Assessing the Efficiency of Open-System Densification on Chemically Treated Dendrocalamus asper Bamboo

Abstract

1. Introduction

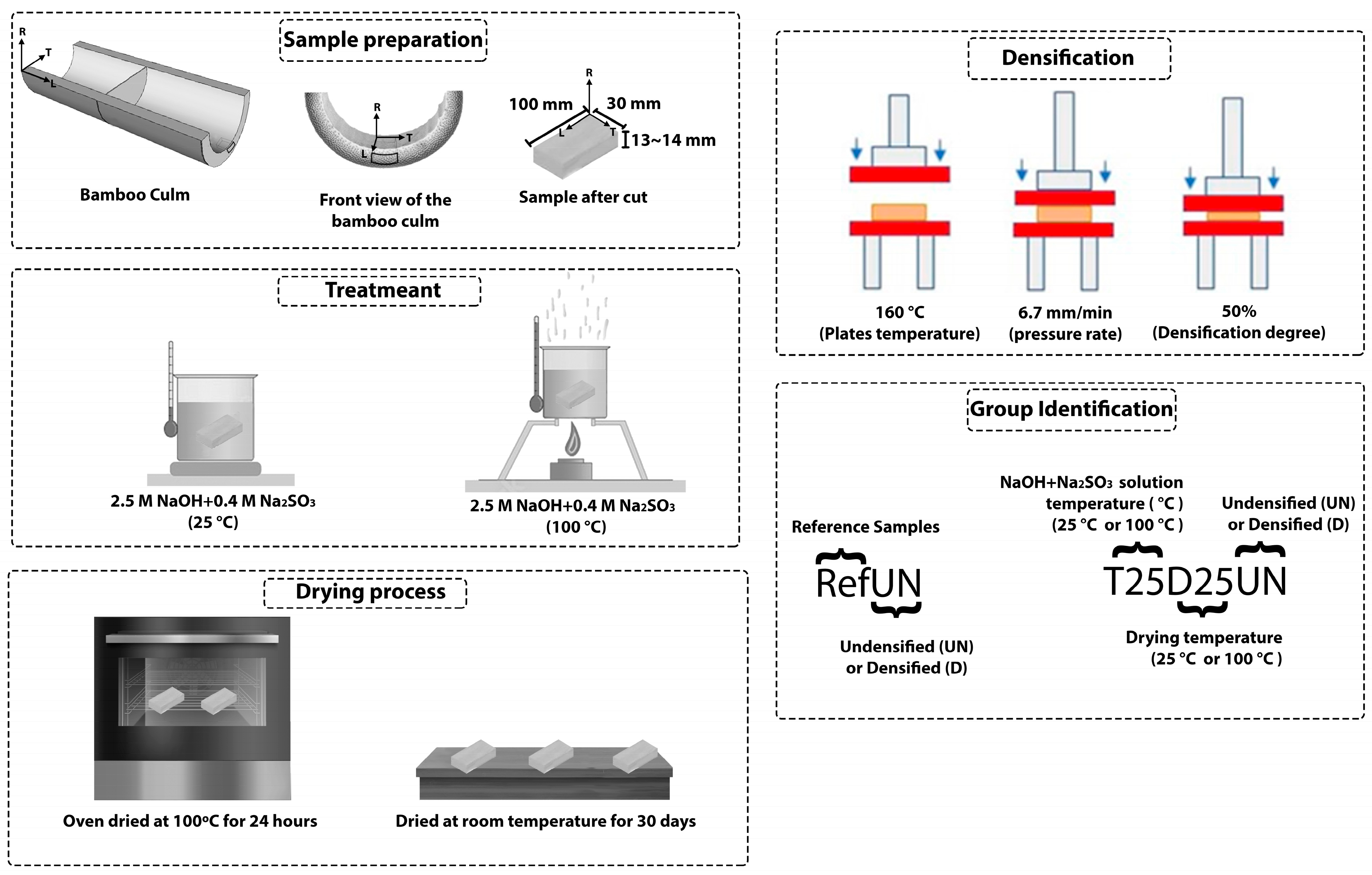

2. Materials and Methods

2.1. Material and Sample Acquisition

