Novel Flame-Retardant Wood-Polymer Composites by Using Inorganic Mineral Huntite and Hydromagnesite: An Aspect of Application in Electrical Engineering

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Compounding

- -

- Temperature of the extruder zones—(170–185) °C;

- -

- Screw rotation speed—190 rpm;

- -

- Pressure—10 bar.

2.3. Characterization

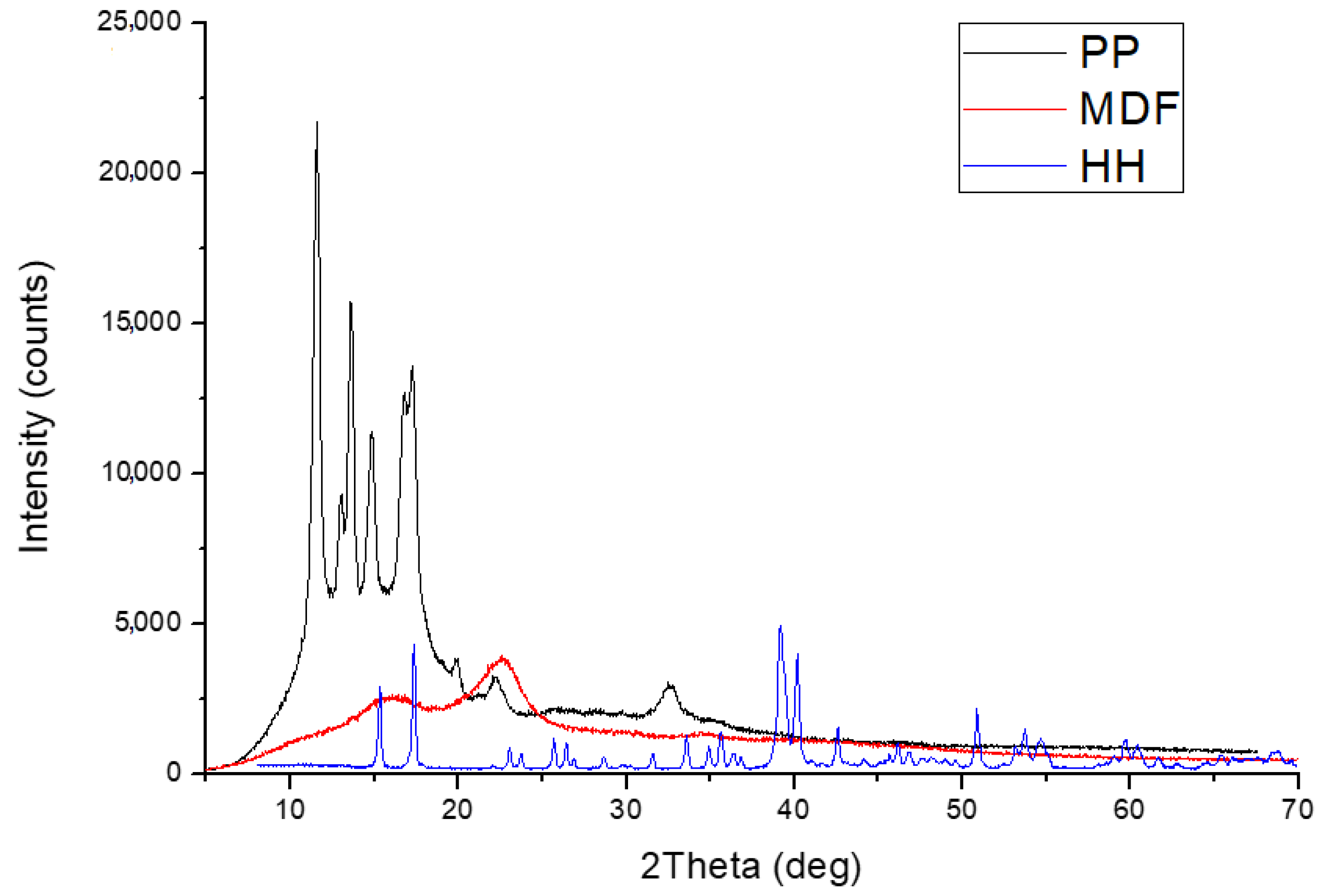

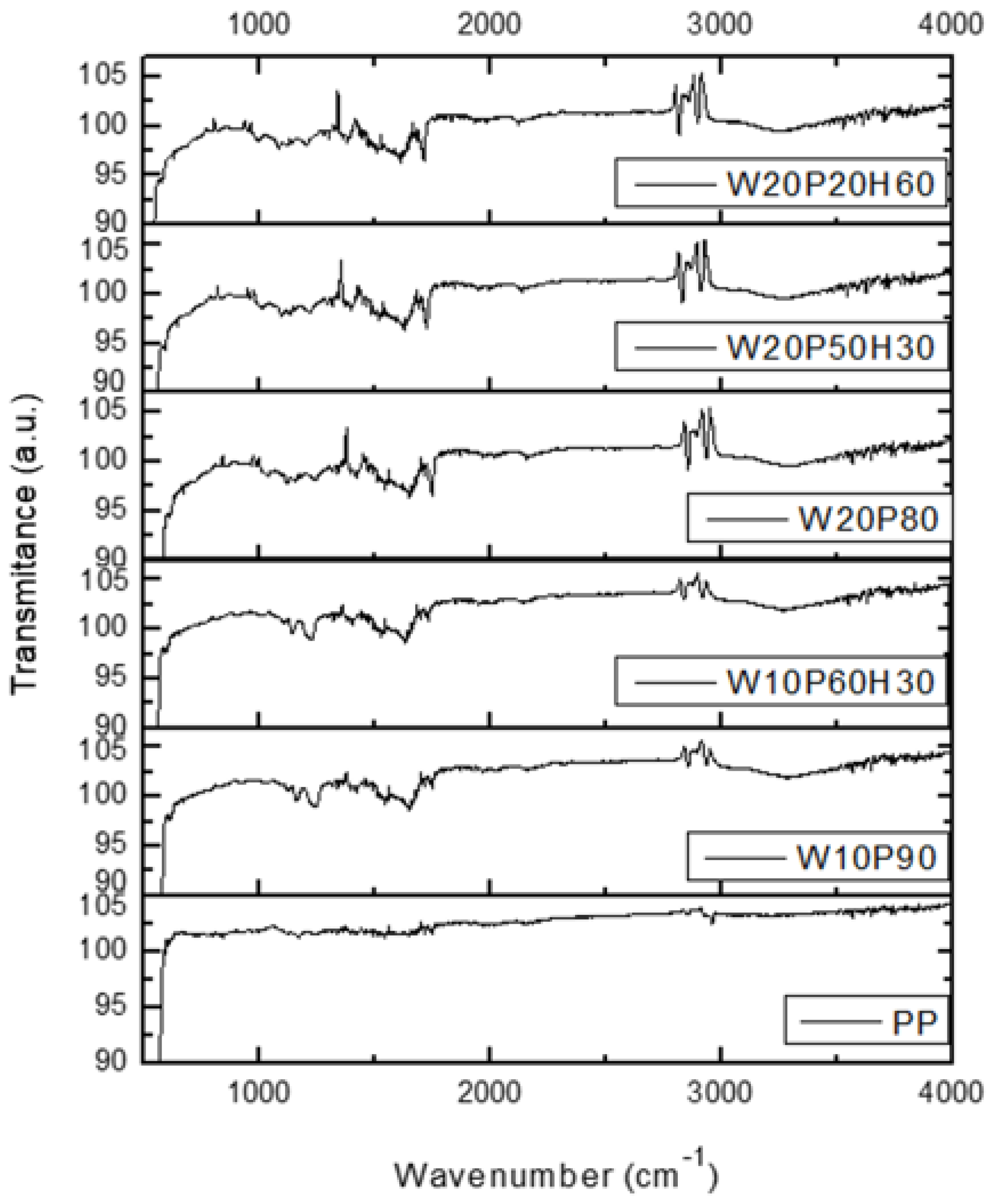

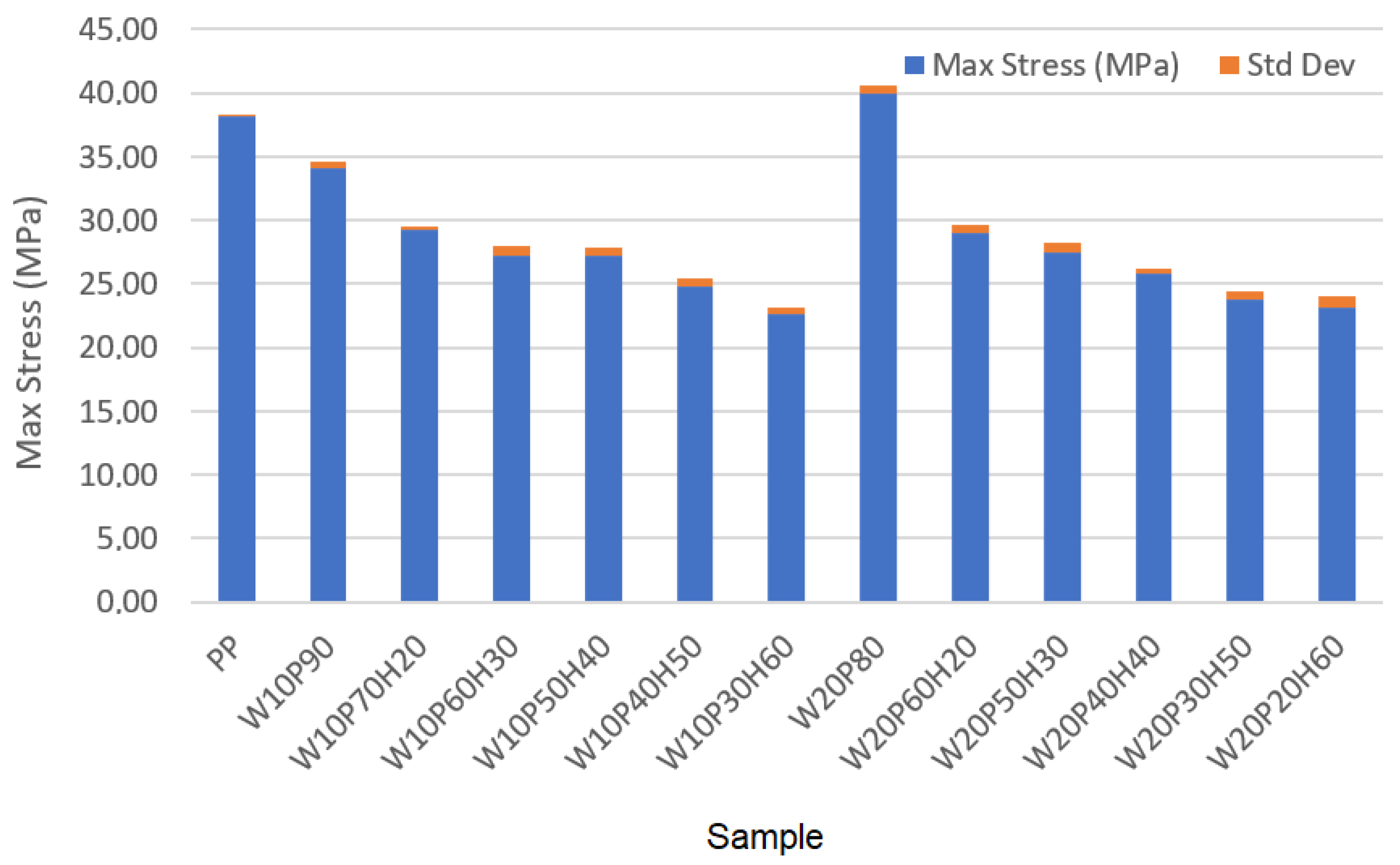

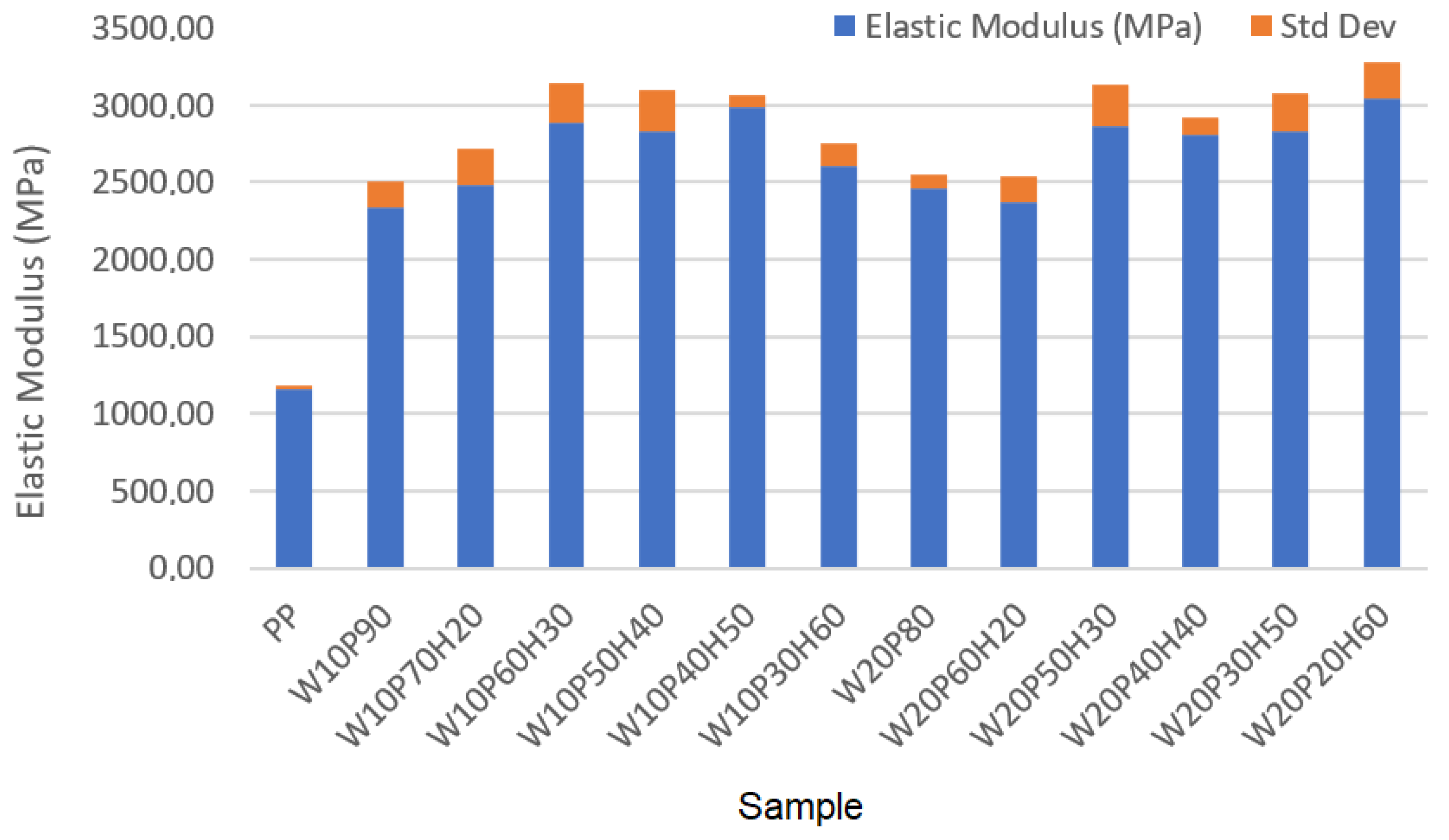

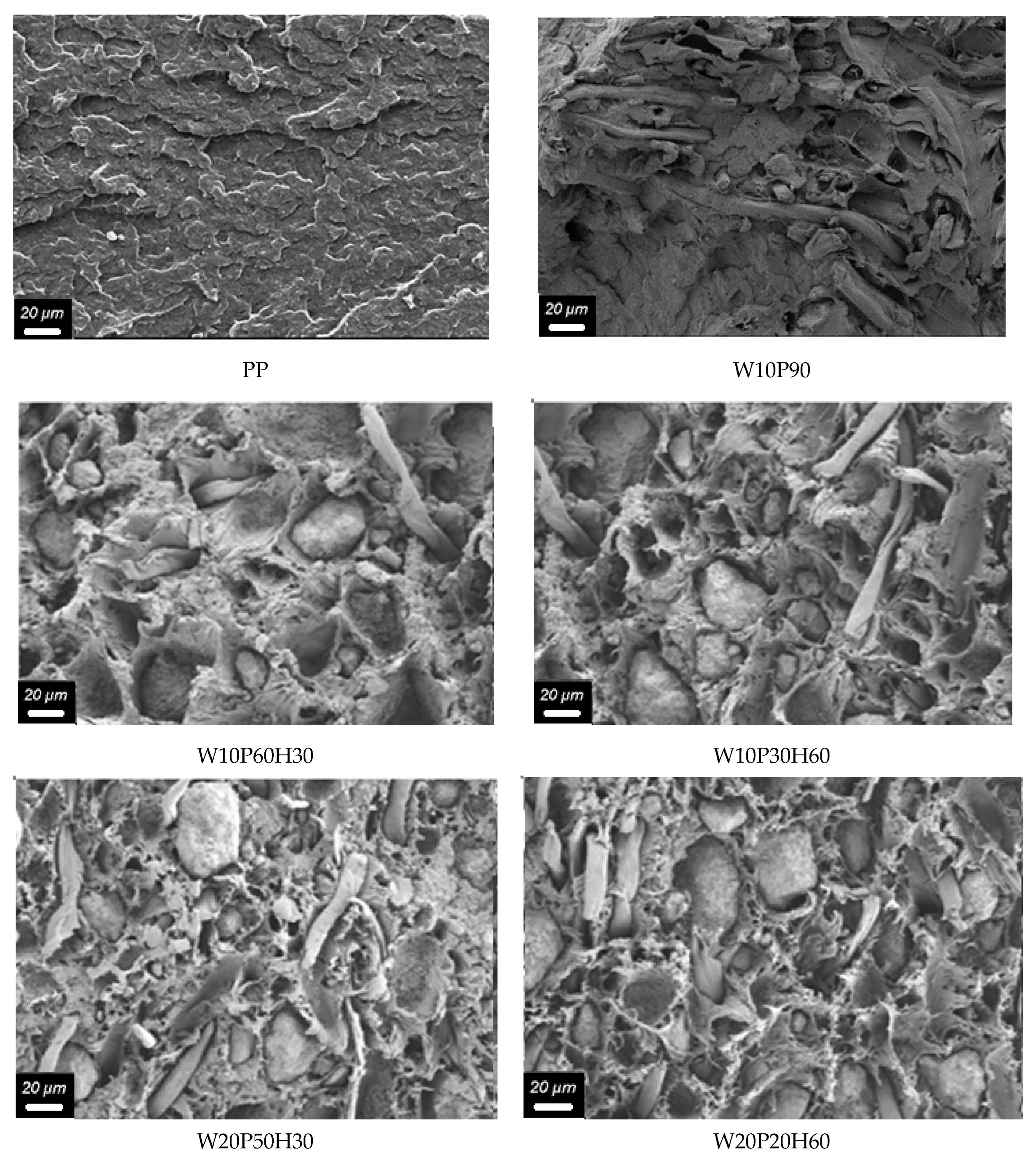

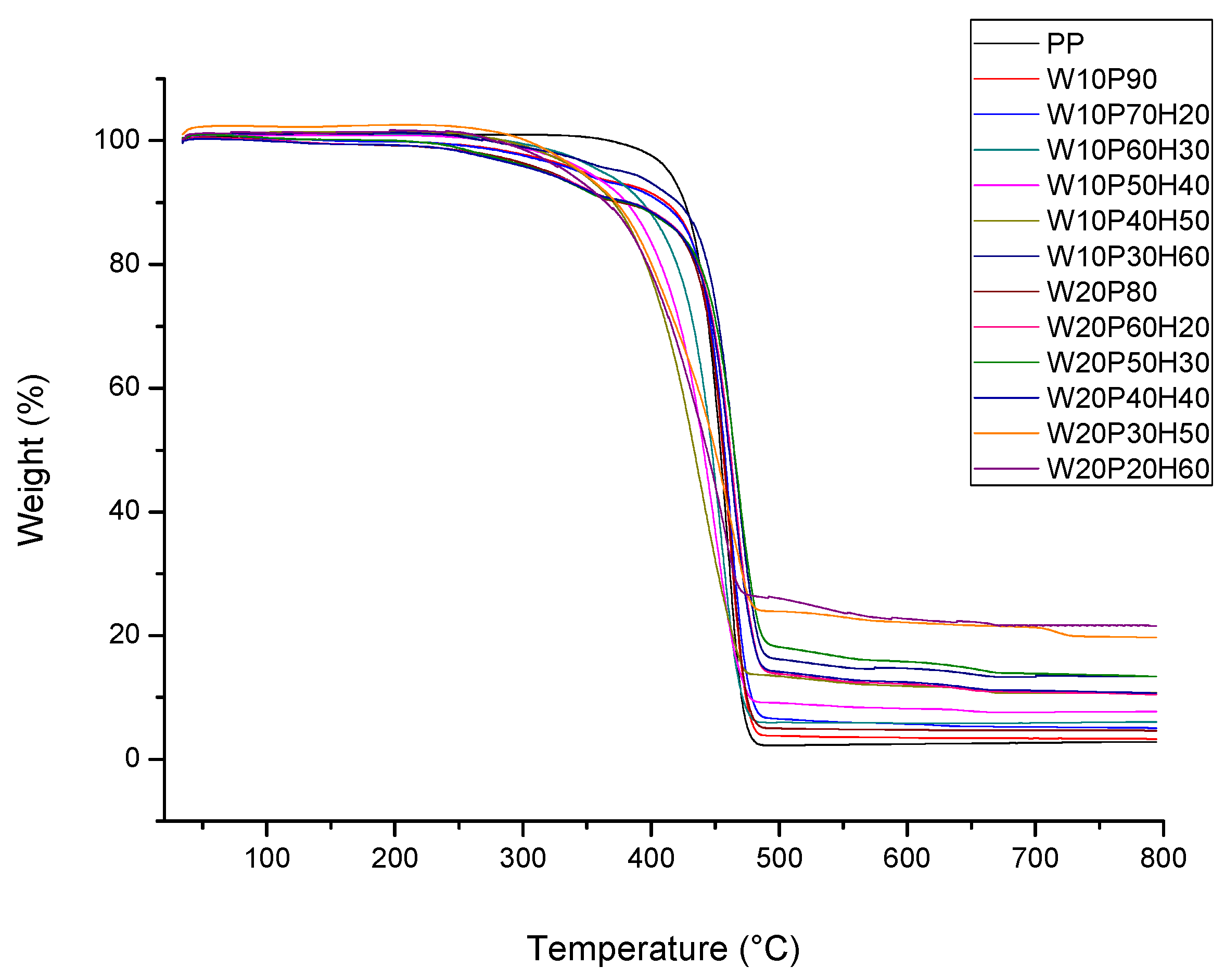

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Szydło, Z.A. History of Fire. Chem. Didact. Ecol. Metrol. 2017, 24, 23–43. [Google Scholar] [CrossRef]

- Negi, P.; Pathani, A.; Bhatt, B.C.; Swami, S.; Singh, R.; Gehlot, A.; Thakur, A.K.; Gupta, L.R.; Priyadarshi, N.; Twala, B.; et al. Integration of Industry 4.0 Technologies in Fire and Safety Management. Fire 2024, 7, 335. [Google Scholar] [CrossRef]

