Experimental Study on Acoustic Emission Characteristics of Modified Phosphogypsum at Different Loading Rates

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- (1)

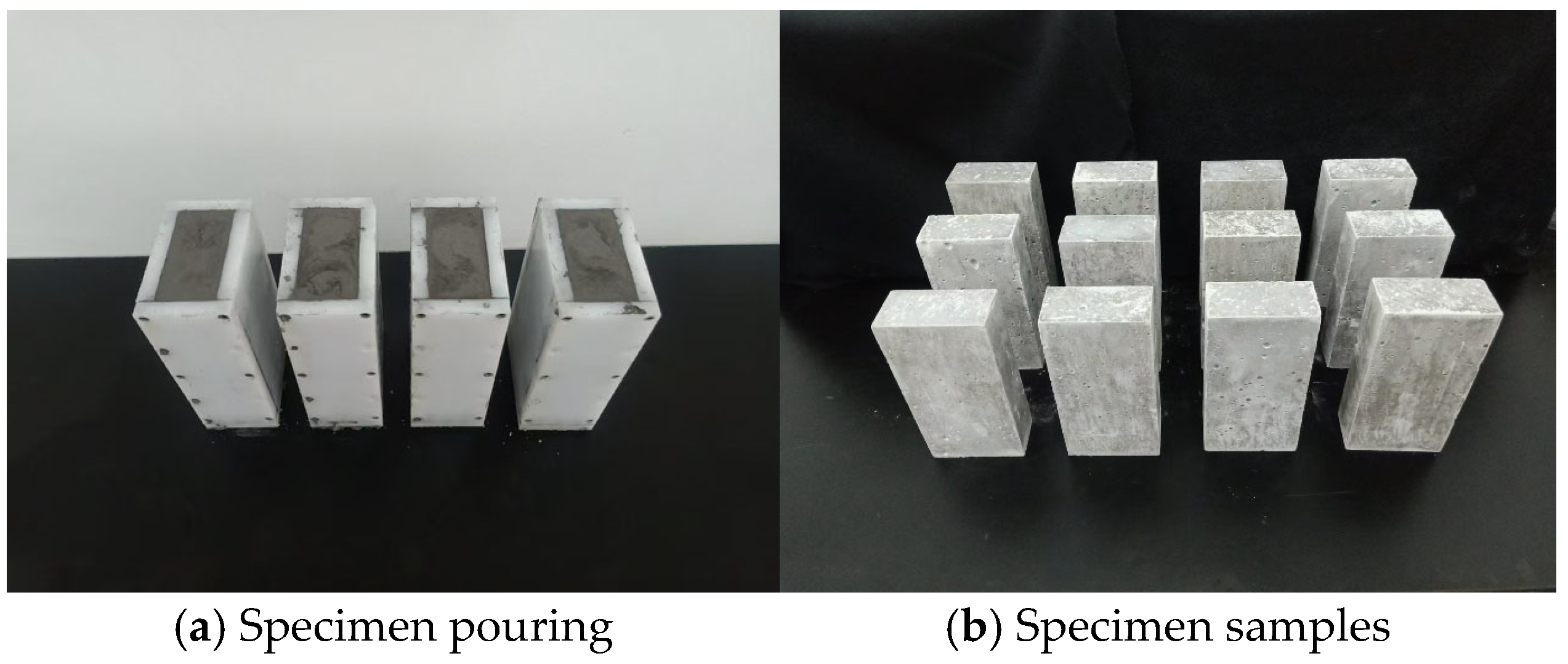

- The length, width, and height of the specimen casting mold are 75, 37.5, and 150 mm, respectively. The actual amount of each material required is calculated according to the material ratio scheme in Table 1 and weighed in a container.

- (2)

- First, the semi-aqueous phosphogypsum and quicklime are thoroughly mixed. Subsequently, melamine water reducer and water are added while continuously stirring the thick mud mixture until homogeneity is achieved. The resulting mixture is then poured into the mold (Figure 1a).

- (3)

- After disassembling the mold of the poured MPG specimen, the molded MPG test sample is obtained by curing it under natural conditions for 28 days (Figure 1b).

2.2. Theoretical Methods

- (1)

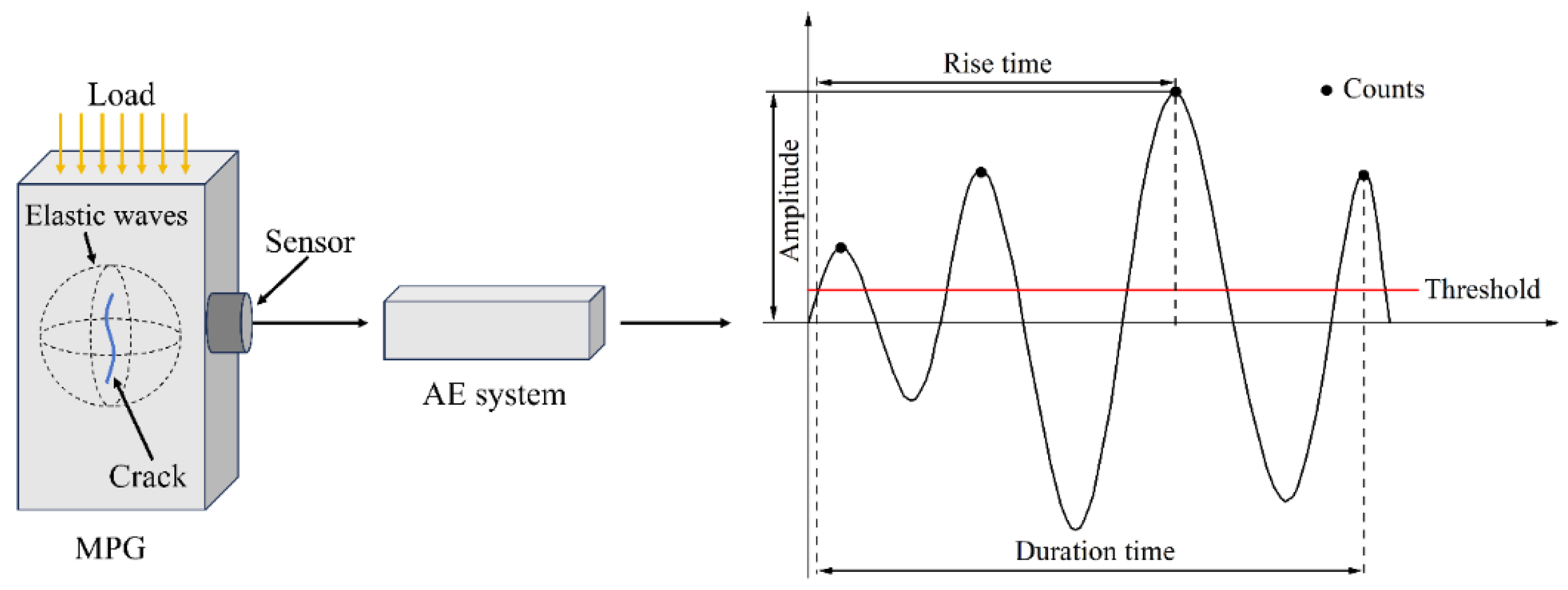

- Threshold: A specific value, usually set to reduce noise processing, can be monitored and recorded when the signal strength exceeds this value, in dB.

