Abstract

The article provides a brief overview of technologies and methods for processing dispersed metallic waste generated during ferroalloy production, including high-carbon ferrochrome (HCFeCr). It is noted that the most cost-effective and rational method for reusing metallic dust is briquetting. Considering the development of briquetting technologies, as well as the latest equipment and binder materials involved in this process, aspiration dust from ferrochrome crushing can be fully utilized in metallurgical recycling. To verify this assumption, laboratory studies were conducted using polymer-based binders and liquid glass as a baseline option. The methodology of briquetting using both laboratory and industrial presses is described, along with an assessment of the mechanical properties of the briquettes. The studies indicate that the introduction of an inert filler (gas-cleaning dust) into the metallic dust composition improves the briquetting ability of the mixture by enhancing adhesion between metal particles and the binder. The obtained industrial briquette samples exhibit high mechanical strength, ensuring their further use in metallurgical processing. The study concludes that semi-dry briquetting using hydraulic vibropresses is a promising approach for the utilization of dispersed ferroalloy waste.

1. Introduction

One of the key stages in the final phases of high-carbon ferrochrome (HCFeCr) production is the crushing and screening of metal ingots. These processes are carried out in crushing and screening complexes (CSC) or production lines that include jaw crushers, screens, and conveyor systems [1]. The technological operations of crushing and fractionation inevitably result in the formation of certain amounts of fine fractions and dispersed metallic dust in addition to commercial-sized fractions. The latter is captured by a dry aspiration system, which is also an integral part of the CSC.

Screening fines are reused in metal casting technology as a bedding material, partially fusing with the ingot, or are sold to consumers at a discounted price. However, similar utilization of metallic dust is not feasible due to its high dispersity. More than 96% of the material consists of powder with a particle size of less than 0.071 mm, as clearly demonstrated in Table 1 below.

Table 1.

Fractional Composition of Dust from HCFeCr Crushing.

Currently, the metallic dust generated from HCFeCr crushing (hereinafter referred to as aspiration dust, or AD) is disposed of in industrial plants by remelting in ore-smelting furnaces to produce FeCr-600 and FeCr-650 grades using complex thermite technology. Several thousand tons of AD formed at domestic enterprises are remelted annually using this method [2,3,4].

The main and significant drawback of the applied method is the high rate of mechanical losses of AD during furnace charging, as well as dust emissions from the furnace itself during the remelting process. This is clearly illustrated in Figure 1.

Figure 1.

Carryover of aspiration dust (AD) from the furnace during remelting.

According to preliminary data, losses may amount to up to 15% of the annual volume of AD generated. Given this, there is a need to minimize or eliminate such losses through rational methods of recycling.

When aspiration dust (AD) is carried off, it primarily settles on the power supply components and electrode contact pads, as well as on the electrode lifting systems of the furnace. This leads to short circuits, damage to the power supply elements, and contributes to the burning through of the copper electrode contact pads. In addition, the presence of this dust causes jamming of the electrode lifting mechanisms, which can lead to their failure.

The primary and significant drawback of the current method is the high mechanical loss of aspiration dust (AD) during furnace charging, as well as dust carryover from the furnace itself during remelting. Literature sources describe various methods for processing dispersed ferroalloys, including their use in powder metallurgy [5], self-propagating high-temperature synthesis (SHS) methods [6,7,8], direct remelting, and for producing modifiers [9,10,11]. However, these methods have several disadvantages, such as complex technological operations and stringent requirements for the chemical composition of the final product.

For example, our earlier pilot-scale industrial tests on the injection of aspiration dust (AP) into liquid metal in a ladle using an injection unit were accompanied by significant heat losses and the formation of large amounts of metal crusts. Metal losses in the form of solidified deposits amounted to 30% of the molten metal mass. Taking this into account, further tests on injecting AP directly into the furnace melt were discontinued. The decision was based on the small volume of slag-metal melt formed in the furnace during smelting (6–7 tons, excluding the melt used to form the hearth lining), as well as the design of the furnace itself. The furnace used for loose AD remelting is an open-type furnace with a high heat loss coefficient. In the case of AP injection into the furnace, bath cooling would occur, requiring additional heat input and, consequently, increased energy consumption.

In this regard, the most rational approach for processing metallic dust is its preliminary agglomeration, followed by remelting in smelting furnaces [12,13]. Given the physical characteristics of AD—such as high dispersity, low wettability, and the sharp-edged shape of metal particles—the optimal agglomeration method in this case is briquetting [14].