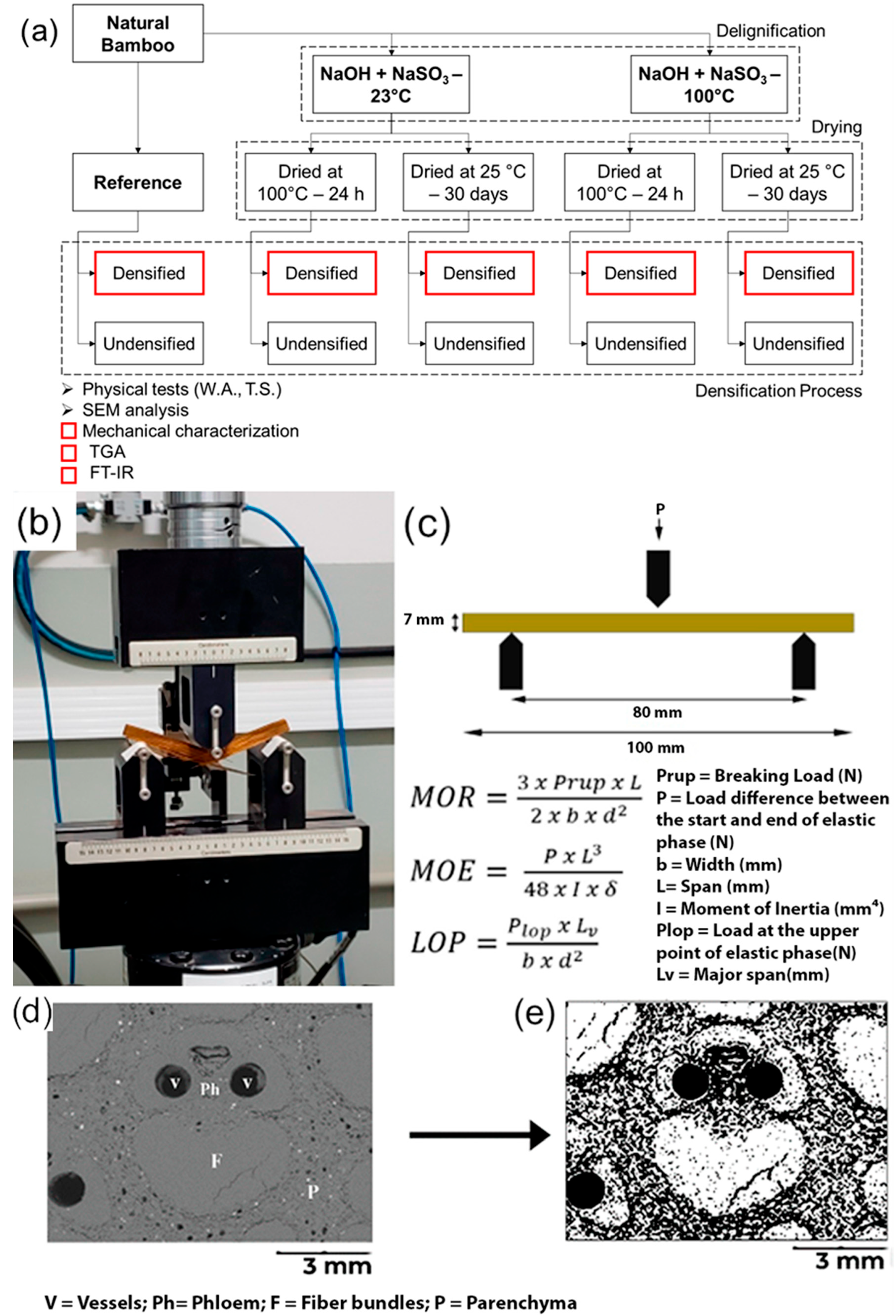

2.2. Methods

2.2.1. Delignification

2.2.2. Drying Process

2.2.3. Densification Process

2.2.4. Physical Properties

2.2.5. Mechanical Analysis

2.2.6. Image Analysis

