Abstract

This study investigates the influence of the HfB2 content and sintering method on the mechanical behavior of Ti2AlC-based composites. Compositions containing 0–10 wt.% HfB2 are processed via conventional and microwave sintering at 1200 °C for 30 min. X-ray diffraction and scanning electron microscopy analyses have confirmed the formation of the Ti2AlC and HfB2 phases, whereas the TiC phase is predominantly observed in samples processed by conventional sintering. The highest hardness (~475 HV) and compressive strength (~450 MPa) are that of the composite containing 5 wt.% HfB2 associated with a porosity reduction of approximately 10%. These improvements are attributed to the enhanced densification and microstructural refinement achieved via microwave processing. The findings underscore the potential of HfB2 addition and microwave sintering in tailoring the structure–property relationships of the Ti2AlC composites, enabling applications at high-temperature filtration, thermal barriers, and self-lubricating components.

1. Introduction

MAX phases are represented by the convention formula Mn+1AXn, which are included in the family of ternary layered carbides and nitrides. These exhibit an outstanding combination of metallic and ceramic properties. Ti2AlC is a member of the 211 MAX phase group that has gained significant attention for its high stiffness (elastic modulus of ~277 GPa), moderate hardness, good thermal and electrical conductivity, and notable damage tolerance [1,2,3]. However, its application remains limited in high-load or harsh thermal environments because of its insufficient hardness and strength [4]. Thus, tailoring its microstructure through reinforcement and advanced processing routes is essential to fully exploit its potential. This combination of properties makes the Ti2AlC suitable for high-temperature structural applications in aerospace, automotive, and nuclear industries [5,6]. However, despite these advantages, the Ti2AlC exhibits moderate mechanical strength and hardness, which limits its broader use in load-bearing applications. Therefore, reinforcing Ti2AlC with secondary phases such as SiC and Al2O3 has been explored to improve its mechanical properties [7,8,9].

Some investigations have explored the versatility of the Ti2AlC MAX phase ceramics in a variety of functional applications. Liu et al. [10] have enhanced microwave absorption via Lewis acid molten salt etching of the Ti2AlC powders, while Suh et al. [11] have demonstrated the thermal self-healing capability of the phase at different temperatures. Laska et al. [12] have applied the Ti2AlC coatings on γ-TiAl alloys, aiming to improve oxidation resistance. Other studies have explored spark plasma sintering [13], the MAX metal lamellar structures with good mechanical properties [14], and corrosion resistance in saline solution [15]. Furthermore, Huang et al. [16] have discussed the thermal stability of Ti2AlC and Ag/Ti2AlC composites.

Among various ceramic reinforcements, the HfB2 stands out for its exceptional hardness (~25 GPa), high melting point (>3000 °C), and excellent thermal stability. Its combination with the Ti2AlC has a potential to create composites suitable for extreme environments. One of the most effective reinforcement strategies involves the introduction of high-strength ceramic phases. For instance, adding Al2O3 fibers to the Ti2AlC composites has resulted in enhanced flexural strength (~697 MPa) and fracture toughness (~9.83 MPa·m1/2), comparable to SiCf/SiC composites [8]. Similarly, reinforcing the Ti2AlC with TiB2 through in situ reaction hot pressing improved its compressive strength and oxidation resistance at high temperatures (600–900 °C) [17]. Nanostructured reinforcements, such as the nano-Ti2AlC particles, have also shown remarkable improvements in the mechanical response of the Ti2AlC-based composites [18,19]. The introduction of submicron-sized Ti2AlC particles into TiAl matrices increased compressive strength to ~2171 MPa and fracture strain to ~31% due to enhanced interfacial bonding and controlled dislocation mobility [19]. Moreover, nano-Ti2AlC reinforcements into the TiAl matrices have increased the strength–plasticity synergy by inducing dislocation multiplication and twin formation at the grain boundaries. This mechanism improves the load transfer and promotes energy dissipation during deformation. This has promoted composites with higher toughness and damage tolerance [19].

The incorporation of Ti2AlC into composite materials has increased both the mechanical and thermal properties, which makes the potential candidate suitable for high-temperature applications. Studies have shown that the Ti2AlC significantly improves the oxidation resistance and mechanical strength of ultrahigh-temperature ceramics, particularly in the HfB2-based systems, by reducing porosity and increasing densification during sintering [20]. Furthermore, the addition of ceramic reinforcements, e.g., TiB2 and Al2O3, into the Ti-Al-C matrices has been reported [21,22]. Consequently, its corresponding fracture toughness and wear resistance are increased, which is associated with superior strength and thermal stability [21,22]. Nevertheless, only a limited number of studies have explored the effect of the HfB2 content on the Ti2AlC, especially in combination with alternative sintering routes such as microwave processing. This knowledge gap motivates the current investigation. The formation of the core–shell structures, such as ZrC/Ti2AlC, further refines the microstructure, leading to improved hardness and oxidation resistance under extreme conditions [23]. These findings suggest that optimizing the composition and processing conditions of the Ti2AlC-based composites provides the development of advanced materials for aerospace, automotive, and energy applications.

Microwave sintering has emerged as a promise-processing route for Ti2AlC-based composites [24,25,26,27,28,29,30]. Unlike conventional sintering, where heat is transferred from the surface to the interior, microwave sintering generates heat uniformly throughout the sample, reducing thermal gradients and promoting rapid densification [31,32]. This leads to finer microstructures, reduced porosity, and improved mechanical properties.

This study aims to investigate the influence of the different HfB2 contents (i.e., 0, 2.5, 5, 7.5, and 10 wt.%) on the microstructure and mechanical properties of the Ti2AlC composites processed through both the conventional and microwave sintering. The goal is to identify the optimal HfB2 content and sintering route. With this, improved hardness and compressive strength are attained while the porosity is decreased. The findings provide valuable insights into the development of high-performance Ti2AlC-based composites for structural and high-temperature applications. The contribution of this study lies in the correlation between the microstructural array and porosity, consequently affecting the mechanical performance under two distinct sintering regimes positively. With this, resulting insights for future applications in high-temperature filtration, wear-resistant components, and energy systems are obtained.

