A Unified Microstructure-Based Constitutive Model for a Ni-Based Superalloy and Its Application in the Forging Processes of Disk

Abstract

1. Introduction

2. Development of a Constitutive Model

2.1. Constitutive Law

2.2. Microstructural Evolution

2.2.1. Dislocation Evolution

2.2.2. DRX Fraction Evolution

2.2.3. Grain Size Evolution

2.2.4. Dissolution of δ Phase

2.2.5. Damage Fraction Evolution

2.3. Identification of Model Parameters

3. Analysis and Discussion on the Developed Model

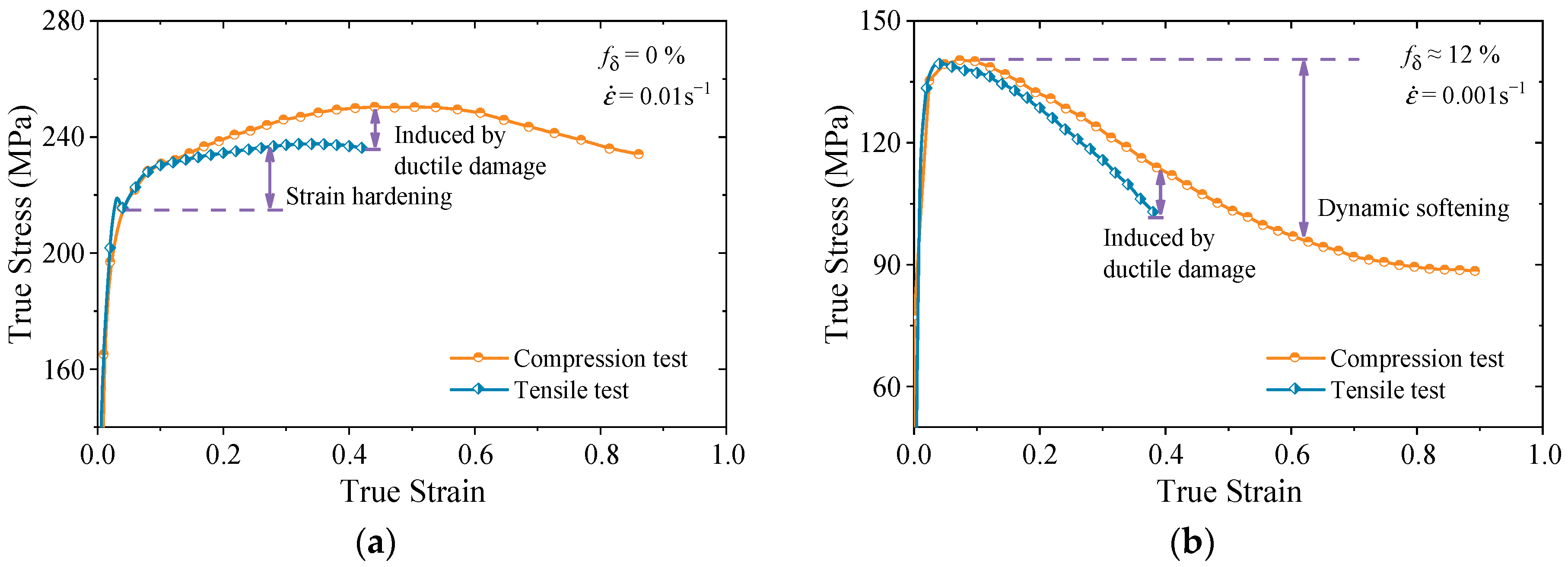

3.1. Prediction and Validation of the Developed Constitutive Models

3.2. Evaluation and Comparison of Prediction Accuracy

3.3. Effects of Initial δ Phase Contents on Microstructure Evolution

4. Application of the Constitutive Model in Forging Processes

4.1. The FE Integrated Computational Method

4.2. Experimental Validatio

5. Verification and Analysis of the Application Case with Disk Forging

6. Conclusions

- (1)

- The proposed model can quantitatively capture the evolution of dislocation density, DRX volume fraction, average grain size, δ phase dissolution ratio, and damage volume fraction. Validation against uniaxial tension and compression rheological curves demonstrated high accuracy, with an AARE of less than 3% and the R2 greater than 0.95.

