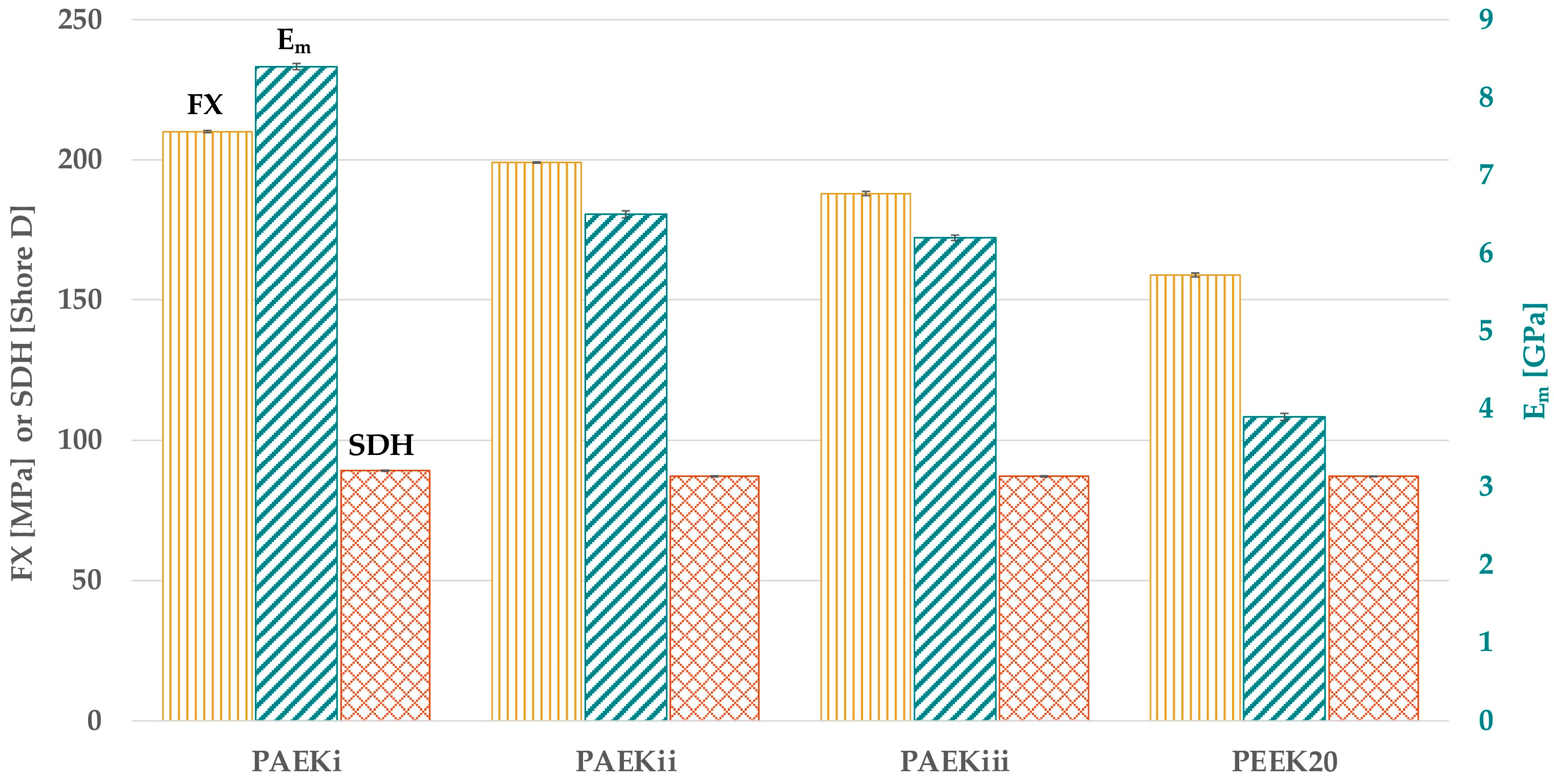

3.4. Mechanical Properties of Experimental PAEK Compounds and Effect of Two-Body Wear

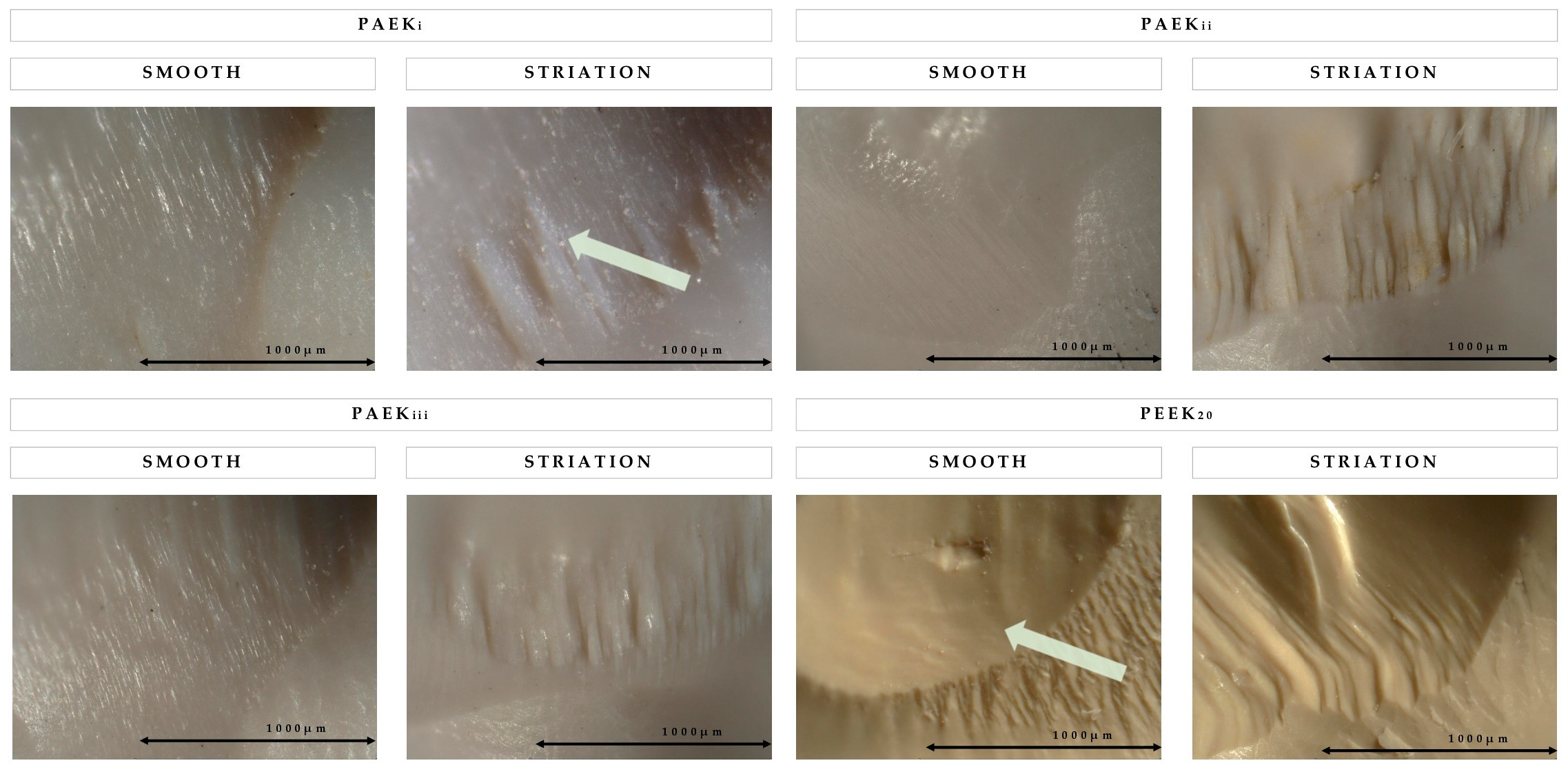

3.5. Qualitative Analysis of Abrasion Area

4. Discussion

5. Conclusions

- Silica-based fillers at 20 wt% led to increased flexural strength, elastic modulus, and shore D hardness compared with no filler, which could provide sufficient mechanical properties for monolithic fixed prostheses.

