Effect of Elevated Temperature on Mechanical Properties and Shielding Performance of Magnetite–Serpentine Radiation-Proof Concrete

Abstract

1. Introduction

2. Materials and Methods

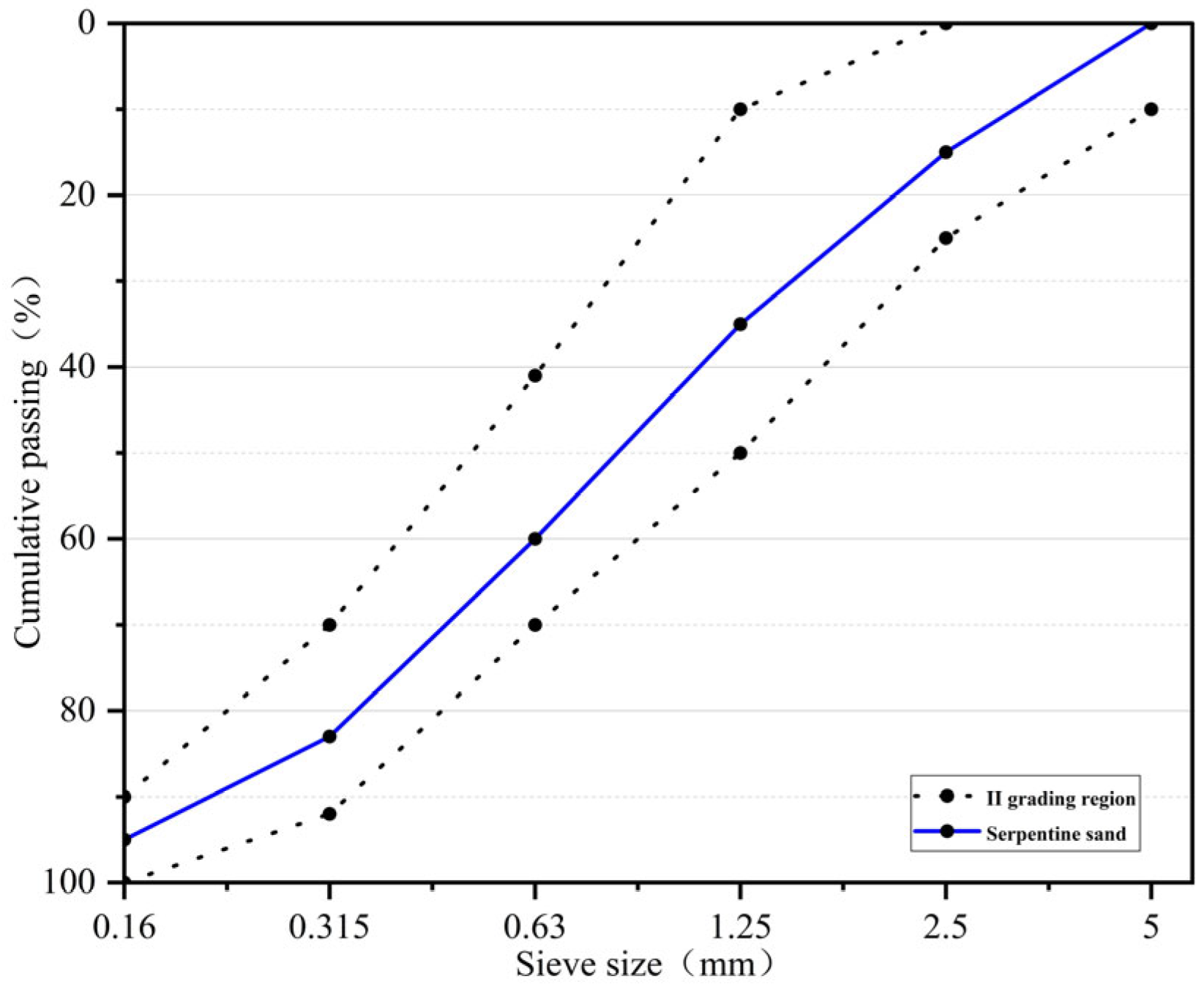

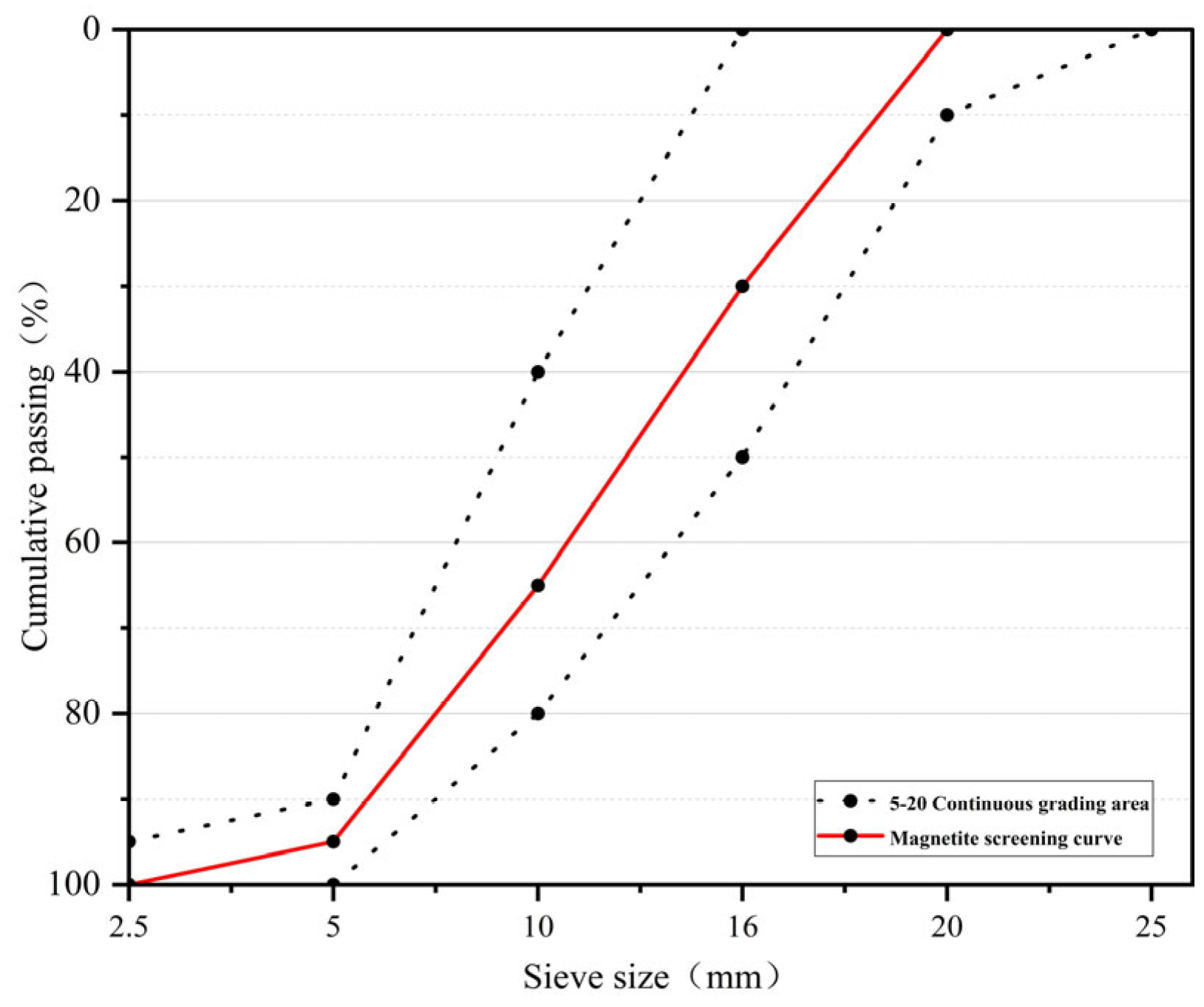

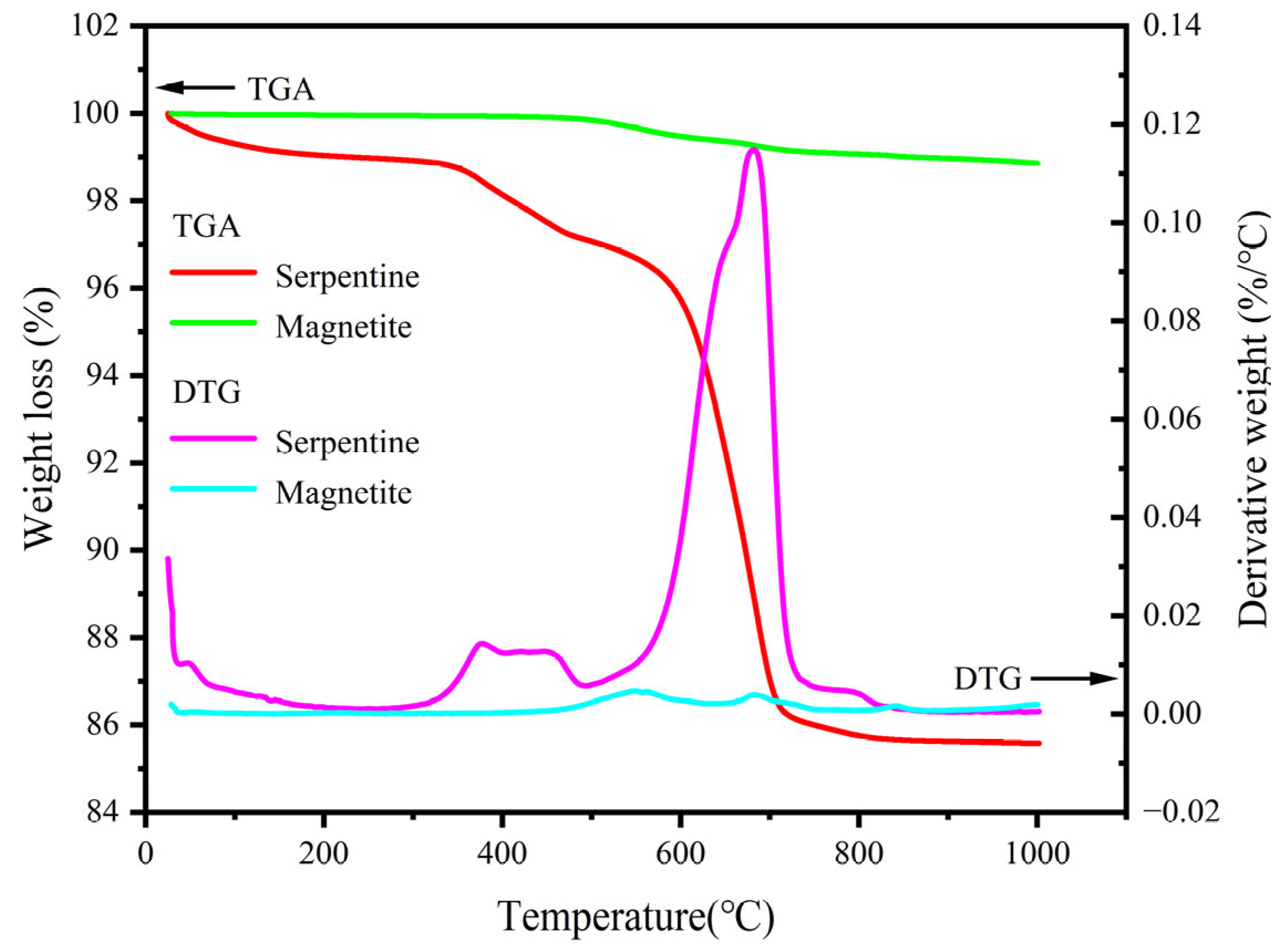

2.1. Materials

2.2. Mix Design

2.3. Test Method

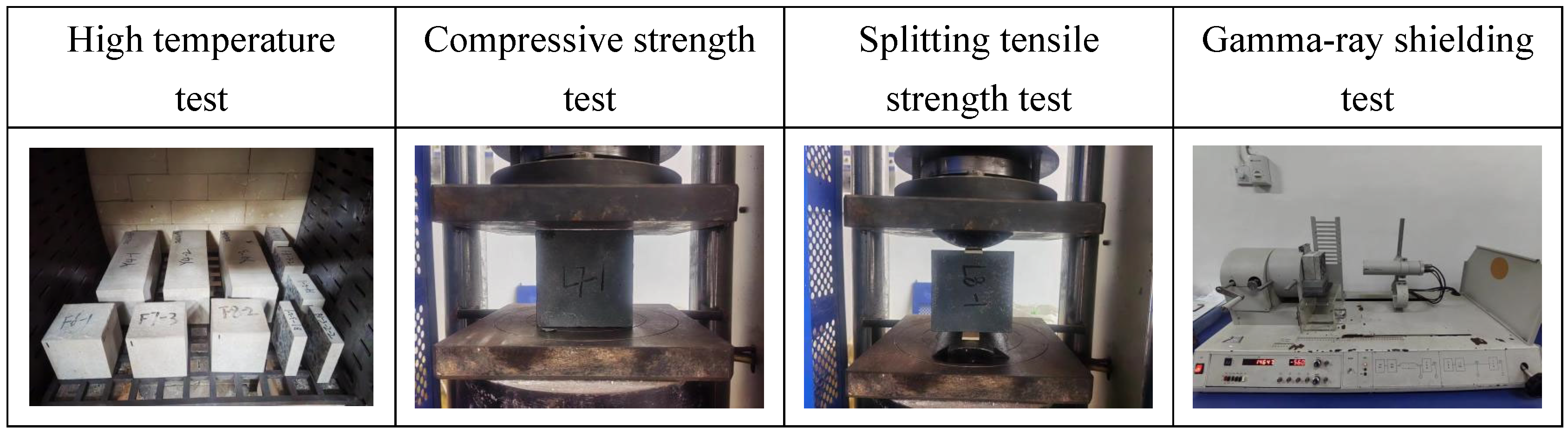

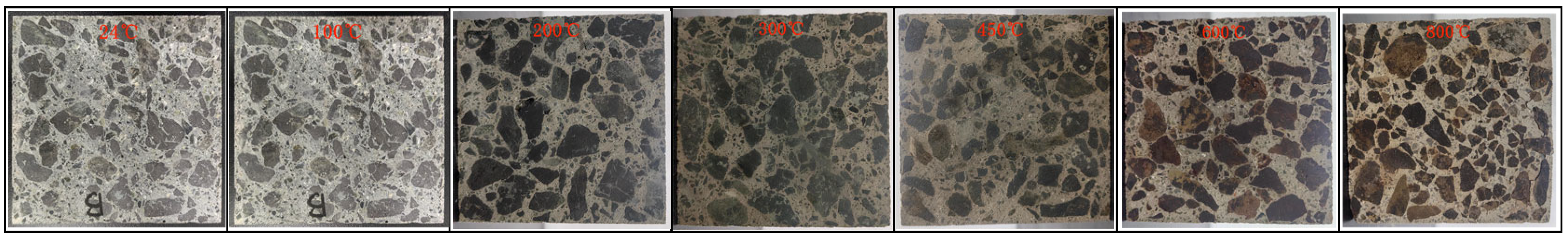

2.3.1. Apparent Characteristic Test

2.3.2. Mass Loss Test

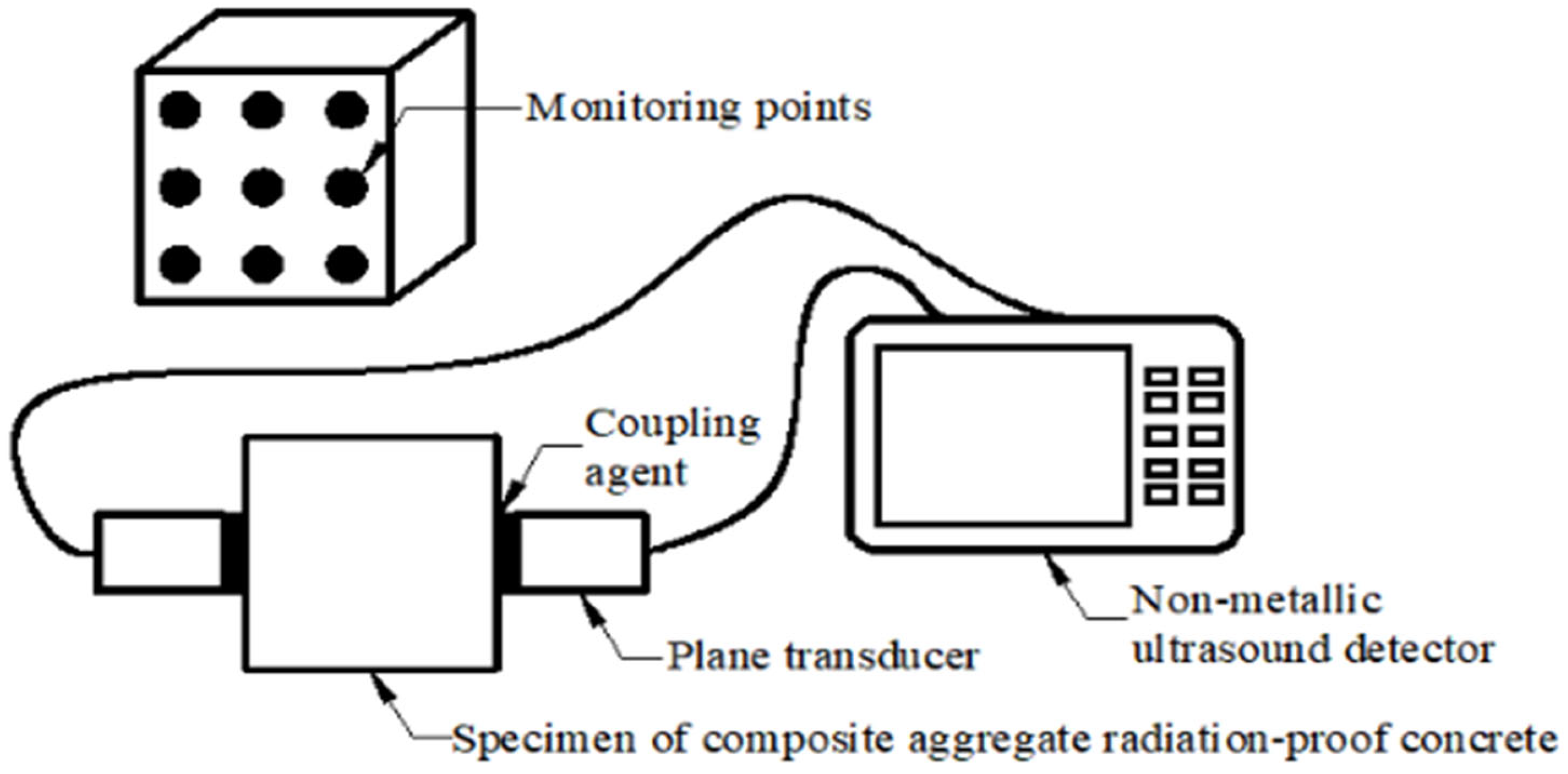

2.3.3. Ultrasonic Nondestructive Testing

2.3.4. Mechanical Property Test

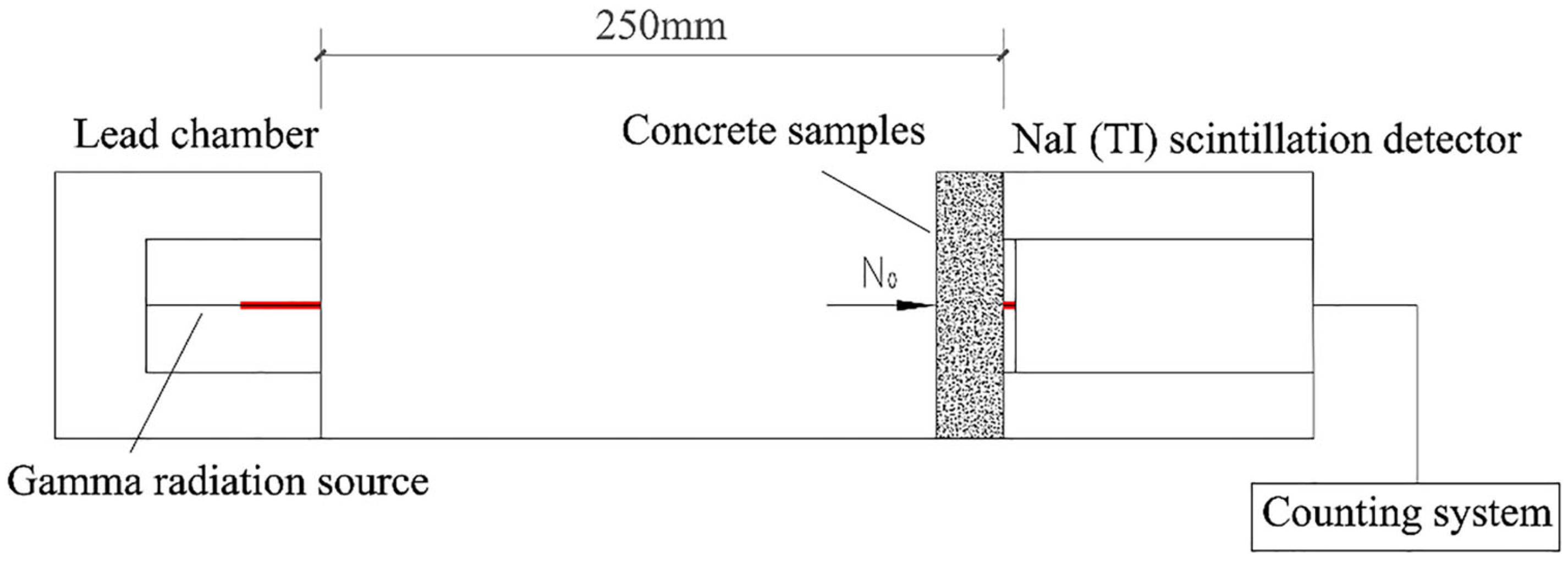

2.3.5. γ-Ray Shielding Performance Test

3. Results