- (2)

- Mechanistic analysis revealed that the dissolution of the δ phase exhibits strain-dependent kinetics, with a dissolution rate that is faster under compression compared with tension. Additionally, tensile stress induces damage accumulation that is proportional to the initial δ phase content, while compressive stress suppresses damage formation below a critical strain threshold.

- (3)

- The implementation of FE software facilitated the analysis of eight critical regions in disk forging. The predicted recrystallization fraction and average grain size maintained an AARE of less than 8%. Maximum recrystallization and grain refinement occurred in near-surface regions that experienced severe plastic deformation.

- (4)

- High-temperature tensile tests conducted at 650 °C across four regions demonstrated less than 5% variation in strength but over 40% difference in plasticity. Subsurface areas exhibited optimal ductility, achieving 14.61% elongation, while sub-central zones experienced constrained deformation. These findings validate the model’s predictive accuracy and highlight the industrial applicability of the computational method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Farabi, E.; Rielli, V.V.; Godor, F.; Gruber, C.; Stanojevic, A.; Oberwinkler, B.; Ringer, S.P.; Primig, S. Advancing Structure—Property Homogeneity in Forged Alloy 718 Engine Disks: A Pathway towards Enhanced Performance. Mater. Des. 2024, 242, 112987. [Google Scholar] [CrossRef]

- Xu, L.P.; Zhang, R.L.; Hao, M.Q.; Xiong, L.; Jiang, Q.; Li, Z.X.; Wang, Q.Y.; Wang, X.P. A Data-Driven Low-Cycle Fatigue Life Prediction Model for Nickel-Based Superalloys. Comput. Mater. Sci. 2023, 229, 112434. [Google Scholar] [CrossRef]

- Zhao, Z.N.; Li, L.; Yang, W.Z.; Zeng, Y.; Lian, Y.D.; Yue, Z.F. A Comprehensive Study of the Anisotropic Tensile Properties of Laser Additive Manufactured Ni-Based Superalloy after Heat Treatment. Int. J. Plast. 2022, 148, 103147. [Google Scholar] [CrossRef]

- Gao, S.; He, X.K.; Tang, Z.X.; Dong, W.J.; Liu, Z.D.; Bao, H.S. Hot Deformation Behavior and Hot Working Window of a Solid Solution Strengthened Ni-Cr-Fe-Based Superalloy. J. Mater. Res. Technol. 2024, 29, 1377–1389. [Google Scholar] [CrossRef]

- Xie, B.C.; Yu, H.; Sheng, T.; Xiong, Y.H.; Ning, Y.Q.; Fu, M.W. DDRX and CDRX of an As-Cast Nickel-Based Superalloy during Hot Compression at γ’ Sub-/Super-Solvus Temperatures. J. Alloys Compd. 2019, 803, 16–29. [Google Scholar] [CrossRef]

- Tian, Y.H.; Zhang, P.; Zhao, G.H.; Li, H.Y.; Ma, L.F.; Li, J. A Systematic Study on Thermo-Mechanical Behavior, Processing Maps and Recrystallization Mechanism of Incoloy825 Superalloy during Hot Compression. J. Mater. Res. Technol. 2024, 28, 4551–4566. [Google Scholar] [CrossRef]

- Wu, L.; Osada, T.; Watanabe, I.; Yokokawa, T.; Kobayashi, T.; Kawagishi, K. Strength Prediction of Ni-Base Disc Superalloys: Modified Γ’ Hardening Models Applicable to Commercial Alloys. Mater. Sci. Eng. A 2021, 799, 140103. [Google Scholar] [CrossRef]