2. Materials and Methods

2.1. Composites Preparation and Powder Metallurgy Stages

The initial powders of Ti (99.4%, 100 mesh), Al (99.8%, 325 mesh), and TiC (99%, 325 mesh) were used to constitute the Ti2AlC (TAC) composition, following a stoichiometric Ti:Al:TiC ratio. The powders were mixed manually in an agate mortar for approximately 20 min at room temperature (25 ± 2 °C), without binder or lubricant, to ensure homogeneity and to avoid particle size modification. No ball milling was utilized for this reason. For the sample compaction, a cylindrical steel die (ASTM A6 [33], diameter 8 ± 0.5 mm) was used. A uniaxial pressure of 975 ± 50 MPa was applied for 2 min. The green compacts were then sealed in quartz ampoules under vacuum (10−2 mbar). The heat treatments were performed at 400 °C, 600 °C, and 1200 °C ± 10 °C for 30 min, using both the conventional and microwave sintering systems (FMO1600, Fortelab, São Carlos, Brazil). For the microwave process, a frequency of 2.45 GHz and a maximum power of 1.2 kW were applied. Temperature during microwave sintering was monitored by using a thermocouple (Type K) and maintained within a precision of ±10 °C throughout the treatment. The sintering parameters of 1200 °C for 30 min, experimentally optimized, were chosen to balance the densification of the Ti2AlC matrix with the preservation of the HfB2 reinforcement, preventing excessive grain growth and interfacial reactions. Microwave sintering differs from conventional heating due to its rapid volumetric heating and strong interfacial field interactions. This intensifies local diffusion and densification kinetics at particle contacts, even with short holding times. Consequently, the short cycle and low thermal budget limit long-range diffusion, preserving the distribution and integrity of the HfB2 phase. Triplicate is adopted for each condition, and the resulting property values (e.g., hardness, porosity) exhibited short standard deviations (<10%). This suggests that possible temperature fluctuations have no substantial effects on the reproducibility and reliability of the results. The literature reports that such slight fluctuations have not significantly affected the densification or phase formation in the MAX-phase ceramics processed by microwave sintering. After synthesizing the Ti2AlC phase, HfB2 powder (99%, 325 mesh, Sigma-Aldrich) was added to distinctive contents (0, 5, 7.5, and 10 wt.%). The HfB2 powder was commercially purchased from Sigma-Aldrich (St. Louis, MO, USA), with a nominal purity of 99% and an average particle size corresponding to 325 mesh (~ 45 μm). The as-received powders are constituted of irregular-shaped particles, as provided by the supplier. It must be noted that no additional purification or milling was used. The intention behind this was to avoid altering its original particle size distribution. The HfB2 and Ti2AlC powders were manually homogenized, as aforementioned. Sequentially, the resulting mixtures were compacted, encapsulated, and heat-treated under the same conditions. Before the sintering, each one of the examined samples was adequately weighed (1.2 ± 0.1 g). Three specimens of each composition were adopted to ensure statistical reliability.

2.2. Microstructural Observations

X-ray diffraction (XRD) analysis was performed using a diffractometer (Panalytical diffractometer, X’Pert model, Malvern, UK) in Bragg–Brentano geometry, equipped with CuKα radiation and a Ni filter. Scanning electron microscopy (SEM TESCAN® model VEGA3, Brno, Czech Republic) images were acquired. An energy-dispersive X-ray spectroscopy (EDS) detector associated with SEM analyses was also utilized. For SEM characterizations, all samples were polished using SiC papers (up to 1200 grit) and polished with 1 μm diamond paste. SEM observations were performed at an accelerating voltage of 15 kV and a working distance of ~10 mm.

2.3. Relative Density, Hardness, and Compressive Strength Measurements

The Archimedes method was used to determine both the green and sintered densities. For this purpose, a specific gravity measurement kit SMK-401 (Shimadzu, Kyoto, Japan) was used. Vickers hardness measurements (Buehler—Wilson VH1102, Lake Bluff, IL, USA), using 10 s preloading, were attained on the polished surface. At least 10 indentations were carried out for each examined sample. The measurements were taken on polished surfaces to minimize the influence of surface irregularities, and average values were calculated.

The mechanical characterization was carried out using a universal electro-hydraulic servo testing machine operating under controlled ambient conditions (25 ± 2 °C). The tests were conducted at a constant crosshead speed of approximately 25 mm/min, corresponding to a nominal strain rate of 2 × 10−4 s−1, in accordance with standard procedures for quasi-static compression testing. This setup ensures consistent loading conditions for the accurate assessment of the mechanical performance. The tests were conducted according to ASTM standard E8/E8M-24 [34], and triplicate experimentation was adopted to ensure reproducibility. The cylindrical specimens with diameters of 8 (±0.5) mm and a height-to-diameter ratio of ~1.2 were prepared and examined. No lubricant was applied, and the temperature at 25 (±2) °C was also adopted.

3. Results

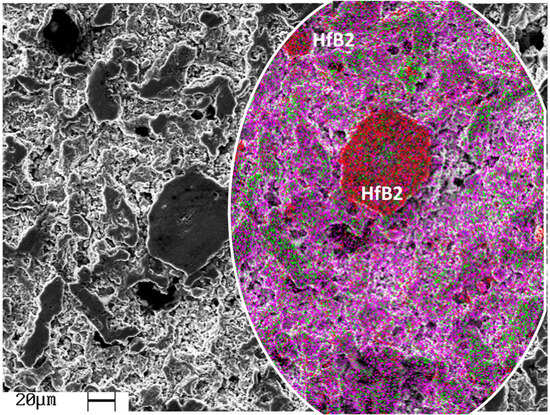

Figure 1 shows a typical scanning electron microscopy micrograph of the heat-treated Ti2AlC/5HfB2 composite at 1200 °C for 30 min. This micrograph reveals a typical morphology obtained when a conventional powder metallurgy route is applied. Both the Ti2AlC and HfB2 grains are clearly identified.

Figure 1.

Typical SEM images of the heat-treated Ti2AlC/5.0HfB2 composites at 1200 °C for 30 min. The inset presents the EDS elemental mapping, where titanium (Ti) is represented in magenta, aluminum (Al) in green, and hafnium (Hf) in red. The elemental maps highlight the spatial distribution of the constituents and support the identification of the HfB2 reinforcement within the Ti2AlC matrix.

Energy-dispersive spectroscopy (EDS) analysis has revealed the elemental distribution, as shown in Figure 1. As expected, Ti and Al are the dominant elements. It should be noted that C quantification is not precise due to low spectral energy. Figure 1 also shows a more uniform distribution of the HfB2 spheroid-like particles, which appears closely related to the observed porosity level. This seems to be intimately associated with the porosity level attained. The absence of interfacial microcracking suggests good compatibility between the Ti2AlC matrix and HfB2 reinforcement.