3.1. Apparent Characteristic Analysis

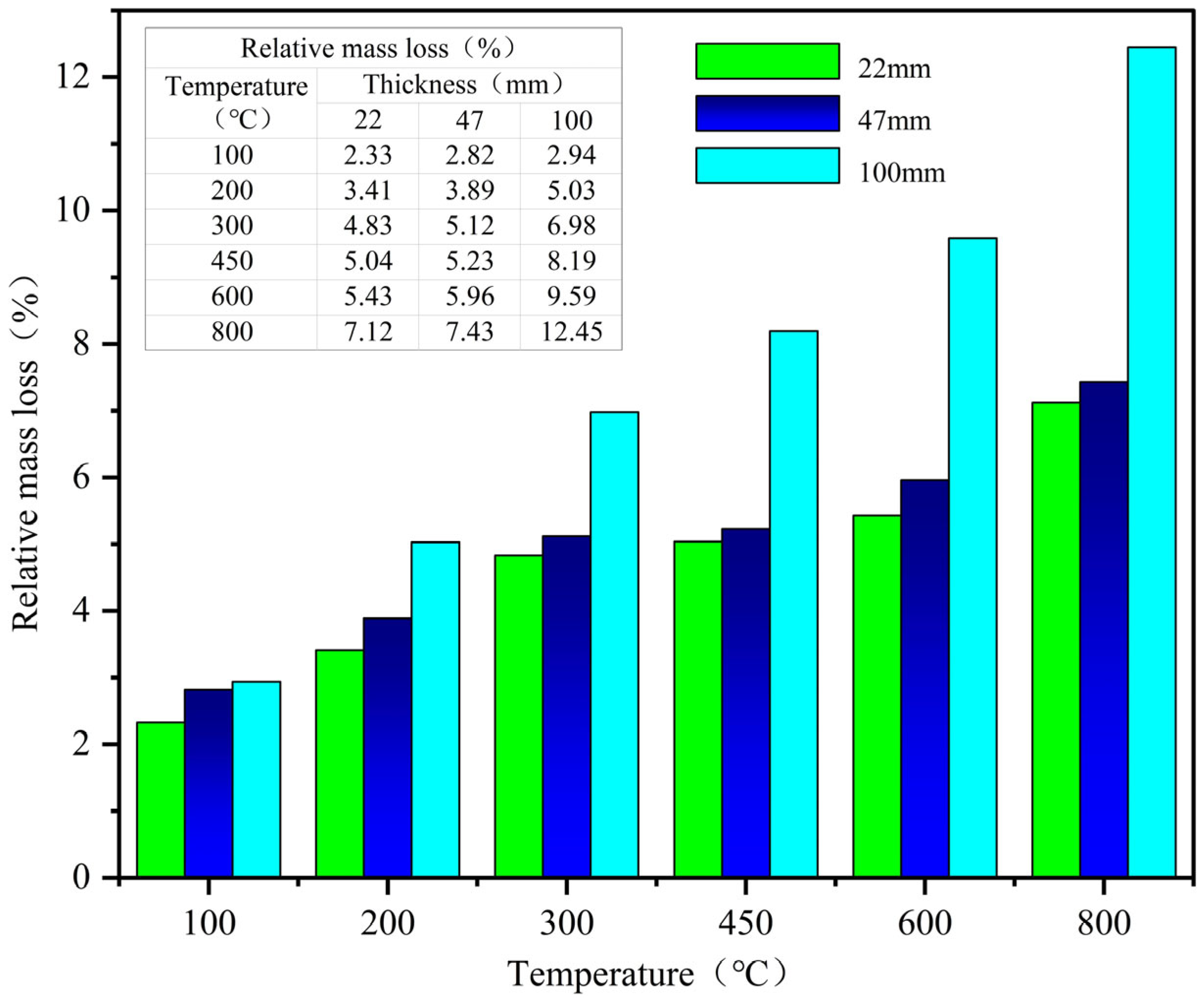

3.2. Mass Loss

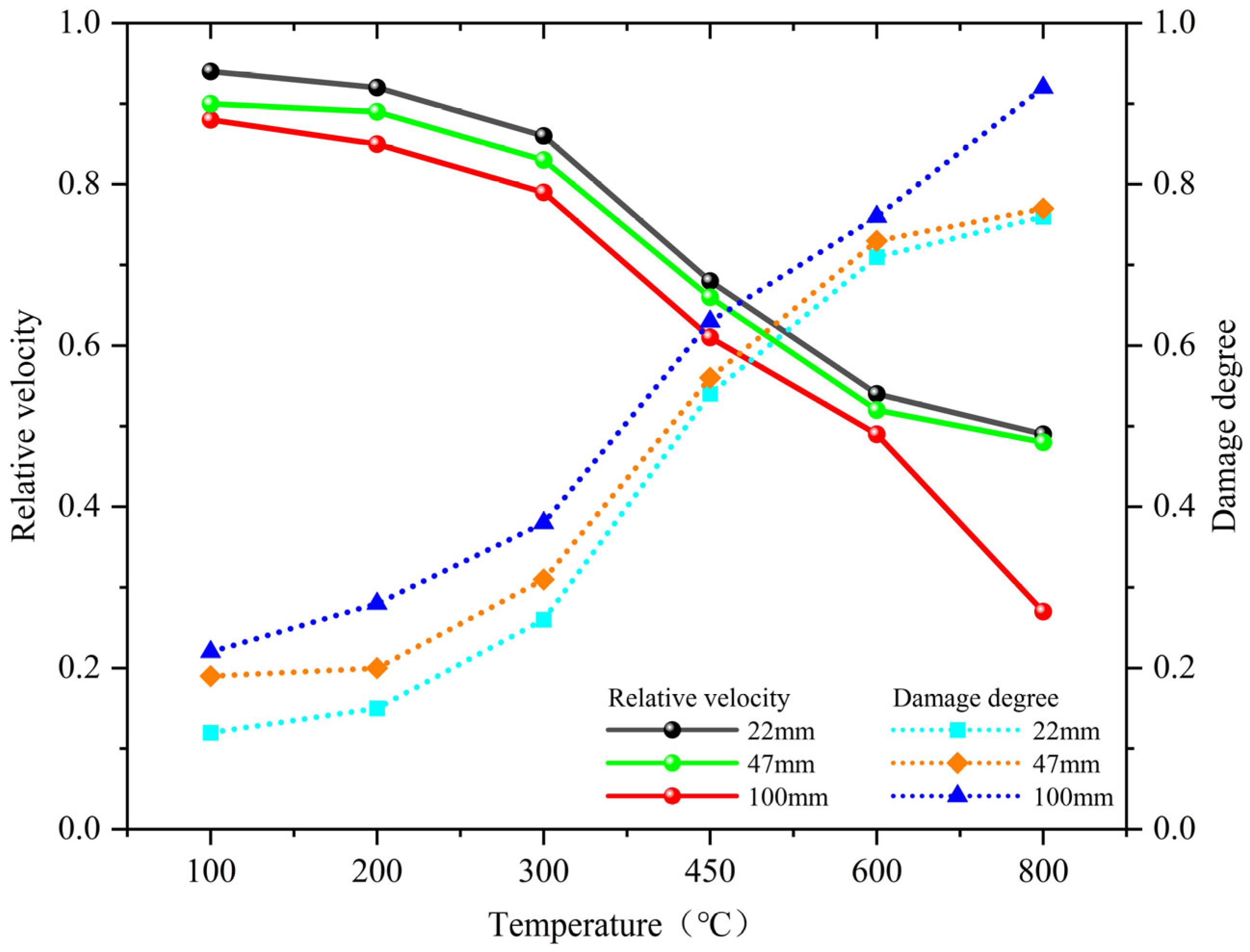

3.3. Ultrasonic Nondestructive Test

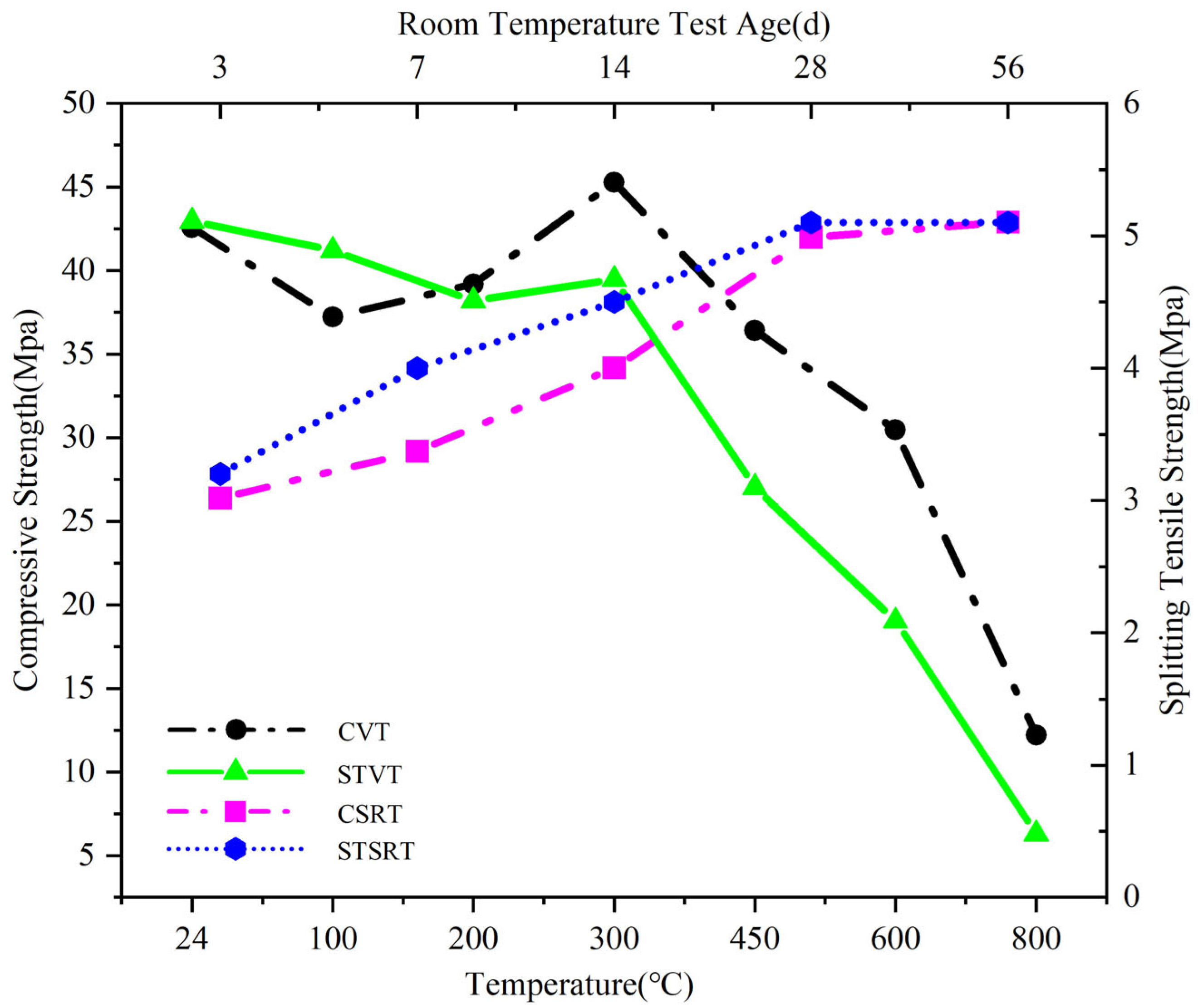

3.4. Mechanical Properties

3.4.1. Mechanical Properties at Normal Temperatures

3.4.2. Compressive Strength Under Different Temperatures

3.4.3. Splitting Tensile Strength Under Different Temperatures

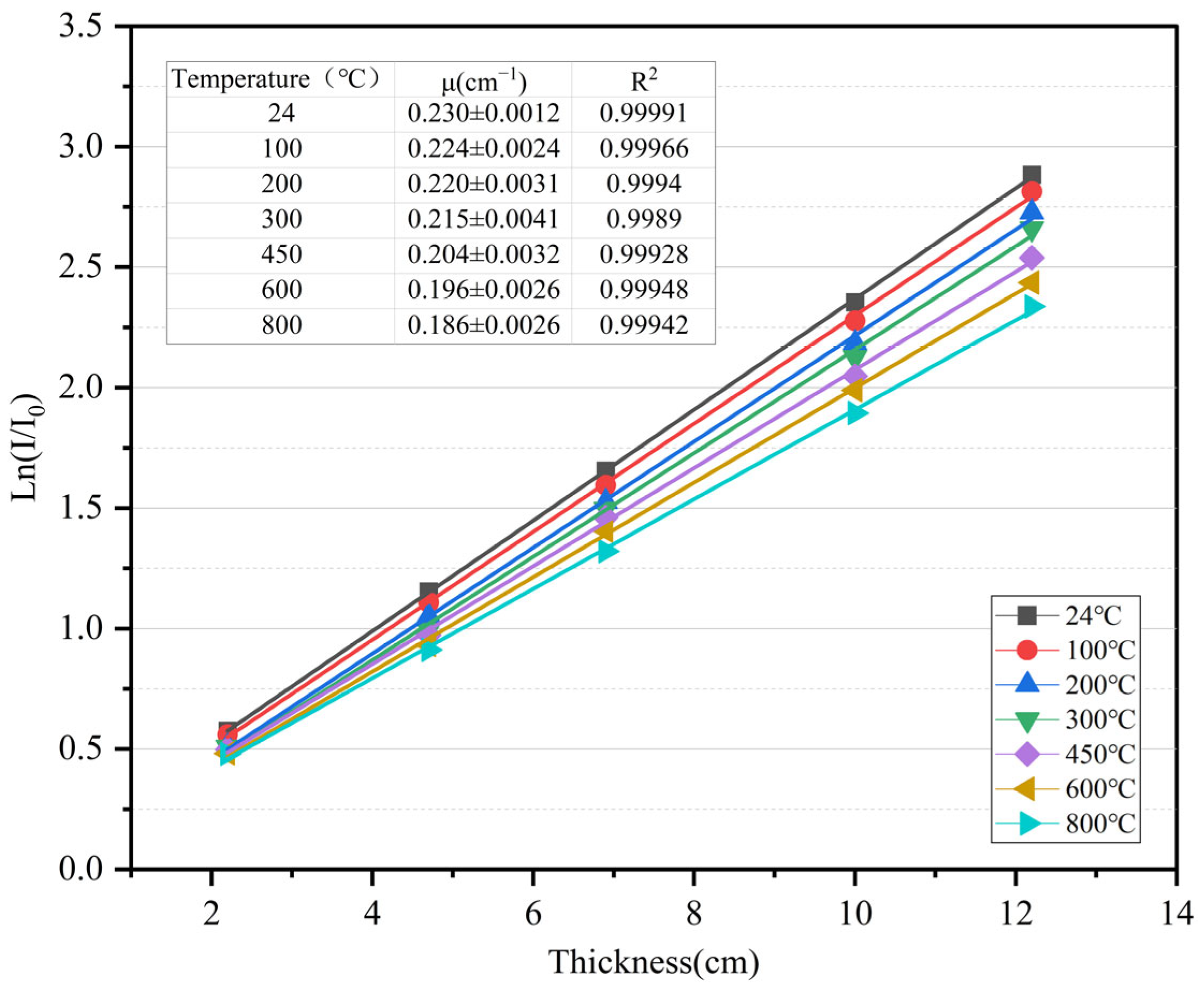

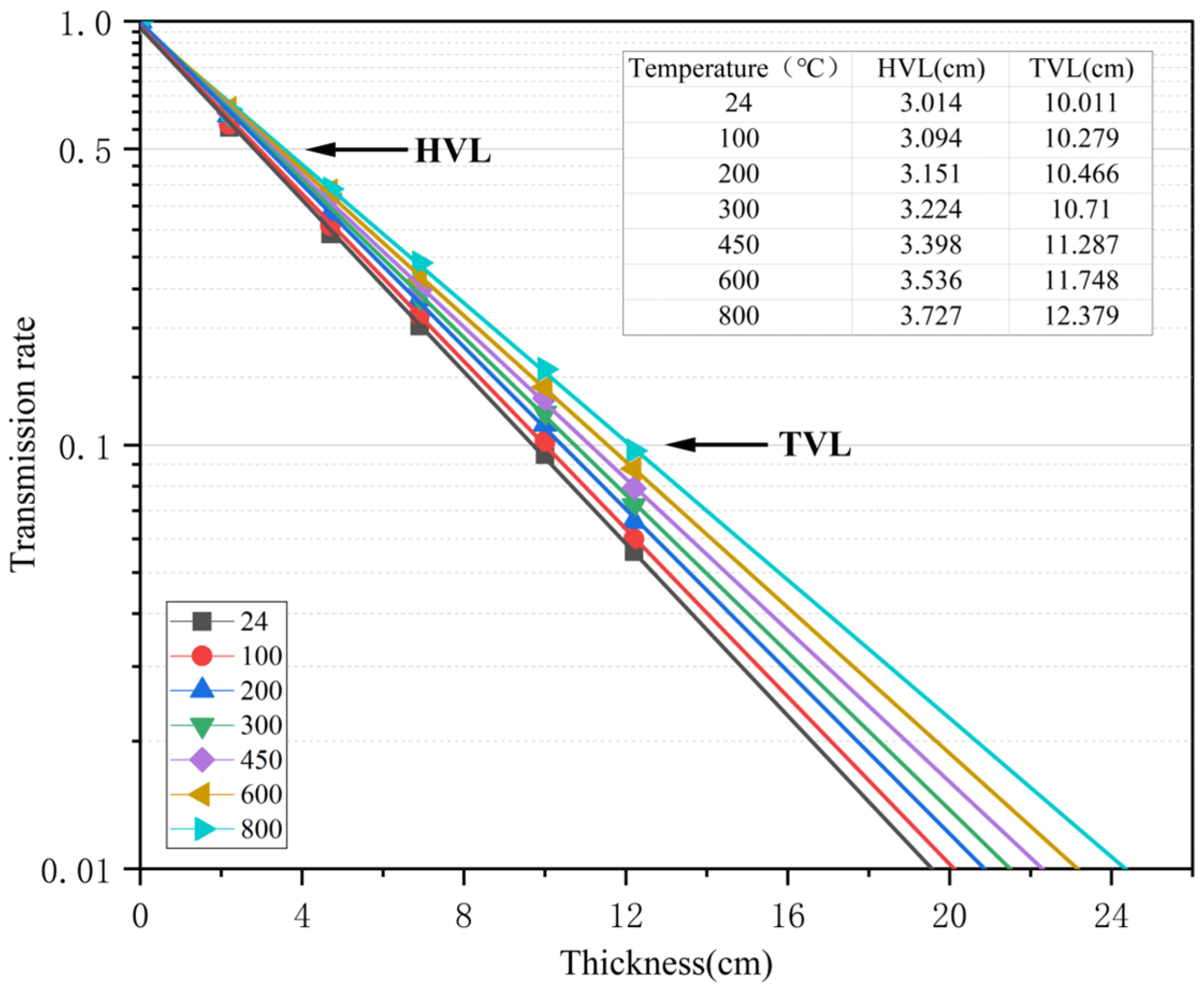

3.5. γ-Ray Shielding Performance

4. Discussion

4.1. Apparent Characteristic Analysis

4.2. Mass Loss Analysis

4.3. Ultrasonic Detection Analysis

4.4. Analysis of Mechanical Properties

