Assessment of the Drone Arm’s Plastic–Metal Joint Mechanical Resistance Following Natural and Artificial Aging of the 3D-Printed Plastic Component

Abstract

1. Introduction

2. Materials and Methods

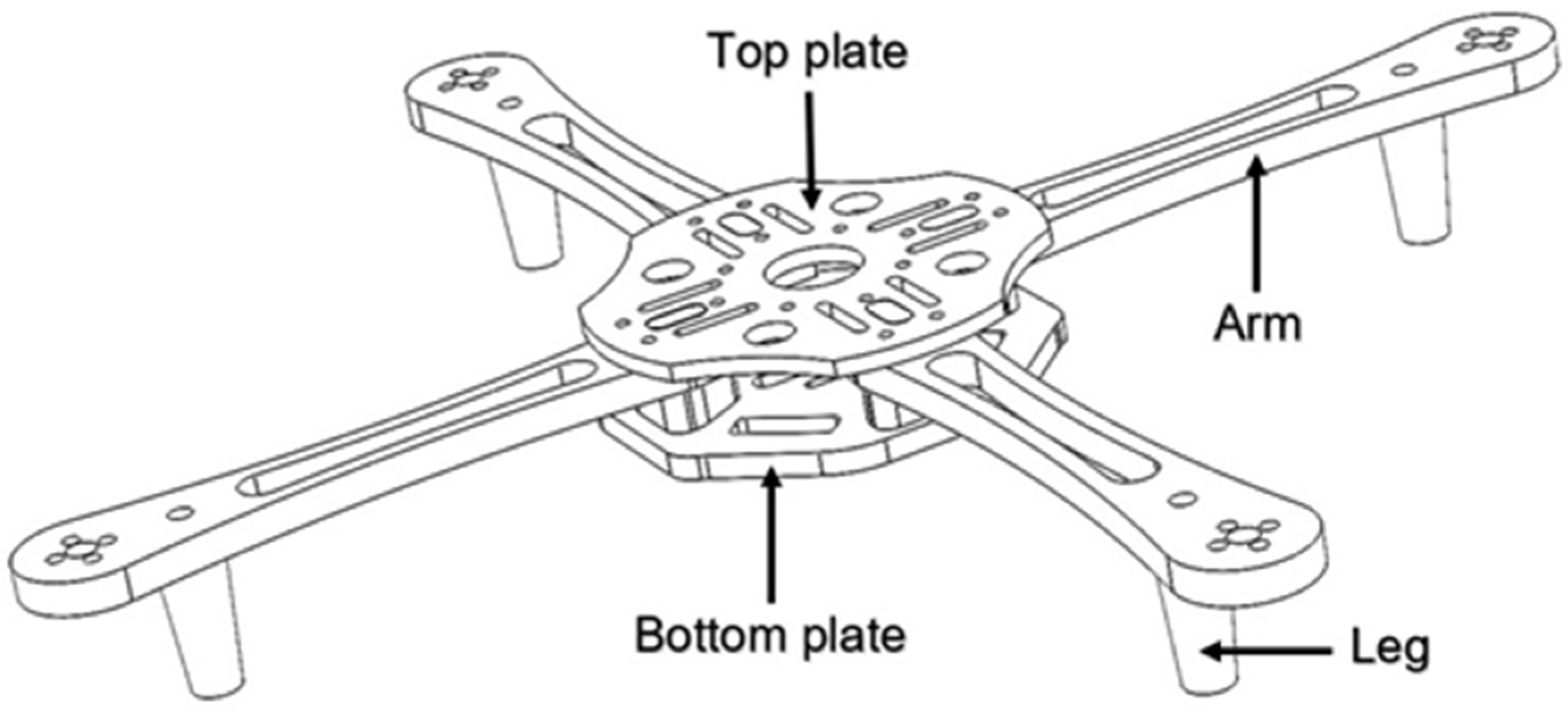

2.1. Drone and Drone Arm Design

2.2. Employed Materials and Methodology

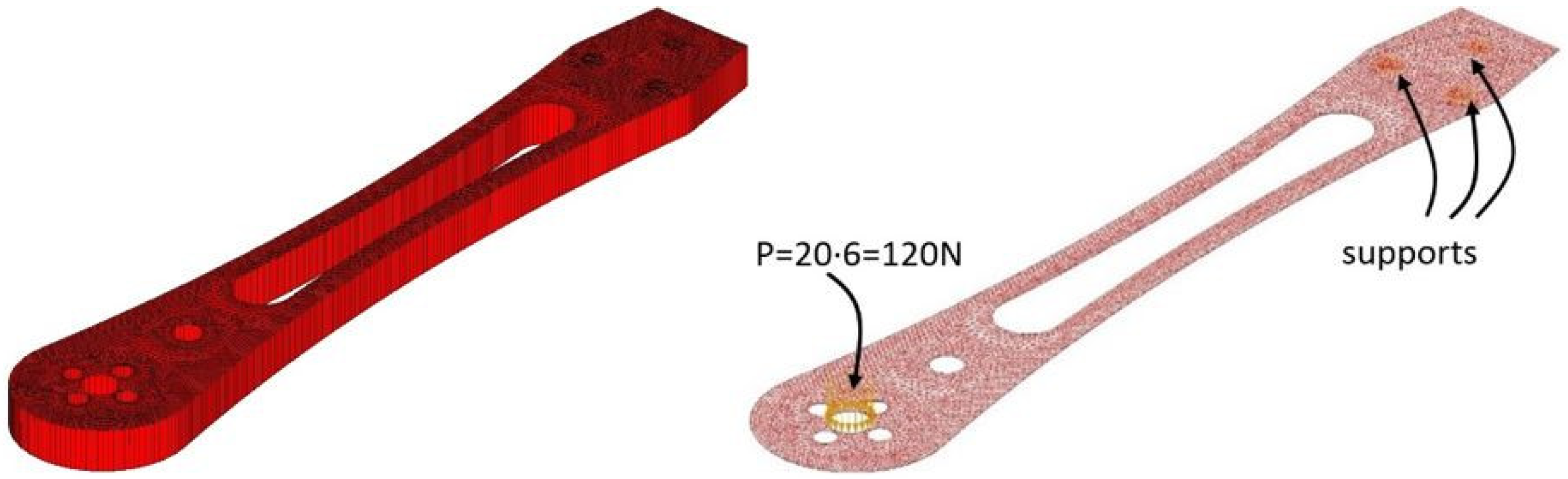

2.3. Numerical Analysis—Methodology

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chekurov, S. Additive Manufacturing Needs and Practices in the Finnish Industry. Master’s Thesis, Aalto University, Espoo, Finland, 2014. [Google Scholar]

- Choi, S.H.; Samavedam, S. Modelling and optimisation of rapid prototyping. Comput. Ind. 2002, 47, 39–53. [Google Scholar] [CrossRef]

- Abibe, A.B.; Amancio-Filho, S.T. Staking of Polymer–Metal Hybrid Structures. In Joining of Polymer-Metal Hybrid Structures: Principles and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2018; pp. 249–274. [Google Scholar]

- Mohanavel, V.; Ali, K.A.; Ranganathan, K.; Jeffrey, J.A.; Ravikumar, M.M.; Rajkumar, S. The roles and applications of additive manufacturing in the aerospace and automobile sector. Mater. Today Proc. 2021, 47, 405–409. [Google Scholar] [CrossRef]

- Trochitz, J.; Kupfer, R.; Gude, M. Process-integrated embedding of metal inserts in continuous fibre reinforced thermoplastics. Procedia CIRP 2019, 85, 84–89. [Google Scholar] [CrossRef]

- Biron, M. Thermoplastics and Thermoplastic Composites; William Andrew: Norwich, NY, USA, 2018. [Google Scholar]