- The filler content had a stronger effect on the elastic modulus than on flexural strength.

- Silanization of calcium silicate with aminosilane led to increased mechanical properties.

- Smaller particle sizes and lower elastic modulus led to a higher abrasion resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 2BW | Two-body wear |

| CS | Calcium silicate |

| Em | Elastic modulus |

| EPC | Experimental PAEK compounds |

| FDP | Fixed dental prostheses |

| FP | Feldspar |

| FS | Fumed silica |

| FX | Flexural strength |

| MSH | Magnesium silicate hydrate |

| NF | No filler |

| PAEK | Polyaryletherketones |

| PEEK | Polyetheretherketone |

| PEEK20 | BioHPP |

| PEEK25 | BioHPP plus |

| PEK | Polyetherketone |

| PEKK | Polyetherketoneketone |

| SDH | Shore D hardness |

| TDP | Temporary dental prostheses |

Appendix A

| Groups | Flexural Strength [MPa] | E-Modulus [GPa] | Shore Hardness [Shore D] | |||

|---|---|---|---|---|---|---|

| Min/Median/Max ** | Mean ± SD (95% CI) | Min/Median/Max ** | Mean ± SD (95% CI) | Min/Median/Max ** | Mean ± SD (95% CI) | |

| Type of filler * | ||||||

| FS | 179/184/186 c,d | 183 ± 1.2 | 4.2/4.2/4.6 b | 4.3 ± 0.08 | 85/86/86 c | 86 ± 0.2 |

| (179;187) | (4.1;4.5) | (84;87) | ||||

| CS | 196/199/201 e | 199 ± 0.9 | 6.5/6.6/6.8 e | 6.6 ± 0.05 | 84/86/87 b | 86 ± 0.5 |

| (195;202) | (6.5;6.8) | (83;88) | ||||

| FP | 178/179/180 c | 179 ± 0.3 | 5.5/5.9/6.1 d | 5.9 ± 0.11 | 85/85/86 c | 85 ± 0.2 |

| (177;180) | (5.5;6.2) | (83;86) | ||||

| MSH | 183/187/190 d | 187 ± 1.2 | 7.5/7.7/7.8 f | 7.7 ± 0.05 | 82/83/84 b | 83 ± 0.3 |

| (182;191) | (7.5;7.8) | (81;84) | ||||

| None | 168/168/170 b | 168 ± 0.4 | 3.9/4.0/4.2 a,b | 4.1 ± 0.05 | 76/78/80 a | 78 ± 0.7 |

| (166;170) | (3.9;4.2) | (75;81) | ||||

| PEEK20 | 154/160/162 a | 159 ± 1.4 | 3.6/3.9/4.1 a | 3.9 ± 0.10 | 86/87/87 c | 87 ± 0.2 |

| (154;163) | (3.6;4.1) | (84;88) | ||||

| PEEK25 | 157/161/163 a | 161 ± 1.0 | 5.3/5.3/5.4 c | 5.3 ± 0.02 | 86/87/88 d | 87 ± 0.4 |

| (156;164) | (5.3;5.4) | (85;89) | ||||

| Filler content * | ||||||

| 20% | 207/215/217 a | 214 ± 1.7 | 6.7/6.7/6.9 a | 6.8 ± 0.06 | 84/86/87 a | 86 ± 0.5 |

| (207;219) | (6.6;6.9) | (83;88) | ||||

| 25% | 214/219/223 b | 219 ± 1.7 | 7.1/7.3/7.5 b | 7.3 ± 0.07 | 86/87/88 a,b | 87 ± 0.4 |

| (213;225) | (7.1;7.5) | (85;89) | ||||

| 30% | 222/224/225 b | 224 ± 0.5 | 8.0/8.1/8.5 c | 8.2 ± 0.09 | 87/88/89 b | 88 ± 0.3 |

| (221;226) | (8.0;8.5) | (86;89) | ||||

| Silanization FP * | Flexural Strength [MPa] | E-Modulus [GPa] | Shore Hardness [Shore D] | |||