4.4.1. Effect of Thermal Gradients on Compressive Strength

4.4.2. Effect of Thermal Gradients on Splitting Tensile Strength

4.5. γ-Ray Shielding Performance

4.6. Correlation Analysis

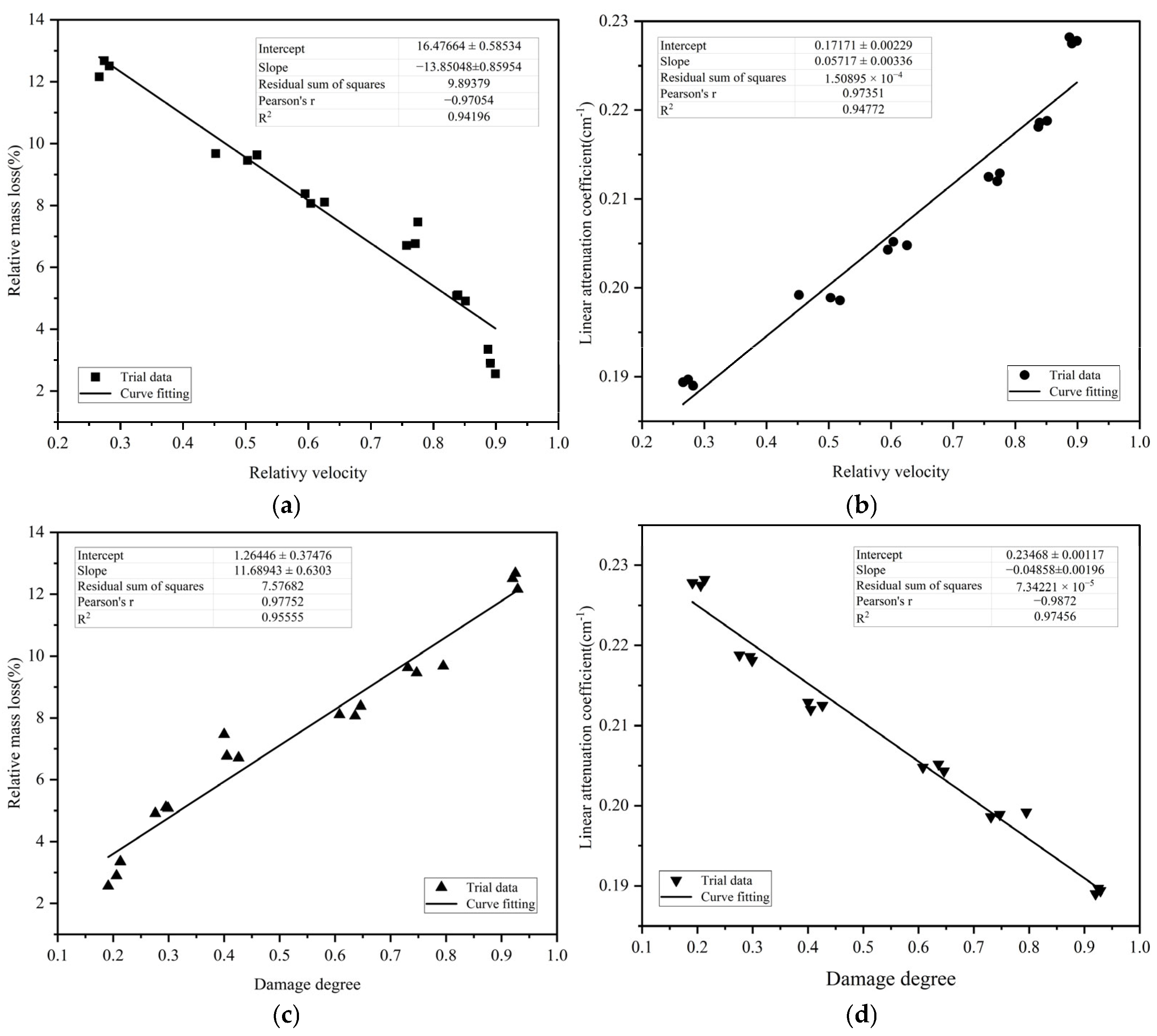

- (1)

- Relationship between relative mass loss and relative wave velocity, as shown in Figure 13a.

- (2)

- Relationship between linear attenuation coefficient and relative wave velocity, as shown in Figure 13b.

- (3)

- Relationship between relative mass loss and damage degree, as shown in Figure 13c.

- (4)

- Relationship between linear attenuation coefficient and damage degree, as shown in Figure 13d.

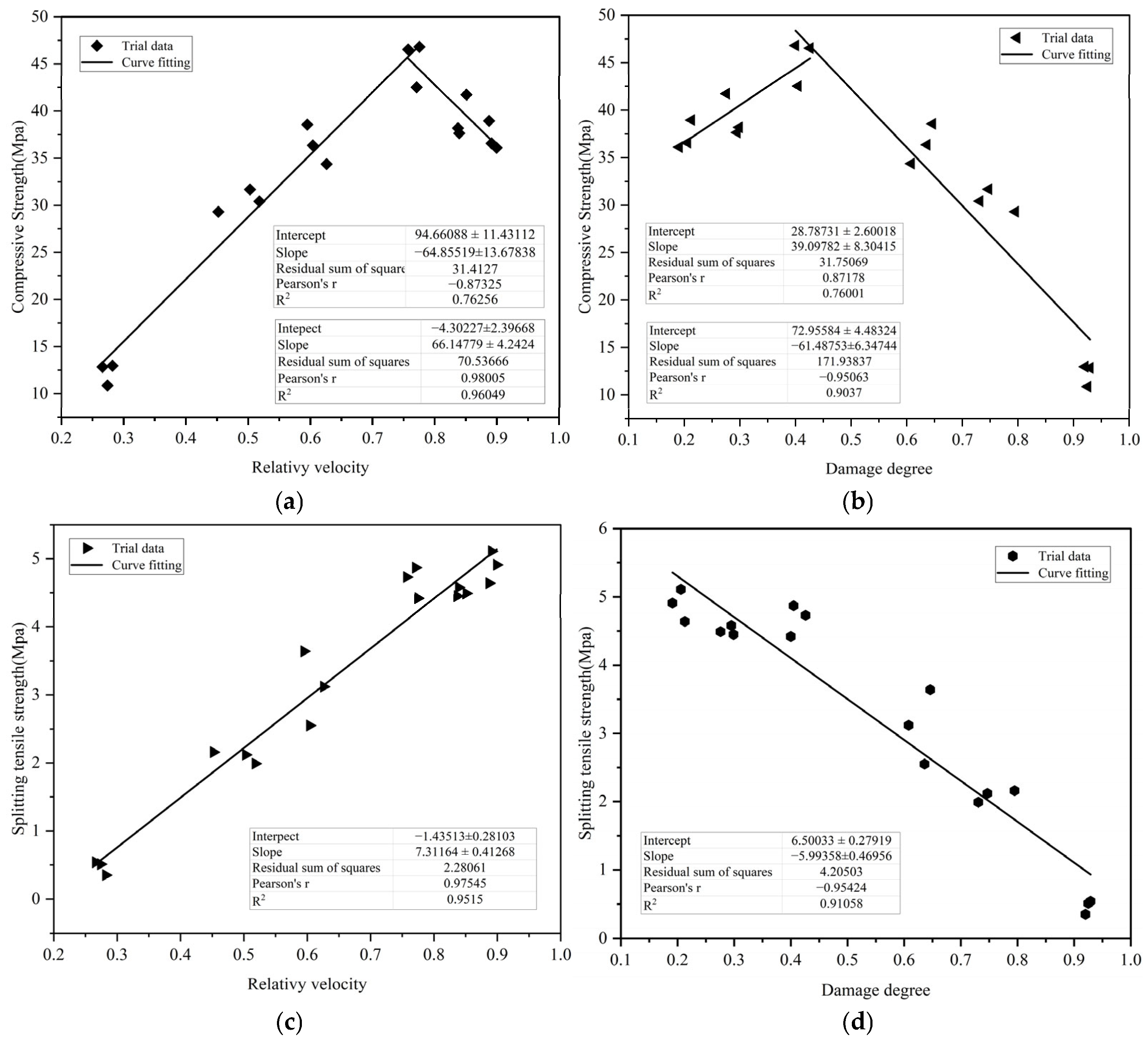

- (1)