- Ni, X.; Zhang, K.; Zheng, Z.; Wang, W.; Hu, S. Application of Composite Dry Powders for Simultaneous Fire Extinguishment and Liquid Solidification of Methanol. Fire 2025, 8, 69. [Google Scholar] [CrossRef]

- Yilmaz Atay, H. Novel eco-friendly flame retardant wood composites reinforced by huntite and hydromagnesite minerals. Wood Mater. Sci. Eng. 2021, 17, 648–658. [Google Scholar] [CrossRef]

- Rabajczyk, A.; Zielecka, M.; Popielarczyk, T.; Sowa, T. Nanotechnology in Fire Protection—Application and Requirements. Materials 2021, 14, 7849. [Google Scholar] [CrossRef] [PubMed]

- Rabajczyk, A.; Zielecka, M.; Gniazdowska, J. Application of Nanotechnology in Extinguishing Agents. Materials 2022, 15, 8876. [Google Scholar] [CrossRef]

- Bras, M.L.; Wilkie, C.A.; Bourbigot, S. Fire Retardancy of Polymers—New Applications of Mineral Fillers; The Royal Society of Chemistry: Sawston, UK, 2005; pp. 4–6. [Google Scholar]

- Loboichenko, V.; Wilk-Jakubowski, J.L.; Levterov, A.; Wilk-Jakubowski, G.; Statyvka, Y.; Shevchenko, O. Using the burning of polymer compounds to determine the applicability of the acoustic method in fire extinguishing. Polymers 2024, 16, 3413. [Google Scholar] [CrossRef]

- Shcherbak, O.; Loboichenko, V.; Skorobahatko, T.; Shevchenko, R.; Levterov, A.; Pruskyi, A.; Khrystych, V.; Khmyrova, A.; Fedorchuk-Moroz, V.; Bondarenko, S. Study of Organic Carbon-Containing Additives to Water Used in Fire Fighting, in Terms of Their Environmental Friendliness. Fire Tech. 2024, 60, 3739–3765. [Google Scholar] [CrossRef]

- Nabipour, H.; Shi, H.; Wang, X.; Hu, X.; Song, L.; Hu, Y. Flame retardant Cellulose-Based hybrid hydrogels for firefighting and fire prevention. Fire Tech. 2022, 58, 2077–2091. [Google Scholar] [CrossRef]

- Wicklein, B.; Kocjan, D.; Carosio, F.; Camino, G.; Bergström, L. Tuning the nanocellulose–borate interaction to achieve highly flame retardant hybrid materials. Chem. Mater. 2016, 28, 1985–1989. [Google Scholar] [CrossRef]

- LaRocco, J.; Tahmina, Q.; Essel, S.; Simonis, J. Firefighting with Conductive Aerosol-Assisted Vortex Rings. Technologies 2025, 13, 10. [Google Scholar] [CrossRef]

- Sałasińska, K.; Mizera, K.; Celiński, M.; Kozikowski, P.; Mirowski, J.; Gajek, A. Thermal properties and fire behavior of a flexible poly (vinyl chloride) modified with complex of 3-aminotriazole with zinc phosphate. Fire Saf. J. 2021, 122, 103326. [Google Scholar] [CrossRef]

- Teng, T.J.; Mat Arip, M.N.; Sudesh, K.; Nemoikina, A.; Jalaludin, Z.; Ng, E.P.; Lee, H.L. Conventional technology and nanotechnology in wood preservation: A review. BioResources 2018, 13, 9220–9252. [Google Scholar] [CrossRef]

- Oliveira, A.K.F.; d’Almeida, J.R.M. Description of the mechanical behavior of different thermoset composites reinforced with Manicaria saccifera fibers. J. Compos. Mater. 2014, 48, 1189–1196. [Google Scholar] [CrossRef]