- Anand, K.; Elangovan, S. Optimizing the ultrasonic inserting parameters to achieve maximum pull–out strength using response surface methodology and genetic algorithm integration technique. Measurement 2017, 99, 145–154. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T.; Dos Santos, J.F. Joining of polymers and polymer–metal hybrid structures: Recent developments and trends. Polym. Eng. Sci. 2009, 49, 1461–1476. [Google Scholar] [CrossRef]

- Meschut, G.; Merklein, M.; Brosius, A.; Drummer, D.; Fratini, L.; Füssel, U.; Gude, M.; Homberg, W.; Martins, P.A.F.; Bobbert, M.; et al. Review on mechanical joining by plastic deformation. J. Adv. Join. Process. 2022, 5, 100113. [Google Scholar] [CrossRef]

- Stokes, V.K. Joining methods for plastics and plastic composites: An overview. Polym. Eng. Sci. 1989, 29, 1310–1324. [Google Scholar] [CrossRef]

- Fürst, T.; Göhlich, D. Innovative high-strength screw connections for additive manufactured thermoplastic components. Int. J. Adv. Manuf. Tech. 2024, 135, 4669–4682. [Google Scholar] [CrossRef]

- Miklavec, M.; Klemenc, J.; Kostanjevec, A.; Fajdiga, M. Properties of a metal–nonmetal hybrid joint with an improved shape of the metal insert. Exp. Tech. 2015, 39, 69–76. [Google Scholar] [CrossRef]

- Inceoglu, S.; Ferrara, L.; McLain, R.F. Pedicle screw fixation strength: Pullout versus insertional torque. Spine J. 2004, 4, 513–518. [Google Scholar] [CrossRef]

- Gebhardt, J.; Fleischer, J. Experimental investigation and performance enhancement of inserts in composite parts. Procedia CIRP 2014, 23, 7–12. [Google Scholar] [CrossRef]

- Kastner, T.; Troschitz, J.; Vogel, C.; Behnisch, T.; Gude, M.; Modler, N. Investigation of the Pull-out behaviour of metal threaded inserts in thermoplastic fused-layer modelling (FLM) components. J. Manuf. Mater. Process. 2023, 7, 42. [Google Scholar] [CrossRef]

- Seemann, R.; Krause, D. Numerical modelling of partially potted inserts in honeycomb sandwich panels under pull-out loading. Compos. Struct. 2018, 203, 101–109. [Google Scholar] [CrossRef]

- Stefan, A.; Pelin, G.; Pelin, C.E.; Petre, A.R.; Marin, M. Manufacturing process, mechanical behavior and modeling of composites structures sandwich panel. INCAS Bull. 2021, 13, 183–191. [Google Scholar] [CrossRef]

- Pujari, R. Ageing Performance of Biodegradable PLA for Durable Applications. Ph.D. Thesis, College of Engineering Technology, Rochester Institute of Technology, Rochester, NY, USA, 25 August 2021. Available online: https://scholarworks.rit.edu/cgi/viewcontent.cgi?article=12092&context=theses (accessed on 27 August 2024).

- White, J.R. Polymer ageing: Physics, chemistry or engineering? Time to reflect. Cr. Chim. 2006, 9, 1396–1408. [Google Scholar] [CrossRef]

- Broughton, W.R.; Maxwell, A.S. Accelerated Aging of Polymeric Materials; Measurement Good Practice Guide No. 103; National Physical Laboratory: Teddington, UK, 2023. [Google Scholar]

- Orellana-Barrasa, J.; Tarancón, S.; Pastor, J.Y. Effects of Accelerating the Ageing of 1D PLA Filaments after Fused Filament Fabrication. Polymers 2022, 15, 69. [Google Scholar] [CrossRef]

- Hasan, M.S.; Ivanov, T.; Vorkapić, M.; Simonović, A.; Daou, D.; Kovacević, A.; Milovanović, A. Impact of aging effect and heat treatment on the tensile properties of PLA (poly lactic acid) printed parts. Mater. Plast. 2020, 57, 147–159. [Google Scholar] [CrossRef]

