Microstructure and Mechanical Performance of PBF-LB/M 316L Stainless Steel

Abstract

1. Introduction

2. Experimental Section

3. Result and Discussion

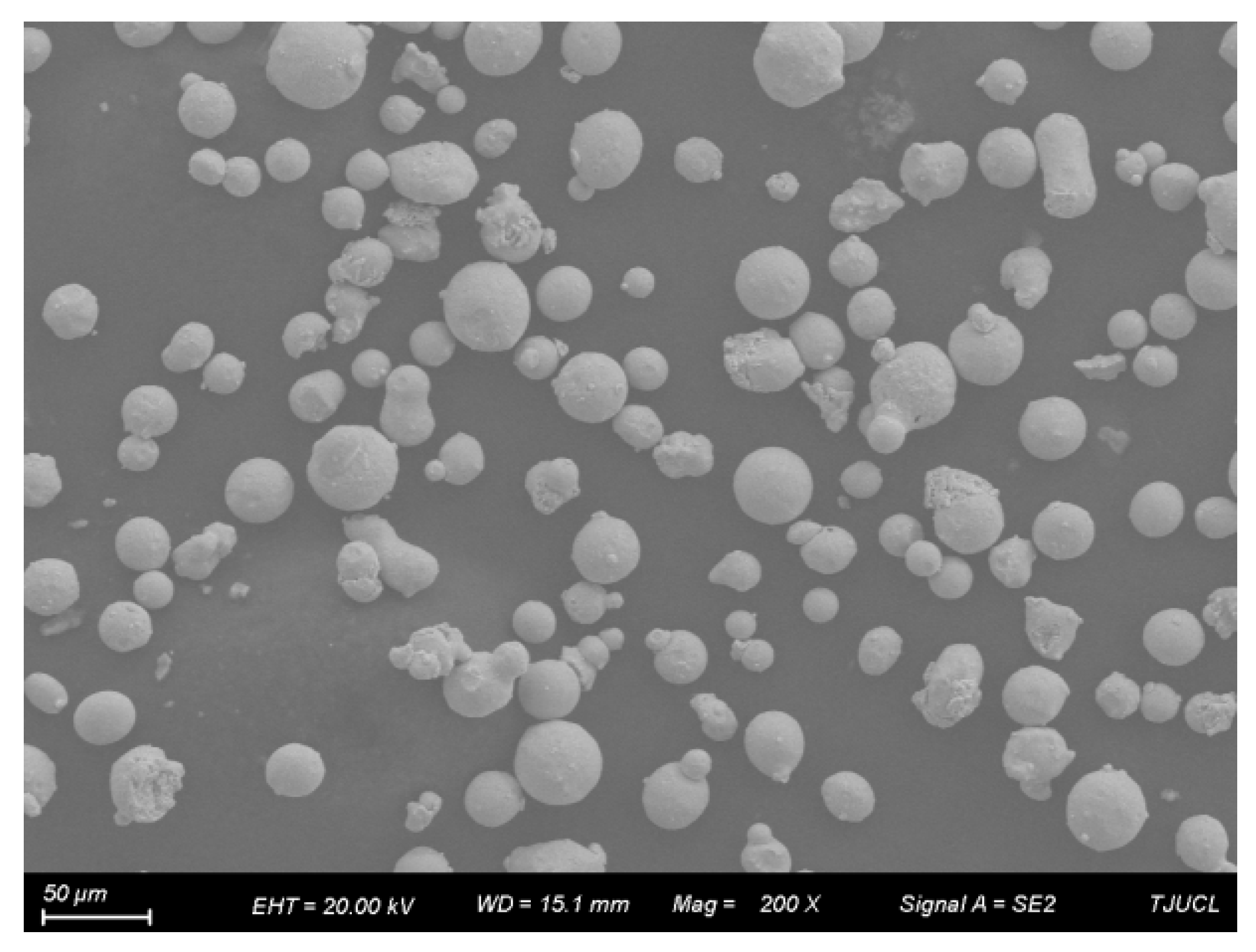

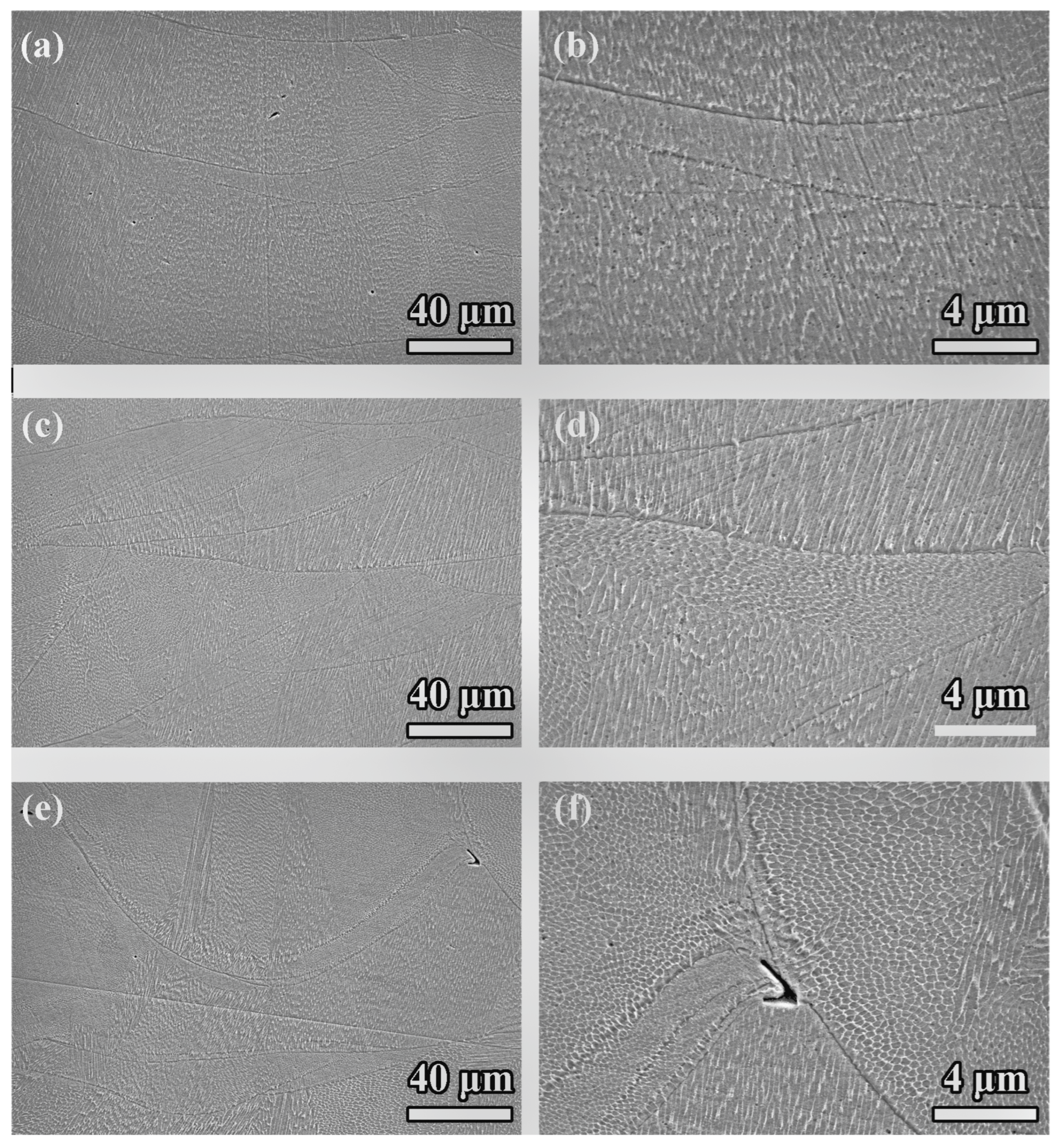

