Effects of Process Parameters on Pulsed Laser Micromachining for Glass-Based Microfluidic Devices

Abstract

1. Introduction

2. Background and Methodology

2.1. Materials of Microfluidic Devices

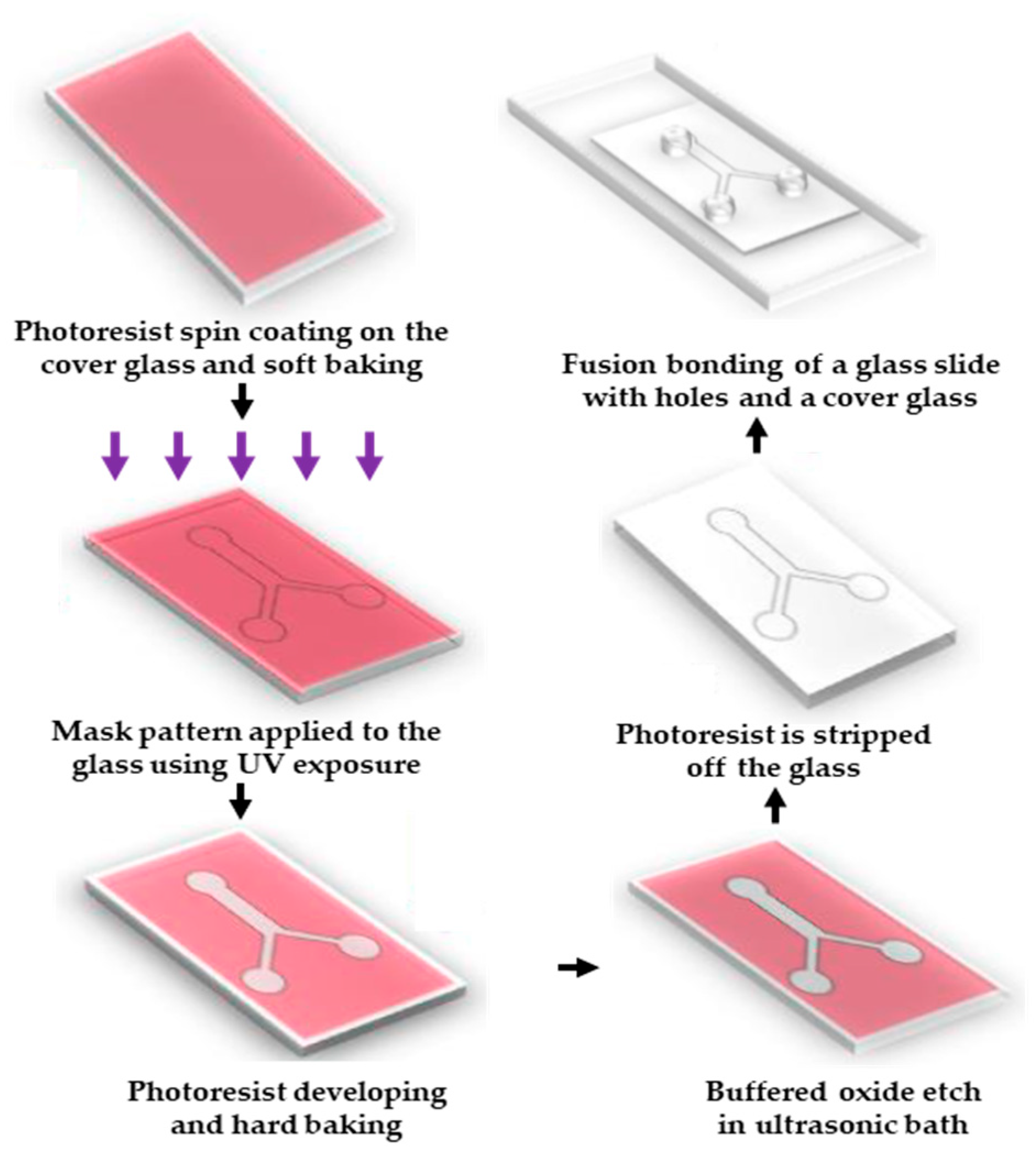

2.2. Fabrication Methods of Glass-Based Microfluidic Devices

2.3. Types of Laser-Based Fabrication Methods for Glass-Based Microfluidics

2.4. Methodology

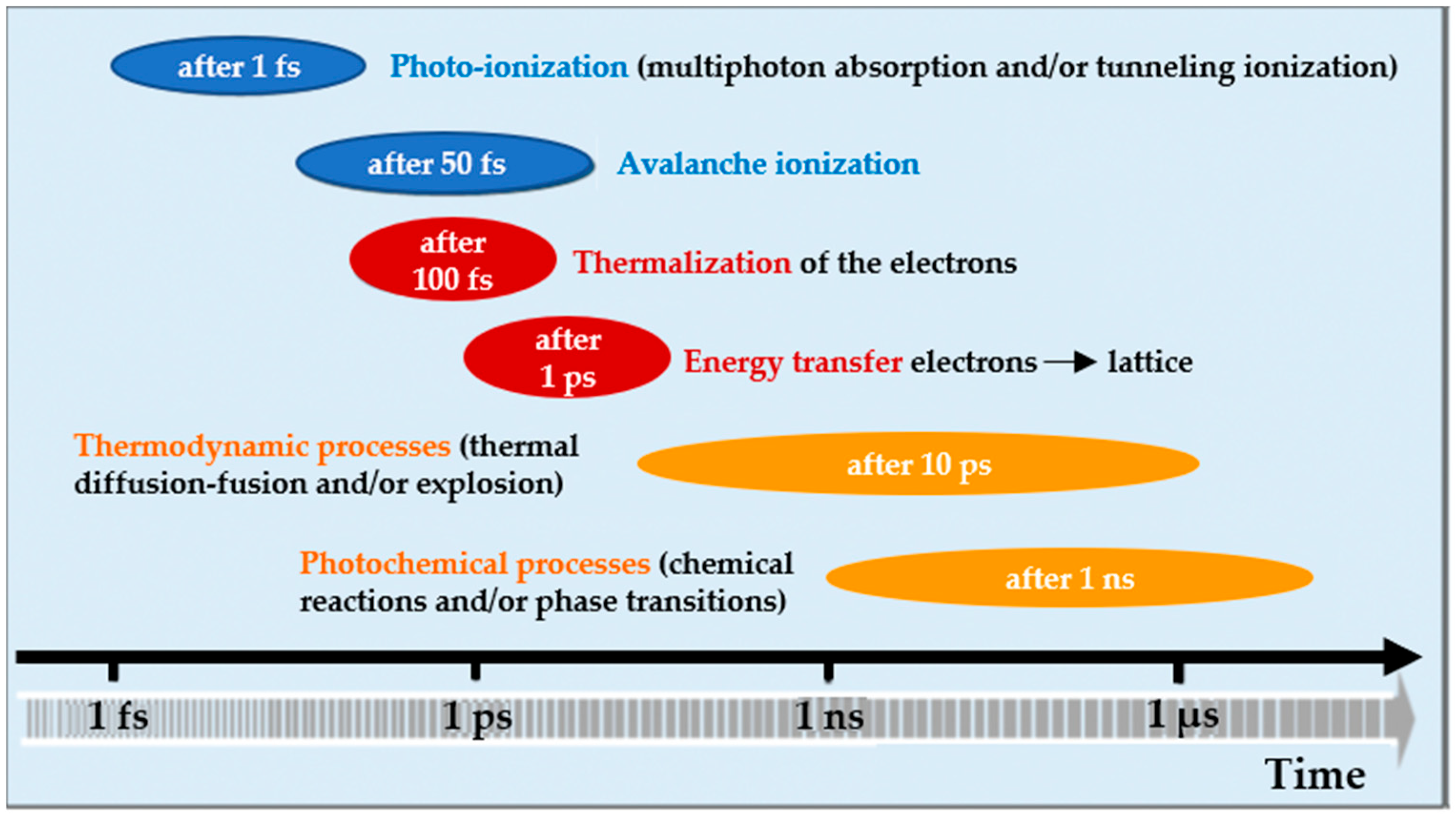

3. Direct Pulsed Laser Processing for Glass Microfabrication

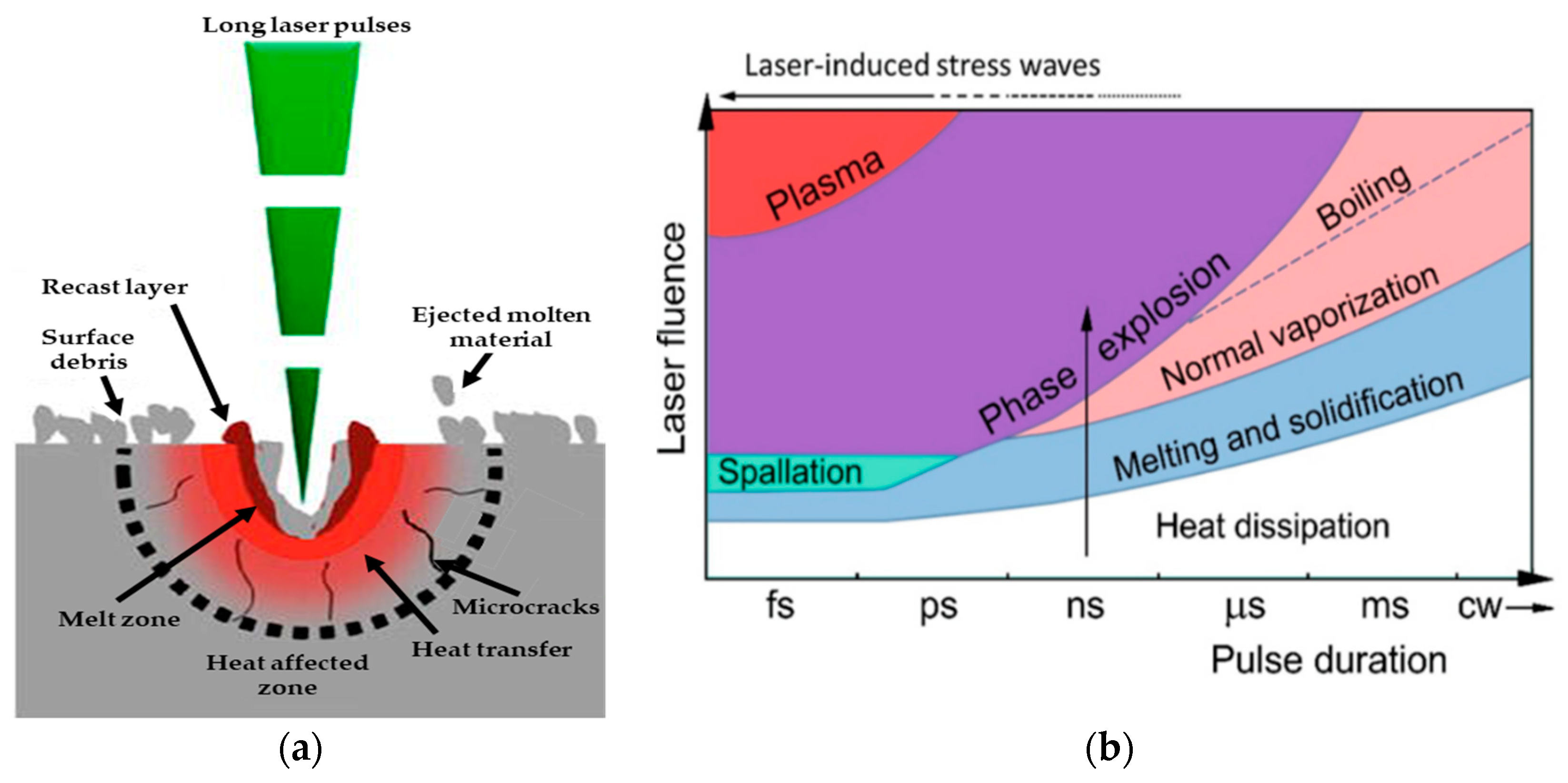

3.1. Long-Pulse Laser Micromachining of Glass

3.1.1. Effects of Laser Fluence in Long-Pulse Micromachining

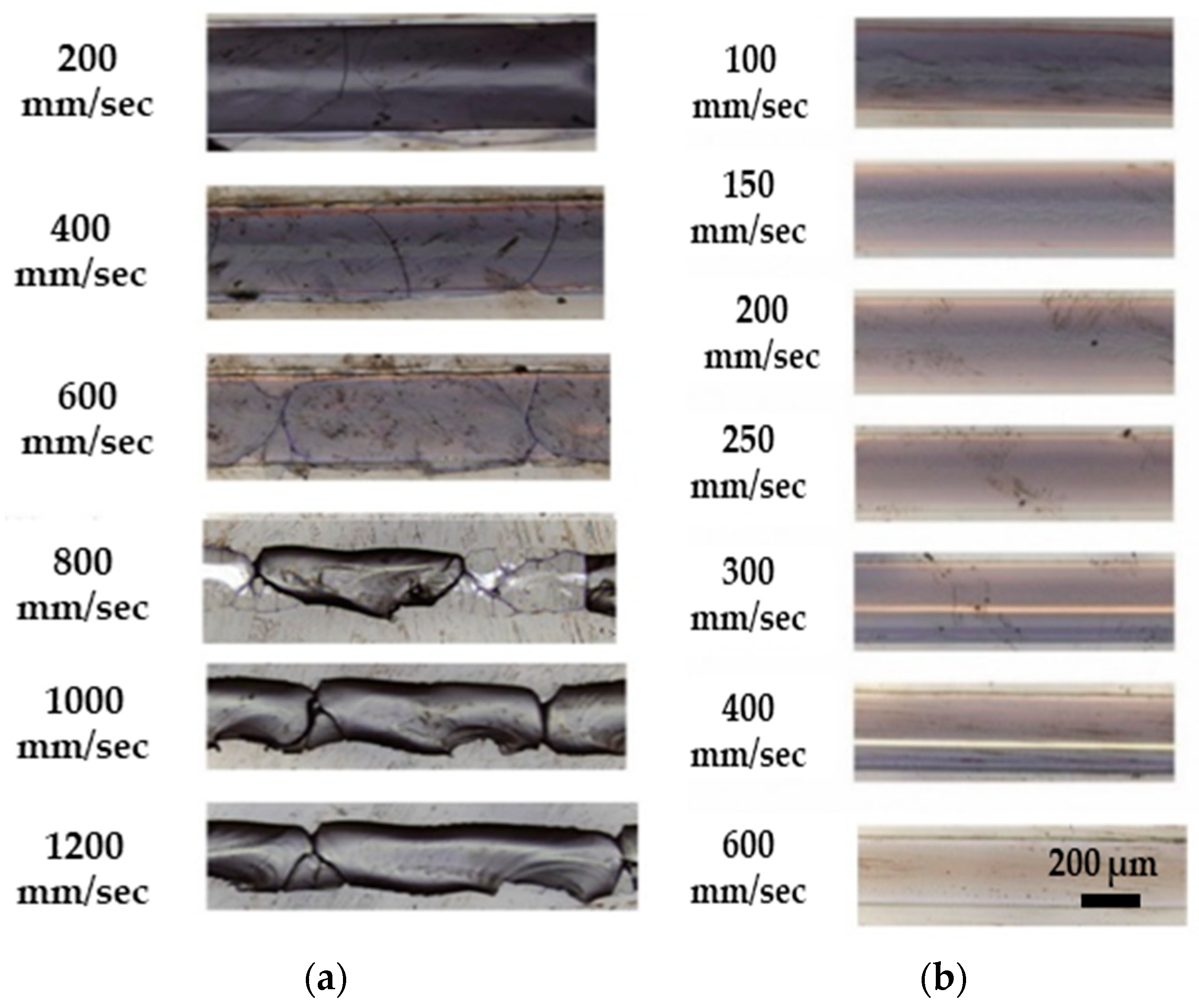

3.1.2. Effects of Scanning Speed in Long-Pulse Micromachining

3.1.3. Effects of Pulse Duration in Long-Pulse Micromachining

3.1.4. Effects of Repetition Rate in Long-Pulse Micromachining

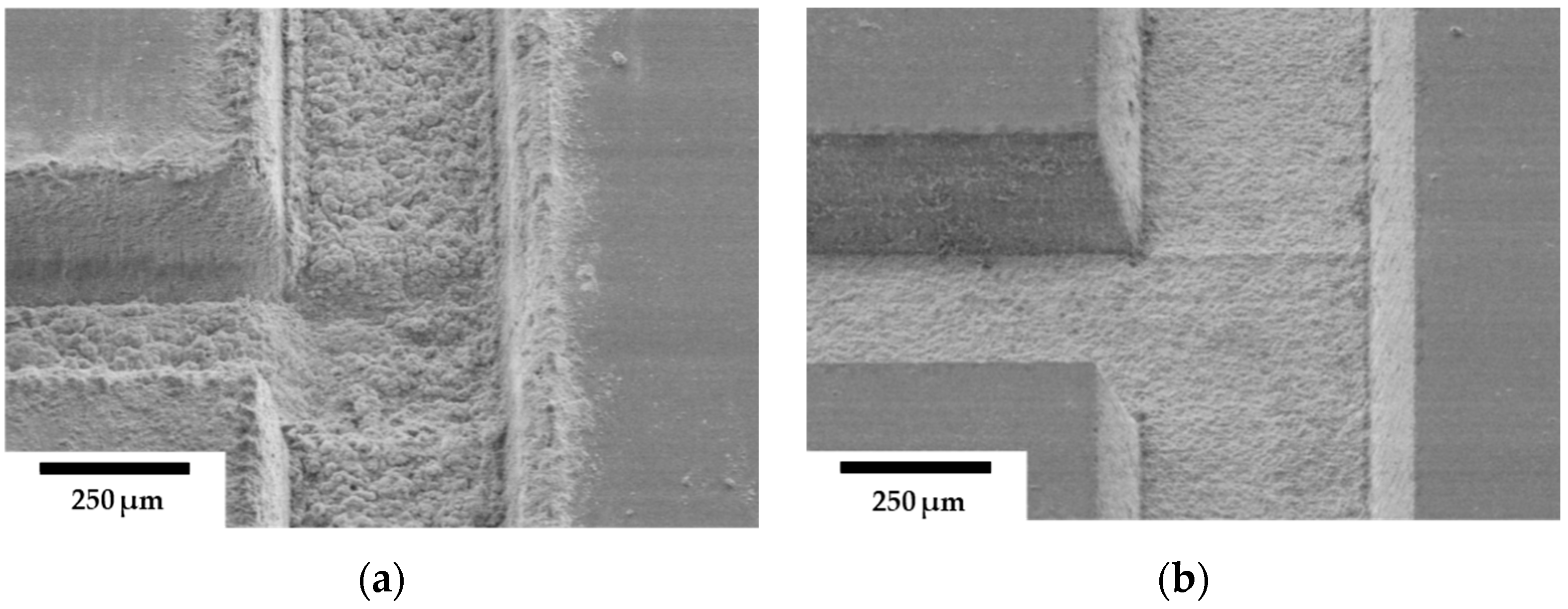

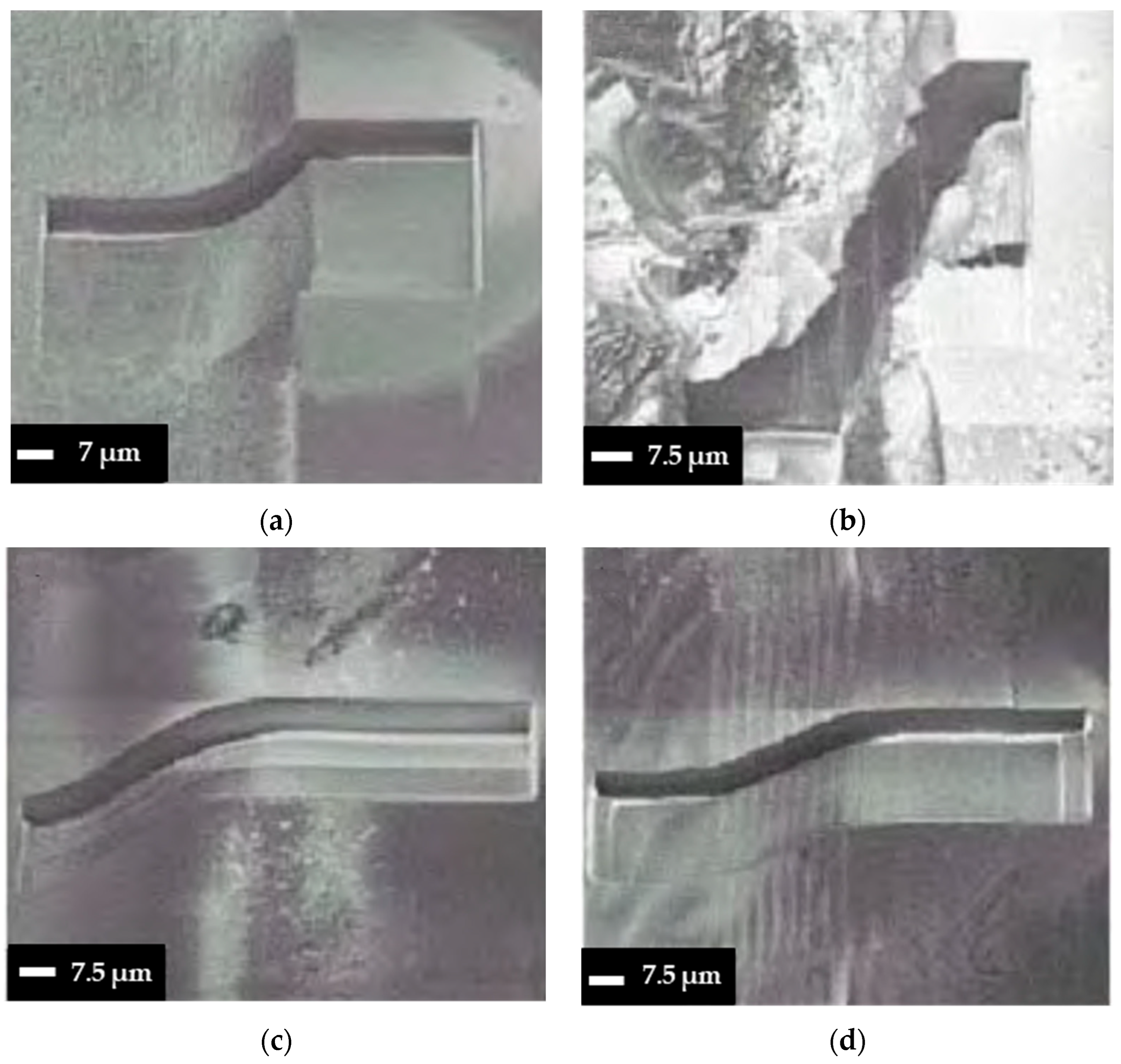

3.1.5. Effects of Laser Wavelength in Long-Pulse Micromachining

3.1.6. Effects of Glass Type in Long-Pulse Micromachining

3.1.7. Summary of Reviewed Studies on Long-Pulse Laser Micromachining

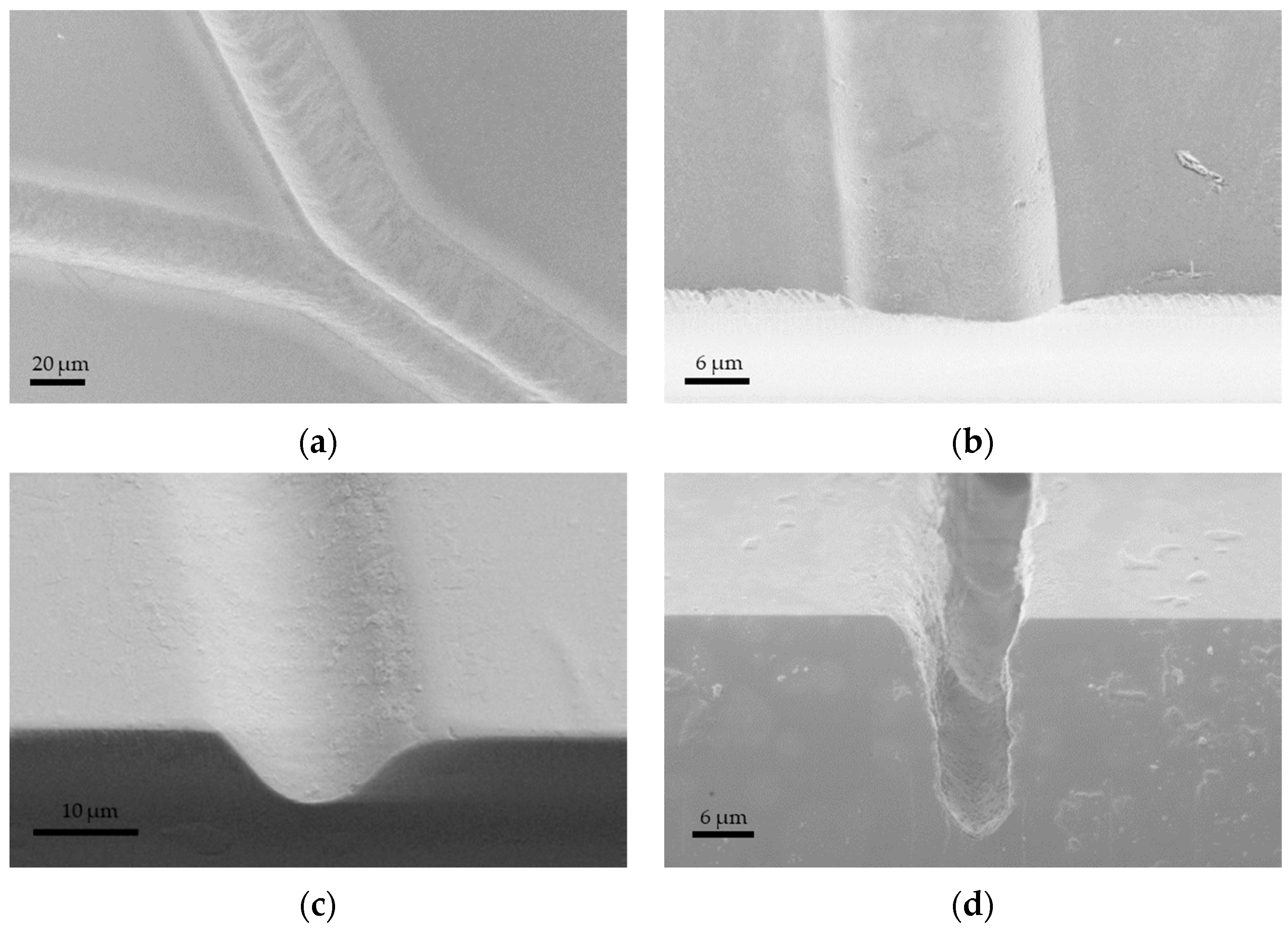

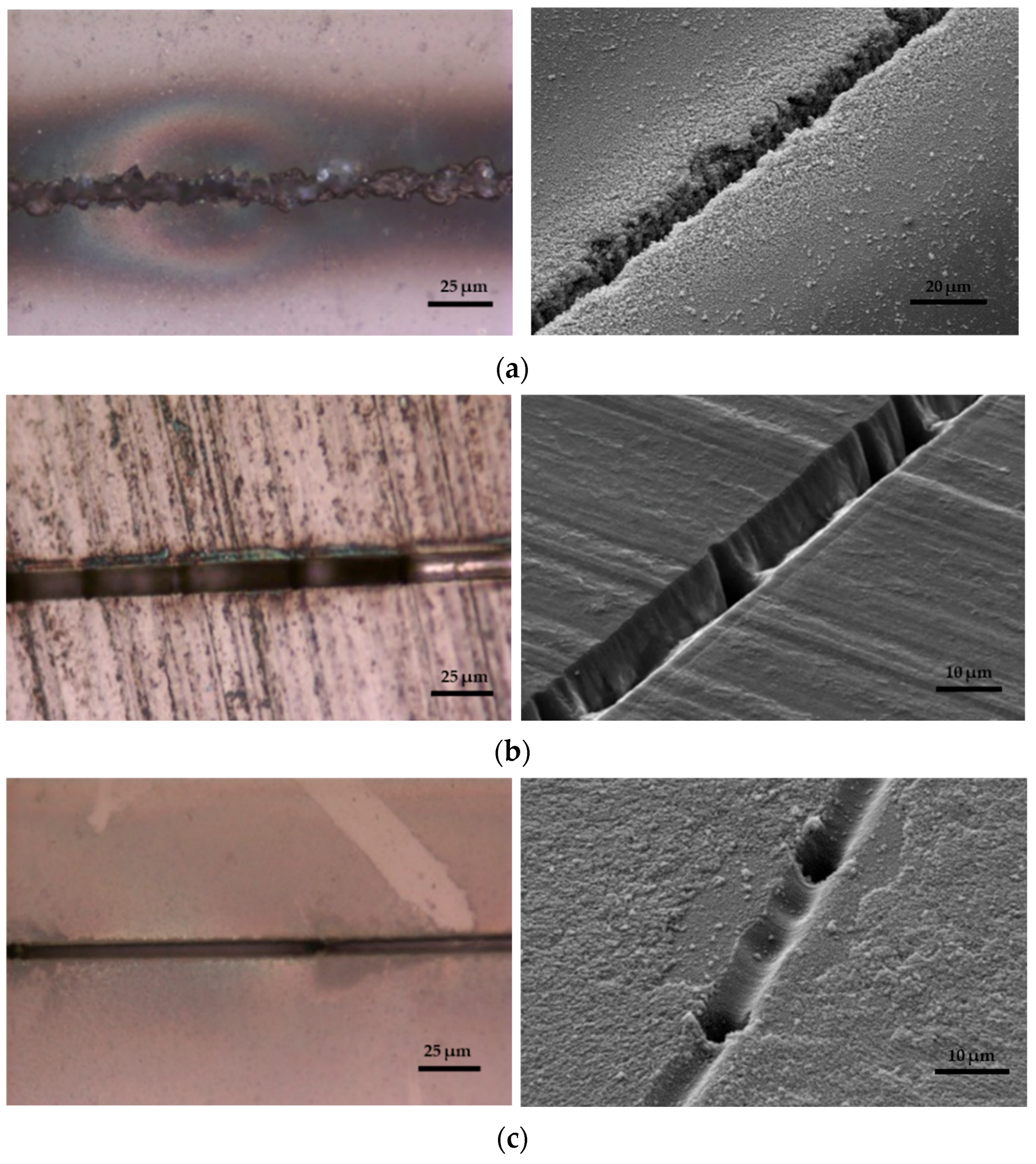

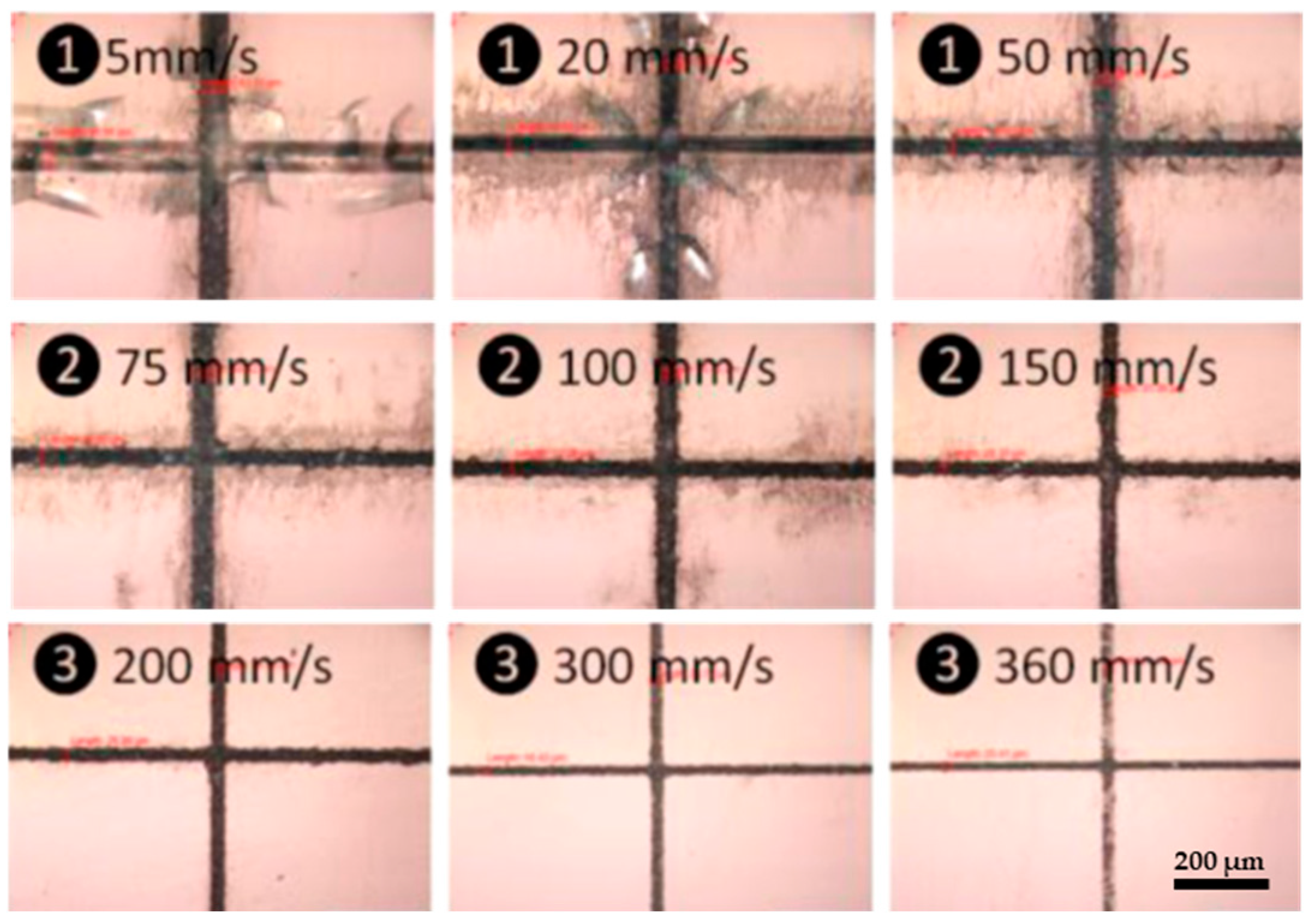

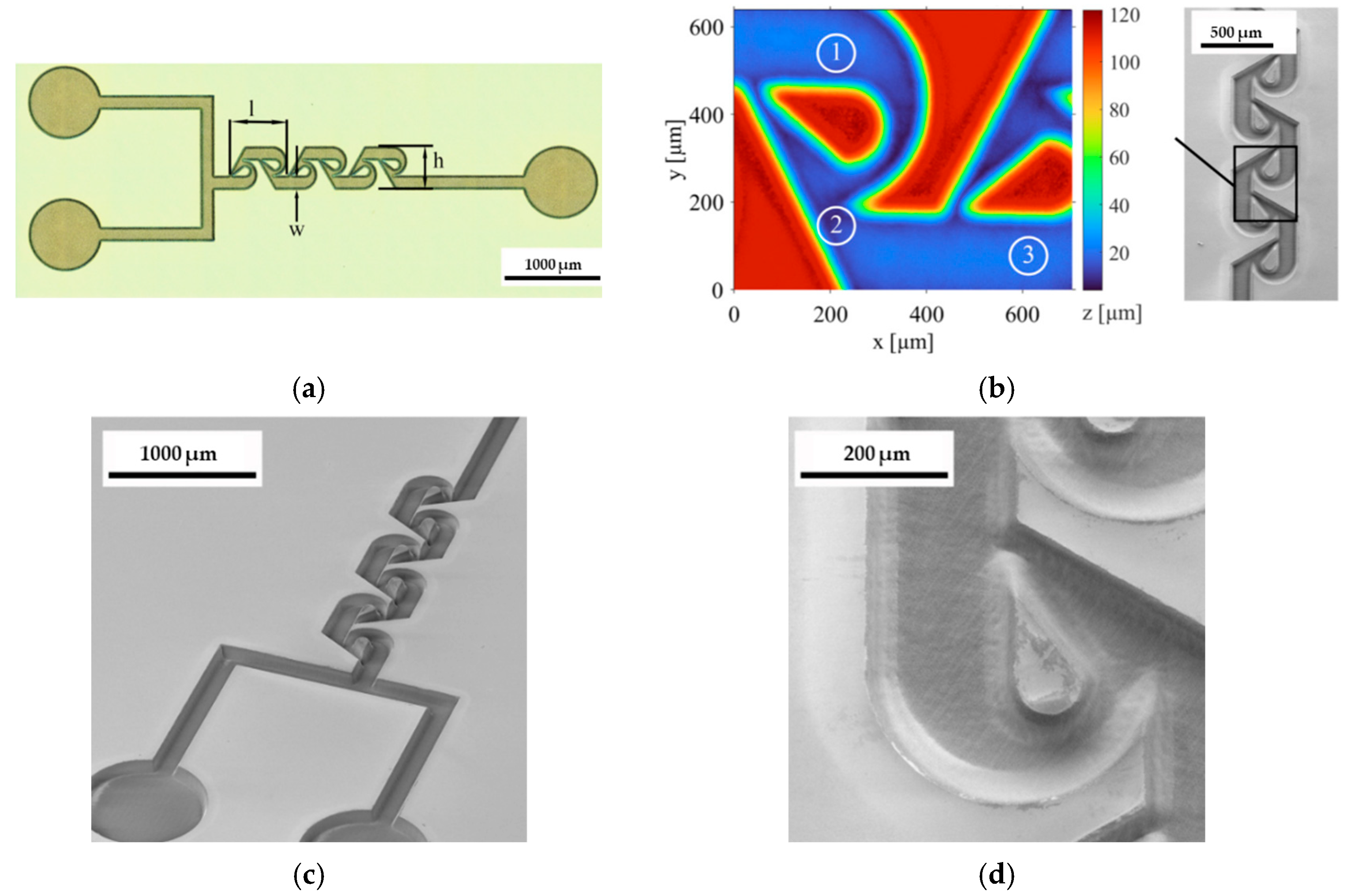