- Relationship between compressive strength and relative wave velocity after different temperatures, as shown in Figure 14a.

- (2)

- Relationship between compressive strength and damage degree after different temperatures, as shown in Figure 14b.

- (3)

- Relationship between splitting tensile strength and relative wave velocity after different temperatures, as shown in Figure 14c.

- (4)

- Relationship between splitting tensile strength and damage degree after different temperatures, as shown in Figure 14d.

5. Conclusions

- (1)

- The mass loss rate of magnetite–serpentine radiation shielding concrete increased with the increase in temperature. In the test temperature range, the mass loss rate of specimens at 600 °C−800 °C was most affected by temperature, as well as penetrating cracks. The mass loss rate of 100 mm specimen reached 12.45% at 800 °C and caused spalling phenomenon.

- (2)

- The compressive strength of magnetite–serpentine radiation-proof concrete was increased by 20.3% when mixed with 30% of granulated blast furnace slag to replace cement after 600 °C, the mechanical property rate of decrease is the fastest, the compressive strength at 800 °C was 12.22 MPa, and the splitting tensile strength was 0.48 MPa.

- (3)

- The relative wave velocity of magnetite–serpentine radiation shielding concrete is inversely correlated with temperature and distance measurement, while the damage degree is positively correlated. The relative wave velocity of the 100 mm specimen at 800 °C was 0.27 and the damage degree was 0.92.

- (4)

- The thicker the specimen, the stronger the radiation protection ability of magnetite–serpentine radiation shielding concrete. The higher the temperature, the lower the linear attenuation coefficient. The γ-ray shielding ability of 12.2 cm specimen was about 5 times that of 2.2 cm specimen at normal temperatures. At 800 °C, the linear attenuation coefficient of the specimen decreased to 80.1% of that at normal temperatures. The half-layer and ten-layer values at 100 °C, 200 °C, 300 °C, 450 °C, 600 °C, and 800 °C were 102.7%, 104.5%, 107.0%, 112.7%, 117.3%, and 123.7% of those at normal temperatures, respectively.