3.1. SEM Analysis

3.1.1. Cross-Sectional SEM Analysis

3.1.2. Surface-Sectional SEM Analysis

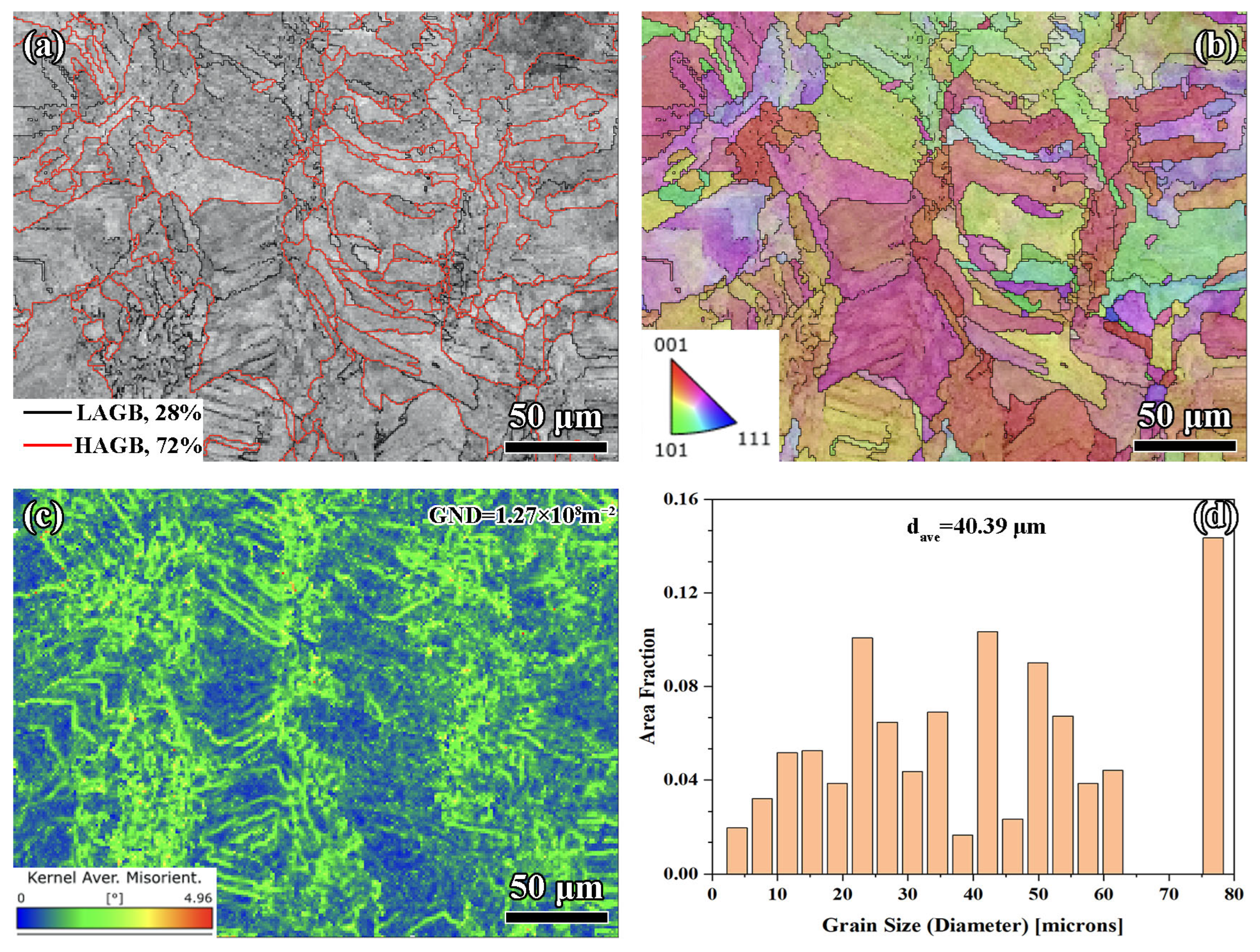

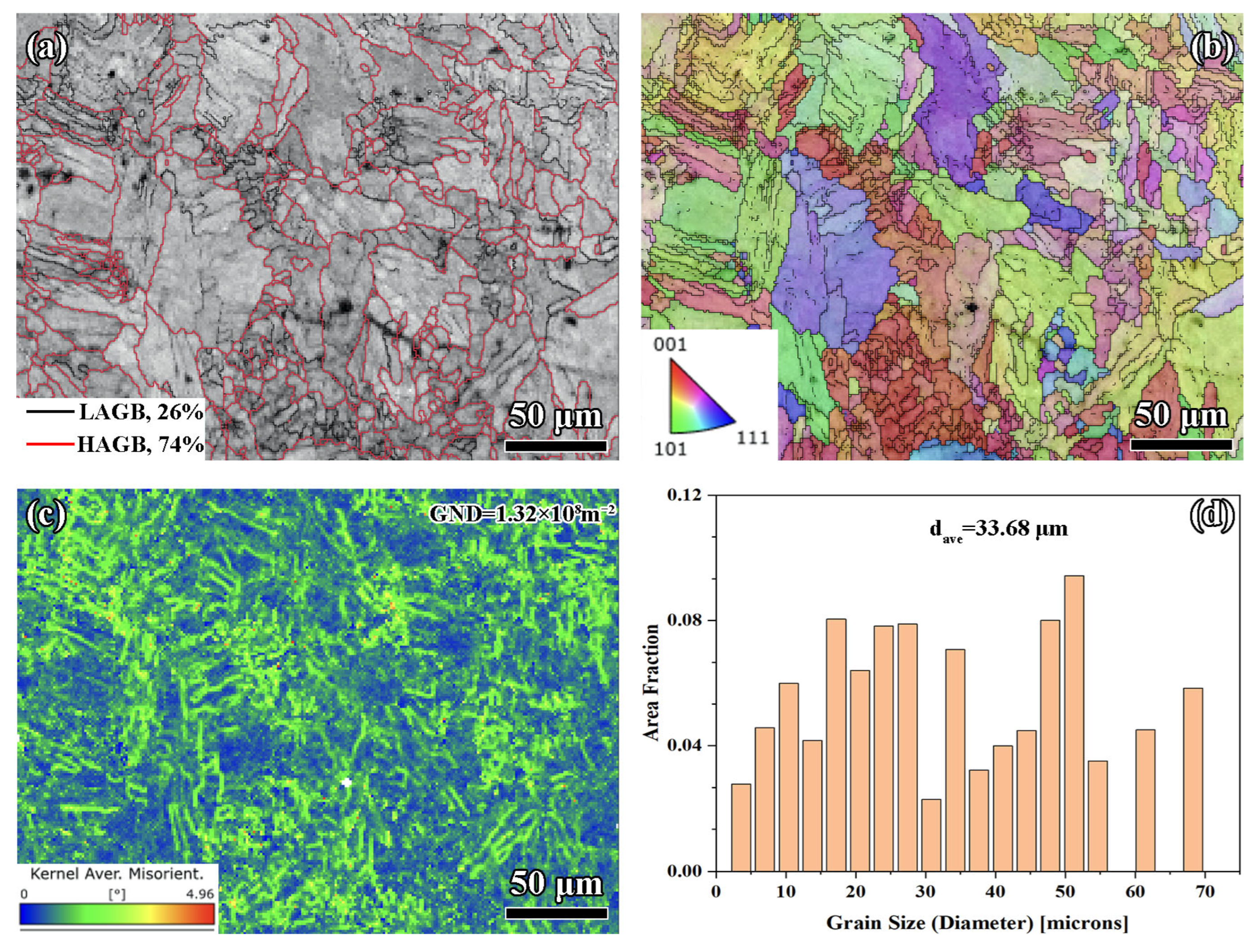

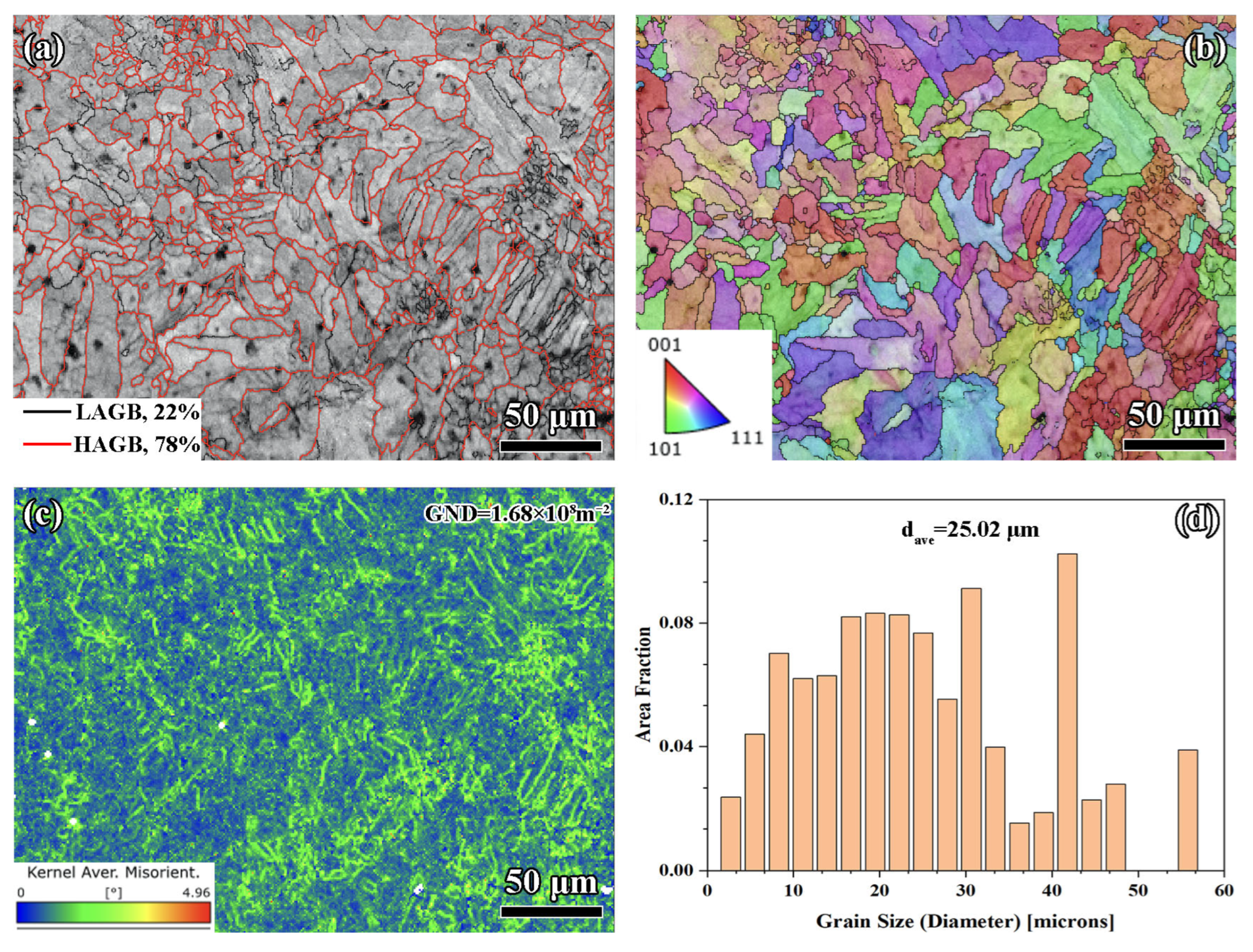

3.2. EBSD Analysis