One of the well-known methods for agglomerating fine-grained raw materials for subsequent metallurgical processing is the so-called cold briquetting. There are existing techniques for producing briquettes from fine ores and concentrates, metallurgical production waste, and carbon-containing dusts [15,16,17,18,19,20,21]. Using dispersed materials in agglomerated form, on the one hand, prevents their entrainment by off-gases, and on the other, ensures sufficient gas permeability of the charge column in metallurgical units. Therefore, agglomerated materials must possess sufficiently high cold and hot strength properties [22,23,24].

In other words, briquettes must retain their integrity at all stages of the metallurgical process. Each type of metallurgical raw material has its own technological features for briquette production, as well as specific types of binders. In turn, the choice of binder must consider the specific characteristics of the briquetting process depending on the nature of the solids. With proper binder selection, it is possible to ensure the required strength properties of briquettes both in the cold state and at metallurgical process temperatures. Moreover, the binder should not introduce harmful impurities into the final alloy or increase slag generation.

While inorganic binders such as cement and bentonite have long been used for agglomeration in ferrous metallurgy, polymer-based organic binders are currently gaining popularity and may potentially replace inorganic ones entirely [25,26].

Typically, polymer binders decompose at high temperatures without releasing hazardous decomposition products and completely volatilize.

Taking into account the experience of domestic enterprises in processing dusts from dry gas cleaning systems of ferroalloy furnaces—and the lack of industrial experience in processing metallic dust—the research focused on the agglomeration of aspiration dust (AD) generated during the crushing of high-carbon ferrochrome.

Briquetting was selected as the base processing technology, as it is the most accessible and economically justified method for the utilization of fine materials.

Unlike traditional approaches based on direct remelting or agglomeration using standard binders, this study proposes using dry gas cleaning baghouse dust (GCD) as a filler in the briquetting of aspiration dust.

Laboratory and industrial tests of the briquetting technology were carried out, aimed at adapting the existing briquetting equipment fleet at industrial facilities to new types of polymer-based binders, replacing conventionally used sodium silicate, cement, and bentonite.

The application of a modified mixture composition enabled the production of an industrial batch of briquettes that met mechanical and thermal strength requirements and confirmed the feasibility of their metallurgical processing into commercially acceptable ferrochrome by chemical composition at an industrial scale.

2. Materials and Methods

At the initial stage of laboratory experiments, various mixture compositions were prepared, selecting types of binders and inert materials to address cases of poor adhesion with aspiration dust (AD). Two materials were selected as binders, sodium liquid glass (LG) and a polymer binder based on lignosulfonate (polymer). The choice of liquid glass as a binder in amounts up to 6% (based on the dry weight of the briquetted material) was based on many years of experience at the Donskoy Ore-Dressing and Processing Plant in briquetting fine chromite ores [27]. Meanwhile, polymer-based binders have proven effective in the agglomeration of fine chrome-containing materials [28].

Combinations of both binders were also considered, based on literature data. According to sources [29,30], the addition of lignosulfonate can modify liquid glass by imparting it with higher binding properties. As an inert filler, dry gas cleaning dust (GCD) from ferroalloy furnaces was used. The chemical compositions of AD and GCD are presented in Table 2 and Table 3.

Table 2.

Chemical composition of aspiration dust (AD), %.

Table 3.

Chemical composition of dry gas cleaning dust (DCBD), %.

Next, all mixture variants for briquetting were consolidated into a single table. When compiling the mixture options presented in Table 4, the results of previously conducted laboratory and industrial experiments [27,31] were taken into account.

Table 4.

Compositions of mixtures for briquetting.

After dosing the components of the charge according to Table 4, dry mixing was carried out in an EIRICH EL1 mixer until the mixture was completely homogenized. The resulting mixture was then moistened, and mixing continued until a homogeneous consistency was achieved. The moisture content varied between 3% and 5% of the dry material weight. The finished mixture was poured into a mold (mold channel diameter—30 mm) and briquetted on a press model IP-1000-1 (Techpribor Plant, Moscow, Russia) with a compression force of 30 kN per briquette (with a calculated force of 425 kg per cm2). The resulting briquettes, 30 mm in diameter and 40 mm in height, were subjected to forced drying in a Nabertherm TR 420 (Nabertherm GmbH, Lilienthal, Germany) drying oven at a temperature of 120 °C for 3 h. After drying, the breaking strength of the briquettes was measured on a test press model RB-1000 (Techpribor Plant, Moscow, Russia). The strength of the raw briquettes was also measured separately. For strength measurements, 10 briquettes were selected from each batch and sequentially placed with the long axis perpendicular to the pressing punch of the test press, and the strength measurement process was carried out with an acceptable deviation of 3 kg for raw briquettes and 10 kg for dried briquettes.