2.2.7. Chemical Analysis

2.2.8. Thermogravimetric Analysis

3. Results and Discussion

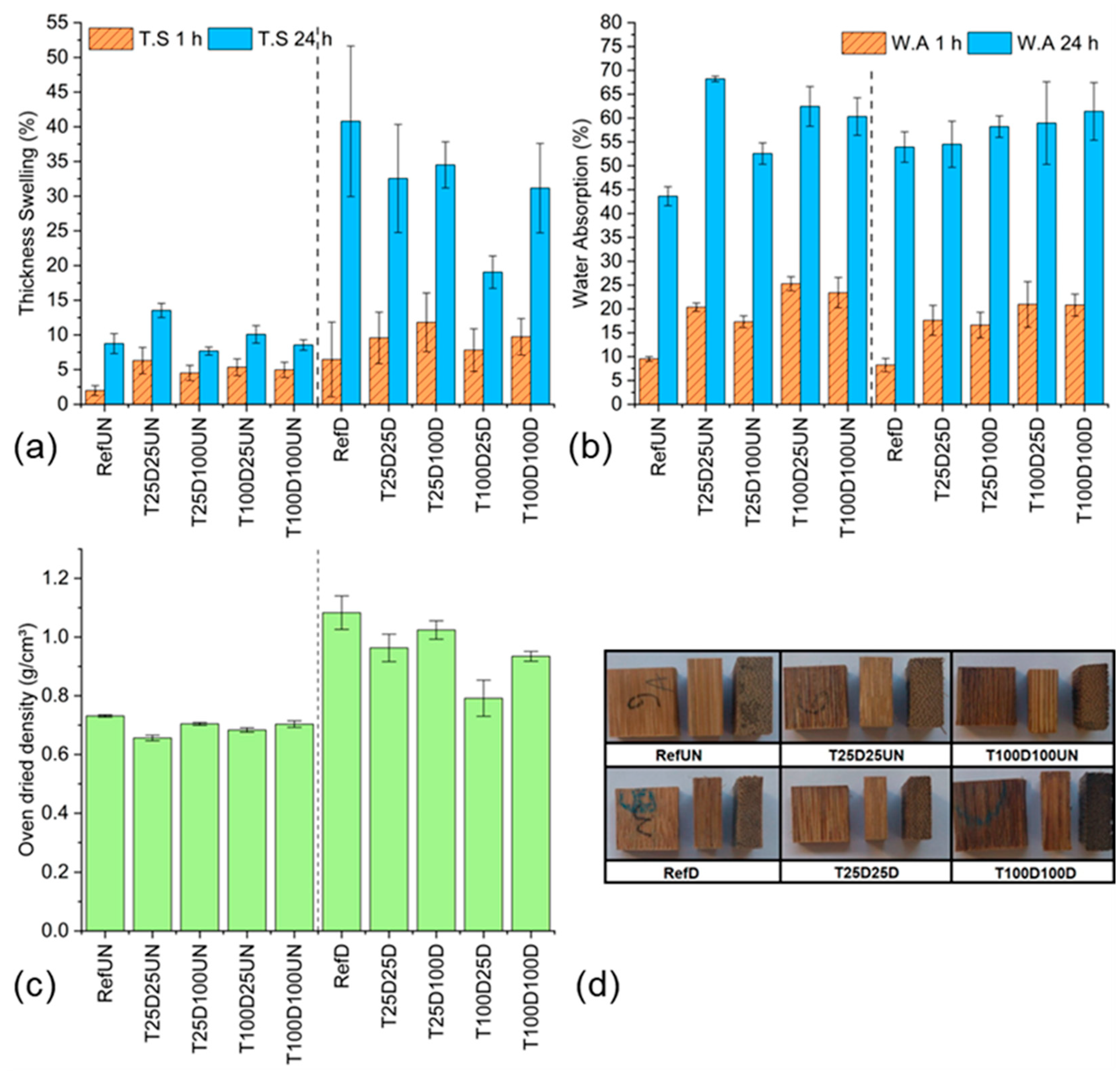

3.1. Physical Properties

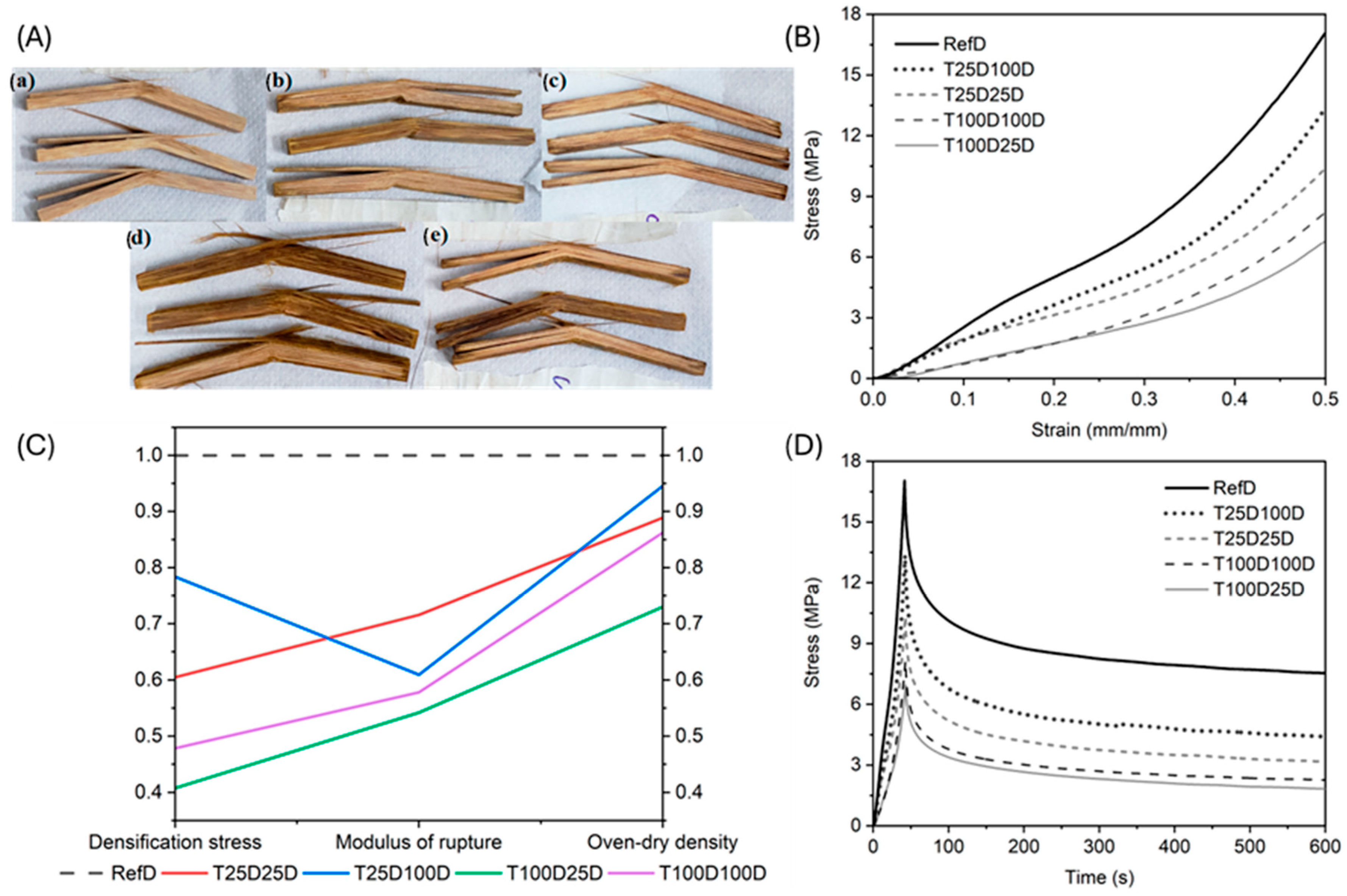

3.2. Mechanical Characterization

