Pressure-Dependent Meso-Scale Evolution of Dispersed Foam and Field-Application Clogging Mitigation Strategies for EPB Shield Tunnelling Through Highly Cohesive Clay

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.1.1. Surfactant and Dispersant

2.1.2. Clay Specimen

2.2. Test Condition

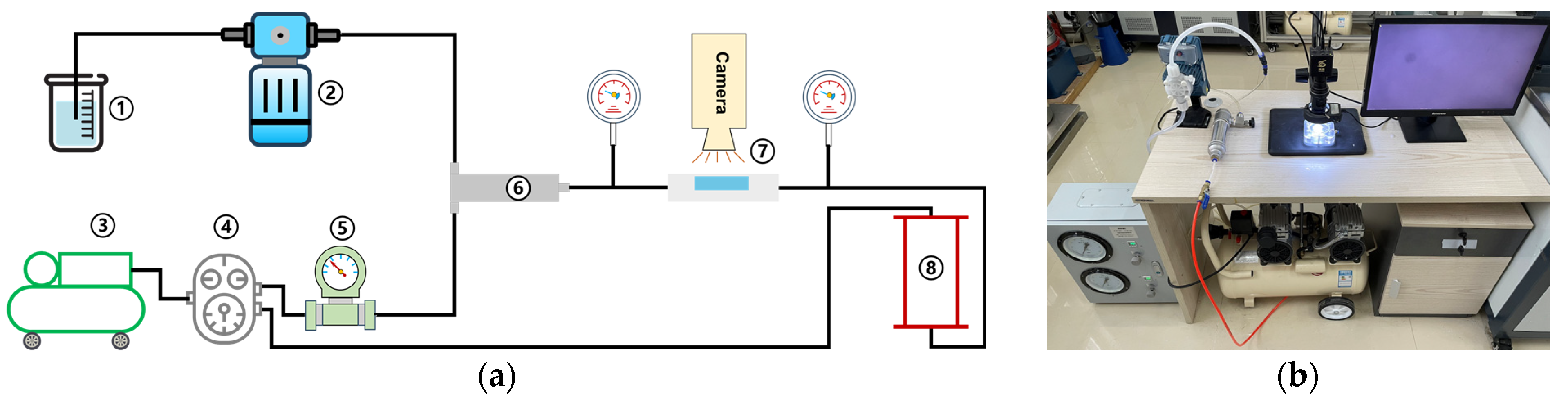

2.3. Test Apparatus and Procedure