It should be noted that when briquetting the mixture with pure AD (variants No. 1–6), regardless of the binder type, the raw briquettes had extremely low strength and were easily destroyed. Increasing the compression force led to the formation of deep transverse cracks and ruptures, indicating over-pressing. This is clearly demonstrated in Figure 2.

Figure 2.

Appearance of Briquettes.

The introduction of inert fillers in the form of gas-cleaning dust (GCD) did not stabilize the briquetting process in mixtures where liquid glass was used as a binder (mixtures No. 7–10). However, in the remaining mixtures, the addition of inert fillers had a positive effect (mixtures No. 11–18). The measured strength characteristics of the resulting briquettes for each mixture variant are presented in Table 5.

Table 5.

Breaking strength results of briquettes.

According to Table 3, briquettes from almost all mixture variants exhibit high mechanical strength, meeting the required 150 kg per briquette standard for briquetted chrome raw materials used in domestic enterprises. However, special attention should be given to briquettes with the highest green strength. Given that industrial briquetting equipment subjects raw briquettes to significant mechanical stress (such as screening and manual handling), mixtures with the highest green strength should be prioritized. The best-performing mixtures under these conditions are No. 13 and No. 14, which combine AD and GCD while using a polymer-based binder. The polymer binder used is widely applied in non-ferrous metallurgy, particularly in the agglomeration of copper-containing raw materials, and should not pose any technological or environmental difficulties [32,33]. They are widely used as a binder and plasticizer in the production of cast iron, steel, ore agglomeration, acid pickling, metal hardening, etc. Furthermore, due to the small amount of polymer binder used, it cannot have a significant impact on the final melting products of high-carbon ferrochrome (slag, metal).

Following the laboratory-scale briquetting results, test trials were conducted on industrial presses to produce full-scale industrial samples.

Briquetting was carried out using semi-dry pressing on an industrial hydraulic vibropress of the TITAN-Z3 model (TechnoMashStroy LLC, Smolensk, Russia). The press characteristics are presented in Table 6. Briquetting was performed according to the methodology described below without changing the compositions of the briquetted mixtures.

Table 6.

Technical Specifications of the TITAN-Z3 Vibropress.

3. Results and Discussion

The briquetting materials and binder were weighed separately and then loaded into a single-screw mixer for dry mixing, which lasted 7 min. Water was then added, and wet mixing continued for approximately 7 min until the water was fully distributed throughout the mixture. Periodically, the mixer blades were cleaned of adhering material. After mixing was completed, the prepared mixture was extracted from the mixer and loaded into the receiving compartment (feeder) of the vibropress. The press was then activated to produce briquettes. The resulting briquettes had a uniform hexagonal shape, with each side measuring 40 mm in width and a briquette height of 80–83 mm. The appearance of the briquettes is shown in Figure 3.

Figure 3.

Appearance of the briquettes.

The briquettes were subjected to forced drying at a temperature of 120 °C and also dried under natural conditions for three days. Initially, it was planned to dry the briquettes for three hours, as in laboratory experiments. However, after the specified drying time, the core of the briquette remained insufficiently dried (Figure 4). To eliminate this issue, the drying time was extended to five hours.

Figure 4.

Briquette core after 3 h of drying.

Upon completion of drying under both natural and forced conditions, measurements of the briquettes’ strength characteristics were conducted, including splitting, impact, drop resistance, and abrasion. The splitting strength of the briquettes was measured using a testing press model IP-50. The impact and abrasion strength measurements were carried out according to the methodology based on GOST 15137-77 [34] (Figure 5). The total iron content was determined following GOST 22772.4-77 [35].

Figure 5.

General view of the testing drum.

The sample for testing is loaded into the drum, securely closed with a lid, and then set in motion. After completing 200 rotations, the drum is stopped, and the entire material is unloaded and sieved first through a sieve with a 5 mm mesh size. The fraction smaller than 5 mm is then further sieved through a sieve with a 0.5 mm mesh size. The obtained fractions—greater than 5 mm, between 5 mm and 0.5 mm, and smaller than 0.5 mm—are weighed separately.

The impact strength of the briquettes (X) in percentage is calculated using the following formula:

The abrasion resistance of the briquettes (X1) in percentage is calculated using the following formula:

where

- m1—mass of the fraction larger than 5 mm after drum testing, kg;

- m2—mass of the fraction between 5 mm and 0.5 mm after drum testing, kg;

- m3—mass of the fraction smaller than 0.5 mm after drum testing, kg.

