Material Characterization and Stress-State-Dependent Failure Criteria of AASHTO M180 Guardrail Steel: Experimental and Numerical Investigation

Abstract

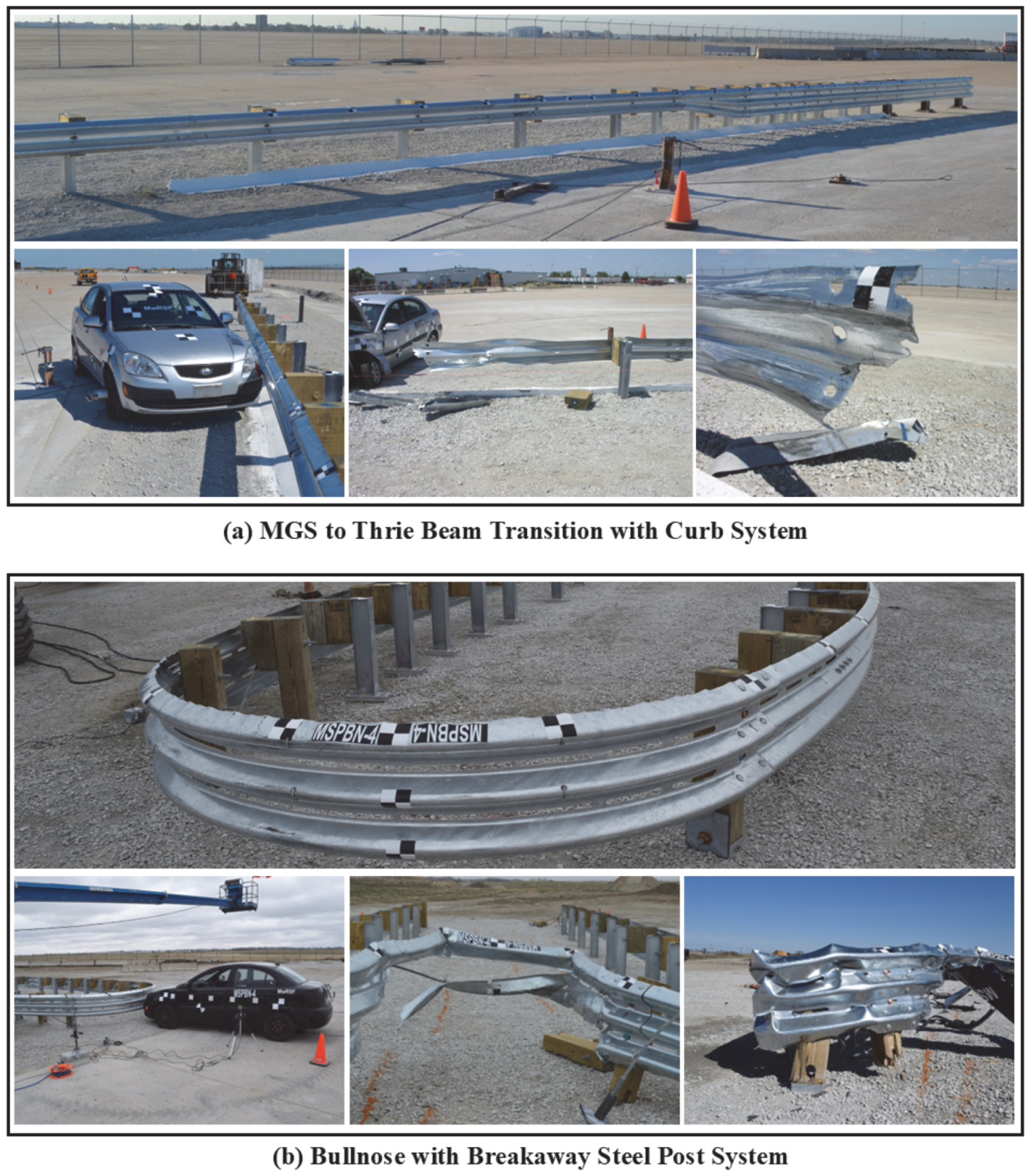

1. Introduction

2. Preliminary Knowledge

3. Experimental Testing and Material Characterization

3.1. Material Selection

3.2. Development of Component Testing Program