|---|---|---|---|---|---|---|

| Min/Median/Max ** | Mean ± SD (95% CI) | Min/Median/Max ** | Mean ± SD (95% CI) | Min/Median/Max ** | Mean ± SD (95% CI) | |

| Methylsilane | 195/197/198 b | 197 ± 0.5 (194;199) | 5.6/6.0/6.5 b | 6.0 ± 0.15 (5.6;6.4) | 85/86/86 a | 86 ± 0.2 (83;87) |

| Vinylsilane | 188/189/190 a | 189 ± 0.4 (187;191) | 5.4/5.5/5.5 a | 5.5 ± 0.03 (5.4;5.5) | 85/86/87 a | 86 ± 0.3 (84;87) |

| None | 190/192/194 a | 192 ± 0.7 (188;194) | 4.9/5.4/5.6 a | 5.4 ± 0.13 (5.0;5.7) | 85/86/87 a | 86 ± 0.4 (84;88) |

| Silanization CS * | ||||||

| Alkylsilane | 185/186/188 a | 186 ± 0.5 (183;188) | 6.6/6.7/7.1 a | 6.7 ± 0.09 (6.5;7.0) | 84/85/85 a | 85 ± 0.2 (83;86) |

| Aminosilane | 207/215/217 c | 214 ± 1.7 (207;219) | 6.7/6.7/6.9 a | 6.8 ± 0.06 (6.6;6.9) | 87/88/88 b | 88 ± 0.2 (86;89) |

| None | 196/199/201 b | 199 ± 0.9 (195;202) | 6.5/6.6/6.8 a | 6.6 ± 0.05 (6.5;6.8) | 84/86/87 a | 86 ± 0.5 (83;88) |

| Experimental PAEK compounds (EPCs) | ||||||

| PAEKi | 208/210/213 d | 210 ± 0.8 (207;213) | 8.1/8.4/8.6 c | 8.4 ± 0.08 (8.2;8.6) | 88/89/90 a | 89 ± 0.4 (87;90) |

| PAEKii | 198/199/200 c | 199 ± 0.4 (197;201) | 6.3/6.6/6.8 b | 6.5 ± 0.09 (6.2;6.8) | 86/87/88 a | 87 ± 0.4 (86;88) |

| PAEKiii | 185/189/193 b | 188 ± 1.5 (183;193) | 6.0/6.2/6.4 b | 6.2 ± 0.07 (6.0;6.4) | 86/87/88 a | 87 ± 0.4 (85;87) |

| PEEK20 | 154/160/162 a | 159 ± 1.4 (155;162) | 3.6/3.9/4.1 a | 3.9 ± 0.09 (3.6;4.1) | 86/87/87 a | 87 ± 0.2 (85;87) |

| Vertical Loss [µm] | ||||||||

|---|---|---|---|---|---|---|---|---|

| 100,000 Cycles | 200,000 Cycles | 300,000 Cycles | 400,000 Cycles | |||||

| Min/Median/Max * | Mean ± SD (95% CI) | Min/Median/Max * | Mean ± SD (95% CI) | Min/Median/Max * | Mean ± SD (95% CI) | Min/Median/Max * | Mean ± SD (95% CI) | |

| PAEKi | −152/−302 /−371 b | −284 ± 25 (−226;−340) | −189/−367 /−443 b | −338 ± 27 (−275;−401) | −205/−408 /−471 b | −372 ± 28 (−307;−436) | −212/−436 /−513 b | −403 ± 32 (−330;−475) |

| PAEKii | −178/−252 /−423 b | −274 ± 27 (−212;−336) | −234/−301 /−481 b | −322 ± 26 (−261;−382) | −267/−331 /−511 b | −356 ± 27 (−294;−417) | −282/−363 /−535 b | −383 ± 27 (−319;−445) |

| PAEKiii | −175/−236 /−297 b | −238 ± 15 (−204;271) | −200/−285 /−375 b | −294 ± 20 (−246;−341) | −235/−330 /−424 b | −333 ± 22 (−280;−384) | −256/−359 /−469 b | −361 ± 25 (−302;−418) |

| PEEK20 | −105/−175 /−216 a | −157 ± 13 (−126;−187) | −135/−201 /−269 a | −195 ± 16 (−157;−231) | −167/−220 /−319 a | −229 ± 18 (−187;−270) | −208/−235 /−360 a | −262 ± 18 (−219;−303) |