The next measurements were conducted to determine the hot strength of the briquettes (hot crushing strength). For this purpose, the muffle furnace Nabertherm TR 420 was heated to a temperature of 1000 °C. Once the target temperature was reached, the furnace door was opened, and the briquettes were placed inside. The door was then closed, and the holding process began. The briquettes remained in the furnace for approximately 15 min to allow for temperature equalization, as some heat is lost when the door is opened. After the holding time was completed, the briquettes were removed from the furnace and tested for crushing strength using a compression testing machine (Figure 6).

Figure 6.

Measurement of the hot crushing strength of briquettes.

After completing all measurements of the briquettes’ strength characteristics (crushing, impact, drop, abrasion, and hot strength), the results were consolidated into Table 7. This table also includes the enterprise’s internal standard requirements for briquetted raw materials.

Table 7.

Strength Characteristics of Briquettes.

The obtained briquette samples from the AD and GCD mixture demonstrate sufficient crushing strength, exceeding the target values for this parameter. The mechanical strength indicators for drop resistance, impact, and abrasion—simulating the mechanical loads during transportation to the smelting units—also show high values, surpassing the target requirements.

The hot strength of the briquettes ranges from 32 to 45 kg/briquette, compared to the target value of 40 kg/briquette.

Overall, the conducted experiments demonstrated the feasibility of briquetting ASP, provided that an inert material such as PSG is added to the mixture. The amount of PSG introduced at a ratio of 20:80 and a binder consumption of 3% (of the dry mass of ASP and PSG) ensures the production of briquettes with high strength characteristics, sufficient for further metallurgical processing. Increasing the binder consumption to 4% does improve the strength characteristics of the briquettes, but it leads to higher costs due to the binder price and also results in a lower hot strength index.

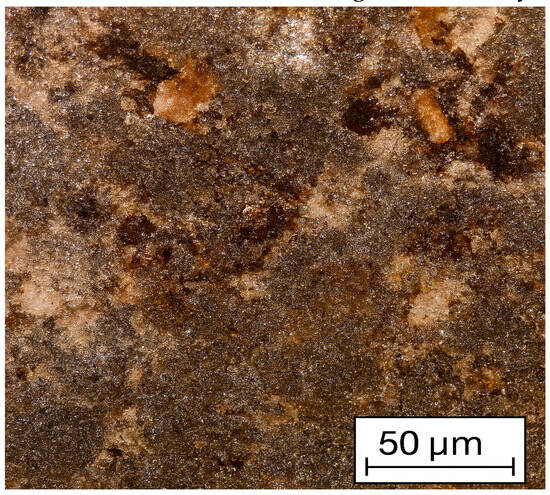

Due to the low wettability (adhesion to the binder) of ASP particles, the addition of PSG serves as a kind of shell-filler. Due to its dispersion (87% of the fraction is −0.02 mm compared to 96% of the fraction being −0.071 mm for ASP) and low bulk density (0.2 t/m3 compared to 2–4 t/m3 for ASP), it allows for almost complete encapsulation of the metal particles. The addition of the polymer binder leads to the formation of adhesive films on the surfaces of PSG particles, which, in turn, hold the ASP particles together in the form of a framework. This statement aligns well with the work [36], where fine chrome ore briquetting was conducted. The mentioned work states that the polymer forms a film on the surface of the chrome ore grains, thereby creating a thin adhesive surface (Figure 7).

Figure 7.

Microphotograph of the structure of a chrome ore briquette under natural light [34].

Considering that PSG is a dispersed chrome ore captured by the aspiration system, it is most likely that this hardening mechanism is at work in the briquettes made from a mixture of AD and PSG. The high strength characteristics of the briquettes, including enhanced resistance to impact, abrasion, and hot strength, prevent the dispersion of AD particles, as seen in their smelting in bulk. This, in turn, will contribute to a more complete involvement of AD in the smelting process with minimal losses.

Next, based on the obtained results, a pilot batch of briquettes weighing 63 tons (dry weight) was produced according to option No. 13 with the aim of conducting industrial tests for their smelting. The pilot-industrial tests for the smelting of briquettes made from a mixture of AD and PSG were carried out on an industrial open-type shaft furnace with a transformer power of 16 MVA.

Typically, in the smelting of ferrochrome grades FX 600-650 using complex thermoreduction, several types of metal concentrates from HC FeCr production, as well as LC-MCFeCr metal concentrate, are used. To minimize errors in evaluating technical and economic Indicators (TEI), it was decided to use only one type of metal concentrate (from HC FeCr).