2.3.1. Foam Evolution Mechanism

2.3.2. Adhesion Characteristics Test of Conditioned Soil

3. Results and Discussion

3.1. Effect of HDT Content on Foam Evolution Mechanism Under Different Pressures

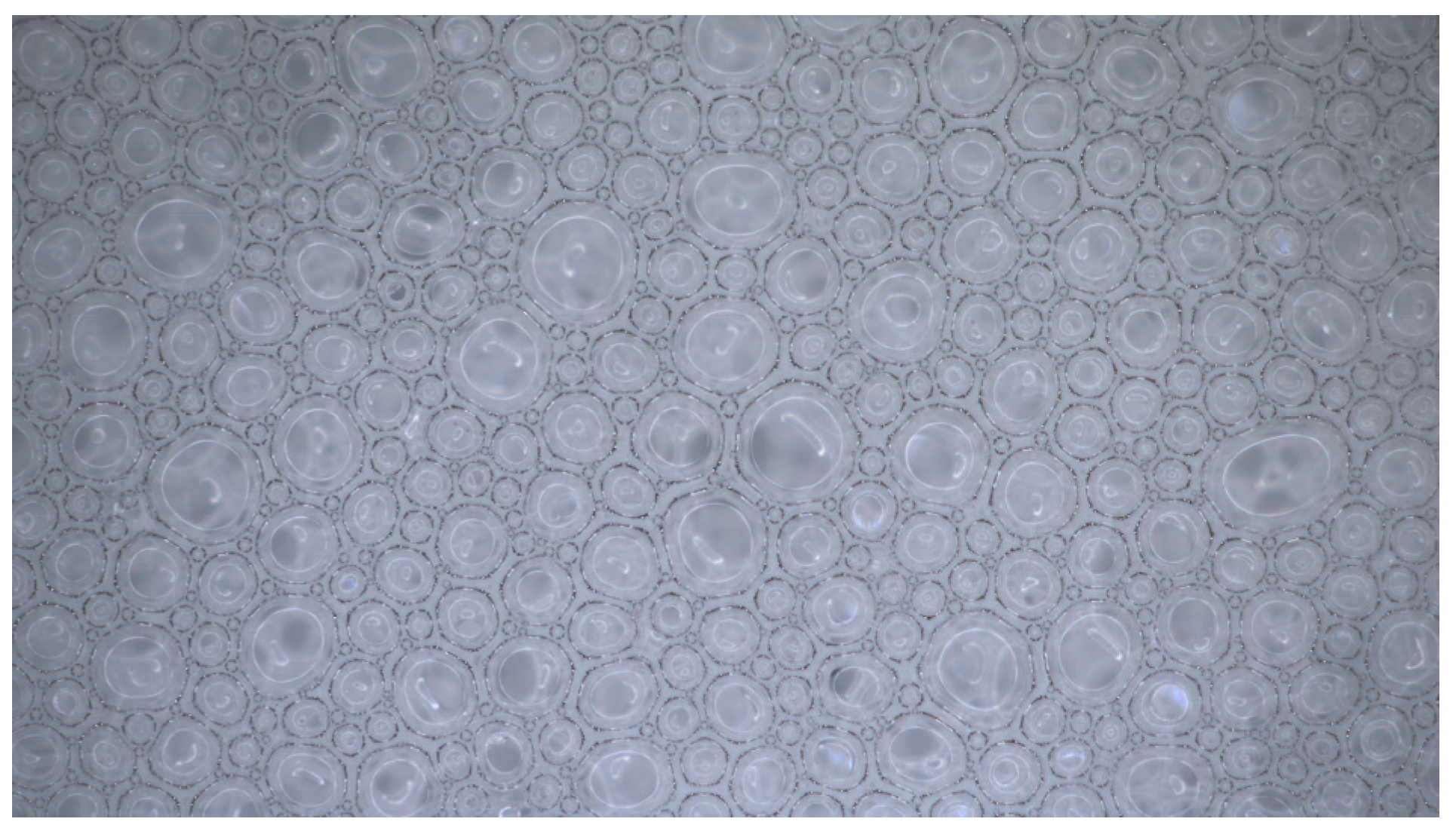

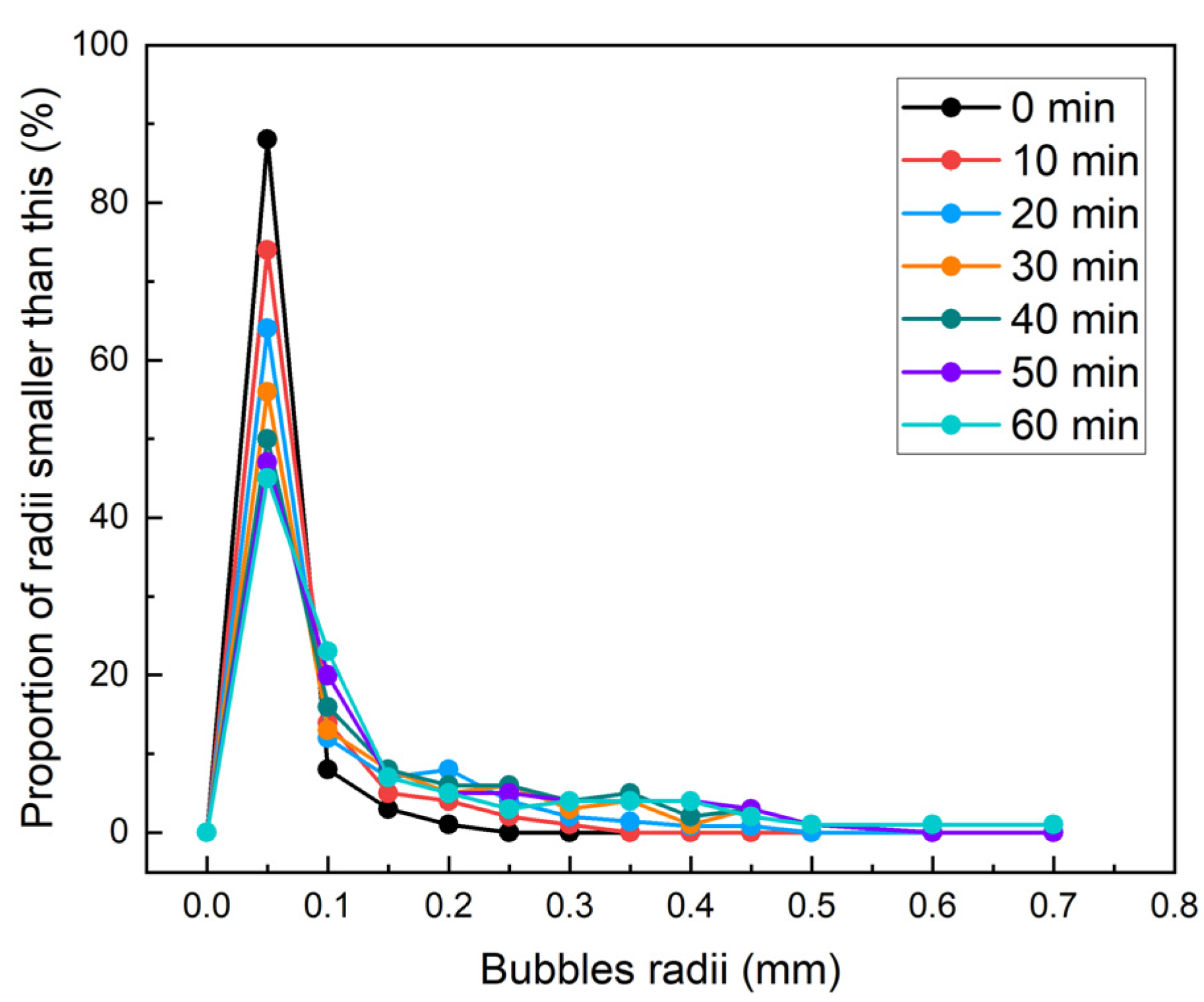

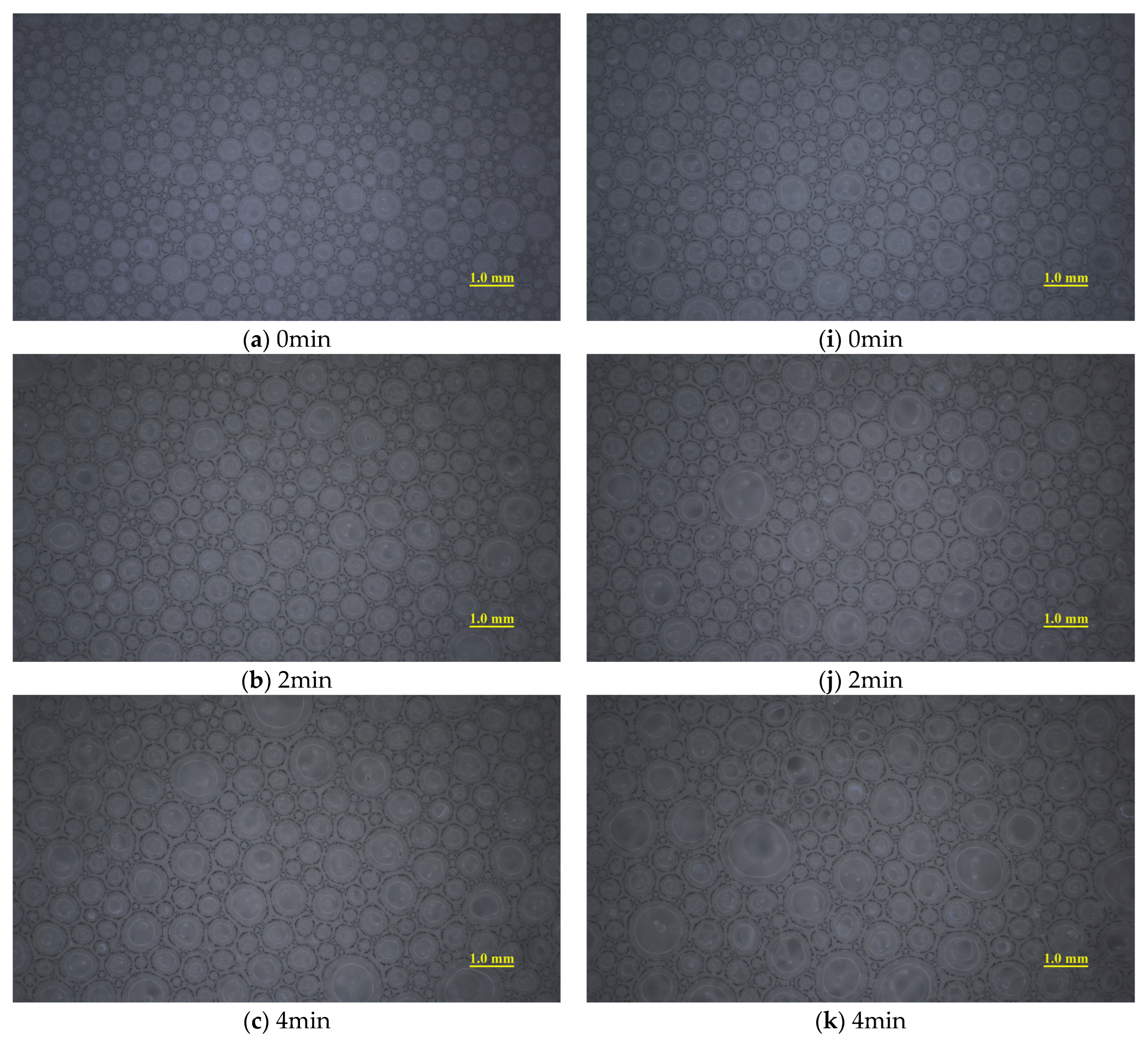

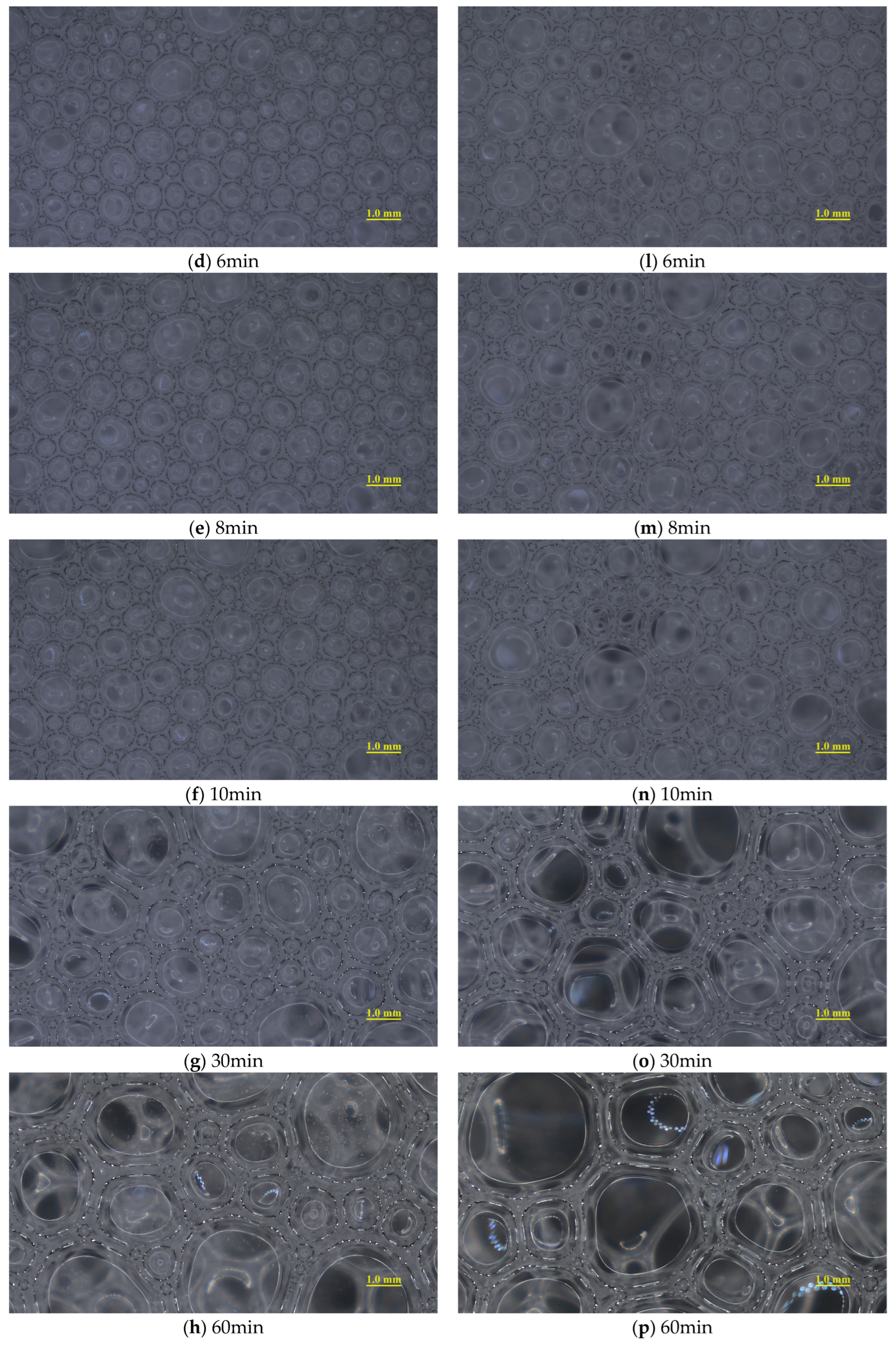