A homogeneously distributed porous morphology is observed, which is consistent with the apparent porosity results shown in Figure 2. The porosity reaches approximately 18 ± 1.3%.

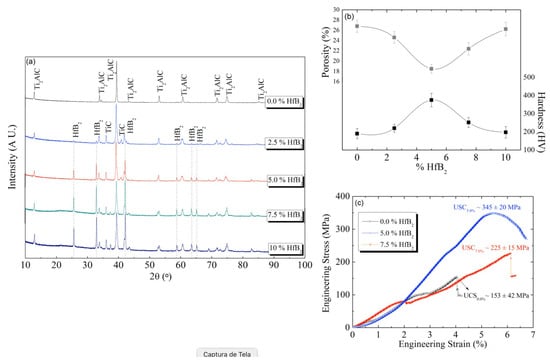

Figure 2.

(a) XRD results of the Ti2AlC/xHfB2 conventionally sintered at 1200 °C for 30 min. The ‘x’ index corresponds with the distinctive HfB2 contents; (b) experimental results of the apparent porosity (upper) and hardness (lower) of the heat-treated Ti2AlC/xHfB2 composites conventionally at 1200 °C for 30 min; (c) experimental curves of the stress vs. strain of the conventionally heat-treated Ti2AlC/xHfB2 composites at 1200 °C for 30 min.

Figure 2a shows the XRD patterns of the Ti2AlC/xHfB2 composites. The samples were conventionally sintered in a furnace at 1200 °C for 30 min. The XRD patterns reveal the Ti2AlC formation in all examined samples. This phase belongs to space group 194, with lattice parameters a = 0.304 nm and c = 1.374 nm. Additionally, the HfB2 is identified in space group 191, with the lattice parameters a = 0.314 nm and c = 0.347 nm [35]. The crystallite size and residual microstrain of the Ti2AlC sample were evaluated by using X-ray diffraction peak broadening analysis. Considering those four most intense diffraction peaks, the average crystallite size was found to be approximately 55.7 nm, while the average microstrain was about 0.11%. These values are characteristics of the well-crystallized MAX phase ceramics, which indicates that efficient sintering is promoted [36,37]. The relatively large crystallite size suggests substantial grain growth during heat treatment, which is consistent with a typical sample that was conventionally sintered for a long-term period at high temperatures. Meanwhile, the moderate level of residual microstrain indicates a good degree of structural relaxation, implying that most of the internal stresses generated during synthesis were successfully decreased. These findings are in good agreement with previously reported investigations when conventional sintering of the Ti2AlC is applied [36,37].

Although the HfB2 content increases, no deleterious effect on the Ti2AlC phase formation kinetics was observed, which is expected since the HfB2 has a low self-diffusion coefficient. The intensity of the HfB2 phase increases with the increase in the HfB2 content. No peak shift was observed for the Ti2AlC or HfB2 reflections, suggesting minimal lattice distortion due to the additive.

When sintering is carried out at 1200 °C for 30 min, the formation of the TiC as an intermediate and thermodynamically stable phase is observed. This stability is consistent with previous studies [38,39,40] on the Ti–Al–C system, which demonstrates that the TiC tends to persist at high temperatures due to its high melting point and strong crystallography associated with the Ti2AlC. The presence of the TiC at this stage is commonly attributed to local stoichiometric variations or incomplete reactions, as also previously reported [38,39,40]. This phase is identified at 2θ angles of approximately 42° and 36°, corresponding to planes (111) and (200), respectively, as also previously reported [35].

The apparent densities were determined using the Ti2AlC theoretical density and the rule of mixtures. The density values, wet mass (mwet), and dry mass (mdry), along with the apparent porosity (AP) of the material, were determined as described in Equation (1).

where mapp represents the apparent mass of the examined samples.

The lowest porosity level is that of the Ti2AlC/5HfB2 composite containing 5 wt.% HfB2. When comparing the composite without the HfB2 and the Ti2AlC/5HfB2 composite, a decrease of approximately 6% is observed. The microhardness values of each examined composite are correlated with the porosity results, as shown in Figure 2b.

An inverse correlation between the hardness and porosity as a function of the HfB2 content was established. The highest hardness is that of the Ti2AlC/5HfB2 composite (375 ± 87 HV), representing an increase of approximately 50% in HV values. Additionally, this composite sample also exhibited the lowest porosity level. This trend confirms that densification plays a predominant role in determining the mechanical response over potential grain refinement or phase changes.

The composition with 5% HfB2 exhibits the lowest porosity and highest hardness due to an optimal balance between sintering efficiency and mechanical reinforcement. At this concentration, the HfB2 particles are uniformly distributed, promoting better grain cohesion and reducing porosity through enhanced mass diffusion. The presence of the HfB2 also strengthens the matrix by impeding dislocation movement, leading to higher hardness. High HfB2 contents induce agglomeration and the TiC formation, increasing porosity and reducing mechanical performance. Therefore, 5% HfB2 represents the ideal balance between structural integrity and mechanical strength.

Figure 2c displays the stress (σ) vs. strain (ε) curves in engineering format for the Ti2AlC/xHfB2 composites heat-treated at 1200 °C for 30 min. These results are consistent with the previously mentioned hardness and porosity values. The highest ultimate compressive strength (UCS) of ~345 MPa is that of the Ti2AlC/5HfB2 composite, while the intermediate UCS (~225 MPa) corresponds to the Ti2AlC/7.5HfB2 composite. The lowest UCS (~153 MPa) is that of the composite without the HfB2, demonstrating the strengthening effect of this dopant up to 5 wt.%.

This trend is also evident in the experimental yield strengths (YSs), which are ~250, 160, and 105 MPa, respectively. These YS values are approximately 1.4 times lower than the corresponding UCS values. From a mechanical perspective, these results appear to be associated with the inhibition of cavity formation and intergranular sliding. At room temperature (25 ± 2 °C), the plastic deformation induces the kinking and delamination of the Ti2AlC grains. Since both the Ti2AlC/2HfB2 and Ti2AlC/10HfB2 composites exhibit lower UCS than the other examined samples, their corresponding curves were not considered in the discussion. Standard deviation values remained below 10% in all cases, indicating reliable mechanical behavior and reasonable sample reproducibility.