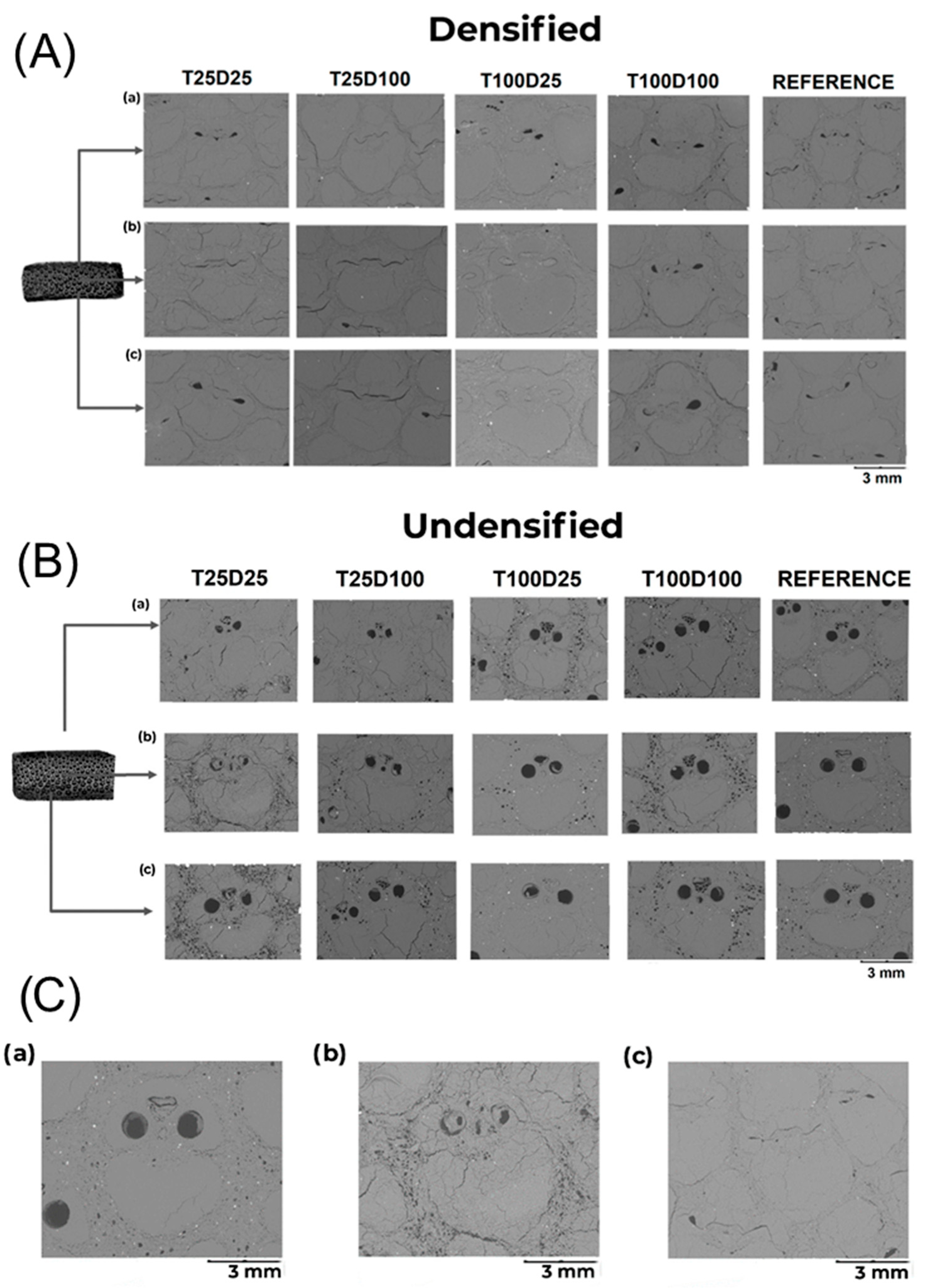

3.3. Image Analysis

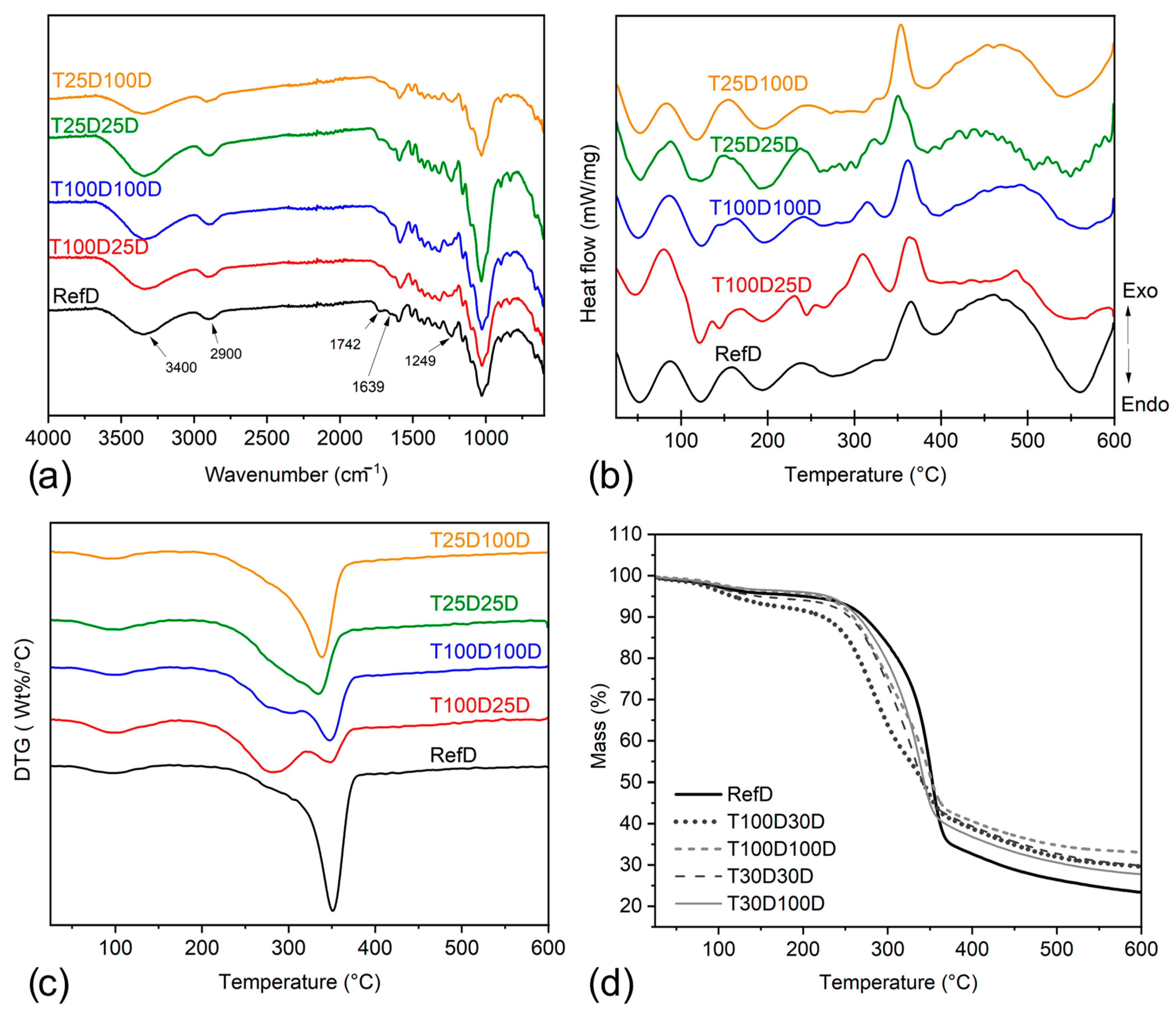

3.4. Chemical and Thermogravimetric Analyses

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, Y.; Fahmy, M.F.M.; Pan, Z.; Zhan, Y.; Wang, R.; Wang, B.; Feng, B. Experimental study on basic mechanical properties of new BFRP-bamboo sandwich structure. Constr. Build. Mater. 2020, 264, 120642. [Google Scholar] [CrossRef]

