Comparative LCA Analysis of Selected Recycling Methods for Carbon Fibers and Socio-Economic Analysis

Abstract

1. Introduction

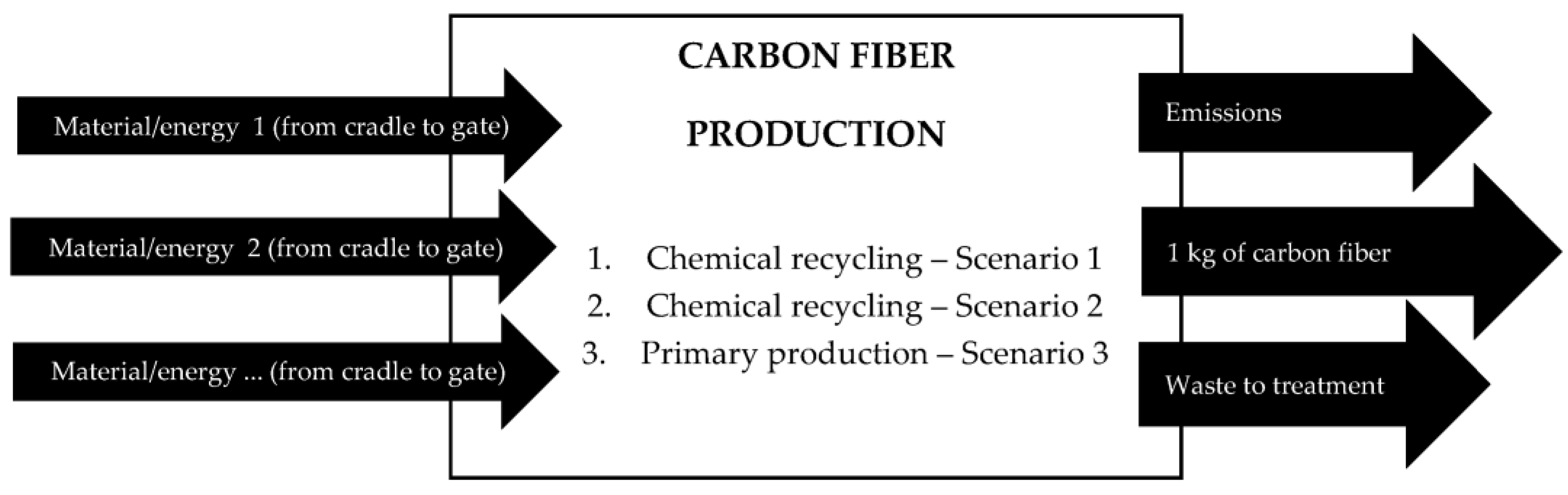

2. Materials and Methods

2.1. Goal and Scope Definition

- To evaluate the potential environmental impact and identify key drivers for the developed recycling processes (Scenario 1 and 2);

- To compare the recycling of the secondary carbon fiber with the primary production.