According to the test program, three days before the start of briquette smelting, the furnace was switched to the following charge composition:

- -

- AD (bulk)—1 ton;

- -

- Metal concentrate fraction 0–5 mm (Cr content not less than 45%)—8 tons;

- -

- Chromite ore—1 ton;

- -

- Ferrosilicochrome (FeSiCr)—0.4 tons;

- -

- Lime—0.8 tons.

The chemical composition data of the charge materials used during the industrial tests are presented in Table 8.

Table 8.

Chemical Composition of Charge Materials, %.

The above charge composition was adopted as the baseline variant and was processed over three days, during which 27 smelts were conducted. The charging of AP into the furnace was accompanied by intense dust formation, complicating its uniform distribution in the furnace bath. Additionally, dust emissions into the workshop atmosphere were observed, bypassing the gas cleaning system.

Furthermore, periodic ejections of AD from the furnace were noted during its smelting, along with overheating of the taphole areas and furnace pockets. The tapping and casting of the melt were carried out in accordance with the established regulations for smelting processes in the specified furnace. Metal and slag samples were taken using a ladle sampling method. After each tap, the weight of the produced slag and metal ingots was measured without fail.

After completing the baseline period, briquettes were introduced as a replacement for bulk AD. During the experimental period, the furnace operated with the following charge composition:

- -

- Briquettes AD—1.3 tons

- -

- Metal concentrate fraction 0–5 mm (Cr content not less than 45%)—8 tons

- -

- Chromite ore—0.9 tons

- -

- FeSiCr—0.4 tons

- -

- Lime—0.8 tons

During the experimental period, 48 smelts were conducted over six days. The furnace personnel noted the absence of dust formation and the convenience of briquette charging, which allowed for uniform material distribution across the entire furnace bath.

Additionally, during the experimental period, AD ejections during smelting ceased, and overheating of the furnace pockets and taphole areas was no longer observed. All technological operations related to smelting and casting were carried out in accordance with the established regulations for the remelting process.

The technical and economic indicators of the baseline and experimental periods are presented in Table 9.

Table 9.

Technical and Economic Indicators (TEI) of HCFeCr Smelting in the Furnace Using AD.

During the experimental period, 48 smelts were conducted over 6 days. The furnace personnel noted the absence of dusting and the ease of loading briquettes, which allowed for an even distribution of the material throughout the furnace bath. Briquettes were mainly loaded around the perimeter of the furnace, which allowed for a uniform drop into the forming liquid melt. In this case, the briquettes prevented the formation of slag rings on the bath perimeter, while their mass helped them sink well into the liquid melt near the arc combustion zone. This loading method compensated for the absence of a well-developed surface of ferrochrome in the briquettes and increased the melt’s absorption of AD (from the briquette composition).

During the experimental period, AD emissions during the smelting process ceased, as well as heating of the furnace pockets and tuyères. All technological operations for melting and pouring were carried out according to the existing regulations for smelting processes. Additionally, during the industrial trial period using briquettes, the temperature of the furnace lining, the temperature of the exhaust gases, and the thickness of the furnace slag after pouring were monitored. In comparison with the baseline period, when using briquettes, the furnace lining temperature and exhaust gas temperature remained at the same level, while the slag thickness decreased on average by 80 mm. Furthermore, the freezing of the furnace bottom ceased, with an increase in its depth, indicating that the melt temperature was sufficient.

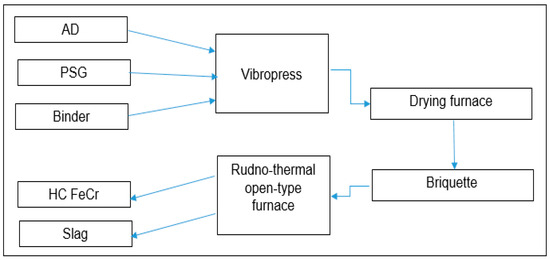

The block diagram of the Experimental Industrial Testing (EPI) period with briquettes is shown in Figure 8.

Figure 8.

Block diagram of the process during the EPI period.

The technical and economic indicators of the baseline and experimental periods are presented in Table 10.

Table 10.

Technical and Economic Indicators of Ferrochrome Production on the Furnace Using AD.

The results of industrial trials show that during the test period, there was an increase in the specific volume of metal produced. The specific reduction in metallic chromium losses with dust decreased from 10 kg/t under the baseline mode to 0.58 kg/t during the test period. At the same time, a reduction in the specific consumption of electric power by 364 kWh/t (Cr) and electrodes by 0.13 kg/t (Cr) was observed.