The microwave heat treatment is recognized as a distinctive manufacturing route for sintering the Ti2AlC/xHfB2 composites. This process involves emitting microwaves into the material, which absorbs the electromagnetic energy and generates heat [41]. When conventional sintering is adopted, only the material is heated, and heat is not transferred among objects by conduction, radiation, or convection. In contrast, during the microwave heat treatment, the heat is initially generated inside the material and then distributed throughout the entire volume [42]. Zhou et al. have also used microwave heating to sinter the Ti2AlC, achieving 96.6% phase purity [43]. Using the same processing parameters, new samples were produced and subjected to the microwave heat treatment at 1200 °C for 30 min.

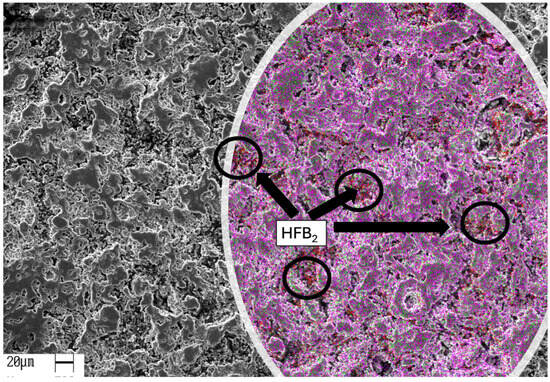

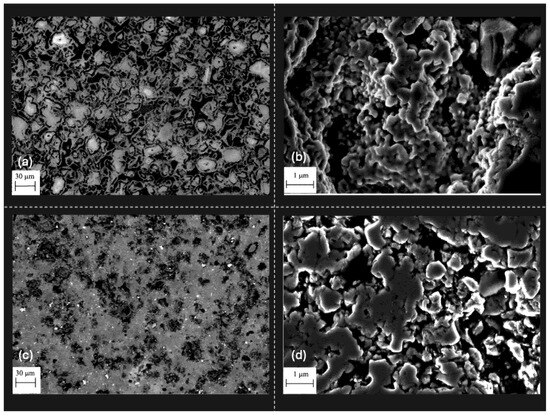

Figure 3 shows typical SEM images of the sintered Ti2AlC/5HfB2 composite subjected to the microwave heat treatment at 1200 °C for 30 min. A typical BSE image shows a polished surface with a different microstructural arrangement compared to the conventionally treated sample. A microstructure with more needle-like particles is observed. Although needle-like particle clusters are typically characterized in the M2AX alloys [43,44,45], the smallest particles in the clusters are observed when microwave sintering is adopted, as depicted in Figure 3. This morphology, more prevalent under microwave sintering, is associated with rapid diffusion and with a directional growth mechanism triggered by internal heating.

Figure 3.

Typical SEM images of the heat-treated Ti2AlC/5.0HfB2 composites at 1200 °C for 30 min using microwave heating. The inset presents the EDS elemental mapping, where titanium (Ti) is represented in magenta, aluminum (Al) in green, and hafnium (Hf) in red. The elemental maps highlight the spatial distribution of the constituent elements and support the identification of the HfB2 reinforcement within the Ti2AlC matrix.

From the XRD results, as demonstrated in Figure 4a, it is worth noting that a complete formation of the Ti2AlC phase is attained. In addition, it is also found that the intensity peaks (at XRD patterns) of the HfB2 are increased with the increasing HfB2 content. This occurrence is also observed when the conventional heat treatment is also carried out. Also, the intermetallic TiC as a secondary phase is constituted.

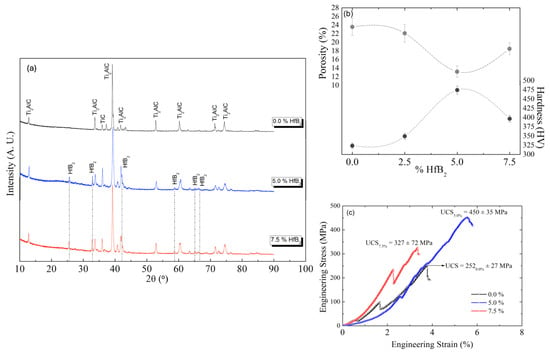

Figure 4.

(a) XRD results of the heat-treated Ti2AlC/0HfB2, Ti2AlC/5HfB2, and Ti2AlC/7.5HfB2 composites by using the microwave treatment at 1200 °C for 30 min. (b) Apparent porosity (upper) and hardness (lower) of the heat-treated Ti2AlC/xHfB2 composites using the microwave treatment at 1200 °C for 30 min. (c) Stress vs. strain engineering curve of the heat-treated Ti2AlC/xHfB2 composites using the microwave (MW) at 1200 °C for 30 min.

For the Ti2AlC sample processed by microwave-assisted sintering, the analysis of the four most intense X-ray diffraction peaks revealed an average crystallite size of approximately 38.1 nm and an average residual microstrain of 0.10%. The crystallite size is smaller than the conventionally sintered sample (55.7 nm). This demonstrates the effectiveness of microwave processing in limiting grain growth due to its rapid heating rates and shorter dwell times. The quantitative phase analysis highlights the effectiveness of both sintering methods in promoting the formation of the Ti2AlC phase. However, conventional sintering led to a slightly higher phase purity (97 vol%) compared to microwave sintering (92 vol%). This difference may be attributed to the rapid heating rates and potential local thermal gradients inherent to microwave processing, which can favor the persistence of secondary phases such as TiC. Despite the marginally lower Ti2AlC content in the microwave-sintered samples, the method still offers significant advantages in terms of energy efficiency and microstructural refinement.

Figure 4b shows both the apparent porosity and hardness results of the Ti2AlC/xHfB2 composites with the three distinct HfB2 contents. Consistent with our previous observations using conventional heating, the Ti2AlC/5HfB2 composite exhibits a lower porosity level. When the 5 wt.% HfB2 content is used, the porosity level decreases by about 10% (i.e., from ~23% to ~13%). In contrast, when the 7.5 wt.% HfB2 content is used, the porosity increases, as also observed with the conventional sintering. The decrease in the porosity is associated with an increase in the hardness. The highest UCS value is that of the Ti2AlC/5HfB2 composite (~474 ± 33 HV), followed by the composites with 7.5 and 2.5 wt.% HfB2, respectively.

An analogous pattern emerges under the conventional sintering. These results indicate that the microwave sintering positively influences the mechanical behavior of the Ti2AlC/5HfB2 composite.