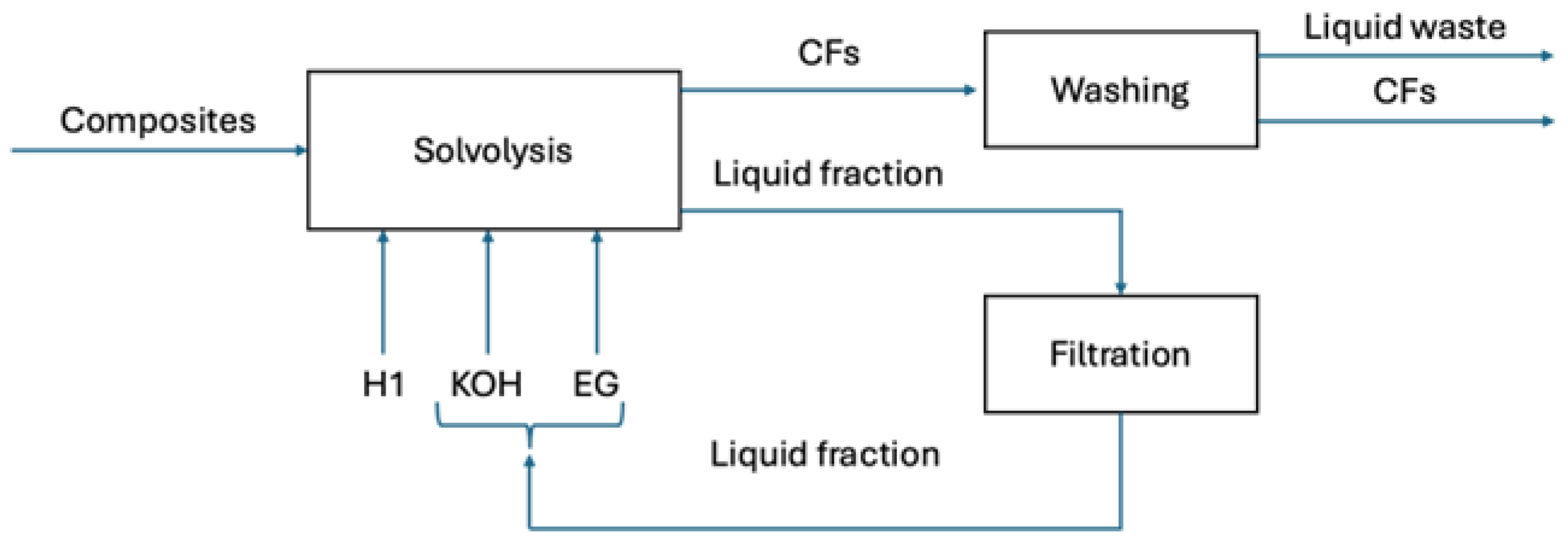

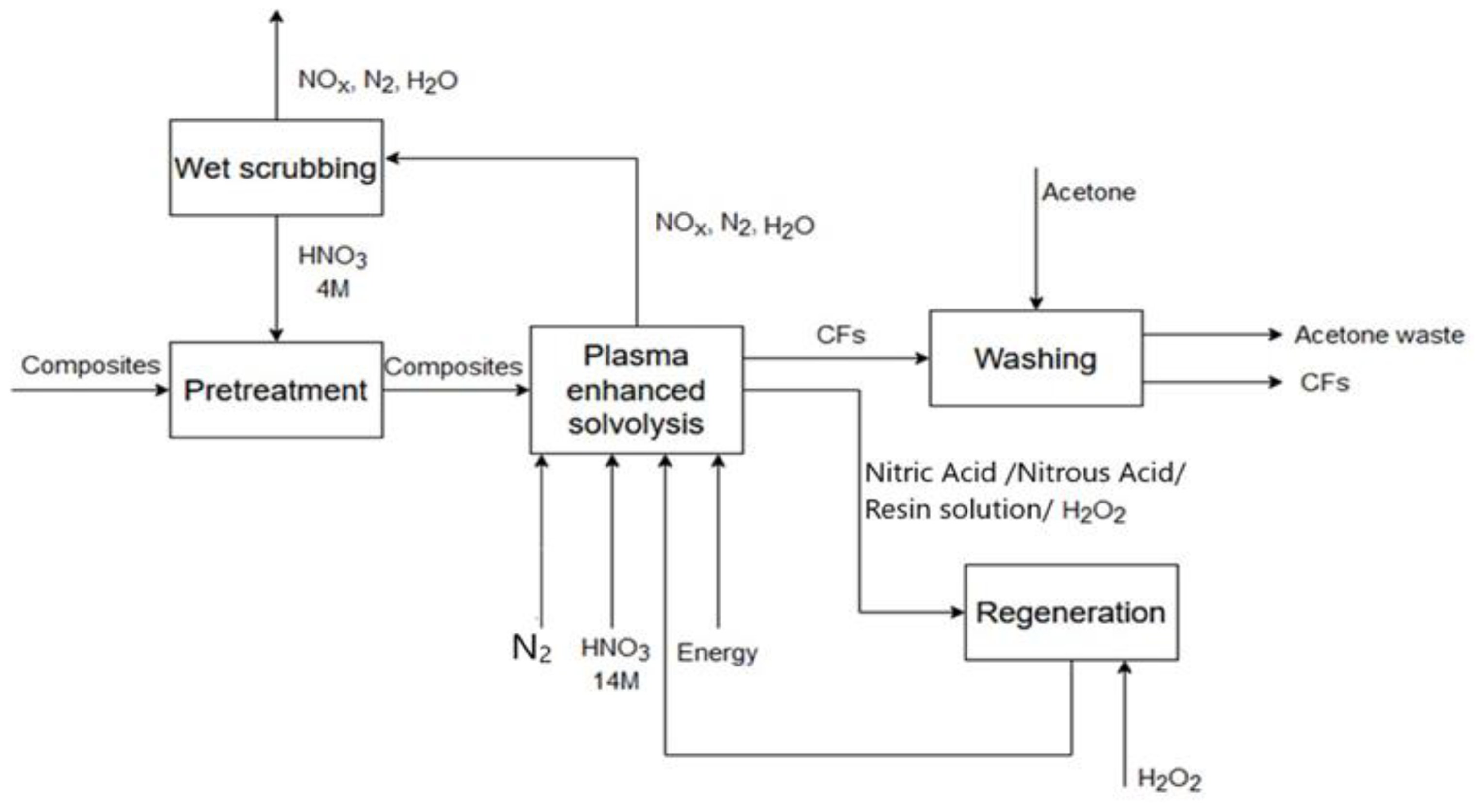

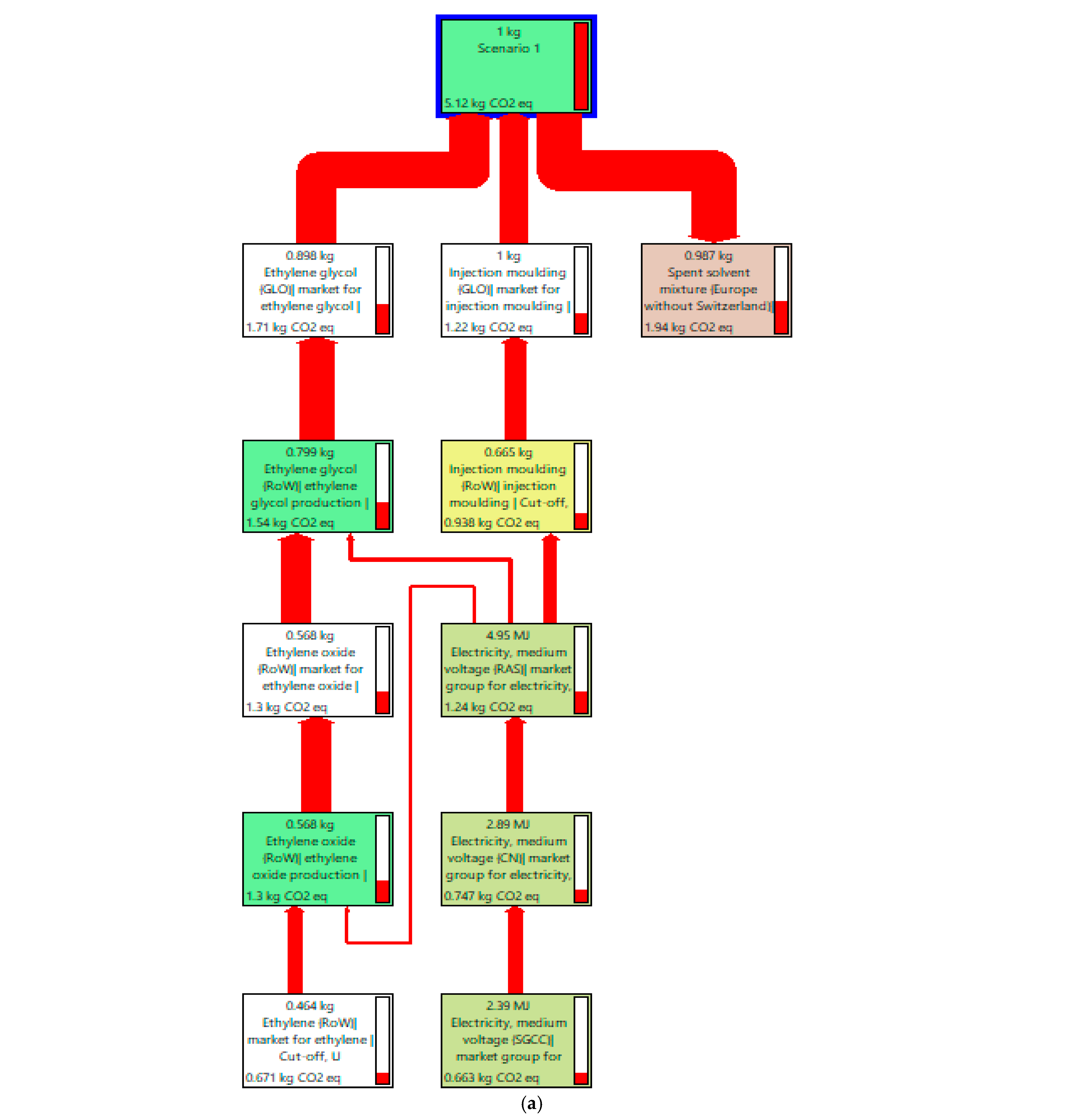

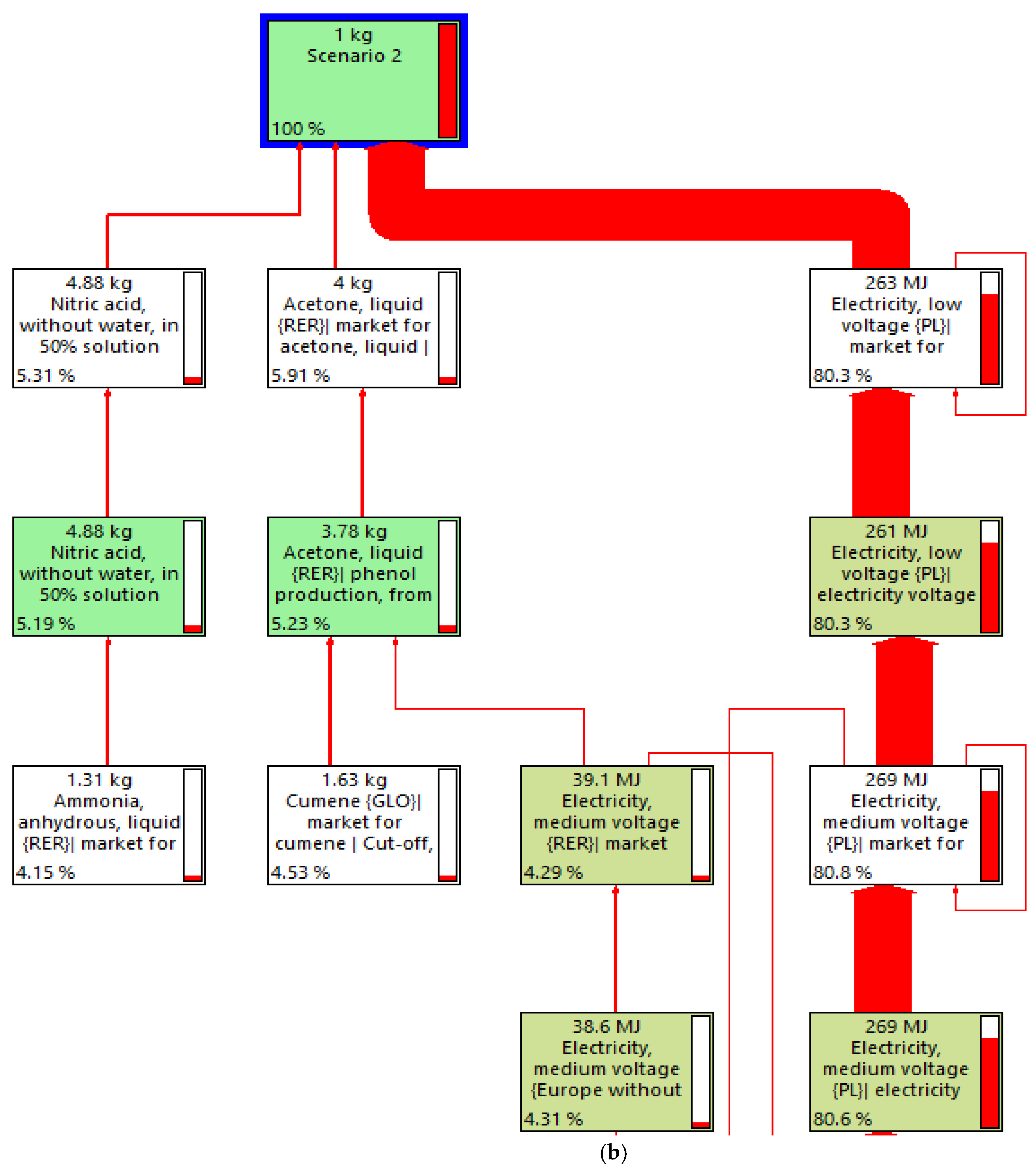

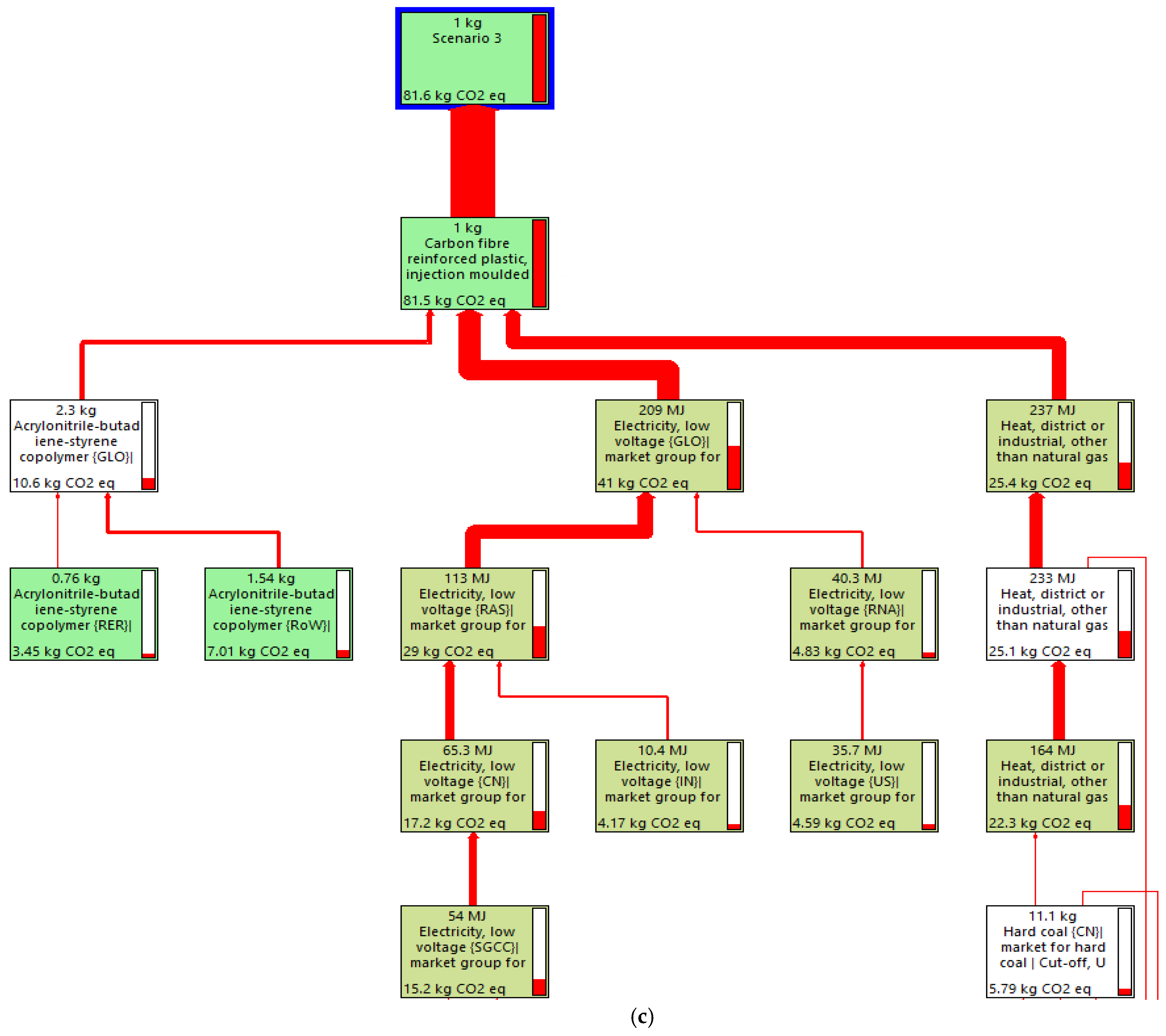

2.2. Life Cycle Inventory (LCI)

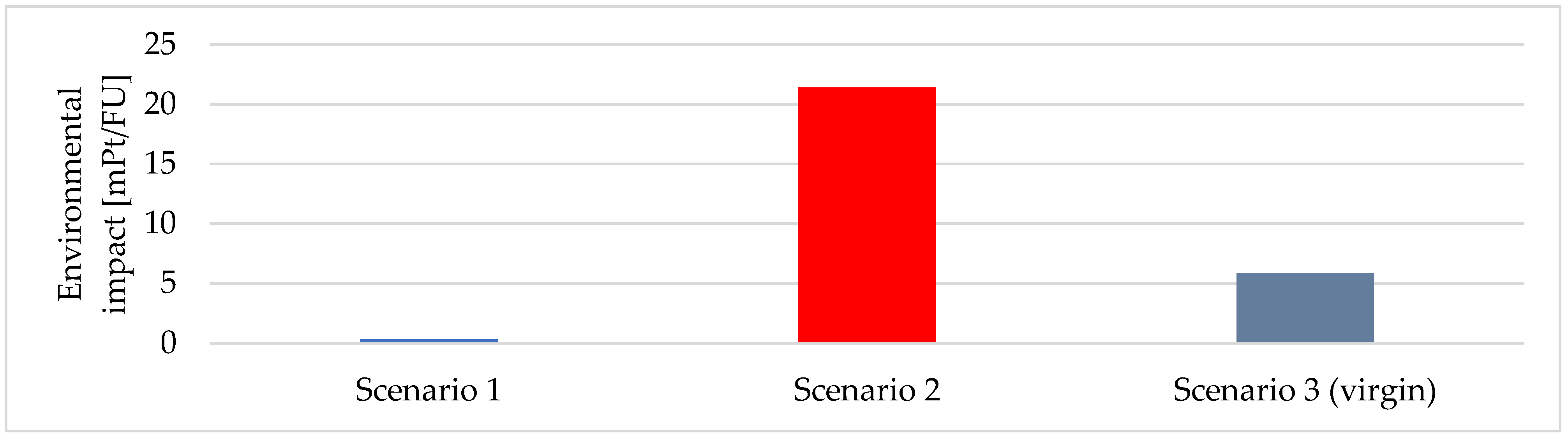

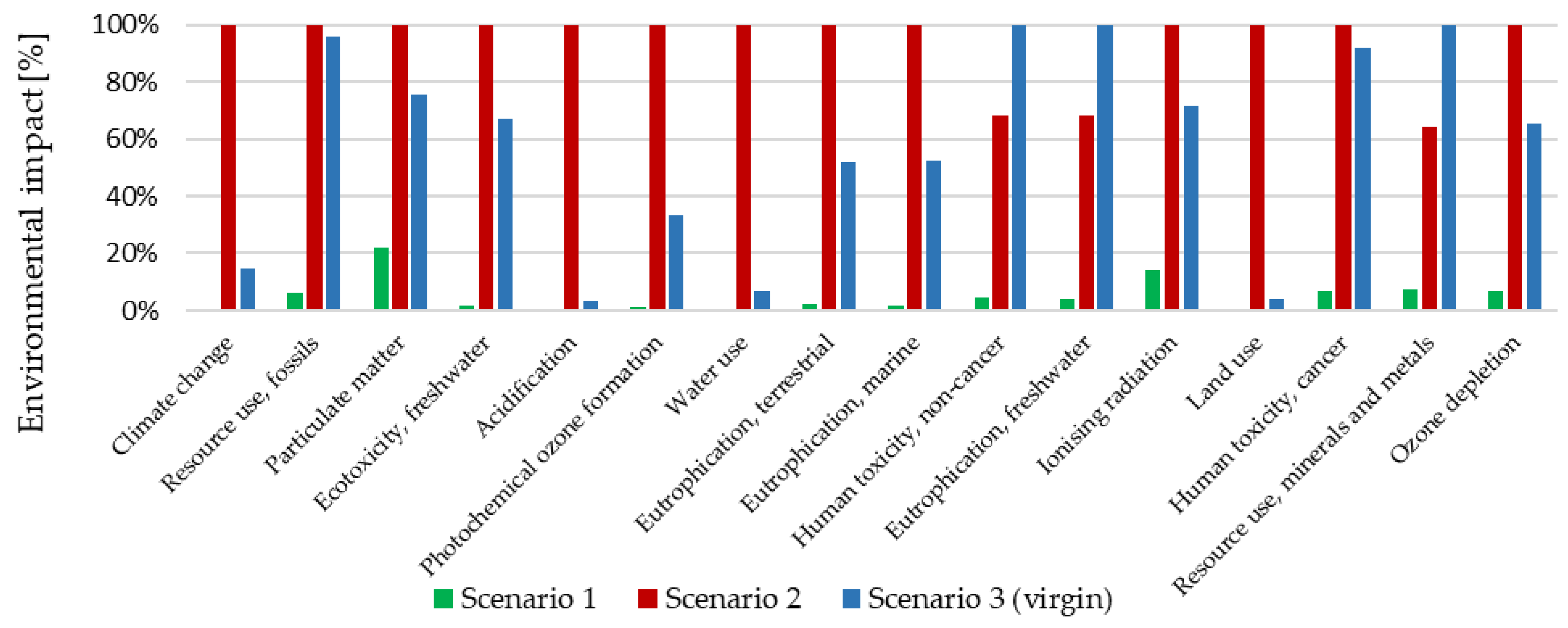

2.3. Life Cycle Impact Assessment (LCIA)

3. Results

4. Socio-Economic Analysis

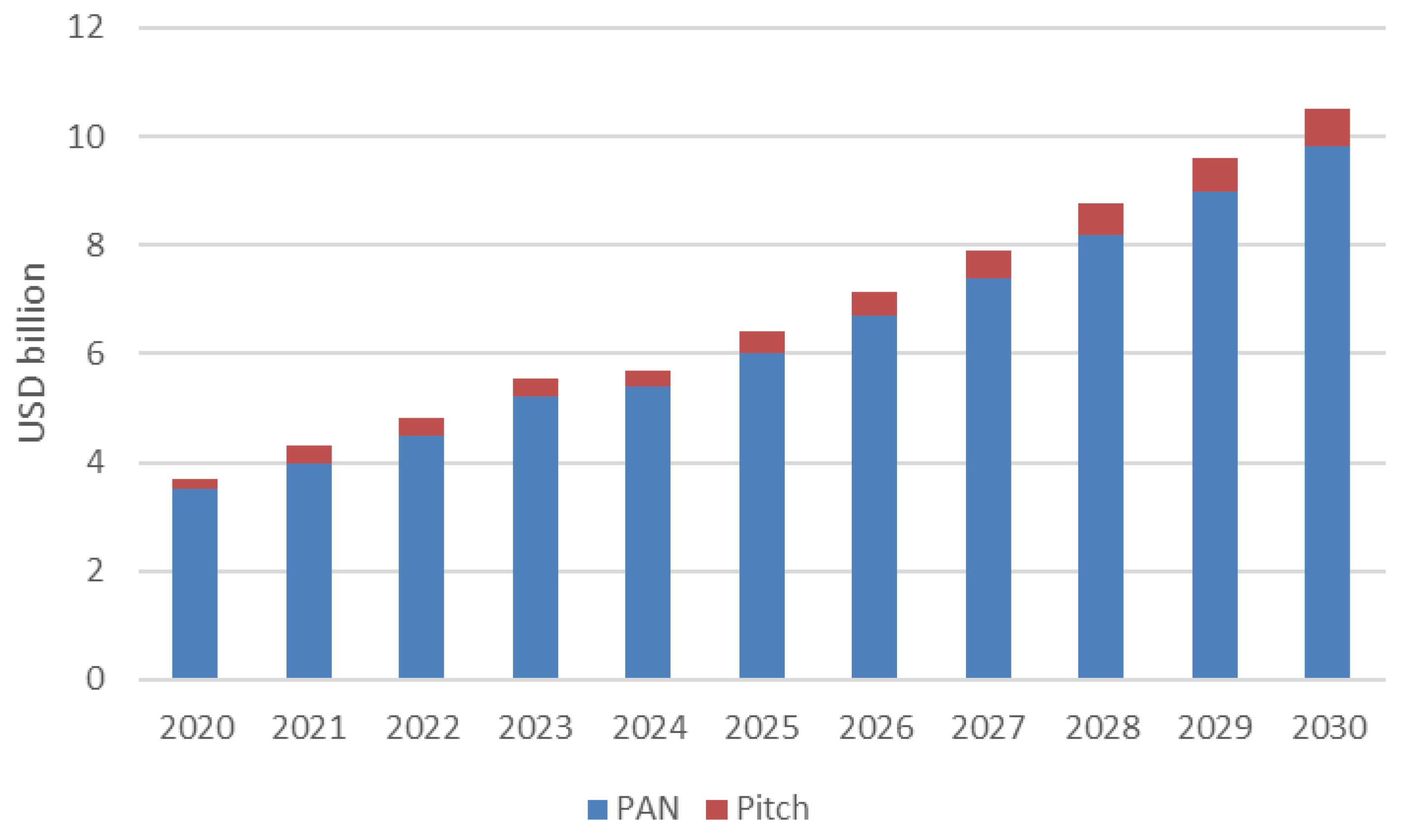

Carbon Fiber Market

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alwaeli, M.; Gołaszewski, J.; Pizoń, J.; Andrzejewska, A.; Szwan, P.; Ceglarz, K.; Buchta, W.; Jachnik, T.; Złotoś, J. Weryfikacja przydatności kruszywa produkowanego z odpadów hutniczych do produkcji betonu wraz z analizą LCA (ang. Verification of the suitability of aggregate produced from metallurgical waste for concrete production, including LCA analysis). PM News 2019, 19, 28. (In Polish) [Google Scholar]