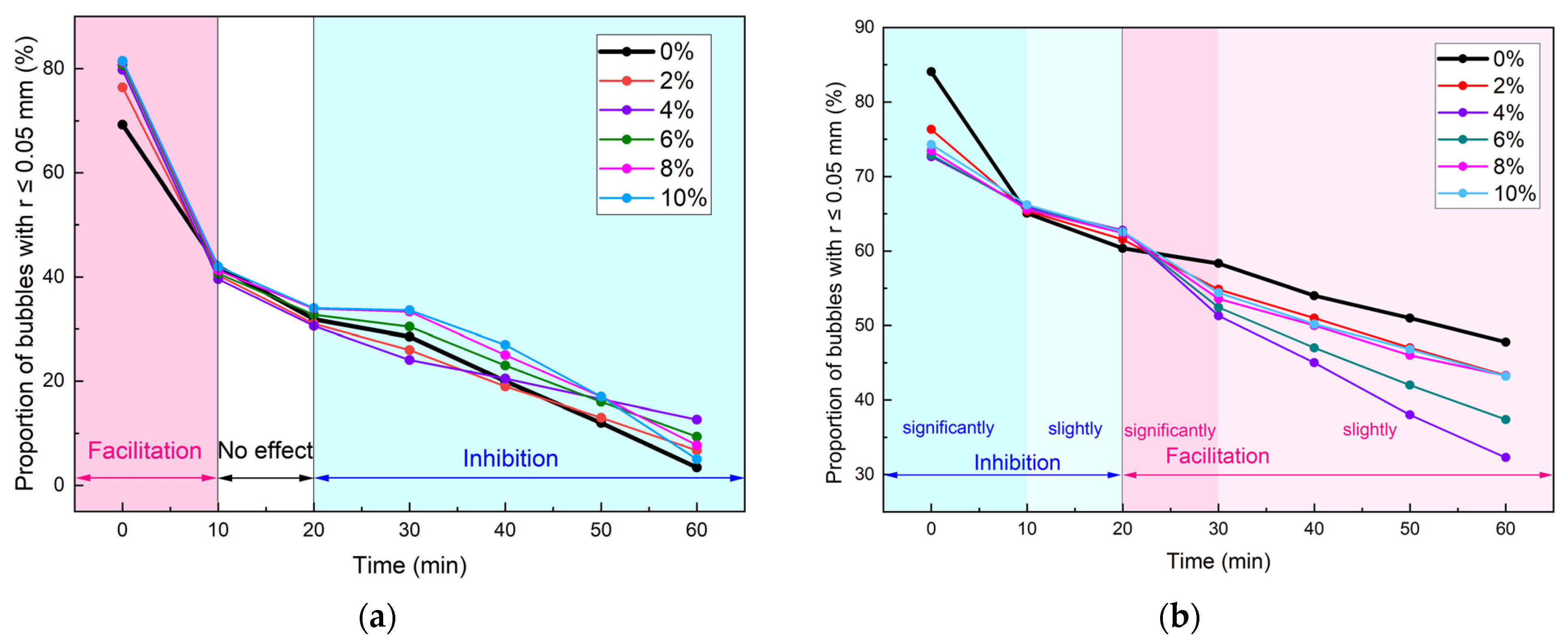

3.1.1. Bubble Size Distribution and Temporal Evolution of Foam

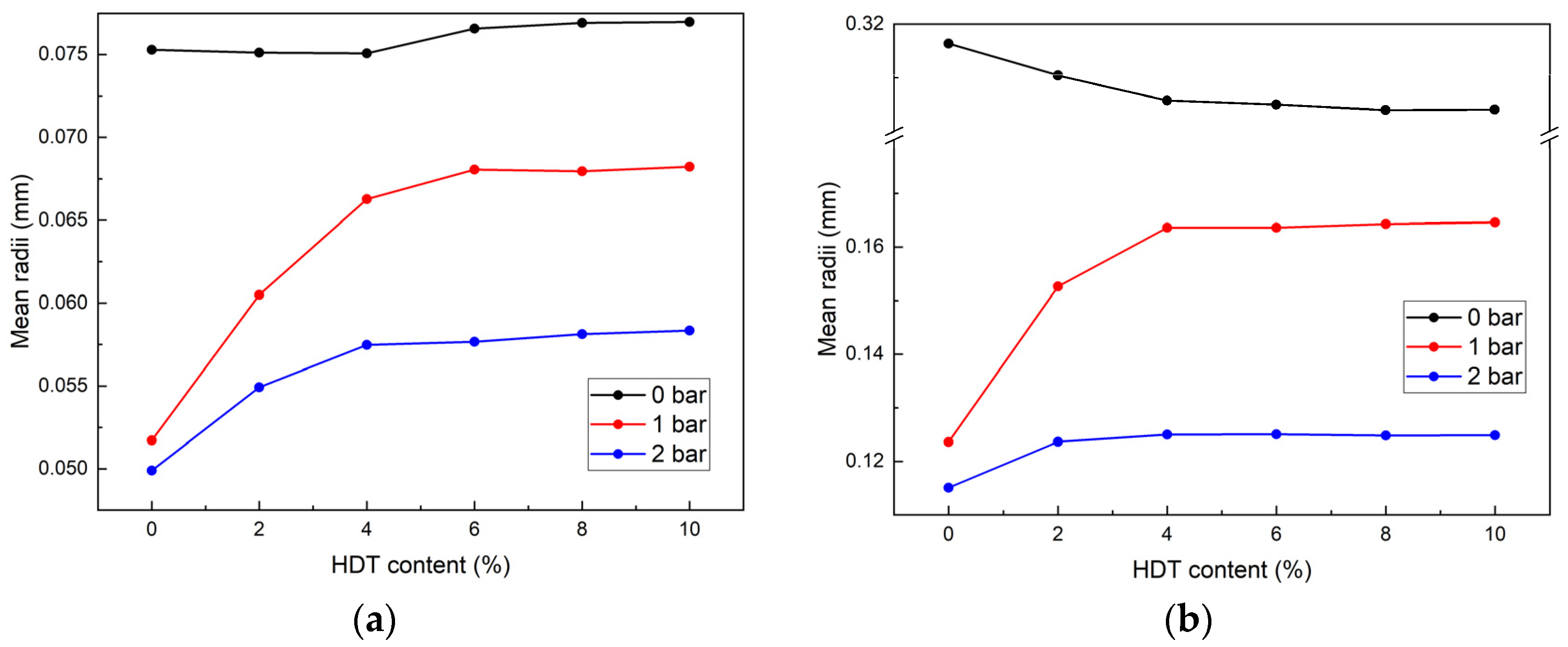

3.1.2. Mean Radii Evolution of the Foam

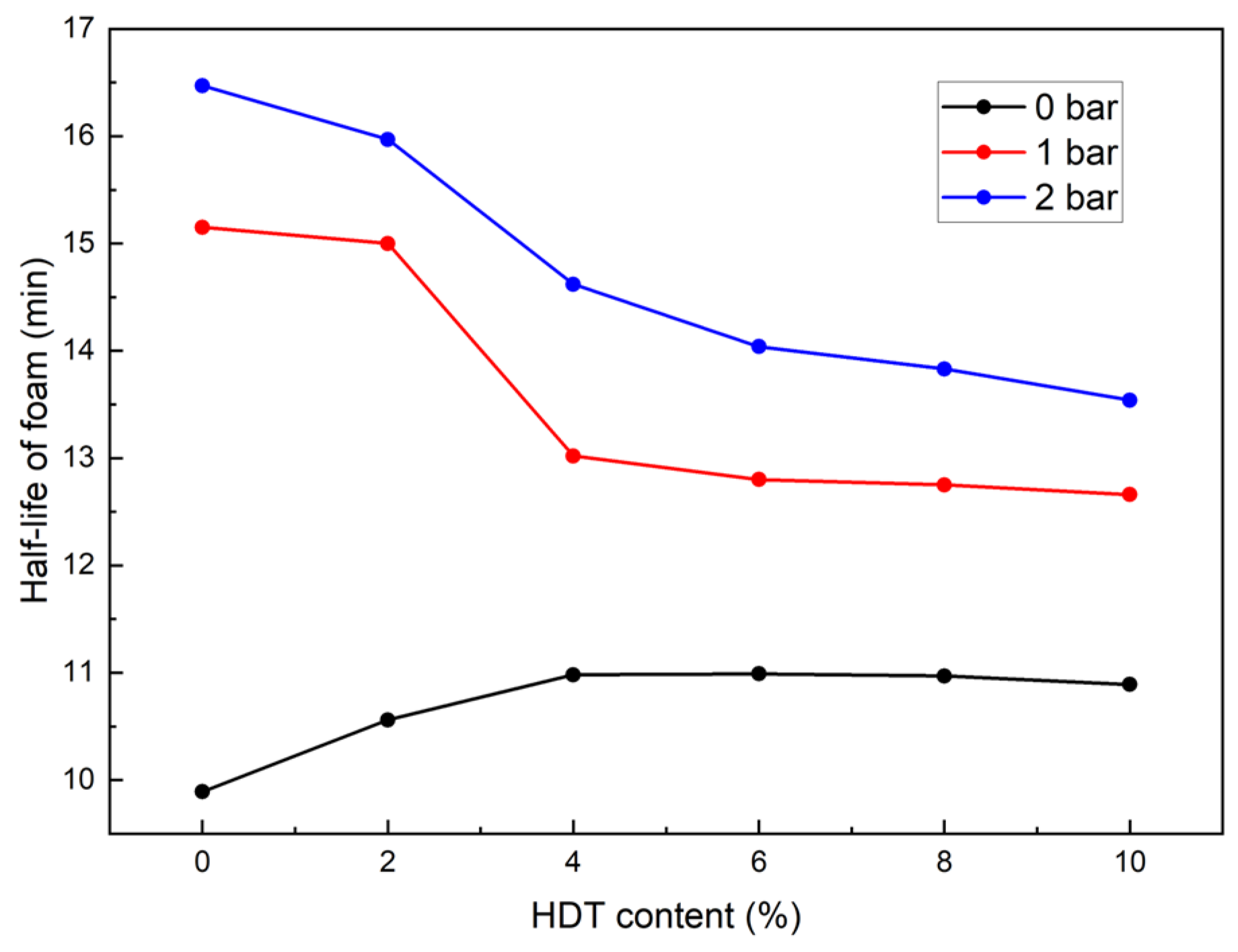

3.2. Effect of HDT Content on Foam Half-Life Under Different Air Pressures

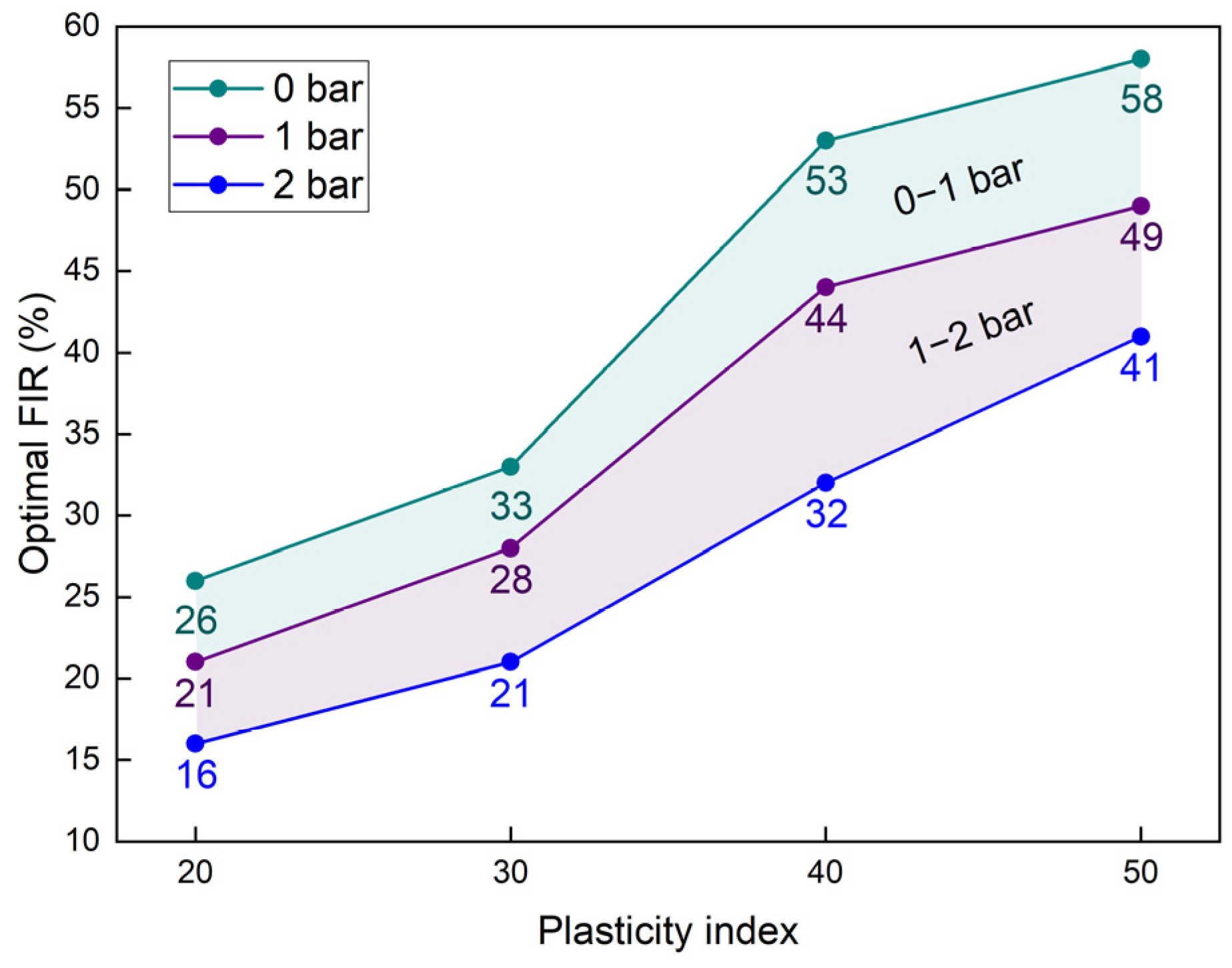