- Liu, H.; Jiao, Q.; Pan, T.; Liu, W.; Li, S.; Zhu, X.; Zhang, T. Aging behavior of biodegradable polylactic acid microplastics accelerated by UV/H2O2 processes. Chemosphere 2023, 337, 139360. [Google Scholar] [CrossRef]

- Podzorova, M.V.; Tertyshnaya, Y.V.; Pantyukhov, P.V.; Popov, A.A.; Nikolaeva, S.G. Influence of ultraviolet on polylactide degradation. In Proceedings of the International Conference on Advanced Materials with Hierarchical Structure for New Technologies and Reliable Structures 2017 (AMHS’17), Tomsk, Russia, 9–13 October 2017. [Google Scholar]

- Souissi, S.; Bennour, W.; Khammassi, R.; Elloumi, A. Mechanical properties of 3D printed parts: Effect of ultraviolet PLA filaments ageing and water absorption. J. Elastom. Plast. 2023, 55, 184–200. [Google Scholar] [CrossRef]

- Sedlak, J.; Joska, Z.; Jansky, J.; Zouhar, J.; Kolomy, S.; Slany, M.; Svasta, A.; Jirousek, J. Analysis of the mechanical properties of 3D-printed plastic samples subjected to selected degradation effects. Materials 2023, 16, 3268. [Google Scholar] [CrossRef]

- Maxwell, A.; Broughton, W.; Dean, G.; Sims, G. Review of Accelerated Ageing Methods and Lifetime Prediction Techniques for Polymeric Materials; NPL Report DEPC MPR 016; National Physical Laboratory: Middlesex, UK, 2005; ISSN 1744-0270. [Google Scholar]

- Al-Haddad, L.A.; Jaber, A.A.; Giernacki, W.; Khan, Z.H.; Ali, K.M.; Tawafik, M.A.; Humaidi, A.J. Quadcopter unmanned aerial vehicle structural design using an integrated approach of topology optimization and additive manufacturing. Designs 2024, 8, 58. [Google Scholar] [CrossRef]

- Martinetti, A.; Margaryan, M.; van Dongen, L. Simulating mechanical stress on a micro Unmanned Aerial Vehicle (UAV) body frame for selecting maintenance actions. Procedia Manuf. 2018, 16, 61. [Google Scholar] [CrossRef]

- Satpathy, C.; Vani, A.; Spurgeon, J. Autonomous Multi-Rotor UAVs: A Holistic Approach to Design, Optimization, and Fabrication. In Proceedings of the International Conference on Mechanical and Aerospace Engineering (ICAMAE), Bangalore, India, 28–30 November 2023. [Google Scholar]

- Tripolitsiotis, A.; Prokas, N.; Kyritsis, S.; Dollas, A.; Papaefstathiou, I.; Partsinevelos, P. Dronesourcing: A modular, expandable multi-sensor UAV platform for combined, real-time environmental monitoring. Int. J. Remote Sens. 2017, 38, 2757–2770. [Google Scholar] [CrossRef]

- Sharma, S. Drone Development from Concept to Flight: Design, Assemble, and Discover the Applications of Unmanned Aerial Vehicles; Packt Publishing Ltd.: Birmingham, UK, 2024. [Google Scholar]

- Dougherty, M.J. Drones; Amber Books Ltd.: London, UK, 2015; Available online: https://www.amberbooks.co.uk/book/drones/ (accessed on 15 March 2025).

- Peksa, J.; Mamchur, D. A review on the state of the art in copter drones and flight control systems. Sensors 2024, 24, 3349. [Google Scholar] [CrossRef] [PubMed]

- Regino Prado, J.L. Economic Optimization of Drone Structure for Industrial Indoor Use by Additive Manufacturing. Master’s Thesis, Politecnico di Torino, Turin, Italy, 2022. Available online: https://webthesis.biblio.polito.it/25676/ (accessed on 20 December 2024).