Figure 4c shows the experimental stress (σ) vs. strain (ε) curves, in engineering format, of the heat-treated Ti2AlC/xHfB2 composites at 1200 °C for 30 min at environmental temperature (25 ± 2 °C). As expected, these were similar to the results obtained with the conventional heat treatment. When the HfB2 content is increased up to 5 wt.%, the compressive strength is increased. The lowest UCS value (~252 ± 27 MPa) and YS of ~180 MPa are observed in the Ti2AlC/0HfB2 sample (without HfB2). The highest UCS (~450 ± 35 MPa) is that of the sample with 5 wt.% HfB2, while the intermediate UCS (~327 ± 27 MPa) was obtained in the Ti2AlC/7.5HfB2 composite. Both the Ti2AlC/5HfB2 and Ti2AlC/7.5HfB2 composites exhibit YS values approximately 1.4 times lower than their corresponding UCS values. This is consistent with results when the conventional heat treatment is adopted. Due to the microwave treatment and the resulting finer morphology, oscillations in the stress–strain curve, mainly after the elastic region, are observed. This seems to be associated with the number of dislocations generated when the needle-like morphology is mechanically demanded.

When comparing the mechanical responses of the conventional and microwave treatments, the UCS and YS values of the former are approximately 1.6 times higher than the latter ones. This trend is consistent not only for the 5 wt.% HfB2 content but also for all other examined composites. When comparing the two treatments (Figure 2 and Figure 4), an interesting observation regarding elongation is noted. For instance, the Ti2AlC composites without the HfB2 content exhibit average elongations of ~4%, regardless of the heat treatment adopted. When considering the HfB2 content, the conventional treatment results have demonstrated similar elongations.

In contrast, the microwave treatment results promote slightly decreased elongation values. However, this decrease is more pronounced in the 7.5 wt.% HfB2 composite (~3.5% vs. ~6% with conventional treatment). Although the elongation typically decreases with increasing UCS, a more pronounced deleterious effect is observed in composites with higher HfB2 content.

4. Discussion

A comparison between conventional sintering and microwave-assisted sintering reveals significant microstructural implications (Figure 5), with a direct impact on the final properties of the materials. While conventional heating relies on external thermal conduction, promoting gentler temperature gradients and prolonged processing times, microwave sintering operates through direct and selective volumetric heating. This intensifies the diffusion kinetics at localized scales. This characteristic results in the formation of more refined microstructures (Figure 5a,b). Associated with this, a noticeable reduction in the average particle size and residual porosity is achieved. The direct interaction of the electromagnetic field with the ceramic matrix favors the non-thermal sintering mechanisms, such as intergranular coupling and differential heating. These effects contribute to more homogeneous densification and improved control of the grain morphology. The powder mixture was manually homogenized in an agate mortar for approximately 20 min at room temperature (25 ± 2 °C), without the addition of binders or lubricants, to preserve the original particle size and morphology. Although no SEM or EDS characterization was conducted on the mixed powder, the post-sintering microstructural analysis at low magnification indicates a satisfactory distribution of HfB2 within the Ti2AlC matrix, suggesting that the mixing protocol was effective in achieving initial homogeneity.

Figure 5.

SEM micrographs of the Ti2AlC composite with 5 wt.% HfB2 sintered via (a,b) microwave-assisted heating and (c,d) conventional sintering. The microstructure obtained by the microwave sintering shows densification and refined grain distribution improved when compared with the conventionally sintered sample.

These mentioned microstructural modifications not only affect the mechanical behavior, inducing improvements in both the hardness and toughness, but they also indicate a promising path for the development of advanced ceramics. This suggests superior performance with applications at high temperatures. These findings highlight the potential of microwave sintering as a disruptive technology for the engineering of refractory materials and functional composites.

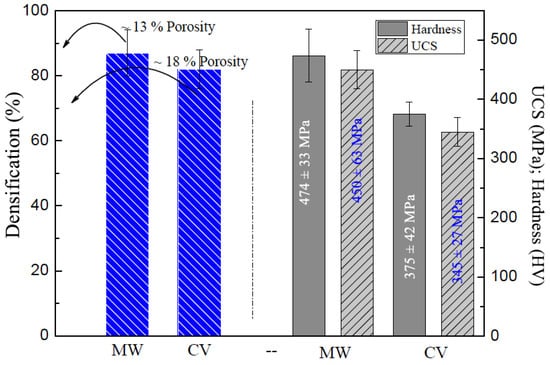

Microwave heating has promoted more efficient interparticle cohesion and refinement of the microstructure. This has also decreased the apparent porosity. The quantitative analyses reveal that the sample sintered by using the microwave exhibited a porosity of 13%, in contrast to the 18% observed when the sample was subjected to conventional sintering (Figure 6). This means a relative reduction of approximately 28%, highlighting the superior effectiveness of microwave heating in eliminating intergranular pores. Such performance is associated with the volumetric and rapid nature of microwave heating, which promotes uniform densification and accelerates the diffusion mechanisms within the material, even in shorter treatment times.

Figure 6.

Comparative analysis concatenating mechanical behavior (UCS and hardness) and densification of the Ti2AlC/xHfB2 composites using both the MW (microwave) and CV (conventional) treatments.

A comparative analysis of the mechanical properties of the examined composites under two different heat treatments is shown in Figure 6. This analysis indicates that lower porosity levels improve mechanical performance. Furthermore, the morphology refinement is achieved with the microwave treatment.

From the experimental results of the mechanical strength and densification levels, another important parameter is determined, namely the specific strength (SS), which is defined as the UCS divided by the sintered density. This reflects the combination of the mechanical strength and lightweight effect. The specific strength (SS) for the MW (microwave) treatment is ~118 ± 6 × 103 m2/s2 (ρ = 3.64 × 103 kg/m3), while the CV (conventional) treatment yields a SS of ~95 ± 5 × 103 m2/s2 (ρ = 3.46 × 103 kg/m3) (Table 1). These results suggest that the MW treatment is a viable alternative for the sintering of the studied composites. Additionally, microwave sintering produces the desired phase while preventing TiC formation typically constituted during conventional sintering. This mechanical improvement, combined with the suppression of the undesirable TiC formation, positions microwave sintering as a promising method for the cost-effective production of Ti2AlC-based components.

Table 1.

Comparative values of the physical and mechanical properties of the samples sintered by conventional and microwave heating. The measurements of apparent porosity, Vickers hardness, compressive strength limit, and specific resistance are compiled, highlighting the distinct effects of sintering mechanisms on the microstructure and mechanical performance of the material.