- Jiao, Y.X.; Qi, Q.Q.; Gong, Y.M.; Gao, Y.F.; Chen, H.Q.; Chen, F.; Zhou, F.W.; Li, X.X. Research on Hot Deformation Behavior and Microstructure Evolution Mechanism of GH4169 Superalloy. Mater. Today Commun. 2024, 40, 109958. [Google Scholar] [CrossRef]

- Zhou, W.; Chen, K.X.; Wang, Y.L.; Zhu, Y.Z.; Qin, J.W.; Zhao, Y.Y.; Wang, Z.D.; Chen, X.H.; Zuo, L.L. Microstructural Evolution of Grain Refinement in Superalloy Inconel 718 during Low Temperature and Slow Strain Rate Hot Compression. J. Mater. Res. Technol. 2024, 30, 1751–1757. [Google Scholar] [CrossRef]

- Poloczek, Ł.; Rauch, Ł.; Wilkus, M.; Bachniak, D.; Zalecki, W.; Pidvysotsk’yy, V.; Kuziak, R.; Pietrzyk, M. Physical and Numerical Simulations of Closed Die Hot Forging and Heat Treatment of Forged Parts. Materials 2021, 14, 15. [Google Scholar] [CrossRef]

- Yuan, Z.W.; Wang, S.L.; Zhang, H.; Li, F.G.; Ma, R.; Bai, J. Microstructure Evolution and Dynamic Recrystallization Behavior of SLM GH3536 Superalloy During Hot Deformation. Met. Mater. Int. 2023, 29, 3356–3370. [Google Scholar] [CrossRef]

- Schulz, B.; Leitner, T.; Hafok, M.; Primig, S. Advancements in Processing of Ni-Based Superalloys by Microstructure Engineering via Discontinuous Γ’ Break-Down. Materialia 2023, 31, 101873. [Google Scholar] [CrossRef]

- Lin, J.L.; Liu, Y.H.; Dean, T.A. A Review on Damage Mechanisms, Models and Calibration Methods under Various Deformation Conditions. Int. J. Damage Mech. 2005, 14, 299–319. [Google Scholar] [CrossRef]

- Kareem, S.A.; Anaele, J.U.; Olanrewaju, O.F.; Adewale, E.D.; Osondu-Okoro, N.C.; Aikulola, E.O.; Falana, S.O.; Gwalani, B.; Bodunrin, M.O.; Alaneme, K.K. Insights into Hot Deformation of Medium Entropy Alloys: Softening Mechanisms, Microstructural Evolution, and Constitutive Modelling—A Comprehensive Review. J. Mater. Res. Technol. 2024, 29, 5369–5401. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M. A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working. Mater. Des. 2011, 32, 1733–1759. [Google Scholar] [CrossRef]

- Shokry, A.; Gowid, S.; Mulki, H.; Kharmanda, G. On the Prediction of the Flow Behavior of Metals and Alloys at a Wide Range of Temperatures and Strain Rates Using Johnson–Cook and Modified Johnson–Cook-Based Models: A Review. Materials 2023, 16, 1574. [Google Scholar] [CrossRef]

- Yan, P.H.; Bai, J.; Yuan, Z.W.; Wang, S.L.; Ma, R.; Zheng, J.C. Constitutive Equation and Hot Deformation Behavior of SLM-GH3536 Alloy. JOM 2023, 75, 4819–4831. [Google Scholar] [CrossRef]

- Sun, J.; Li, J.H.; Huang, Z.Y.; Wang, P. Constitutive Equation and Microstructure Evolution during Isothermal Compression of an Fe-26.6Mn-9.8Al-1.0C Lightweight Steel. Appl. Phys. A 2023, 129, 529. [Google Scholar] [CrossRef]