References

- Cho, K.; Rajan, G.; Farrar, R.; Prentice, L.; Prusty, B. Dental resin composites: A review on materials to product realizations. Compos. Part B Eng. 2022, 230, 109495. [Google Scholar] [CrossRef]

- Maloo, L.M.; Toshniwal, S.H.; Reche, A.; Paul, P.; Wanjari, M.B. A Sneak Peek Toward Polyaryletherketone (PAEK) Polymer: A Review. Cureus 2022, 14, e31042. [Google Scholar] [CrossRef]

- Alqurashi, H.; Khurshid, Z.; Syed, A.U.Y.; Rashid Habib, S.; Rokaya, D.; Zafar, M.S. Polyetherketoneketone (PEKK): An emerging biomaterial for oral implants and dental prostheses. J. Adv. Res. 2020, 28, 87–95. [Google Scholar] [CrossRef]

- Tanguy, C. Mechanical Performances of PEKK Thermoplastic Composites Linked to Their Processing Parameters. Ph.D. Dissertation, l’École Nationale Supérieure d’Arts et Métiers, Paris, France, 2017. [Google Scholar]

- Wang, Y.; Jin, Y.; Chen, Y.; Han, T.; Chen, Y.; Wang, C. A preliminary study on surface bioactivation of polyaryletherketone by UV-grafting with PolyNaSS: Influence on osteogenic and antibacterial activities. J. Biomater. Sci. Polym. Ed. 2022, 33, 1845–1865. [Google Scholar] [CrossRef]

- Horák, Z.; Pokorný, D.; Fulín, P.; Slouf, M.; Jahoda, D.; Sosna, A. Polyetheretherketon (PEEK)—I. část: Perspektivní materiál pro ortopedickou a traumatologickou praxi [Polyetheretherketone (PEEK). Part I: Prospects for use in orthopaedics and traumatology]. Acta Chir. Orthop. Traumatol. Cech. 2010, 77, 463–469. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Huang, M.; Dang, P.; Xie, J.; Zhang, X.; Yan, X. PEEK in Fixed Dental Prostheses: Application and Adhesion Improvement. Polymers 2022, 14, 2323. [Google Scholar] [CrossRef] [PubMed]

- Pu, F.; Yu, Y.; Zhang, Z.; Wu, W.; Shao, Z.; Li, C.; Feng, J.; Xue, L.; Chen, F. Research and Application of Medical Polyetheretherketone as Bone Repair Material. Macromol. Biosci. 2023, 23, e2300032. [Google Scholar] [CrossRef]

- Stock, V.; Wagner, C.; Merk, S.; Roos, M.; Schmidlin, P.R.; Eichberger, M.; Stawarczyk, B. Retention force of differently fabricated telescopic PEEK crowns with different tapers. Dent. Mater. J. 2016, 35, 594–600. [Google Scholar] [CrossRef]

- Prechtel, A.; Reymus, M.; Edelhoff, D.; Hickel, R.; Stawarczyk, B. Comparison of various 3D printed and milled PAEK materials: Effect of printing direction and artificial aging on Martens parameters. Dent. Mater. 2020, 36, 197–209. [Google Scholar] [CrossRef]

- Najeeb, S.; Zafar, M.S.; Khurshid, Z.; Siddiqui, F. Applications of polyetheretherketone (PEEK) in oral implantology and prosthodontics. J. Prosthodont. Res. 2016, 60, 12–19. [Google Scholar] [CrossRef]

- Parate, K.P.; Naranje, N.; Vishnani, R.; Paul, P. Polyetheretherketone Material in Dentistry. Cureus 2023, 15, e46485. [Google Scholar] [CrossRef] [PubMed]

- Yousry, M.A.; Hussein, S.A.; Al Abbassy, F.H. Evaluation of shear bond strength of high-performance polymers to its resin veenering and to dentin (in vitro study). Alex. Dent. J. 2018, 43, 62–68. [Google Scholar] [CrossRef]