- (2)

- Amplitude: The maximum amplitude value of the AE signal waveform, in dB.

- (3)

- Event count: AE signals greater than the threshold are recorded as an AE event.

- (4)

- Rise time: The time interval from the first time the AE signal exceeds the threshold value to the maximum amplitude, in μs.

- (5)

- Duration: The time interval from when the AE signal is greater than the threshold value for the first time to when it is less than the threshold value, in μs.

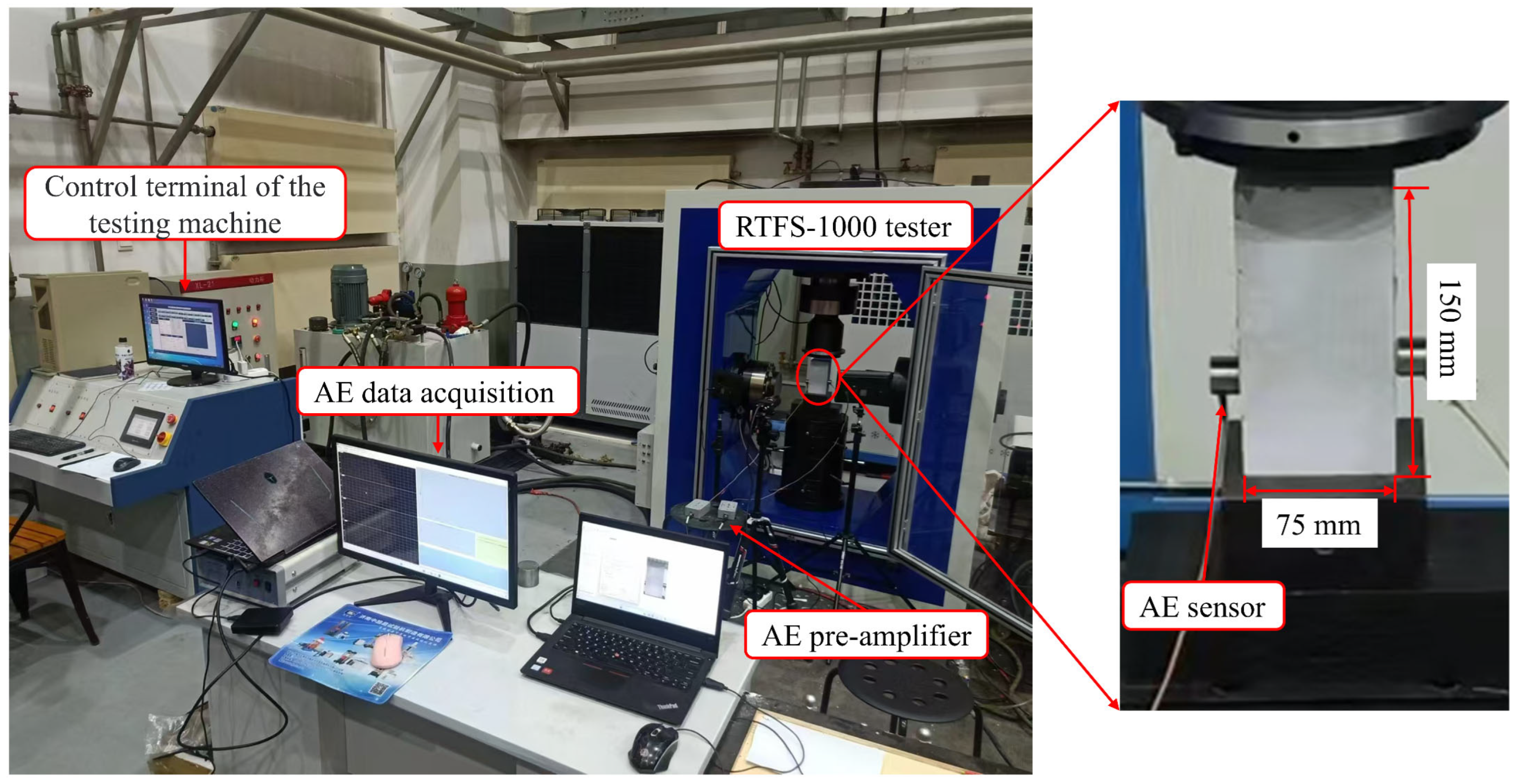

2.3. Test System

2.4. Test Methods

3. Results and Discussion

3.1. Characteristics of Damage and Mechanical Properties

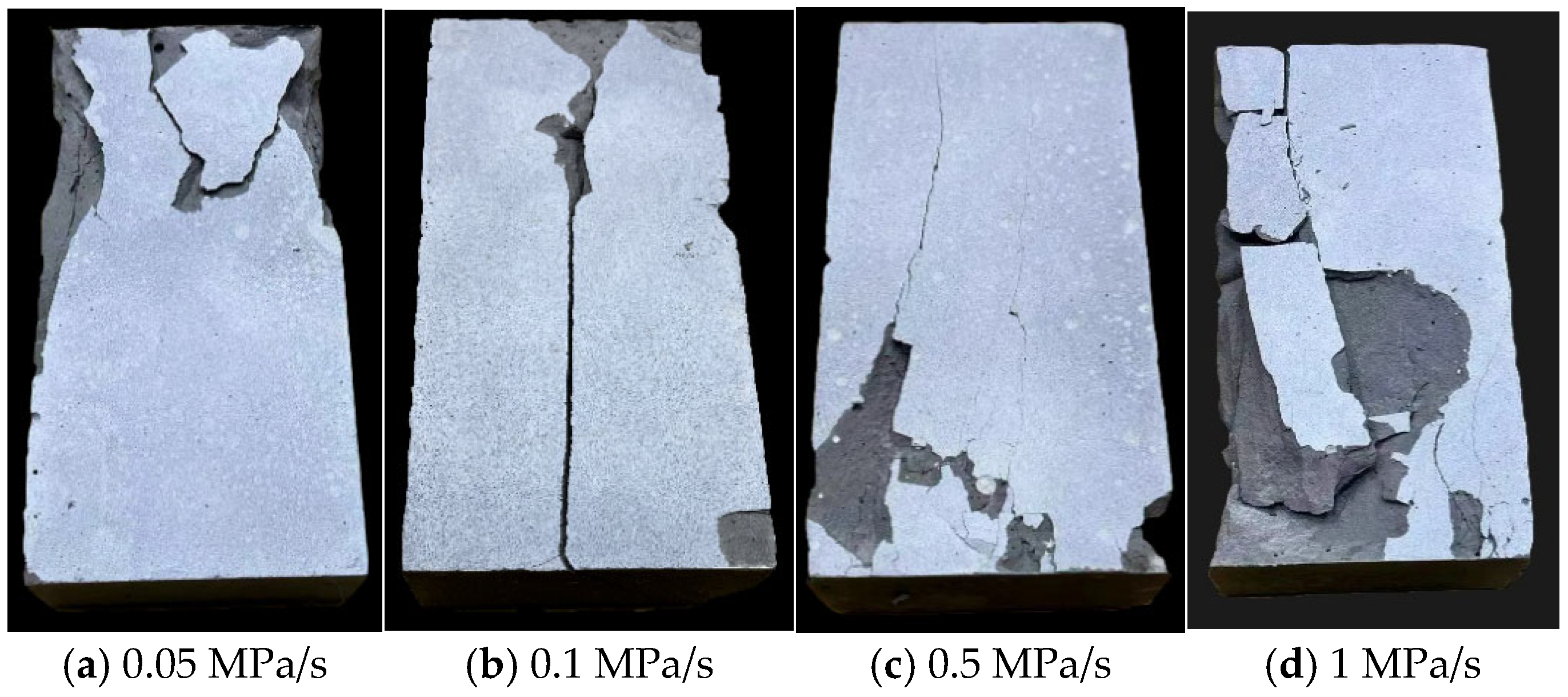

3.1.1. Destruction Characteristics

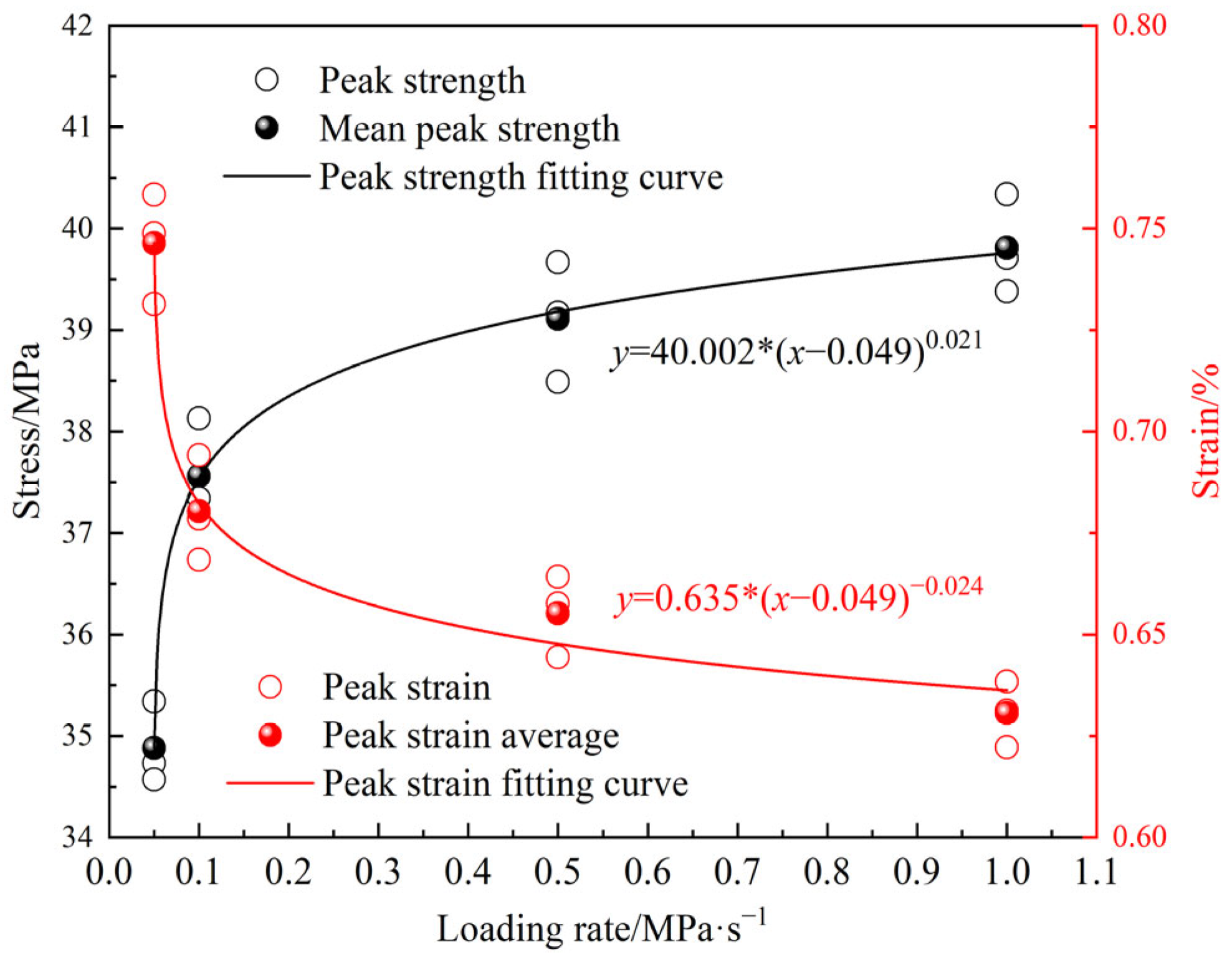

3.1.2. Mechanical Properties

3.2. AE Characteristics

