Compressive Behavior of Fully Grouted Concrete Bond Beam Block Masonry Prisms

Abstract

1. Introduction

2. Materials and Experimental Programs

2.1. Materials Properties

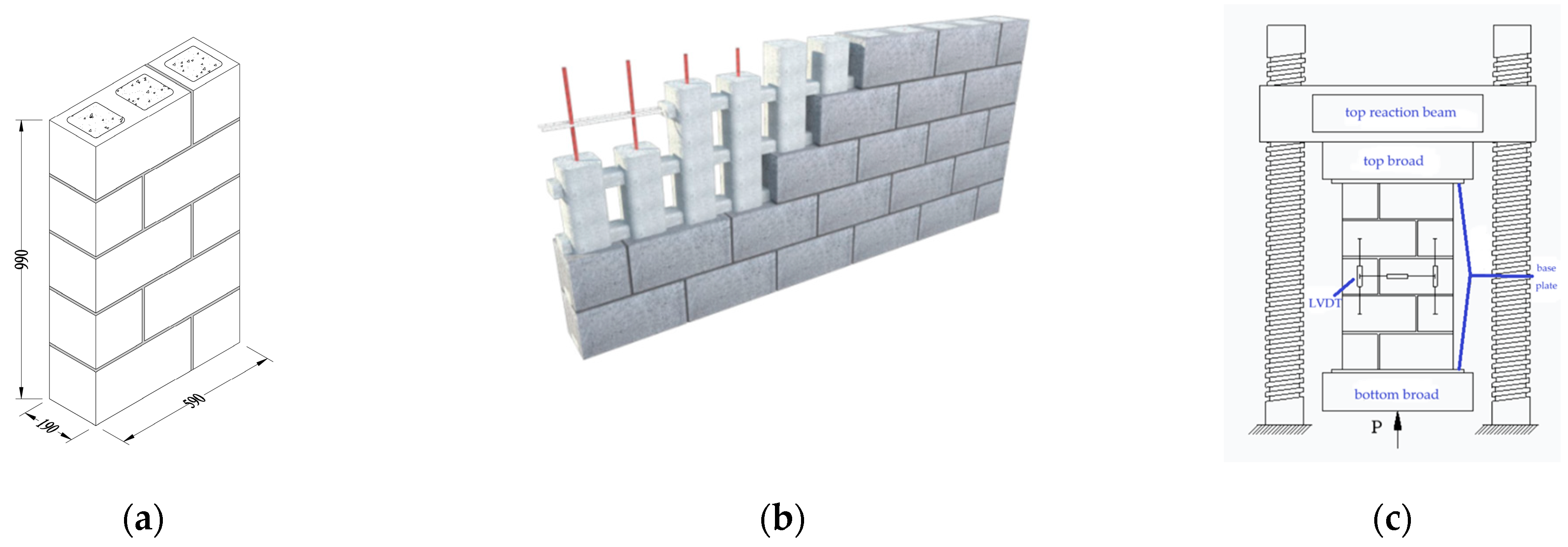

2.2. Specimen Details

2.3. Testing Methodology

3. Results and Discussion

3.1. Failure Modes

3.2. Effect of Block Strength

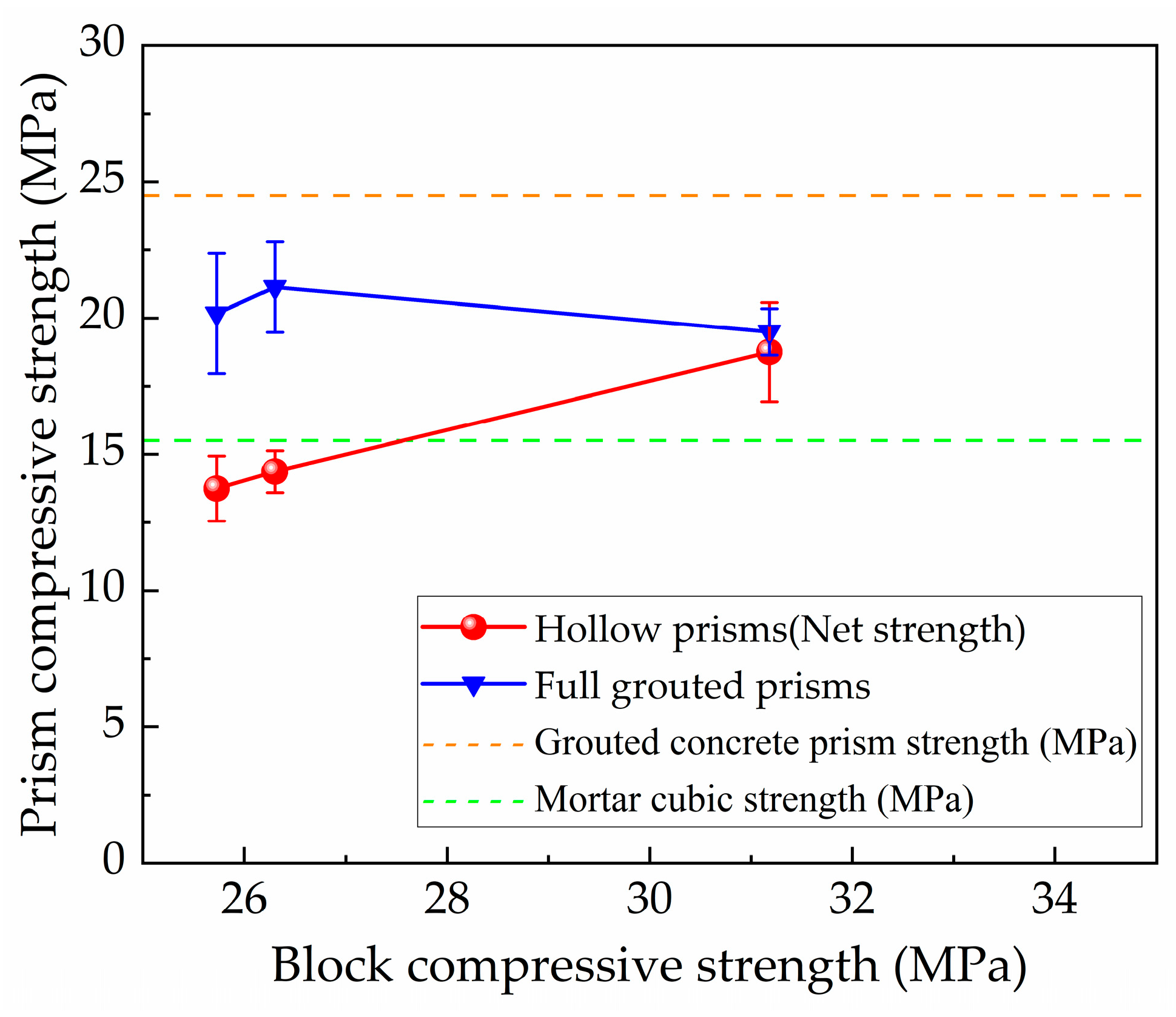

3.3. Effect of Grout Strength

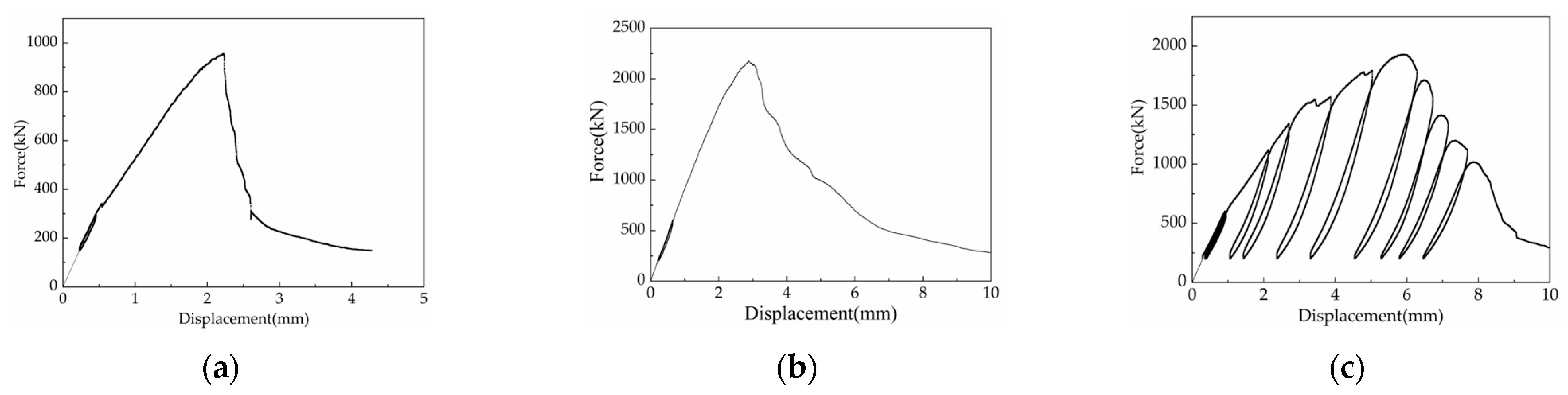

3.4. Loading Pattern

3.5. Comparison with the Fully Grouted Concrete Masonry Prisms Built with Stretcher Block

3.6. Stress-Strain Curves

3.7. Model Comparison

4. Conclusions

- Hollow concrete block masonry prisms under uniaxial compression failed by splitting with vertical cracks, whereas fully grouted bond beam block prisms failed by spalling of the block shells and crushing of the concrete core. The ratio of cracking load to peak strength varied from 0.71 to 0.85 for hollow prisms and from 0.76 to 0.83 for grouted prisms.

- The compressive strength of fully grouted concrete bond beam block prisms increased with increasing grout strength but was insignificantly affected by variations in block strength. Although a simple superposition of grout strength and hollow prism strength overestimates the actual prism strength, the