- Roy, M.; Kubacki, J.; Psiuk, B.; Mrozek-Wilczkiewicz, A.; Malarz, K.; Corti, A.; Pompella, A.; Szade, J. Photofunctionalization effect and biological ageing of PEEK, TiO2 and ZrO2 abutments material. Mater. Sci. Eng. C Mater. Biol. Appl. 2021, 121, 111823. [Google Scholar] [CrossRef]

- Gupta, A.K.; Gupta, R.; Gill, S. Evaluation of the failure modes and load-bearing capacity of different surface-treated polyether ether ketone copings veneered with lithium di-silicate compared to polyether ether ketone copings veneered with composite: An in vitro study. J. Indian Prosthodont. Soc. 2021, 21, 295–303. [Google Scholar] [CrossRef] [PubMed]

- Villefort, R.F.; Diamantino, P.J.S.; von Zeidler, S.L.V.; Borges, A.L.S.; Silva-Concílio, L.R.; de Siqueira Ferreira Anzaloni Saavedra, G.; Tribst, J.P.M. Mechanical Response of PEKK and PEEK As Frameworks for Implant-Supported Full-Arch Fixed Dental Prosthesis: 3D Finite Element Analysis. Eur. J. Dent. 2022, 16, 115–121. [Google Scholar] [CrossRef]

- Abhay, S.S.; Ganapathy, D.; Veeraiyan, D.N.; Ariga, P.; Heboyan, A.; Amornvit, P.; Rokaya, D.; Srimaneepong, V. Wear Resistance, Color Stability and Displacement Resistance of Milled PEEK Crowns Compared to Zirconia Crowns under Stimulated Chewing and High-Performance Aging. Polymers 2021, 13, 3761. [Google Scholar] [CrossRef] [PubMed]

- Papathanasiou, I.; Kamposiora, P.; Papavasiliou, G.; Ferrari, M. The use of PEEK in digital prosthodontics: A narrative review. BMC Oral Health 2020, 20, 217. [Google Scholar] [CrossRef] [PubMed]

- Hári, J.; Pukánszky, B. Nanocomposites: Preparation, Structure, and Properties. In Applied Plastics Engineering Handbook; Kutz, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2011; pp. 109–142. [Google Scholar]

- Aminoroaya, A.; Neisiany, R.E.; Khorasani, S.N.; Panahi, P.; Das, O.; Madry, H.; Cucchiarini, M.; Ramakrishna, S. A review of dental composites: Challenges, chemistry aspects, filler influences, and future insights. Compos. Part B Eng. 2021, 216, 108852. [Google Scholar] [CrossRef]

- Ilie, N.; Hilton, T.J.; Heintze, S.D.; Hickel, R.; Watts, D.C.; Silikas, N.; Stansbury, J.W.; Cadenaro, M.; Ferracane, J.L. Academy of Dental Materials guidance—Resin composites: Part I—Mechanical properties. Dent. Mater. 2017, 33, 880–894. [Google Scholar] [CrossRef]

- Rodríguez, H.A.; Kriven, W.M.; Casanova, H. Development of mechanical properties in dental resin composite: Effect of filler size and filler aggregation state. Mater. Sci. Eng. C Mater. Biol. Appl. 2019, 101, 274–282. [Google Scholar] [CrossRef]

- Lümkemann, N.; Eichberger, M.; Stawarczyk, B. Different PEEK qualities irradiated with light of different wavelengths: Impact on Martens hardness. Dent. Mater. 2017, 33, 968–975. [Google Scholar] [CrossRef] [PubMed]

- Shinkai, K.; Taira, Y.; Suzuki, S.; Kawashima, S.; Suzuki, M. Effect of filler size and filler loading on wear of experimental flowable resin composites. J. Appl. Oral Sci. 2018, 26, e20160652. [Google Scholar] [CrossRef] [PubMed]

- Bechir, E.S.; Bechir, A.; Gioga, C.; Manu, R.; Burcea, A.; Dascalu, I.T. The advantages of BioHPP polymer as superstructure material in oral implantology. Mater. Plast. 2016, 53, 394–398. [Google Scholar]