3.2. Short-Pulse Laser Micromachining of Glass

3.2.1. Impact of Fluence on Short-Pulse Micromachining

3.2.2. Impact of Scanning Speed on Short-Pulse Micromachining

3.2.3. Impact of Pulse Duration on Short-Pulse Micromachining

3.2.4. Impact of Repetition Rate on Short-Pulse Micromachining

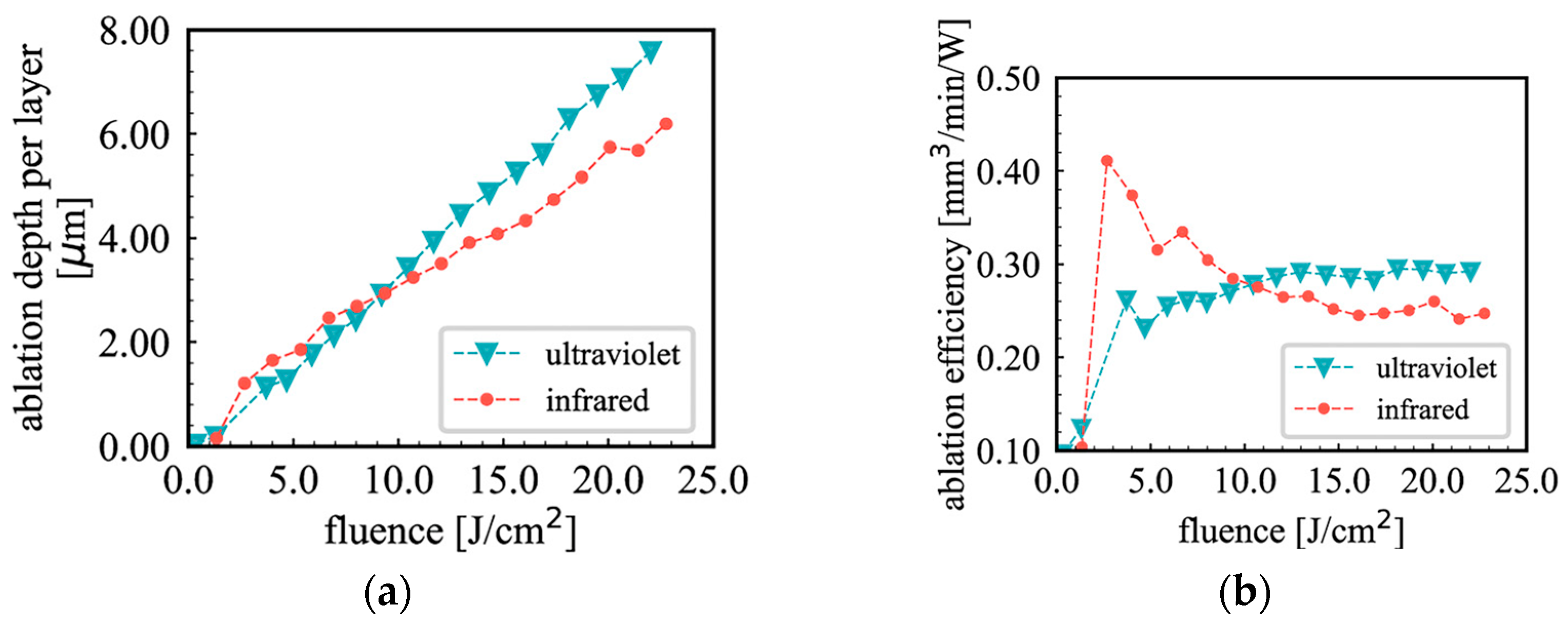

3.2.5. Impact of Laser Wavelength on Short-Pulse Micromachining

3.2.6. Impact of Glass Type on Short-Pulse Micromachining

3.2.7. Summary of Reviewed Studies of Short-Pulse Laser Micromachining

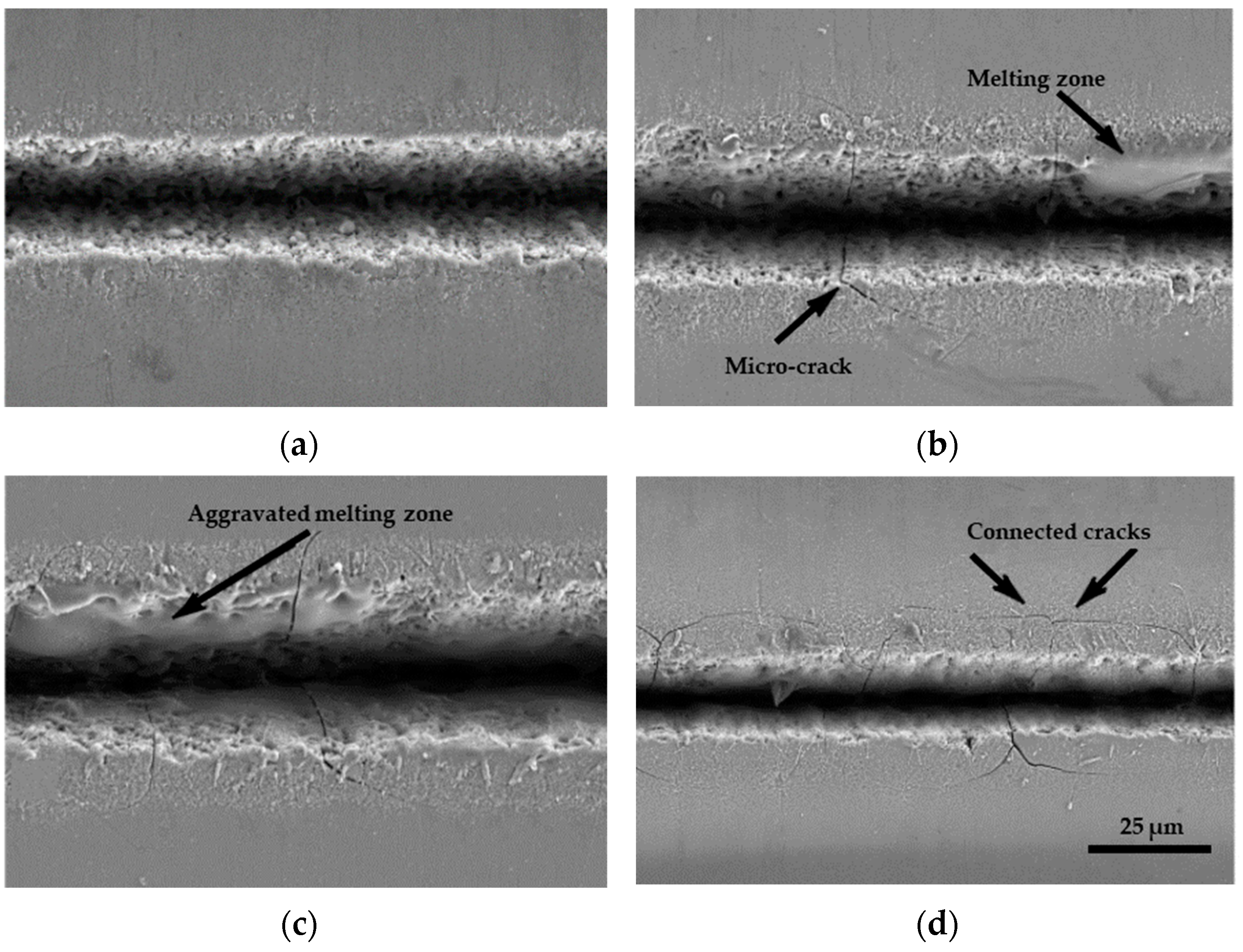

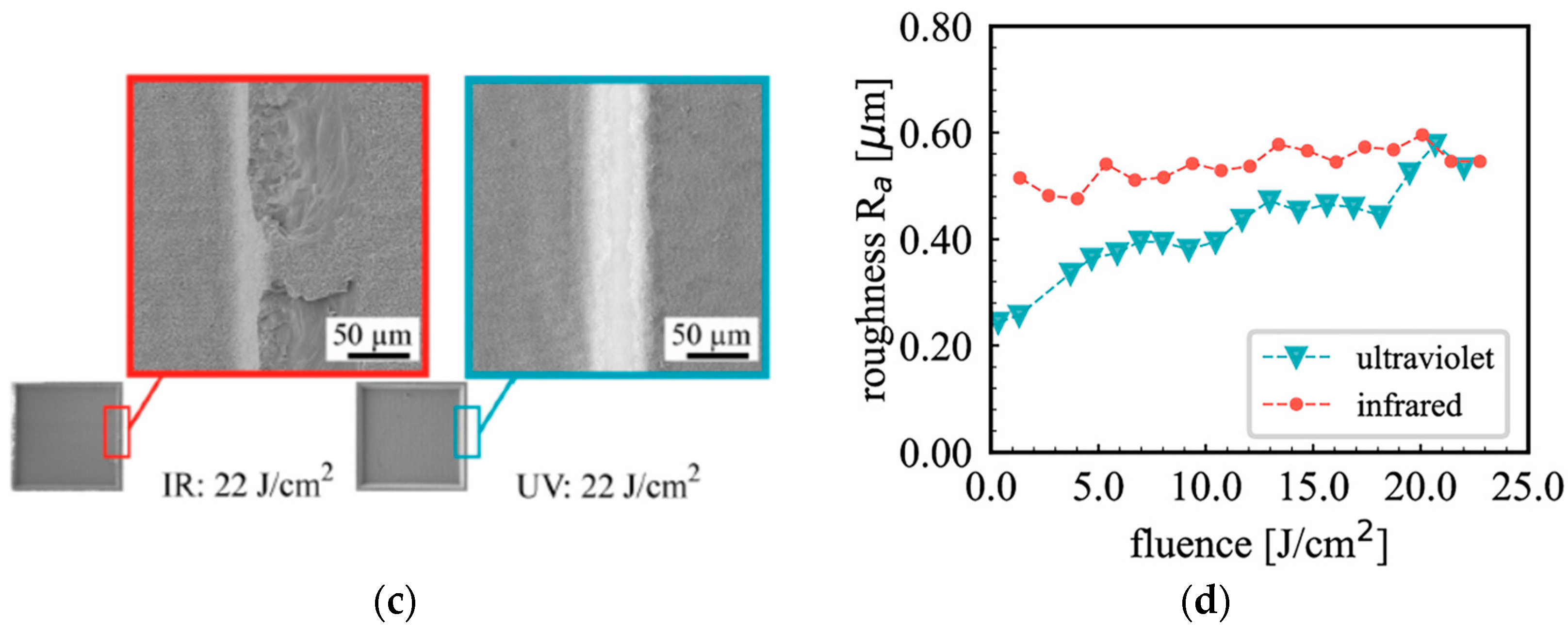

3.3. Ultrashort-Pulse Laser Micromachining of Glass

3.3.1. Effects of Laser Fluence in Ultrashort-Pulse Micromachining

3.3.2. Effects of Scanning Speed in Ultrashort-Pulse Micromachining

3.3.3. Effects of Pulse Duration in Ultrashort-Pulse Micromachining

3.3.4. Effects of Repetition Rate in Ultrashort-Pulse Micromachining

3.3.5. Effects of Laser Wavelength in Ultrashort-Pulse Micromachining

3.3.6. Effects of Glass Type in Ultrashort-Pulse Micromachining

3.3.7. Summary of Reviewed Studies of Ultrashort-Pulse Laser Micromachining

3.4. Comparison of Long, Short, and Ultrashort Laser Processing in Glass Micromachining

4. Discussion

4.1. Comparative Analysis of Pulsed Laser Regimes in Glass Micromachining