- Prasad, K.S.; Panda, S.K.; Kar, S.K.; Murty, S.V.S.N.; Sharma, S.C. Constitutive Modelling and Formability Prediction of Inconel-718 Sheet at Elevated Temperatures for Space Applications. Adv. Mater. Process. Technol. 2022, 8, 518–541. [Google Scholar] [CrossRef]

- Liu, C.Y.; Guo, S.; Liang, S.C.; Li, R.W.; Barella, S.; Peng, Y.; Qian, X.M.; Gruttadauria, A.; Belfi, M.; Sun, J.L.; et al. Constitutive Description of Work Hardening and Dynamic Softening Behavior under Variable Deformation States. J. Mater. Process. Technol. 2023, 322, 118188. [Google Scholar] [CrossRef]

- Xu, H.; Li, Y.G.; Li, H.Y.; Wang, J.B.; Liu, G.M.; Song, Y.H. Constitutive Equation and Characterization of the Nickel-Based Alloy 825. Metals 2022, 12, 1496. [Google Scholar] [CrossRef]

- Shi, D.J.; Zhang, F.; He, Z.Y.; Zhan, Z.L.; Gao, W.; Li, Z.L. Constitutive Equation and Dynamic Recovery Mechanism of High Strength Cast Al-Cu-Mn Alloy during Hot Deformation. Mater. Today Commun. 2022, 33, 104199. [Google Scholar] [CrossRef]

- Li, G.F.; Jiang, Y.; Fan, L.F.; Xiao, X.; Wang, D.; Zhang, X.K. Constitutive Model of 25CrMo4 Steel Based on IPSO-SVR and Its Application in Finite Element Simulation. Mater. Today Commun. 2023, 35, 106338. [Google Scholar] [CrossRef]

- Katika, H.; Damoda, R.K.; Davidson, M.J.; Seetharam, R.; Kasagani, V.V.N. Characteristics of Work Hardening and Constitutive Models Comparison of Powder Metallurgy Al-5.6Zn-2Mg Alloy during Hot Compression. J. Cent. South Univ. 2024, 31, 346–368. [Google Scholar] [CrossRef]

- Tan, C.Z.; Li, C.J.; Liu, Z.Q. Application of Machine Learning in Constitutive Relationship Prediction of Porous Titanium Materials for Artificial Bone. Metals 2024, 14, 634. [Google Scholar] [CrossRef]

- Guo, S.; Liu, C.Y.; Li, R.W.; Tao, S.R.; Barella, S.; Peng, Y.; Gruttadauria, A.; Belfi, M.; Liu, Y.; Qu, X.B.; et al. A Hot Deformation Constitutive Model Applicable for Complete Austenite and Dynamic Ferrite Transformation Interval. Mater. Sci. Eng. A 2024, 918, 147419. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Li, H.; Zhang, S.; Luo, J.; Teng, J.H.; Lv, Y.L.; Li, M.Q. Hot Tensile Deformation Behavior and Constitutive Models of GH3230 Superalloy Double-Sheet. Materials 2023, 16, 803. [Google Scholar] [CrossRef]

- Ling, C.; Ren, X.P.; Wang, X.P.; Li, Y.H.; Liu, Z.Q.; Wang, B.; Zhao, J.F. Dynamic Mechanical Properties and Modified Johnson-Cook Model Considering Recrystallization Softening for Nickel-Based Powder Metallurgy Superalloys. Materials 2024, 17, 670. [Google Scholar] [CrossRef]

- Cheng, X.; Wang, R.M.; Chen, X.L.; Jin, S.S.; Qian, Q.K.; Wu, H. An Optimized Strain-Compensated Arrhenius Constitutive Model of GH4169 Superalloy Based on Hot Compression. Materials 2024, 17, 3400. [Google Scholar] [CrossRef]