- Mostafa, K.H.; Thabet, A.S.; Elnady, A.O. Design and Manufacturing of X-Shape Quadcopter. Int. J. Eng. Res. 2021, 8, 12–20. [Google Scholar]

- Kuantama, E.; Craciun, D.; Tarca, R. Quadcopter body frame model and analysis. Ann. Univ. Oradea 2016, 25, 71–74. [Google Scholar] [CrossRef]

- Schöllig, A.; Augugliaro, F.; D’Andrea, R. A platform for dance performances with multiple quadrocopters. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS)—Workshop on Robots and Musical Expressions, Taipei, Taiwan, 18–22 October 2010; Volume 147, pp. 1–8. [Google Scholar]

- Singh, R.; Kumar, R.; Mishra, A.; Agarwal, A. Structural analysis of quadcopter frame. Mater. Today Proc. 2020, 22, 3320–3329. [Google Scholar] [CrossRef]

- Šostakaitė, L.; Šapranauskas, E.; Rudinskas, D.; Rimkus, A.; Gribniak, V. Investigating additive manufacturing possibilities for an unmanned aerial vehicle with polymeric materials. Polymers 2024, 16, 2600. [Google Scholar] [CrossRef]

- Creality. Available online: https://www.creality.com/ (accessed on 10 March 2025).

- Baran, E.H.; Erbil, H.Y. Surface modification of 3D printed PLA objects by fused deposition modeling: A review. Colloids Interfaces 2019, 3, 43. [Google Scholar] [CrossRef]

- Butt, J.; Hewavidana, Y.; Mohaghegh, V.; Sadeghi-Esfahlani, S.; Shirvani, H. Hybrid manufacturing and experimental testing of glass fiber enhanced thermoplastic composites. J. Manuf. Mater. Process. 2019, 3, 96. [Google Scholar] [CrossRef]

- Vorkapić, M.; Ivanov, T. Algorithm for Applying 3D Printing in Prototype Realization in Accordance with Circular Production and the 6R Strategy: Case—Enclosure for Industrial Temperature Transmitter. In Experimental Research and Numerical Simulation in Applied Sciences, Proceedings of the International Conference of Experimental and Numerical Investigations and New Technologies, CNNTech 2022, Zlatibor, Serbia, 5–8 July 2022; Mitrovic, N., Mladenovic, G., Mitrovic, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2022; Volume 564, pp. 44–78. [Google Scholar]

- Marczis, B.; Czigány, T. Polymer joints. Period. Polytech. Mech. Eng. 2002, 46, 117–126. [Google Scholar]

- Faria Neto, A.; Costa, A.F.B.; de Lima, M.F. Use of factorial designs and the response surface methodology to optimize a heat staking process. Exp. Tech. 2018, 42, 319–331. [Google Scholar] [CrossRef]

- Woern, A.L.; McCaslin, J.R.; Pringle, A.M.; Pearce, J.M. RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament. Hardwarex 2018, 4, e00026. [Google Scholar] [CrossRef]

- Sullivan, G.; Crawford, L. The heat stake advantage. In Plastics Decorating Magazine; Peterson Media Group: Topeka, KS, USA, 2003; pp. 11–12. [Google Scholar]

- Datta, P.; Goettert, J. Method for polymer hot embossing process development. Microsyst. Technol. 2007, 13, 265–270. [Google Scholar] [CrossRef]

- Menges, F. Spectragryph—Optical Spectroscopy Software, Version 1.x.x, 202x. Available online: http://www.effemm2.de/spectragryph/ (accessed on 21 April 2025).