4.2. Pulsed Laser Micromachining Benefits for Glass Microfluidics

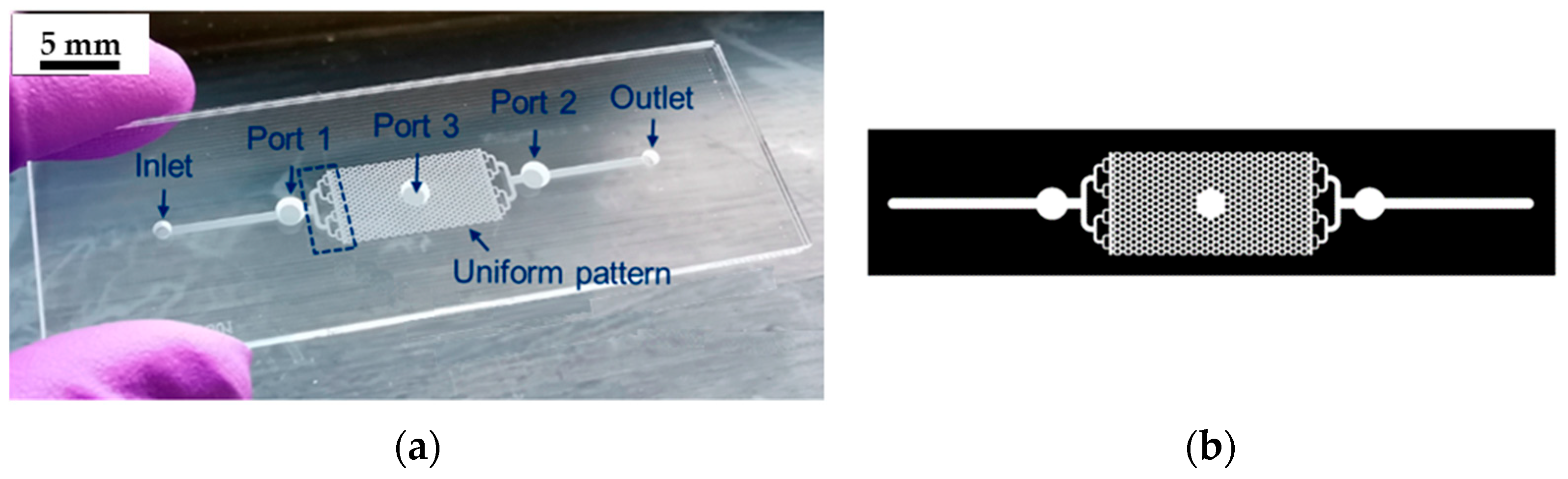

4.2.1. High Precision and Resolution

4.2.2. Minimal Thermal Damage

4.2.3. Rapid Prototyping and Cost-Effectiveness

4.2.4. Superior Cell Adhesion

4.2.5. High-Aspect-Ratio Microchannels

4.2.6. Integration of Sensors and 3D Structures

4.2.7. Reduced Use of Hazardous Chemicals

4.2.8. Hermetically Sealed Devices

5. Conclusions

5.1. Summary

- Fluence is a key parameter because it directly affects the material removal rate, ablation depth, and precision. Across all three regimes, high fluence can accelerate material removal and create deeper cuts by delivering high energy, which increases local heat buildup, lowers the threshold fluence, and deepens optical penetration. However, if the fluence is too high, it may lead to undesirable effects, such as efficiency stabilization due to plasma shielding, thermal damage, cracks, and increased surface roughness. On the other hand, low fluence can improve removal precision but may also extend the fabrication time for microfluidic devices. These findings highlight the impact of high fluence on removal quality, making it crucial to optimize fluence in order to produce high-quality microfluidic channels on glass substrates with high efficiency.

