Preparation and Properties of Nanostructured GaN-Reinforced Cu Matrix Composites

Abstract

1. Introduction

2. Materials and Methods

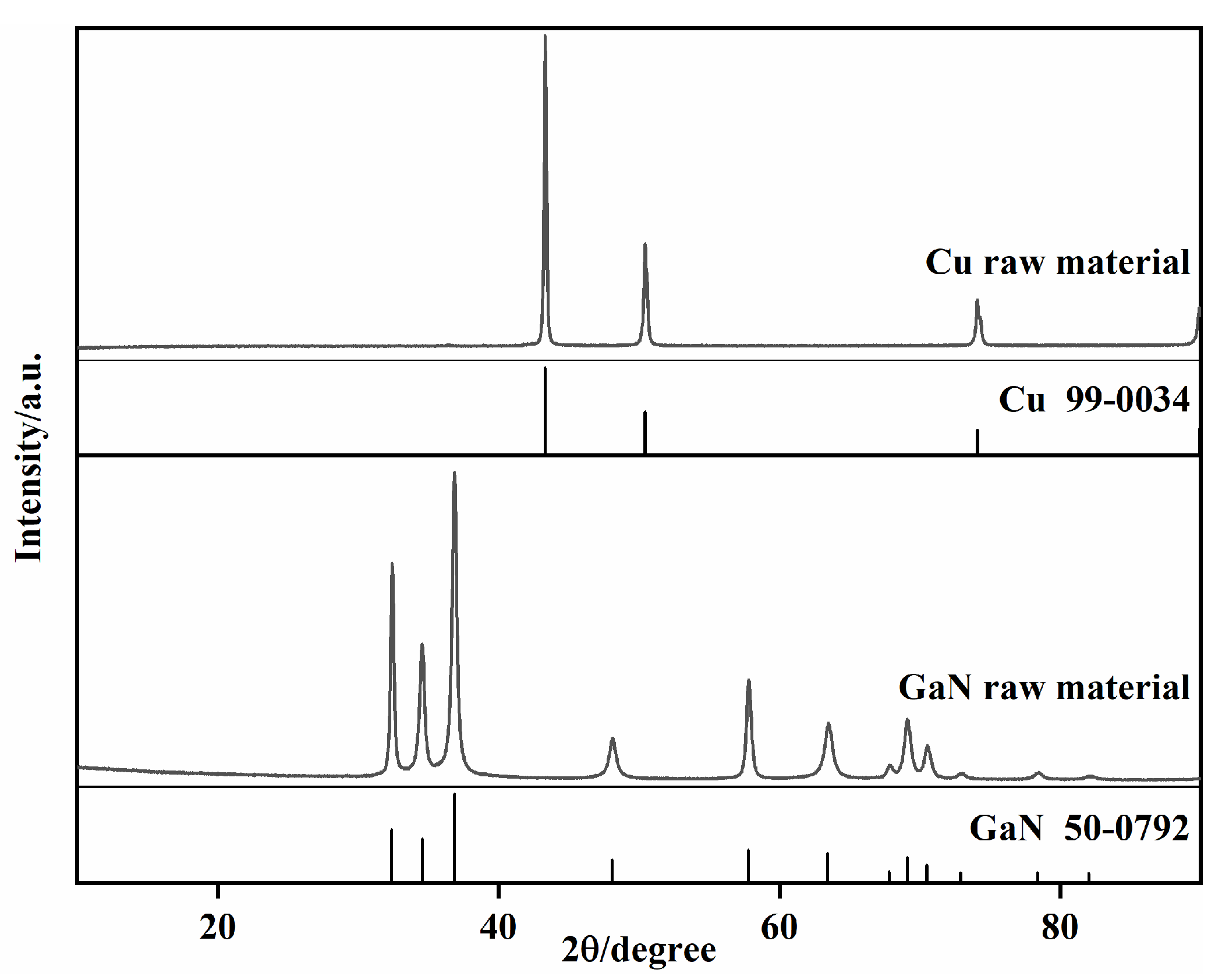

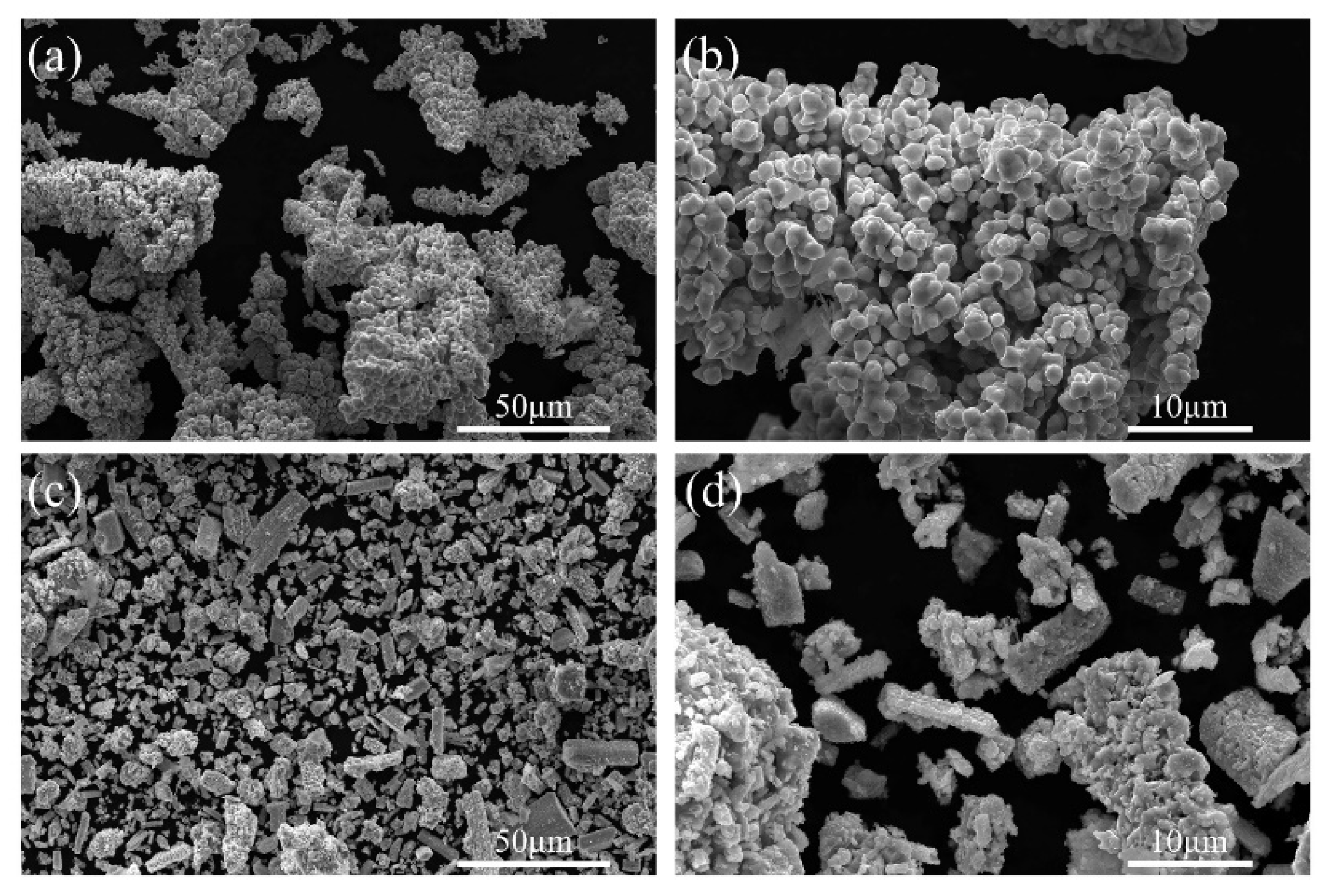

2.1. Materials