- Archila-Santos, H.F.; Ansell, M.P.; Walker, P. Elastic properties of thermo-hydro-mechanically modified bamboo (Guadua angustifolia Kunth) measured in tension. Key Eng. Mater. 2014, 600, 111–120. [Google Scholar]

- Pelit, H.; Sönmez, A.; Budakçi, M. Effects of thermomechanical densification and heat treatment on density and Brinell hardness of scots pine (Pinus sylvestris L.) and Eastern beech (Fagus orientalis L.). Bioresources 2015, 10, 3097–3111. [Google Scholar] [CrossRef]

- Kadivar, M.; Gauss, C.; Ghavami, K.; Savastano, H. Densification of Bamboo: State of the Art. Materials 2020, 13, 4346. [Google Scholar] [CrossRef]

- Gauss, C.; Kadivar, M.; Savastano, H. Effect of disodium octaborate tetrahydrate on the mechanical properties of Dendrocalamus asper bamboo treated by vacuum/pressure method. J. Wood Sci. 2019, 65, 27. [Google Scholar] [CrossRef]

- Dixon, P.G.; Semple, K.E.; Kutnar, A.; Kamke, F.A.; Smith, G.D.; Gibson, L.J. Comparison of the flexural behavior of natural and thermo-hydro-mechanically densified Moso bamboo. Eur. J. Wood Wood Prod. 2016, 74, 633–642. [Google Scholar] [CrossRef]

- Kadivar, M.; Gauss, C.; Tomazello-Filho, M.; Ahrar, A.J.; Ghavami, K.; Savastano, H. Optimization of thermo-mechanical densification of bamboo. Constr. Build. Mater. 2021, 298, 123860. [Google Scholar] [CrossRef]

- Sandberg, D.; Haller, P.; Navi, P. Thermo-hydro and thermo-hydro-mechanical wood processing: An opportunity for future environmentally friendly wood products. Wood Mater. Sci. Eng. 2013, 8, 64–88. [Google Scholar] [CrossRef]

- Schild, G.; Sixta, H.; Testova, L. Multifunctional alkaline pulping, delignification and hemicellulose extraction. Cellul. Chem. Technol. 2010, 44, 35–45. [Google Scholar]

- Kadivar, M.; Gauss, C.; Stanislas, T.T.; Ahrar, A.J.; Charca, S.; Savastano, H. Effect of bamboo species and pre-treatment method on physical and mechanical properties of bamboo processed by flattening-densification. Mater. Chem. Phys. 2022, 291, 126746. [Google Scholar] [CrossRef]

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N.; et al. Processing bulk natural wood into a high-performance structural material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Chen, C.; Mi, R.; Gan, W.; Dai, J.; Jiao, M.; Xie, H.; Yao, Y.; Xiao, S.; Hu, L. A Strong, Tough, and Scalable Structural Material from Fast-Growing Bamboo. Adv. Mater. 2020, 32, 1906308. [Google Scholar] [CrossRef]

- Mania, P.; Kupfernagel, C.; Curling, S. Densification of Delignified Wood: Influence of Chemical Composition on Wood Density, Compressive Strength, and Hardness of Eurasian Aspen and Scots Pine. Forests 2024, 15, 892. [Google Scholar] [CrossRef]

- Andze, L.; Nefjodovs, V.; Andzs, M.; Skute, M.; Zoldners, J.; Kapickis, M.; Dubnika, A.; Locs, J.; Vetra, J. Chemically Pretreated Densification of Juniper Wood for Potential Use in Osteosynthesis Bone Implants. J. Funct. Biomater. 2024, 15, 287. [Google Scholar] [CrossRef]

- Gauss, C.; Harries, K.A.; Kadivar, M.; Akinbade, Y.; Savastano, H. Quality assessment and mechanical characterization of preservative-treated Moso bamboo (P. edulis). Eur. J. Wood Wood Prod. 2020, 78, 257–270. [Google Scholar] [CrossRef]

- ASTM D2395-17; Standard Test Methods for Density and Specific Gravity (Relative Density) of Wood and Wood-Based Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D790-17; Standart Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Eletrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Yuan, J.; Fang, C.; Chen, Q.; Fei, B. Observing bamboo dimensional change caused by humidity. Constr. Build. Mater. 2021, 309, 124988. [Google Scholar] [CrossRef]

- Gauss, C.; Kadivar, M.; Pereira, R.G.F.; Savastano, H., Jr. Assessment of dendrocalamus asper (Schult and schult f.) (Poaceae) bamboo treated with tannin-boron preservatives. Constr. Build. Mater. 2021, 282, 122723. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Effects of chemical treatments on hemp fibre structure. Appl. Surf. Sci. 2013, 276, 13–23. [Google Scholar] [CrossRef]