- According to the research findings, scanning speed also significantly impacts the removal process across all three laser pulse regimes. When scanning speeds are too slow, more laser energy is absorbed, leading to excessive heat accumulation, which can cause thermal damage, such as cracking or surface degradation, negatively affecting ablation quality. Regarding ablation efficiency, slower scanning speeds result in limitations due to an increased plasma shielding effect, particularly with short- and ultrashort-pulses. On the other hand, a significant increase in scanning speed may lead to the formation of very shallow microchannels, as the increased distance between laser pulses results in insufficient energy being delivered to a single spot. Therefore, scanning velocity should be optimized to prevent heat accumulation caused by excessively slow speeds and shallow microchannels resulting from high scanning velocities.

- Optimizing pulse duration ensures higher efficiency, minimal thermal damage, and precise material removal. With long pulses, deeper microchannels can be achieved by extending the pulse duration, as this allows for deeper beam penetration and more heating time. In the case of picosecond and femtosecond pulses, shorter pulses result in higher ablation efficiency due to the higher peak power intensity (W/cm2) associated with these pulses and the lower ablation threshold. Regarding ablation quality, a reduction in quality was observed at longer pulse durations, as this allows mechanical relaxation processes in the glass, leading to a molten and rough surface.

- Optimizing the repetition rate of pulsed lasers is essential for improving efficiency, quality, and precision in glass micromachining, particularly in microfluidic channel fabrication. A high repetition rate leads to high ablation efficiency due to increased local heat accumulation, which reduces the threshold fluence. However, excessive heat accumulation can negatively impact precision and surface quality. At a point, the efficiency may drop due to plasma shielding, especially with short and ultrashort pulses. On the other hand, if the repetition rate is too low, the energy may not be effectively utilized, resulting in reduced ablation efficiency and a slower process.

- The wavelength of the laser light influences its interaction with the glass material. Since different wavelengths are absorbed by the glass to varying degrees, choosing the appropriate wavelength is essential for effective micromachining. With long pulses, shorter wavelengths are more effective for precise material removal, providing high efficiency and minimal thermal effects, such as warping, melting, and thermal stress. In contrast, longer wavelengths are less absorbed by glass and require higher energy to remove the desired material, which may result in lower-quality ablation. Short pulses have the highest removal rate with longer wavelengths, as they allow the laser beam to penetrate deeper into the material and provide a more uniform energy distribution within the glass. However, this comes at the cost of reduced precision and control over the removal process. In the case of ultrashort pulses, highly efficient ablation and higher quality were observed when shorter wavelengths were used at high fluence due to a decrease in the effective penetration depth and ablation threshold fluence. Therefore, selecting the optimal wavelength is crucial for maximizing process efficiency.

- The type of glass significantly influences ablation efficiency, with factors such as chemical composition, melting point, and optical properties playing critical roles. In all three pulsed regimes, the findings show the impact of the glass type on the removal effectiveness and precision. Some glass types, such as soda–lime and borosilicate glass, exhibit higher removal effectiveness due to lower ablation thresholds than fused silica and sapphire. However, materials with high ablation thresholds show a better removal quality because they can handle higher laser intensities without damage.

5.2. Directions for Future Research

- Technological Advancements: A strong focus on advancing beam shaping and scanning strategies is essential to improve precision, efficiency, and the ability to create complex microstructures. In addition, beam shaping can enhance the control over energy distribution, reducing thermal effects and enabling high-aspect-ratio microchannels. Thus, developing new scanning strategies could address current limitations, such as shallow channels at high speeds or excessive heat at low speeds, improving the design complexity for 3D structures.

- Material and Integration: Integrating hybrid materials and combining glass with polymers or other substrates seem likely to be key areas. This approach could lead to multifunctional devices with enhanced properties, such as improved conductivity or flexibility, which is particularly relevant for applications requiring diverse material characteristics.

- Process Optimization: Optimizing laser parameters, such as fluence, scanning speed, and pulse duration, is critical to balancing fabrication efficiency and quality for different glass types. As noted in the review, this is crucial given the trade-offs identified, such as thermal damage at high fluence or reduced depth at fast scanning speeds. Such optimization could involve developing models or simulation tools for real-time parameter adjustment, enhancing process control.

- Three-Dimensional Architectures and Optical Integration: Developing three-dimensional architectures using femtosecond laser processing appears promising, leveraging its unmatched flexibility for designing intricate 3D microfluidic channels and embedding optical features. This could enable advanced applications, such as high-resolution detection systems, particularly in fields like biomedicine. The review emphasizes the potential for integrating micromechanical, microelectronic, and micro-optical components without stacking or bonding substrates.

- Scalability and Industrial Adoption: Focusing on cost-effective and high-throughput fabrication methods to transition from laboratory-scale research to industrial manufacturing will be a main area for development. Recent studies demonstrate rapid manufacturing techniques using pulsed lasers, which could reduce costs and time, facilitating broader adoption.

- Addressing technological challenges, such as reducing initial equipment costs, simplifying operations through user-friendly systems and fewer steps, and improving reliability, is crucial for broader adoption. For instance, short-pulse micromachining (using a picosecond laser) with optimized process parameters can fabricate glass-based microfluidics with an efficiency and quality similar to ultrashort-pulse micromachining (using a femtosecond laser). Thus, the optimization of the process parameters enables the avoidance of the high cost required for femtosecond lasers, such as Ti:sapphire-based systems.

- Exploring interdisciplinary applications, such as quantum photonics, biomedical devices, and environmental monitoring, could expand the technology’s impact. For instance, interdisciplinary applications include single-cell analysis, where precise microfluidic channels enable high-resolution cell studies, and quantum sensing, where glass-based devices could integrate with quantum technologies for advanced detection [11,173]. These fields highlight the potential of laser-fabricated microfluidics in biology and physics.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nguyen, N.-T.; Wereley, S.T.; House, A. Fundamentals and Applications of Microfluidics, 3rd ed.; Artech House: Norwood, MA, USA, 2019; ISBN 9781580539722. [Google Scholar]

- Niculescu, A.G.; Chircov, C.; Bîrcă, A.C.; Grumezescu, A.M. Fabrication and Applications of Microfluidic Devices: A Review. Int. J. Mol. Sci. 2021, 22, 2011. [Google Scholar] [CrossRef] [PubMed]

- Sackmann, E.K.; Fulton, A.L.; Beebe, D.J. The Present and Future Role of Microfluidics in Biomedical Research. Nature 2014, 507, 181–189. [Google Scholar] [CrossRef] [PubMed]

- Preetam, S.; Nahak, B.K.; Patra, S.; Toncu, D.C.; Park, S.; Syväjärvi, M.; Orive, G.; Tiwari, A. Emergence of Microfluidics for next Generation Biomedical Devices. Biosens. Bioelectron. X 2022, 10, 100106. [Google Scholar] [CrossRef]

- Hwang, J.; Cho, Y.H.; Park, M.S.; Kim, B.H. Microchannel Fabrication on Glass Materials for Microfluidic Devices. Int. J. Precis. Eng. Manuf. 2019, 20, 479–495. [Google Scholar] [CrossRef]

- Tang, T.; Yuan, Y.; Yalikun, Y.; Hosokawa, Y.; Li, M.; Tanaka, Y. Glass Based Micro Total Analysis Systems: Materials, Fabrication Methods, and Applications. Sens. Actuators B Chem. 2021, 339, 129859. [Google Scholar] [CrossRef]

- Bezelya, A.; Küçüktürkmen, B.; Bozkır, A. Microfluidic Devices for Precision Nanoparticle Production. Micro 2023, 3, 822–866. [Google Scholar] [CrossRef]

- Pelin, G.; Sonmez, M.; Pelin, C.E. The Use of Additive Manufacturing Techniques in the Development of Polymeric Molds: A Review. Polymers 2024, 16, 1055. [Google Scholar] [CrossRef]

- Alghannam, F.; Alayed, M.; Alfihed, S.; Sakr, M.A.; Almutairi, D.; Alshamrani, N.; Al Fayez, N. Recent Progress in PDMS-Based Microfluidics Toward Integrated Organ-on-a-Chip Biosensors and Personalized Medicine. Biosensors 2025, 15, 76. [Google Scholar] [CrossRef]

- Piacentini, S.; Bragheri, F.; Corrielli, G.; Martínez Vázquez, R.; Paiè, P.; Osellame, R. Advanced Photonic and Optofluidic Devices Fabricated in Glass via Femtosecond Laser Micromachining. Opt. Mater. Express 2022, 12, 3930. [Google Scholar] [CrossRef]

- Aralekallu, S.; Boddula, R.; Singh, V. Development of Glass-Based Microfluidic Devices: A Review on Its Fabrication and Biologic Applications. Mater. Des. 2023, 225, 111517. [Google Scholar] [CrossRef]

- Ren, K.; Zhou, J.; Wu, H. Materials for Microfluidic Chip Fabrication. Acc. Chem. Res. 2013, 46, 2396–2406. [Google Scholar] [CrossRef] [PubMed]

- Choi, K.; Kim, S.W.; Lee, J.H.; Chu, B.; Jeong, D.Y. Eco-Friendly Glass Wet Etching for MEMS Application: A Review. J. Am. Ceram. Soc. 2024, 107, 6497–6515. [Google Scholar] [CrossRef]

- Wlodarczyk, K.L.; Hand, D.P.; Maroto-Valer, M.M. Maskless, Rapid Manufacturing of Glass Microfluidic Devices Using a Picosecond Pulsed Laser. Sci. Rep. 2019, 9, 20215. [Google Scholar] [CrossRef]

- Luo, Z.; Zhang, H.; Chen, R.; Li, H.; Cheng, F.; Zhang, L.; Liu, J.; Kong, T.; Zhang, Y.; Wang, H. Digital Light Processing 3D Printing for Microfluidic Chips with Enhanced Resolution via Dosing- and Zoning-Controlled Vat Photopolymerization. Microsyst. Nanoeng. 2023, 9, 103. [Google Scholar] [CrossRef]

- Keshavarz, M.; Tan, B.; Venkatakrishnan, K. Functionalized Stress Component onto Bio-Template as a Pathway of Cytocompatibility. Sci. Rep. 2016, 6, 35425. [Google Scholar] [CrossRef]

- Karimi, K.; Fardoost, A.; Mhatre, N.; Rajan, J.; Boisvert, D.; Javanmard, M. A Thorough Review of Emerging Technologies in Micro- and Nanochannel Fabrication: Limitations, Applications, and Comparison. Micromachines 2024, 15, 1274. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Ultrafast Lasers-Reliable Tools for Advanced Materials Processing. Light Sci. Appl. 2014, 3, e149. [Google Scholar] [CrossRef]

- Qi, J.; Li, W.; Chu, W.; Yu, J.; Wu, M.; Liang, Y.; Yin, D.; Wang, P.; Wang, Z.; Wang, M.; et al. A Microfluidic Mixer of High Throughput Fabricated in Glass Using Femtosecond Laser Micromachining Combined with Glass Bonding. Micromachines 2020, 11, 213. [Google Scholar] [CrossRef] [PubMed]

- Saunders, J.; Elbestawi, M.; Fang, Q. Ultrafast Laser Additive Manufacturing: A Review. J. Manuf. Mater. Process. 2023, 7, 89. [Google Scholar] [CrossRef]

- Konari, P.R.; Clayton, Y.D.; Vaughan, M.B.; Khandaker, M.; Hossan, M.R. Experimental Analysis of Laser Micromachining of Microchannels in Common Microfluidic Substrates. Micromachines 2021, 12, 138. [Google Scholar] [CrossRef]

- Yasman, N.; Fouzy, R.M.R.M.; Zawawi, M.Z.M. Direct Fabrication of Glass Microfluidic Channel Using CO2 Laser. Mater. Today Proc. 2024, 97, 52–60. [Google Scholar] [CrossRef]

- Gómez-Varela, A.I.; Sanchez, R.; Carnero, B.; Diaz-Gomez, L.; Flores-Arias, M.T.; Bao-Varela, C. Subaquatic Indirect Laser Ablation Technique for Glass Processing. Opt. Express 2022, 30, 37536. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Chen, L.; Wang, F.; Tu, P. A High Precision Scheme for Micro-Channel Processing in Quartz Glass Using Femtosecond Laser. Microw. Opt. Technol. Lett. 2017, 59, 1993–2000. [Google Scholar] [CrossRef]

- Benton, M.; Hossan, M.R.; Konari, P.R.; Gamagedara, S. Effect of Process Parameters and Material Properties on Laser Micromachining of Microchannels. Micromachines 2019, 10, 123. [Google Scholar] [CrossRef]

- Phillips, K.C.; Gandhi, H.H.; Mazur, E.; Sundaram, S.K. Ultrafast Laser Processing of Materials: A Review. Adv. Opt. Photonics 2015, 7, 684. [Google Scholar] [CrossRef]

- Nielsen, J.B.; Hanson, R.L.; Almughamsi, H.M.; Pang, C.; Fish, T.R.; Woolley, A.T. Microfluidics: Innovations in Materials and Their Fabrication and Functionalization. Anal. Chem. 2020, 92, 150–168. [Google Scholar] [CrossRef]

- Juang, Y.J.; Chiu, Y.J. Fabrication of Polymer Microfluidics: An Overview. Polymers 2022, 14, 2028. [Google Scholar] [CrossRef]

- Scott, S.M.; Ali, Z. Fabrication Methods for Microfluidic Devices: An Overview. Micromachines 2021, 12, 319. [Google Scholar] [CrossRef]

- Tsao, C.W. Polymer Microfluidics: Simple, Low-Cost Fabrication Process Bridging Academic Lab Research to Commercialized Production. Micromachines 2016, 7, 225. [Google Scholar] [CrossRef]

- Sugioka, K.; Xu, J.; Wu, D.; Hanada, Y.; Wang, Z.; Cheng, Y.; Midorikawa, K. Femtosecond Laser 3D Micromachining: A Powerful Tool for the Fabrication of Microfluidic, Optofluidic, and Electrofluidic Devices Based on Glass. Lab Chip 2014, 14, 3447–3458. [Google Scholar] [CrossRef]

- Iliescu, C.; Taylor, H.; Avram, M.; Miao, J.; Franssila, S. A Practical Guide for the Fabrication of Microfluidic Devices Using Glass and Silicon. Biomicrofluidics 2012, 6, 016505. [Google Scholar] [CrossRef] [PubMed]

- Gečys, P.; Dudutis, J.; Račiukaitis, G. Nanosecond Laser Processing of Soda-Lime Glass. J. Laser Micro Nanoeng. 2015, 10, 254–258. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Femtosecond Laser Three-Dimensional Micro-and Nanofabrication. Appl. Phys. Rev. 2014, 1, 041303. [Google Scholar] [CrossRef]

- Ionel, L.; Jipa, F.; Bran, A.; Axente, E.; Popescu-Pelin, G.; Sima, F.; Sugioka, K. Effect of Varied Beam Diameter of Picosecond Laser on Foturan Glass Volume Microprocessing. Opt. Express 2024, 32, 20109. [Google Scholar] [CrossRef]

- Deng, W. Development of Glass-Glass Fusion Bonding Recipes for All-Glass Nanofluidic Devices. Bachelor’s Thesis, The Ohio State University, Columbus, OH, USA, 2015. [Google Scholar]

- Liu, X.; Sun, A.; Brodský, J.; Gablech, I.; Lednický, T.; Vopařilová, P.; Zítka, O.; Zeng, W.; Neužil, P. Microfluidics Chips Fabrication Techniques Comparison. Sci. Rep. 2024, 14, 28793. [Google Scholar] [CrossRef]