tested strengths of bond beam prisms were higher than those typically reported for conventional grouted prisms (as inferred from comparison with existing models). For hollow concrete block prisms, increasing block strength led to an increase in prism strength. Grouted masonry exhibited, on average, 35.1% higher peak compressive strength compared to the net-area compressive strength of hollow masonry prisms under equivalent loading conditions.

- No strength recovery was observed when specimens were reloaded during cyclic testing. Although the average ratio of peak strength under cyclic loading to that under monotonic loading was 0.98, the specified compressive strength was found to be statistically insignificant between monotonic and cyclic compression.

- A two-stage polynomial stress–strain constitutive model for grouted masonry is proposed, demonstrating strong agreement with the experimental results. This model is applicable for simulating reinforced masonry shear wall structures and provides supplemental guidelines for Chinese masonry design codes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Drysdale, R.G.; Hamid, A.A. Behavior of Concrete Block Masonry Under Axial Compression. ACI J. Proc. 1979, 76, 707–722. [Google Scholar] [CrossRef]

- Łątka, D. Prediction of Mortar Compressive Strength Based on Modern Minor-Destructive Tests. Materials 2023, 16, 2402. [Google Scholar] [CrossRef]

- Abasi, A.; Banting, B.; Sadhu, A. Experimental Evaluation of Compressive Properties of Early-Age Mortar and Concrete Hollow-Block Masonry Prisms within Construction Stages. Materials 2024, 17, 3970. [Google Scholar] [CrossRef] [PubMed]

- Zahra, T.; Thamboo, J.; Asad, M. Compressive Strength and Deformation Characteristics of Concrete Block Masonry Made with Different Mortars, Blocks and Mortar Beddings Types. J. Build. Eng. 2021, 38, 102213. [Google Scholar] [CrossRef]

- Syiemiong, H.; Marthong, C. Compressive Strength Behavior of Low-Strength Hollow Concrete Block Masonry Prisms. Struct. Eng. Mech. 2021, 80, 689–699. [Google Scholar] [CrossRef]

- Li, S.; Ding, Y.; Xin, J.; Qi, G.; Li, M.; Chen, R.; Zhang, H. Elaborately-Designed High-Service Performance Carbon Refractory Brick through Refreshing the Pore Structure. Constr. Build. Mater. 2025, 475, 141226. [Google Scholar] [CrossRef]

- Sathurshan, M.; Derakhshan, H.; Thamboo, J.; Gill, J.; Inglis, C.; Zahra, T. Compressive Strength in Grouted Dry-Stack Concrete Block Masonry: Experimental and Analytical Predictions. Constr. Build. Mater. 2025, 467, 140411. [Google Scholar] [CrossRef]