- Pelaez-Samaniego, M.R.; Yadama, V.; Lowell, E.; Espinoza-Herrera, R. A review of wood thermal pretreatments to improve wood composite properties. Wood Sci. Technol. 2013, 47, 1285–1319. [Google Scholar] [CrossRef]

- Tserki, V.; Zafeiropoulos, N.E.; Simon, F.; Panayiotou, C. A study of the effect of acetylation and propionylation surface treatments on natural fibres. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1110–1118. [Google Scholar] [CrossRef]

- John, M.J.; Bellmann, C.; Anandjiwala, R.D. Kenaf-polypropylene composites: Effect of amphiphilic coupling agent on surface properties of fibres and composites. Carbohydr. Polym. 2010, 82, 549–554. [Google Scholar] [CrossRef]

- Bessadok, A.; Langevin, D.; Gouanvé, F.; Chappey, C.; Roudesli, S.; Marais, S. Study of water sorption on modified Agave fibres. Carbohydr. Polym. 2009, 76, 74–85. [Google Scholar] [CrossRef]

- Gierlinger, N.; Goswami, L.; Schmidt, M.; Burgert, I.; Coutand, C.; Rogge, T.; Schwanninger, M. In situ FT-IR microscopic study on enzymatic treatment of poplar wood cross-sections. Biomacromolecules 2008, 9, 2194–2201. [Google Scholar] [CrossRef] [PubMed]

- Zakikhani, P.; Zahari, R.; Sultan, M.T.H.; Abang Abdul Majid, D.L. Thermal Degradation of Four Bamboo Species. Bioresources 2015, 11, 414–425. [Google Scholar] [CrossRef]

- Zhou, F.; Cheng, G.; Jiang, B. Effect of silane treatment on microstructure of sisal fibers. Appl. Surf. Sci. 2014, 292, 806–812. [Google Scholar] [CrossRef]

- Chen, H.; Yu, Y.; Zhong, T.; Wu, Y.; Li, Y.; Wu, Z.; Fei, B. Effect of alkali treatment on microstructure and mechanical properties of individual bamboo fibers. Cellulose 2017, 24, 333–347. [Google Scholar] [CrossRef]

| Type of Test | Dimensions (L × W × T *) (mm) | Number of Samples Per Group | Total Number of Samples | Treatment |