- Liu, M.; Qing, Y.; Wu, Y.; Liang, J.; Luo, S. Facile fabrication of superhydrophobic surfaces on wood substrates via a one-step hydrothermal process. Appl. Surf. Sci. 2015, 330, 332–338. [Google Scholar] [CrossRef]

- Lozhechnikova, A.; Bellanger, H.; Michen, B.; Burgert, I.; Österberg, M. Surfactant-free carnauba wax dispersion and its use for layer-by-layer assembled protective surface coatings on wood. Appl. Surf. Sci. 2017, 396, 1273–1281. [Google Scholar] [CrossRef]

- Bütün, F.Y.; Sauerbier, P.; Militz, H.; Mai, C. The effect of fibreboard (MDF) disintegration technique on wood polymer composites (WPC) produced with recovered wood particles. Compos. A Appl. Sci. Manuf. 2019, 118, 312–316. [Google Scholar] [CrossRef]

- Han, G.S.; Ichinose, H.; Takase, S.; Shiraishi, N. Composites of wood and polypropylenes III. J. Japan Wood Res. Soc. 1989, 35, 1100–1104. [Google Scholar]

- Dányádi, L.; Janecska, T.; Szabó, Z.; Nagy, G.; Móczó, J.; Pukánszky, B. Wood flour filled PP composites: Compatibilization and adhesion. Compos. Sci. Technol. 2007, 67, 2838–2846. [Google Scholar] [CrossRef]

- Gulitah, V.; Liew, K.C. Morpho-mechanical properties of wood fiber plastic composite (WFPC) based on three different recycled plastic codes. Int. J. Biobased Plast. 2019, 1, 22–30. [Google Scholar] [CrossRef]

- Kaymakci, A.; Ayrilmis, N. Investigation of correlation between Brinell hardness and tensile strength of wood plastic composites. Compos. B Eng. 2014, 58, 582–585. [Google Scholar] [CrossRef]

- Balsuriya, P.W.; Ye, L.; Mai, Y.W.; Wu, J. Mechanical properties of wood flake–polyethylene composites II interface modification. J. Appl. Polym. Sci. 2002, 83, 2505–2521. [Google Scholar] [CrossRef]

- Kaymakci, A.; Gulec, T.; Khalil, H.S.; Ayrilmis, N. Physical, Mechanical and Thermal properties of wood/zeolite/plastic composites. Maderas Cienc. Tecnol. 2017, 19, 339–348. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Faruk, O.; Huque, M. Physico-mechanical studies of wood fiber reinforced composites. Polym. Plast. Technol. Eng. 2002, 41, 435–451. [Google Scholar] [CrossRef]

- Delviawan, A.; Suzuki, S.; Kojima, Y.; Kobori, H. The influence of filler characteristics on the physical and mechanical properties of wood plastic composite(s). Rev. Agric. Sci. 2019, 7, 1–9. [Google Scholar] [CrossRef]

- Lazrak, C.; Kabouchi, B.; Hammi, M.; Famiri, A.; Ziani, M. Structural study of maritime pine wood and recycled highdensity polyethylene (HDPEr) plastic composite using infrared-ATR spectroscopy X-Ray diffraction, SEM and contact angle measurements. Case Stud. Constr. Mater. 2019, 10, e00227. [Google Scholar] [CrossRef]

- Yılmaz-Atay, H.; Wilk-Jakubowski, J.L. A Review of Environmentally Friendly Approaches in Fire Extinguishing: From Chemical Sciences to Innovations in Electrical Engineering. Polymers 2022, 14, 1224. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.L.; Loboichenko, V.; Wilk-Jakubowski, G.; Yılmaz-Atay, H.; Harabin, R.; Ciosmak, J.; Ivanov, S.; Stankov, S. Acoustic Firefighting Method on the Basis of European Research: A Review: Acoustic Firefighting Method. Akustika 2023, 46, 31–45. [Google Scholar] [CrossRef]

- DARPA. DARPA Demos Acoustics Suppression of Flame. Available online: https://www.youtube.com/watch?v=DanOeC2EpeA&t=9s (accessed on 20 September 2024).

- De Luna, R.G.; Baylon, Z.A.P.; Garcia, C.A.D.; Huevos, J.R.G.; Ilagan, J.L.S.; Rocha, M.J.T. A Comparative Analysis of Machine Learning Approaches for Sound Wave Flame Extinction System Towards Environmental Friendly Fire Suppression. In Proceedings of the TENCON 2023—2023 IEEE Region 10 Conference (TENCON), ChiangMai, Thailand, 31 October–3 November 2023; pp. 479–484. [Google Scholar]

- Loboichenko, V.; Wilk-Jakubowski, J.; Wilk-Jakubowski, G.; Harabin, R.; Shevchenko, R.; Strelets, V.; Levterov, A.; Soshinskiy, A.; Tregub, N.; Antoshkin, O. The Use of Acoustic Effects for the Prevention and Elimination of Fires as an Element of Modern Environmental Technologies. Environ. Clim. Technol. 2022, 26, 319–330. [Google Scholar] [CrossRef]

- Beisner, E.; Wiggins, N.D.; Yue, K.B.; Rosales, M.; Penny, J.; Lockridge, J.; Page, R.; Smith, A.; Guerrero, L. Acoustic flame suppression mechanics in a microgravity environment. Microgravity Sci. Technol. 2015, 27, 141–144. [Google Scholar] [CrossRef]

- Choudhary, S.; Gupta, A.; Sukhwal, S. A study on sound wave fire extinguisher with cooling rate. Int. J. Adv. Eng. Res. Sci. 2020, 7, 505–510. [Google Scholar] [CrossRef]

- Yadav, R.; Shirazi, R.; Choudhary, A.; Yadav, S.; Raghuvanshi, R. Designing of Fire Extinguisher Based on Sound Waves. Int. J. Eng. Adv. Technol. 2020, 9, 927–930. [Google Scholar] [CrossRef]

- Fegade, R.; Rai, K.; Dalvi, S. Extinguishing Fire Using Low Frequency Sound from Subwoofer. Gradiva Rev. J. 2022, 8, 708–713. Available online: https://gradivareview.com/volume-8-issue-10-2022/ (accessed on 19 May 2025).

- Wilk-Jakubowski, J. Experimental Investigation of Amplitude-Modulated Waves for Flame Extinguishing: A Case of Acoustic Environmentally Friendly Technology. Environ. Clim. Technol. 2023, 27, 627–638. [Google Scholar] [CrossRef]

- Pan, D.; Ji, C.; Zhu, T. Characterization of Nonlinear Responses of Non-Premixed Flames to Low-Frequency Acoustic Excitations. Appl. Sci. 2023, 13, 6237. [Google Scholar] [CrossRef]

- Węsierski, T.; Wilczkowski, S.; Radomiak, H. Wygaszanie procesu spalania przy pomocy fal akustycznych. Bezpieczeństwo Tech. Pożarnicza 2013, 30, 59–64. Available online: https://sft.cnbop.pl/pl/bi-tp-vol-2-issue-30-2013-wygaszanie-procesu-spalania-przy-pomocy-fal-akustycznych (accessed on 15 November 2024).