- Fortes, E.S.; Parsekian, G.A.; Fonseca, F.S. Relationship between the Compressive Strength of Concrete Masonry and the Compressive Strength of Concrete Masonry Units. J. Mater. Civ. Eng. 2015, 27, 04014238. [Google Scholar] [CrossRef]

- Dhanasekar, M.; Shrive, N.G. Strength and Deformation of Confined and Unconfined Grouted Concrete Masonry. ACI Struct. J. 2002, 99, 819–826. [Google Scholar] [CrossRef]

- Griniov, V.; Yurkova, K.; Prusak, R. Compressive Load Capacity of Concrete Structures Made of Hollow Blocks with Voids Filled with Concrete of Various Features. Materials 2024, 17, 6262. [Google Scholar] [CrossRef]

- Abasi, A.; Hassanli, R.; Vincent, T.; Manalo, A. Influence of Prism Geometry on the Compressive Strength of Concrete Masonry. Constr. Build. Mater. 2020, 264, 120182. [Google Scholar] [CrossRef]

- Dirks Jonathan, D. Effect of Bond Beams on Stack Pattern Concrete Masonry Walls and an Investigation of Interfacial Interaction of Cut Prisms. Master’s Thesis, University of Windsor, Windsor, ON, Canada, 2023. [Google Scholar]

- Köksal, H.O.; Karakoç, C.; Yildirim, H. Compression Behavior and Failure Mechanisms of Concrete Masonry Prisms. J. Mater. Civ. Eng. 2005, 17, 107–115. [Google Scholar] [CrossRef]

- Fahmy, E.H.; Ghoneim, T.G.M. Behavior of Concrete Block Masonry Prisms under Axial Compression. Can. J. Civ. Eng. 1995, 22, 898–915. [Google Scholar] [CrossRef]

- Hamid, A.A.; Heidebrecht, A.C.; Drysdale, R.G. Shear Strength of Concrete Masonry Joints. J. Struct. Div. 1979, 105, 1227–1240. [Google Scholar] [CrossRef]

- CSA S304.1-04; Design of Masonry Structures. Canadian Standards Association (CSA): Mississauga, ON, Canada, 2004.

- Dhanasekar, M.; Loov, R.E.; McCullough, D.; Shrive, N.G. Stress-strain relations for hollow concrete masonry under cyclic compression. In Proceedings of the 11th International Brick & Block Masonry Conference IB2MaC, Shanghai, China, 14–16 October 1997; pp. 14–16. [Google Scholar]

- Kingsley, G.R.; Atkinson, R.H. Stress-Strain Behavior of Grouted Hollow Unit Masonry; ASCE: Los Angeles, CA, USA, 1986; pp. 587–597. [Google Scholar]

- Huang, L.; Wang, H.C.; Chen, S.Y. Experimental research on compressive behaviors of grouted block masonry with low-strength mortar. Eng. Mech. 2012, 29, 157–161. [Google Scholar]

- Zhang, Z.; Murcia-Delso, J.; Sandoval, C.; Araya-Letelier, G.; Wang, F. In-Plane Shear Strength and Damage Fragility Functions for Partially-Grouted Reinforced Masonry Walls with Bond-Beam Reinforcement. Eng. Struct. 2021, 242, 112569. [Google Scholar] [CrossRef]

- Chi, B.; Yang, X.; Wang, F.; Zhang, Z.; Quan, Y. Experimental Investigation of Effect of Section Configuration on Seismic Performance of an Innovative Integrated Concrete Masonry Wall System. Eng. Struct. 2020, 206, 110163. [Google Scholar] [CrossRef]

- Huang, L.; Liao, L.; Yan, L.; Yi, H. Compressive Strength of Double H Concrete Block Masonry Prisms. J. Mater. Civ. Eng. 2014, 26, 06014019. [Google Scholar] [CrossRef]

- Haach, V.G.; Vasconcelos, G.; Lourenço, P.B. Experimental Analysis of Reinforced Concrete Block Masonry Walls Subjected to In-Plane Cyclic Loading. J. Struct. Eng. 2010, 136, 452–462. [Google Scholar] [CrossRef]