- Towards the Circular Economy Vol. 1: An Economic and Business Rationale for an Accelerated Transition. The Ellen MacArthur Foundation’s Report. 2013, pp. 1–98. Available online: https://www.ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an (accessed on 12 November 2024).

- Completing the Picture: How the Circular Economy Tackles Climate Change. The Ellen MacArthur Foundation. Available online: https://www.ellenmacarthurfoundation.org/completing-the-picture (accessed on 19 November 2024).

- Carbon Fiber Market Projected to Grow Significantly as Increasing Demand for Growing Number of Industries Rises. GlobeNewswire. Available online: https://www.globenewswire.com/news-release/2025/01/14/3009365/0/en/Carbon-Fiber-Market-Projected-to-Grow-Significantly-as-Increasing-Demand-for-Growing-Number-of-Industries-Rises.html (accessed on 7 February 2025).

- Carbon Fiber Market Worth $23.2 Billion by 2033—Exclusive Report. Marketsand Markets. Available online: https://www.prnewswire.com/news-releases/carbon-fiber-market-worth-23-2-billion-by-2033--exclusive-report-by-marketsandmarkets-302036673.html (accessed on 7 February 2025).

- Carbon Fiber Market Size & Forecast [Latest]. Marketsand Markets. Available online: https://www.marketsandmarkets.com/Market-Reports/carbon-fiber-396.html (accessed on 7 February 2025).

- Carbon Fiber Market Size & Trends. Grandviewresearch. Available online: https://www.grandviewresearch.com/industry-analysis/carbon-fiber-market-analysis (accessed on 7 February 2025).

- Tamez, M.B.A.; Taha, I. A Review of Additive Manufacturing Technologies and Markets for Thermosetting Resins and Their Potential for Carbon Fiber Integration. Addit. Manuf. 2021, 37, 101748. [Google Scholar] [CrossRef]

- Zhu, X.; Li, W. Takagi–Sugeno Fuzzy Model Based Shaft Torque Estimation for Integrated Motor–Transmission System. ISA Trans. 2019, 93, 14–22. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; He, L.; Yang, Y.; Wu, C.; Li, X.; Hedrick, J.K. Estimation of Torque Transmitted by Clutch during Shifting Process for Dry Dual Clutch Transmission. Mech. Syst. Signal Process. 2016, 75, 413–433. [Google Scholar] [CrossRef]

- Ursache, Ș.; Cerbu, C.; Hadăr, A. Characteristics of Carbon and Kevlar Fibres, Their Composites and Structural Applications in Civil Engineering—A Review. Polymers 2024, 16, 127. [Google Scholar] [CrossRef]

- Agarwal, N.; Rangamani, A.; Bhavsar, K.; Virnodkar, S.S.; Fernandes, A.A.A.; Chadha, U.; Srivastava, D.; Patterson, A.E.; Rajasekharan, V. An Overview of Carbon-Carbon Composite Materials and Their Applications. Front. Mater. 2024, 11, 1374034. [Google Scholar] [CrossRef]