- (5)

- The damage degree and relative wave velocity have a linear correlation with the relative mass loss, linear attenuation coefficient, compressive strength, and tensile strength, which provide a foundation for the quantitative detection of concrete thermal damage by ultrasonic properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, G.G.; Bi, C.M. Experimental research on the high temperature stability of radiation shielding concrete. Concrete 2011, 8, 48–50. (In Chinese) [Google Scholar]

- Daungwilailuk, T.; Yenchai, C.; Rungjaroenkiti, W.; Pheinsusom, P.; Panwisawas, C.; Pansuk, W. Use of barite concrete for radiation shielding against gamma-rays and neutrons. Constr. Build. Mater. 2022, 326, 126838. [Google Scholar] [CrossRef]

- Khan, M.U.; Ahmad, S.; Naqvi, A.A.; Al-Gahtani, H.J. Shielding performance of heavy-weight ultra-high-performance concrete against nuclear radiation. Prog. Nucl. Energy 2020, 130, 103550. [Google Scholar] [CrossRef]

- Azeez, A.B.; Mohammed, K.S.; Abdullah, M.M.A.B.; Hussin, K.; Sandu, A.V.; Razak, R.A. The Effect of Various Waste Materials’ Contents on the Attenuation Level of Anti-Radiation Shielding Concrete. Materials 2013, 6, 4836–4846. [Google Scholar] [CrossRef]

- Lee, J.; Xi, Y.; Willam, K.; Jung, Y. A multi scale model for modulus of elasticity of concrete at high temperatures. Cem. Concr. Res. 2009, 39, 754–762. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Sikora, P.; Zaporowski, P. Mechanical properties of shielding concrete with magnetite aggregate subjected to high temperature. Procedia Eng. 2015, 108, 39–46. [Google Scholar] [CrossRef]

- Yousef, S.; AlNassar, M.; Naoom, B.; Alhajali, S.; Kharita, M. Heat effect on the shielding and strength properties of some local concretes. Prog. Nucl. Energy 2008, 50, 22–26. [Google Scholar] [CrossRef]

- Han, J.; Xi, Z.; Yu, R.; Guan, J.; Lv, Y.; Li, G. Preparation and Comprehensive Properties of a High-Radiation-Shielding UHPC by Using Magnetite Fine Aggregate. Materials 2022, 15, 978. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Brzozowski, P. Investigation of gamma ray shielding efficiency and physicomechanical performances of heavyweight concrete subjected to high temperature. Constr. Build. Mater. 2019, 195, 574–582. [Google Scholar] [CrossRef]

- Demir, I.; Gümüş, M.; Gökçe, H.S. Gamma ray and neutron shielding characteristics of polypropylene fiber-reinforced heavyweight concrete exposed to high temperatures. Constr. Build. Mater. 2020, 257, 119596. [Google Scholar] [CrossRef]

- Masoud, M.A.; El-Khayatt, A.M.; Kansouh, W.A.; Sakr, K.; Shahien, M.G.; Zayed, A.M. Insights into the effect of the mineralogical composition of serpentine aggregates on the radiation attenuation properties of their concretes. Constr. Build. Mater. 2020, 263, 12141. [Google Scholar] [CrossRef]

- González-Ortega, M.; Segura, I.; Cavalaro, S.; Toralles-Carbonari, B.; Aguado, A.; Andrello, A. Radiological protection and mechanical properties of concretes with EAF steel slags. Constr. Build. Mater. 2014, 51, 432–438. [Google Scholar] [CrossRef]

- Lotfi-Omran, O.; Sadrmomtazi, A.; Nikbin, I.M. The influences of maximum aggregate size and cement content on the mechanical and radiation shielding characteristics of heavyweight concrete. Prog. Nucl. Energy 2020, 121, 103222. [Google Scholar] [CrossRef]

- Mahmoud, M.E.; El-Khatib, A.M.; Badawi, M.S.; Rashad, A.R.; El-Sharkawy, R.M.; Thabet, A.A. Recycled high-density polyethylene plastics added with lead oxide nanoparticles as sustainable radiation shielding materials. J. Clean. Prod. 2018, 176, 276–287. [Google Scholar] [CrossRef]

- Sayyadi, A.; Mohammadi, Y.; Adlparvar, M.R. Mechanical, Durability, and Gamma Ray Shielding Characteristics of Heavyweight Concrete Containing Serpentine Aggregates and Lead Waste Slag. Adv. Civ. Eng. 2023, 2023, 7873637. [Google Scholar] [CrossRef]

- Ouda, A.S. Development of high-performance heavy density concrete using different aggregates for gamma-ray shielding. Prog. Nucl. Energy 2015, 79, 48–55. [Google Scholar] [CrossRef]

- Oto, B.; Yıldız, N.; Akdemir, F.; Kavaz, E. Investigation of gamma radiation shielding properties of various ores. Prog. Nucl. Energy 2015, 85, 391–403. [Google Scholar] [CrossRef]

- Zayed, A.; Masoud, M.; Rashad, A.M.; El-Khayatt, A.; Sakr, K.; Kansouh, W.; Shahien, M. Influence of heavyweight aggregates on the physico-mechanical and radiation attenuation properties of serpentine-based concrete. Constr. Build. Mater. 2020, 260, 120473. [Google Scholar] [CrossRef]

- Łowińska-Kluge, A.; Piszora, P. Effect of gamma irradiation on cement composites observed with XRD and SEM methods in the range of radiation dose 0-1409 MGy. ACTA Phys. Pol. A 2008, 114, 399–411. [Google Scholar] [CrossRef]

- Singh, S.; Singh, K. On the use of green concrete composite as a nuclear radiation shielding material. Prog. Nucl. Energy 2021, 136, 10370. [Google Scholar] [CrossRef]

- Paul, S.P.; Malagavelli, V. Experimental investigation on high volume ground granulated blast furnace slag concrete. IOP Conference Series: Earth Environ. Sci. 2022, 1086, 012044. [Google Scholar] [CrossRef]

- Ayano, T.; Fujii, T. Improvement of concrete properties using granulated blast furnace slag sand. J. Adv. Concr. Technol. 2021, 19, 118–132. [Google Scholar] [CrossRef]

- Shen, D.; Liu, K.; Wen, C.; Shen, Y.; Jiang, G. Early-age cracking resistance of ground granulated blast furnace slag concrete. Constr. Build. Mater. 2019, 222, 278–287. [Google Scholar] [CrossRef]

- Esfahani, S.M.R.A.; Zareei, S.A.; Madhkhan, M.; Ameri, F.; Rashidiani, J.; Taheri, R.A. Mechanical and gamma-ray shielding properties and environmental benefits of concrete incorporating GGBFS and copper slag. J. Build. Eng. 2021, 33, 101615. [Google Scholar] [CrossRef]

- Nojoukambari, T.Y.; Sadrmomtazi, A.; Khoshkbijari, R.K. Influence of Feldspar and Ground Granulated Blast-furnace slag as a partial cement replacement on mechanical properties and thermal durability and environmental impacts of cement mortars. J. Clean. Prod. 2023, 398, 136074. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, I.; Iqbal, M.; Abbas, A.; Khan, K.; Faraz, M.I.; Alabdullah, A.A.; Ullah, S. Computational AI models for investigating the radiation shielding potential of high-density concrete. Materials 2022, 15, 4573. [Google Scholar] [CrossRef]

- El-Samrah, M.G.; Abdel-Rahman, M.A.; El Shazly, R. Effect of heating on physical, mechanical, and nuclear radiation shielding properties of modified concrete mixes. Radiat. Phys. Chem. 2018, 153, 104–110. [Google Scholar] [CrossRef]

- GB 175-2020; Common Portland Cement. Standards Press of China: Beijing, China, 2020.

- GB/T 34008-2017; Radiation Shielding Concrete. Standards Press of China: Beijing, China, 2017.

- GB/T 50081-2019; Standard of Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Guangming Daily Publishing House: Beijing, China, 2010.

- CECS 21: 2000; Technical Specification for Inspection of Concrete Defects by Ultrasonic Method. China City Press: Beijing, China, 2000.

- Thomas, C.; Rico, J.; Tamayo, P.; Ballester, F.; Setién, J.; Polanco, J. Effect of elevated temperature on the mechanical properties and microstructure of heavy-weight magnetite concrete with steel fibers. Cem. Concr. Compos. 2019, 103, 80–88. [Google Scholar] [CrossRef]

- Xing, Z.; Hébert, R.; Beaucour, A.-L.; Ledésert, B.; Noumowé, A. Influence of chemical and mineralogical composition of concrete aggregates on their behaviour at elevated temperature. Mater. Struct. 2024, 47, 1921–1940. [Google Scholar] [CrossRef]

- Ali, S.I.A.; Lublóy, E. Effect of elevated temperature on the magnetite and quartz concrete at different W/C ratios as nuclear shielding concretes. Nucl. Mater. Energy 2022, 33, 101234. [Google Scholar] [CrossRef]

- Suha, I.A.A.; Éva, L. Fire resistance properties of heavyweight magnetite concrete in comparison with normal basalt-and quartz-based concrete. J. Therm. Anal. Calorim. 2022, 147, 11679–11691. [Google Scholar]

- Bentz, D.P.; Ardani, A.; Barrett, T.; Jones, S.Z.; Lootens, D.; Peltz, M.A.; Sato, T.; Stutzman, P.E.; Tanesi, J.; Weiss, W.J. Multi-scale investigation of the performance of limestone in concrete. Constr. Build. Mater. 2015, 75, 1–10. [Google Scholar] [CrossRef]