3.2.1. Scan Spacing of 0.07 mm

3.2.2. Scan Spacing of 0.11 mm

3.2.3. Scan Spacing of 0.15 mm

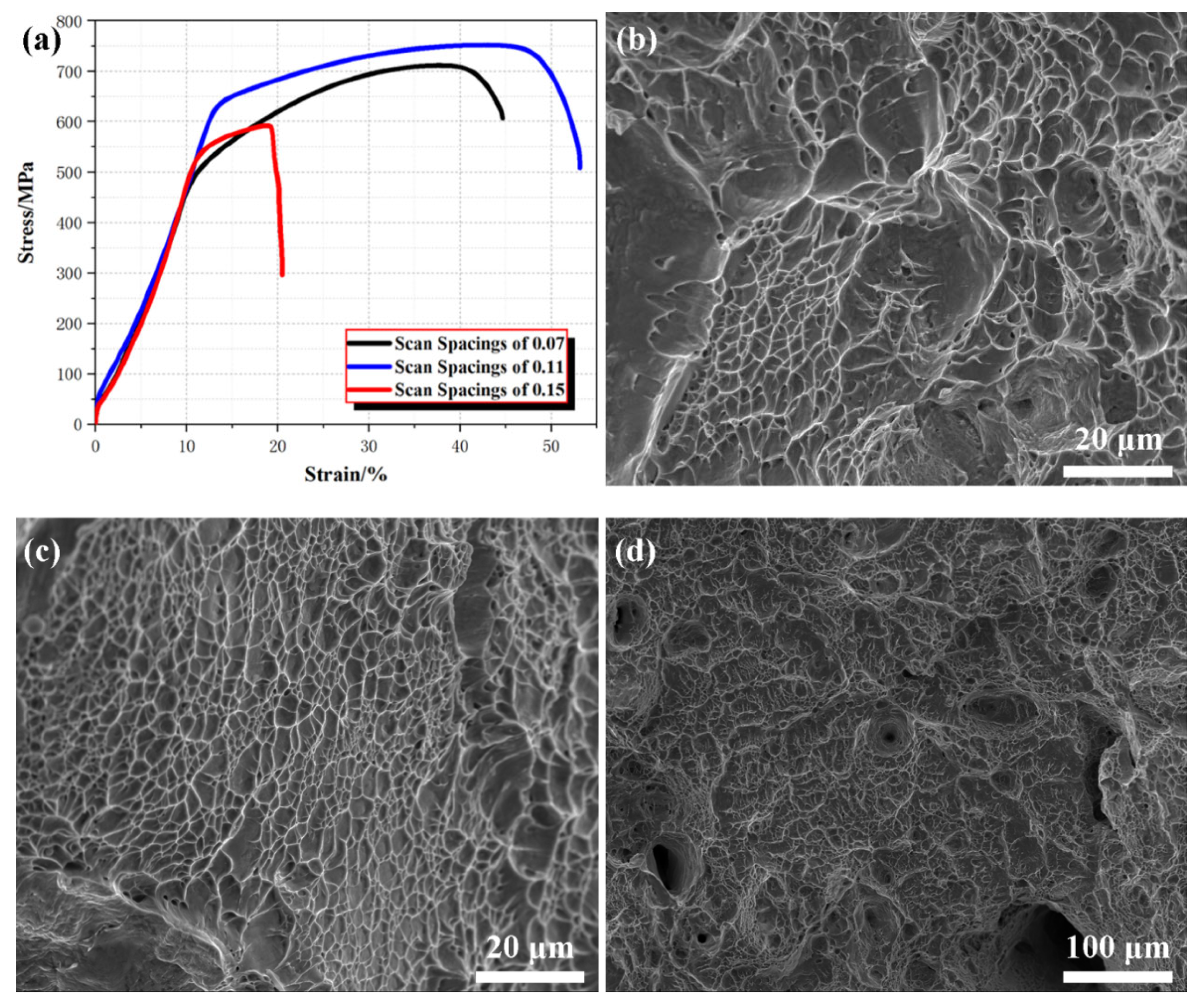

3.3. Tensile Performance

4. Conclusions

- (1)

- SEM and EBSD analyses revealed that scan spacing significantly influenced the microstructure of PBF-LB/M 316L stainless steel. A scan spacing of 0.11 mm exhibited the best balance of energy distribution and thermal conditions, resulting in a uniform and dense microstructure with a higher proportion of high-angle grain boundaries (HAGBs), which enhanced ductility and fracture resistance. In contrast, scan spacings of 0.07 mm and 0.15 mm led to microstructural defects and reduced mechanical properties due to excessive or insufficient energy input.