- Moldovan, C.; Cosma, C.; Milodin, N.L.; Teusan, C.; Berce, P.; Balc, N. Finite Element Analyses of 3D printed composite robot component. Acta Tech. Napoc.-Ser. Appl. Math. Mech. Eng. 2021, 64, 141–152. [Google Scholar]

- Mishra, A.; Pal, S.; Malhi, G.S.; Singh, P.R.A.B.H.A.T. Structural analysis of UAV airframe by using FEM techniques: A review. Int. J. Adv. Sci. Technol. 2020, 29, 195–204. [Google Scholar]

- Huang, Y.; Jiang, J. A critical review of von mises criterion for compatible deformation of polycrystalline materials. Crystals 2023, 13, 244. [Google Scholar] [CrossRef]

- Baltić, M.Z.; Vasić, M.R.; Vorkapić, M.D.; Bajić, D.M.; Piteľ, J.; Svoboda, P.; Vencl, A. PETG as an Alternative Material for the Production of Drone Spare Parts. Polymers 2024, 16, 2976. [Google Scholar] [CrossRef] [PubMed]

- van de Werken, N.; Hurley, J.; Khanbolouki, P.; Sarvestani, A.N.; Tamijani, A.Y.; Tehrani, M. Design considerations and modeling of fiber reinforced 3D printed parts. Compos. Part B-Eng. 2019, 160, 684–692. [Google Scholar] [CrossRef]

- Xu, H.; Yang, X.; Xie, L.; Hakkarainen, M. Conformational footprint in hydrolysis-induced nanofibrillation and crystallization of poly (lactic acid). Biomacromolecules 2016, 17, 985–995. [Google Scholar] [CrossRef]

- Moliner, C.; Finocchio, E.; Arato, E.; Ramis, G.; Lagazzo, A. Influence of the degradation medium on water uptake, morphology, and chemical structure of poly (lactic acid)-sisal bio-composites. Materials 2020, 13, 3974. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Chen, J.; Jia, W.; Huang, K.; Ma, Y. Comparing the Aging Processes of PLA and PE: The Impact of UV Irradiation and Water. Processes 2024, 12, 635. [Google Scholar] [CrossRef]

| Property | Range/Value |

|---|---|

| Density | 1.25 ± 0.05 g/cm3 |

| Water absorption | 0.5% |

| Extruder temperature | 190–230 °C |

| Bed temperature | max. 60 °C |

| Printing speed | 40–100 mm/s |

| Tensile strength | 61 MPa |

| Bending strength | 69 MPa |

| Flexural strength | 78 MPa |

| Impact strength | 0.0105 KJ/m2 |

| Sample Designation Code | IV | V | VI | X | XI | XII |

|---|---|---|---|---|---|---|

| Wall thickness (mm) | 0.8 | 1.2 | 1.6 | 0.8 | 1.2 | 1.6 |

| Wall line contour | 2 | 3 | 4 | 2 | 3 | 4 |

| Top layer number | 2 | 2 | 2 | 4 | 4 | 4 |

| Bottom layer number | 2 | 2 | 2 | 4 | 4 | 4 |

| Designation Code | Pull-Out Force (N) | |||||||

|---|---|---|---|---|---|---|---|---|

| SP | NP-I | NP-II | AP-I | AP-II | AP-III | AP-IV | AP-V | |

| IV | 433 | 211 | 113 | 55 | 60 | 73 | 79 | 89 |

| (SD) | 0.50 | 1.95 | 1.85 | 1.73 | 1.90 | 1.65 | 1.77 | 1.60 |

| V | 442 | 235 | 135 | 71 | 75 | 93 | 97 | 105 |

| (SD) | 0.40 | 1.20 | 1.50 | 1.20 | 4.90 | 4.10 | 4.70 | 3.10 |

| VI | 505 | 275 | 175 | 85 | 91 | 116 | 122 | 131 |

| (SD) | 0.26 | 1.32 | 1.12 | 1.08 | 1.30 | 1.22 | 1.12 | 1.70 |

| X | 578 | 360 | 280 | 132 | 149 | 186 | 195 | 210 |

| (SD) | 0.50 | 1.30 | 1.02 | 1.15 | 1.74 | 1.95 | 1.02 | 1.95 |

| XI | 619 | 405 | 320 | 152 | 175 | 215 | 225 | 245 |

| (SD) | 0.35 | 1.70 | 1.15 | 1.30 | 1.50 | 1.25 | 1.90 | 1.70 |

| XII | 624 | 425 | 345 | 179 | 205 | 230 | 245 | 269 |

| (SD) | 0.85 | 1.90 | 1.15 | 1.75 | 1.57 | 1.45 | 1.95 | 1.30 |

| FTIR Region (cm−1) | Region Type | Sample Side | FTIR Region Integral Value | Degradation Index | |