3.3. Effects of Dispersed Foam Agents on the Adhesion Properties of Conditioned Soil

3.3.1. Effects of Dispersed Foam Agents on Soil Cohesion

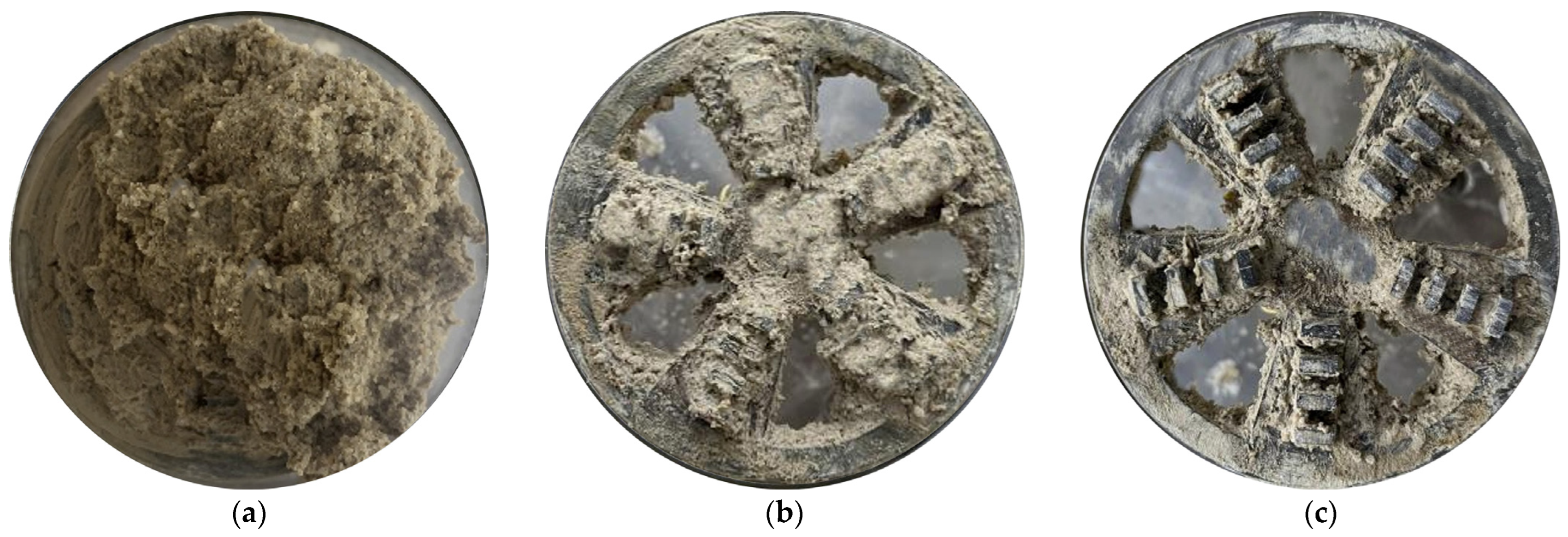

3.3.2. Effect of Dispersed Foam Agents on the Adhesion Amounts of Rotating Cutterheads

4. Engineering Application

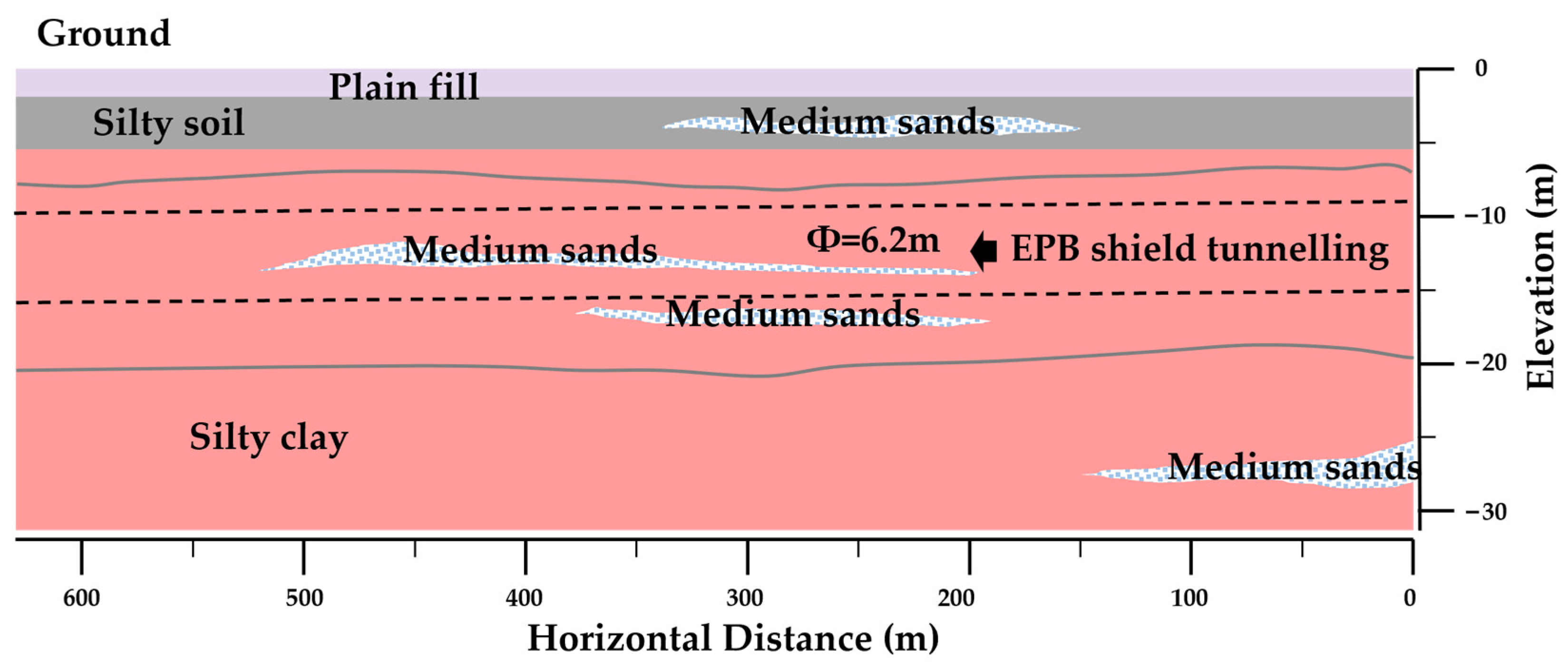

4.1. Project Overview

4.2. Application of Dispersed Foam Agent

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix A.1

Appendix A.2

Appendix A.3

| Test | Apparatus and Reference | Key Input Parameters | Output Metrics |

|---|---|---|---|

| foam evolution mechanism | foam testing system, Wu et al. [7] | (1) p: 0–2 bar (2) Time: 0–60 min (3) cd: 0%–10% | (1) proportion of small bubbles (2) mean radii of foam (3) foam half-life |