The costs of briquetting, taking into account the price of the binder, energy resources, and auxiliary materials, were preliminarily estimated at 30 USD. The additional amount of chromium obtained due to the use of briquettes amounted to 0.491 tons per heat. Thus, given the baseline smelting cost of AD at 112 USD and the selling price of HCFeCr at 2600 USD/t Cr, the economic benefit reached 1135 USD per heat.

4. Conclusions

Agglomeration of AD in its pure form by briquetting is not feasible due to the specific grain morphology and low wettability. The use of filler material in the form of dust from baghouse filters of dry gas cleaning systems in HCFeCr smelting furnaces enhances the interparticle adhesion of AD, ultimately enabling its agglomeration through briquetting.

Moreover, baghouse filter dust serves as an additional source of chromium and a slag-forming component, allowing for the exclusion of recycled slags during AP remelting.

The results of laboratory studies on briquetting were confirmed under industrial conditions. It was found that pressing a mixture of aspiration dust and bag filter dust in an 80:20 ratio using 3% binder (based on the dry weight of both aspiration dust and bag filter dust) through semi-dry pressing on hydraulic presses allows for the production of industrial briquette samples with high strength characteristics.

The conducted research confirmed that briquettes produced using the developed technology exhibit sufficient resistance to splitting, impact, drop, and abrasion, while also maintaining their strength when heated up to 1000 °C. These characteristics allow their use in smelting units without compromising quality.

Industrial trials of HCFeCr smelting using briquettes made from an AD and GCD mixture were conducted, with an assessment of technical and economic indicators (TEI) compared to bulk AD smelting. The following results were achieved:

- -

- Increase in the yield of marketable metal by 16%;

- -

- Reduction in metallic chromium losses with dust from the gas cleaning system from 10 kg/t to 0.58 kg/t;

- -

- Reduction in energy consumption by 13.9%;

- -

- Reduction in electrode consumption by 5.7%.

- -

- Reduction in slag ratio by 13%;

- -

- Reduction in chromite ore consumption by 10%.

Preliminary economic calculations show savings of 1135 USD per heat, confirming the feasibility of using aspiration dust briquetting without increasing the cost of HCFeCr production.

Author Contributions

O.S.: Guidelines and definition of research strategy; writing the article. A.A.: Analysis and interpretation of the obtained data; participation in experimental studies. N.N.: Conducting laboratory experiments; analyzing the results obtained. M.A.: explanation of the theoretical foundations of the processes; organization of scientific experiments. G.A.: Work with reagents, materials, tools; participation in experimental studies. B.K.: Planning of scientific experiments; organization of technological calculations. D.Y.: Conducting laboratory experiments; studying the results obtained. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No AP 23488517).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

Gulnur Abikenova, Nurzhan Nurgali, and Maral Almagambetov were employed by the ERG Research and Engineering Center. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhukebayeva, T.Z.; Akhmediyeva, K.A.; Zholdangarov, E.M. The possibility of using complex ferroalloys in powder metallurgy. StudNet 2020, 3, 615–620. [Google Scholar]

- Sariyev, O.; Musabekov, Z.; Dossekenov, M. Disposal of slag of refined ferrochromium by obtaining a sintered and carbonized construction products. Kompleks. Ispolz. Miner. Syra 2019, 4, 26. [Google Scholar] [CrossRef]

- Sariev, O.; Kelamanov, B.; Zhumagaliyev, Y.; Kim, S.; Abdirashit, A.; Almagambetov, M. Remelting the High-Carbon Ferrochrome Dust in a Direct Current Arc Furnace (DCF). Metalurgija 2020, 59, 533–536. [Google Scholar]

- Sariyev, O.; Kelamanov, B.; Dossekenov, M.; Davletova, A.; Kuatbay, Y.; Zhuniskaliyev, T.; Abdirashit, A.; Gasik, M. Environmental Characterization of Ferrochromium Production Waste (Refined Slag) and Its Carbonization Product. Heliyon 2024, 10, 9. [Google Scholar] [CrossRef] [PubMed]

- Manashev, I.R.; Gavrilova, T.O.; Shatokhin, I.M. Recycling Dispersed Waste of Ferroalloy Production on the Basis of Metallurgical Self-Propagating High-Temperature Synthesis. Izv. Vyssh. Uchebn. Zaved. Chyorn. Metall. 2020, 63, 591. [Google Scholar] [CrossRef]