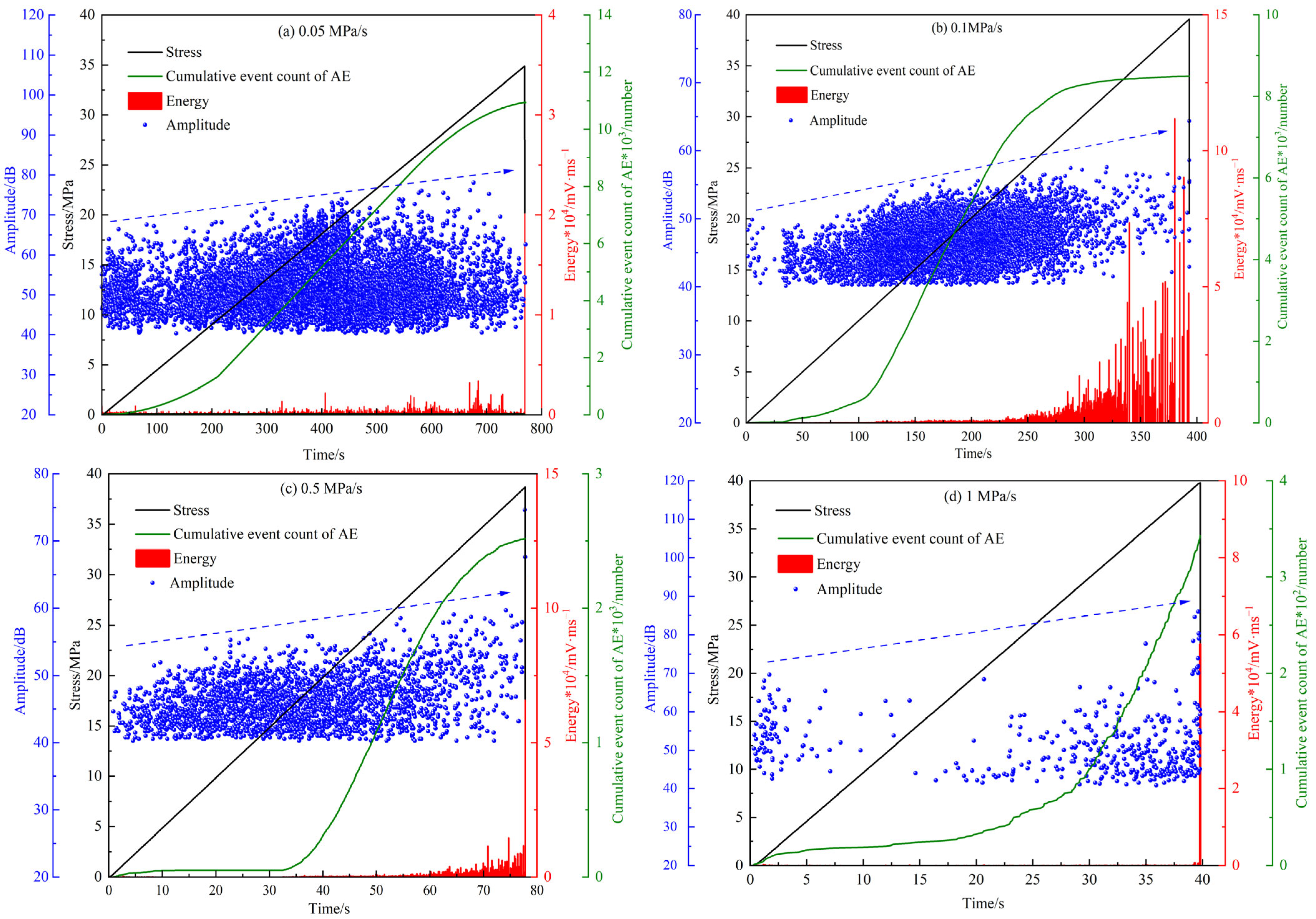

3.2.1. Cumulative Event Count, Amplitude, and Energy Characteristics of AE

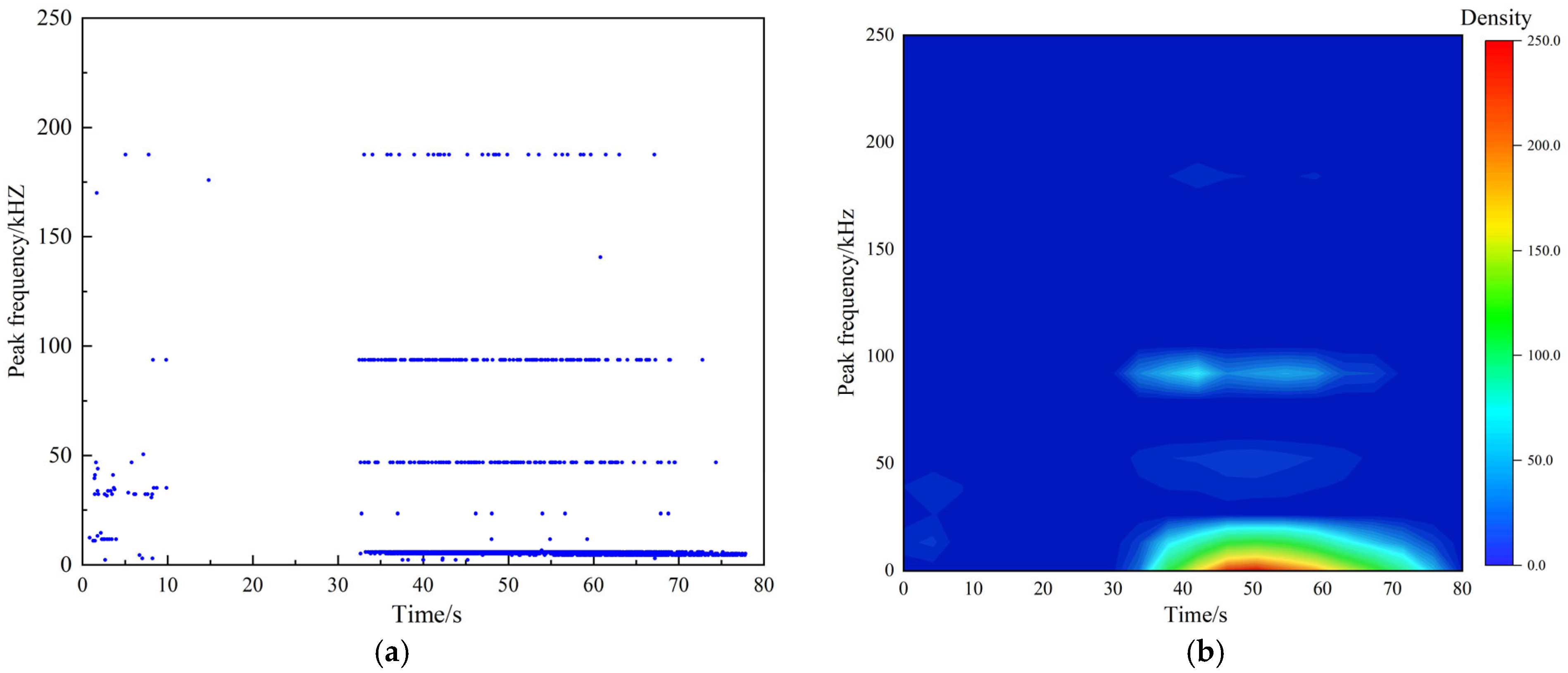

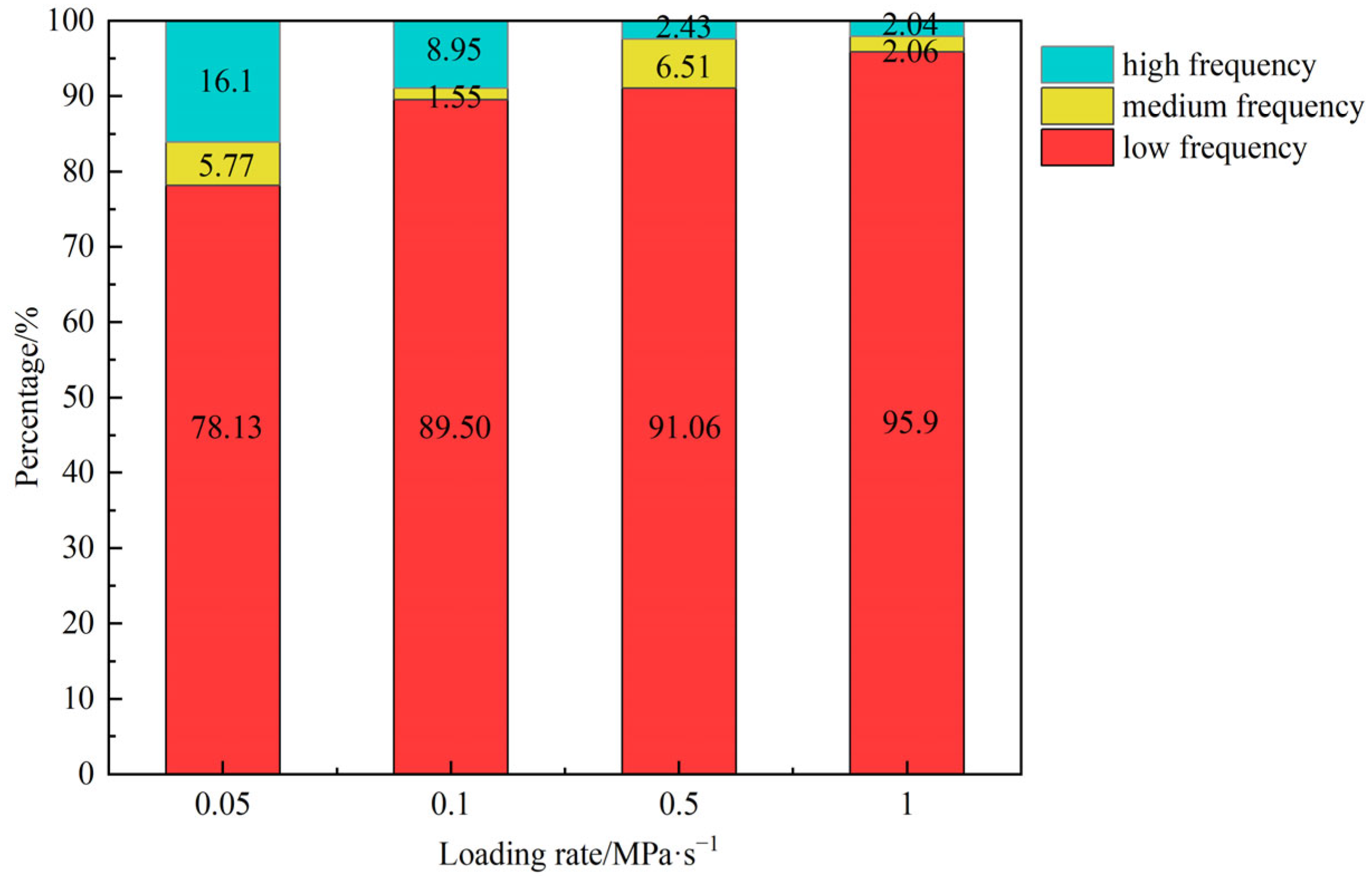

3.2.2. Frequency Characteristics

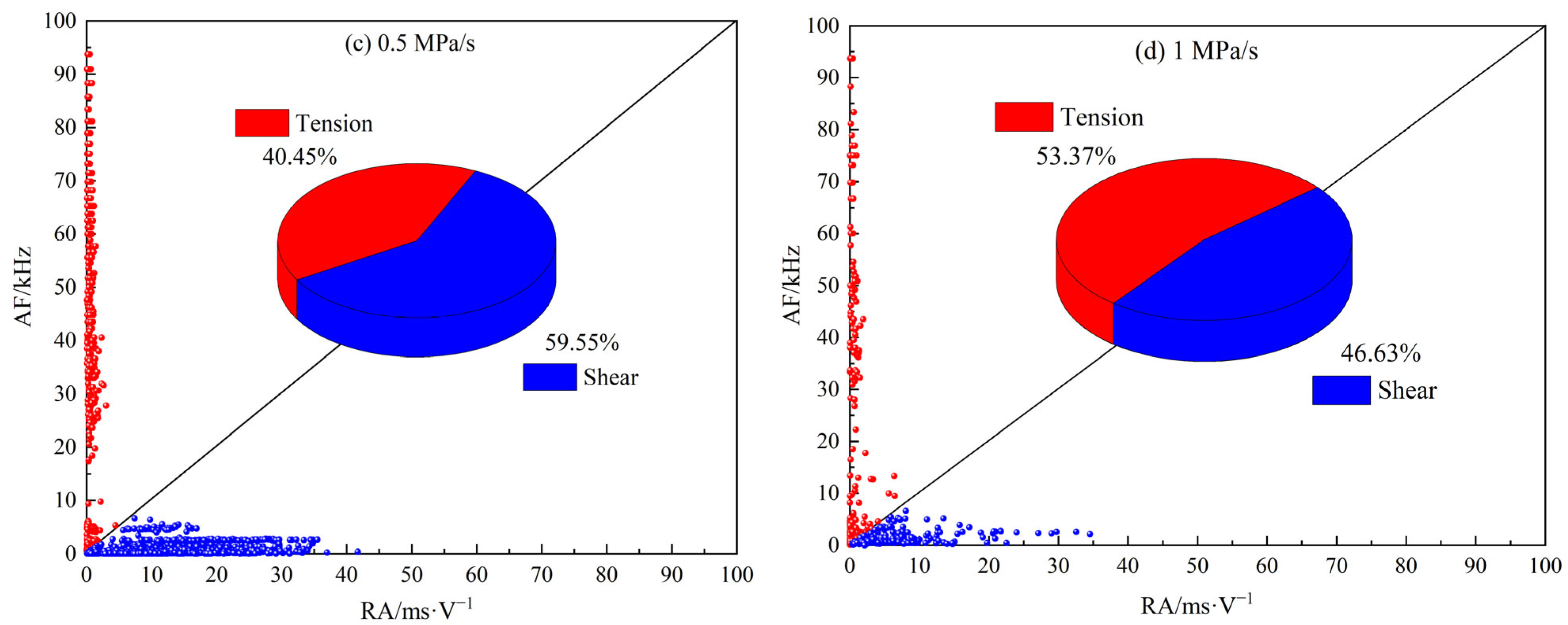

3.2.3. Distribution Characteristics of RA-AF Values

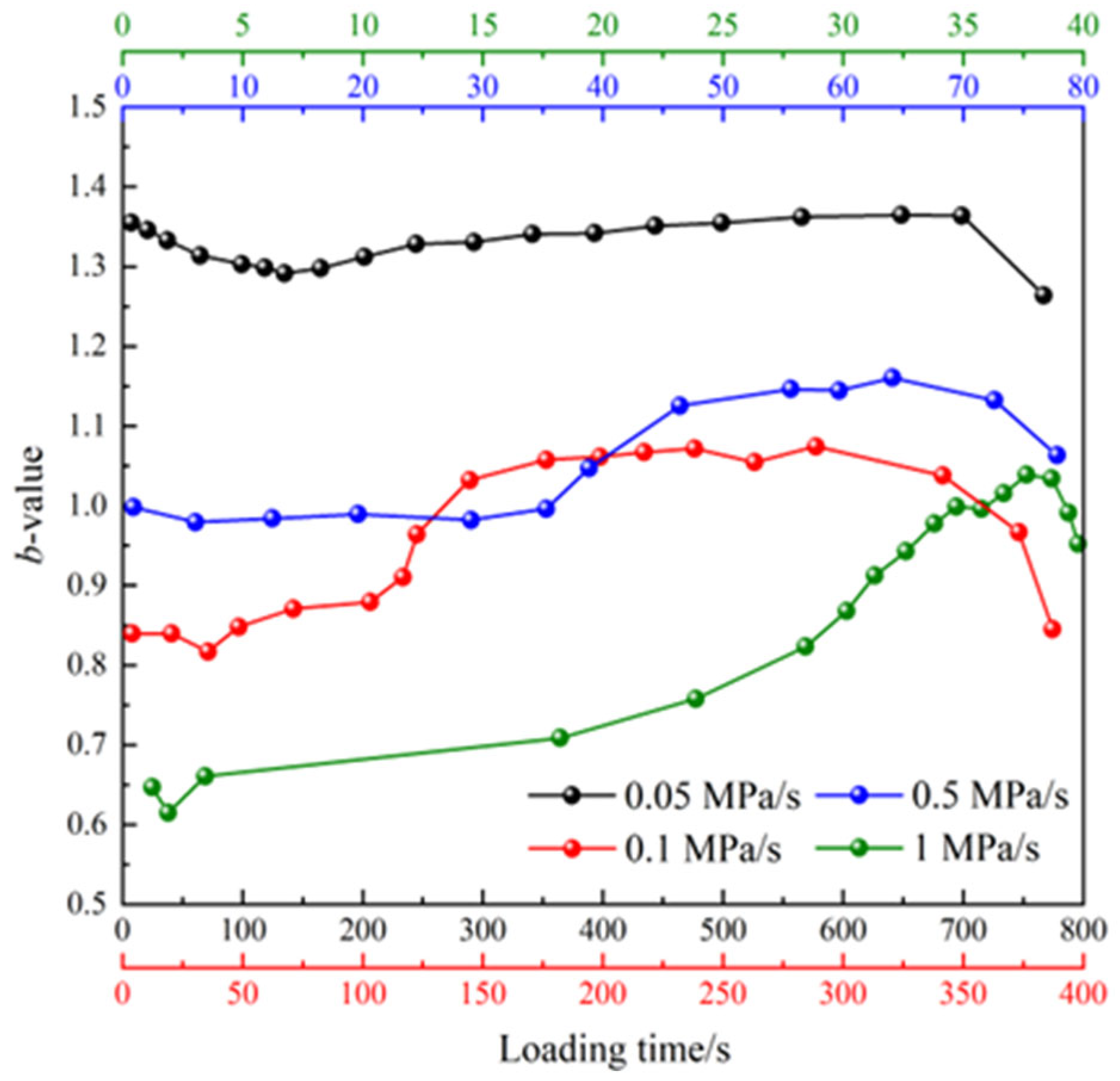

3.2.4. b-Value Characteristics

4. Conclusions

- (1)

- MPG is a typical brittle material, and its mechanical properties are sensitive to loading rate. The peak strength and elastic modulus increase with the increase in loading rate, while the peak strain decreases with the increase in loading rate. When the loading rate is greater than 0.1 MPa/s, the influence of the loading rate on the above mechanical properties gradually decreases.

- (2)

- As the loading rate increases, the maximum cumulative count of AE events gradually decreases, indicating an inverse relationship between the two. Furthermore, the cumulative count of AE events and the loading rate follow a power function relationship. Compared with the lowest loading rate, the cumulative count of AE events at specimen failure was reduced by almost two orders of magnitude at the highest loading rate.

- (3)