- Cong, H.; Zhang, N. Perspectives in Translating Microfluidic Devices from Laboratory Prototyping into Scale-up Production. Biomicrofluidics 2022, 16, 021301. [Google Scholar] [CrossRef]

- Kotz, F.; Arnold, K.; Bauer, W.; Schild, D.; Keller, N.; Sachsenheimer, K.; Nargang, T.M.; Richter, C.; Helmer, D.; Rapp, B.E. Three-Dimensional Printing of Transparent Fused Silica Glass. Nature 2017, 544, 337–339. [Google Scholar] [CrossRef] [PubMed]

- Amin, R.; Knowlton, S.; Hart, A.; Yenilmez, B.; Ghaderinezhad, F. 3D-Printed Microfluidic Devices. Biofabrication 2016, 8, 022001. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.L.; Wang, W.; Ding, H.; Sun, H.B. On-Chip Laser Processing for the Development of Multifunctional Microfluidic Chips. Laser Photonics Rev. 2017, 11, 1600116. [Google Scholar] [CrossRef]

- Pan, C.; Chen, K.; Liu, B.; Ren, L.; Wang, J.; Hu, Q.; Liang, L.; Zhou, J.; Jiang, L. Fabrication of Micro-Texture Channel on Glass by Laser-Induced Plasma-Assisted Ablation and Chemical Corrosion for Microfluidic Devices. J. Mater. Process. Technol. 2017, 240, 314–323. [Google Scholar] [CrossRef]

- Wang, B.-X.; Qi, J.-Y.; Lu, Y.-M.; Zheng, J.-X.; Xu, Y.; Liu, X.-Q. Rapid Fabrication of Smooth Micro-Optical Components on Glass by Etching-Assisted Femtosecond Laser Modification. Materials 2022, 15, 678. [Google Scholar] [CrossRef]

- Kiyama, S.; Matsuo, S.; Hashimoto, S.; Morihira, Y. Examination of Etching Agent and Etching Mechanism on Femotosecond Laser Microfabrication of Channels inside Vitreous Silica Substrates. J. Phys. Chem. C 2009, 113, 11560–11566. [Google Scholar] [CrossRef]

- Young, O.M.; Xu, X.; Sarker, S.; Sochol, R.D. Direct Laser Writing-Enabled 3D Printing Strategies for Microfluidic Applications. Lab Chip 2024, 24, 2371–2396. [Google Scholar] [CrossRef]

- Martin, A.; Teychené, S.; Camy, S.; Aubin, J. Fast and Inexpensive Method for the Fabrication of Transparent Pressure-Resistant Microfluidic Chips. Microfluid. Nanofluid. 2016, 20, 4–11. [Google Scholar] [CrossRef]

- Tseng, A.A.; Chen, Y.T.; Chao, C.L.; Ma, K.J.; Chen, T.P. Recent Developments on Microablation of Glass Materials Using Excimer Lasers. Opt. Lasers Eng. 2007, 45, 975–992. [Google Scholar] [CrossRef]

- Gao, L.; Zhang, Q.; Gu, M. Femtosecond Laser Micro/Nano Processing: From Fundamental to Applications. Int. J. Extrem. Manuf. 2025, 7, 022010. [Google Scholar] [CrossRef]

- Najeeb, S.; Khurshid, Z.; Zafar, M.S.; Ajlal, S. Applications of Light Amplification by Stimulated Emission of Radiation (Lasers) for Restorative Dentistry. Med. Princ. Pract. 2016, 25, 201–211. [Google Scholar] [CrossRef]

- Hamad, A.H. Effects of Different Laser Pulse Regimes (Nanosecond, Picosecond and Femtosecond) on the Ablation of Materials for Production of Nanoparticles in Liquid Solution. In High Energy and Short Pulse Lasers; Viskup, R., Ed.; IntechOpen Limited: London, UK, 2016; ISBN 978-953-51-2607-2. [Google Scholar]

- Chvykov, V. High-Power Lasers. Encyclopedia 2024, 4, 1236–1249. [Google Scholar] [CrossRef]

- Kaligar, A.B.; Kumar, H.A.; Ali, A.; Abuzaid, W.; Egilmez, M.; Alkhader, M.; Abed, F.; Alnaser, A.S. Femtosecond Laser-Based Additive Manufacturing: Current Status and Perspectives. Quantum Beam Sci. 2022, 6, 5. [Google Scholar] [CrossRef]

- Labutin, T.A.; Lednev, V.N.; Ilyin, A.A.; Popov, A.M. Femtosecond Laser-Induced Breakdown Spectroscopy. J. Anal. Spectrom. 2016, 31, 90–118. [Google Scholar] [CrossRef]

- Mansour, H.; Soliman, E.A.; El-Bab, A.M.F.; Matsushita, Y.; Abdel-Mawgood, A.L. Fabrication and Characterization of Microfluidic Devices Based on Boron-Modified Epoxy Resin Using CO2 Laser Ablation for Bio-Analytical Applications. Sci. Rep. 2023, 13, 12623. [Google Scholar] [CrossRef]

- Yu, Y.; Bai, S.; Wang, S.; Hu, A. Ultra-Short Pulsed Laser Manufacturing and Surface Processing of Microdevices. Engineering 2018, 4, 779–786. [Google Scholar] [CrossRef]

- Orazi, L.; Siciliani, V.; Pelaccia, R.; Oubellaouch, K.; Reggiani, B. Ultrafast Laser Micromanufacturing of Microfluidic Devices. Procedia CIRP 2022, 110, 122–127. [Google Scholar] [CrossRef]

- Chen, J.; Lu, X.; Wen, Q.; Jiang, F.; Lu, J.; Lei, D.; Pan, Y. Review on Laser-Induced Etching Processing Technology for Transparent Hard and Brittle Materials. Int. J. Adv. Manuf. Technol. 2021, 117, 2545–2564. [Google Scholar] [CrossRef]

- Jaeggi, B.; Neuenschwander, B.; Remund, S.; Kramer, T. Influence of the Pulse Duration and the Experimental Approach onto the Specific Removal Rate for Ultra-Short Pulses. Laser Appl. Microelectron. Optoelectron. Manuf. (LAMOM) XXII 2017, 10091, 105–114. [Google Scholar] [CrossRef]

- Sola, D.; Peña, J.I. Study of the Wavelength Dependence in Laser Ablation of Advanced Ceramics and Glass-Ceramic Materials in the Nanosecond Range. Materials 2013, 6, 5302–5313. [Google Scholar] [CrossRef]

- Bude, J.; Miller, P.; Baxamusa, S.; Shen, N.; Laurence, T.; Steele, W.; Suratwala, T.; Wong, L.; Carr, W.; Cross, D.; et al. High Fluence Laser Damage Precursors and Their Mitigation in Fused Silica. Opt. Express 2014, 22, 5839. [Google Scholar] [CrossRef]

- Li, W.; Huang, Y.; Rong, Y.; Chen, L.; Zhang, G.; Gao, Z. Analysis and Comparison of Laser Cutting Performance of Solar Float Glass with Different Scanning Modes. Front. Mech. Eng. 2021, 16, 97–110. [Google Scholar] [CrossRef]

- Shugaev, M.V.; Wu, C.; Armbruster, O.; Naghilou, A.; Brouwer, N.; Ivanov, D.S.; Derrien, T.J.-Y.; Bulgakova, N.M.; Kautek, W.; Rethfeld, B.; et al. Fundamentals of Ultrafast Laser-Material Interaction. MRS Bull. 2016, 41, 960–968. [Google Scholar] [CrossRef]

- Tan, C.; Zhao, L.; Chen, M.; Cheng, J.; Zhang, Y.; Zhang, J.; Yan, Z. Heat Accumulation Effect during CO2 Laser Processing of Fused Silica Optics. Results Phys. 2022, 34, 105308. [Google Scholar] [CrossRef]

- Gallais, L.; Douti, D.B.; Commandré, M.; Batavičite, G.; Pupka, E.; Ščiuka, M.; Smalakys, L.; Sirutkaitis, V.; Melninkaitis, A. Wavelength Dependence of Femtosecond Laser-Induced Damage Threshold of Optical Materials. J. Appl. Phys. 2015, 117, 223103. [Google Scholar] [CrossRef]

- Waugh, D.G.; Walton, C.D. Micro-Machining of Diamond, Sapphire and Fused Silica Glass Using a Pulsed Nano-Second Nd:YVO4 Laser. Optics 2021, 2, 169–183. [Google Scholar] [CrossRef]

- Crimella, D.; Jwad, T.; Demir, A.G. Microcutting of Glass with High Ablation Efficiency by Means of a High Power Ps-Pulsed NIR Laser. Opt. Laser Technol. 2023, 166, 9–11. [Google Scholar] [CrossRef]

- Li, X.; Guan, Y. Theoretical Fundamentals of Short Pulse Laser-Metal Interaction: A Review. Nanotechnol. Precis. Eng. 2020, 3, 105–125. [Google Scholar] [CrossRef]

- Shepelin, N.A.; Tehrani, Z.P.; Ohannessian, N.; Schneider, C.W.; Pergolesi, D.; Lippert, T. A Practical Guide to Pulsed Laser Deposition. Chem. Soc. Rev. 2023, 52, 2294–2321. [Google Scholar] [CrossRef] [PubMed]

- Gedvilas, M.; Indrišiunas, S.; Voisiat, B.; Stankevičius, E.; Selskis, A.; Račiukaitis, G. Nanoscale Thermal Diffusion during the Laser Interference Ablation Using Femto-, Pico-, and Nanosecond Pulses in Silicon. Phys. Chem. Chem. Phys. 2018, 20, 12166–12174. [Google Scholar] [CrossRef]

- Grosse, C.; Abo Ras, M.; Varpula, A.; Grigoras, K.; May, D.; Wunderle, B.; Chapuis, P.O.; Gomès, S.; Prunnila, M. Microfabricated Sensor Platform with Through-Glass Vias for Bidirectional 3-Omega Thermal Characterization of Solid and Liquid Samples. Sens. Actuators A Phys. 2018, 278, 33–42. [Google Scholar] [CrossRef]

- Li, Z.; Jia, Y.; Duan, K.; Xiao, R.; Qiao, J.; Liang, S.; Wang, S.; Chen, J.; Wu, H.; Lu, Y.; et al. One-Photon Three-Dimensional Printed Fused Silica Glass with Sub-Micron Features. Nat. Commun. 2024, 15, 2689. [Google Scholar] [CrossRef]

- Li, H.; Luo, J.; Ding, S.; Ding, J. Laser-Machined Micro-Supercapacitors: From Microstructure Engineering to Smart Integrated Systems. Nanoscale 2024, 16, 14574–14588. [Google Scholar] [CrossRef]

- Wang, M.-H.; Qu, J.-L.; Zhu, M. Partially Overlapped Dual Laser Beams to Reduce Ablation Craters∗. Chin. Phys. Lett. 2020, 37, 015202. [Google Scholar] [CrossRef]

- Shugaev, M.V.; He, M.; Levy, Y.; Mazzi, A.; Miotello, A. Laser-Induced Thermal Processes: Heat Transfer, Generation of Stresses, Melting and Solidification, Vaporization, and Phase Explosion. In Handbook of Laser Micro-and Nano-Engineering; Sugioka, K., Ed.; Springer: Berlin/Heidelberg, Germany, 2021; Volume 1, pp. 83–163. ISBN 9783030636470. [Google Scholar]

- Natarajan Jeyaprakash, C.-H.Y. and M.B.K. Practical Applications of Laser Ablation_Laser Machining. In Practical Applications of Laser Ablation; Yang, D., Ed.; IntechOpen: London, UK, 2021; p. 172. ISBN 978-1-83968-304-6. [Google Scholar]

- Wang, J.; Fang, F.; An, H.; Wu, S.; Qi, H.; Cai, Y.; Guo, G. Laser Machining Fundamentals: Micro, Nano, Atomic and Close-to-Atomic Scales. Int. J. Extrem. Manuf. 2023, 5, 012005. [Google Scholar] [CrossRef]

- Umroh, B.; Ginting, A.; Rahman, M.N.A. CO2 Laser Machining on Alumina Ceramic: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1003, 012131. [Google Scholar] [CrossRef]

- Temmler, A.; Braun, K.; Uluz, E. Heat Accumulation and Surface Roughness Evolution in CO2 Nanosecond Laser Ablation of Quartz Glass. Opt. Laser Technol. 2021, 144, 107426. [Google Scholar] [CrossRef]

- Wang, H.; Wen, Q.; Xu, X.; Lu, J.; Jiang, F.; Cui, C. Ablation Characteristics and Material Removal Mechanisms of a Single-Crystal Diamond Processed by Nanosecond or Picosecond Lasers. Opt. Express 2021, 29, 22714. [Google Scholar] [CrossRef] [PubMed]

- Temmler, A.; Weingarten, C.B.; Schober, B.; Uluz, E. Investigation on Laser Beam Figuring of Fused Silica Using Microsecond Pulsed CO2 Laser Radiation. Appl. Surf. Sci. 2021, 555, 149609. [Google Scholar] [CrossRef]

- Lan, B.; Hong, M.H.; Ye, K.D.; Wang, Z.B.; Cheng, S.X.; Chong, T.C. Laser Precision Engineering of Glass Substrates. Jpn. J. Appl. Phys. 2004, 43, 7102–7106. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Ding, Y.; Cheng, B.; Xie, W.; Yang, L. Investigation on the Coaxial-Annulus-Argon-Assisted Water-Jet-Guided Laser Machining of Hard-to-Process Materials. Materials 2023, 16, 5569. [Google Scholar] [CrossRef]

- Quintal, C.C.; Cormont, P.; Gallais, L. Experimental and Numerical Investigation of CO2 Laser Ablation of Fused Silica with Sub-Microsecond Pulses. J. Appl. Phys. 2021, 130, 093106. [Google Scholar] [CrossRef]

- Cheng, J.Y.; Yen, M.H.; Wei, C.W.; Chuang, Y.C.; Young, T.H. Crack-Free Direct-Writing on Glass Using a Low-Power UV Laser in the Manufacture of a Microfluidic Chip. J. Micromech. Microeng. 2005, 15, 1147–1156. [Google Scholar] [CrossRef]

- Shao, K.; Zhou, Q.; Chen, Q.; Liu, Y.; Wang, C.; Li, X. Research Progress of Water–Laser Compound Machining Technology. Coatings 2022, 12, 1887. [Google Scholar] [CrossRef]

- Chen, T.C.; Darling, R.B. Laser Micromachining of the Materials Using in Microfluidics by High Precision Pulsed near and Mid-Ultraviolet Nd:YAG Lasers. J. Mater. Process. Technol. 2008, 198, 248–253. [Google Scholar] [CrossRef]

- Yang, Y.; Miao, L.; Chow, C.L. Relative Significance of Temperature Gradient Components on Cracking Behavior in Glass Panes under Thermal Radiation. Appl. Therm. Eng. 2018, 131, 837–848. [Google Scholar] [CrossRef]

- Brusberg, L.; Queisser, M.; Gentsch, C.; Schröder, H.; Lang, K.D. Advances in CO2-Laser Drilling of Glass Substrates. Phys. Procedia 2012, 39, 548–555. [Google Scholar] [CrossRef]

- Bondarenko, A.G.; Ramos-Velazquez, A.; Shmalko, A.V.; Zakoldaev, R.A. Surface Microfluidics Elements Fabrication by CO2-Laser Writing on Glass: Challenges and Perspectives. Opt. Quantum Electron. 2023, 55, 379. [Google Scholar] [CrossRef]

- Weingarten, C.; Uluz, E.; Schmickler, A.; Braun, K.; Willenborg, E.; Temmler, A.; Heidrich, S. Glass Processing with Pulsed CO2 Laser Radiation. Appl. Opt. 2017, 56, 777. [Google Scholar] [CrossRef] [PubMed]

- Xiong, C.W.; Ho, C.Y.; Qiao, D.K. Analysis of Direct Optical Ablation and Sequent Thermal Ablation for the Ultrashort Pulsed Laser Photo-Thermal Micromachining. Coatings 2020, 10, 1151. [Google Scholar] [CrossRef]

- Ravi-Kumar, S.; Lies, B.; Lyu, H.; Qin, H. Laser Ablation of Polymers: A Review. Procedia Manuf. 2019, 34, 316–327. [Google Scholar] [CrossRef]

- Wlodarczyk, K.L.; Weston, N.J.; Ardron, M.; Hand, D.P. Direct CO2 Laser-Based Generation of Holographic Structures on the Surface of Glass. Opt. Express 2016, 24, 1447. [Google Scholar] [CrossRef]

- Sinev, L.S.; Petrov, I.D. Linear Thermal Expansion Coefficient (at Temperatures from 130 to 800 K) of Borosilicate Glasses Suitable for Silicon Compounds in Microelectronics. Glass Ceram. 2016, 73, 32–35. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L.; Jiang, X.; Jia, B.; Liao, W.; Dai, R.; Chen, J.; Yuan, X.; Jiang, X. Influence of Pulse Length on Heat Affected Zones of Evaporatively-Mitigated Damages of Fused Silica Optics by CO2 Laser. Opt. Lasers Eng. 2020, 125, 105857. [Google Scholar] [CrossRef]

- Gonzalez, J.; Mao, X.L.; Roy, J.; Mao, S.S.; Russo, R.E. Comparison of 193, 213 and 266 Nm Laser Ablation ICP-MS. J. Anal. Spectrom. 2002, 17, 1108–1113. [Google Scholar] [CrossRef]