|---|---|---|---|---|---|

| Day 36 | Day 44 | DI (%) | |||

| 3757–3485 | O–H stretch (hydroxyl) | Down side | 8.354 | 12.91 | −54.6% (↑ OH) |

| Upper side | 13.02 | 13.66 | −4.9% (↑ OH) | ||

| 2836–3054 | C–H stretch (backbone) | Down side | 2.157 | 3.193 | −48.0% (↑ CH) |

| Upper side | 3.963 | 3.333 | 15.9% | ||

| 2439–2255 | C=O shift (CO2/ester) | Down side | 4.002 | 1.546 | 61.4% |

| Upper side | 1.504 | 1.618 | −7.6% (↑) | ||

| 1893–1649 | C=O ester (main) | Down side | 9.834 | 8.485 | 13.7% |

| Upper side | 3.846 | 8.910 | −131.7% (↑) | ||

| 1536–989 | C–O, C–C, skeletal | Down side | 54.39 | 46.82 | 13.9% |

| Upper side | 51.16 | 49.48 | 3.3% | ||

| 805–693 | Crystallinity/order | Down side | 1.290 | 1.210 | 6.2% |

| Upper side | 0.523 | 1.310 | −150.5% (↑) | ||

| FTIR Region (cm−1) | Region Type | Degradation Index DI (%) | ||

| Metal–Plastic Zone | ||||

| Upper Side | Down Side | Upper Side | ||

| 3757–3485 | O–H stretch (hydroxyl) | −5.10 | −14.39 | −17.01 |

| 2836–3054 | C–H stretch (backbone) | −4.20 | −36.98 | −71.80 |

| 2439–2255 | C=O shift (CO2/ester) | −4.25 | +7.85 | −70.51 |

| 1893–1649 | C=O ester (main) | −4.87 | −15.12 | −14.78 |

| 1536–989 | C–O, C–C, skeletal | −5.65 | −10.79 | +1.36 |

| 805–693 | Crystallinity/order | −7.93 | −12.15 | −5.54 |

| FTIR Region (cm−1) | FTIR Region Integral Value | |||

| Out of Metal–Plastic Zone (PLA Zone) | Metal–Plastic Zone | |||

| Upper Side | Down Side | Upper Side | Down Side | |

| 3757–3485 | 13.00 | 12.37 | 14.47 | 14.15 |

| 2836–3054 | 3.326 | 3.192 | 5.483 | 4.372 |

| 2439–2255 | 1.621 | 1.555 | 2.652 | 1.433 |

| 1893–1649 | 8.902 | 8.488 | 9.743 | 9.770 |

| 1536–989 | 49.46 | 46.81 | 46.16 | 51.87 |

| 805–693 | 1.306 | 1.210 | 1.277 | 1.357 |

| Sample | Maximal Stress, σ (MPa) | Strain at Maximal Stress, ε (%) | Modulus of Elasticity, E (MPa) |