- Villain, G.; Thiery, M.; Platret, G. Measurement methods of carbonation profiles in concrete: Thermogravimetry, chemical analysis and gammadensimetry. Cem. Concr. Res. 2007, 37, 1182–1192. [Google Scholar] [CrossRef]

- Xing, Z.; Beaucour, A.-L.; Hebert, R.; Noumowe, A.; Ledesert, B. Influence of the nature of aggregates on the behaviour of concrete subjected to elevated temperature. Cem. Concr. Res. 2011, 41, 392–402. [Google Scholar] [CrossRef]

- Alwaeli, M. Investigation of gamma radiation shielding and compressive strength properties of concrete containing scale and granulated lead-zinc slag wastes. J. Clean. Prod. 2017, 166, 157–162. [Google Scholar] [CrossRef]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Cem. Concr. Res. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Zeng, L.; Zhu, H.; Yan, Z.; Yao, J. Application of ultrasonic in evaluating fire-resistant performance of fiber reinforced concrete. China Build. Mater. Sci. Technol. 2006, 2, 18–22. (In Chinese) [Google Scholar]

- Choi, Y.; Kang, J.-W.; Hwang, T.-Y.; Cho, C.-G. Evaluation of residual strength with ultrasonic pulse velocity relationship for concrete exposed to high temperatures. Adv. Mech. Eng. 2021, 13, 168781402110349. [Google Scholar] [CrossRef]

- Luo, L.; Chen, Z.; Tao, Q.; Xie, L.; Jin, D.; Li, Z.; Deng, D. Effects of high temperatures on the splitting tensile strength and gamma ray shielding performance of radiation shielding concrete. Constr. Build. Mater. 2022, 343, 127953. [Google Scholar] [CrossRef]

- Liu, C.; Chen, Z.; Wu, D.; Tao, Q.; Xie, L. Experimental study on mechanical properties of steel fiber barite concrete after high temperature. New Build. Mater. 2023, 50, 11–16. (In Chinese) [Google Scholar]

- Wang, L.; Du, H.; Liu, X.; Shi, L. Effect of high temperature on compressive strength and ultrasonic wave velocity of C80HPC. Fire Sci. Technol. 2020, 39, 328–330. (In Chinese) [Google Scholar]

- Ahmad, J.; Kontoleon, K.J.; Majdi, A.; Naqash, M.T.; Deifalla, A.F.; Ben Kahla, N.; Isleem, H.F.; Qaidi, S.M.A. A comprehensive review on the ground granulated blast furnace slag (GGBS) in concrete production. Sustainability 2022, 14, 8783. [Google Scholar] [CrossRef]

- Qu, Z.; Liu, Z.; Si, R.; Zhang, Y. Effect of Various Fly Ash and Ground Granulated Blast Furnace Slag Content on Concrete Properties: Experimentsand Modelling. Materials 2022, 15, 3016. [Google Scholar] [CrossRef]

- Zhang, S.; Niu, D.; Wang, Y.; Tian, W.; Luo, D.; Zhang, L. Insight into mechanical properties and microstructure of concrete containing steel slag and ground-granulated blast-furnace slag. J. Sustain. Cem.-Based Mater. 2023, 12, 1169–1180. [Google Scholar] [CrossRef]

- Siddique, R.; Kaur, D. Properties of concrete containing ground granulated blast furnace slag (GGBFS) at elevated temperatures. J. Adv. Res. 2012, 3, 45–51. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, L.; Ma, Y.; Bao, C. Experimental study on mechanical properties of fly ash fine aggregate concrete after high temperature. J. Ningxia Univ. (Nat. Sci. Ed.) 2022, 43, 56–61. (In Chinese) [Google Scholar]

- Liu, Y.; Tao, J. Study on the splitting tensile properties of steel fiber ceramic aggregate concrete at high temperature. China Concr. Cem. Prod. 2023, 3, 51–55. (In Chinese) [Google Scholar]

- Yang, S.; Zhang, L.; Xu, Z. Effect of high temperature on residual splitting strength of desert sand concrete. Struct. Concr. 2023, 24, 3208–3219. [Google Scholar] [CrossRef]

- Yastrebinskii, R.N.; Bondarenko, G.G.; Pavlenko, V.I. Radiation Hardening of Constructional Cement–Magnetite–Serpentinite Composite under Gamma Irradiation at Increased Dose. Inorg. Mater. Appl. Res. 2017, 8, 691–695. [Google Scholar] [CrossRef]

- Mahmoud, K.; Tashlykov, O.; El Wakil, A.; El Aassy, I. Aggregates grain size and press rate dependence of the shielding parameters for some concretes. Prog. Nucl. Energy 2020, 118, 103092. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Almousa, N.; Elsafi, M. Green Conversion of the Hazardous Cathode Ray Tube and Red Mud into Radiation Shielding Concrete. Materials 2022, 15, 5316. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.-M.; Lee, Y.H.; Lee, K.J. Cracking effect on gamma-ray shielding performance in concrete structure. Prog. Nucl. Energy 2007, 49, 303–312. [Google Scholar] [CrossRef]

| Oxides | Chemical Composition(wt%) | |||

|---|---|---|---|---|

| Cement | GBFS | Magnetite | Serpentine | |

| Na2O | 0.24 | - | 0.41 | - |

| MgO | 1.77 | 6.01 | 9.62 | 51.5 |

| Al2O3 | 7.53 | 17.7 | 12.99 | 1.26 |

| SiO2 | 23.73 | 34.5 | 17.19 | 37.42 |

| P2O5 | - | - | 0.41 | 0.04 |

| SO3 | 3.87 | 1.64 | 0.83 | 0.06 |

| K2O | 1.31 | - | 0.42 | 0.14 |

| CaO | 56.45 | 34.0 | 2.86 | 0.65 |

| TiO2 | - | - | 9.96 | - |

| Cr2O3 | - | - | 0.84 | 0.31 |

| Fe2O3 | 4.16 | 1.03 | 43.78 | 8.01 |

| LOI | 0.94 | 5.12 | 0.69 | 0.61 |

| Specific Surface Area (m2/kg) | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | 3d | 28d | 3d | 28d | |

| 333 | 212 | 268 | 28.4 | 52.0 | 5.4 | 8.4 |

| Material Type | Apparent Density (kg/m3) | Crush Value index (%) | Absorption (%) | Moisture Content (%) |

|---|---|---|---|---|

| Magnetite | 4400 | 0.35 | 0.2 | 0.1 |

| Serpentine | 2520 | - | 7.1 | 0.7 |

| Concrete Code | GBFS (%) | 7d (MPa) | 28d (MPa) |

|---|---|---|---|

| MS0 | 0 | 24.4 | 34.9 |

| MS1 | 10 | 26.5 | 37.1 |

| MS2 | 20 | 27.0 | 38.9 |

| MS3 | 30 | 29.2 | 42.0 |

| MS4 | 40 | 26.8 | 37.6 |

| Impact Factors | Code | Standardized Value | Starting Value | ||||

|---|---|---|---|---|---|---|---|

| Low | Medium | High | Low | Medium | High | ||

| Water-binder ratio | A | −1 | 0 | 1 | 0.4 | 0.45 | 0.5 |

| Sand ratio | B | −1 | 0 | 1 | 0.29 | 0.325 | 0.36 |

| Water consumption | C | −1 | 0 | 1 | 220 | 235 | 250 |

| Concrete Type | W/B | Mix Proportion (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|---|

| Cement | Magnetite | Serpentinite | GBFS | Water | Water-Reducing Agent | Defoaming Agent | ||

| MF | 0.4 | 403 | 1409 | 641 | 173 | 230 | 1.7 | 8.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Liu, Z.; Chen, Z.; Wu, Q.; Tao, Q. Effect of Elevated Temperature on Mechanical Properties and Shielding Performance of Magnetite–Serpentine Radiation-Proof Concrete. Materials 2025, 18, 2686. https://doi.org/10.3390/ma18122686

Wu D, Liu Z, Chen Z, Wu Q, Tao Q. Effect of Elevated Temperature on Mechanical Properties and Shielding Performance of Magnetite–Serpentine Radiation-Proof Concrete. Materials. 2025; 18(12):2686. https://doi.org/10.3390/ma18122686

Chicago/Turabian StyleWu, Dan, Zehua Liu, Zhenfu Chen, Qiongfang Wu, and Qiuwang Tao. 2025. "Effect of Elevated Temperature on Mechanical Properties and Shielding Performance of Magnetite–Serpentine Radiation-Proof Concrete" Materials 18, no. 12: 2686. https://doi.org/10.3390/ma18122686

APA StyleWu, D., Liu, Z., Chen, Z., Wu, Q., & Tao, Q. (2025). Effect of Elevated Temperature on Mechanical Properties and Shielding Performance of Magnetite–Serpentine Radiation-Proof Concrete. Materials, 18(12), 2686. https://doi.org/10.3390/ma18122686