- Deng, H.P.; Wang, X.L.; Yang, J.Y.; Gongye, F.J.; Li, S.S.; Peng, S.X.; Zhang, J.S.; Xiao, G.Q.; Zhou, J. A New Constitutive Model Based on Taylor Series and Partial Derivatives for Predicting High-Temperature Flow Behavior of a Nickel-Based Superalloy. Materials 2024, 17, 3424. [Google Scholar] [CrossRef]

- Li, Y.Q.; Zhang, Z.M.; Cheng, J.Y.; Liu, Z.F.; Yin, C.; Wang, C.; Guo, J.Z. The Integration of ANN and FEA and Its Application to Property Prediction of Dual-Performance Turbine Disks. Materials 2024, 17, 3045. [Google Scholar] [CrossRef] [PubMed]

- Uz, M.M.; Hazar Yoruç, A.B.; Cokgunlu, O.; Aydoğan, C.S.; Yapici, G.G. A Comparative Study on Phenomenological and Artificial Neural Network Models for High Temperature Flow Behavior Prediction in Ti6Al4V Alloy. Mater. Today Commun. 2022, 33, 104933. [Google Scholar] [CrossRef]

- Jiang, F.; Fei, L.Y.; Jiang, H.; Zhang, Y.M.; Feng, Z.Y.; Zhao, S.D. Constitutive Model Research on the Hot Deformation Behavior of Ti6Al4V Alloy under Wide Temperatures. J. Mater. Res. Technol. 2023, 23, 1062–1074. [Google Scholar] [CrossRef]

- Tize, M.P.; Dhondapure, P.; Jahazi, M.; Tongne, A.; Pantalé, O. Artificial Neural Network-Based Critical Conditions for the Dynamic Recrystallization of Medium Carbon Steel and Application. Metals 2023, 13, 1746. [Google Scholar] [CrossRef]

- Bakhshan, H.; Oñate, E.; Carbonell i Puigbó, J.M. A Review of the Constitutive Modelling of Metals and Alloys in Machining Process. Arch. Comput. Methods Eng. 2024, 31, 1611–1658. [Google Scholar] [CrossRef]

- Chen, J.L.; Li, S.T.; Ma, S.; Chen, Y.Q.; Liu, Y.; Tian, Q.W.; Zhong, X.T.; Song, J.X. The Anti-Penetration Performance and Mechanism of Metal Materials: A Review. Engineering 2024, 40, 131–157. [Google Scholar] [CrossRef]

- Li, W.G.; Ma, J.Z.; Kou, H.B.; Shao, J.X.; Zhang, X.Y.; Deng, Y.; Tao, Y.; Fang, D.N. Modeling the Effect of Temperature on the Yield Strength of Precipitation Strengthening Ni-Base Superalloys. Int. J. Plast. 2019, 116, 143–158. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Wan, M.; Meng, B. Multiscale Modeling of Coupling Mechanisms in Electrically Assisted Deformation of Ultrathin Sheets: An Example on a Nickel-Based Superalloy. Int. J. Mach. Tools Manuf. 2021, 162, 103689. [Google Scholar] [CrossRef]

- He, D.G.; Chen, X.Y.; Lin, Y.C. The Improved Physically-Mechanism Constitutive Model for a Ni-Mo-Cr-Based Superalloy with the Pre-Precipitation of μ Phase in Hot Forming. J. Alloys Compd. 2024, 997, 174934. [Google Scholar] [CrossRef]

- Yan, Z.; Hu, J.; Sun, S. Experimental Investigations and Constitutive Modeling of the Dynamic Recrystallization Behavior of a Novel GH4720Li Superalloys with Yttrium Micro-Alloying. Materials 2024, 17, 3840. [Google Scholar] [CrossRef]

- Gabb, T.P.; Kantzos, P.T.; Telesman, J.; Gayda, J.; Sudbrack, C.K.; Palsa, B. Fatigue Resistance of the Grain Size Transition Zone in a Dual Microstructure Superalloy Disk. Int. J. Fatigue 2011, 33, 414–426. [Google Scholar] [CrossRef]