- Huang, Y.; Wang, M.; Yang, K.; Xu, C.; Wu, K. Role of Acoustic Wave on Extinguishing Flames Coupling with Water Mist. Case Stud. Therm. Eng. 2022, 38, 102367. [Google Scholar] [CrossRef]

- Im, H.G.; Law, C.K.; Axelbaum, R.L. Opening of the Burke-Schumann Flame Tip and the Effects of Curvature on Diffusion Flame Extinction. Proc. Combust. Inst. 1991, 23, 551–558. [Google Scholar] [CrossRef]

- Zhu, P.; Wang, Q.; Pan, D.; Zhu, T.; Ji, C. Experimental Study on Transient Ignition Characteristics of Acoustic Excited Methane Jet Diffusion Flames. Appl. Sci. 2022, 12, 9719. [Google Scholar] [CrossRef]

- Friedman, A.N.; Stoliarov, S.I. Acoustic extinction of laminar line-flames. Fire Saf. J. 2017, 93, 102–113. [Google Scholar] [CrossRef]

- McKinney, D.J.; Dunn-Rankin, D. Acoustically driven extinction in a droplet stream flame. Combust. Sci. Technol. 2007, 161, 27–48. [Google Scholar] [CrossRef]

- Koklu, M.; Taspinar, Y.S. Determining the extinguishing status of fuel flames with sound wave by machine learning methods. IEEE Access 2021, 9, 207–216. [Google Scholar] [CrossRef]

- Zargar, O.A.; Andrade, A.X.; Hu, S.-C.; Shih, Y.-C.; Leggett, G. Review—Recent developments on applying acoustic waves for efficiency improvements of different thermofluids systems. Int. J. Thermofluids 2024, 22, 100614. [Google Scholar] [CrossRef]

- Xiong, C.; Wang, Z.; Huang, X. Acoustic Flame Extinction by the Sound Wave or Speaker-Induced Wind? Fire Saf. J. 2021, 126, 103479. [Google Scholar] [CrossRef]

- Loboichenko, V.; Wilk-Jakubowski, G.; Wilk-Jakubowski, J.L.; Ciosmak, J. Application of Low-Frequency Acoustic Waves to Extinguish Flames on the Basis of Selected Experimental Attempts. Appl. Sci. 2024, 14, 8872. [Google Scholar] [CrossRef]

- Shi, X.; Tian, Z.; Lu, Y.; Ye, Q. Research Status and Progress of Acoustic Fire Extinguishing Technology. Fire 2025, 8, 129. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.; Wilk-Jakubowski, G.; Loboichenko, V. Experimental Attempts of Using Modulated and Unmodulated Waves in Low-Frequency Acoustic Wave Flame Extinguishing Technology: A Review of Selected Cases. Stroj. Vestn. J. Mech. Eng. 2024, 70, 270–281. [Google Scholar] [CrossRef]

- NASA. Earth Science—Applied Sciences. Monitoring Fires with Fast-Acting Data. Available online: https://appliedsciences.nasa.gov/our-impact/story/monitoring-fires-fast-acting-data (accessed on 25 November 2024).

- Goldsmith, A. Wireless Communications; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Propagation Data and Prediction Methods for the Planning of Indoor Radiocommunication Systems and Radio Local Area Networks in the Frequency Range 900 MHz to 100 GHz; Recommendation ITU-R P.1238-7; International Telecommunication Union: Geneva, Switzerland, 2012.

- Baldini, G.; Sturman, T.; Dalode, A.; Kropp, A.; Sacchi, C. An emergency communication system based on software-defined radio. J. Wireless Com. Netw. 2014, 169. [Google Scholar] [CrossRef]

- Šerić, L.; Stipanicev, D.; Krstinić, D. ML/AI in Intelligent Forest Fire Observer Network. In Proceedings of the 3rd EAI International Conference on Management of Manufacturing Systems, Dubrovnik, Croatia, 6–8 November 2018. [Google Scholar] [CrossRef]

- Chen, Y.; Morton, D.C.; Randerson, J.T. Remote sensing for wildfire monitoring: Insights into burned area, emissions, and fire dynamics. One Earth 2024, 7, 1022–1028. [Google Scholar] [CrossRef]

- Suematsu, N.; Oguma, H.; Eguchi, S.; Kameda, S.; Sasanuma, M.; Kuroda, K. Multi-mode SDR VSAT against big disasters. In Proceedings of the European Microwave Conference ’13, Nuremberg, Germany, 6–10 October 2013. [Google Scholar]

- Zeng, L.; Zhang, C.; Qin, P.; Zhou, Y.; Cai, Y. One Method for Predicting Satellite Communication Terminal Service Demands Based on Artificial Intelligence Algorithms. Appl. Sci. 2024, 14, 6019. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Akbulut, T.; Dundar, T.; White, R.H.; Mengeloglu, F.; Buyuksari, U.; Candan, Z.; Avci, E. Effect of boron and phosphate compounds on physical, mechanical, and fire properties of wood-polypropylene composites. Constr. Build. Mater. 2012, 33, 63–69. [Google Scholar] [CrossRef]

- Terzi, E. Thermal degradation of particleboards incorporated with colemanite and common boron-based fire retardants. BioResources 2018, 13, 4239–4251. [Google Scholar] [CrossRef]

- Torgal, F.P.; Diamanti, M.V.; Nazari, A.; Granqvist, C.G.; Pruna, A.; Amirkhanian, S. (Eds.) Nanotechnology in Eco-Efficient Construction: Materials, Processes and Applications, 2nd ed.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Cambridge, UK, 2019. [Google Scholar]

- Arao, Y.; Nakamura, S.; Tomita, Y.; Takakuwa, K.; Umemura, T.; Tanaka, T. Improvement on fire retardancy of wood flour/polypropylene composites using various fire retardants. Polym. Degrad. Stab. 2014, 100, 79–85. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Y.Z. A review on flame retardant technology in China. Part I: Development of flame retardants. Polym. Adv. Technol. 2009, 21, 1–26. [Google Scholar] [CrossRef]

- Candan, Z.; Ayrilmis, N.; Dundar, T.; Atar, M. Fire performance of LVL panels treated with fire retardant chemicals. Wood Res. 2012, 57, 651–658. Available online: https://www.woodresearch.sk/wr/201204/14.pdf (accessed on 15 January 2025).