| cohesion of conditioned clay | unsaturated soil direct shear system, Peña Duarte [26] | (1) PI: 20–50 (2) foam or dispersed foam (3) FIR: 0–100% | (1) cohesion of conditioned clay |

| cutterhead rotation adhesion of conditioned clay | cutterhead rotation adhesion testing system, Jakobsen et al. [27] | (1) PI: 20–50 (2) foam or dispersed foam (3) FIR: 0–100% (4) p: 0–2 bar | (1) adhesion amount of conditioned clay (2) loss ratio of adhesion amount of conditioned clay |

Appendix B

| p (bar) | cd (%) | Proportion of Bubbles with r ≤ 0.05 mm (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| 0 min | 10 min | 20 min | 30 min | 40 min | 50 min | 60 min | ||

| 0 | 0 | 69.27 | 42.03 | 31.88 | 28.52 | 20.00 | 12.00 | 3.39 |

| 2 | 76.38 | 40.32 | 31.02 | 25.98 | 19.00 | 13.00 | 6.68 | |

| 4 | 79.76 | 39.60 | 30.61 | 24.07 | 20.50 | 16.51 | 12.64 | |

| 6 | 80.77 | 40.68 | 32.74 | 30.46 | 23.13 | 16.01 | 9.33 | |

| 8 | 81.35 | 41.23 | 33.91 | 33.33 | 25.06 | 17.11 | 7.69 | |

| 10 | 81.51 | 42.21 | 34.00 | 33.62 | 27.00 | 17.12 | 5.09 | |

| 1 | 0 | 84.05 | 65.07 | 60.36 | 58.33 | 53.98 | 51.08 | 47.77 |

| 2 | 76.33 | 65.37 | 61.56 | 54.85 | 51.02 | 47.02 | 43.30 | |

| 4 | 72.66 | 65.93 | 62.77 | 51.32 | 44.93 | 38.11 | 32.28 | |

| 6 | 72.88 | 65.72 | 62.56 | 52.43 | 46.89 | 41.97 | 37.38 | |

| 8 | 73.44 | 65.58 | 62.41 | 53.59 | 49.95 | 46.01 | 43.27 | |

| 10 | 74.31 | 66.22 | 62.66 | 54.43 | 50.20 | 46.82 | 43.27 | |

| 2 | 0 | 89.22 | 72.44 | — | — | — | — | — |

| 2 | 76.31 | 72.89 | — | — | — | — | — | |

| 4 | 70.6 | 69.35 | — | — | — | — | — | |

| 6 | 70.67 | 69.12 | — | — | — | — | — | |

| 8 | 70.12 | 68.95 | — | — | — | — | — | |

| 10 | 69.95 | 68.78 | — | — | — | — | — | |

| p (bar) | cd (%) | Mean Radii (mm) | ||||||

|---|---|---|---|---|---|---|---|---|

| 0 min | 10 min | 20 min | 30 min | 40 min | 50 min | 60 min | ||

| 0 | 0 | 0.07529 | 0.31635 | 0.56112 | 0.71089 | 0.85332 | 0.98213 | 1.12007 |

| 2 | 0.07511 | 0.31041 | — | — | — | — | — | |

| 4 | 0.07507 | 0.30573 | 0.46072 | 0.62104 | 0.73053 | 0.82076 | 0.9201 | |

| 6 | 0.07657 | 0.30498 | — | — | — | — | — | |

| 8 | 0.07692 | 0.30395 | — | — | — | — | — | |

| 10 | 0.07698 | 0.30403 | — | — | — | — | — | |

| 1 | 0 | 0.05171 | 0.12362 | 0.17131 | 0.22055 | 0.26011 | 0.31003 | 0.34032 |

| 2 | 0.06049 | 0.15262 | — | — | — | — | — | |

| 4 | 0.06627 | 0.16365 | 0.22019 | 0.27048 | 0.33016 | 0.371316 | 0.40469 | |

| 6 | 0.06807 | 0.16363 | — | — | — | — | — | |

| 8 | 0.06796 | 0.16432 | — | — | — | — | — | |

| 10 | 0.06824 | 0.16461 | — | — | — | — | — | |

| 2 | 0 | 0.04990 | 0.11509 | 0.16052 | 0.19133 | 0.21117 | 0.21801 | 0.23032 |

| 2 | 0.05492 | 0.12366 | — | — | — | — | — | |

| 4 | 0.05747 | 0.12497 | 0.17039 | 0.22017 | 0.26035 | 0.29042 | 0.32007 | |

| 6 | 0.05766 | 0.12502 | — | — | — | — | — | |

| 8 | 0.05812 | 0.12483 | — | — | — | — | — | |

| 10 | 0.05834 | 0.12487 | — | — | — | — | — | |

| p (bar) | Half-Life (min) | |||||

|---|---|---|---|---|---|---|

| 0% | 2% | 4% | 6% | 8% | 10% | |

| 0 | 9.88 | 10.57 | 10.97 | 10.98 | 10.97 | 10.88 |

| 1 | 15.15 | 15 | 13.02 | 12.8 | 12.75 | 12.67 |

| 2 | 16.47 | 15.97 | 14.62 | 14.03 | 13.83 | 13.53 |

| Conditioner | Foam | Dispersed Foam | |||||||

|---|---|---|---|---|---|---|---|---|---|

| PI | 20 | 30 | 40 | 50 | 20 | 30 | 40 | 50 | |

| Cohesion (kPa) | 0% | 15.00 | 23.00 | 31.29 | 38.59 | 15.00 | 23.00 | 31.29 | 38.59 |