- Lin, Y.C.; He, M.; Chen, M.S.; Wen, D.X.; Chen, J. Effects of Initial δ Phase (Ni3Nb) on Hot Tensile Deformation Behaviors and Material Constants of Ni-Based Superalloy. Trans. Nonferrous Met. Soc. China 2016, 26, 107–117. [Google Scholar] [CrossRef]

- Chen, Z.J.; Lin, Y.C.; He, D.G.; Lou, Y.M.; Chen, M.S. A Unified Dislocation Density-Based Model for an Aged Polycrystalline Ni-Based Superalloy Considering the Coupled Effects of Complicate Deformation Mechanisms and Initial δ Phase. Mater. Sci. Eng. A 2021, 827, 142062. [Google Scholar] [CrossRef]

- Zhang, H.B.; Wang, B.Y.; Zhang, H.J.; Wang, X.; Wang, J.P. An Internal State Variables Constitutive Model for Ni-Based Superalloy Considering the Influence of Second Phase and Its Application in Flexible Skew Rolling. J. Mater. Process. Technol. 2024, 331, 118518. [Google Scholar] [CrossRef]

- Lemaitre, J. A Continuous Damage Mechanics Model for Ductile Fracture. J. Eng. Mater. Technol. 1985, 107, 83–89. [Google Scholar] [CrossRef]

- Ahmadi, M.R.; Povoden-Karadeniz, E.; Whitmore, L.; Stockinger, M.; Falahati, A.; Kozeschnik, E. Yield Strength Prediction in Ni-Base Alloy 718Plus Based on Thermo-Kinetic Precipitation Simulation. Mater. Sci. Eng. A 2014, 608, 114–122. [Google Scholar] [CrossRef]

- Sellars, C.M.; McTegart, W.J. On the Mechanism of Hot Deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and Phenomenology of Strain Hardening: The FCC Case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Fan, X.G.; Yang, H. Internal-State-Variable Based Self-Consistent Constitutive Modeling for Hot Working of Two-Phase Titanium Alloys Coupling Microstructure Evolution. Int. J. Plast. 2011, 27, 1833–1852. [Google Scholar] [CrossRef]

- Cordero, Z.C.; Knight, B.E.; Schuh, C.A. Six Decades of the Hall-Petch Effect—A Survey of Grain-Size Strengthening Studies on Pure Metals. Int. Mater. Rev. 2016, 61, 495–512. [Google Scholar] [CrossRef]

- Tang, X.F.; Wang, B.Y.; Huo, Y.M.; Ma, W.Y.; Zhou, J.; Ji, H.C.; Fu, X.B. Unified Modeling of Flow Behavior and Microstructure Evolution in Hot Forming of a Ni-Based Superalloy. Mater. Sci. Eng. A 2016, 662, 54–64. [Google Scholar] [CrossRef]

- Lin, J.G.; Liu, Y.; Farrugia, D.C.J.; Zhou, M. Development of Dislocation-Based Unified Material Model for Simulating Microstructure Evolution in Multipass Hot Rolling. Philos. Mag. 2005, 85, 1967–1987. [Google Scholar] [CrossRef]

- Cao, J.; Lin, J. A Study on Formulation of Objective Functions for Determining Material Models. Int. J. Mech. Sci. 2008, 50, 193–204. [Google Scholar] [CrossRef]

- He, D.G.; Yan, X.T.; Lin, Y.C.; Zhang, S.; Chen, Z.J. Microstructure Evolution and Constitutive Model for a Ni-Mo-Cr Base Alloy in Double-Stages Hot Compression with Step-Strain Rates. Mater. Charact. 2022, 194, 112385. [Google Scholar] [CrossRef]

- Lin, J.G.; Dean, T.A. Modelling of Microstructure Evolution in Hot Forming Using Unified Constitutive Equations. J. Mater. Process. Technol. 2005, 167, 354–362. [Google Scholar] [CrossRef]