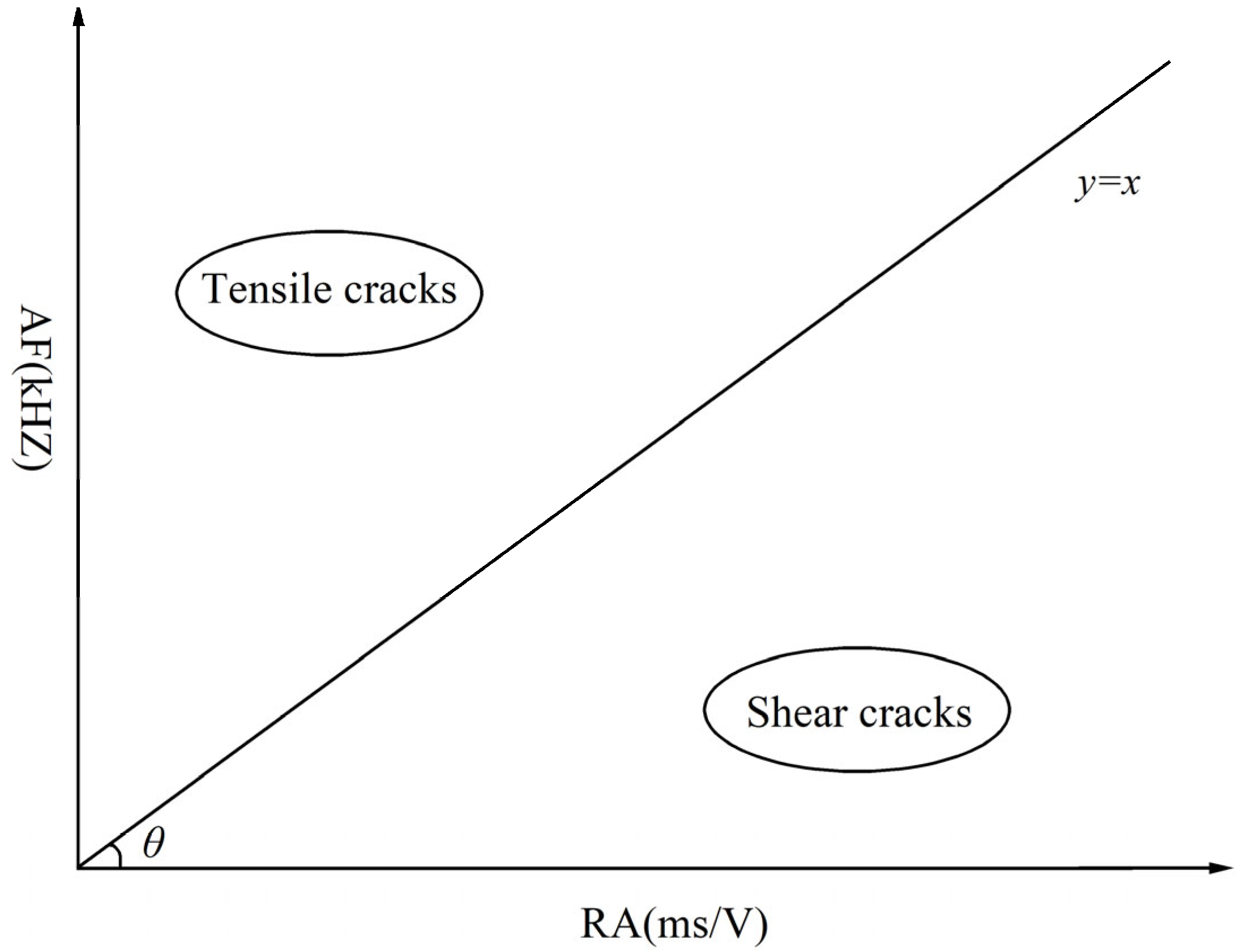

- With the increase in loading rate, large-scale macroscopic damage becomes increasingly significant, leading to a gradual increase in the proportion of low-frequency AE signals. In addition, the rupture mechanism of MPG has also changed to a certain extent, and the distribution of RA-AF data points shows that the proportion of tensile cracks has gradually increased.

- (4)

- The b-values show considerable variation across different loading rates. Generally, the b-value decreases with an increase in the loading rate, indicating that small-scale damage is more prevalent at lower loading rates, while more severe damage tends to occur at higher loading rates. For loading rates of 0.5 MPa/s and 1 MPa/s, the b-value drops sharply in the later stage of loading, which is usually considered a precursor of macroscopic failure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ines, H.; Sarra, E.; Mounir, F.; Karima, H. Investigation of phosphogypsum valorization by the integration of the Merseburg method. New J. Chem. 2020, 44, 8010–8017. [Google Scholar]

- Dong, W.; Sun, N.; Deng, X.; Chen, Z.; Zhang, Y.; Chi, R.; Hu, L. Study on the occurrence state of main components of phosphogypsum dihydrate and its impurity distribution. RSC Adv. 2024, 14, 22280–22291. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.; Liu, X.; Wang, C.; Qu, G.; Liu, L.; Chen, B.; Zhao, C.; Liu, S.; Li, J. New dawn of solid waste resource treatment: Preparation of high-performance building materials from waste-gypsum by mechanical technology. Constr. Build. Mater. 2022, 318, 126204. [Google Scholar] [CrossRef]

- Guerrero, J.; Gutiérrez-Álvarez, I.; Hierro, A.; Pérez-Moreno, S.; Olías, M.; Bolívar, J. Seasonal evolution of natural radionuclides in two rivers affected by acid mine drainage and phosphogypsum pollution. Catena 2021, 197, 104978. [Google Scholar] [CrossRef]

- He, S.; Yang, L.; Hu, G.; Cao, J. Deep removal of phosphate impurities in phosphogypsum by two-step crystal transformation for use as Portland cement retarder. J. Build. Eng. 2023, 79, 107831. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, X.; Shi, Y.; Zhu, Q.; Du, J. Reuse of phosphogypsum pretreated with water washing as aggregate for cemented backfill. Sci. Rep. 2022, 12, 16091. [Google Scholar] [CrossRef]

- Cao, W.; Yi, W.; Peng, J.; Li, J.; Yin, S. Recycling of phosphogypsum to prepare gypsum plaster: Effect of calcination temperature. J. Build. Eng. 2022, 45, 103511. [Google Scholar] [CrossRef]

- Jiang, W.; Jiang, Y.; Li, P.; Liu, D.; Ren, Y.; Li, D.; Liu, Z.; Chen, Y.; Ye, Y. Reuse of phosphogypsum and phosphorus ore flotation tailings as adsorbent: The adsorption performance and mechanism of phosphate. J. Phys. Chem. Solids 2023, 178, 111313. [Google Scholar] [CrossRef]

- Efremova, S.; Akanova, N.; Sharkov, T.; Yakhkind, M. Efficiency of the use of neutralized phosphogypsum, phosphorite processing waste, in agriculture. Environ. Qual. Manag. 2020, 30, 5–11. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, K.; Yu, M.; Dong, X.; Sarwar, M.; Yang, H. Facet-engineering strategy of phosphogypsum for production of mineral slow-release fertilizers with efficient nutrient fixation and delivery. Waste Manag. 2024, 182, 259–270. [Google Scholar] [CrossRef]

- Yassine, E.; Mohammed, B.; Hanan, B. Obtaining nano calcium fluoride and ammonium sulfate from phosphogypsum. Phosphorus Sulfur Silicon Relat. Elem. 2024, 199, 178–186. [Google Scholar]

- Amine, E.; Hicham, N.; Ghita, L.; Ahmed, B.; Rahma, B. Comparative adsorption studies of cadmium ions on phosphogypsum and natural clay. Sci. Afr. 2021, 13, e00960. [Google Scholar]