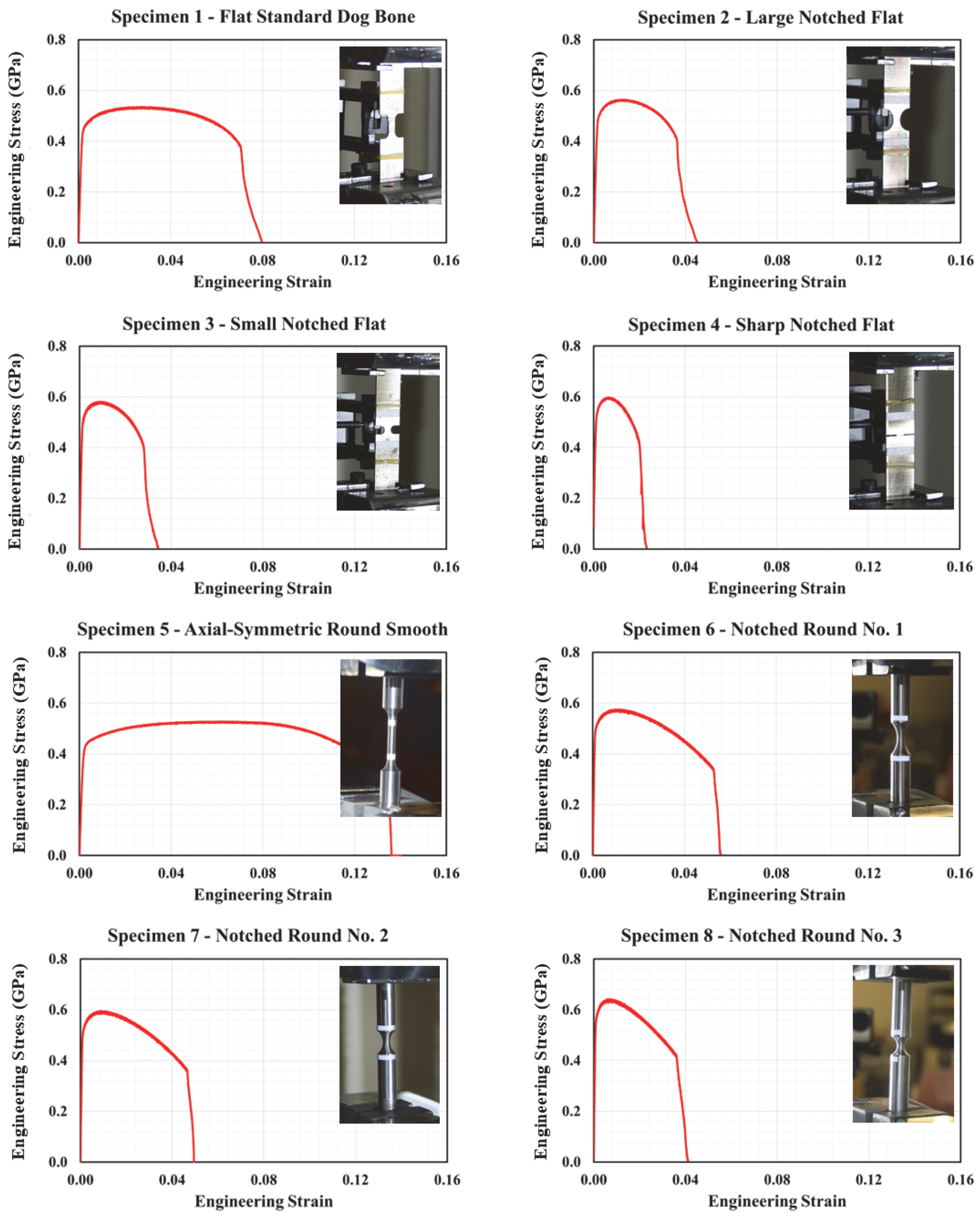

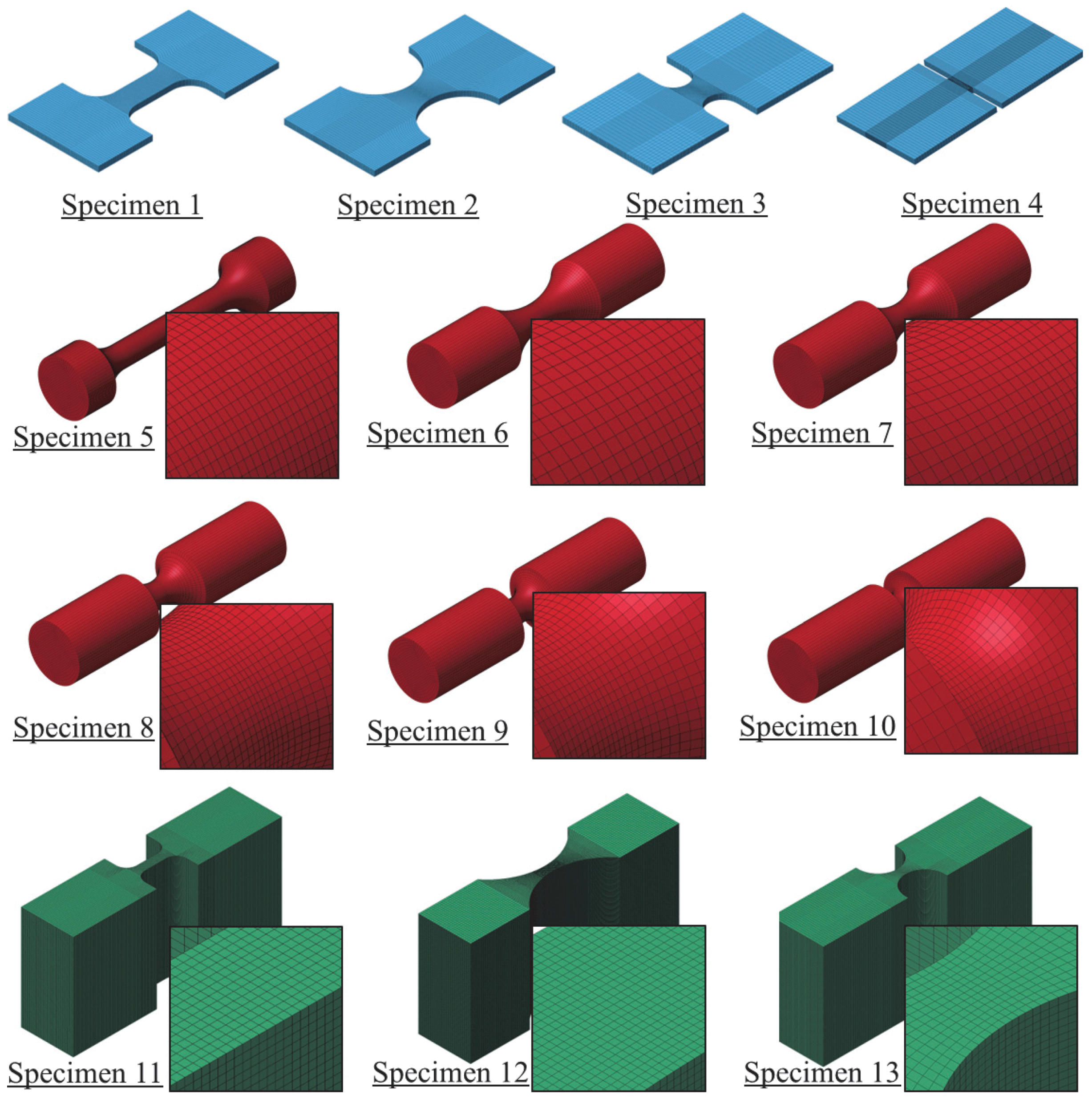

3.2.1. Tension Specimens

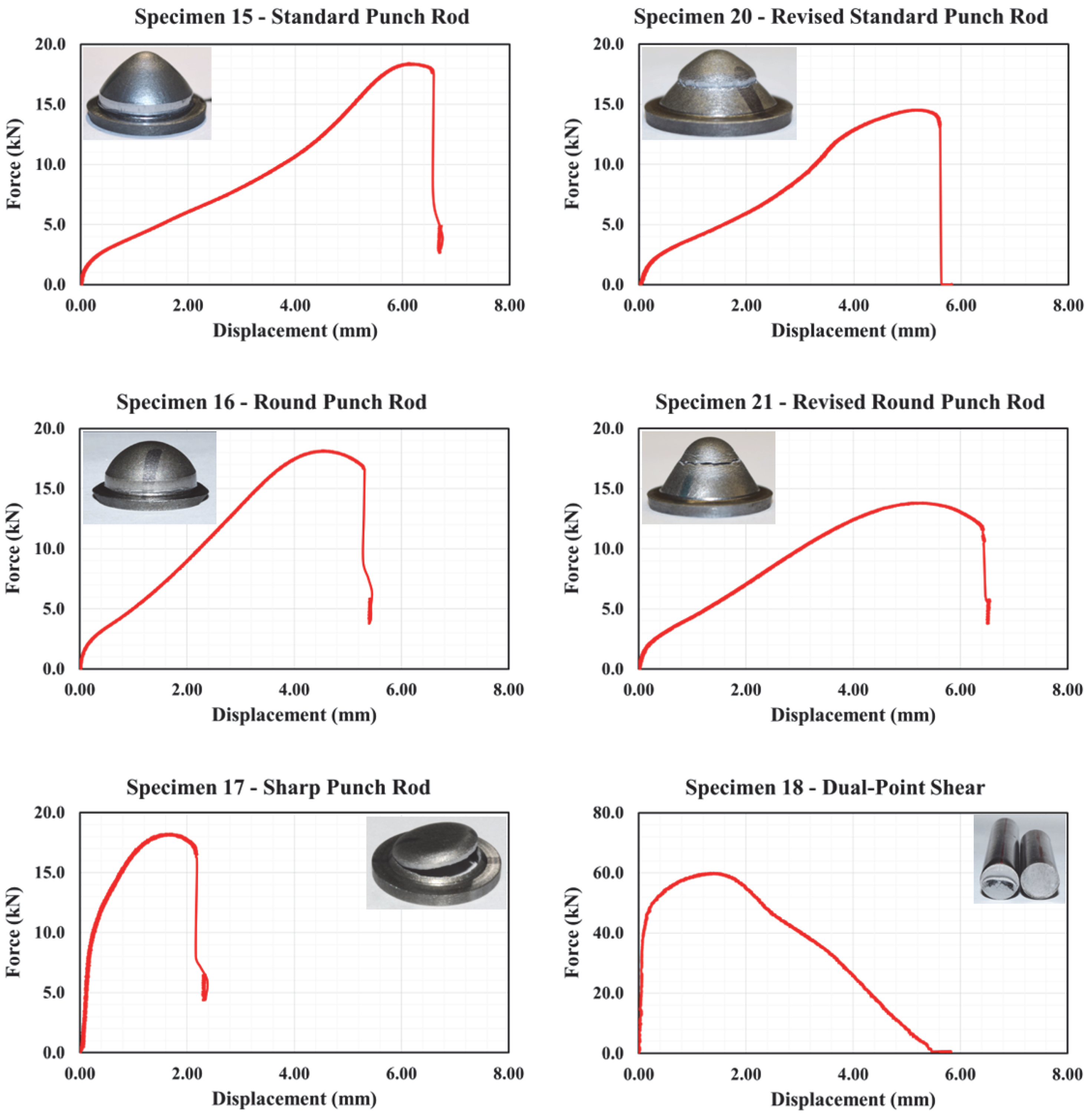

3.2.2. Compression and Punch Specimens

3.2.3. Shear and Torsion Specimens

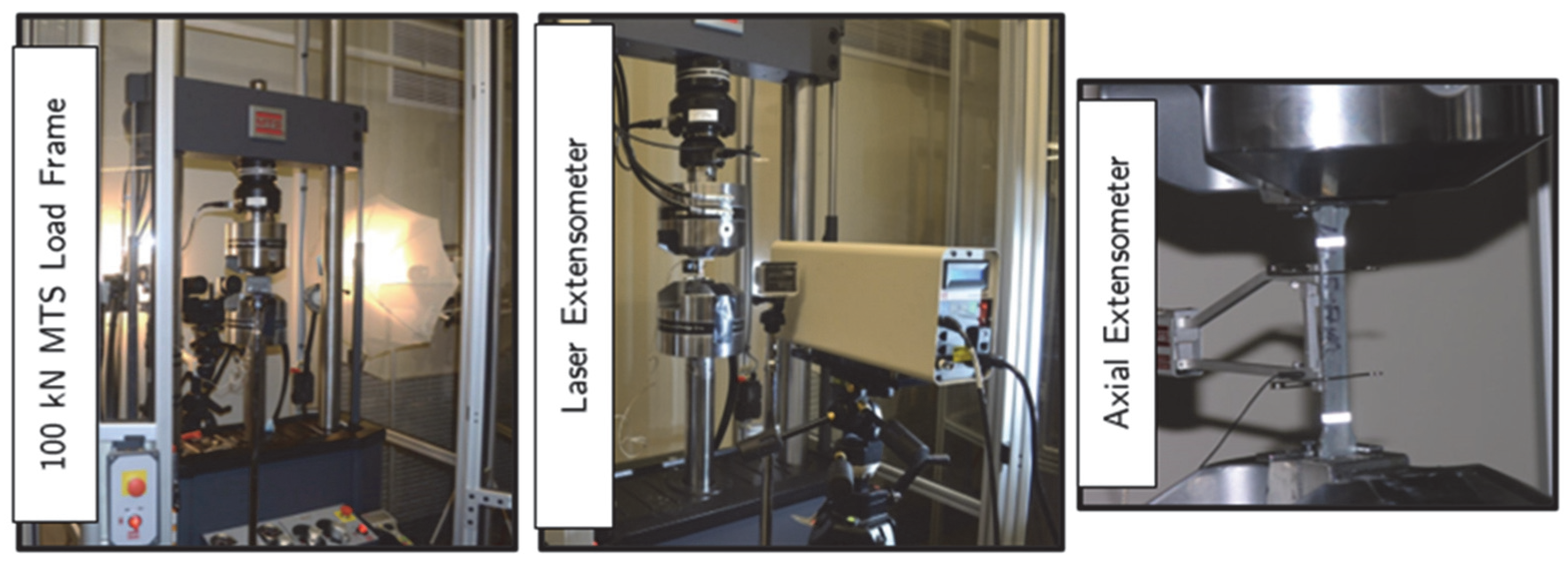

3.3. Testing Setup and Instrumentation

3.4. Testing Matrix

3.5. Testing Results

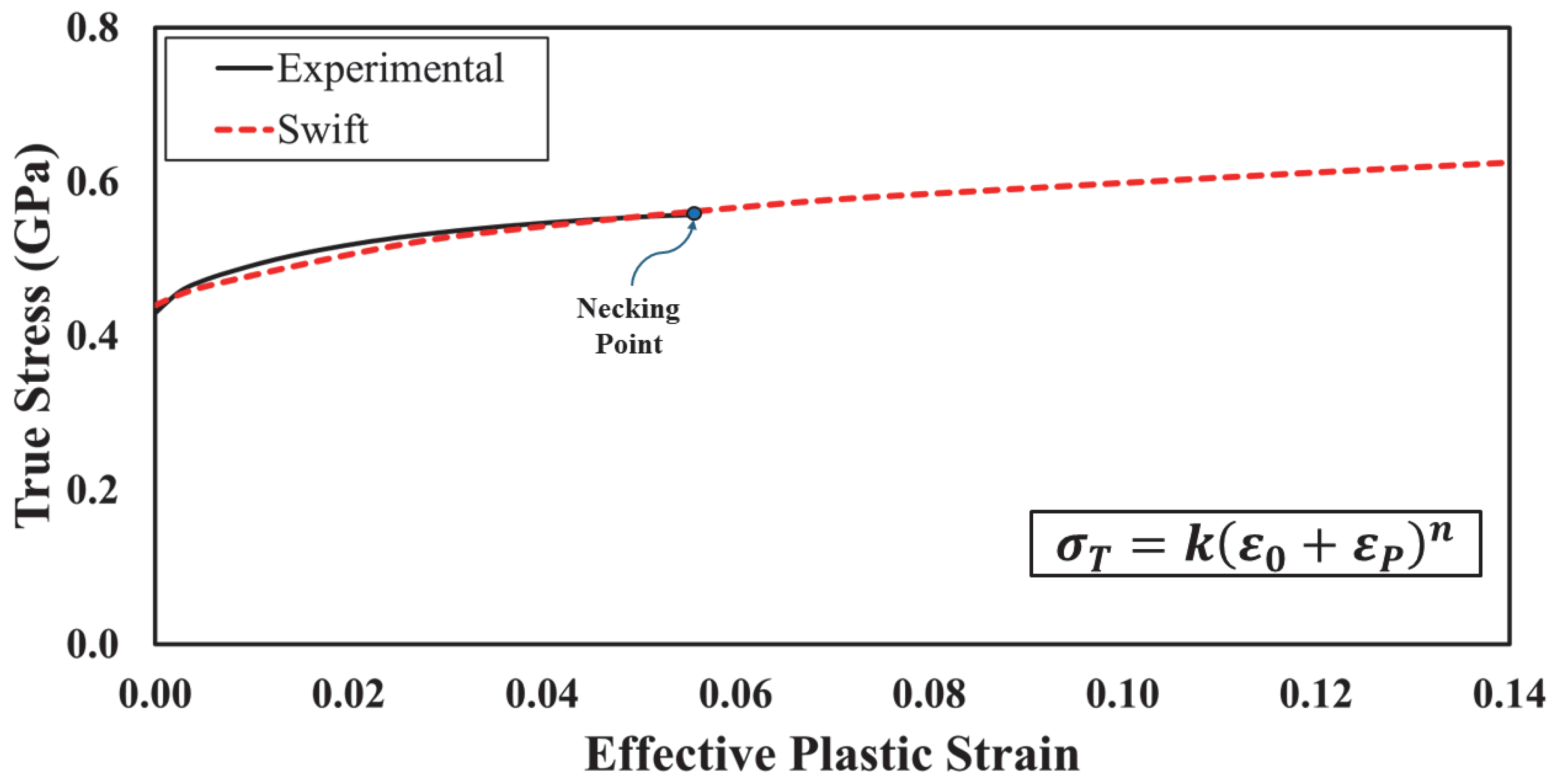