- Chang, B.P.; Thakur, S.; Mohanty, A.K. Novel sustainable biobased flame retardant from functionalized vegetable oil for enhanced flame retardancy of engineering plastic. Sci. Rep. 2019, 9, 15971. [Google Scholar] [CrossRef]

- Hornsby, P.R. Fire retardant fillers for polymers. Int. Mater. Rev. 2001, 46, 199–210. [Google Scholar] [CrossRef]

- Song, K.; Guo, J.Z.; Liu, C. Polymer-Based Multifunctional Nanocomposites and Their Applications; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Gao, M.; Sun, C.; Wang, C. Thermal degradation of wood treated with flame retardants. J. Therm. Anal. Calorim. 2006, 85, 765–769. [Google Scholar] [CrossRef]

- Atay, H.Y.; Çelik, E. Use of Turkish huntite/hydromagnesite mineral in plastic materials as a flame retardant. Polym. Compos. 2010, 31, 1692–1700. [Google Scholar] [CrossRef]

- Atay, H.Y.; Çelik, E. Mechanical properties of flame-retardant huntite and hydromagnesite-reinforced polymer composites. Polym. Plast. Technol. Eng. 2013, 52, 182–188. [Google Scholar] [CrossRef]

- Atay, G.Y.; Loboichenko, V.; Wilk-Jakubowski, J.Ł. Investigation of calcite and huntite/hydromagnesite mineral in co-presence regarding flame retardant and mechanical properties of wood composites. Cem. Wapno Beton 2024, 29, 40–53. [Google Scholar] [CrossRef]

- Yilmaz Atay, H.; Türkmen, M. Use of hornbeam, pine and MDF waste in wood-polymer composites as construction elements. J. Indian Acad. Wood. Sci. 2022, 19, 110–120. [Google Scholar] [CrossRef]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- UL 94; Tests for Flammability of Plastic Materials for Parts in Devices and Appliances. UL Standard Ed. 6; UL Solutions: Northbrook, IL, USA, 2013.

- Walker, J. Primary Wood Processing: Principles and Practice, 2nd ed.; Springer: Dordrecht, The Netherlands, 2004. [Google Scholar]

- Wang, X.; Liu, J.; Chai, Y. Thermal, mechanical, and moisture absorption properties of wood-TiO2 composites prepared by a sol-gel process. Bioresources 2012, 7, 893–901. [Google Scholar] [CrossRef]

- Adhikary, K.B.; Pang, S.; Staiger, M.P. Dimensional stability and mechanical behaviour of wood plastic composites based on recycled and virgin high-density polyethylene (HDPE). Compos. Part B 2008, 39, 807–815. [Google Scholar] [CrossRef]

- Krause, K.C.; Sauerbier, P.; Koddenberg, T.; Krause, A. Utilization of Recycled Material Sources for Wood-Polypropylene Composites: Effect on Internal Composite Structure, Particle Characteristics and Physico-Mechanical Properties. Fibers 2018, 6, 86. [Google Scholar] [CrossRef]

- LeVan, S.L. Chemistry of Fire Retardancy; U.S. Department of Agriculture: Madison, WI, USA, 1984; pp. 531–574.

- Kovačević, Z.; Flinčec Grgac, S.; Bischof, S. Progress in Biodegradable Flame Retardant Nano-Biocomposites. Polymers 2021, 13, 741. [Google Scholar] [CrossRef]

- Future Content. Fire Retardant Material—A History. Available online: https://specialistworkclothing.wordpress.com/2014/03/05/fire-retardant-material-a-history (accessed on 20 February 2025).

| No. | Sample Name | Description | PP (%) | Wood (%) | Huntite Hydromagnesite (%) |

|---|---|---|---|---|---|

| 1 | PP | 100 | – | – | |

| 2 | W10P90 | 10% Wood-90% Polymer | 90 | 10 | – |

| 3 | W10P70H20 | 10% Wood-70% Polymer-20% Huntite hydromagnesite | 70 | 10 | 20 |

| 4 | W10P60H30 | 10% Wood-60% Polymer-30% Huntite hydromagnesite | 60 | 10 | 30 |

| 5 | W10P50H40 | 10% Wood-50% Polymer-40% Huntite hydromagnesite | 50 | 10 | 40 |

| 6 | W10P40H50 | 10% Wood-40% Polymer-50% Huntite hydromagnesite | 40 | 10 | 50 |

| 7 | W10P30H60 | 10% Wood-30% Polymer-60% Huntite hydromagnesite | 30 | 10 | 60 |

| 8 | W20P80 | 20% Wood-80% Polymer | 80 | 20 | – |

| 9 | W20P60H20 | 20% Wood-60% Polymer-20% Huntite hydromagnesite | 60 | 20 | 20 |

| 10 | W20P50H30 | 20% Wood-50% Polymer-30% Huntite hydromagnesite | 50 | 20 | 30 |

| 11 | W20P40H40 | 20% Wood-40% Polymer-40% Huntite hydromagnesite | 40 | 20 | 40 |

| 12 | W20P30H50 | 20% Wood-30% Polymer-50% Huntite hydromagnesite | 30 | 20 | 50 |

| 13 | W20P20H60 | 20% Wood-20% Polymer-60% Huntite hydromagnesite | 20 | 20 | 60 |

| UL94 Rating | Definition of Rating |

|---|---|

| HB | Slow burning on a horizontal part. |

| V-2 | Burning stops within 30 s on a part allowing for drops of vertical flammable plastic. |

| V-1 | Burning stops within 30 s on a vertical part allowing for drops plastic that are not inflames. |

| V-0 | Burning stops within 10 s on a vertical part allowing for drops plastic that are not inflames. |

| 5VB | Burning stops within 60 s on a vertical part allowing for drops plastic that are not inflames, plaque specimens may develop a hole. |

| 5VA | Burning stops within 30 s on a vertical part allowing for drops plastic that are not inflames, plaque specimens may not develop a hole. |