- Li, B.; Li, L.; Chen, X.; Ma, Y.; Zhou, M. Modification of phosphogypsum using circulating fluidized bed fly ash and carbide slag for use as cement retarder. Constr. Build. Mater. 2022, 338, 127630. [Google Scholar] [CrossRef]

- Máduar, M.; Campos, M.; Mazzilli, B.; Villaverde, F. Assessment of external gamma exposure and radon levels in a dwelling constructed with phosphogypsum plates. J. Hazard. Mater. 2011, 190, 1063–1067. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.; Cai, D.; Wu, J.; Sun, D.; Deng, Y.; Wang, Y. Utilization of waste phosphogypsum and absorbent polymer in preparing hollow particles and its application in lightweight blocks. Mater. Today Sustain. 2024, 27, 100871. [Google Scholar] [CrossRef]

- Rong, K.; Lan, W.; Li, H. Industrial Experiment of Goaf Filling Using the Filling Materials Based on Hemihydrate Phosphogypsum. Minerals 2020, 10, 324. [Google Scholar] [CrossRef]

- Xiao, L.; Zhang, J.; Luo, Y.; Qi, X.; Hussain, J.; Jiang, G. Innovative approach to enhancing phosphogypsum mechanical properties and stabilizing/solidifying contaminants. Sustain. Chem. Pharm. 2024, 41, 101712. [Google Scholar] [CrossRef]

- Wu, Q.; Zhang, H.; Jia, X. Optimizing compressive capacity: A comprehensive study on cast-in-situ phosphogypsum walls with varied high-thickness ratios and eccentricity distances. Case Stud. Constr. Mater. 2024, 20, e03025. [Google Scholar] [CrossRef]

- Xiao, M.; Ju, F.; Ning, P.; Li, K. Mechanical and Acoustic Emission Behavior of Gangue Concrete under Uniaxial Compression. Materials 2019, 12, 3318. [Google Scholar] [CrossRef]

- Zhai, M.; Xu, C.; Xue, L.; Cui, Y.; Dong, J. Loading rate dependence of staged damage behaviors of granite under uniaxial compression: Insights from acoustic emission characteristics. Theor. Appl. Fract. Mech. 2022, 122, 103633. [Google Scholar] [CrossRef]

- Wang, X.; Wang, E.; Liu, X.; Zhou, X. Failure mechanism of fractured rock and associated acoustic behaviors under different loading rates. Eng. Fract. Mech. 2021, 247, 107674. [Google Scholar] [CrossRef]

- Feng, Z.; Chen, X.; Feng, L.; Nin, Y.; Shi, Z. Uniaxial compression failure characteristics of 60-year-old bridge concrete under different loading rates. Case Stud. Constr. Mater. 2022, 17, e01276. [Google Scholar] [CrossRef]

- Wu, S.; Qin, G.; Cao, J. Deformation, Failure, and Acoustic Emission Characteristics under Different Lithological Confining Pressures. Materials 2022, 15, 4257. [Google Scholar] [CrossRef] [PubMed]

- Zheng, K.; Zhao, Y.; Wang, C.; Bi, J. Influence of distinct testing methods on the mode-I fracture toughness of Longmaxi shale. Theor. Appl. Fract. Mech. 2024, 129, 104213. [Google Scholar] [CrossRef]

- Li, N.; Feng, Q.; Yue, W.; Sun, S.; Li, Y.; Li, G.; Shi, W. Experimental study on mechanical and acoustic emission characteristics of sedimentary sandstone under different loading rates. Front. Earth Sci. 2023, 11, 1224645. [Google Scholar] [CrossRef]

- Chen, C.; Fan, X.; Chen, X. Experimental investigation of concrete fracture behavior with different loading rates based on acoustic emission. Constr. Build. Mater. 2020, 237, 117472. [Google Scholar] [CrossRef]

- Eid, R.; Muravin, B.; Kovler, K. Acoustic Emission Monitoring of High-Strength Concrete Columns Subjected to Compressive Axial Loading. Materials 2020, 13, 3114. [Google Scholar] [CrossRef]

- Federation of Construction Materials Industries. Monitoring Method for Active Cracks in Concrete by Acoustic Emission (JCMS-Ⅲ B5706); Federation of Construction Materials Industries: Tokyo, Japan, 2003. [Google Scholar]

- Ohno, K.; Ohtsu, M. Crack classifcation in concrete based on acoustic emission. Constr. Build. Mater. 2010, 24, 2339–2346. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Z.; Li, X.; Gong, F.; Du, K. Experimental study on the effect of strain rate on rock acoustic emission characteristics. Int. J. Rock Mech. Min. Sci. 2020, 133, 104420. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Mpalaskas, A.C.; Matikas, T.E. Acoustic signature of different fracture modes in marble and cementitious materials under flexural load. Mech. Res. Commun. 2013, 47, 39–43. [Google Scholar] [CrossRef]

- Cao, A.; Jing, G.; Ding, Y.; Liu, S. Mining-induced static and dynamic loading rate effect on rock damage and acoustic emission characteristic under uniaxial compression. Saf. Sci. 2019, 116, 86–96. [Google Scholar] [CrossRef]

- Rao, M.V.M.S.; Lakshmi, K.J.P. Analysis of b-value and improved b-value of acoustic emissions accompanying rock fracture. Curr. Sci. 2005, 89, 1577–1582. [Google Scholar]

| Material Composition | Hemihydrate Phosphogypsum | Quicklime | Melamine Water-Reducing Agent | Water |

|---|---|---|---|---|

| Percentage composition | 97% | 3% | 1% | 29.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Zhang, J.; Le, Q.; Wang, D.; Ding, J.; Xu, C. Experimental Study on Acoustic Emission Characteristics of Modified Phosphogypsum at Different Loading Rates. Materials 2025, 18, 2491. https://doi.org/10.3390/ma18112491

Zhang B, Zhang J, Le Q, Wang D, Ding J, Xu C. Experimental Study on Acoustic Emission Characteristics of Modified Phosphogypsum at Different Loading Rates. Materials. 2025; 18(11):2491. https://doi.org/10.3390/ma18112491

Chicago/Turabian StyleZhang, Bo, Ji Zhang, Qiaoli Le, Duoduo Wang, Jiangtao Ding, and Chaohua Xu. 2025. "Experimental Study on Acoustic Emission Characteristics of Modified Phosphogypsum at Different Loading Rates" Materials 18, no. 11: 2491. https://doi.org/10.3390/ma18112491

APA StyleZhang, B., Zhang, J., Le, Q., Wang, D., Ding, J., & Xu, C. (2025). Experimental Study on Acoustic Emission Characteristics of Modified Phosphogypsum at Different Loading Rates. Materials, 18(11), 2491. https://doi.org/10.3390/ma18112491