3.6. Elastic and Plastic Flow Parameters Extraction

4. Finite Element Analysis

4.1. Material Models

4.1.1. Tabulated Johnson–Cook Model

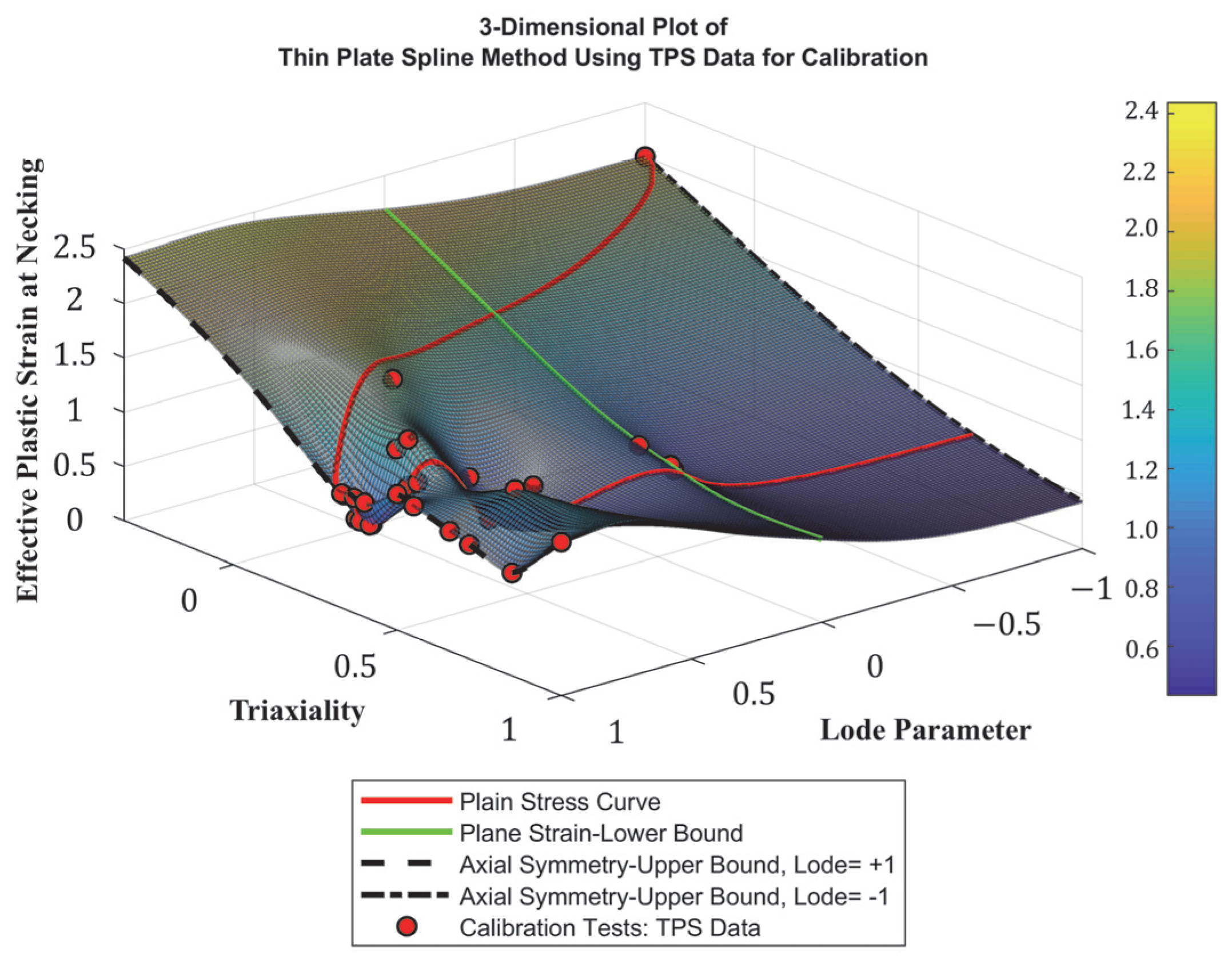

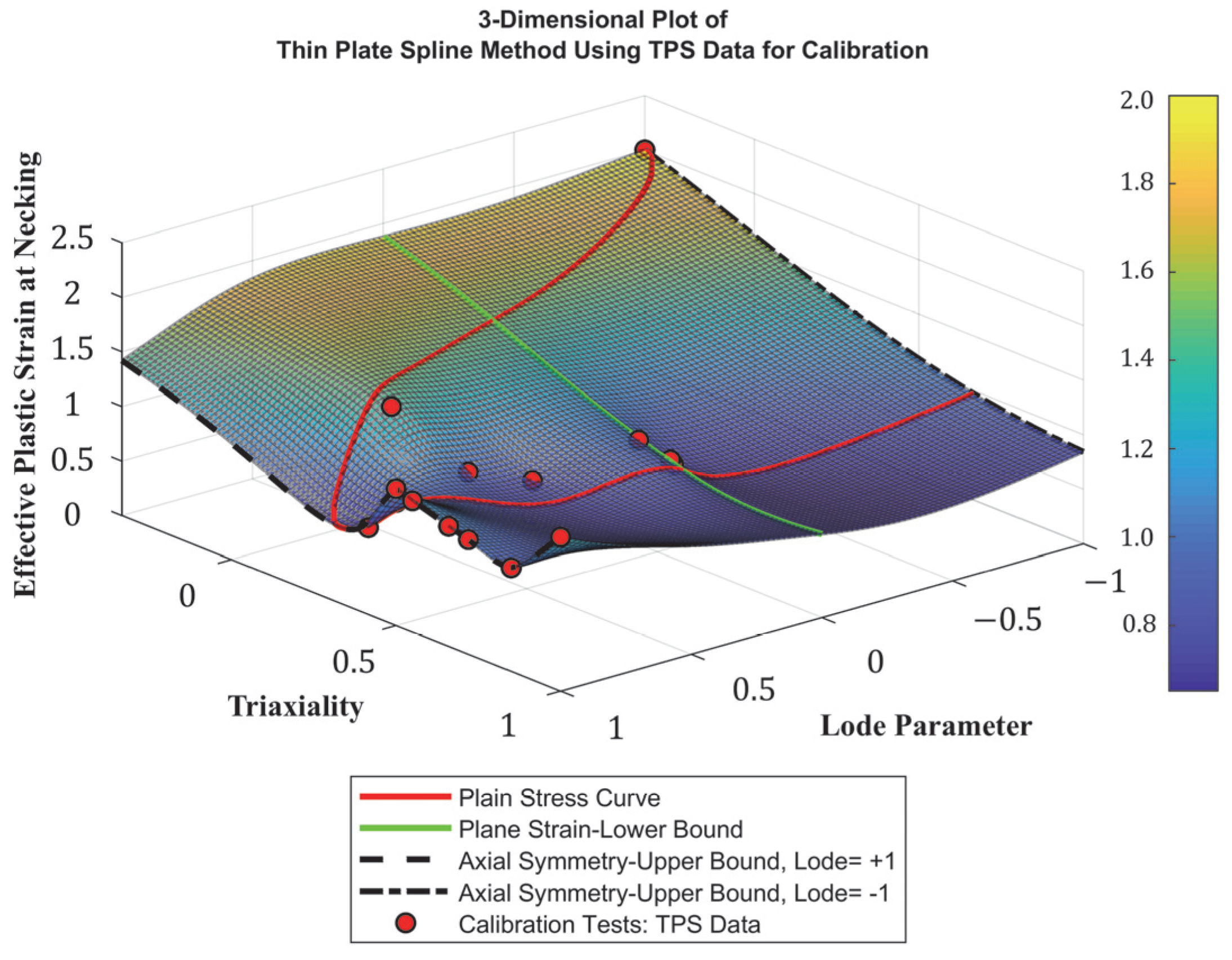

4.1.2. Generalized Incremental Stress-State-Dependent Model (GISSMO)

4.1.3. Piecewise-Linear Plasticity Model

4.2. Development of Stress-State-Dependent Failure Surface

