Coordinated Regulation of Mechanical Behavior and Residual Stress of 9Cr-3W-3Co Steel Based on Jominy Test

Abstract

1. Introduction

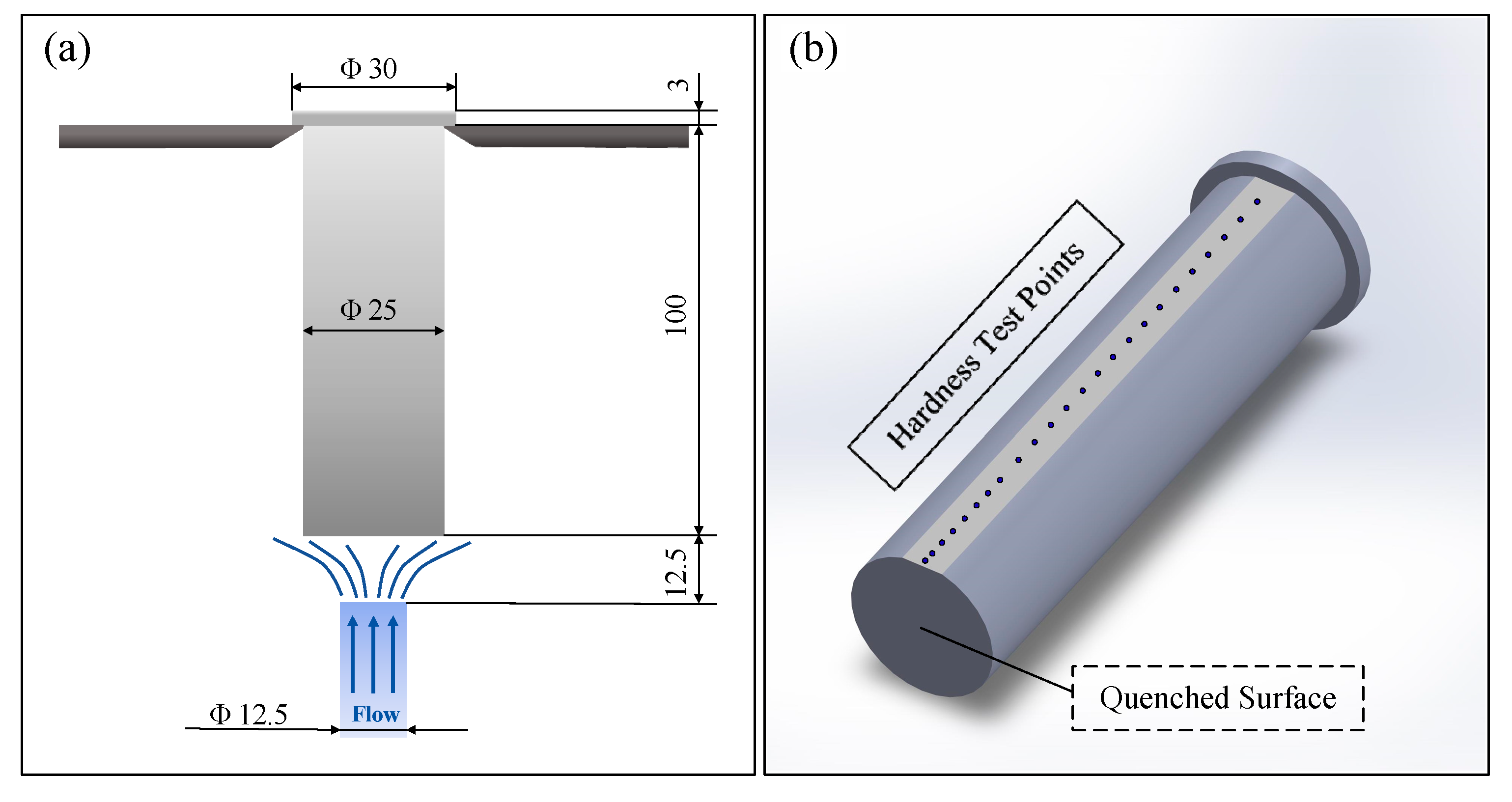

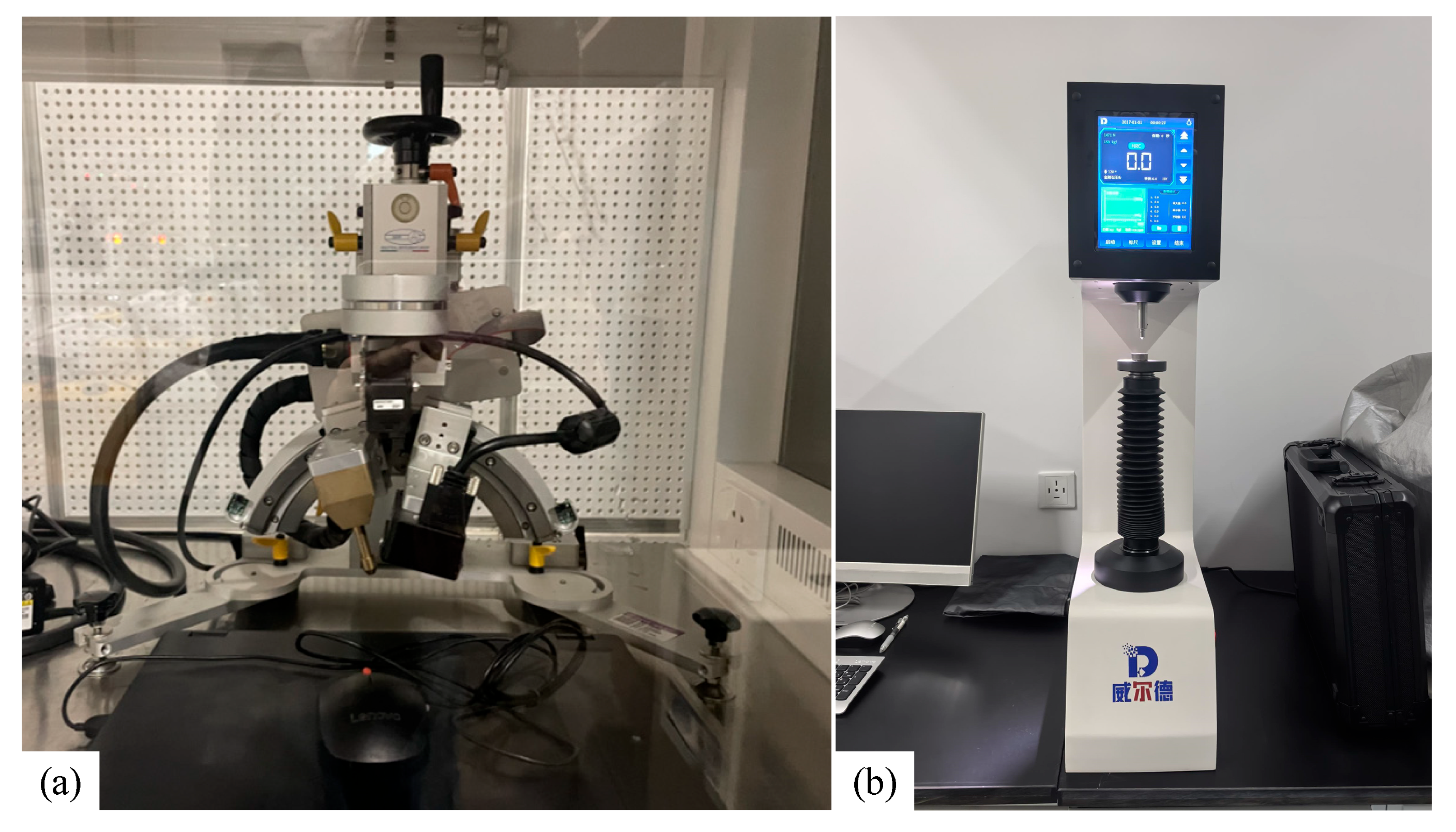

2. Experimental Conditions and Approach on Simulation

2.1. Materials Composition and Experimental Methods

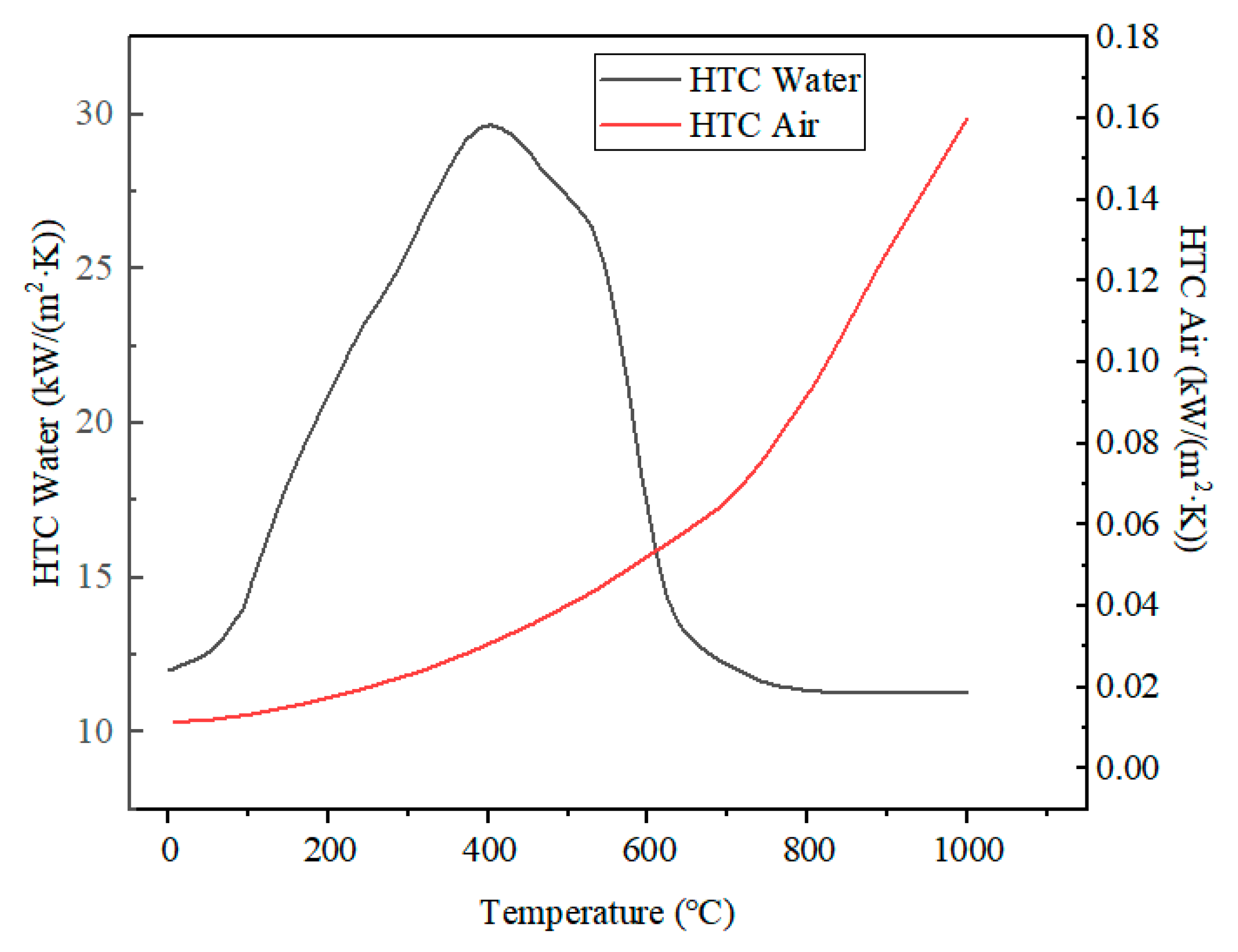

2.2. Boundary Conditions of Simulation

3. Results Discussion