- He, D.G.; Lin, Y.C.; Jiang, X.Y.; Yin, L.X.; Wang, L.H.; Wu, Q. Dissolution Mechanisms and Kinetics of δ Phase in an Aged Ni-Based Superalloy in Hot Deformation Process. Mater. Des. 2018, 156, 262–271. [Google Scholar] [CrossRef]

- Oyane, M.; Sato, T.; Okimoto, K.; Shima, S. Criteria for Ductile Fracture and Their Applications. J. Mech. Work. Technol. 1980, 4, 65–81. [Google Scholar] [CrossRef]

- Hambli, R.; Reszka, M. Fracture Criteria Identification Using an Inverse Technique Method and Blanking Experiment. Int. J. Mech. Sci. 2002, 44, 1349–1361. [Google Scholar] [CrossRef]

- Chen, X.M.; Yu, Y.J.; Lin, Y.C.; Hu, H.W.; Nie, L.Y.; Zhou, X.J.; Zhang, J.; Lu, X.Z. Revealing the Influence of Initial δ Phase on High-Temperature Low-Cycle Fatigue Behavior of GH4169 Superalloy. Eng. Fail. Anal. 2025, 168, 109029. [Google Scholar] [CrossRef]

- Wen, D.X.; Zhang, M.; Xiong, Y.B.; Wang, W.H.; Li, J.J. Constitutive Modeling Hot Tensile Behavior of Ti6Al4V Alloy by Considering Phase Transformation and Damage Mechanisms. Mater. Sci. Eng. A 2024, 890, 145887. [Google Scholar] [CrossRef]

- Rielli, V.V.; Godor, F.; Gruber, C.; Stanojevic, A.; Oberwinkler, B.; Primig, S. Effects of Processing Heterogeneities on the Micro- to Nanostructure Strengthening Mechanisms of an Alloy 718 Turbine Disk. Mater. Des. 2021, 212, 110295. [Google Scholar] [CrossRef]

- Chen, M.S.; Cai, H.W.; Lin, Y.C.; Wang, G.Q.; Li, H.B.; Liu, A.; Li, Z.H.; Peng, S. Investigation on Mechanism of Microstructure Evolution during Multi-Process Hot Forming of GH4169 Superalloy Forging. Materials 2024, 17, 1697. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.S.; Zou, Z.H.; Lin, Y.C.; Li, H.B.; Yuan, W.Q. Effects of Annealing Parameters on Microstructural Evolution of a Typical Nickel-Based Superalloy during Annealing Treatment. Mater. Charact. 2018, 141, 212–222. [Google Scholar] [CrossRef]

- Chen, M.S.; Chen, Q.; Lou, Y.M.; Lin, Y.C.; Li, H.B.; Ma, Y.Y.; Wang, G.Q. Effect of Cooling Recrystallization Annealing Treatment on Properties of an Initial Aged Deformed GH4169 Superalloy. Mater. Sci. Eng. A 2022, 831, 142232. [Google Scholar] [CrossRef]

- Chen, F.; Zhu, H.J.; Chen, W.; Ou, H.A.; Cui, Z.S. Multiscale Modeling of Discontinuous Dynamic Recrystallization during Hot Working by Coupling Multilevel Cellular Automaton and Finite Element Method. Int. J. Plast. 2021, 145, 103064. [Google Scholar] [CrossRef]

- Zhu, H.; Ou, H.A. Constitutive Modelling of Hot Deformation Behaviour of Metallic Materials. Mater. Sci. Eng. A 2022, 832, 142473. [Google Scholar] [CrossRef]