- (2)

- Although the EBSD results for the 0.15 mm scan spacing indicated the smallest average grain size and the highest GND density, the tensile performance was the weakest, primarily due to the presence of significant porosity. This suggested that, compared to microstructural features, good forming quality, i.e., minimizing defects such as porosity and lack of fusion, was fundamental for ensuring the mechanical performance and structural integrity of parts.

- (3)

- The surface morphology produced at 0.11 mm scan spacing was the smoothest and most uniform, with significantly reduced defects such as porosity and lack of fusion. This uniformity in surface and grain structure directly contributed to the highest ultimate tensile strength (750 MPa) and fracture elongation (53%).

Statement on Novelty

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Zaeh, M.F.; Branner, G. Investigations on residual stresses and deformations in selective laser melting. Prod. Eng. 2010, 4, 35–45. [Google Scholar] [CrossRef]

- Kovačócy, P.; Martinkovič, M.; Šimeková, B.; Hnilica, M.; Kovaříková, I.; Macháček, J.; Krbaťa, M. Influence of laser beam welding parameters on local mechanical properties of duplex stainless steel joints. Acta Polytech. CTU Proc. 2024, 50, 13–17. [Google Scholar] [CrossRef]

- Zhong, Y.; Liu, L.; Wikman, S.; Cui, D.; Shen, Z. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Qiao, R.; Yan, X. The Characterization of Fatigue Damage of 316L Stainless Steel Parts Formed by Selective Laser Melting with Harmonic Generation Technique. Materials 2022, 15, 718. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Ma, W.J.; Ren, Y.J.; Liu, S.F.; Wang, Y.; Wang, W.L.; Tang, H.P. Subgrain microstructures and tensile properties of 316L stainless steel manufactured by selective laser melting. J. Iron Steel Res. Int. 2021, 28, 1159–1167. [Google Scholar] [CrossRef]

- Xu, Y.; Li, T.; Cao, X.; Tan, Y.; Luo, P. Compressive Properties of 316L Stainless Steel Topology Optimized Lattice Structures Fabricated by Selective Laser Melting. Adv. Eng. Mater. 2020, 23, 2000957. [Google Scholar] [CrossRef]

- Ahmadi, A.; Mirzaeifar, R.; Moghaddam, N.S.; Turabi, A.S.; Karaca, H.E.; Elahinia, M. Effect of manufacturing parameters on mechanical properties of 316L stainless steel parts fabricated by selective laser melting: A computational framework. Mater. Des. 2016, 112, 328–338. [Google Scholar] [CrossRef]

- Saxena, P.; Gajera, H.; Shah, D.; Pancholi, N. Effect of SLM process parameters on hardness and microstructure of stainless steel 316 material. Mater. Today Proc. 2022, 50, 1653–1659. [Google Scholar] [CrossRef]

- Zhou, C.; Wu, F.; Tang, D.; Zhang, Z.; Zhang, L.; Zheng, J. Effect of subcritical-temperature heat treatment on corrosion of SLM SS316L with different process parameters. Corros. Sci. 2023, 218, 111214. [Google Scholar] [CrossRef]

- Yang, W.; Liu, T.; Hu, Z.; Ni, X.; Deng, X.; Wang, A.; Luo, Y.; Xie, F.; Chen, Z.; Liu, J.; et al. Microstructure and mechanical behavior of selective laser melted cast carbide reinforced 316 L stainless steel matrix composites. Int. J. Refract. Met. Hard Mater. 2024, 123, 106753. [Google Scholar] [CrossRef]

- Kong, Z.; Wang, X.; Hu, N.; Jin, Y.; Tao, Q.; Xia, W.; Lin, X.-M.; Vasdravellis, G. Mechanical properties of SLM 316L stainless steel plate before and after exposure to elevated temperature. Constr. Build. Mater. 2024, 444, 137786. [Google Scholar] [CrossRef]

- Tong, M.; Zhang, H.; Chen, C.; Hao, J.; Chen, Z.; Wang, F.; Li, R.; Wang, B. Influence of laser power and scanning speed on microstructure evolutions and mechanical properties of the SLM fabricated Al–Mg–Mn–Sc–Zr alloy. J. Mater. Res. Technol. 2024, 33, 5018–5029. [Google Scholar] [CrossRef]

- Montero-Sistiaga, M.L.; Godino-Martinez, M.; Boschmans, K.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Microstructure evolution of 316L produced by HP-SLM (high power selective laser melting). Addit. Manuf. 2018, 23, 402–410. [Google Scholar] [CrossRef]