|---|---|---|---|---|

| Physical properties | 21 × 21 × (6.5–7) | 5 | 25 | Densified |

| 21 × 21 × (13–14) | 3 | 15 | Undensified | |

| Image analysis | 21 × 21 × (6.5–7) | 1 | 5 | Densified |

| 21 × 21 × (13–14) | 1 | 5 | Undensified | |

| Three-point bending test | 100 × 8 × 7 | 9 | 45 | Densified |

| TGA andFT-IR | Bamboo powder | - | - | Densified |

| Density (g/cm3)—Mean (SD) | |||

|---|---|---|---|

| Undensified groups | |||

| Treatment | Oven-dried | 1 h water immersion | 24 h water immersion |

| RefUN | 0.731 a (0.004) | 0.773 a (0.021) | 0.907 a (0.005) |

| T25D25UN | 0.656 a (0.010) | 0.714 a (0.008) | 0.897 a (0.012) |

| T25D100UN | 0.704 a (0.005) | 0.747 a (0.020) | 0.945 a (0.014) |

| T100D25UN | 0.683 a (0.007) | 0.792 a (0.0007) | 0.946 a (0.024) |

| T100D100UN | 0.703 a (0.011) | 0.788 a (0.022) | 0.969 a (0.015) |

| Densified groups | |||

| Treatment | Oven-dried | 1 h water immersion | 24 h water immersion |

| RefD | 1.083 a (0.057) | 1.078 a (0.022) | 1.076 a (0.042) |

| T25D25D | 0.963 b,c (0.047) | 1.009 a (0.039) | 1.067 a (0.022) |

| T25D100D | 1.024 a,c (0.031) | 1.039 a (0.049) | 1.289 a (0.421) |

| T100D25D | 0.791 d (0.062) | 0.740 b,c (0.333) | 1.017 a (0.055) |

| T100D100D | 0.934 b (0.017) | 1.001 a,c (0.013) | 1.083 a (0.026) |

| Water Abs (%)—Mean (SD) | ||

|---|---|---|

| Undensified groups | ||

| Treatment | 1 h | 24 h |

| RefUN | 9.51 a (0.50) | 43.63 a (2.00) |

| T25D25UN | 20.36 b,c (0.88) | 68.21 b (0.59) |

| T25D100UN | 17.29 b (1.25) | 52.56 a,c (2.22) |

| T100D25UN | 25.27 c (1.48) | 62.46 b,c (4.16) |

| T100D100UN | 23.40 b,c (3.18) | 60.32 b,c (3.94) |

| Densified groups | ||

| Treatment | 1 h | 24 h |

| RefD | 8.23 a (1.41) | 53.92 a (3.20) |

| T25D25D | 17.59 b (3.16) | 54.51 a (4.84) |

| T25D100D | 16.59 b (2.69) | 58.21 a (2.25) |

| T100D25D | 20.93 b (4.79) | 58.95 a (8.65) |

| T100D100D | 20.80 b (2.29) | 61.40 a (6.03) |

| Thickness Swelling (%)—Mean (SD) | ||

|---|---|---|

| Undensified groups | ||

| Treatment | 1 h | 24 h |

| RefUN | 1.98 a (0.71) | 8.75 a (1.43) |

| T25D25UN | 6.29 a (1.90) | 13.53 a (1.02) |

| T25D100UN | 4.52 a (1.09) | 7.68 a (0.58) |

| T100D25UN | 5.34 a (1.21) | 10.08 a (1.27) |

| T100D100UN | 4.97 a (1.10) | 8.55 a (0.76) |

| Densified groups | ||

| Treatment | 1 h | 24 h |

| RefD | 6.46 a (5.39) | 40.79 a (10.85) |

| T25D25D | 9.56 a (3.72) | 32.55 a (7.79) |

| T25D100D | 11.81 a (4.24) | 34.50 a (3.33) |

| T100D25D | 7.81 a (3.08) | 19.05 b,c (2.33) |

| T100D100D | 9.74 a (2.63) | 31.15 a,c (6.44) |

| Treatment | MOR (MPa) | S-MOR (MPa) | LOP (MPa) | S-LOP (MPa) | MOE (GPa) | S-MOE (GPa) | EE (kJ/m2) |

|---|---|---|---|---|---|---|---|

| RefD | 266.7 a (27.8) | 246.3 | 174.2 a (23.5) | 160.8 | 19.2 a (2.6) | 17.7 | 19.5 a (10.5) |

| T25D25D | 190.9 b (13.9) | 198.2 | 118.3 b (9.71) | 122.8 | 14.7 b (1.3) | 15.3 | 20.4 a (3.3) |

| T25D100D | 162.5 c (19.2) | 158.7 | 118.7 b (17.8) | 115.9 | 15.8 b (2.6) | 15.4 | 20.2 a (5.9) |

| T100D25D | 144.6 c (18.3) | 182.8 | 90.9 c (10.9) | 114.9 | 12.9 b (3.2) | 16.3 | 14.1 a (6.9) |

| T100D100D | 154.2 c (20.0) | 165.1 | 102.1 b,c (23.2) | 109.3 | 14.6 b (2.3) | 15.6 | 13.0 a (0.8) |

| Treatment | Average Fiber Fraction |

|---|---|

| RefUN | 52.13% |

| T25D25UN | 65.98% |

| T25D100UN | 63.29% |

| T100D25UN | 60.92% |

| T100D100UN | 59.71% |

| RefD | 66.15% |

| T25D25D | 61.64% |

| T25D100D | 62.45% |

| T100D25D | 54.84% |

| T100D100D | 52.81% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira de Godoy Junior, A.L.; Kadivar, M.; do Amaral, L.M.; Azevedo, A.G.d.S.; Molano, J.C.A.; Biazar, E.; Savastano Junior, H. Assessing the Efficiency of Open-System Densification on Chemically Treated Dendrocalamus asper Bamboo. Materials 2025, 18, 2719. https://doi.org/10.3390/ma18122719

Pereira de Godoy Junior AL, Kadivar M, do Amaral LM, Azevedo AGdS, Molano JCA, Biazar E, Savastano Junior H. Assessing the Efficiency of Open-System Densification on Chemically Treated Dendrocalamus asper Bamboo. Materials. 2025; 18(12):2719. https://doi.org/10.3390/ma18122719

Chicago/Turabian StylePereira de Godoy Junior, André Luiz, Marzieh Kadivar, Leo Maia do Amaral, Adriano Galvão de Souza Azevedo, Juan Camilo Adrada Molano, Esmaeil Biazar, and Holmer Savastano Junior. 2025. "Assessing the Efficiency of Open-System Densification on Chemically Treated Dendrocalamus asper Bamboo" Materials 18, no. 12: 2719. https://doi.org/10.3390/ma18122719

APA StylePereira de Godoy Junior, A. L., Kadivar, M., do Amaral, L. M., Azevedo, A. G. d. S., Molano, J. C. A., Biazar, E., & Savastano Junior, H. (2025). Assessing the Efficiency of Open-System Densification on Chemically Treated Dendrocalamus asper Bamboo. Materials, 18(12), 2719. https://doi.org/10.3390/ma18122719