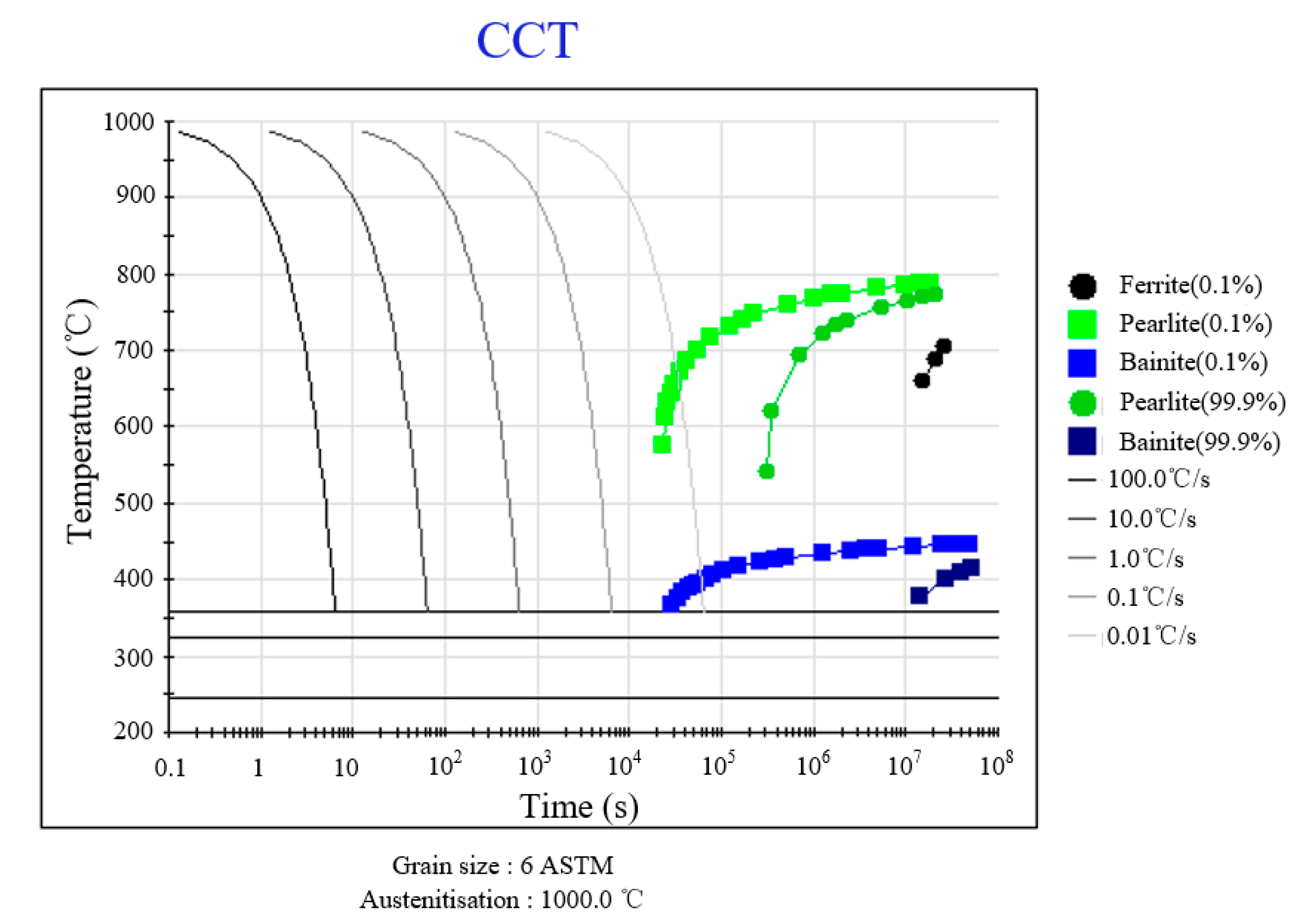

3.1. Thermodynamics Calculations

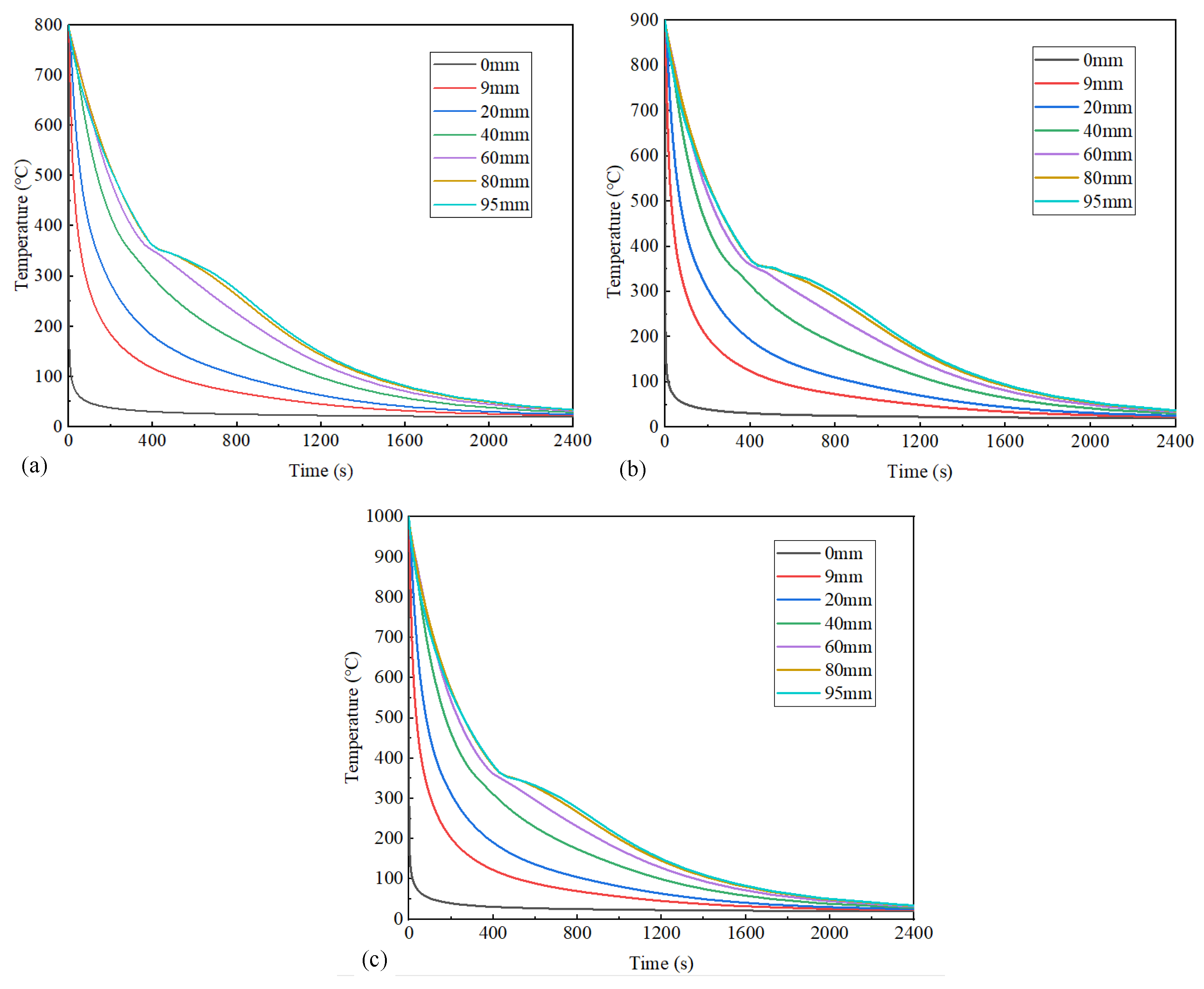

3.2. Heat Transfer and Temperature Field by FEM

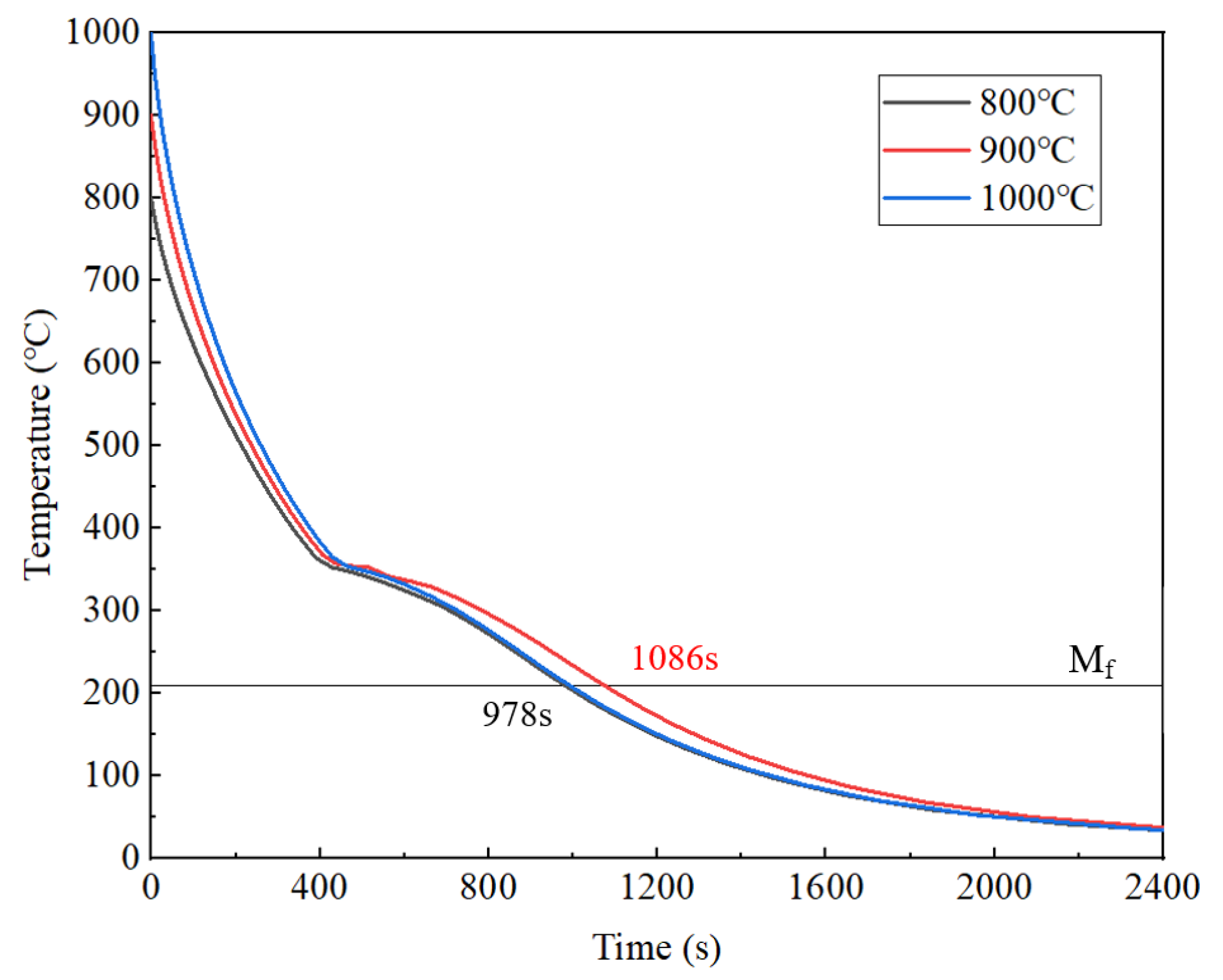

3.2.1. Overall Axial Temperature Gradient

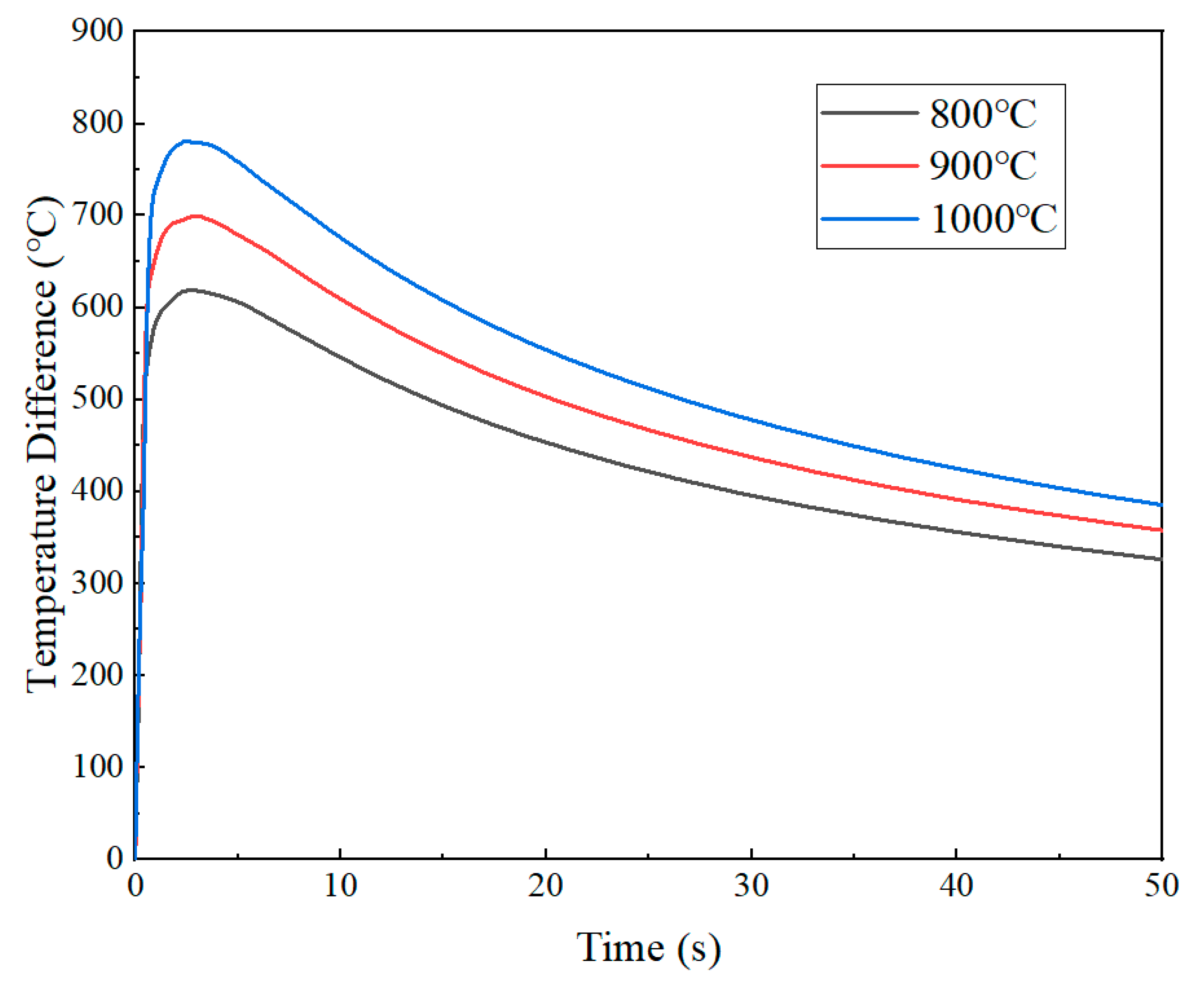

3.2.2. Local Axial Temperature Gradient near the Quenched Surface

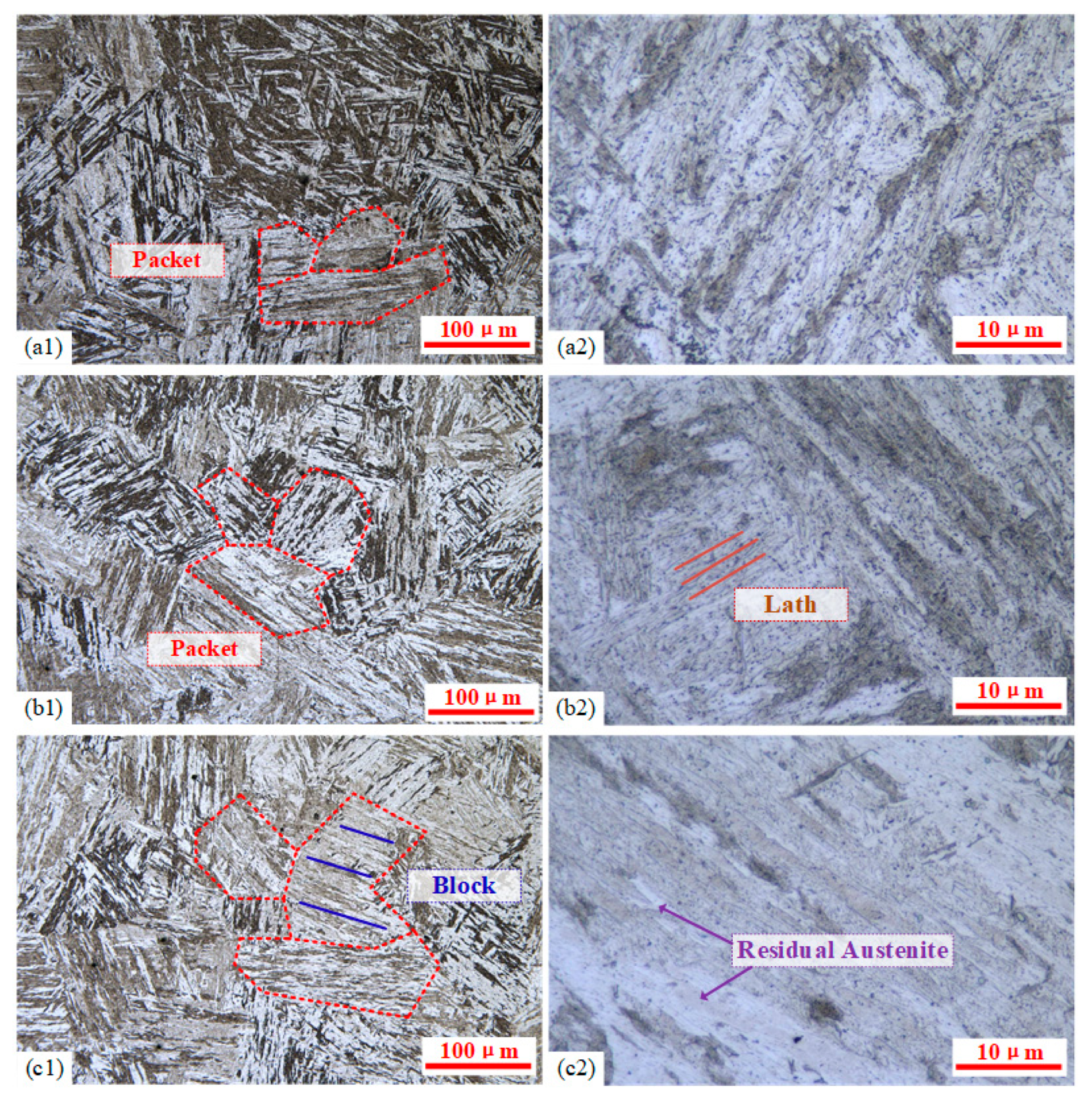

3.3. Effect of Austenitizing Temperature on Hardness and Microstructure