- Tang, Y.; Li, Q.; Fang, Z.; Allegre, O.J.; Tang, Y.; Perrie, W.; Zhu, G.; Whitehead, D.; Schille, J.; Loeschner, U.; et al. Extending the operational limit of a cooled spatial light modulator exposed to 200 W average power for holographic picosecond laser materials processing. Opt. Laser Technol. 2025, 181, 111589. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Uggowitzer, P.J.; Wegener, K. Influence of SLM scan-speed on microstructure, precipitation of Al3Sc particles and mechanical properties in Sc- and Zr-modified Al-Mg alloys. Mater. Des. 2018, 140, 134–143. [Google Scholar] [CrossRef]

- Zhao, W.; Xiang, H.; Yu, R.; Mou, G. Effects of laser scanning speed on the microstructure and mechanical properties of 2205 duplex stainless steel fabricated by selective laser melting. J. Manuf. Process. 2023, 94, 1–9. [Google Scholar] [CrossRef]

- Song, C.; Deng, Z.; Zou, Z.; Liu, L.; Xu, K.; Yang, Y. Pure tantalum manufactured by laser powder bed fusion: Influence of scanning speed on the evolution of microstructure and mechanical properties. Int. J. Refract. Met. Hard Mater. 2022, 107, 105882. [Google Scholar] [CrossRef]

- Nguyen, Q.B.; Luu, D.N.; Nai, S.M.L.; Zhu, Z.; Chen, Z.; Wei, J. The role of powder layer thickness on the quality of SLM printed parts. Arch. Civ. Mech. Eng. 2018, 18, 948–955. [Google Scholar] [CrossRef]

- Bakhtiarian, M.; Omidvar, H.; Mashhuriazar, A.; Sajuri, Z.; Gur, C.H. The effects of SLM process parameters on the relative density and hardness of austenitic stainless steel 316L. J. Mater. Res. Technol. 2024, 29, 1616–1629. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Y.; Liang, H.; Yao, M.; Jiang, X. Effect of process parameters on residual stresses in SLM-formed bionic porous titanium alloy structures. Mater. Today Commun. 2024, 39, 108539. [Google Scholar]

- Agyapong, J.; Mateos, D.; Czekanski, A.; Boakye-Yiadom, S. Investigation of effects of process parameters on microstructure and fracture toughness of SLM CoCrFeMnNi. J. Alloys Compd. 2024, 987, 173998. [Google Scholar] [CrossRef]

- Yang, X.G.; Li, B.; Wang, M.L.; Guo, S.Q.; Miao, G.L.; Shi, D.Q.; Fan, Y.S. Correlation between microstructures and mechanical properties of a SLM Ni-based superalloy after different post processes. J. Mater. Res. Technol. 2024, 32, 955–966. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Cai, Z.; Zhu, Y.; Han, C.; He, S.; He, Y.; Tai, Z.; Trofimov, V.; Yang, Y. Effects of Different Process Strategies on Surface Quality and Mechanical Properties of 316L Stainless Steel Fabricated via Hybrid Additive-Subtractive Manufacturing. Zhōngguó Jīguāng 2023, 50, 163–174. [Google Scholar]

- Stephenson, P.; Haghdadi, N.; DeMott, R.; Liao, X.; Ringer, S.; Primig, S. Effect of scanning strategy on variant selection in additively manufactured Ti-6Al-4V. Addit. Manuf. 2020, 36, 101581. [Google Scholar] [CrossRef]

- Su, X.B.; Yang, Y.Q.; Liu, J. Theoretical Study on Overlapping Mechanism in SLM Based on Interlayer-Staggered Scan Strategy. Appl. Mech. Mater. 2011, 44–47, 1482–1486. [Google Scholar] [CrossRef]

- Ge, Y.S. Mechanical Properties and Failure Analysis of Selective Laser Melting 316L Stainless Steel. Master’s Dissertation, Anhui Jianzhu University, Hefei, China, 2022. (In Chinese). [Google Scholar]

- GB/T-228.1-2021; Metallic Materials-Tensile Testing Part 1: Method of Test at Room Temperature. Standardization Administration of China: Beijing, China, 2021.

- ASTM E2627-13; Standard Practice for Determining Average Grain Size Using Electron Backscatter Diffraction (EBSD) in Fully Recrystallized Polycrystalline Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- Zhao, J.X.; Zhong, R.; Lu, G.Y.; Xia, D.X.; Cong, J.H.; Shang, C.J. Exploring variations in toughness contributions across different types of high-angle grain boundaries in bainitic steels. Mater. Lett. 2025, 379, 137632. [Google Scholar] [CrossRef]

- Sato, R.; Takai, K. Quantitative hydrogen trap states on high-angle grain boundaries and at dislocations in iron. Scr. Mater. 2023, 228, 115339. [Google Scholar] [CrossRef]

- Su, M.; Qi, X.; Xu, L.; Feng, Q.; Han, Y.; Zhao, L. Microstructural and mechanical analysis of 6063-T6 aluminum alloy joints bonded by friction stir welding. J. Mater. Sci. 2022, 57, 15078–15093. [Google Scholar] [CrossRef]