| 10% | 14.50 | 22.20 | 30.18 | 36.11 | 10.87 | 17.10 | 23.25 | 29.70 | |

| 20% | 10.90 | 19.20 | 28.25 | 33.62 | 1.80 | 10.31 | 17.37 | 22.20 | |

| 30% | 6.80 | 15.40 | 24.76 | 30.78 | 1.20 | 2.10 | 12.09 | 15.40 | |

| 40% | 4.70 | 10.21 | 20.35 | 26.00 | 1.10 | 1.40 | 3.83 | 9.90 | |

| 50% | 4.60 | 10.19 | 16.88 | 19.60 | 1.10 | 1.38 | 2.84 | 4.35 | |

| 60% | 4.60 | 10.19 | 16.01 | 19.50 | 1.10 | 1.35 | 2.61 | 3.72 | |

| 70% | 4.60 | 10.15 | 15.79 | 19.48 | 1.10 | 1.35 | 2.34 | 3.71 | |

| 80% | 4.60 | 10.15 | 15.8 | 19.47 | 1.10 | 1.35 | 2.30 | 3.70 | |

| 90% | 4.60 | 10.15 | 15.82 | 19.46 | 1.10 | 1.35 | 2.28 | 3.70 | |

| 100% | 4.50 | 10.15 | 15.73 | 19.46 | 1.10 | 1.35 | 2.29 | 3.70 | |

| Conditioner | Foam | Dispersed Foam | |||||

|---|---|---|---|---|---|---|---|

| p (bar) | 0 | 1 | 2 | 0 | 1 | 2 | |

| Adhesion amount (g) | 0% | 89 | 98 | 104 | 89 | 98 | 104 |

| 10% | 76 | 81 | 77 | 62 | 48 | 38 | |

| 20% | 70 | 65 | 64 | 35 | 26 | 18 | |

| 30% | 61 | 57 | 57 | 25 | 19 | 15 | |

| 40% | 53 | 50 | 53 | 15 | 14 | 14 | |

| 50% | 48 | 43 | 52 | 10 | 12 | 13 | |

| 60% | 42 | 42 | 52 | 9 | 11 | 14 | |

| 70% | 38 | 42 | 52 | 8 | 11 | 14 | |

| 80% | 37 | 42 | 52 | 9 | 11 | 13 | |

| 90% | 38 | 42 | 53 | 8 | 11 | 14 | |

| 100% | 37 | 43 | 52 | 9 | 11 | 13 | |

| Conditioner | Foam | Dispersed Foam | |||||

|---|---|---|---|---|---|---|---|

| p (bar) | 0 | 1 | 2 | 0 | 1 | 2 | |

| Loss ratio (%) | 0% | 0 | 0 | 0 | 0 | 0 | 0 |

| 10% | 14.61 | 17.35 | 25.96 | 30.34 | 51.02 | 63.46 | |

| 20% | 21.35 | 33.67 | 38.46 | 60.67 | 73.47 | 82.69 | |

| 30% | 31.46 | 41.84 | 45.19 | 71.91 | 80.61 | 85.58 | |

| 40% | 40.45 | 48.98 | 49.04 | 83.15 | 85.71 | 86.54 | |

| 50% | 46.07 | 56.12 | 50 | 88.76 | 87.76 | 87.5 | |

| 60% | 52.81 | 57.14 | 50 | 89.89 | 88.78 | 86.54 | |

| 70% | 57.30 | 57.14 | 50 | 91.01 | 88.78 | 86.54 | |

| 80% | 58.43 | 57.14 | 50 | 89.89 | 88.78 | 87.5 | |

| 90% | 57.30 | 57.14 | 49.04 | 91.01 | 88.78 | 86.54 | |

| 100% | 58.43 | 56.12 | 50 | 89.89 | 88.78 | 87.50 | |

References

- Liu, P.; Yang, Z.; Ji, F.; Chen, P.; Hu, Q.; He, X. Study on Mudcake disintegration in clayey strata during shield tunneling: Effects of dispersants and bentonite slurry. Heliyon 2024, 10, e30663. [Google Scholar] [CrossRef] [PubMed]

- Alberto-Hernandez, Y.; Kang, C.; Yi, Y.; Bayat, A. Clogging potential of tunnel boring machine (TBM): A review. Int. J. Geotech. Eng. 2017, 12, 316–323. [Google Scholar] [CrossRef]

- Fang, Y.; Zhuo, B.; Wang, Y.; Luo, H.; Sun, J.; Yao, Y. Metal-soil interface adhesion in clay clogging during shield tunneling: Theo-retical model and experimental validation. Undergr. Space 2024, 15, 188–202. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, Z.; Liu, P.; Yang, Z.; Pan, Q.; Chen, W. On the critical particle size of soil with clogging potential in shield tunneling. J. Rock Mech. Geotech. Eng. 2022, 15, 477–485. [Google Scholar] [CrossRef]

- Thewes, M.; Hollmann, F. Assessment of clay soils and clay-rich rock for clogging of TBMs. Tunn. Undergr. Space Technol. 2016, 57, 122–128. [Google Scholar] [CrossRef]

- Cui, J.; Xu, G.; Fang, Y.; Chen, Z.; Yao, Z.; Tao, L.; Qu, L. Experimental assessment of Soil/metal interface adhesion behaviours of EPB shield Machines. Tunn. Undergr. Space Technol. 2022, 131, 104835. [Google Scholar] [CrossRef]

- Wu, Y.; Nazem, A.; Meng, F.; Mooney, M.A. Experimental study on the stability of foam-conditioned sand under pressure in the EPBM chamber. Tunn. Undergr. Space Technol. 2020, 106, 103590. [Google Scholar] [CrossRef]

- Wu, Y.; Mooney, M.A.; Cha, M. An experimental examination of foam stability under pressure for EPB TBM tunneling. Tunn. Undergr. Space Technol. 2018, 77, 80–93. [Google Scholar] [CrossRef]

- Ye, X.; Wang, S.; Yang, J.; Sheng, D.; Xiao, C. Soil Conditioning for EPB Shield Tunneling in Argillaceous Siltstone with High Content of Clay Minerals: Case Study. Int. J. Geomech. 2017, 17, 05016002. [Google Scholar] [CrossRef]

- Peila, D.; Oggeri, C.; Borio, L. Using the Slump Test to Assess the Behavior of Conditioned Soil for EPB Tunneling. Environ. Eng. Geosci. 2009, 15, 167–174. [Google Scholar] [CrossRef]

- Zumsteg, R.; Plötze, M.; Puzrin, A.M. Effect of Soil Conditioners on the Pressure and Rate-Dependent Shear Strength of Different Clays. J. Geotech. Geoenviron. Eng. 2012, 138, 1138–1146. [Google Scholar] [CrossRef]

- Zumsteg, R.; Puzrin, A.M. Stickiness and adhesion of conditioned clay pastes. Tunn. Undergr. Space Technol. 2012, 31, 86–96. [Google Scholar] [CrossRef]

- de Oliveira, D.G.; Thewes, M.; Diederichs, M.S. Clogging and flow assessment of cohesive soils for EPB tunnelling: Proposed laboratory tests for soil characterisation. Tunn. Undergr. Space Technol. 2019, 94, 103110. [Google Scholar] [CrossRef]

- Peila, D.; Picchio, A.; Martinelli, D.; Negro, E.D. Laboratory tests on soil conditioning of clayey soil. Acta Geotech. 2015, 11, 1061–1074. [Google Scholar] [CrossRef]

- Martinelli, D.; Todaro, C.; Luciani, A.; Peila, D. Use of a large triaxial cell for testing conditioned soil for EPBS tunnelling. Tunn. Undergr. Space Technol. 2019, 94, 103126. [Google Scholar] [CrossRef]

- Zhuo, B.; Fang, Y.; Wang, Y. Soil conditioning and screw conveying characteristics laboratory tests for EPB tunnelling in me-dium-weathered mudstone stratum. Tunn. Undergr. Space Technol. 2024, 156, 106257. [Google Scholar] [CrossRef]

- Chen, Z.; Bezuijen, A.; Fang, Y.; Wang, K.; Deng, R. Experimental study and field validation on soil clogging of EPB shields in completely decomposed granite. Tunn. Undergr. Space Technol. 2022, 120, 104300. [Google Scholar] [CrossRef]

- Fang, Y.; Zhuo, B.; Zhang, R.; Wang, Y.; Dou, L.; Yao, Y. Soil conditioning of clay based on interface adhesion mechanism: Micro-scopic simulation and laboratory experiment. Undergr. Space 2024, 18, 239–255. [Google Scholar] [CrossRef]

- Zhuo, B.; Zhang, R.; Fang, Y.; Wang, Y.; Yao, Y. A study on soil conditioning for cohesive soils with high content of clay minerals: Microscopic simulation and laboratory experiment. Tunn. Undergr. Space Technol. 2023, 140, 105334. [Google Scholar] [CrossRef]

- Liu, P.; Wang, S.; Ge, L.; Thewes, M.; Yang, J.; Xia, Y. Changes of Atterberg limits and electrochemical behaviors of clays with dispersants as conditioning agents for EPB shield tunnelling. Tunn. Undergr. Space Technol. 2018, 73, 244–251. [Google Scholar] [CrossRef]