- Salkynbaev, B.Z.; Dosekenov, M.S.; Manashev, I.R. Utilization of High-Carbon Ferrochrome Metal Powder by Self-Propagating High-Temperature Synthesis (SHS) Method. Bull. K. Zhubanov Aktobe Reg. Univ. 2024, 77, 124–129. [Google Scholar]

- Manashev, I.R. Utilization of dispersed ferroalloys by the SHS method. In Proceedings of the International Scientific Conference “Physicochemical Fundamentals of Metallurgical Processes Named After Academician A.M. Samarin”, Vyksa, Russia, 2022; p. 364. [Google Scholar]

- Kanaev, Y.P.; Bondarev, A.A.; Brylyakov, V.I. Mastering the remelting of ferrosilicon fines to produce pure grades of ferrosilicon and complex modifiers. Stal 2000, 10, 67. [Google Scholar]

- Kochkin, V.D.; Aliferov, A.I.; Zolotarev, V.V. Methods and installations for the disposal of fine ferroalloy screenings. Vestn. Samara State Tech. Univ. Ser. Tech. Sci. 2023, 31, 91. [Google Scholar]

- Zhunusova, A.K.; Mamonov, A.; Zhunusov, A.K. Processing of ferrochrome aspiration dust. Nauka Tekh. Kazakhstana 2016, 3–4, 66. [Google Scholar]

- Shevko, V.M.; Badikova, A.D.; Tuleev, M.A. Possibility of Producing Manganoferrosilicochrome Alloy from Ferroalloy Dust. Int. J. Appl. Fundam. Res. 2021, 6, 74–81. [Google Scholar]

- Bayul, K.V.; Khudyakov, A.u.; Vashchenko, S.V. Technologies and equipment for briquetting fine-grained materials in ferroalloy production. Nov. Nauk. Kazakhstana 2018, 4, 108. [Google Scholar]

- Bizhanov, A.M.; Kurunov, I.F. Briquettes of Extrusion (Brex)—A New Stage in the Agglomeration of Raw Materials for Ferrous Metallurgy, 3rd ed.; Metallurgizdat: Moscow, Russia, 2017; p. 234. [Google Scholar]

- Maimur, B.N.; Khudyakov, A.Y.; Petrenko, V.I.; Vashchenko, V.; Bayl, K.V. Briquetting of metallurgical raw materials. Relevance and ways of developing the method. Byul. Chyornaya Metall. 2016, 1, 74. [Google Scholar]

- Nazimko, E.I. Pelletizing of Materials as a Method of Utilizing Various Wastes. In Current Issues of Biodiversity and Nature Management: Proceedings of the 2nd National Scientific and Practical Conference Dedicated to the 20th Anniversary of the Department of Marine Ecology of Kerch State Maritime Technological University, Kerch, Russia, 15–17 May 2019; Arial: Simferopol, Russia, 2019; pp. 367–373. [Google Scholar]

- Diez, M.A.; Alvarez, R.; Cimadevilla, J.L.G. Briquetting of Carbon-Containing Wastes from Steelmaking for Metallurgical Coke Production. Fuel 2013, 114, 216–223. [Google Scholar] [CrossRef]

- Brozova, S.; Pustejovska, P.; Bilik, J.; Jursova, S.; Zbrankova, M.; Havranek, J. Innovated Technologies of Recycling of Metallic Wastes: Modification of Existing Industrial Processes. N. Trends Prod. Eng. 2019, 2, 361–367. [Google Scholar] [CrossRef][Green Version]

- Murthy, Y.R.; Kapure, G.U.; Tripathy, S.K.; Sahu, G.P. Recycling of Ferromanganese Gas Cleaning Plant (GCP) Sludge by Novel Agglomeration. Waste Manag. 2018, 80, 457–465. [Google Scholar] [CrossRef]

- Baisanov, A.; Vorobkalo, N.; Shabanov, Y.; Mussin, A.; Sharieva, S.; Makishev, A. Test Results of Crystalline Silicon Melting Process from Briquetted Monocharge Obtained from Microsilica. Processes 2024, 12, 1911. [Google Scholar] [CrossRef]

- Baisanov, A.; Vorobkalo, N.; Baisanova, A.; Mussin, A.; Sharieva, S.; Makishev, A. A new approach to the recycling of silicon production waste (microsilica) as a raw material for metallurgical processing. Silicon 2024, 16, 6361–6375. [Google Scholar] [CrossRef]

- Kelamanov, B.; Sariev, O.; Akuov, A.; Samuratov, Y.; Sultamuratova, Z.; Orynbassar, R. Study of nickel briquettes by thermographic method. Metalurgija 2022, 61, 217–220. [Google Scholar]