- Nieto, D.; Arines, J.; O’Connor, G.M.; Flores-Arias, M.T. Single-Pulse Laser Ablation Threshold of Borosilicate, Fused Silica, Sapphire, and Soda-Lime Glass for Pulse Widths of 500 Fs, 10 Ps, 20 Ns. Appl. Opt. 2015, 54, 8596. [Google Scholar] [CrossRef] [PubMed]

- Perrone, E.; Cesaria, M.; Zizzari, A.; Bianco, M.; Ferrara, F.; Raia, L.; Guarino, V.; Cuscunà, M.; Mazzeo, M.; Gigli, G.; et al. Potential of CO2-Laser Processing of Quartz for Fast Prototyping of Microfluidic Reactors and Templates for 3D Cell Assembly over Large Scale. Mater. Today Bio 2021, 12, 100163. [Google Scholar] [CrossRef] [PubMed]

- Mccormick, W.B. Diffractive Optical Lens Design and Fabrication for Integrated Monitoring of Microelectromechanical Lateral Comb Resonators; West Virginia University: Morgantown, WV, USA, 2004. [Google Scholar]

- Fan, X.; Rong, Y.; Zhang, G.; Wu, C.; Luo, Y.; Huang, Y. High-Profile-Quality Microchannels Fabricated by UV Picosecond Laser for Microfluidic Mixing. Opt. Laser Technol. 2024, 170, 110314. [Google Scholar] [CrossRef]

- Rihakova, L.; Chmelickova, H. Laser Micromachining of Glass, Silicon, and Ceramics. Adv. Mater. Sci. Eng. 2015, 2015, 6. [Google Scholar] [CrossRef]

- Ongaro, C.; Betti, A.; Zardin, B.; Siciliani, V.; Orazi, L.; Bertacchini, J.; Borghi, M. An Alternative Solution for Microfluidic Chip Fabrication. J. Phys. Conf. Ser. 2022, 2385, 012029. [Google Scholar] [CrossRef]

- Bieda, M.; Siebold, M.; Lasagni, A.F. Fabrication of Sub-Micron Surface Structures on Copper, Stainless Steel and Titanium Using Picosecond Laser Interference Patterning. Appl. Surf. Sci. 2016, 387, 175–182. [Google Scholar] [CrossRef]

- Tănase, M.; Bulmaci, M.; Stan, C.; Doinel, R.; Cosgarea, M.; Pop, S.; Maniu, A. Laser Nasal Surgery (Review). Exp. Ther. Med. 2023, 25, 108. [Google Scholar] [CrossRef]

- Li, F.; Liu, D.; Ji, L.; Cui, Y.; Zhao, X.; Ma, W.; Sui, Z.; Gao, Y. Low Coherence Laser Pulse Amplification Theory for Rare Earth Ions Doped Glass Medium. Opt. Express 2022, 30, 44434. [Google Scholar] [CrossRef]

- Song, D.; Wang, J.; Wu, X.; Gao, L.; Yang, J.; Liu, X.; Luo, Q.; Wang, D.; Wang, Y. Microscopic Processing of Transparent Material with Nanosecond and Ultrafast Lasers. Micromachines 2024, 15, 1101. [Google Scholar] [CrossRef]

- Raciukaitis, G. Ultra-Short Pulse Lasers for Microfabrication: A Review. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 1–12. [Google Scholar] [CrossRef]

- Franz, D.; Häfner, T.; Kunz, T.; Roth, G.L.; Rung, S.; Esen, C.; Hellmann, R. Ultrashort Pulsed Laser Drilling of Printed Circuit Board Materials. Materials 2022, 15, 3932. [Google Scholar] [CrossRef] [PubMed]

- Hidai, H.; Matsusaka, S.; Chiba, A.; Morita, N. Heat Accumulation in Microdrilled Glass from Ultraviolet Laser Ablation. Appl. Phys. A Mater. Sci. Process. 2015, 120, 357–367. [Google Scholar] [CrossRef]

- Zubauskas, L.; Markauskas, E.; Vyšniauskas, A.; Stankevič, V.; Gečys, P. Comparative Analysis of Microlens Array Formation in Fused Silica Glass by Laser: Femtosecond versus Picosecond Pulses. J. Sci. Adv. Mater. Devices 2024, 9, 100804. [Google Scholar] [CrossRef]

- Markauskas, E.; Zubauskas, L.; Voisiat, B.; Gečys, P. Efficient Water-Assisted Glass Cutting with 355 Nm Picosecond Laser Pulses. Micromachines 2022, 13, 785. [Google Scholar] [CrossRef]

- Markauskas, E.; Zubauskas, L.; Gečys, P. Efficient Milling and Cutting of Borosilicate Glasses through a Thin Flowing Water Film with a Picosecond Laser. J. Manuf. Processes 2021, 68, 898–909. [Google Scholar] [CrossRef]

- Rahman, T.U.; Rehman, Z.U.; Ullah, S.; Qayyum, H.; Shafique, B.; Ali, R.; Liaqat, U.; Dogar, A.H.; Qayyum, A. Laser-Induced Plasma-Assisted Ablation (LIPAA) of Glass: Effects of the Laser Fluence on Plasma Parameters and Crater Morphology. Opt. Laser Technol. 2019, 120, 105768. [Google Scholar] [CrossRef]

- Wlodarczyk, K.L.; Brunton, A.; Rumsby, P.; Hand, D.P. Picosecond Laser Cutting and Drilling of Thin Flex Glass. Opt. Lasers Eng. 2016, 78, 64–74. [Google Scholar] [CrossRef]

- Wlodarczyk, K.L.; Carter, R.M.; Jahanbakhsh, A.; Lopes, A.A.; Mackenzie, M.D.; Maier, R.R.J.; Hand, D.P.; Maroto-Valer, M.M. Rapid Laser Manufacturing of Microfluidic Devices from Glass Substrates. Micromachines 2018, 9, 409. [Google Scholar] [CrossRef]

- Martan, J.; Prokešová, L.; Moskal, D.; Ferreira de Faria, B.C.; Honner, M.; Lang, V. Heat Accumulation Temperature Measurement in Ultrashort Pulse Laser Micromachining. Int. J. Heat Mass Transf. 2021, 168, 120866. [Google Scholar] [CrossRef]

- Wang, Z.K.; Seow, W.L.; Wang, X.C.; Zheng, H.Y. Effect of Laser Beam Scanning Mode on Material Removal Efficiency in Laser Ablation for Micromachining of Glass. J. Laser Appl. 2015, 27, S28004. [Google Scholar] [CrossRef]

- Chen, X.; Li, T.; Shen, J. CO2 Laser Ablation of Microchannel on PMMA Substrate for Effective Fabrication of Microfluidic Chips. Int. Polym. Process. 2016, 31, 233–238. [Google Scholar] [CrossRef]

- Fissi, L.E.L.; Xhurdebise, V.; Francis, L.A. Effects of Laser Operating Parameters on Piezoelectric Substrates Micromachining with Picosecond Laser. Micromachines 2015, 6, 19–31. [Google Scholar] [CrossRef]

- Hodgson, N.; Heming, S.; Steinkopff, A.; Haloui, H.; Lee, T.S. Ultrafast Laser Ablation at 1035 Nm, 517 Nm and 345 Nm as a Function of Pulse Duration and Fluence. In Proceedings of the Lasers in Manufacturing Conference, Munich, Germany, 24–27 June 2019; p. 345. [Google Scholar]

- Bauer, L.; Keller, U.; Russ, S.; Kumkar, M.; Faißt, B.; Weber, R.; Graf, T. Influence of Pulse Duration on the Glass Cutting Process. In Proceedings of the Lasers in Manufacturing Conference 2015, Munich, Germany, 22–25 June 2015. [Google Scholar]

- Mitchell, R.A.; Schumacher, D.W.; Chowdhury, E.A. Modeling Crater Formation in Femtosecond-Pulse Laser Damage from Basic Principles. Opt. Lett. 2015, 40, 2189. [Google Scholar] [CrossRef] [PubMed]

- Endo, T.; Tani, S.; Sakurai, H.; Kobayashi, Y. Probing Thermal Dissipation Dimensionality to Laser Ablation in the Pulse Duration Range from 300 Fs to 1 Μs. Opt. Express 2023, 31, 36027. [Google Scholar] [CrossRef]

- Ly, S.; Shen, N.; Negres, R.A.; Carr, C.W.; Alessi, D.A.; Bude, J.D.; Rigatti, A.; Laurence, T.A. The Role of Defects in Laser-Induced Modifications of Silica Coatings and Fused Silica Using Picosecond Pulses at 1053 Nm: I Damage Morphology. Opt. Express 2017, 25, 15161. [Google Scholar] [CrossRef]

- Bernhard Klimt and Colleagues Picosecond Lasers: The Power of Cold Ablation. Available online: https://optics.org/article/39899 (accessed on 10 April 2025).

- Karimelahi, S.; Abolghasemi, L.; Herman, P.R. Rapid Micromachining of High Aspect Ratio Holes in Fused Silica Glass by High Repetition Rate Picosecond Laser. Appl. Phys. A Mater. Sci. Process. 2014, 114, 91–111. [Google Scholar] [CrossRef]

- Deepu, P.; Jagadesh, T. A Review on Short and Ultrashort Pulsed Laser Microdrilling: Materials, Mechanism, Methods, and Applications. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 408. [Google Scholar] [CrossRef]

- Sikora, A.; Grojo, D.; Sentis, M. Wavelength Scaling of Silicon Laser Ablation in Picosecond Regime. J. Appl. Phys. 2017, 122, 045702. [Google Scholar] [CrossRef]

- Eymard, J.; Clerc, R.; Duveiller, V.; Commault, B.; Hebert, M. Characterization of UV–Vis–NIR Optical Constants of Encapsulant for Accurate Determination of Absorption and Backscattering Losses in Photovoltaics Modules. Sol. Energy Mater. Sol. Cells 2022, 240, 111717. [Google Scholar] [CrossRef]

- Hazzan, K.E.; Pacella, M.; See, T.L. Laser Processing of Hard and Ultra-Hard Materials for Micro-Machining and Surface Engineering Applications. Micromachines 2021, 12, 895. [Google Scholar] [CrossRef] [PubMed]

- Lawrence, J. (Ed.) Advances in Laser Materials Processing; Series in Welding and Other Joining Technologies; Woodhead Publishing: Cambridge, UK, 2018; ISBN 9780857092649. [Google Scholar]

- Qin, M.; Zhao, X.; Fan, H.; Leng, R.; Yu, Y.; Li, A.; Gao, B. Ultrafast Laser Processing for High-Aspect-Ratio Structures. Nanomaterials 2024, 14, 1428. [Google Scholar] [CrossRef] [PubMed]

- Gamaly, E.G.; Rode, A.V. Physics of Ultra-Short Laser Interaction with Matter: From Phonon Excitation to Ultimate Transformations. Prog. Quantum Electron. 2013, 37, 215–323. [Google Scholar] [CrossRef]

- He, Z.; Lei, L.; Lin, S.; Tian, S.; Tian, W.; Yu, Z.; Li, F. Metal Material Processing Using Femtosecond Lasers: Theories, Principles, and Applications. Materials 2024, 17, 3386. [Google Scholar] [CrossRef]

- Orazi, L.; Romoli, L.; Schmidt, M.; Li, L. Ultrafast Laser Manufacturing: From Physics to Industrial Applications. CIRP Ann. 2021, 70, 543–566. [Google Scholar] [CrossRef]

- Yankov, G.; Garasz, K.; Tá Nski, M.; Kocik, M.; Iordanova, E.; Yankov, G.; Karatodorov, S.; Grozeva, M. The Effect of Process Parameters in Femtosecond Laser. Bulg. J. Phys. 2016, 43, 110–120. [Google Scholar]

- Jiang, L.; Wang, A.D.; Li, B.; Cui, T.H.; Lu, Y.F. Electrons Dynamics Control by Shaping Femtosecond Laser Pulses in Micro/Nanofabrication: Modeling, Method, Measurement and Application. Light Sci. Appl. 2018, 7, 17134. [Google Scholar] [CrossRef]

- Tan, D.; Sharafudeen, K.N.; Yue, Y.; Qiu, J. Femtosecond Laser Induced Phenomena in Transparent Solid Materials: Fundamentals and Applications. Prog. Mater. Sci. 2016, 76, 154–228. [Google Scholar] [CrossRef]

- Bulgakova, N.M.; Zhukov, V.P.; Collins, A.R.; Rostohar, D.; Derrien, T.J.Y.; Mocek, T. How to Optimize Ultrashort Pulse Laser Interaction with Glass Surfaces in Cutting Regimes? Appl. Surf. Sci. 2015, 336, 364–374. [Google Scholar] [CrossRef]

- Stonyte, D.; Jukna, V.; Paipulas, D. Direct Laser Ablation of Glasses with Low Surface Roughness Using Femtosecond UV Laser Pulses. J. Laser Micro Nanoeng. 2022, 17, 121–126. [Google Scholar] [CrossRef]

- Xu, S.-Z.; Yao, C.-Z.; Dou, H.-Q.; Liao, W.; Li, X.-Y.; Ding, R.-J.; Zhang, L.-J.; Liu, H.; Yuan, X.-D.; Zu, X.-T. An Investigation on 800 Nm Femtosecond Laser Ablation of K9 Glass in Air and Vacuum. Appl. Surf. Sci. 2017, 406, 91–98. [Google Scholar] [CrossRef]

- Mačernyte, L.; Skruibis, J.; Vaičaitis, V.; Sirutkaitis, R.; Balachninaite, O. Femtosecond Laser Micromachining of Soda-Lime Glass in Ambient Air and under Various Aqueous Solutions. Micromachines 2019, 10, 354. [Google Scholar] [CrossRef] [PubMed]

- Aljekhedab, F.; Zhang, W.; Haugen, H.K.; Wohl, G.R.; El-Desouki, M.M.; Fang, Q. Influence of Environmental Conditions in Bovine Bone Ablation by Ultrafast Laser. J. Biophotonics 2019, 12, e201800293. [Google Scholar] [CrossRef] [PubMed]

- Jia, X.; Zhao, X. Ultrafast Laser Direct Drilling of High Aspect Ratio Microchannels in Fused Silica: Insights on Channel Self-Termination Mechanisms. Opt. Laser Technol. 2023, 157, 108766. [Google Scholar] [CrossRef]

- Zhao, X.; Shin, Y.C. Femtosecond Laser Drilling of High-Aspect Ratio Microchannels in Glass. Appl. Phys. A Mater. Sci. Process. 2011, 104, 713–719. [Google Scholar] [CrossRef]

- Yang, Y.; Bischoff, K.; Mücke, D.; Esen, C.; Hellmann, R. UV-Ultrashort Pulsed Laser Ablation of Fused Silica. J. Laser Appl. 2024, 36, 012019. [Google Scholar] [CrossRef]

- Liao, K.; Wang, W.; Wang, C.; Cheung, C.F. Fabrication of Microchannels on Silica Glass by Femtosecond Laser Multi-Scan: From Surface Generation Mechanism to Morphology Control. Ceram. Int. 2024, 50, 49634–49642. [Google Scholar] [CrossRef]

- Xu, S.; Qiu, J.; Jia, T.; Li, C.; Sun, H.; Xu, Z. Femtosecond Laser Ablation of Crystals SiO2 and YAG. Opt. Commun. 2007, 274, 163–166. [Google Scholar] [CrossRef]

- Xu, S.-Z.; Sun, K.; Yao, C.-Z.; Liu, H.; Miao, X.-X.; Jiang, Y.-L.; Wang, H.-J.; Jiang, X.-D.; Yuan, X.-D.; Zu, X.-T. Periodic Surface Structures on Dielectrics upon Femtosecond Laser Pulses Irradiation. Opt. Express 2019, 27, 8983. [Google Scholar] [CrossRef]

- Lopez, J.; Niane, S.; Bonamis, G.; Balage, P.; Audouard, E.; Hönninger, C.; Mottay, E.; Manek-Hönninger, I. Percussion Drilling in Glasses and Process Dynamics with Femtosecond Laser GHz-Bursts. Opt. Express 2022, 30, 12533. [Google Scholar] [CrossRef]

- Shaheen, M.E.; Gagnon, J.E.; Fryer, B.J. Experimental Study on 785 Nm Femtosecond Laser Ablation of Sapphire in Air. Laser Phys. Lett. 2015, 12, 66103. [Google Scholar] [CrossRef]

- Zhang, K.; Jiang, L.; Li, X.; Shi, X.; Yu, D.; Qu, L.; Lu, Y. Femtosecond Laser Pulse-Train Induced Breakdown in Fused Silica: The Role of Seed Electrons. J. Phys. D Appl. Phys. 2014, 47, 435105. [Google Scholar] [CrossRef]

- Tsibidis, G.D.; Skoulas, E.; Papadopoulos, A.; Stratakis, E. Convection Roll-Driven Generation of Supra-Wavelength Periodic Surface Structures on Dielectrics upon Irradiation with Femtosecond Pulsed Lasers. Phys. Rev. B 2016, 94, 2–6. [Google Scholar] [CrossRef]