- Wang, B.; Ma, S.; Yan, S.; Zhu, J. Readily recyclable carbon fiber reinforced composites based on degradable thermosets: A review. Green Chem. 2019, 21, 5781–5796. [Google Scholar] [CrossRef]

- Borjan, D.; Knez, Ž.; Knez, M. Recycling of Carbon Fiber-Reinforced Composites—Difficulties and Future Perspectives. Materials 2021, 14, 4191. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades. Compos. Part B-Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Jiang, G.; Pickering, S.J.; Walker, G.S. Softening behaviour of epoxy polymers used in carbon fibre reinforced composites during pyrolysis. Polym. Degrad. Stab. 2008, 93, 800–810. [Google Scholar] [CrossRef]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.-A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Carbon Fiber Market Analysis: Industry Market Size, Plant Capacity, Production, Operating Efficiency, Demand & Supply, End-User Industries, Sales Channel, Regional Demand, Foreign Trade, Company Share, Manufacturing Process, 2015–2035. Chemanalyst. Available online: https://www.chemanalyst.com/industry-report/carbon-fiber-market-676 (accessed on 24 May 2025).

- Global Carbon Fibers & Carbon Fiber Reinforced Plastics (CFRP) Market—Products, Applications and Production Capacities. Industry-Experts. Available online: https://industry-experts.com/verticals/chemicals-and-materials/carbon-fibers-and-carbon-fiber-reinforced-plastics-cfrp-a-global-market-overview (accessed on 24 May 2025).

- Meng, F.; Cui, Y.; Pickering, S.; Mckechnie, J. From aviation to aviation: Environmental and financial viability of closed-loop recycling of carbon fibre composite. Compos. Part B Eng. 2020, 200, 108362. [Google Scholar] [CrossRef]

- Mishnaevsky, L. Sustainable End-of-Life Management of Wind Turbine Blades: Overview of Current and Coming Solutions. Materials 2021, 14, 1124. [Google Scholar] [CrossRef]

- Mishnaevsky, J.L. Recycling of wind turbine blades: Recent developments. Curr. Opin. Green Sustain. Chem. 2023, 39, 100746. [Google Scholar] [CrossRef]

- Wajda, A.; Brociek, R.; Pleszczyński, M. Optimization of Energy Recovery from Hazardous Waste in a Waste Incineration Plant with the Use of an Application. Processes 2022, 10, 462. [Google Scholar] [CrossRef]

- Xu, M.; Ji, H.; Wu, Y.; Di, J.; Meng, X.; Jiang, H.; Lu, Q. The Pyrolysis of End-of-Life Wind Turbine Blades under Different Atmospheres and Their Effects on the Recovered Glass Fibers. Compos. Part B Eng. 2023, 251, 110493. [Google Scholar] [CrossRef]

- Ginder, R.; Ozcan, S. Recycling of Commercial E-glass Reinforced Thermoset Composites via Two Temperature Step Pyrolysis to Improve Recovered Fiber Tensile Strength and Failure Strain. Recycling 2019, 4, 24. [Google Scholar] [CrossRef]

- Muzyka, R.; Mumtaz, H.H.; Sobek, S.; Werle, S.; Adamek, J.; Semitekolos, D.; Charitidis, C.A.; Tiriakidou, T.; Sajdak, M. Solvolysis and oxidative liquefaction of the end-of-life composite wastes as an element of the circular economy assumptions. J. Clean. Prod. 2024, 478, 143916. [Google Scholar] [CrossRef]

- Branfoot, C.; Folkvord, H.; Keith, M.; Leeke, G.A. Recovery of Chemical Recyclates from Fibre-Reinforced Composites: A Review of Progress. Polym. Degrad. Stab. 2023, 215, 110447. [Google Scholar] [CrossRef]

- Czajkowski, A.; Wajda, A.; Poranek, N.; Bhadoria, S.; Remiorz, L. Prediction of the Market of End-of-Life Photovoltaic Panels in the Context of Common EU Management System. Energies 2023, 16, 284. [Google Scholar] [CrossRef]

- Bogacka, M.; Iluk, T.; Pikoń, K.; Sciążko, M.; Stec, M.; Czaplicki, A.; Wajda, A. Life Cycle Assessment (LCA) of the Use of Metallurgical Process Gas for Heat and Electricity, Combined with Salt Removal from Discarded Water. Sustainability 2022, 14, 1205. [Google Scholar] [CrossRef]

- Repp, L.; Hekkert, M.; Kirchherr, J. Circular Economy-Induced Global Employment Shifts in Apparel Value Chains: Job Re-duction in Apparel Production Activities, Job Growth in Reuse and Recycling Activities. Resour. Conserv. Recycl. 2021, 171, 105621. [Google Scholar] [CrossRef]

- Lawal, S.O. The Economics of Recycling: A Review Compiled with Tax and Subsidiary, Implication for Government, Decision-Makers, Enterprises, Community, and Analysis Cost/Benefit and Market. ASEAN J. Sci. Eng. Mater. 2024, 3, 141–164. [Google Scholar]

- Lindhal, M.; Ekermann, L. Structure for Categorization of EcoDesign Methods and Tools. In Re-Engineering Manufacturing for Sustainability, Proceedings of the 20th CIRP International Conference on Life Cycle Engineering, Singapore, 17–19 April 2013; Nee, A.Y.C., Song, B., Ong, S.K., Eds.; Springer: Singapore, 2013; pp. 117–122. [Google Scholar] [CrossRef]

- Fiksel, J. Design for Environment. A Guide to Sustainable Product Development, 2nd ed.; McGraw-Hill: New York, NY, USA, 2012; p. 410. [Google Scholar]

- Joachimiak-Lechman, K. LCA in Environmental Management Systems—Results of Individual Interviews with Selected Enterprises from Poland and Sweden. J. Environ. Prot. 2013, 4, 694–700. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Brussels, Belgium, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Brussels, Belgium, 2006.

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; Koning, A.; van de Oers, L.; Sleeswijk, A.W.; Suh, S.; Udo de Haes, H.A.; et al. Handbook on Life Cycle Assessment. Operational Guide to the ISO Standards. III: Scientific Background, 1st ed.; Kluwer Academic Publishers: Dordrech, The Netherlands, 2002; pp. 1–314. [Google Scholar]

- European Commission, Joint Research Centre, Institute for Environment and Sustainability. ILCD International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Detailed Guidance, 1st ed.; Office of the European Union: Luxembourg, 2010; pp. 1–417. Available online: https://eplca.jrc.ec.europa.eu/uploads/ILCD-Handbook-General-guide-for-LCA-DETAILED-GUIDANCE-12March2010-ISBN-fin-v1.0-EN.pdf (accessed on 13 March 2025).