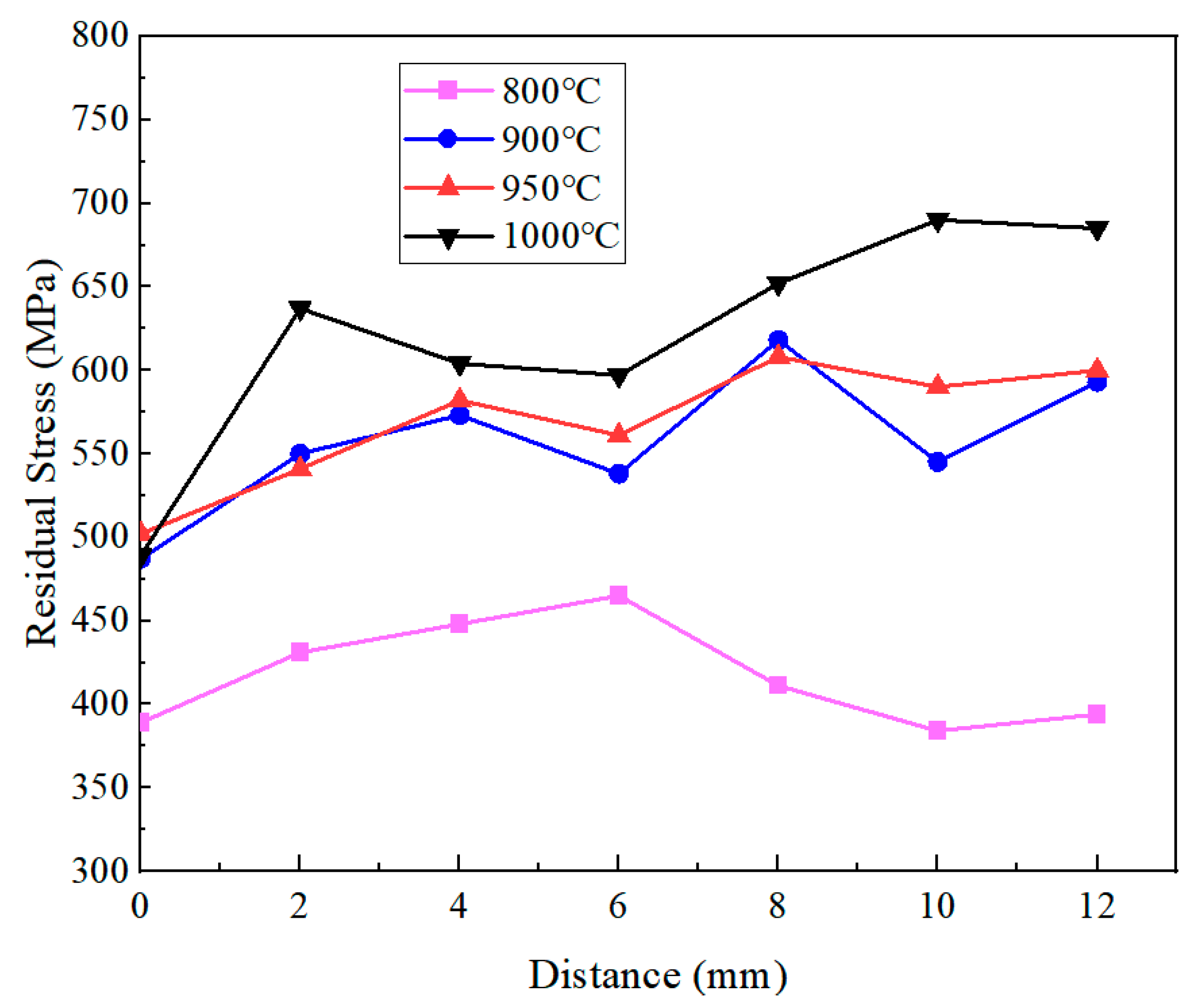

3.4. Residual Stress Analysis

3.4.1. Formation Mechanism of Residual Stress in Quenching Process

3.4.2. Effect of Austenitizing Temperature on Residual Stress

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, X.K.; Liu, Z.D.; Wang, T.J.; Peng, J.Q.; Nie, Y.H.; Shen, G.Q. Development progress of heat-resistant materials and forgings for ultra-supercritical steam turbine rotor in China. China Metall. 