- Abd El-Fattah, A.; Youssef, H.; Gepreel, M.A.H.; Abbas, R.; Kandil, S. Surface Morphology and Mechanical Properties of Polyether Ether Ketone (PEEK) Nanocomposites Reinforced by Nano-Sized Silica (SiO2) for Prosthodontics and Restorative Dentistry. Polymers 2021, 13, 3006. [Google Scholar] [CrossRef] [PubMed]

- Zhong, F.; Xie, P.; Hou, R.; Niu, W.; Huang, J.; Hu, F.; Zheng, G.; Liu, H.; Qu, T.; Zhu, Y. Improved performance of sulfonated poly ether ether ketone/three-dimensional hierarchical molybdenum disulfide nanoflower composite proton exchange membrane for fuel cells. J. Mater. Sci. 2021, 56, 6531–6548. [Google Scholar] [CrossRef]

- Dunlop, M.J.; Bissessur, R. Nanocomposites based on graphene analogous materials and conducting polymers: A review. J. Mater. Sci. 2020, 55, 6721–6753. [Google Scholar] [CrossRef]

- Micovic Soldatovic, D.; Liebermann, A.; Huth, K.C.; Stawarczyk, B. Fracture load of different veneered and implant-supported 4-UNIT cantilever PEEK fixed dental prostheses. J. Mech. Behav. Biomed. Mater. 2022, 129, 105173. [Google Scholar] [CrossRef]

- Coldea, A.; Swain, M.V.; Thiel, N. Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent. Mater. 2013, 29, 419–426. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Eichberger, M.; Uhrenbacher, J.; Wimmer, T.; Edelhoff, D.; Schmidlin, P.R. Three-unit reinforced polyetheretherketone composite FDPs: Influence of fabrication method on load-bearing capacity and failure types. Dent. Mater. J. 2015, 34, 7–12. [Google Scholar] [CrossRef]

- Alexakou, E.; Damanaki, M.; Zoidis, P.; Bakiri, E.; Mouzis, N.; Smidt, G.; Kourtis, S. PEEK High Performance Polymers: A Review of Properties and Clinical Applications in Prosthodontics and Restorative Dentistry. Eur. J. Prosthodont. Restor. Dent. 2019, 27, 113–121. [Google Scholar]

- Jovanović, M.; Živić, M.; Milosavljević, M. A potential application of materials based on a polymer and CAD/CAM composite resins in prosthetic dentistry. J. Prosthodont. Res. 2021, 65, 137–147. [Google Scholar] [CrossRef] [PubMed]

- Hahnel, S.; Schultz, S.; Trempler, C.; Ach, B.; Handel, G.; Rosentritt, M. Two-body wear of dental restorative materials. J. Mech. Behav. Biomed. Mater. 2011, 4, 237–244. [Google Scholar] [CrossRef] [PubMed]

- Ilie, N.; Hickel, R. Resin composite restorative materials. Aust. Dent. J. 2011, 56 (Suppl. S1), 59–66. [Google Scholar] [CrossRef]

- Lümkemann, N.; Eichberger, M.; Stawarczyk, B. Bonding to Different PEEK Compositions: The Impact of Dental Light Curing Units. Materials 2017, 10, 67. [Google Scholar] [CrossRef]

- Silthampitag, P.; Chaijareenont, P.; Tattakorn, K.; Banjongprasert, C.; Takahashi, H.; Arksornnukit, M. Effect of surface pretreatments on resin composite bonding to PEEK. Dent. Mater. J. 2016, 35, 668–674. [Google Scholar] [CrossRef]

- Aydınoğlu, A.; Yoruç, A.B.H. Effects of silane-modified fillers on properties of dental composite resin. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 79, 382–389. [Google Scholar] [CrossRef] [PubMed]

- Yadav, S.; Gangwar, S. The effectiveness of functionalized nano-hydroxyapatite filler on the physical and mechanical properties of novel dental restorative composite. Int. J. Polym. Mater. Polym. Biomater. 2019, 69, 907–918. [Google Scholar] [CrossRef]