- Marinis, D.; Markatos, D.; Farsari, E.; Amanatides, E.; Mataras, D.; Pantelakis, S. A Novel Plasma-Enhanced Solvolysis as Alternative for Recycling Composites. Polymers 2024, 16, 2836. [Google Scholar] [CrossRef]

- Ekvall, T.; Björklund, A.; Sandin, G.; Jelse, K. Modeling recycling in life cycle Assessment. In Technical Report: Towards Sustainable Waste Management; The Swedish Life Cycle Centre: Gothenburg, Sweden, 2020; pp. 1–138. Available online: https://www.lifecyclecenter.se/wp-content/uploads/2020_05_Modeling-recyling-in-life-cycle-assessment-1.pdf (accessed on 6 December 2023).

- Semitekolos, D.; Terzopoulou, S.; Amanatides, E.; Sajdak, M.; Zecchi, S.; Marinis, D.; Farsari, E.; Sobek, S.; Werle, S.; Tagliaferro, A.; et al. Performance Restoration of Chemically Recycled Carbon Fibres Through Surface Modification with Sizing. Polymers 2025, 17, 33. [Google Scholar] [CrossRef]

- Recommendation 2021/2279/EU Commission Recommendation (EU) of 15 December 2021 on the Use of the Environmental Footprint Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organizations. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32021H2279 (accessed on 13 March 2025).

- Zhang, Z. Recovery and Reuse of Thermosetting Carbon Fibre Reinforced Composites. In Proceedings of the 4th International Conference on Materials Chemistry and Environmental Engineering, London, UK, 13–19 January 2024; Available online: https://www.ewadirect.com/proceedings/ace/article/view/11998/pdf (accessed on 26 May 2025).

- Global Carbon Fiber Capacity to Double by 2030|Carbon Fibers & Carbon Fiber Reinforced Plastics Market Products, Applications and Production Capacities Report 2025. GlobeNewswire. Available online: https://www.globenewswire.com/news-release/2025/05/02/3073125/28124/en/Global-Carbon-Fiber-Capacity-to-Double-by-2030-Carbon-Fibers-Carbon-Fiber-Reinforced-Plastics-Market-Products-Applications-and-Production-Capacities-Report-2025.html (accessed on 26 May 2025).

- Carbon Fiber Composite Materials. Toray. Available online: https://www.toray.com/global/products/carbon-fiber/ (accessed on 24 May 2025).

- Carbon Fiber & Composite Materials. Mitsubishi Chemical Group. Available online: https://www.mcgc.com/english/ (accessed on 24 May 2025).

- Carbon Fiber. Hexcel. Available online: https://www.hexcel.com/Products/Carbon-Fiber/ (accessed on 24 May 2025).

- Overview of our Materials. Sglcarbon. Available online: https://www.sglcarbon.com/en/markets-solutions/material/material-overview/ (accessed on 24 May 2025).

- Inston, D. ELG Carbon Fibre Open House Showcases Recycling Technology. Composites World 2017. Available online: https://www.gen2carbon.com/wp-content/uploads/2021/07/Composites-World-June-2017.pdf (accessed on 26 May 2025).

| Recycling Method | Description | Key Limitations | Source |

|---|---|---|---|

| Mechanical Recycling | Grinding/shredding CFRP into small particles for fillers or low-grade reuse | Fibers are short and damaged; Loss of mechanical properties; Low-value recycled product | [15] |

| Thermal Recycling | Pyrolysis or fluidized bed to burn off resin and recover fibers | High energy demand; Potential fiber surface degradation; Emission of VOCs without control | [16] |

| Chemical Recycling (Solvolysis) | Use of solvents under heat/pressure to dissolve matrix and recover clean fibers | Complex solvent handling; High process cost and time; Challenges in scaling up and purifying recovered oligomers | [17] |

| Name of Input/Output | Amount | Unit |

|---|---|---|

| Inputs | ||

| Wasted carbon fiber component (B&T Composites) | 1.44 | kg |

| Transport of wasted carbon fiber component, lorry 16–32, Euro 5 (100 km) | 1.44 × 102 | kgkm |

| Solvent (closed looped circulation) | 5.74 | kg |

| Ethylene glycol | 8.97 × 10−1 | kg |

| Potassium Hydroxide | 8.97 × 10−2 | kg |

| Electricity (low voltage, at grid, Poland) | 2.16 | kWh |

| Outputs | ||

| Reclaimed carbon fiber | 1.00 | kg |

| Solvent (closed looped circulation) | 5.74 | kg |

| Liquid waste | 9.87 × 10−1 | kg |

| Name of Input/Output | Amount | Unit |

|---|---|---|

| Inputs | ||

| Wasted carbon fiber component (B&T Composites) | 1.67 | kg |

| Transport of wasted carbon fiber component, lorry 16–32, Euro 5 (100 km) | 1.67 × 102 | kgkm |

| Nitric Acid 65%/H2O2 30% (closed looped circulation) | 2.77 × 101 | kg |

| Nitrogen gas | 1.63 × 101 | kg |

| Acetone | 4.00 | kg |

| Electricity (low voltage, at grid, Poland) | 7.17 × 101 | kWh |

| Outputs | ||

| Reclaimed carbon fiber | 1.00 | kg |

| NOX gasses that enter the wet scrubber | 6.83 | kg |

| NOX gasses that escape the wet scrubber | 5.00 | kg |

| Wet scrubbing solution (HNO3) | 1.83 | kg |

| Nitric Acid/Nitrous Acid/Resin solution/H2O2 (closed looped circulation) | 2.08 × 101 | kg |

| Nitrogen gas | 1.63 × 101 | kg |

| Acetone/resin residuals | 4.00 | kg |

| Impact Category | Scenario 1 | Scenario 2 | Scenario 3 (Virgin) | |||

|---|---|---|---|---|---|---|

| mPt | % | mPt | % | mPt | % | |

| Single Score | 3.31 × 10−1 | 100% | 2.14× 101 | 100% | 5.85 | 100% |

| Climate change | 1.43 × 10−1 | 43% | 2.38 | 11% | 2.27 | 39% |

| Resource use, fossils | 8.77 × 10−2 | 27% | 1.36 | 6% | 1.25 | 21% |

| Particulate matter | 2.09 × 10−2 | 6% | 1.38 | 6% | 9.24 × 10−1 | 16% |

| Ecotoxicity, freshwater | 1.79 × 10−2 | 5% | 8.24 × 10−2 | 0.4% | 6.21 × 10−2 | 1.1% |

| Acidification | 1.58 × 10−2 | 5% | 3.41 | 16% | 5.02 × 10−1 | 9% |

| Photochemical ozone formation | 1.58 × 10−2 | 5% | 6.85 | 32% | 2.71 × 10−1 | 5% |

| Water use | 1.07 × 10−2 | 3% | 1.60 × 10−1 | 0.7% | 1.04 × 10−1 | 2% |

| Eutrophication, terrestrial | 6.50 × 10−3 | 2% | 2.38 | 11% | 1.55 × 10−1 | 3% |