2023, 33, 1–11. [Google Scholar]

- Wang, D.X.; Du, J.F.; Sun, S.W.; Yang, H.S.; Li, L.P.; Qiao, Z. Development of 9–12% Cr Heat-resistant Steels Used for Ultra-Supercritical Steam Turbine Rotor. Dongfang Turbine 2024, 2, 56–60. [Google Scholar]

- Yan, W.; Wang, W.; Shan, Y.Y.; Yang, K. Microstructural stability of 9–12%Cr ferrite/martensite heat-resistant steels. Front. Mater. Sci. 2013, 7, 1–27. [Google Scholar] [CrossRef]

- He, H.S.; Yu, L.M.; Liu, C.X.; Li, H.J.; Gao, Q.Z.; Liu, Y.C. Research Progress of a Novel Martensitic Heat-Resistant Steel G115. Acta Metall. Sin. 2022, 58, 311–323. [Google Scholar]

- Yan, P.; Liu, Z.D.; Bao, H.S.; Weng, Y.Q.; Liu, W. Effect of normalizing temperature on the strength of 9Cr-3W-3Co martensitic heat resistant steel. Mater. Sci. Eng. A 2014, 597, 148–156. [Google Scholar] [CrossRef]

- Yan, P.; Liu, Z.D.; Bao, H.S.; Weng, Y.Q.; Liu, W. Effect of tempering temperature on the toughness of 9Cr-3W-3Co martensitic heat resistant steel. Mater. Des. 2014, 54, 874–879. [Google Scholar] [CrossRef]

- Li, Q.; Chen, Z.Z.; Jiang, X.L. Development and engineering manufacture technology of 9~12% Cr high and medium pressure rotor material. Iron Steel 2021, 56, 40–49. [Google Scholar]

- Zhu, H.B.; Zhao, Y.Q.; Shi, S.; Huang, X.G.; Wang, X.M. Analysis on austenite continuous cooling behavior and hardenability of 1300 MPa medium-thick plates. China Metall. 2024, 34, 132–141. [Google Scholar]

- Wang, B.B.; Zhu, X.D.; Zhang, L.C.; Zhou, X.Y.; Wu, H.H.; Wang, S.Z.; Wu, G.L.; Gao, J.H.; Zhao, T.H.; Mao, X.P. Influence of typical elements and heat treatment parameters on hardenability in steel: A review. J. Iron Steel Res. Int. 2024. [Google Scholar] [CrossRef]