- Zhang, G.; Sun, Y.; Xu, Y. Review of Briquette Binders and Briquetting Mechanism. Renew. Sustain. Energy Rev. 2018, 82, 477–487. [Google Scholar] [CrossRef]

- Kuskov, V.; Kuskova, Y.; Udovitsky, V. Effective Processing of the Iron Ores. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 21, p. 02010. [Google Scholar] [CrossRef]

- Makhambetov, Y.; Akhmetov, A.; Gabdullin, S.; Shabanov, Y.; Toleukadyr, R.; Saulebek, Z.; Myrzagaliyev, A. Study of ferrochrome smelting technology using briquettes with various carbonaceous reducers. Acta Metall. Slovaca 2024, 30, 113–119. [Google Scholar] [CrossRef]

- Khadyev, Y.A.; Antonova, M.V. Influence of Binder Composition on the Properties of Composite Material. In Youth and the 21st Century—2020: Proceedings of the 10th International Youth Scientific Conference, Kursk, Russia, 19–20 February 2020; Southwest State University: Kursk, Russia, 2020; pp. 411–413. [Google Scholar]

- Yulenkov, N.S.; Muravskiy, A.A.; Litosov, G.E. Properties of Polyacrylamide and Pentanpentol Compositions. In Science Today: Problems and Solutions, Proceedings of the International Scientific and Practical Conference, Vologda, Russia, 29 May 2019; EDP Sciences: Les Ulis, France, 2019; pp. 52–53. [Google Scholar]

- Shashkin, V.N.; Loginov, N.M.; Bagautdinov, T.A.; Fursenko, A.F.; Utemisov, B.K. Ore Beneficiation Technology and Briquetting of Concentrates at the Plants of JSC “Donskoy GOK”. Gorn. Zhurnal 2001, 11, 32–34. [Google Scholar]

- Laikhan, S.A.; Ulmaganbetov, N.A.; Salkynbaev, B.Z. Methods of Pelletizing Fine Chromium Raw Materials from the Kempirsay Deposit Using a Polymeric Binder. Min. J. Kazakhstan 2023, 41–47. [Google Scholar]

- Shadrin, N.I.; Volokita, V.Y.; Kuchmiy, N.I.; Ivanov, V.A.; Laptaev, V.P. Method for Preparing a Water Glass Binder for the Production of Foundry Molds and Cores; USSR Author’s Certificate No. 1156806; Published in Bulletin No. 35; State Committee for Inventions and Discoveries under the Council of Ministers of the USSR: Moscow, Russia, 1989. [Google Scholar]

- Kukuy, D.M. Study on the Modification of Aqueous Sodium Silicate Solutions with Inorganic Materials. In Proceedings Collection, Metallurgiya, Minsk, Belarus, 20 April 1984; pp. 76–78. [Google Scholar]

- Sariyev, O.; Abdirashit, A.; Almagambetov, M.; Nurgali, N.; Kelamanov, B.; Yessengaliyev, D.; Mukhambetkaliyev, A. Assessment of Physicochemical Properties of Dust from Crushing High-Carbon Ferrochrome: Methods for Agglomeration. Materials 2025, 18, 903. [Google Scholar] [CrossRef] [PubMed]

- Sadykov, T.S.; Akhmedov, K.K. Application of Polymer Binders in Briquetting of Copper-Containing Wastes. Izvestiya of Higher Educational Institutions. Ferr. Metall. 2019, 4, 50–55. [Google Scholar]

- Aboulkas, A.; El Harfi, K.; El Bouadili, A. Non-Conventional Binders in Agglomeration of Mineral Raw Materials: Application to Copper-Bearing Fines. Miner. Eng. 2010, 23, 745–750. [Google Scholar] [CrossRef]

- GOST 15137-77; Method for Determining Strength in a Rotating Drum. Iron and Manganese Ores, Agglomerates, and Pellets. State Committee for Standards of the Council of Ministers of the USSR: Moscow, Russia, 1977.

- GOST 22772.4-77; Manganese Ores, Concentrates and Agglomerates. Methods for Determination of Iron Content (Total). State Committee for Standards of the Council of Ministers of the USSR: Moscow, Russia, 1979.

- Aksenova, V.V.; Alimbaev, S.A.; Pavlov, A.V.; Mustafin, R.M. Briquetting of Porous Alumina-Containing Materials with Organic Binders. Izvestiya. Ferr. Metall. 2021, 64, 323–329. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).