Barsoum et al. [1] have reported that the compressive strength varies with the grain size. Specifically, a coarser grain size (100 to 200 μm) results in a compressive strength of ~390 MPa, whereas a finer grain size (~25 μm) leads to a compressive strength of ~540 MPa.

In this investigation, the starting particle sizes were ~150 μm (100 mesh) for Ti and 45 μm (325 mesh) for both Al and graphite. These results are consistent with those previously reported by Barsoum et al. [1]. However, while Barsoum’s results were obtained with conventional processing, the current study demonstrates that similar or superior properties can be achieved using microwave sintering, potentially reducing energy costs and time. Additionally, the findings suggest that the Ti2AlC phase can be manufactured using powder metallurgy without additional processing steps, resulting in lower production costs.

This study demonstrates that the mechanical performance of the Ti2AlC/xHfB2 composites is significantly influenced by the heat treatment method and the HfB2 content. The results indicate that the microwave heat treatment effectively improves both the densification and mechanical strength of the composites due to enhanced microstructural refinement and reduced porosity. The highest ultimate compressive strength (UCS) of ~450 MPa and the highest specific strength (SS) of ~118 × 103 m2/s2 are obtained for the composite with 5 wt.% HfB2 under microwave treatment. It is important to note that microwave sintering operates via a fundamentally different mechanism compared to conventional heating, promoting rapid volumetric heating and strong interfacial field interactions. This leads to enhanced local diffusion and densification kinetics, especially at particle contacts, even under short dwell times. However, due to the lower overall thermal budget and short sintering cycle, microwave sintering naturally limits long-range diffusion, which in turn preserves the distribution and integrity of the HfB2 phase within the matrix [30].

The observed increase in hardness may be partially attributed to the presence of HfB2 particles, which, according to previous studies, can act as obstacles to dislocation motion in ceramic-reinforced composites [19,46,47]. While this mechanism is consistent with the literature, it is important to note that it was not directly verified in this work due to the absence of TEM or EBSD analysis.

In contrast, the conventional sintering resulted in a higher porosity (~18%) and a lower specific strength (~95 × 103 m2/s2). The microwave treatment has promoted the formation of the Ti2AlCphase while effectively suppressing the formation of the TiC. This is more prominent in the conventionally treated samples. Furthermore, the increase in the HfB2 content beyond 5 wt.% led to an increase in the porosity and a decrease in mechanical strength, highlighting the importance of optimizing the HfB2 content.

The findings confirm that microwave sintering is a viable alternative to produce Ti2AlC-based composites with improved mechanical properties and reduced production costs. The enhanced mechanical behavior and microstructural stability achieved with microwave sintering indicate that this method is a promising approach for manufacturing high-performance Ti2AlC composites. Future work should focus on exploring the long-term mechanical and thermal stability of these composites under different environmental conditions. In summary, this study provides a pathway for engineering Ti2AlC-based composites with superior performance using scalable and energy-efficient techniques. This advances the practical implementation of MAX phase ceramics at high temperatures and in high-stress environments.

5. Conclusions

Based on the experimental results, the following conclusions can be drawn:

- Both the conventional and microwave-assisted sintering enables the successful formation of the Ti2AlC phase using an optimized Ti:TiC:Al stoichiometry (1.2:1:1), achieving phase purity of up to 97%.

- Incorporating 5 wt.% HfB2 maximizes mechanical performance, with substantial improvements in hardness, compressive strength, and reduced porosity, independent of the sintering route adopted.

- The microwave processing further refines the microstructural arrays, resulting in the mechanical properties approximately 1.6 times higher than those obtained by the conventional methods.

- These findings establish powder metallurgy with microwave sintering as an efficient, scalable route for the advanced Ti2AlC-based composites suitable for demanding high-temperature applications.

Author Contributions

Conceptualization, A.D.B.; methodology, M.d.S.D.D. and A.D.B.; validation, M.d.S.D.D., Y.A.M., G.d.S.P., W.R.O. and E.L.O.; formal analysis, Y.A.M., G.d.S.P., W.R.O. and E.L.O.; investigation, M.d.S.D.D.; resources, A.D.B.; data curation, G.d.S.P.; writing—original draft preparation, A.D.B. and M.d.S.D.D.; writing—review and editing, Y.A.M., G.d.S.P. and W.R.O.; visualization, Y.A.M. and G.d.S.P.; supervision, A.D.B.; project administration, A.D.B.; funding acquisition, A.D.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP), grant number 16/13352-0; Fundação de Apoio ao Ensino, Pesquisa e Extensão (FAEPEX-UNICAMP), grant numbers 2259/19 and 2020/19; Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), grant number 305207/2023-7.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors gratefully acknowledge the support provided by the funding agencies Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP), Fundação de Apoio ao Ensino, Pesquisa e Extensão (FAEPEX-UNICAMP), and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq). The authors also wish to thank Luis Garcia for his valuable technical assistance.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| XRD | X-ray diffraction |

| SEM | Scanning electron microscopy |

| EDS | Energy-dispersive X-ray spectroscopy |

| AP | Apparent Porosity |

| UCS | Ultimate compressive strength |

| YS | Yield Strength |

| SS | Specific Strength |

| MW | Microwave |

| CV | Conventional |

| FAPESP | Fundação de Amparo à Pesquisa do Estado de São Paulo |

| CNPq | Conselho Nacional de Desenvolvimento Científico e Tecnológico |

| FAEPEX | Fundação de Apoio ao Ensino, Pesquisa e Extensão |

References

- Barsoum, M.W.; El-Raghy, T.; Ali, M. Processing and Characterization of Ti2AlC, Ti2AlN, and Ti2AlC0.5N0.5. Metall. Mat. Trans. A 2000, 31, 1857–1865. [Google Scholar] [CrossRef]

- Hu, L.; Benitez, R.; Basu, S.; Karaman, I.; Radovic, M. Processing and Characterization of Porous Ti2AlC with Controlled Porosity and Pore Size. Acta Mater. 2012, 60, 6266–6277. [Google Scholar] [CrossRef]

- Eklund, P.; Beckers, M.; Jansson, U.; Högberg, H.; Hultman, L. The M+1AX Phases: Materials Science and Thin-Film Processing. Thin Solid. Films 2010, 518, 1851–1878. [Google Scholar] [CrossRef]

- Tallman, D.J.; Anasori, B.; Barsoum, M.W. A Critical Review of the Oxidation of Ti2AlC, Ti3AlC2 and Cr2AlC in Air. Mater. Res. Lett. 2013, 1, 115–125. [Google Scholar] [CrossRef]