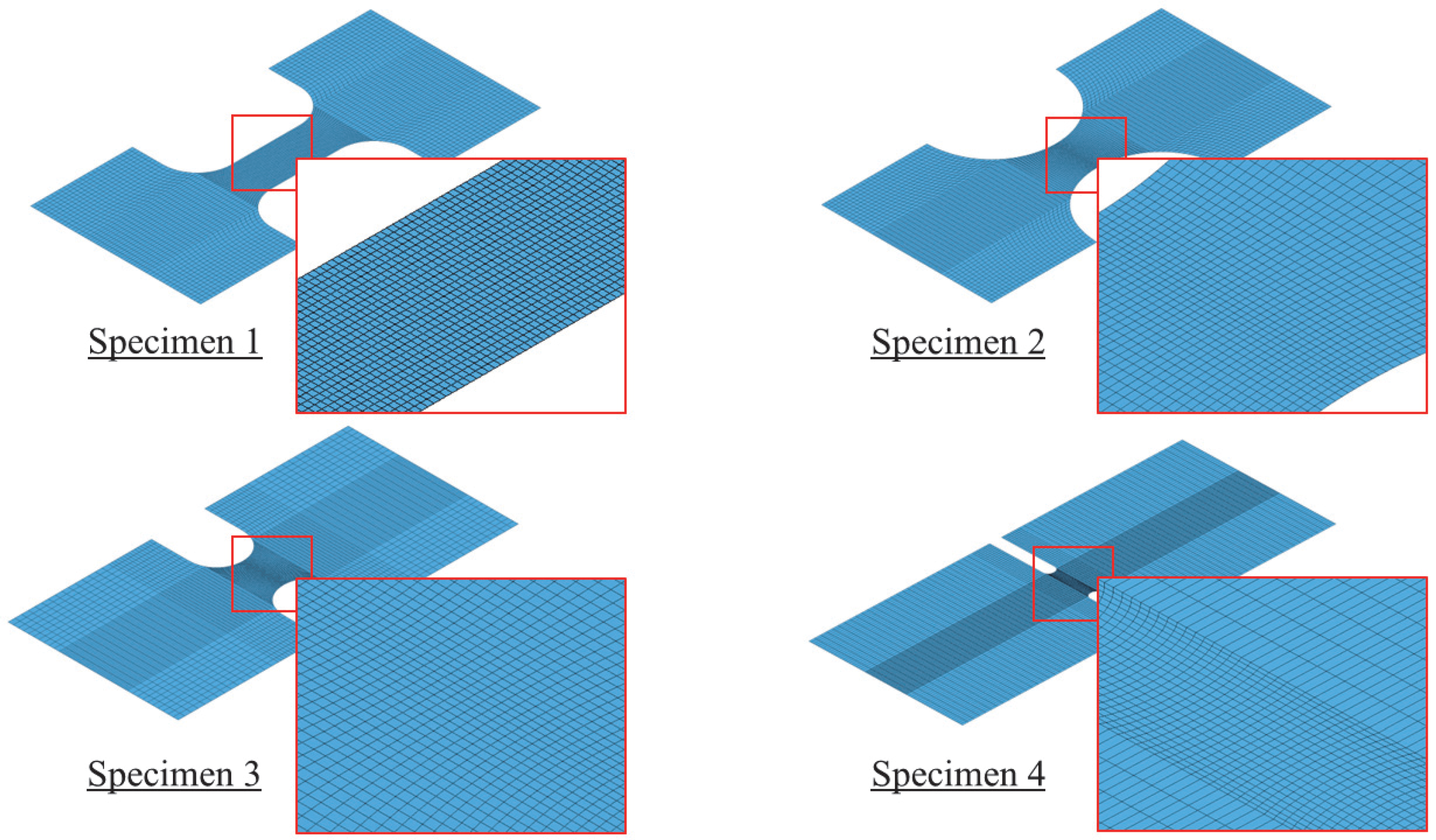

4.3. FE Models Development

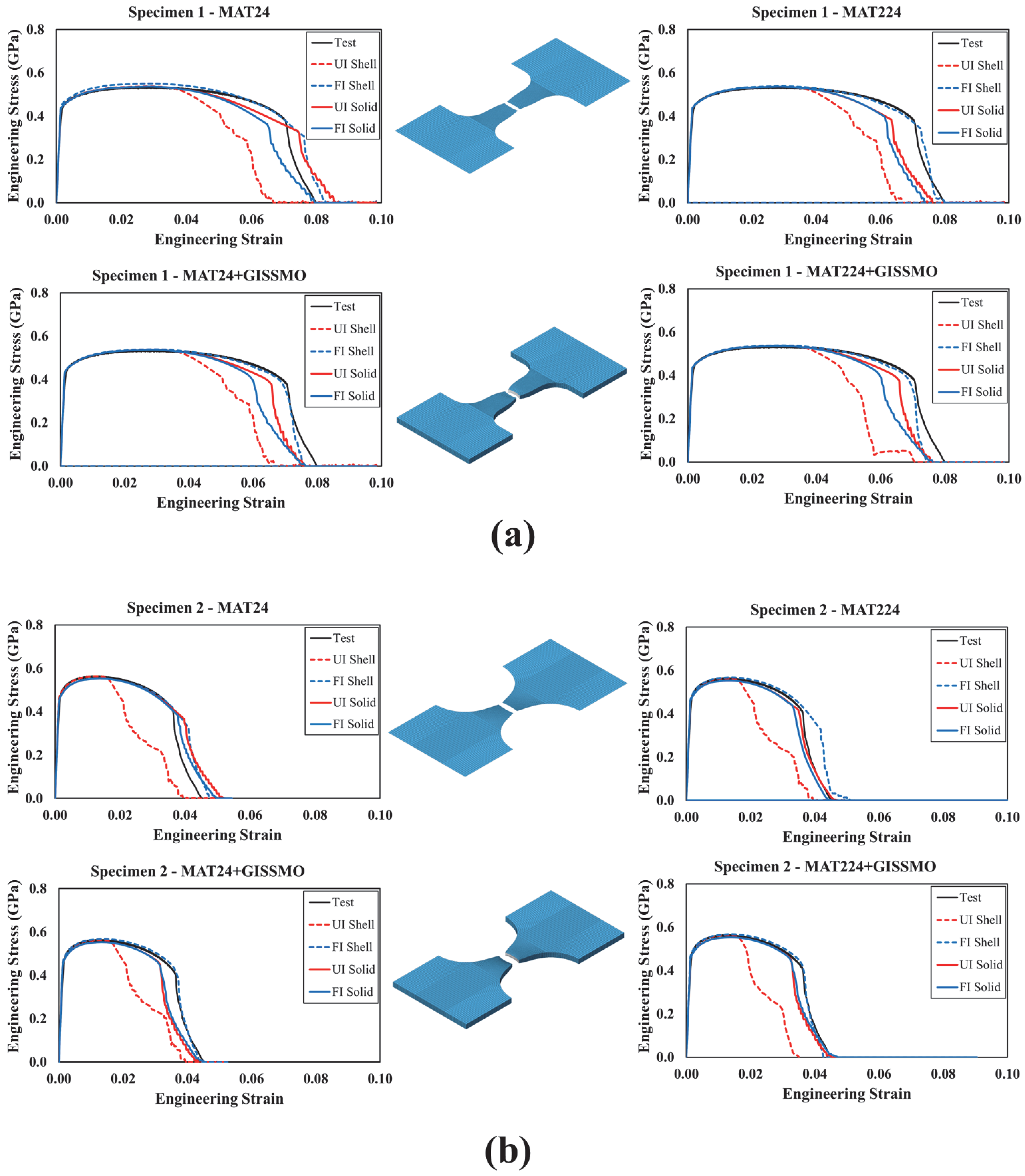

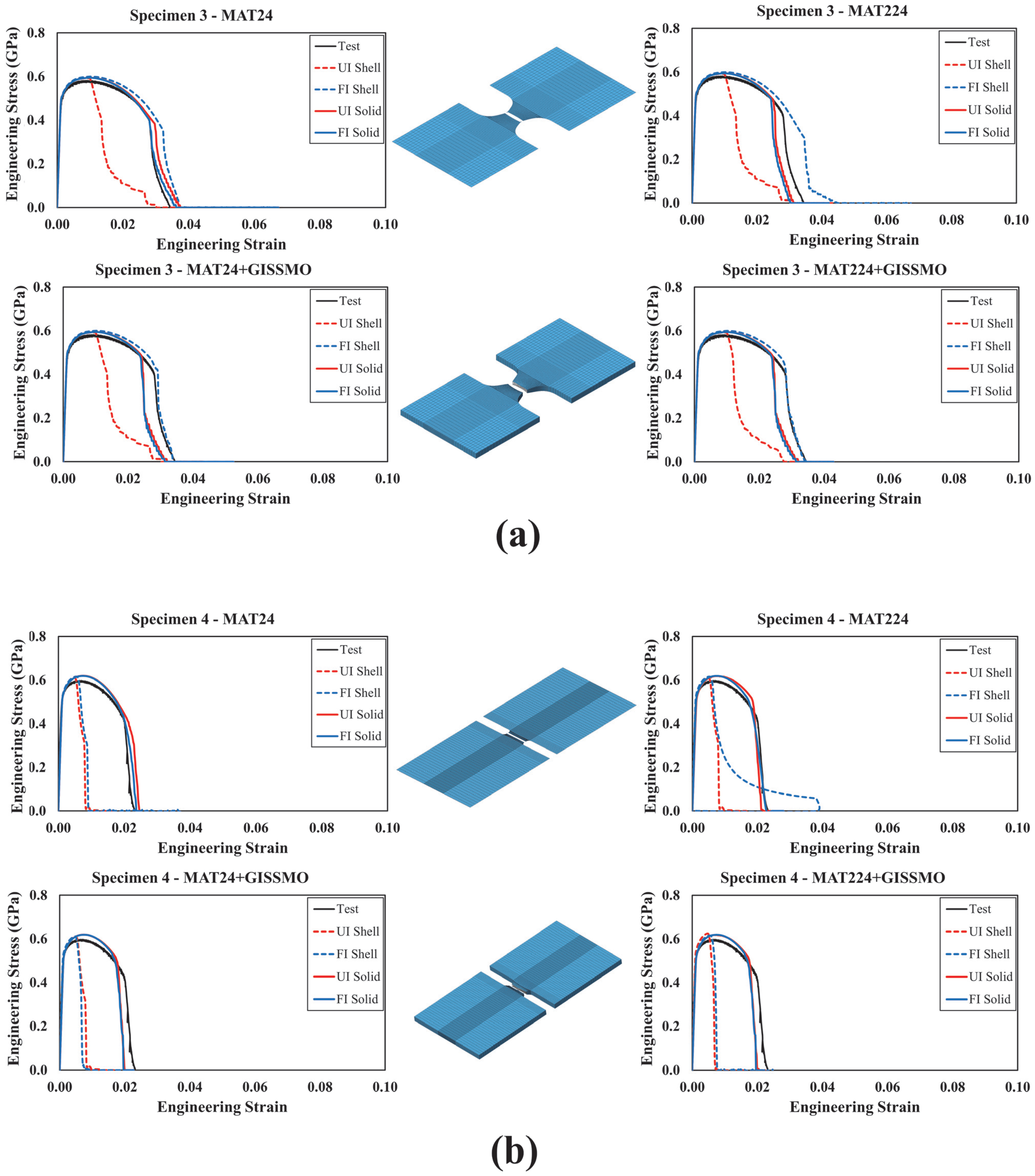

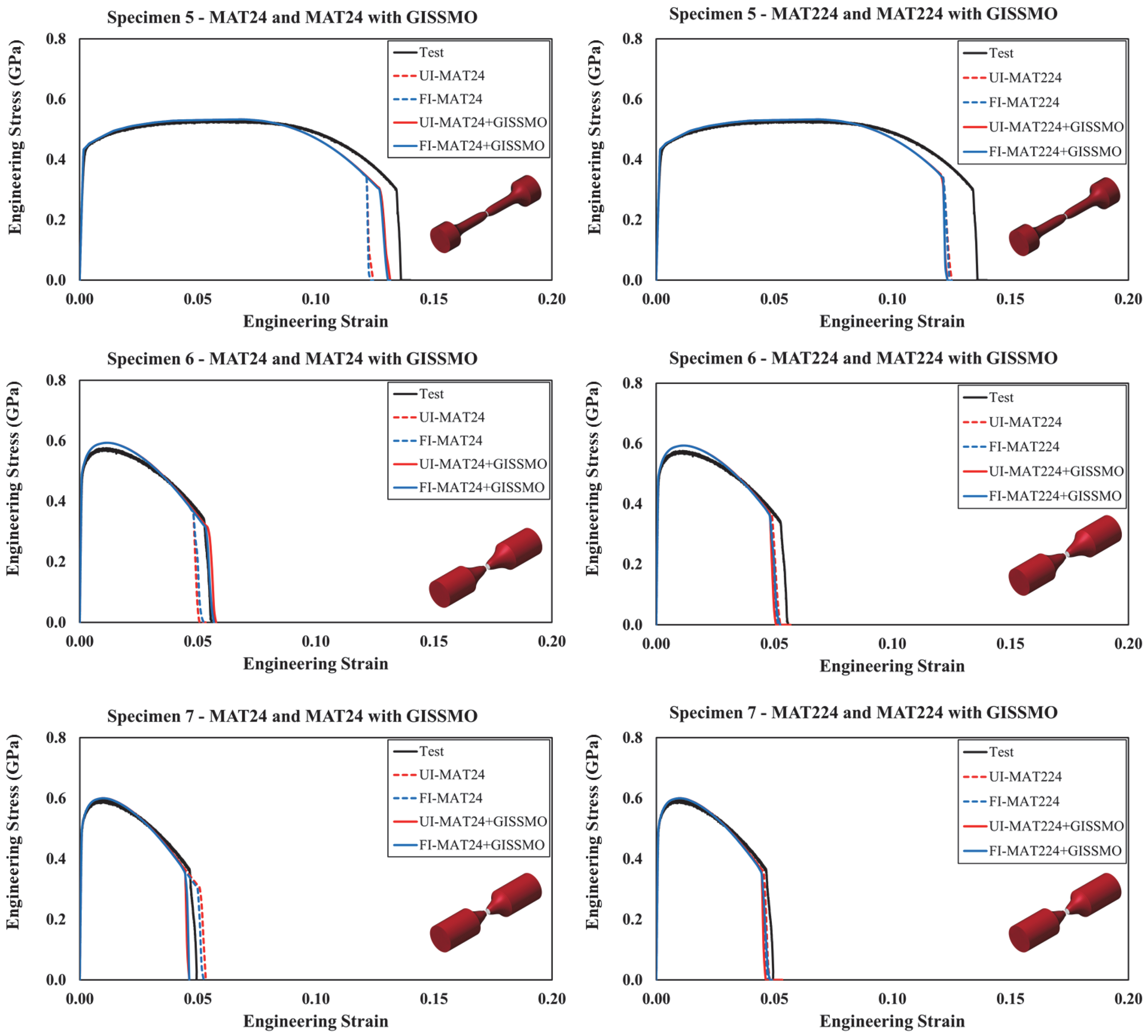

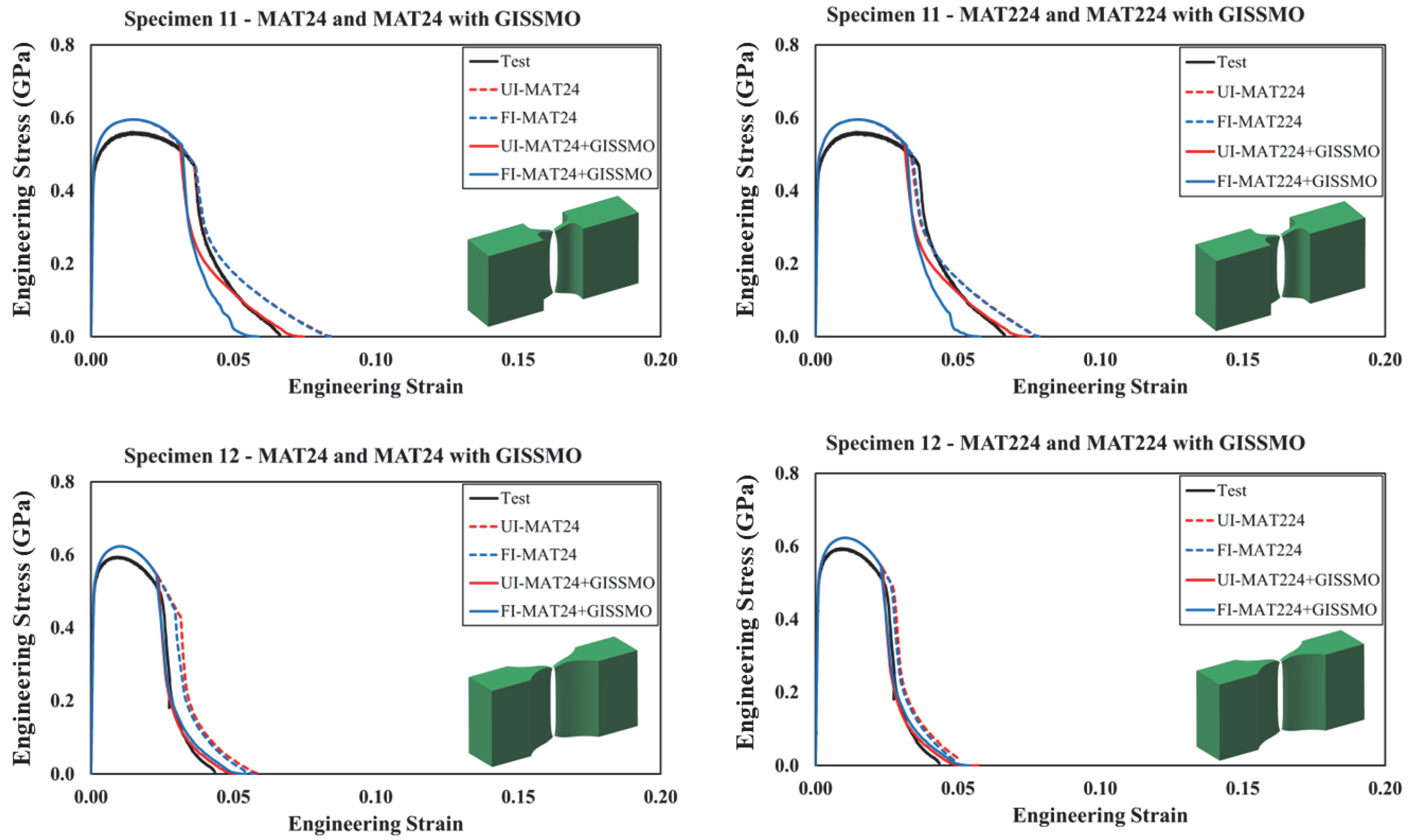

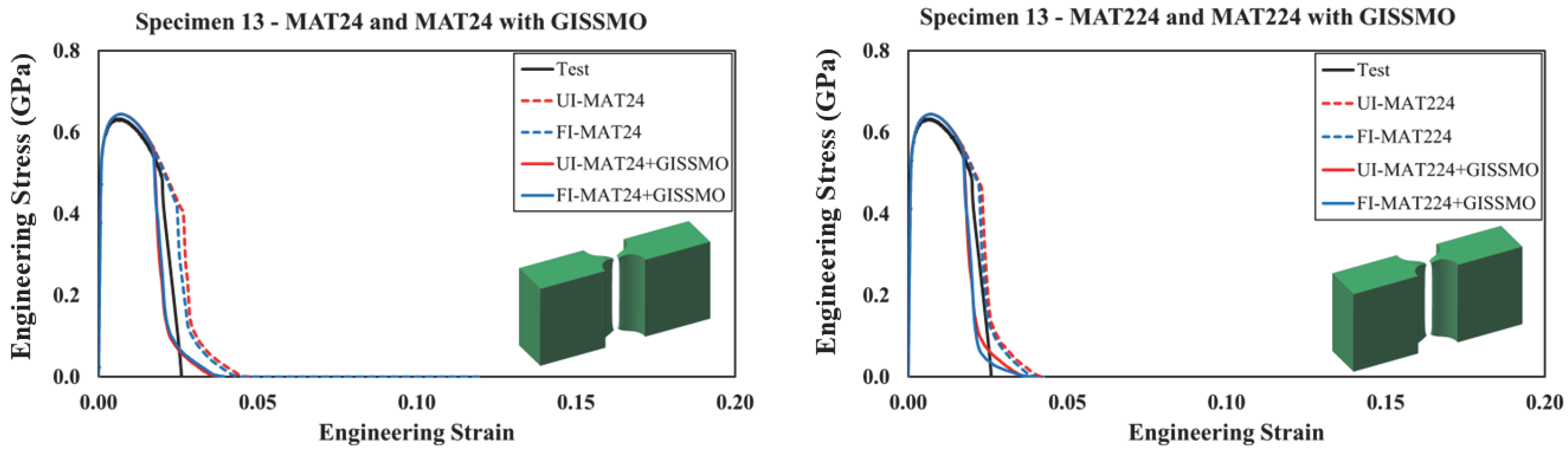

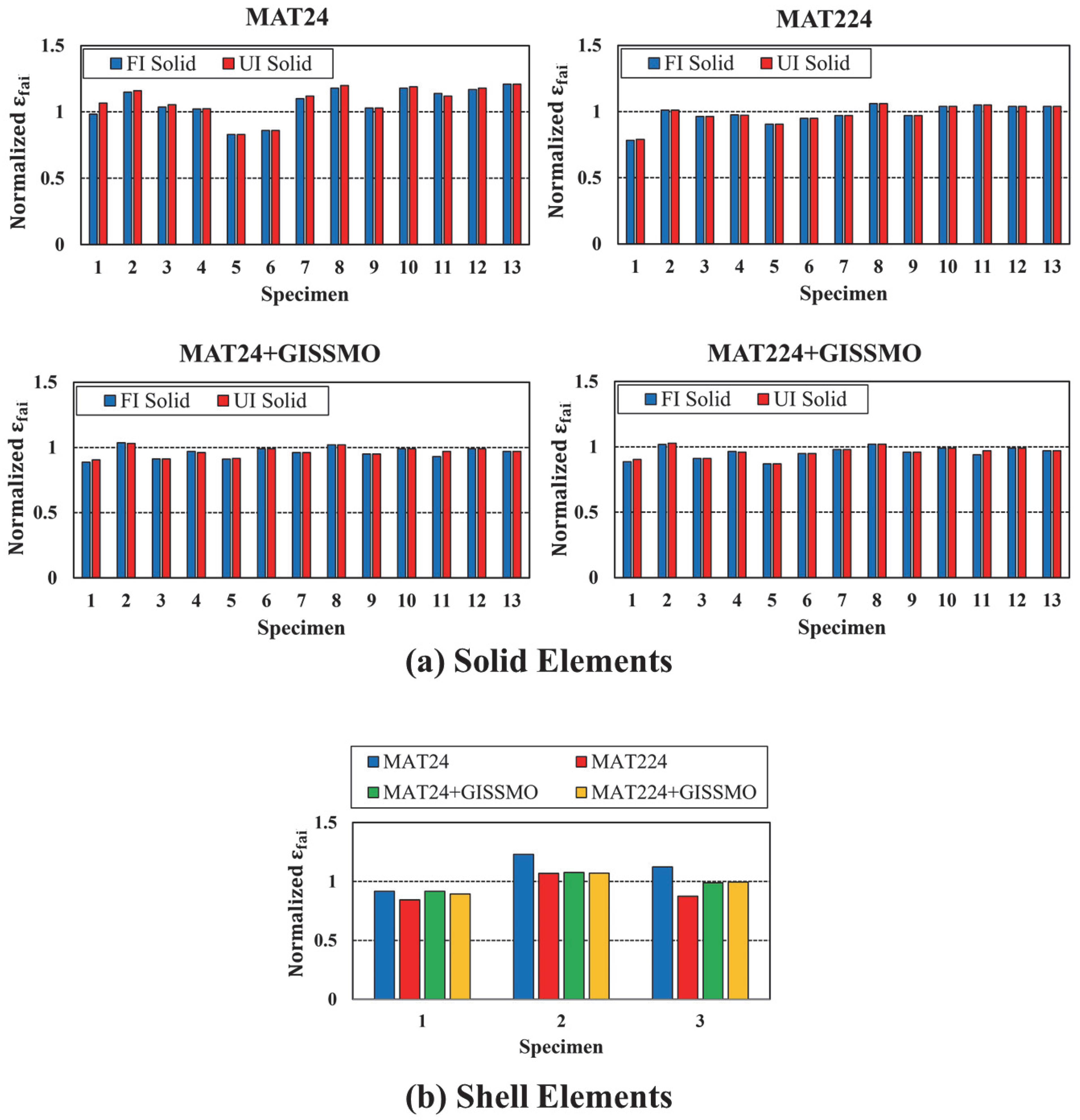

5. FE Simulation Results

6. Summary and Conclusions

- The developed failure surface and material parameters allow accurate simulation of guardrail steel fracture under complex loading conditions.

- GISSMO played a critical role in improving prediction accuracy, particularly under multiaxial stress states, and its coupling with MAT24 and MAT224 resulted in significantly better agreement with experimental results.

- While both MAT224 and GISSMO can implement the failure surface, slight differences in response are due to GISSMO’s ability to couple damage evolution with flow stress, which MAT224 lacks.

- Fully integrated shell elements (FI) outperformed under-integrated (UI) ones in capturing experimental trends, though shell elements alone were insufficient for capturing complex stress states.