| Eutrophication, marine | 4.20 × 10−3 | 1.3% | 3.04 | 14% | 1.03 × 10−1 | 2% |

| Human toxicity, non-cancer | 2.70 × 10−3 | 0.8% | 1.45 × 10−1 | 0.7% | 7.58 × 10−2 | 1.3% |

| Eutrophication, freshwater | 2.20 × 10−3 | 0.7% | 1.67 × 10−1 | 0.8% | 5.53 × 10−2 | 0.9% |

| Ionizing radiation | 1.30 × 10−3 | 0.4% | 1.96 × 10−2 | 0.1% | 2.86 × 10−2 | 0.5% |

| Land use | 9.00 × 10−4 | 0.3% | 1.45 × 10−2 | 0.1% | 2.13 × 10−2 | 0.4% |

| Human toxicity, cancer | 8.00 × 10−4 | 0.2% | 3.63 × 10−2 | 0.2% | 1.89 × 10−2 | 0.3% |

| Resource use, minerals and metals | 4.00 × 10−4 | 0.1% | 3.60 × 10−3 | 0.02% | 5.60 × 10−3 | 0.1% |

| Ozone depletion | 1.00 × 10−4 | 0.03% | 7.00 × 10−4 | 0.00% | 5.00 × 10−4 | 0.0% |

| Impact Category | Unit | Scenario 1 | Scenario 2 | Scenario 3 (Virgin) |

|---|---|---|---|---|

| Acidification | mol H+ eq | 1.42 × 10−2 | 3.06 | 4.50 × 10−1 |

| Climate change | kg CO2 eq | 5.12 | 8.54 × 101 | 8.16 × 101 |

| Ecotoxicity, freshwater | CTUe | 5.30 × 101 | 2.43 × 102 | 1.83 × 102 |

| Particulate matter | disease inc. | 1.39 × 10−7 | 9.17 × 10−6 | 6.14 × 10−6 |

| Eutrophication, marine | kg N eq | 2.80 × 10−3 | 2.01 | 6.77 × 10−2 |

| Eutrophication, freshwater | kg P eq | 1.00 × 10−4 | 9.60 × 10−3 | 3.20 × 10−3 |

| Eutrophication, terrestrial | mol N eq | 3.08 × 10−2 | 1.14 × 101 | 7.40 × 10−1 |

| Human toxicity, cancer | CTUh | 6.48 × 10−10 | 2.94 × 10−8 | 1.53 × 10−8 |

| Human toxicity, non-cancer | CTUh | 1.89 × 10−8 | 1.01 × 10−6 | 5.30 × 10−7 |

| Ionizing radiation | kBq U-235 eq | 1.13 × 10−1 | 1.65 | 2.41 |

| Land use | Pt | 9.19 | 1.50 × 102 | 2.20 × 102 |

| Ozone depletion | kg CFC11 eq | 8.30 × 10−8 | 5.81 × 10−7 | 4.15 × 10−7 |

| Photochemical ozone formation | kg NMVOC eq | 1.35 × 10−2 | 5.86 | 2.32 × 10−1 |

| Resource use, fossils | MJ | 6.86 × 101 | 1.06 × 103 | 9.76 × 102 |

| Resource use, minerals and metals | kg Sb eq | 3.37 × 10−7 | 3.03 × 10−6 | 4.72 × 10−6 |

| Water use | m3 depriv. | 1.44 | 2.15 × 101 | 1.40 × 101 |

| Category | Impact/Description |

|---|---|

| Job creation | Recycling generates employment in sectors such as collection, processing, and the production of new products from secondary raw materials. |

| Increase in economic competitiveness | The use of secondary raw materials reduces production costs and makes the economy less dependent on the import of primary raw materials. |

| Innovations in recycling technology drive the development of new industrial sectors. | |

| Costs and savings related to recycling | Costs of selective waste collection systems and processing technologies. |

| Savings resulting from a reduced need for waste landfilling and lower costs of extracting natural resources. | |

| Social environmental awareness | Environmental education and changing consumption habits. |

| Social campaigns and local government initiatives promoting waste segregation. | |

| Health benefits | Reduced environmental pollution improves air, water, and soil quality. |

| Lower emissions of harmful substances decrease the incidence of pollution-related diseases. | |

| Impact on quality of life | Recycling promotes a cleaner environment and reduces the number of illegal dumpsites. |

| Increased availability of secondary raw materials supports the development of a circular economy. | |

| Environmental awareness | Increasing environmental awareness influences the formation of more sustainable consumption habits, promotes waste segregation, and encourages responsible resource management. Environmental education and social campaigns inspire people to take everyday actions for environmental protection, such as reducing plastic use, reusing products, or choosing local and eco-friendly goods. Greater awareness makes society more likely to demand systemic change, support pro-environmental initiatives, and pressure companies and institutions to adopt more sustainable strategies. In the long run, this leads to improved quality of life, reduced pollution, and healthier ecosystems, benefiting both people and the planet. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poranek, N.; Pikoń, K.; Generowicz-Caba, N.; Mańka, M.; Kulczycka, J.; Marinis, D.; Farsari, E.; Amanatides, E.; Lewandowska, A.; Sajdak, M.; et al. Comparative LCA Analysis of Selected Recycling Methods for Carbon Fibers and Socio-Economic Analysis. Materials 2025, 18, 2660. https://doi.org/10.3390/ma18112660

Poranek N, Pikoń K, Generowicz-Caba N, Mańka M, Kulczycka J, Marinis D, Farsari E, Amanatides E, Lewandowska A, Sajdak M, et al. Comparative LCA Analysis of Selected Recycling Methods for Carbon Fibers and Socio-Economic Analysis. Materials. 2025; 18(11):2660. https://doi.org/10.3390/ma18112660

Chicago/Turabian StylePoranek, Nikolina, Krzysztof Pikoń, Natalia Generowicz-Caba, Maciej Mańka, Joanna Kulczycka, Dimitrios Marinis, Ergina Farsari, Eleftherios Amanatides, Anna Lewandowska, Marcin Sajdak, and et al. 2025. "Comparative LCA Analysis of Selected Recycling Methods for Carbon Fibers and Socio-Economic Analysis" Materials 18, no. 11: 2660. https://doi.org/10.3390/ma18112660

APA StylePoranek, N., Pikoń, K., Generowicz-Caba, N., Mańka, M., Kulczycka, J., Marinis, D., Farsari, E., Amanatides, E., Lewandowska, A., Sajdak, M., Werle, S., & Sobek, S. (2025). Comparative LCA Analysis of Selected Recycling Methods for Carbon Fibers and Socio-Economic Analysis. Materials, 18(11), 2660. https://doi.org/10.3390/ma18112660