- Andriukaitis, D.; Vargalis, R.; Šerpytis, L.; Drevinskas, T.; Kornyšova, O.; Stankevičius, M.; Bimbiraitė-Survilienė, K.; Kaškonienė, V.; Maruškas, A.S.; Jonušauskas, L. Fabrication of Microfluidic Tesla Valve Employing Femtosecond Bursts. Micromachines 2022, 13, 1180. [Google Scholar] [CrossRef] [PubMed]

- Shin, S. Review of High-Precision Femtosecond Laser Materials Processing for Fabricating Microstructures: Effects of Laser Parameters on Processing Quality, Ablation Efficiency, and Microhole Shape. J. Laser Appl. 2024, 15, 37–48. [Google Scholar] [CrossRef]

- Wang, M.; Cheng, J.; Li, M.; He, F.; Deng, W. Viscosity and Thermal Expansion of Soda-Lime-Silica Glass Doped with Gd2O3 and Y2O3. Solid State Sci. 2012, 14, 1233–1237. [Google Scholar] [CrossRef]

- Aggarwal, R.L.; Ramdas, A.K. Physical Properties of Diamond and Sapphire; CRC Press: Boca Raton, FL, USA, 2019; ISBN 9781000001624. [Google Scholar]

- Sun, P.; Zhou, Y.; Sima, G.; Li, Z.; Cao, L. Design and Fabrication of Glass-Based Integrated Passive Devices. In Proceedings of the 2018 19th International Conference on Electronic Packaging Technology, ICEPT 2018, Shanghai, China, 8–11 August 2018; pp. 59–63. [Google Scholar]

- Aymerich, M.; de Aldana, J.R.; Canteli, D.; Molpeceres, C.; Flores-Arias, M.T. Microchannels Fabricated by Laser: From the Nanosecond to the Femtosecond Pulse Duration. In Proceedings of the International Conference on Photonics, Optics and Laser Technology, Valletta, Malta, 17–29 February 2020; pp. 64–67. [Google Scholar]

- Zhang, J.; Tao, S.; Chen, W.; Wang, B.; Ou, Z.; Zhao, J. Laser Processing Transparent Materials with Nanosecond, Picosecond and Femtosecond Pulses for Industrial Applications. In Proceedings of the Laser applications in microelectronic and optoelectronic manufacturing (LAMOM) XXIII. SPIE, San Francisco, CA, USA, 29–31 January 2018; p. 33. [Google Scholar]

- Ozkan, A.; Leonard, M.; Dunsky, C.; MacKay, J.; Phaneuf, M. Glass Processing Using Microsecond, Nanosecond and Femtosecond Pulsed Lasers. In Proceedings of the PICALO 2004—1st Pacific International Conference on Applications of Laser and Optics, Conference Proceedings, Melbourne, Australia, 19–21 April 2004; Volume 4978, pp. 1–5. [Google Scholar]

- Rudolph, P.; Bonse, J.; Krüger, J.; Kautek, W. Femtosecond- and Nanosecond-Pulse Laser Ablation of Bariumalumoborosilicate Glass. Appl. Phys. A Mater. Sci. Process. 1999, 69, 763–766. [Google Scholar] [CrossRef]

- Al Javed, M.O.; Bin Rashid, A. Laser-Assisted Micromachining Techniques: An Overview of Principles, Processes, and Applications. Adv. Mater. Process. Technol. 2024, 1–44. [Google Scholar] [CrossRef]

- Kunar, S.; Talib, N.B.; Mandal, G. Advanced Machining and Micromachining Processes; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2025; ISBN 9780191600920. [Google Scholar]

- Costa, L.; Terekhov, A.; Rajput, D.; Hofmeister, W.; Jowhar, D.; Wright, G.; Janetopoulos, C. Femtosecond Laser Machined Microfluidic Devices for Imaging of Cells during Chemotaxis. J. Laser Appl. 2011, 23, 042001. [Google Scholar] [CrossRef]

- Ferreira, M.; Carvalho, V.; Ribeiro, J.; Lima, R.A.; Teixeira, S.; Pinho, D. Advances in Microfluidic Systems and Numerical Modeling in Biomedical Applications: A Review. Micromachines 2024, 15, 873. [Google Scholar] [CrossRef]

- García, D.N.; O’Connor, G. Laser-Based Fabrication for Microfluidics Devices on Glass for Medical Applications. In Advances in Microfluidics—New Applications in Biology, Energy, and Materials Sciences; InTechOpen: Rijeka, Croatia, 2016. [Google Scholar]

- Svec, F.; Lv, Y. Advances and Recent Trends in the Field of Monolithic Columns for Chromatography. Anal. Chem. 2015, 87, 250–273. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.; Chu, W.; Wang, P.; Li, W.; Wang, Z.; Cheng, Y. Water-Assisted Laser Drilling of High-Aspect-Ratio 3D Microchannels in Glass with Spatiotemporally Focused Femtosecond Laser Pulses. Opt. Mater. Express 2019, 9, 1971. [Google Scholar] [CrossRef]

- He, F.; Liao, Y.; Lin, J.; Song, J.; Qiao, L.; Cheng, Y.; He, F.; Sugioka, K. Femtosecond Laser Fabrication of Monolithically Integrated Microfluidic Sensors in Glass. Sensors 2014, 14, 19402–19440. [Google Scholar] [CrossRef] [PubMed]

- Wlodarczyk, K.L.; Macpherson, W.N.; Hand, D.P.; Maroto-Valer, M.M. Manufacturing of Microfluidic Devices with Interchangeable Commercial Fiber Optic Sensors. Sensors 2021, 21, 7493. [Google Scholar] [CrossRef]

- Kim, S.; Kim, J.; Joung, Y.H.; Choi, J.; Koo, C. Bonding Strength of a Glass Microfluidic Device Fabricated by Femtosecond Laser Micromachining and Direct Welding. Micromachines 2018, 9, 639. [Google Scholar] [CrossRef]

- Corrielli, G.; Crespi, A.; Osellame, R. Femtosecond Laser Micromachining for Integrated Quantum Photonics. Nanophotonics 2021, 10, 3789–3812. [Google Scholar] [CrossRef]

| Fabrication Method | Description | Pros | Cons | Examples of Glass Types Used |

|---|---|---|---|---|

| Photolithography [12] | Uses UV light and mask to pattern photoresist, followed by etching | High precision and resolution for microchannels | Requires cleanroom facilities and a multi-step process increases complexity and cost | Borosilicate glass (e.g., Borofloat 33), soda–lime glass, and Foturan glass |

| Wet chemical etching [5] | Uses etchants like HF to remove glass, often with photolithography | Cost-effective, produces well-defined geometries, and is often paired with photolithography | Involves hazardous chemicals and requires precise control of etching conditions | Fused silica, soda–lime glass, and Foturan glass |

| Soft lithography [13] | Creates molds (e.g., PDMS) for shaping or bonding with glass | Simple and low-cost, facilitates replication, and hybridizes with glass bonding | Limited by polymer mold stability and requires some cleanroom facilities | Borosilicate glass (Pyrex) |

| 3D printing [39] | Rapid prototyping without cleanroom, custom designs possible | Rapid prototyping, enables complex, custom designs, and no cleanroom is needed | Limited material compatibility and lower resolution compared to other methods | Fused silica and ultra-thin glass |

| Laser ablation [20] | Uses lasers to remove or modify glass, maskless approach | High precision; no cleanroom or masks required; creates complex 3D structures | High initial equipment cost; requires expertise to optimize laser parameters | Fused silica, borosilicate glass (e.g., Borofloat 33), quartz, and Foturan glass |

| Factors | Description | Abbreviations |

|---|---|---|

| Fluence | Energy delivered per unit area | F (J/cm2) |

| Scanning speed | Laser travel speed during processing | Vscan (mm/s) |

| Pulse duration | Time across a pulse at its full-width half maximum (FWHM) | tp (s) |

| Repetition rate | Number of pulses per second | PRR (Hz) |

| Wavelength | Laser output wavelength | λ (nm) |

| Laser beam diameter | The diameter of the laser beam on the sample | dL (µm) |

| Peak power | Maximum peak power attained by a single pulse | Pp (W) |

| Average power | Total average output power utilized in material processing | Pavg (W) |

| Studied Effect | Laser Type | tp | PRR (kHz) | Vscan (mm/s) | Glass Type | Notes |

|---|---|---|---|---|---|---|

| Fluence (F) | CO2 laser (λ = 10.6 μm, dL = 240 μm) [78] | 300 ns | 20 | 20 | Quartz | Efficiency increased from 0.7 × 10−3 to 18 × 10−3 mm3/J as the F increased from 1.12 to 7.18 J/cm2. |

| Nd:YAG laser (λ = 355 nm) [79] | 12 ns | 30 | 5 | Diamond | Removal rate increased from 0.45 × 10−10 to 3.34 × 10−10 g/pulse as the F increased from 11.41 to 47.91 J/cm2. | |

| CO2 laser (λ = 10.6 μm, dL = 300 μm) [80] | 45 μs | 1 | 20 | Fused silica | Ablation depth increased from 0.04 to 10 μm as the F increased from 3 to 5.8 J/cm2. | |

| Nd:YAG laser (λ = 355 nm, dL = 15 μm) [81] | 30 ns | 5 | 20 | Soda–lime | Depth increased from 12 to 50 μm as F increased from 20 to 100 J/cm2, then saturated at 50 μm for fluences above 100 J/cm2. | |

| CO2 laser (λ = 10.6 μm, dL = 240 μm) [78] | 300 ns | 150 | 750 | Quartz | Surface roughness (Sa) increased to 0.75 μm as F increased from 0.80 to 2 J/cm2. | |

| CO2 laser (λ = 10.6 μm, dL = 347 μm) [83] | N/A | 5 | 2000 | Soda–lime | Clear surface melting and solidification cracks form around the channels when the energy deposition rate exceeds 6.0 J/(cm2·s). | |

| Nd:YAG laser (λ = 266 nm, dL = 6 μm) [84] | 10 ns | 4.5 | 0.2–0.6 | Borofloat | Crack-free channels at low energy (78 μJ). | |

| Scanning speed (Vscan) | Nd:YAG laser (λ = 266 nm) [86] | ns | 5 | 5–10 | Pyrex | Removal rate increased from 10 to 18 μm/pulse as Vscan risen from 5 to 10 mm/s. |

| CO2 laser (λ = 10.6 μm, dL= 400 μm) [22] | 45 μs | 20 | 100–600 | K-PSFn214 | Depth increased from 4 μm to 10 μm as Vscan decreased from 600 to 100 mm/s. | |

| CO2 laser (λ = 10.6 μm) [21] | N/A | N/A | 5–25 | Microscope glass | Depth decreased from 55.8 μm to 22.4 μm as Vscan increased from 5 to 25 mm/s. | |

| CO2 laser (λ = 10.6 μm, dL = 400 μm) [22] | 50 μs | 20 | 100–1200 | K-PSFn214 | Visible microcracks in channels at all applied Vscan. | |

| CO2 laser (λ = 10.6 μm, dL = 62 μm) [89] | N/A | 8 | 50–65 | Fused silica | Surface roughness increased from 350 nm to 1500 nm with decreasing Vscan. | |

| pulse duration (tp) | CO2 laser (λ = 10.6 μm, dL = 300 μm) [80] | 54–185 μs | 1 | N/A | Fused silica | Depth increased from 3.5 nm to over 8.2 μm as tp increased from 54 to 185 μs. |

| CO2 laser (λ = 10.6 μm, dL = 266 μm) [91] | 300–1000 μs | 130 | N/A | Fused silica | Depth increased from 5 μm to 44 μm as tp increased from 300 to 1000 μs. | |

| CO2 laser (λ = 10.6 μm, dL = 35 μm) [93] | 1–200 μs | 0.2 | N/A | Fused silica, borosilicate | Shorter tp reduced HAZ and cracking. | |

| CO2 laser (λ = 10.6 μm, dL = 90 μm) [95] | 5–90 μs | 0.5 | 75 | Fused silica | HAZ thickness increased from 3 μm to 9.6 μm with longer tp. | |

| Repetition rate (PRR) | CO2 laser (λ = 10.6 μm, dL = 240 μm) [78] | 300 ns | 20–150 | 20 | Quartz | Efficiency increased from 5 × 10−3 to 12 × 10−3 mm3/J as PRR increased from 20 to 150 kHz. |

| CO2 laser (λ = 10.6 μm, dL = 300 μm) [80] | 100 μs | 0.2–3.2 | 20 | Fused silica | A 500% depth increase with PRR from 300 Hz to 3200 Hz. | |

| Nd:YVO4 laser (λ = 1064 nm, dL = 20 μm) [23] | 20 ns | 8–16 | 200 | Soda–lime | Bottom roughness increased from 12 μm to 19 μm as PRR increased from 8 to 16 kHz, with cracks and surface irregularities observed for PRR above 10 kHz. | |

| Wavelength (λ) | Nd:YAG laser (λ = 355 and 266 nm) [86] | ns | N/A | 10 | Pyrex and sapphire | Removal rate at 266 nm: 23 μm/pulse (Pyrex), 0.8 μm/pulse (sapphire). At 355 nm, lower rates: 4 μm/pulse (Pyrex) and 0.4 μm/pulse (sapphire), with the 266 nm laser providing better precision. |

| Glass types | Nd:YVO4 laser (λ = 1064 nm, dL = 19 μm) [97] | 20 ns | N/A | N/A | Soda–lime, borosilicate, fused silica, sapphire | Threshold values: 116 J/cm2 (soda–lime), 954 J/cm2 (borosilicate), 1054 J/cm2 (fused silica), 1100 J/cm2 (sapphire). |

| CO2 laser (λ = 10.6 μm, dL = 35 μm) [93] | 20 μs | 0.2 | N/A | Fused silica, borosilicate | Higher removal rate for borosilicate (up to 3.5 μm/pulse) compared to fused silica (2 μm/pulse). | |

| CO2 laser (λ = 10.6 μm, dL = 35 μm) [98] | N/A | 1 | N/A | Quartz, B270, Borofloat, Pyrex, soda–lime | Quartz microchannels exhibited smoother surfaces and fewer microcracks than other glass types. | |

| Nd:YVO4 laser (λ = 355 nm, dL = 1 μm) [65] | 1.3 ns | 5 | 100 | Fused silica, diamond, sapphire | Cracking and deformation in fused silica glass, minor cracking, and minimal distortion in other glass types. |

| Studied Effect | Laser Type | tp | PRR (kHz) | Vscan (mm/s) | Glass Type | Notes |

|---|---|---|---|---|---|---|

| Fluence (F) | Picosecond laser (λ = 355 nm, dL = 13.8 μm) [100] | 10 ps | 800 | N/A | Soda–lime | Crater depth increased from 0.035 to 0.143 μm as F increased from 3.28 to 6.49 J/cm2 |

| Picosecond laser (λ = 355 nm, dL = 15 μm) [111] | 10 ps | 800 | 200 | Borosilicate | Efficiency increased from 0.1 to 3.2 μm3/μJ as F increased from 2 to 3 J/cm2, then stabilized around 3.2 μm3/μJ for F values exceeding 3 J/cm2 | |

| Picosecond laser (λ = 1064 nm, dL = 27 μm) [112] | 13 ps | 100 | 2 | Borosilicate | Efficiency rose from 0.9 to 1.8 μm3/μJ as F increased from 5.5 to 12 J/cm2, then stabilized at approximately 1.6 μm3/μJ for F above 12 J/cm2 | |

| Thin-disk laser (λ = 355 nm, dL = 10 μm) [114] | 6 ps | 20 | 100 | Thin glass | Effective cutting speed increased from 5 to 19 mm/s as F increased from 10 to 15 J/cm2, then stabilized beyond 15 J/cm2 | |

| Picosecond laser (λ = 515 nm, dL = 21 μm) [115] | 6 ps | 100 | 150 | Borosilicate | Slight increase in average surface roughness from 1.55 µm to 1.72 µm as F increased from 16 to 33 J/cm2 | |

| Picosecond laser (λ = 515 nm, dL = 24 μm) [14] | 6 ps | 20 | 40 | Borofloat 33 | Surface roughness remained around 1.6 µm, with minimal variation across F ranging from 11 to 31 J/cm2 | |

| Thin-disk laser (λ = 343 nm, dL = 10 μm) [114] | 6 ps | 20 | 100 | AF32 Eco thin glass | A small HAZ (<20 μm) appeared around holes produced at F values ranging from 20 to 37 J/cm2, with no microcracks observed | |

| Picosecond laser (λ = 1064 nm, dL= 60 μm) [79] | 10 ps | 200 | 5 | Diamond | Cracks and chipping at F of 1.41 and 2.83 J/cm2 | |

| Scanning speed (Vscan) | Picosecond laser (λ = 355 nm, dL = 15 μm) [111] | 10 ps | 653 | 200–1000 | Borosilicate | Optimal Vscan was 800 mm/s, achieving 5.75 μm3/μJ ablation efficiency, compared to 3.25 and 4 μm3/μJ at 200 and 1000 mm/s, respectively |

| Picosecond laser (λ = 1064 nm, dL = 25 μm) [117] | <12 ps | 50 | 5–360 | Glass | Cracks and debris below 75 mm/s, cracks disappeared and debris remained between 75–150 mm/s, no cracks or debris above 150 mm/s | |