- Agne, M.T.; Anasori, B.; Barsoum, M.W. Reactions Between Ti2AlC, B4C, and Al and Phase Equilibria at 1000 °C in the Al-Ti-B-C Quaternary System. J. Phase Equilibria Diffus. 2015, 36, 169–182. [Google Scholar] [CrossRef]

- Keerthipalli, T.; Aepuru, R.; Biswas, A. Mechanical and Tribological Behaviour of Ti2AlC Reinforced Hypereutectic Aluminium Alloy Matrix Composite Fabricated by Vacuum Assisted Induction Melting: Experimental and Theoretical Modelling. Int. J. Met. 2024, 18, 1173–1191. [Google Scholar] [CrossRef]

- Zhu, J.; Ye, L.; He, L. Microstructure and Mechanical Properties of in Situ Synthesized Ti2AlC/Al2O3 Composites. Mater. Sci. Eng. A 2012, 547, 6–11. [Google Scholar] [CrossRef]

- Su, J.; Zhang, X.; Li, J.; Guo, H.; Wang, B.; Bai, Z. Al2O3 Fiber-Reinforced MAX Phase Ceramic Matrix Composite. Ceram. Int. 2024, 50, 25400–25411. [Google Scholar] [CrossRef]

- Spencer, C.B.; Córdoba, J.M.; Obando, N.H.; Radovic, M.; Odén, M.; Hultman, L.; Barsoum, M.W. The Reactivity of Ti2AlC and Ti3SiC2 with SiC Fibers and Powders up to Temperatures of 1550°C. J. Am. Ceram. Soc. 2011, 94, 1737–1743. [Google Scholar] [CrossRef]

- Liu, Y.; Jia, Q.; Yan, Y.; Yuan, N.; Luo, W.; Yuan, X.; Wang, L.; Guo, S. Lewis Acid Molten Salt Etched Porous Lamellar Ti2AlC Powders for Enhanced Microwave Absorption. Ceram. Int. 2024, 50, 8546–8550. [Google Scholar] [CrossRef]

- Suh, M.; Lee, D.H.; Sloof, W.G.; Lee, K.S. Effect of Temperature on the Healing Capacity and Mechanical Properties of Ti2AlC MAX Phase Ceramics. Int. J. Appl. Ceram. Technol. 2024, 21, 2757–2770. [Google Scholar] [CrossRef]

- Laska, N.; Swadźba, R.; Nellessen, P.; Helle, O.; Anton, R. Oxidation Behavior of Ti2AlC MAX Phase-Based Coating on a γ-TiAl Alloy TiAl48-2-2 Produced by DC Magnetron Sputtering. Surf. Coat. Technol. 2024, 480, 130601. [Google Scholar] [CrossRef]

- Shichalin, O.O.; Ivanov, N.P.; Seroshtan, A.I.; Nadaraia, K.V.; Simonenko, T.L.; Gurin, M.S.; Kornakova, Z.E.; Shchitovskaya, E.V.; Barkhudarov, K.V.; Tsygankov, D.K.; et al. Spark Plasma Sintering of Ti2AlC/TiC MAX-Phase Based Composite Ceramic Materials and Study of Their Electrochemical Characteristics. Ceram. Int. 2024, 50, 53120–53128. [Google Scholar] [CrossRef]

- Supakul, S.; Jain, M.; Yaddanapudi, K.; Gruber, J.; El-Atwani, O.; Tucker, G.J.; Pathak, S. Synthesis, Microstructure and Micro-Mechanical Characterization of Metal (Nb, Ti)—MAX Phase (Ti2AlC) Nanolaminates. Mater. Sci. Eng. A 2024, 910, 146905. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Wang, K.; Wang, Z.; Ma, G.; Ke, P.; Wang, A. Highly Dense Passivation Enhanced Corrosion Resistance of Ti2AlC MAX Phase Coating in 3.5 Wt.% NaCl Solution. Corros. Sci. 2024, 228, 111820. [Google Scholar] [CrossRef]

- Huang, R.; Xu, G.; Zhao, C.; Wu, Q.; Yu, L.; Wu, C. The Thermal Stability of Ti2AlC and Ag/Ti2AlC in Ar and Air. Mater. Charact. 2024, 213, 114050. [Google Scholar] [CrossRef]

- Wang, W.; Xu, J.; Zuo, J.; Ma, K.; Li, Y.; He, G.; Li, M. Oxidation Resistance of In Situ Reaction/Hot Pressing Synthesized Ti2AlC–20% TiB2 Composite at 600–900 °C in Air. Acta Metall. Sin. (Engl. Lett.) 2024, 37, 739–748. [Google Scholar] [CrossRef]

- Ma, T.; Li, Q.; Wang, Y.; Wang, X.; Dong, D.; Zhu, D. Microstructure and Mechanical Properties of Micro-Nano Ti2AlC-Reinforced TiAl Composites. Intermetallics 2022, 146, 107563. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, P.; Wang, A.; Xie, J.; Hou, B. Fabrication, Microstructure and Mechanical Properties of TiAl Matrix Composite Reinforced by Submicro/Nano-Ti2AlC. Mater. Charact. 2023, 203, 113141. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Nagornov, I.A.; Lysenkov, A.S.; Papynov, E.K.; Shichalin, O.O.; Belov, A.A.; Kolodeznikov, E.S.; Mokrushin, A.S.; Simonenko, N.P.; Kuznetsov, N.T. Effect of Ti2AlC on Sintering of Ultrahigh-Temperature Ceramics Based on HfB2–HfO2–SiC System. Russ. J. Inorg. Chem. 2024, 69, 2151–2163. [Google Scholar] [CrossRef]

- Yeh, C.-L.; Chan, Y.-C. Effects of Ti/Al Ratio on Formation of Ti-Al Intermetallics/TiB2 Composites by SHS from Ti-Al-B Powder Mixtures. Processes 2024, 12, 1237. [Google Scholar] [CrossRef]

- Yang, J.; Tan, S.; Xiao, G.; Wang, B.; Jiang, W.; Yang, X.; Zhang, H. The Influence of B4C Content on the Pore Structure of Reaction-Synthesized Porous Ti3AlC2-TiB2 Composite Ceramics. Ceram. Int. 2024, 50, 39975–39982. [Google Scholar] [CrossRef]