|---|---|---|---|

| IV-1 | 18.07 | 8.22 | 1056 |

| IV-2 | 17.70 | 7.92 | 1605 |

| IV-3 | 18.07 | 8.59 | 1253 |

| V-1 | 19.23 | 9.19 | 1276 |

| V-2 | 19.41 | 8.43 | 1083 |

| V-3 | 18.51 | 9.20 | 1762 |

| VI-1 | 20.28 | 14.48 | 1416 |

| VI-2 | 20.22 | 12.95 | 1853 |

| VI-3 | 20.26 | 11.57 | 1851 |

| X-1 | 27.18 | 20.30 | 3522 |

| X-2 | 28.52 | 11.61 | 2520 |

| X-3 | 28.79 | 12.42 | 2705 |

| XI-1 | 28.12 | 15.64 | 2962 |

| XI-2 | 27.78 | 15.19 | 2691 |

| XI-3 | 28.86 | 9.84 | 2375 |

| XII-1 | 28.24 | 12.44 | 2901 |

| XII-2 | 28.04 | 15.38 | 2388 |

| XII-3 | 28.52 | 11.94 | 2800 |

| Parameter | Symbol/Formula | Value | Unit |

|---|---|---|---|

| Applied force (perpendicular to leg axis) | P | 120 | N |

| Moment arm (to critical section) | r | 148 | mm |

| Critical section width (2 × 6 mm) | b | 12 | mm |

| Critical section height | h | 10 | mm |

| Yield stress of plastic | fy | 20 | MPa |

| Bending moment | M = P × r | 17,760 | N·mm |

| Moment of inertia of the section | I = (b × h3)/12 | 1000 | mm4 |

| Section modulus | W = I/(h/2) | 200 | mm3 |

| Maximum stress at the critical section | fmax = M/W | 88.8 | MPa |

| Yield stress | fy | 18.1 | MPa |

| fmax > fy | 88.8 > 18.1 | Yes | — |

| Critical force causing plasticity | Pcr = (fy × W)/r | 24.46 | N |

| Applied force (P = 120 N) > Pcr | 120 > 24.46 | Yes (plasticity) | — |

| Confidence level 10% | CL = fy × 0.90 | 16.29 | N |

| Confidence level 20% | CL = fy × 0.80 | 14.48 | N |

| Allowed concentration arm load 10% | ACL = 10/9.81 | 1.66 | kg |

| Allowed concentration arm load 20% | ACL = 20/9.81 | 1.47 | kg |

| Sample | IV | V | VI | X | XI | XII |

|---|---|---|---|---|---|---|

| ACL 10% per drone arm (kg) | 1.59 | 1.67 | 1.78 | 2.48 | 2.50 | 2.70 |

| ACL 20% per drone arm (kg) | 1.46 | 1.53 | 1.63 | 2.38 | 2.29 | 2.31 |

| Drone payload capacity with ACL 10% (kg) | 6.36 | 6.68 | 7.12 | 9.92 | 10 | 10.8 |

| Drone payload capacity with ACL 20% (kg) | 5.84 | 6.12 | 6.52 | 9.52 | 9.16 | 9.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasić, M.R.; Vučetić, S.; Miljić, V.; Vorkapić, M.; Terzić, A.; Ćosić, M.; Bajić, D.M. Assessment of the Drone Arm’s Plastic–Metal Joint Mechanical Resistance Following Natural and Artificial Aging of the 3D-Printed Plastic Component. Materials 2025, 18, 2591. https://doi.org/10.3390/ma18112591

Vasić MR, Vučetić S, Miljić V, Vorkapić M, Terzić A, Ćosić M, Bajić DM. Assessment of the Drone Arm’s Plastic–Metal Joint Mechanical Resistance Following Natural and Artificial Aging of the 3D-Printed Plastic Component. Materials. 2025; 18(11):2591. https://doi.org/10.3390/ma18112591

Chicago/Turabian StyleVasić, Miloš R., Snežana Vučetić, Vesna Miljić, Miloš Vorkapić, Anja Terzić, Mladen Ćosić, and Danica M. Bajić. 2025. "Assessment of the Drone Arm’s Plastic–Metal Joint Mechanical Resistance Following Natural and Artificial Aging of the 3D-Printed Plastic Component" Materials 18, no. 11: 2591. https://doi.org/10.3390/ma18112591

APA StyleVasić, M. R., Vučetić, S., Miljić, V., Vorkapić, M., Terzić, A., Ćosić, M., & Bajić, D. M. (2025). Assessment of the Drone Arm’s Plastic–Metal Joint Mechanical Resistance Following Natural and Artificial Aging of the 3D-Printed Plastic Component. Materials, 18(11), 2591. https://doi.org/10.3390/ma18112591