| Pulse duration (tp) | Yb-fiber laser (λ = 1035, 517, and 345 nm, dL = 20 μm) [120] | 1.5–14 ps | 250 | N/A | BK7 | At F = 3.2 J/cm2 and 1035 nm, there is a 37% increase in etching rate with 1.5 ps pulses compared to 10 ps. At F = 4 J/cm2 and 517 nm, ablation rate of 0.65 mm3/(W·min) at 1.5 ps, 0.48 mm3/(W·min) at 14 ps. At F = 1.8 J/cm2 and 345 nm, ablation rate of 0.50 mm3/(W·min) at 1.5 ps, 0.10 mm3/(W·min) at 10 ps |

| Picosecond laser (λ = 1053 nm, dL = 50 μm) [124] | 0.4–60 ps | 10 | N/A | Fused silica | Smooth craters at 1.8 ps pulses, damage morphologies with local defects or vulnerable areas at longer tp | |

| Repetition rate (PRR) | Picosecond laser (λ = 1000 nm, dL = 25 μm) [125] | <10 ps | 500–2000 | N/A | Glass | Removal rate reached 14 mm3/min at 2000 kHz, compared to 2 mm3/min at 500 kHz |

| Nd:YVO4 laser (λ = 532 nm, dL = 3.4 μm) [126] | 12 ps | 200–1000 | 0.1 | Fused silica | Depths of 1 mm, 500 µm, and 200 µm at 200, 400, and 1000 kHz, respectively, with a large HAZ (>100 µm at 400 kHz and 200 µm at 1000 kHz) around the entrance, and no HAZ at 200 kHz | |

| Picosecond laser (λ = 1064 nm, dL = 26.5 μm) [66] | 10 ps | 400–800 | 5000 | Soda–lime | 70% reduction in cutting efficiency at 800 kHz compared to 400 kHz | |

| Picosecond laser (λ = 1064 nm, dL = 27 μm) [110] | 13 ps | 400–650 | 1000 | Borosilicate | Heat accumulation effects became more pronounced as the PRR increased from 400 to 650 kHz | |

| Picosecond laser (λ = 355 nm, dL = 13.6 μm) [100] | 10 ps | 500– 800 | 4000 | Soda–lime | Irregular edges at higher PRR (600–800 kHz) compared to 500 kHz | |

| Wavelength (λ) | Thin-disk laser (λ = 1030, 515, and 343 nm, dL = 22.5 μm) [114] | 6 ps | 400 | 2000 | AF32 glass | Highest cutting speed (110 mm/s) was attained at 1030 nm, compared to 70 mm/s at 515 nm and 30 mm/s at 343 nm, with the best cutting quality observed at 343 nm |

| Yb-Fiber laser (λ = 1035, 517, and 345 nm, dL = 25 μm) [120] | 5 ps | 250 and 500 | N/A | BK7 | The highest ablation rate, 0.25 mm3/(W·min), occurred at 1035 nm, compared to 0.21 mm3/(W·min) at 517 nm and 0.15 mm3/(W·min) at 343 nm | |

| Glass types | Thin-disk laser (λ = 1030 nm, dL = 19 μm) [97] | 10 ps | N/A | N/A | Soda–lime, fused silica, sapphire, borosilicate | Soda–lime and borosilicate glasses exhibited lower ablation thresholds of 9.54 and 9.40 J/cm2, respectively, compared to fused silica (11.02 J/cm2) and sapphire (13.05 J/cm2) |

| Studied Effect | Laser Type | tp | PRR (kHz) | Vscan (mm/s) | Glass Type | Notes |

|---|---|---|---|---|---|---|

| Fluence (F) | Ti:sapphire laser (λ = 800 nm, dL = 27 μm) [141] | 35 fs | 0.01 | N/A | Borosilicate | The ablation rate increased from 0.19 to 0.63 μm/pulse as the F rose from 0.9 to 3.5 J/cm2, stabilizing at 0.65 μm/pulse for F between 3.5 and 11 J/cm2 |

| Yb:KGW laser (λ = 1030 nm, dL = 20 μm) [142] | 280 fs | 60 | 100 | Soda–lime | Groove depth increased from 55 to 90 µm as F rose from 9.5 to 23.5 J/cm2 | |

| Femtosecond laser (λ = 1030 nm, dL = 7.9 μm) [144] | 190 fs | 1 | 100 | Fused silica | Channel depth > 850 µm at 1958 J/cm2, compared to 150 µm at 244 J/cm2. Smooth sidewalls at 1101.7 J/cm2 and lower F, rougher sidewalls at higher F like 1958 J/cm2 | |

| Femtosecond laser (λ = 343 nm, dL = 14.5 μm) [146] | 220 fs | 50 | 100 | Fused silica | Topological changes or chipping at cavity edges as F increased from 5 to 22 J/cm2. Surface roughness: 0.37 µm at 5 J/cm2, 0.54 µm at 22 J/cm2 | |

| Scanning speed (Vscan) | Yb:KGW laser (λ = 1030 nm, dL = 20 μm) [142] | 280 fs | 60 | 50–300 | Soda–lime | Groove depth decreased to 40 µm as Vscan increased to 300 mm/s, compared to 135 µm at 50 mm/s |

| Yb:KGW laser (λ = 1030 nm, dL = 7.9 μm) [144] | 190 fs | 1 | 0.020–0.5 | Fused silica | The channel depth increased from 400 to 750 µm as Vscan rose from 20 to 150 μm/s, then decreased to 250 µm as Vscan further increased to 500 μm/s | |

| Ti:sapphire laser (λ = 800 nm) [24] | 100 fs | 1 | 0.5–2 | Quartz | At lower Vscan (<1.5 mm/s), ablation quality improved, but at Vscan below 0.5 mm/s, heat accumulation caused tiny cracks. At higher Vscan (>1.5 mm/s), etching quality deteriorated | |

| Pulse duration (tp) | Ti:sapphire laser (λ = 800 nm, dL = 27 μm) [141] | 35–500 fs | 0.01 | N/A | Borosilicate | Ablation rate: 0.22 μm/pulse with 500 fs pulses and rough surface, 0.65 μm/pulse with 35 fs pulses and smooth crater |

| Repetition rate (PRR) | Yb-doped laser (λ = 1030 nm, dL = 3.8 μm) [150] | 500 fs | 0.005–200 | N/A | Soda–lime | Etching depth increased from 147 to 350 µm as PRR rose from 5 Hz to 20 kHz with excellent quality, but beyond 20 kHz, the depth decreased, and a HAZ appeared on the surface |

| Ti:sapphire laser (λ = 800 nm, dL = 27 μm) [141] | 35 f | 0.01–0.5 | N/A | Borosilicate | Ablation rates were 0.69 µm/pulse at 10 Hz, 0.51 µm/pulse at 100 Hz, and 0.48 µm/pulse at 500 Hz, with microcracks forming at 500 Hz | |

| Wavelength (λ) | Femtosecond laser (λ = 1030 and 343 nm, dL = 14.5 μm) [146] | 220 fs | 50 | 100 | Fused silica | At low F, the IR laser achieved a significant removal depth per layer, while the UV laser enhanced depth at higher F and notably improved surface quality |

| Glass types | Yb-doped laser (λ = 1030 nm, dL = 3.8 μm) [150] | 500 fs | 10 | N/A | Soda–lime, sapphire, borosilicate (AF32), fused silica | Sapphire and soda–lime exhibited higher microchannel depths (250 and 240 µm, respectively) than AF32 and fused silica (180 and 115 µm, respectively), although fused silica showed superior removal quality |

| Feature | Material | Long-Pulse Laser (≥ns) | Short-Pulse Laser (ps) | Ultrashort-Pulse Laser (fs) |

|---|---|---|---|---|

| Ablation threshold | Soda–lime | High | Medium | Low [97] |

| Borosilicate | ||||

| Fused silica | ||||

| Sapphire | ||||

| Bariumalumo–borosilicate glass | Low | Low | Low [162] | |

| Ablation efficiency | Soda–lime | Low | High | High [159] |

| Sapphire | Low | Medium | High [160] | |

| BK-7 | ----- | High | Low [120] | |

| Diamond | High | Low [79] | ----- | |

| Ablation quality | Fused silica | Low | ----- | High [161] |

| BK-7 | High | ----- | Low [161] | |

| Diamond | High | Low [79] | ----- | |

| Fused silica | ----- | Low | High [110] | |

| Thermal damage | Fused silica | High | ----- | Low [161] |

| BK-7 | ||||

| Surface roughness | Soda–lime | Low | High | High [127] |

| Fused silica | High | ----- | Low [161] | |

| BK-7 | Low | ----- | Low [161] | |

| Fused silica | Low | High [110] |

| Parameter | Pulse Duration | Range Studied | Optimal for Efficiency | Optimal for Quality | Notable Trends |

|---|---|---|---|---|---|

| Fluence (F) | Long (≥ns) [78,79,80,81] | 0.8–132.3 J/cm2 | High F (e.g., 100 J/cm2) | Low F (e.g., 0.8 J/cm2) | Efficiency increases with F, while quality decreases due to thermal damage |

| Short (ps) [100,111,112,114] | 2–37 J/cm2 | Moderate F (e.g., 3–15 J/cm2) | Low to moderate F (e.g., 3–20 J/cm2) | Efficiency increases to a threshold, then stabilizes due to plasma shielding, while quality degrades at high F | |

| Ultrashort (fs) [141,142,144,146] | 0.9–1958 J/cm2 | High F (e.g., up to 1958 J/cm2) | Low to moderate F (e.g., 5–1101 J/cm2) | Efficiency increases with F, but high F increases roughness and microcracking | |

| Scanning speed (Vscan) | Long (≥ns) [21,22,86,89] | 5–1200 mm/s | Moderate (e.g., 10 mm/s) | High (e.g., 600 mm/s) | Slower speeds increase depth but risk thermal damage, while faster speeds improve quality |

| Short (ps) [111,117] | 5–1000 mm/s | Moderate (e.g., 800 mm/s) | High (e.g., >150 mm/s) | Efficiency peaks at optimal speed; slower speeds cause cracks, while faster speeds reduce depth | |

| Ultrashort (fs) [24,142,144] | 20 μm/s–300 mm/s | Optimal (e.g., 150 μm/s) | Moderate (e.g., 1.5 mm/s) | Slower speeds maximize depth to a threshold, then stabilize, but risk heat buildup; faster speeds enhance quality | |

| Pulse duration (tp) | Long (≥ns) [80,91,93,95] | 5–1000 μs | Longer tp (e.g., 1000 μs) | Shorter tp (e.g., 5 μs) | Longer tp increases depth and expands HAZ, while shorter tp reduces thermal effects |

| Short (ps) [120,124] | 1.5–60 ps | Shorter tp (e.g., 1.5 ps) | Shorter tp (e.g., 1.5 ps) | Shorter tp enhances efficiency and quality by minimizing thermal diffusion | |

| Ultrashort (fs) [141] | 35–500 fs | Shorter tp (e.g., 35 fs) | Shorter tp (e.g., 35 fs) | Shorter tp enhances efficiency and quality by reducing HAZ and enabling precise ablation | |

| Repetition rate (PRR) | Long (≥ns) [23,78,80] | 0.2–150 kHz | High (e.g., 150 kHz) | Low (e.g., 300 Hz) | Higher PRR boosts efficiency through heat accumulation but risks thermal damage, impacting quality |

| Short (ps) [66,100,110,125,126] | 200–2000 kHz | Moderate (e.g., 2000 kHz) | Low to moderate (e.g., <600 kHz) | High PRR increases efficiency but causes thermal damage above threshold | |

| Ultrashort (fs) [141,150] | 5 Hz–200 kHz | Moderate (e.g., 20 kHz) | Low (e.g., <20 kHz) | Efficiency peaks at moderate PRR; high PRR increases HAZ and degrades quality | |

| Wavelength (λ) | Long (≥ns) [86,96] | 193–355 nm | Shorter λ (e.g., 266 nm) | Shorter λ (e.g., 193 nm) | Shorter λ improves absorption and precision, while longer λ increases thermal effects |

| Short (ps) [114,120] | 343–1035 nm | Longer λ (e.g., 1035 nm) | Shorter λ (e.g., 343 nm) | Longer λ enhances efficiency through deeper penetration; shorter λ improves quality | |

| Ultrashort (fs) [146] | 343–1030 nm | Varies (IR low F, UV high F) | Shorter λ (e.g., 343 nm) | Shorter λ reduces roughness and improves quality; efficiency varies with F | |

| Glass type | Long (≥ns) [65,93,97,98] | Soda–lime, borosilicate, fused silica, sapphire, quartz, B270, Pyrex, and diamond | Low threshold (e.g., soda–lime) | High threshold (e.g., quartz) | Low-threshold glasses are effective at ablation but may compromise quality, whereas high-threshold glasses improve quality |

| Short (ps) [97] | Soda–lime glass, fused silica, sapphire, and borosilicate | Low threshold (e.g., soda–lime) | High threshold (e.g., fused silica) | Lower thresholds increase efficiency, while higher thresholds enhance quality | |

| Ultrashort (fs) [150] | Soda–lime, sapphire, borosilicate (AF32), and fused silica | Low threshold (e.g., soda–lime) | Low thermal expansion (e.g., fused silica) | Low threshold boosts efficiency; low thermal expansion reduces cracking and improves quality |

| Benefit | Application | Highlighted Features | Laser Parameters (tp, λ, PRR, F, Vscan) |

|---|---|---|---|

| High precision and resolution | Fine, intricate designs (e.g., single-cell analysis, high-density arrays) | Feature sizes down to 3 μm, roughness ~0.8 μm | 160 fs, 800 nm, 250 kHz, 0.1–0.5 mm/s, and up to 1.4 W [165] |

| Minimal thermal damage | Biomedical devices | Negligible HAZ, withstands up to 620 °C | Femtosecond, ultrashort-pulse, high peak intensity, not specified [31] |

| Rapid prototyping and cost-effectiveness | Prototyping, small batch production for research and development | Fabrication in <2 h, 18 min for pattern | 6 ps, 515 nm, up to 40 kHz, up to 80 mm/s, and up to 62.8 μJ [14,115] |

| Superior cell adhesion | Better cell attachment on glass surfaces in tissue engineering and cell studies | Higher cell density vs. PMMA at 30 min | CO2 laser, 5–25 mm/s, 4.5–18 W, not specified [21] |

| High aspect ratio microchannels | Fabricates long, narrow channels with high depth-to-width ratio for separation processes and reactors | Aspect ratio of ~30 for 10 mm thick glass | 40 fs, 800 nm, 1 kHz, and 4 mJ (spatiotemporal focusing, not specified) [169] |

| Integration of sensors and 3D structures | Real-time monitoring in various applications | Embedding sensors for in situ measurements | 6 ps, 515 nm, up to 40 kHz, up to 80 mm/s, and up to 62.8 μJ [14] |

| Reduced use of hazardous chemicals | Sustainable manufacturing | No use of projection masks, dangerous chemicals | 6 ps, 515 nm, up to 40 kHz, up to 80 mm/s, and up to 62.8 μJ [14] |

| Hermetically sealed devices | Contamination-free operations | Bonding strength: 1.45 ± 0.15 MPa | 300 fs to 10 ps, 1300 nm, and 10 μJ for patterning, 2.7 μJ for welding, 500 kHz, 100 mm/s for patterning, and 20 mm/s for welding [172] |

| Area | Focus | Key Challenge | Expected Outcome |

|---|---|---|---|

| Beam Shaping and Scanning | Enhance precision with advanced techniques | Controlling energy distribution | Complex, high-aspect-ratio structures |

| Hybrid Material Integration | Combining glass with polymers | Material compatibility | Multifunctional devices |

| Parameter Optimization | Fine-tuning fluence, speed, etc. | Balancing efficiency and quality | High-quality microchannels |

| 3D Architectures | Optimize for intricate designs and optics | Integration complexity | Advanced detection systems |

| Industrial Scalability | Cost-effective and high-throughput methods | Scaling costs and processes | Industrial adoption |

| Technological Challenges | Reduce costs and improve accessibility | High equipment cost, expertise | Broader adoption |

| Interdisciplinary Applications | Expand into quantum and biomedical fields | Application-specific optimization | Broader impacts in emerging fields |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alayed, M.; Al Fayez, N.; Alfihed, S.; Alshamrani, N.; Alghannam, F. Effects of Process Parameters on Pulsed Laser Micromachining for Glass-Based Microfluidic Devices. Materials 2025, 18, 2657. https://doi.org/10.3390/ma18112657

Alayed M, Al Fayez N, Alfihed S, Alshamrani N, Alghannam F. Effects of Process Parameters on Pulsed Laser Micromachining for Glass-Based Microfluidic Devices. Materials. 2025; 18(11):2657. https://doi.org/10.3390/ma18112657

Chicago/Turabian StyleAlayed, Mrwan, Nojoud Al Fayez, Salman Alfihed, Naif Alshamrani, and Fahad Alghannam. 2025. "Effects of Process Parameters on Pulsed Laser Micromachining for Glass-Based Microfluidic Devices" Materials 18, no. 11: 2657. https://doi.org/10.3390/ma18112657

APA StyleAlayed, M., Al Fayez, N., Alfihed, S., Alshamrani, N., & Alghannam, F. (2025). Effects of Process Parameters on Pulsed Laser Micromachining for Glass-Based Microfluidic Devices. Materials, 18(11), 2657. https://doi.org/10.3390/ma18112657