- Hori, N.; Inoue, N.; Purushotam, D.; Nishida, T.; Kobayashi, J. Experimental and Analytical Studies on Earthquake Resisting Behaviour of Confined Concrete Block Masonry Structures. Earthq. Eng. Struct. Dyn. 2006, 35, 1699–1719. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Influence of Parameter Uncertainty on the Low-carbon Design Optimization of Reinforced Concrete Continuous Beams. Struct. Concr. 2022, 24, 855–871. [Google Scholar] [CrossRef]

- Al-Ahdal, A.; AbdelRahman, B.; Galal, K. Compressive, Shear, and Tensile Behaviors of Concrete Masonry: Experimental and Numerical Study. Constr. Build. Mater. 2025, 458, 139266. [Google Scholar] [CrossRef]

- Xin, R.; Jia, F.; Hamid, M.A.R.; Ma, R.; Lu, Z. Experimental Study on the In-Plane Seismic Performance of Fully Grouted Interlocking Block Walls. J. Build. Eng. 2024, 97, 110851. [Google Scholar] [CrossRef]

- Cascardi, A.; Verre, S.; Ombres, L.; Aiello, M.A. Carbon Fabric Reinforced Cementitious Mortar Confinement of Concrete Cylinders: The Matrix Effect for Multi-Ply Wrapping. Compos. Struct. 2024, 332, 117919. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, F. Experimental Investigation into the Seismic Performance of Prefabricated Reinforced Masonry Shear Walls with Vertical Joint Connections. Appl. Sci. 2021, 11, 4421. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, F.; Chi, B. Seismic Performance of Shear-Critical Prefabricated Reinforced Masonry Shear Walls with Innovative Vertical Joint Connections. Eng. Struct. 2020, 219, 110958. [Google Scholar] [CrossRef]

- GB50003-2011; Code for Design of Masonry Structures. Code of China: Beijing, China, 2011.

- Ganesan, T.P.; Ramamurthy, K. Behavior of Concrete Hollow-Block Masonry Prisms under Axial Compression. J. Struct. Eng. 1992, 118, 1751–1769. [Google Scholar] [CrossRef]

- Liu, J. The Effect of Height-to-Thickness Ratio on the Compressive Strength of Concrete Masonry. Master’s Thesis, University of Windsor, Windsor, ON, Canada, 2012. [Google Scholar]

- Barbosa, C.S.; Lourenço, P.B.; Hanai, J.B. On the Compressive Strength Prediction for Concrete Masonry Prisms. Mater. Struct. 2009, 43, 331–344. [Google Scholar] [CrossRef]

- Liang, B.; Zhang, H.; Liu, Z.; Hou, J. The Influence of Different Types of Mortar on the Compressive Strength of Masonry. J. Build. Eng. 2023, 65, 105635. [Google Scholar] [CrossRef]

- Ring, T.; Das, S. Compressive Strength of Concrete Masonry Beams. ACI Struct. J. 2012, 109, 369. [Google Scholar] [CrossRef]

- Voon, K.C.; Ingham, J.M. Experimental In-Plane Shear Strength Investigation of Reinforced Concrete Masonry Walls. J. Struct. Eng. 2006, 132, 400–408. [Google Scholar] [CrossRef]

- Priestley, M.J.N.; Elder, D.M. Stress-Strain Curves for Unconfined and Confined Concrete Masonry. ACI J. Proc. 1983, 80, 192–201. [Google Scholar] [CrossRef]

| Pattern | Net/Gross Ratio | Compressive Strength (MPa) | Secant Modulus at 40% of Ultimate Stress (MPa) | |||

|---|---|---|---|---|---|---|

| Average | Coefficient of Variation | Average | Standard Deviation | Average | Standard Deviation | |

| B1 | 0.527 (10) | 0.016 | 25.73 (15) | 2.22 | 16533 (3) | 1370 |

| B2 | 0.528 (10) | 0.010 | 26.30 (15) | 2.42 | 18367 (3) | 717 |

| B3 | 0.530 (10) | 0.005 | 31.18 (15) | 4.62 | 20746 (3) | 597 |

| Pattern | Concrete Composition C1:S2:G3 | w/c Ratio | 28 Days Compressive Strength (MPa) | Secant Modulus Between 50% and 70% of Ultimate Stress (MPa) | |