- Wang, S.; Liu, P.; Hu, Q.; Zhong, J. Effect of dispersant on the tangential adhesion strength between clay and metal for EPB shield tunnelling. Tunn. Undergr. Space Technol. 2020, 95, 103144. [Google Scholar] [CrossRef]

- Fang, Y.; Chen, Z.; Song, T.; Wang, K.; Zhou, K. New clogging potential assessment method for conditioned soil based on modified pullout and direct shear tests. Acta Geotech. 2022, 18, 3307–3322. [Google Scholar] [CrossRef]

- Wan, Z.; Li, S.; Yuan, C.; Zhao, S.; Wang, M.; Lu, Q.; Hou, W. Soil Conditioning for EPB Shield Tunneling in Silty Clay and Weathered Mudstone. Int. J. Geomech. 2021, 21, 06021020. [Google Scholar] [CrossRef]

- Zhuo, B.; Fang, Y.; Zhu, M.; Yubo, W.; Yuxiang, Y.; Gongyun, X. Combined conditioning of dispersant and foam agent for the soil with different clay minerals: An experimental study. Bull. Eng. Geol. Environ. 2023, 82, 248. [Google Scholar] [CrossRef]

- EFNARC. Specification and Guidelines for the Use of Specialist Products for Mechanised Tunnelling (TBM) in Soft Ground and Hard Rock; EFNARC: Farnham, Surrey, UK, 2005. [Google Scholar]

- Peña Duarte, M.Á. Foam as a Soil Conditioner in Tunnelling: Physical and Mechanical Properties of Conditioned Sands. Ph.D. Thesis, University of Oxford, Oxford, UK, 2007. [Google Scholar]

- Jakobsen, P.D.; Langmaack, L.; Dahl, F.; Breivik, T. Development of the Soft Ground Abrasion Tester (SGAT) to predict TBM tool wear, torque and thrust. Tunn. Undergr. Space Technol. 2013, 38, 398–408. [Google Scholar] [CrossRef]

- Zhao, S.; Li, S.; Wan, Z.; Wang, X.; Wang, M.; Yuan, C. Effects of anti-clay agents on bubble size distribution and stability of aqueous foam under pressure for earth pressure balance shield tunneling. Colloid Interface Sci. Commun. 2021, 43, 100424. [Google Scholar] [CrossRef]

- Stevenson, P. (Ed.) Foam Engineering: Fundamentals and Applications; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Zhao, S.; Li, S.; Wang, P.; Yuan, C.; Wan, Z.; Wang, M. Mesoscopic Measurement Method of Foam Half-life for Soil Conditioning of Earth Pressure Balance Shield. Zongguo Gonglu Xuebao 2022, 35, 195–202. [Google Scholar] [CrossRef]

- Zheng, D.; Bezujien, A. Pore pressure measurements in saturated sand in front of an approaching EPB and laboratory investigations. Acta Geotech. 2023, 19, 4055–4068. [Google Scholar] [CrossRef]

- Feng, Z.; Wang, S.; Qu, T.; Zheng, X.; Ling, F. Experimental study on workability and permeability of sandy soils conditioned with thickened foam. J. Rock Mech. Geotech. Eng. 2023, 16, 532–544. [Google Scholar] [CrossRef]

- Sebastiani, D.; Vilardi, G.; Bavasso, I.; Di Palma, L.; Miliziano, S. Classification of foam and foaming products for EPB mechanized tunnelling based on half-life time. Tunn. Undergr. Space Technol. 2019, 92, 103044. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, M.; Huang, P.; Xu, C.; Wang, Y.; Hu, Y. Soil conditioning for EPB shield tunneling in coastal silty clay strata: Laboratory research and field application. Int. J. Geomech. 2024, 24, 04023289. [Google Scholar] [CrossRef]

- Jin, G.; Lu, Y.; Shiau, J.S.; Huang, M.; Lai, F.; Feng, M. Consequence and interaction of foaming agent components on soil conditioning of gravel-clay strata for EPB shield tunnelling. Tunn. Undergr. Space Technol. 2025, 157, 106364. [Google Scholar] [CrossRef]

| Materials | Physical State | Density (g/cm3) | Chemical Composition |

|---|---|---|---|

| AES | transparent viscous fluid | 1.06 | Sodium Alcohol Ether Sulfate |

| HDT | transparent liquid | 1.20 | Crosslinked Sodium Polyacrylate |

| foam stabilizer | transparent light-yellow viscous liquid | 1.05 | Cocamidopropyl Betaine |

| PI | Mass Ratio (Bentonite–Illite–Kaolin) | Moisture Content (%) |

|---|---|---|

| 20 | 0.5:2:3 | 40 |

| 30 | 1:2:3 | 50 |

| 40 | 1.5:1:2 | 55 |

| 50 | 1:1:1 | 60 |

| Clay Mineral | Physical State | Density (g/cm3) | Chemical Composition | D10 (μm) 1 | D50 (μm) 1 | D90 (μm) 1 |

|---|---|---|---|---|---|---|

| Bentonite | Light-yellow powder | 2.20 | Montmorillonite | 1.708 | 5.297 | 23.650 |

| Illite powder | Light-green powder | 2.65 | Illite | 1.273 | 3.476 | 14.335 |

| Kaolin | White powder | 2.60 | Kaolinite | 0.895 | 2.260 | 9.037 |

| PI | D10 (μm) 1 | D50 (μm) 1 | D90 (μm) 1 |

|---|---|---|---|

| 20 | 0.951 | 2.582 | 10.970 |

| 30 | 0.982 | 2.896 | 13.630 |

| 40 | 1.054 | 3.157 | 13.910 |

| 50 | 1.117 | 3.550 | 15.360 |

| Study | Site/Stratum | Conditioning Materials | FIR | Key Field Results | Clogging Status |

|---|---|---|---|---|---|

| This study | Jinan Metro, silty clay | Dispersed foam | 30% | Torque ↓42% (3000→1750 kN·m); advance rate ↑133% | Fully resolved |

| Wan et al. [23] | Changchun Metro, weathered mudstone | Foam + anti-clay agent | 70% | Torque ↓~30% (3500→2500 kN·m); adhesion ↓88% | Partially resolved |

| Lu et al. [34] | Fuzhou Metro, coastal silty clay | Dispersed foam | 40–50% | Torque ↓~15% (avg. 250 kN·m); foam usage ↓18.6% | Largely resolved |

| Jin et al. [35] | Fujian, gravel-clay | RSM-optimized foam | 50% | Thrust ↓4.6%; torque ↓9%; cost ↓19% | Reduced clogging risk |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, S.; Peng, K.; Bai, J. Pressure-Dependent Meso-Scale Evolution of Dispersed Foam and Field-Application Clogging Mitigation Strategies for EPB Shield Tunnelling Through Highly Cohesive Clay. Materials 2025, 18, 2716. https://doi.org/10.3390/ma18122716

Zhao S, Peng K, Bai J. Pressure-Dependent Meso-Scale Evolution of Dispersed Foam and Field-Application Clogging Mitigation Strategies for EPB Shield Tunnelling Through Highly Cohesive Clay. Materials. 2025; 18(12):2716. https://doi.org/10.3390/ma18122716

Chicago/Turabian StyleZhao, Shisen, Kefeng Peng, and Jinliang Bai. 2025. "Pressure-Dependent Meso-Scale Evolution of Dispersed Foam and Field-Application Clogging Mitigation Strategies for EPB Shield Tunnelling Through Highly Cohesive Clay" Materials 18, no. 12: 2716. https://doi.org/10.3390/ma18122716

APA StyleZhao, S., Peng, K., & Bai, J. (2025). Pressure-Dependent Meso-Scale Evolution of Dispersed Foam and Field-Application Clogging Mitigation Strategies for EPB Shield Tunnelling Through Highly Cohesive Clay. Materials, 18(12), 2716. https://doi.org/10.3390/ma18122716