- Ji, C.; Wang, H.; Li, M.; Zhu, J.; Xie, W.; Shao, G.; Xu, H.; Lu, H.; Zhang, R. Microstructure and Mechanical Properties of High-Entropy Diboride-Based Ceramic Assisted by Ti3AlC2 Additive. Ceram. Int. 2024, 50, 30810–30820. [Google Scholar] [CrossRef]

- Bortolozo, A.D.; Cremasco, A.; Floriano, R.; Contieri, R.J. Effects of Microwave Heating in Nanolaminated Nb2GeC Synthesis. Ceram. Int. 2016, 42, 16343–16348. [Google Scholar] [CrossRef]

- Lin, M.-S.; Chu, K.-R. On the Non-Thermal Mechanisms in Microwave Sintering of Materials. Materials 2025, 18, 668. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Cheng, Y.; Jiang, Z.; Wang, Z.; Yuan, J. Microwave Sintering of Ti(C,N)-Based Cermets: Study of the Magnetic Effect on Metal Phase. Mater. Chem. Phys. 2024, 313, 128717. [Google Scholar] [CrossRef]

- Aman, B.; Acharya, S.; Reeja-Jayan, B. Making the Case for Scaling Up Microwave Sintering of Ceramics. Adv. Eng. Mater. 2024, 26, 2302065. [Google Scholar] [CrossRef]

- Kumar, C.S.; Sharma, A.K.; Ostap, Z.; Ragulya, A.V. Microstructural and Mechanical Properties of Microwave Sintered Bulk Titanium Nitride Nanoceramics. Ceram. Int. 2024, 50, 29293–29305. [Google Scholar] [CrossRef]

- Calado, L.D.; Padilha, G.S.; Osório, W.R.; Bortolozo, A.D. Designing Sintering Time for a TiSiC Compound: A Microwave and Conventional Comparison. Int. J. Adv. Manuf. Technol. 2019, 104, 1561–1570. [Google Scholar] [CrossRef]

- Su, W.X.; Wang, H.M.; Li, G.R.; Zhang, Y.F. Evolution of Microstructure and Mechanical Properties of Aluminum Matrix Composites Reinforced with Dual-Phase Heterostructures. Mater. Sci. Eng. A 2024, 901, 146500. [Google Scholar] [CrossRef]

- Batienkov, R.V.; Bol’shakova, A.N.; Khudnev, A.A. Microwave Sintering of Metal Powder Materials (Review). Metallurgist 2022, 65, 1163–1173. [Google Scholar] [CrossRef]

- Rybakov, K.I.; Olevsky, E.A.; Krikun, E.V. Microwave Sintering: Fundamentals and Modeling. J. Am. Ceram. Soc. 2013, 96, 1003–1020. [Google Scholar] [CrossRef]

- ASTM A6/A6M-24b; Standard Specification for General Requirements for Rolled Structural Steel Bars, Plates, Shapes, and Sheet Piling. ASTM: West Conshohocken, PA, USA, 2024.

- ASTM E8/E8M-24; Standard Test Methods for Tension Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2024.

- Villars, P.; Cenzual, K. Pearson’s Crystal Data: Crystal Structure Database for Inorganic Compounds; ASM International: Materials Park, OH, USA, 2007. [Google Scholar]

- Aydinyan, S. Synthesis of Ti2AlC MAX Phase and Ti2C MXene by Activated Combustion. Ceram. Int. 2024, 50, 12263–12269. [Google Scholar] [CrossRef]

- Córdoba Gallego, J.M. Pressureless Sintering Kinetics Analysis of Ti3SiC2 and Ti2AlC Powdered MAX Phases. Discov. Mater. 2024, 4, 26. [Google Scholar] [CrossRef]

- Lin, Z.J.; Zhuo, M.J.; Zhou, Y.C.; Li, M.S.; Wang, J.Y. Microstructural Characterization of Layered Ternary Ti2AlC. Acta Mater. 2006, 54, 1009–1015. [Google Scholar] [CrossRef]

- Yeh, C.L.; Shen, Y.G. Effects of TiC and Al4C3 Addition on Combustion Synthesis of Ti2AlC. J. Alloys Compd. 2009, 470, 424–428. [Google Scholar] [CrossRef]

- Zhou, W.B.; Mei, B.C.; Zhu, J.Q.; Hong, X.L. Rapid Synthesis of Ti2AlC by Spark Plasma Sintering Technique. Mater. Lett. 2005, 59, 131–134. [Google Scholar] [CrossRef]

- Huang, J.; Xu, G.; Liang, Y.; Hu, G.; Chang, P. Improving Coal Permeability Using Microwave Heating Technology—A Review. Fuel 2020, 266, 117022. [Google Scholar] [CrossRef]

- Oghbaei, M.; Mirzaee, O. Microwave versus Conventional Sintering: A Review of Fundamentals, Advantages and Applications. J. Alloys Compd. 2010, 494, 175–189. [Google Scholar] [CrossRef]

- Zhou, W.; Li, K.; Zhu, J.; Tian, S.; Zhu, D. Low-temperature Synthesis of High-purity Ti2AlC Powder by Microwave Sintering. Micro Nano Lett. 2018, 13, 798–800. [Google Scholar] [CrossRef]

- Hossein-Zadeh, M.; Ghasali, E.; Mirzaee, O.; Mohammadian-Semnani, H.; Alizadeh, M.; Orooji, Y.; Ebadzadeh, T. An Investigation into the Microstructure and Mechanical Properties of V2AlC MAX Phase Prepared by Microwave Sintering. J. Alloys Compd. 2019, 795, 291–303. [Google Scholar] [CrossRef]

- Wang, Q.; Hu, C.; Cai, S.; Sakka, Y.; Grasso, S.; Huang, Q. Synthesis of High-Purity Ti3 SiC2 by Microwave Sintering. Int. J. Appl. Ceram. Technol. 2014, 11, 911–918. [Google Scholar] [CrossRef]

- Liu, P.; Hou, B.; Wang, A.; Xie, J.; Wang, Z.; Ye, F. Superior Strength-Plasticity Synergy in a Heterogeneous Lamellar Ti2AlC/TiAl Composite with Unique Interfacial Microstructure. J. Mater. Sci. Technol. 2023, 159, 21–32. [Google Scholar] [CrossRef]

- Yu, W.; Guénolé, J.; Ghanbaja, J.; Vallet, M.; Guitton, A. Frank Partial Dislocation in Ti2AlC-MAX Phase Induced by Matrix-Cu Diffusion. Scr. Mater. 2021, 191, 34–39. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).