|---|---|---|---|---|---|

| Average | Standard Deviation | ||||

| C1 | 1:2.0:3.5 | 0.6 | 33.1 (3) | 1.05 | 4720 |

| C2 | 1:1.9:3.1 | 0.6 | 36.6 (6) | 0.87 | 6052 |

| C3 | 1:1.4:2.6 | 0.5 | 43.1 (3) | 0.46 | 8235 |

| Block Type | Grout Type | |||

|---|---|---|---|---|

| Hollow | C1 | C2 | C3 | |

| B1 | HB1 (3) | G1B1 (9) | G2B1 (3) | - |

| B2 | HB2 (3) | - | G2B2 (12) | - |

| B3 | HB3 (3) | - | G2B3 (3) | G3B3 (9) |

| Specimen Pattern | Block Strength (MPa) | Grouted Concrete Strength (MPa) | Monotonic Loading | Cyclic Loading | |||

|---|---|---|---|---|---|---|---|

| Specimens Tested | Crack to Peak Stress | Compressive Strength (MPa) | Specimens Tested | Compressive Strength (MPa) | |||

| HB1 | 25.73 | - | 3 | 0.84 (0.14) | 7.23 (0.15) | - | - |

| HB2 | 26.30 | - | 3 | 0.82 (0.09) | 7.64 (0.11) | - | - |

| HB3 | 31.18 | - | 3 | 0.71 (0.07) | 9.94 (0.10) | - | - |

| G2B1 | 25.73 | 36.6 | 3 | 0.80 (0.21) | 20.17 (0.11) | - | - |

| G2B3 | 31.18 | 36.6 | 3 | 0.76 (0.04) | 19.50 (0.04) | - | - |

| G1B1 | 25.73 | 33.1 | 5 | 0.81 (0.10) | 18.05 (0.05) | 4 | 17.73 (0.03) |

| G2B2 | 26.30 | 36.6 | 6 | 0.83 (0.12) | 21.14 (0.08) | 6 | 20.84 (0.07) |

| G3B3 | 31.18 | 43.1 | 3 | 0.79 (0.08) | 25.17 (0.13) | 6 | 24.69 (0.10) |

| Pattern and Type | Compression Strength (MPa) | Mean Strength (MPa) | Cov 3 | Specified Strength (MPa) | Kp 4 | Ks 5 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G1B1 | M 1 | 17.17 | 17.48 | 19.45 | 17.91 | 18.24 | - | 18.05 | 0.05 | 16.60 | 0.98 | 0.99 |

| C 2 | 17.31 | 17.96 | 18.42 | 17.22 | - | - | 17.73 | 0.03 | 16.79 | |||

| G2B2 | M1 | 20.73 | 19.02 | 20.91 | 22.64 | 23.50 | 20.01 | 21.14 | 0.08 | 18.41 | 0.99 | 1.00 |

| C 2 | 18.61 | 20.35 | 20.18 | 22.99 | 21.80 | 21.09 | 20.84 | 0.07 | 18.37 | |||

| G3B3 | M 1 | 23.48 | 28.53 | 23.50 | - | - | - | 25.17 | 0.12 | 20.38 | 0.98 | 0.99 |

| C 2 | 28.55 | 24.88 | 26.58 | 22.61 | 23.14 | 22.35 | 24.69 | 0.10 | 20.61 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, F.; Hang, Y.; Wang, F.; Wang, S. Compressive Behavior of Fully Grouted Concrete Bond Beam Block Masonry Prisms. Materials 2025, 18, 2589. https://doi.org/10.3390/ma18112589

Zhu F, Hang Y, Wang F, Wang S. Compressive Behavior of Fully Grouted Concrete Bond Beam Block Masonry Prisms. Materials. 2025; 18(11):2589. https://doi.org/10.3390/ma18112589

Chicago/Turabian StyleZhu, Fei, Yongcheng Hang, Fenglai Wang, and Shengbao Wang. 2025. "Compressive Behavior of Fully Grouted Concrete Bond Beam Block Masonry Prisms" Materials 18, no. 11: 2589. https://doi.org/10.3390/ma18112589

APA StyleZhu, F., Hang, Y., Wang, F., & Wang, S. (2025). Compressive Behavior of Fully Grouted Concrete Bond Beam Block Masonry Prisms. Materials, 18(11), 2589. https://doi.org/10.3390/ma18112589