- Song, L.; Sarikaya, R.; Ye, Q.; Misra, A.; Tamerler, C.; Spencer, P. Multifunctional monomer acts as co-initiator and crosslinker to provide autonomous strengthening with enhanced hydrolytic stability in dental adhesives. Dent. Mater. 2020, 36, 284–295. [Google Scholar] [CrossRef]

- Šinkovec, R.; Mušič, B. Effect of Organosilane Coupling Agents on Thermal, Rheological and Mechanical Properties of Silicate-Filled Epoxy Molding Compound. Materials 2020, 13, 177. [Google Scholar] [CrossRef]

- Hermanson, G.T. Silane coupling agents. In Bioconjugate Techniques, 3rd ed.; Academic Press: Cambridge, MA, USA, 2013; pp. 535–548. [Google Scholar]

- Domka, L.; Krysztafkiewicz, A.; Kozak, M. Silane Modified Fillers for Reinforcing Polymers. Polym. Polym. Compos. 2002, 10, 541–552. [Google Scholar] [CrossRef]

- Kaifu, Y. Tooth wear and compensatory modification of the anterior dentoalveolar complex in humans. Am. J. Phys. Anthropol. 2000, 111, 369–392. [Google Scholar] [CrossRef]

- Schmeiser, F.; Arbogast, F.; Ruppel, H.; Mayinger, F.; Reymus, M.; Stawarczyk, B. Methodology investigation: Impact of crown geometry, crown, abutment and antagonist material and thermal loading on the two-body wear of dental materials. Dent. Mater. 2022, 38, 266–280. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, U.; Khalid, H.; Ghafoor, S.; Javaid, A.; Asif, A.; Khan, A.S. Analyses on mechanical and physical performances of nano-apatite grafted glass fibers based dental composites. Mater. Chem. Phys. 2021, 263, 124188. [Google Scholar] [CrossRef]

- Raszewski, Z.; Kulbacka, J.; Pakuła, D.; Brząkalski, D.; Przekop, R.E. Feldspar-Modified Methacrylic Composite for Fabrication of Prosthetic Teeth. Materials 2023, 16, 3674. [Google Scholar] [CrossRef]

- EN ISO 10477:2020; Dentistry—Polymer-based crown and veneering materials. ISO: Geneva, Switzerland, 2020.

| Components | PAEKi | PAEKii | PAEKiii |

|---|---|---|---|

| PEEK | 35 | 70 | 70 |

| PEK | 35 | 0 | 0 |

| Calcium silicate (d50 = 4 µm); wide particle size distribution | 30 | 0 | 0 |

| Calcium silicate (d50 = 4 µm); narrow particle size distribution | 0 | 30 | 25 |

| Feldspar d50 = 1 µm | 0 | 0 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmeiser, F.; Schramm, W.; Mayinger, F.; Baumert, U.; Stawarczyk, B. Effect of Filler Type, Content, and Silanization on the Flexural Strength, Elastic Modulus, Shore D Hardness, and Two-Body Wear of PAEK Compounds. Materials 2025, 18, 2736. https://doi.org/10.3390/ma18122736

Schmeiser F, Schramm W, Mayinger F, Baumert U, Stawarczyk B. Effect of Filler Type, Content, and Silanization on the Flexural Strength, Elastic Modulus, Shore D Hardness, and Two-Body Wear of PAEK Compounds. Materials. 2025; 18(12):2736. https://doi.org/10.3390/ma18122736

Chicago/Turabian StyleSchmeiser, Felix, Wofgang Schramm, Felicitas Mayinger, Uwe Baumert, and Bogna Stawarczyk. 2025. "Effect of Filler Type, Content, and Silanization on the Flexural Strength, Elastic Modulus, Shore D Hardness, and Two-Body Wear of PAEK Compounds" Materials 18, no. 12: 2736. https://doi.org/10.3390/ma18122736

APA StyleSchmeiser, F., Schramm, W., Mayinger, F., Baumert, U., & Stawarczyk, B. (2025). Effect of Filler Type, Content, and Silanization on the Flexural Strength, Elastic Modulus, Shore D Hardness, and Two-Body Wear of PAEK Compounds. Materials, 18(12), 2736. https://doi.org/10.3390/ma18122736