- Jin, M.; Lian, J.S.; Jiang, Z.H. A new method for prediction of Jominy curve of structural steel. Acta Metall. Sin. 2006, 42, 405–410. [Google Scholar]

- Zhu, Y.F.; Gu, J.L.; Zhou, H.H.; Wang, Z.X.; Zhang, J.W. End-quenching experimental curves and simulation calculation of 18CiNiMo7-6 steel for high-speed railway gears. Heat Treat. Met. 2022, 47, 237–243. [Google Scholar]

- Lu, S.M.; Wan, L.; Zheng, S.J.; Li, M.N.; Xu, Z.D.; Wang, H. Numerical simulation and experimental study of temperature field and microstructure field during quenching of nuclear steel. J. Cent. South Univ. Sci. Technol. 2024, 55, 2527–2537. [Google Scholar]

- Yang, Z.Y.; Wang, M.; Zhang, M.M.; Shao, C.; Wang, H. Analysis of the Causes and Control of High Hardenability of Gear Steel 18CrNiMo7-6HL. JOM 2025, 77, 271–281. [Google Scholar] [CrossRef]

- Feng, X.W.; Wang, Y.X.; Han, J.X.; Li, Z.; Jiang, L.; Yang, B. Numerical Simulation and Experimental Verification of the Quenching Process for Ti Microalloying H13 Steel Used to Shield Machine Cutter Rings. Metals 2024, 14, 313. [Google Scholar] [CrossRef]

- GB/T223.4-2008; Alloyed Steel-Determination of Manganese Content-Potentiometric or Visual Titration Method. Standard Publishing House: Beijing, China, 2008.

- GB/T5124.3-2017; Hardmetals—Part 3: Determination of Cobalt-Potentiometric Method. Standard Publishing House: Beijing, China, 2017.

- Yang, L.X.; Ma, L.T.; Chen, Z.Z.; Li, X.J. Effect of tempering temperature on microstructure and hardness of 9Cr-3W-3Co martensitic steel. Heat Treat. Met. 2018, 43, 153–158. [Google Scholar]

- GB/T225-2006; Steel-Hardenability Test by End Quenching (Jominy Test). Standard Publishing House: Beijing, China, 2006.

- Feng, X.W.; Zhang, K.; Liu, J.J.; Shi, R.X.; Sun, B.W.; Liu, S.; Li, Z.P.; Yang, B. Numerical simulation and experimental verification of heat treatment after forging of SA508-3 steel for steam generator. Heat Treat. Met. 2024, 49, 55–61. [Google Scholar]

- Medina-Juárez, I.; Oliveira, D.A.J.; Moat, J.R.; Garcia-Pastor, F.A. On the Accuracy of Finite Element Models Predicting Residual Stresses in Quenched Stainless Steel. Metals 2019, 9, 1308. [Google Scholar] [CrossRef]

- Koistinen, D.P.; Marburger, R.E. A general equation prescribing the extent of the austenite-martensite transformation in pure iron-carbon alloys and plain carbon steels. Acta Metall. 1959, 7, 59–60. [Google Scholar] [CrossRef]

- Landgraf, P.; Birnbaum, P.; Meza-García, E.; Grund, T.; Kräusel, V.; Lampke, T. Jominy End Quench Test of Martensitic Stainless Steel X30Cr13. Metals 2021, 11, 1071. [Google Scholar] [CrossRef]

- Li, H.Z.; Liang, J.; Xu, L.Y.; Wang, B. Effect of cyclic normalization on microstructure and impact toughness of 9Cr3W3Co steel. Trans. Mater. Heat Treat. 2017, 38, 67–71. [Google Scholar]

| Element | C | Si | Mn | S | Cr | Ni |

|---|---|---|---|---|---|---|

| Content (wt.%) | 0.081 | 0.16 | 0.49 | 0.0024 | 8.93 | 0.044 |

| Element | V | Co | W | Nb | B | Al |

| Content (wt.%) | 0.23 | 3.08 | 2.52 | 0.06 | 0.022 | 0.013 |

| Material | Rm/MPa Tensile Strength | Rp0.2/MPa Yield Strength | A/% Elongation | Z/% Rate of Reduction |

|---|---|---|---|---|

| 9Cr3W3Co | 1027 | 983 | 18.5 | 20.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, H.; Zhu, L.; Ma, Q.; Huo, J.; Liu, J.; Wang, Z. Coordinated Regulation of Mechanical Behavior and Residual Stress of 9Cr-3W-3Co Steel Based on Jominy Test. Materials 2025, 18, 2508. https://doi.org/10.3390/ma18112508

Lyu H, Zhu L, Ma Q, Huo J, Liu J, Wang Z. Coordinated Regulation of Mechanical Behavior and Residual Stress of 9Cr-3W-3Co Steel Based on Jominy Test. Materials. 2025; 18(11):2508. https://doi.org/10.3390/ma18112508

Chicago/Turabian StyleLyu, Hongru, Lin Zhu, Qingxian Ma, Jie Huo, Jiamian Liu, and Zhuolin Wang. 2025. "Coordinated Regulation of Mechanical Behavior and Residual Stress of 9Cr-3W-3Co Steel Based on Jominy Test" Materials 18, no. 11: 2508. https://doi.org/10.3390/ma18112508

APA StyleLyu, H., Zhu, L., Ma, Q., Huo, J., Liu, J., & Wang, Z. (2025). Coordinated Regulation of Mechanical Behavior and Residual Stress of 9Cr-3W-3Co Steel Based on Jominy Test. Materials, 18(11), 2508. https://doi.org/10.3390/ma18112508