- He, X.; Deng, Y.; Guo, X. In-situ EBSD tensile revealing the evolution mechanism of high angle grain boundaries in Al–Zn–Mg alloy profile with heterogeneous structures. Mater. Sci. Eng. A 2024, 901, 146539. [Google Scholar] [CrossRef]

- Rezaei, M.J.; Sedighi, M.; Pourbashiri, M. Developing a new method to represent the low and high angle grain boundaries by using multi-scale modeling of crystal plasticity. J. Alloys Compd. 2023, 939, 168844. [Google Scholar] [CrossRef]

- Su, M.; Xu, L.; Yin, X.; Han, Y.; Zhao, L. Investigations of Tungsten Inert Gas and Metal Active Gas Joints of SUS301L Stainless Steel: Electron Backscatter Diffraction Characterization and Fatigue Performance. J. Mater. Eng. Perform. 2023, 32, 4071–4082. [Google Scholar] [CrossRef]

- Joo, M.R.; Jeon, J.H.; Jeon, J.G.; Lee, S.J.; Choi, K.M.; Oh, T.W.; Lee, J.W.; Shin, S.E.; Choi, H.J.; Kang, H.; et al. High-ductility aluminium alloys including small sub-grains with wide low angle boundary. J. Alloys Compd. 2023, 934, 167868. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, J.; Liu, S.; Zhang, Y.; Deng, Y. Quench-induced contributions of high angle grain boundary and low angle grain boundary to exfoliation corrosion propagation in an AlZnMgCu alloy. J. Mater. Res. Technol. 2021, 15, 6866–6870. [Google Scholar] [CrossRef]

- Su, M.; Xu, L.; Peng, C.; Han, Y.; Zhao, L. Fatigue short crack growth, model and EBSD characterization of marine steel welding joint. Int. J. Fatigue 2022, 156, 106689. [Google Scholar] [CrossRef]

- Su, M.; Hu, C.; Xu, L.; Feng, C.; Han, Y.; Zhao, L. Fatigue short crack growth: Overload-induced acceleration/retardation behavior. Int. J. Fatigue 2023, 175, 107772. [Google Scholar] [CrossRef]

- Kubin, L.P.; Mortensen, A. Geometrically necessary dislocations and strain-gradient plasticity: A few critical issues. Scr. Mater. 2003, 48, 119–125. [Google Scholar] [CrossRef]

- Lin, D.; Xu, L.; Han, Y.; Zhang, Y.; Jing, H.; Zhao, L.; Minami, F. Structure and mechanical properties of a FeCoCrNi high-entropy alloy fabricated via selective laser melting. Intermetallics 2020, 127, 106963. [Google Scholar] [CrossRef]

- Hall, O.E. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. Sect. B 1951, 643, 747–752. [Google Scholar] [CrossRef]

- Horiuchi, R.; Otsuka, M. Mechanism of High Temperature Creep of Aluminum-Magnesium Solid Solution Alloys. Trans. Jpn. Inst. Met. 1972, 13, 284–293. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, L.; Wang, Q.; Yan, K.; Zou, J. Defects and tensile properties of 6013 aluminum alloy T-joints by friction stir welding. Mater. Des. 2014, 57, 146–155. [Google Scholar] [CrossRef]

- Su, M.-L.; Li, J.-S.; Qi, W.-J.; Li, J.-N. Impact performance and microstructures of thick TA1 titanium alloy sheets welded by vacuum electron beam. Phys. Scr. 2019, 94, 115703. [Google Scholar] [CrossRef]

- Su, M.-L.; Li, J.-N.; Liu, K.-G.; Qi, W.-J.; Weng, F.; Zhang, Y.-B.; Li, J.-S. Mechanical property and characterization of TA1 titanium alloy sheets welded by vacuum electron beam welding. Vacuum 2019, 159, 315–318. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, H.; Wang, R.; Wang, T.; Du, S.; Su, M. Microstructure and Mechanical Performance of PBF-LB/M 316L Stainless Steel. Materials 2025, 18, 2720. https://doi.org/10.3390/ma18122720

Cai H, Wang R, Wang T, Du S, Su M. Microstructure and Mechanical Performance of PBF-LB/M 316L Stainless Steel. Materials. 2025; 18(12):2720. https://doi.org/10.3390/ma18122720

Chicago/Turabian StyleCai, Haoyu, Renche Wang, Tao Wang, Shuaishuai Du, and Molin Su. 2025. "Microstructure and Mechanical Performance of PBF-LB/M 316L Stainless Steel" Materials 18, no. 12: 2720. https://doi.org/10.3390/ma18122720

APA StyleCai, H., Wang, R., Wang, T., Du, S., & Su, M. (2025). Microstructure and Mechanical Performance of PBF-LB/M 316L Stainless Steel. Materials, 18(12), 2720. https://doi.org/10.3390/ma18122720