- Solid elements (UI and FI) proved more appropriate in multiaxial loading scenarios, with UI solids recommended for their balance of accuracy and computational efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Abbreviations

| Abbreviation | Definition |

| AASHTO | American Association of State Highway and Transportation Officials |

| ASTM | American Society for Testing and Materials |

| MASH | Manual of Assessing Safety Hardware |

| FEA | Finite Element Analysis |

| LS-DYNA | Livermore Software Technology Corporation—Dynamic Nonlinear Analysis (FEA Software) |

| Cauchy stress tensor | |

| Hydrostatic stress | |

| Deviatoric stress | |

| Trace of the stress tensor, which is the sum of its diagonal components | |

| I | The second-order identity tensor |

| P | Pressure |

| Stress invariants | |

| double contraction of the deviatoric stress tensor with itself | |

| Von Mises or average stress | |

| Stress triaxiality | |

| Lode parameter | |

| Third deviatoric stress invariant | |

| DIC | Digital Image Correlation |

| True uniaxial stress | |

| True uniaxial strain | |

| , , and | Swift plasticity model constants |

| MAT224 | Tabulated Johnson–Cook LS-DYNA’s material model |

| MAT24 | Piecewise Linear Plasticity LS-DYNA’s material model |

| GISSMO | Generalized Incremental Stress-State-Dependent Model |

| ELFORM | Element formulation in LS-DYNA |

| FI | Fully Integrated elements |

| UI | Under Integrated elements |

References

- Humphrey, B.M.; Faller, R.K.; Bielenberg, R.W.; Reid, J.D. Improved Methodologies in Modeling and Predicting Failure in AASHTO M-180 Guardrail Steel Using Finite Element Analysis-Phase I; Midwest Roadside Safety Facility (MwRSF), University of Nebraska–Lincoln: Lincoln, NE, USA, 2016. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). Manual for Assessing Safety Hardware (MASH), 2nd ed.; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2016. [Google Scholar]

- Gabauer, D.J.; Kusano, K.D.; Marzougui, D.; Opiela, K.; Hargrave, M.; Gabler, H.C. Pendulum testing as a means of assessing the crash performance of longitudinal barrier with minor damage. Int. J. Impact Eng. 2010, 37, 1121–1137. [Google Scholar] [CrossRef]

- Mohr, D.; Henn, S. Calibration of Stress-triaxiality Dependent Crack Formation Criteria: A New Hybrid Experimental–Numerical Method. Exp. Mech. 2007, 47, 805–820. [Google Scholar] [CrossRef]

- Winkelbauer, B.J.; Putjenter, J.G.; Rosenbaugh, S.K.; Lechtenberg, K.A.; Bielenberg, R.W.; Faller, R.K.; Reid, J.D. Dynamic Evaluation of MGS Stiffness Transition with Curb; Midwest Roadside Safety Facility: Lincoln, NE, USA, 2014. [Google Scholar]

- Bielenberg, R.W.; Ahlers, T.J.; Faller, R.K.; Holloway, J.C. MASH Testing of Bullnose with Breakaway Steel Posts (Test Nos. MSPBN-4 Through MSPBN-8). 2020. Available online: https://mwrsf.unl.edu/researchhub/files/Report393/TRP-03-418-20.pdf (accessed on 23 May 2025).

- Basaran, M.; Wölkerling, S.D.; Feucht, M.; Neukamm, F.; Weichert, D.; DAIMLER AG, Sindelfingen. An extension of the GISSMO damage model based on lode angle dependence. LS-DYNA Anwenderforum 2010, 15, 15. [Google Scholar]

- Kim, J.-H.; Serpantié, A.; Barlat, F.; Pierron, F.; Lee, M.-G. Characterization of the post-necking strain hardening behavior using the virtual fields method. Int. J. Solids Struct. 2013, 50, 3829–3842. [Google Scholar] [CrossRef]

- AASHTO M 180-12; Standard Specification for Corrugated Sheet Steel Beams of Highway Gaurdrail. AASHTO Designation: Washington, DC, USA, 2012.

- Yu, M. Advances in strength theories for materials under complex stress state in the 20th century. Appl. Mech. Rev. 2002, 55, 169–218. [Google Scholar] [CrossRef]

- Won, J.Y.; Kim, C.; Hong, S.; Yoon, H.-S.; Park, J.K.; Lee, M.-G. Evaluation of crush performance of extruded aluminum alloy tubes based on finite element analysis with ductile fracture modeling. Thin-Walled Struct. 2024, 200, 111937. [Google Scholar] [CrossRef]

- Lou, Y.; Chen, L.; Clausmeyer, T.; Tekkaya, A.E.; Yoon, J.W. Modeling of ductile fracture from shear to balanced biaxial tension for sheet metals. Int. J. Solids Struct. 2017, 112, 169–184. [Google Scholar] [CrossRef]

- Yang, X.; Guo, Y.; Li, Y. A new ductile failure criterion with stress triaxiality and Lode dependence. Eng. Fract. Mech. 2023, 289, 109394. [Google Scholar] [CrossRef]

- Bridgman, P.W. Studies in Large Plastic Flow and Fracture: With Special Emphasis on the Effects of Hydrostatic Pressure; Harvard University Press: Cambridge, MA, USA, 1964. [Google Scholar] [CrossRef]

- Bao, Y. Prediction of Ductile Crack Formation in Uncracked Bodies. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2003. [Google Scholar]

- Wierzbicki, T.; Bao, Y.; Lee, Y.-W.; Bai, Y. Calibration and evaluation of seven fracture models. Int. J. Mech. Sci. 2005, 47, 719–743. [Google Scholar] [CrossRef]

- Carney, K.S.; DuBois, P.A.; Buyuk, M.; Kan, S. Generalized, Three-Dimensional Definition, Description, and Derived Limits of the Triaxial Failure of Metals. J. Aerosp. Eng. 2009, 22, 280–286. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. A new model of metal plasticity and fracture with pressure and Lode dependence. Int. J. Plast. 2008, 24, 1071–1096. [Google Scholar] [CrossRef]

- Jia, L.-J.; Ge, H.; Shinohara, K.; Kato, H. Experimental and Numerical Study on Ductile Fracture of Structural Steels under Combined Shear and Tension. J. Bridge Eng. 2016, 21, 04016008. [Google Scholar] [CrossRef]

- Bai, Y.; Teng, X.; Wierzbicki, T. On the application of stress triaxiality formula for plane strain fracture testing. J. Eng. Mater. Technol. 2009, 131, 021002. [Google Scholar] [CrossRef]

- Landes, J.D.; McCabe, D.E.; Boulet, J.A.M. Fracture Mechanics: Twenty-Fourth Volume; ASTM International: West Conshohocken, PA, USA, 1994; Volume 1207. [Google Scholar]

- Ganjiani, M. A damage model for predicting ductile fracture with considering the dependency on stress triaxiality and Lode angle. Eur. J. Mech.-A/Solids 2020, 84, 104048. [Google Scholar] [CrossRef]

- Topilla, L.; Toros, S. Analysis of the Fracture Behaviour of Dual-phase Steels Using the GISSMO and Johnson Cook Models. Trans. FAMENA 2023, 47, 79–95. [Google Scholar] [CrossRef]

- Andrade, F.X.C.; Feucht, M.; Haufe, A.; Neukamm, F. An incremental stress state dependent damage model for ductile failure prediction. Int. J. Fract. 2016, 200, 127–150. [Google Scholar] [CrossRef]

- Buyuk, M. Development of a Tabulated Thermo-Viscoplastic Material Model with Regularized Failure for Dynamic Ductile Failure Prediction of Structures Under Impact Loading; The George Washington University: Washington, DC, USA, 2013. [Google Scholar]

- Gao, X.; Zhang, G.; Roe, C. A Study on the Effect of the Stress State on Ductile Fracture. Int. J. Damage Mech. 2010, 19, 75–94. [Google Scholar] [CrossRef]

- Kiran, R.; Khandelwal, K. Experimental Studies and Models for Ductile Fracture in ASTM A992 Steels at High Triaxiality. J. Struct. Eng. 2014, 140, 04013044. [Google Scholar] [CrossRef]

- Shen, F.; Pan, B.; Wang, S.; Lian, J.; Münstermann, S. Influence of stress states on cleavage fracture in X70 pipeline steels. J. Pipeline Sci. Eng. 2022, 2, 100072. [Google Scholar] [CrossRef]

- Brünig, M.; Schmidt, M.; Gerke, S. A fracture criterion for ductile metals based on critical damage parameters: Dedicated to Professor Holm Altenbach on the occasion of his 65th birthday. Contin. Mech. Thermodyn. 2021, 33, 1011–1022. [Google Scholar] [CrossRef]

- Brünig, M.; Schmidt, M.; Gerke, S. Numerical analysis of stress-state-dependent damage and failure behavior of ductile steel based on biaxial experiments. Comput. Mech. 2021, 68, 1–11. [Google Scholar] [CrossRef]

- Zhang, Z.; Shen, F.; Liu, H.; Könemann, M.; Münstermann, S. Temperature-dependent deformation and fracture properties of low-carbon martensitic steel in different stress states. J. Mater. Res. Technol. 2023, 25, 1931–1943. [Google Scholar] [CrossRef]

- Testa, G.; Ricci, S.; Iannitti, G.; Ruggiero, A.; Bonora, N. Modeling ductile fracture in third stress invariant sensitive materials: Application to Al 2024-T351. Mech. Mater. 2023, 179, 104584. [Google Scholar] [CrossRef]

- Brünig, M.; Zistl, M.; Gerke, S. Biaxial experiments on characterization of stress-state-dependent damage in ductile metals. Prod. Eng. Res. Devel. 2020, 14, 87–93. [Google Scholar] [CrossRef]

- Brünig, M.; Koirala, S.; Gerke, S. A stress-state-dependent damage criterion for metals with plastic anisotropy. Int. J. Damage Mech. 2023, 32, 811–832. [Google Scholar] [CrossRef]

- Svanberg, A. Numerical Methods for Simulating the Metal Shearing Process: A Novel Numerical Model for the Punching of Metals. Master’s Thesis, Luleå University of Technology, Luleå, Sweden, 2019. [Google Scholar]

- Irgens, F. Continuum Mechanics; Springer Science & Business Media: New York, NY, USA, 2008. [Google Scholar]

- Fung, Y.C.; Tong, P.; Chen, X.H. Classical and Computational Solid Mechanics, 2nd ed.; World Scientific: Singapore, 2017; Volume 2, ISBN 978-981-4713-64-1. [Google Scholar]

- Huang, Y.; Jiang, J. A critical review of von mises criterion for compatible deformation of polycrystalline materials. Crystals 2023, 13, 244. [Google Scholar] [CrossRef]

- Schmidt, J.D.; Bielenberg, R.W.; Reid, J.D.; Faller, R.K. Numerical Investigation on the Performance of Steel Guardrail Systems with Varied Mechanical Properties; Midwest Roadside Safety Facility, University of Nebraska-Lincoln: Lincoln, NE, USA, 2013. [Google Scholar]

- Schrum, K.D.; Sicking, D.L.; Faller, R.K.; Reid, J.D. Predicting the Dynamic Fracture of Steel via a Non-Local Strain-Energy Density Failure Criterion; The University of Nebraska-Lincoln: Lincoln, NE, USA, 2014. [Google Scholar]

- ASTM A572-15; Standard Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel. ASTM: West Conshohocken, PA, USA, 2015.