- Luo, Z.J.; Tang, H.; Zeng, F.C.; Guo, N.C.; Xu, H.Y.; Zhang, H.B.; Qi, L.F. An Effective Technique for Producing High Performance IN718 Forgings Using Hammers. J. Mater. Process. Technol. 1991, 28, 383–390. [Google Scholar] [CrossRef]

| Constants | Value | Constants | Value | Constants | Value |

|---|---|---|---|---|---|

| 0.035 | −334.2 | 1.450 | |||

| 1.928 × 10−9 | 6.204 × 103 | 0.843 | |||

| 0.661 | 0.051 | 0.078 | |||

| 291.5 | 0.545 | 2.054 × 10−3 | |||

| 438.2 | 0.360 | 0.433 | |||

| 2.786 | 6.091 × 10−3 | 0.067 | |||

| 1.509 | 0.153 | 5.882 × 104 | |||

| 1.114 | 1.722 × 104 | 3.319 × 105 | |||

| 6.843 | 4.026 | 8.562 × 103 | |||

| 1.268 | 0.349 | 5.375 × 104 | |||

| −2.470 × 10−3 | 0.761 | 1.624 × 105 | |||

| 2.694 × 104 | 9.837 × 104 | 59.12 | |||

| 1.971 × 105 | 2.875 × 105 | 7.556 × 1012 | |||

| 3.806 × 104 | 0.411 | ||||

| 3.139 × 105 | 1.029 |

| Temperature/°C | 500 | 700 | 900 | 1000 | 1100 |

|---|---|---|---|---|---|

| Coefficient of heat conduction/N·s−1·°C−1 | 18.47 | 24.15 | 25.72 | 26.32 | 29.01 |

| Young’s modulus/GPa | 174 | 163 | 134 | 115 | 98 |

| Heat capacity/N·mm−2·°C−1 | 4.28 | 5.02 | 5.35 | 5.53 | 5.69 |

| Specimens | Yield Stress (MPa) | Tensile Stress (MPa) | Elongation (%) | Reduction in Area (%) |

|---|---|---|---|---|

| Standard [60] | 1000 | 1170 | 12 | 15 |

| S1 | 1016 | 1154 | 14.61 | 12.61 |

| S2 | 1027 | 1167 | 11.92 | 15.70 |

| S3 | 1019 | 1151 | 10.76 | 15.62 |

| S4 | 1013 | 1149 | 11.25 | 20.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, N.-F.; Lin, Y.-C.; Li, S.-X.; Ling, Y.-H.; Yang, J.; Chen, M.-S.; Cai, H.-W.; Chen, Z.-J.; Wu, G.-C. A Unified Microstructure-Based Constitutive Model for a Ni-Based Superalloy and Its Application in the Forging Processes of Disk. Materials 2025, 18, 2526. https://doi.org/10.3390/ma18112526

Zeng N-F, Lin Y-C, Li S-X, Ling Y-H, Yang J, Chen M-S, Cai H-W, Chen Z-J, Wu G-C. A Unified Microstructure-Based Constitutive Model for a Ni-Based Superalloy and Its Application in the Forging Processes of Disk. Materials. 2025; 18(11):2526. https://doi.org/10.3390/ma18112526

Chicago/Turabian StyleZeng, Ning-Fu, Yong-Cheng Lin, Shu-Xin Li, Yun-Han Ling, Jin Yang, Ming-Song Chen, Hong-Wei Cai, Zi-Jian Chen, and Gui-Cheng Wu. 2025. "A Unified Microstructure-Based Constitutive Model for a Ni-Based Superalloy and Its Application in the Forging Processes of Disk" Materials 18, no. 11: 2526. https://doi.org/10.3390/ma18112526

APA StyleZeng, N.-F., Lin, Y.-C., Li, S.-X., Ling, Y.-H., Yang, J., Chen, M.-S., Cai, H.-W., Chen, Z.-J., & Wu, G.-C. (2025). A Unified Microstructure-Based Constitutive Model for a Ni-Based Superalloy and Its Application in the Forging Processes of Disk. Materials, 18(11), 2526. https://doi.org/10.3390/ma18112526