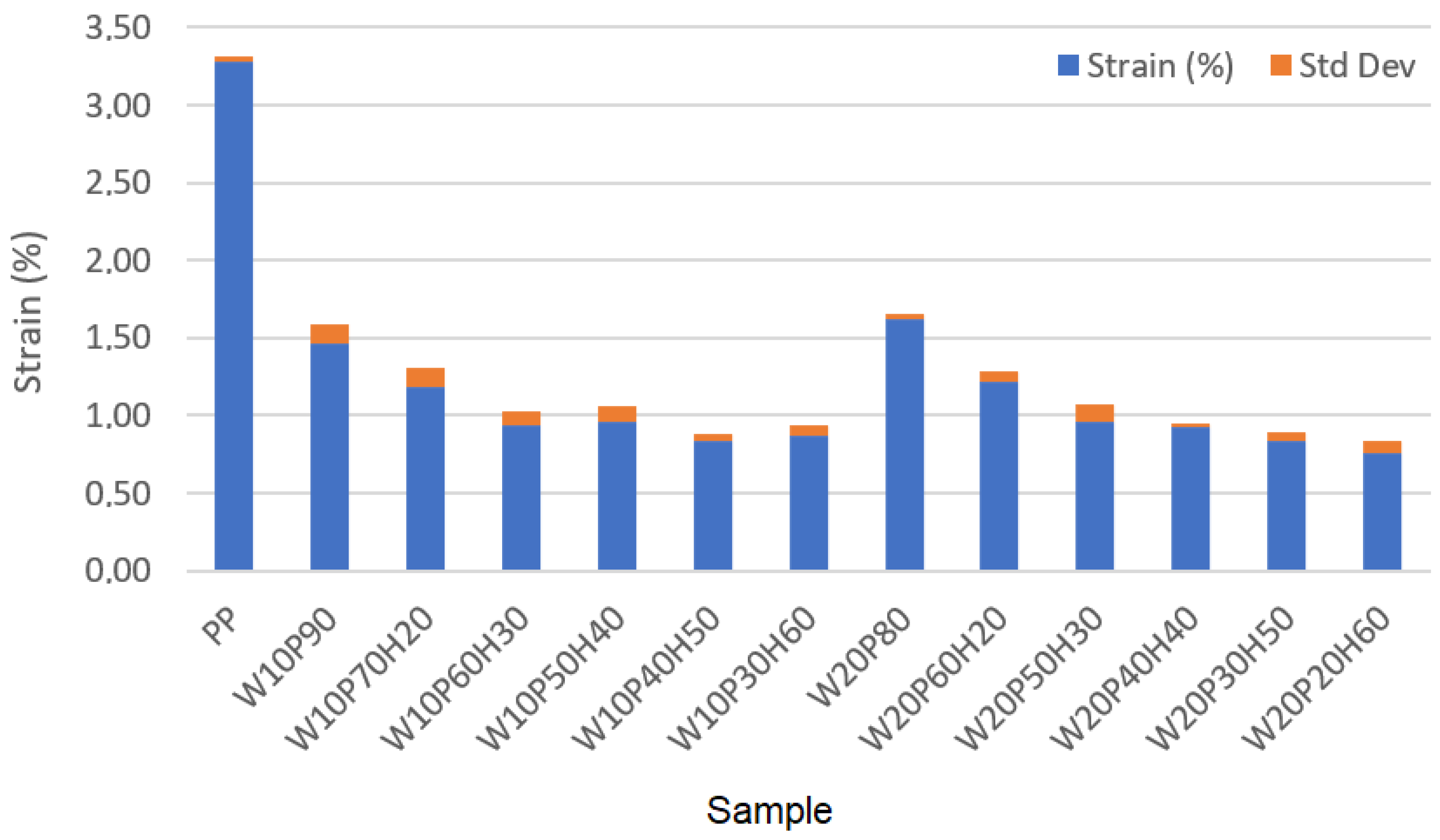

| No. | Sample Name | Max Stress (MPa) | Std. Dev. | Strain (%) | Std. Dev. | Elastic Modulus (MPa) | Std. Dev. |

|---|---|---|---|---|---|---|---|

| 1 | PP | 38.16 | 0.15 | 3.28 | 0.03 | 1163.41 | 15.69 |

| 2 | W10P90 | 34.13 | 0.45 | 1.46 | 0.13 | 2337.67 | 172.85 |

| 3 | W10P70H20 | 29.24 | 0.21 | 1.18 | 0.13 | 2477.97 | 235.00 |

| 4 | W10P60H30 | 27.16 | 0.81 | 0.94 | 0.09 | 2889.36 | 257.88 |

| 5 | W10P50H40 | 27.22 | 0.65 | 0.96 | 0.10 | 2835.42 | 268.35 |

| 6 | W10P40H50 | 24.78 | 0.64 | 0.83 | 0.05 | 2985.54 | 85.48 |

| 7 | W10P30H60 | 22.65 | 0.48 | 0.87 | 0.06 | 2603.45 | 150.31 |

| 8 | W20P80 | 39.89 | 0.74 | 1.62 | 0.04 | 2462.35 | 91.98 |

| 9 | W20P60H20 | 28.96 | 0.68 | 1.22 | 0.06 | 2373.77 | 166.42 |

| 10 | W20P50H30 | 27.45 | 0.84 | 0.96 | 0.11 | 2859.38 | 274.55 |

| 11 | W20P40H40 | 25.87 | 0.29 | 0.92 | 0.03 | 2811.96 | 107.03 |

| 12 | W20P30H50 | 23.78 | 0.64 | 0.84 | 0.05 | 2830.95 | 241.21 |

| 13 | W20P20H60 | 23.11 | 0.86 | 0.76 | 0.08 | 3040.79 | 240.95 |

| No. | Sample Name | Flame Applying Time (s) | Burning Time (s) | UL 94 (Vertical) Rating |

|---|---|---|---|---|

| 1 | PP | 10 s | 30 s | Out of spec. |

| 2 | W10P90 | 10 s | 30 s | Out of spec. |

| 3 | W10P70H20 | 10 s | 30 s | Out of spec. |

| 4 | W10P60H30 | 10 s | 30 s | Out of spec. |

| 5 | W10P50H40 | 10 s 30 s | No burning 38 s | V-1 |

| 6 | W10P40H50 | 10 s 30 s | No burning 19 s | V-0 |

| 7 | W10P30H60 | 10 s 30 s | No burning 7 s | V-0 |

| 8 | W20P80 | 10 s | 30 s | Out of spec. |

| 9 | W20P60H20 | 10 s | 30 s | Out of spec. |

| 10 | W20P50H30 | 10 s 30 s | No burning 35 s | V-1 |

| 11 | W20P40H40 | 10 s 30 s | No burning 35 s | V-1 |

| 12 | W20P30H50 | 10 s 30 s | No burning 12 s | V-0 |

| 13 | W20P20H60 | 10 s 30 s | No burning 3 s | V-0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atay, G.Y.; Wilk-Jakubowski, J.L.; Loboichenko, V. Novel Flame-Retardant Wood-Polymer Composites by Using Inorganic Mineral Huntite and Hydromagnesite: An Aspect of Application in Electrical Engineering. Materials 2025, 18, 2652. https://doi.org/10.3390/ma18112652

Atay GY, Wilk-Jakubowski JL, Loboichenko V. Novel Flame-Retardant Wood-Polymer Composites by Using Inorganic Mineral Huntite and Hydromagnesite: An Aspect of Application in Electrical Engineering. Materials. 2025; 18(11):2652. https://doi.org/10.3390/ma18112652

Chicago/Turabian StyleAtay, Gül Yılmaz, Jacek Lukasz Wilk-Jakubowski, and Valentyna Loboichenko. 2025. "Novel Flame-Retardant Wood-Polymer Composites by Using Inorganic Mineral Huntite and Hydromagnesite: An Aspect of Application in Electrical Engineering" Materials 18, no. 11: 2652. https://doi.org/10.3390/ma18112652

APA StyleAtay, G. Y., Wilk-Jakubowski, J. L., & Loboichenko, V. (2025). Novel Flame-Retardant Wood-Polymer Composites by Using Inorganic Mineral Huntite and Hydromagnesite: An Aspect of Application in Electrical Engineering. Materials, 18(11), 2652. https://doi.org/10.3390/ma18112652