- Mirone, G. Role of stress triaxiality in elastoplastic characterization and ductile failure prediction. Eng. Fract. Mech. 2007, 74, 1203–1221. [Google Scholar] [CrossRef]

- Seidt, J.D. Development of a New Metal Material Model in LS-DYNA Part 3: Plastic Deformation and Ductile Fracture of 2024 Aluminum Under Various Loading Conditions; Finnal Report, DOT/FAA/TC-13/25; Federal Aviation Administration (FAA): Washington, DC, USA, 2014; p. 3. [Google Scholar]

- Faridmehr, I.; Osman, M.H.; Adnan, A.B.; Nejad, A.F.; Hodjati, R.; Azimi, M. Correlation between engineering stress-strain and true stress-strain curve. Am. J. Civ. Eng. Archit. 2014, 2, 53–59. [Google Scholar] [CrossRef]

- Bhonge, P.S.; Lankarani, H.M. Fine-tuning nonlinear finite element analysis methodology for aircraft seat certification using component level testing and validation. Int. J. Veh. Struct. Syst. 2011, 3, 129–138. [Google Scholar] [CrossRef]

- Paul, S.K.; Roy, S.; Sivaprasad, S.; Bar, H.N.; Tarafder, S. Identification of Post-necking Tensile Stress–Strain Behavior of Steel Sheet: An Experimental Investigation Using Digital Image Correlation Technique. J. Mater. Eng Perform 2018, 27, 5736–5743. [Google Scholar] [CrossRef]

- Swift, H. Plastic instability under plane stress. J. Mech. Phys. Solids 1952, 1, 1–18. [Google Scholar] [CrossRef]

- Vasko, T. A User Guide for *MAT_TABULATED_JOHNSON_COOK in LS-DYNA. LS-DYNA Aerospace Working Group. 2021. Available online: https://awg.ansys.com/tiki-download_file.php?fileId=2001 (accessed on 23 May 2025).

- Hallquist, J.O. LS-DYNA® Keyword User’s Manual: Volumes I, II, and III LSDYNA R7; 1. Livermore Software Technology Corporation, Livermore (LSTC): Livermore, CA, USA, 2014; p. 1265. [Google Scholar]

- Andrade, F.; Feucht, M.; Haufe, A. On the Prediction of Material Failure in LS-DYNA®: A Comparison Between GISSMO and DIEM. 2014. Available online: https://lsdyna.ansys.com/wp-content/uploads/2025/02/on-the-prediction-of-material-failure-in-ls-dyna-a-comparison-between-gissmo-and-diem.pdf (accessed on 23 May 2025).

- Neukamm, F.; Feucht, M.; Haufe, A. Considering Damage History in Crashworthiness Simulations. In Proceedings of the 7th European LS-DYNA Conference, Salzburg, Austria, 14–15 May 2009. [Google Scholar]

- Haufe, A.; Neukamm, F.; Feucht, M.; DuBois, P.; Borvall, T. A comparison of recent damage and failure models for steel materials in crashworthiness application in LS-DYNA. In Proceedings of the 11th International LS-DYNA Users Conference, Dearborn, MI, USA, 6–8 June 2010; pp. 6–8. [Google Scholar]

- Han, F.; Lian, C.; Zhang, J.; Jiang, H. Plasticity and Fracture Characterization of Advanced High-Strength Steel: Experiments and Modeling. In Forming the Future; Daehn, G., Cao, J., Kinsey, B., Tekkaya, E., Vivek, A., Yoshida, Y., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 1947–1959. ISBN 978-3-030-75380-1. [Google Scholar]

- Effelsberg, J.; Haufe, A.; Feucht, M.; Neukamm, F.; Du Bois, P. On parameter identification for the GISSMO damage model. In Proceedings of the 12th International LS-DYNA Users Conference, Metal Forming, Detroit, MI, USA, 3–5 June 2012; pp. 1–12. [Google Scholar]

- Cowper, G.R.; Symonds, P.S. Strain-Hardening and Strain-Rate Effects in the Impact Loading of Cantilever Beams; Brown University: Providence, RI, USA, 1957. [Google Scholar]

- Wierzbicki, T.; Xue, L. On the Effect of the Third Invariant of the Stress Deviator on Ductile Fracture; Technical Report; Impact and Crashworthiness Laboratory: Cambridge, MA, USA, 2005; p. 136. [Google Scholar]

- Stals, L.; Roberts, S. Smoothing large data sets using discrete thin plate splines. Comput. Vis. Sci. 2006, 9, 185–195. [Google Scholar] [CrossRef]

- Bao, X.; Li, B. Residual strength of blast damaged reinforced concrete columns. Int. J. Impact Eng. 2010, 37, 295–308. [Google Scholar] [CrossRef]

| Material | Yield Strength ksi (MPa) | Ultimate Strength ksi (MPa) | Elongation (% in 2 in.) |

|---|---|---|---|

| AASHTO Specification M-180 Minimum Values | 50 (345) | 70 (483) | 12% |

| Median Values of Compiled Material Available on the Market | 63.2 (436) | 74.8 (516) | 27.1% |

| Selected Material Mean Values from Material Certificate | 65 (448) | 74 (510) | 30.5% |

| Specimen No. | Yield Strength (MPa) | Ultimate Strength (MPa) | Effective Strain at Failure (DIC) |

|---|---|---|---|

| 1 | 444 | 547 | 0.82 |

| 2 | 488 | 567 | 0.63 |

| 3 | 499 | 582 | 0.76 |

| 4 | 533 | 615 | 0.54 |

| 5 | 432 | 527 | 1.45 |

| 6 | 489 | 567 | 1.22 |

| 7 | 498 | 595 | 1.13 |

| 8 | 530 | 624 | 1.23 |

| 9 | 546 | 640 | 0.82 |

| 10 | 587 | 678 | 1.40 |

| 11 | 445 | 561 | 1.04 |

| 12 | 503 | 599 | 0.98 |

| 13 | 538 | 633 | 0.57 |

| Specimen No. | Maximum Force (kN) | Maximum Displacement (mm) |

|---|---|---|

| 14 | 250 | 7.165 |

| 15 | 18.7 | 6.330 |

| 16 | 18.2 | 4.536 |

| 17 | 18.2 | 1.666 |

| 18 | 59.6 | NA |

| 20 | 13.3 | 5.552 |

| 21 | 13.8 | 5.248 |

| Parameter | Value |

|---|---|

| Mass density (kg/m3) | 7850 |

| Elastic modulus (MPa) | 1.993 × 105 |

| Yield strength (MPa) | 439.6 |

| Poisson’s ratio | 0.295 |

| Plastic failure strain | 1.400 |

| Effective Plastic Strain | Effective Stress (GPa) |

|---|---|

| 0.000 | 0.4396 |

| 0.005 | 0.4634 |

| 0.025 | 0.5174 |

| 0.040 | 0.5419 |

| 0.075 | 0.5807 |

| 0.145 | 0.6278 |

| 0.300 | 0.6870 |

| 0.500 | 0.7329 |

| 0.700 | 0.7652 |

| 0.900 | 0.7903 |

| 1.000 | 0.8010 |

| 1.200 | 0.8201 |

| 1.400 | 0.8365 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alomari, Q.A.; Yosef, T.Y.; Bielenberg, R.W.; Faller, R.K.; Negahban, M.; Zhang, Z.; Li, W.; Humphrey, B.M. Material Characterization and Stress-State-Dependent Failure Criteria of AASHTO M180 Guardrail Steel: Experimental and Numerical Investigation. Materials 2025, 18, 2523. https://doi.org/10.3390/ma18112523

Alomari QA, Yosef TY, Bielenberg RW, Faller RK, Negahban M, Zhang Z, Li W, Humphrey BM. Material Characterization and Stress-State-Dependent Failure Criteria of AASHTO M180 Guardrail Steel: Experimental and Numerical Investigation. Materials. 2025; 18(11):2523. https://doi.org/10.3390/ma18112523

Chicago/Turabian StyleAlomari, Qusai A., Tewodros Y. Yosef, Robert W. Bielenberg, Ronald K. Faller, Mehrdad Negahban, Zesheng Zhang, Wenlong Li, and Brandt M. Humphrey. 2025. "Material Characterization and Stress-State-Dependent Failure Criteria of AASHTO M180 Guardrail Steel: Experimental and Numerical Investigation" Materials 18, no. 11: 2523. https://doi.org/10.3390/ma18112523

APA StyleAlomari, Q. A., Yosef, T. Y., Bielenberg, R. W., Faller, R. K., Negahban, M., Zhang, Z., Li, W., & Humphrey, B. M. (2025). Material Characterization and Stress-State-Dependent Failure Criteria of AASHTO M180 Guardrail Steel: Experimental and Numerical Investigation. Materials, 18(11), 2523. https://doi.org/10.3390/ma18112523