2.2. Experiments

2.3. Characterization

3. Results and Discussion

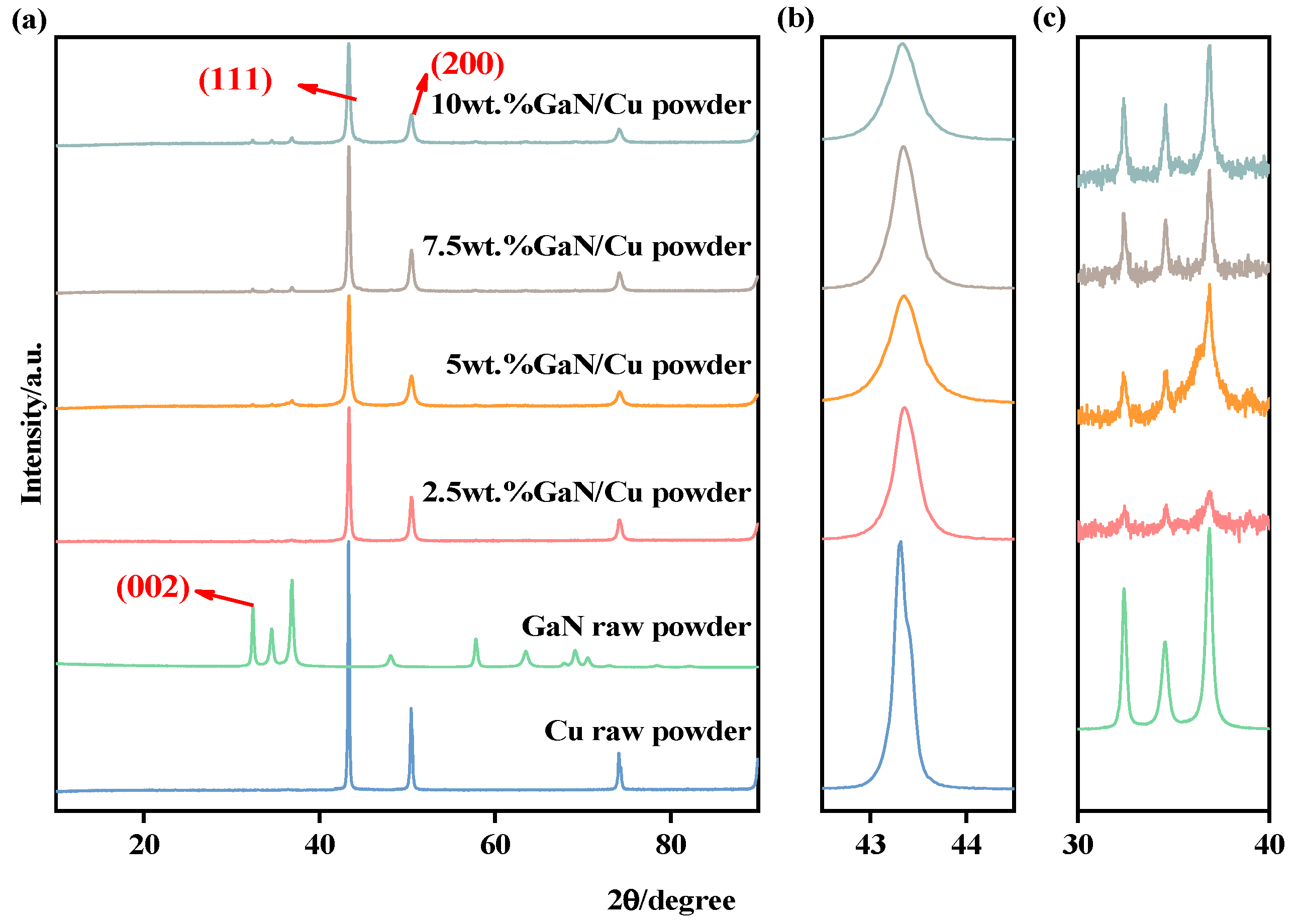

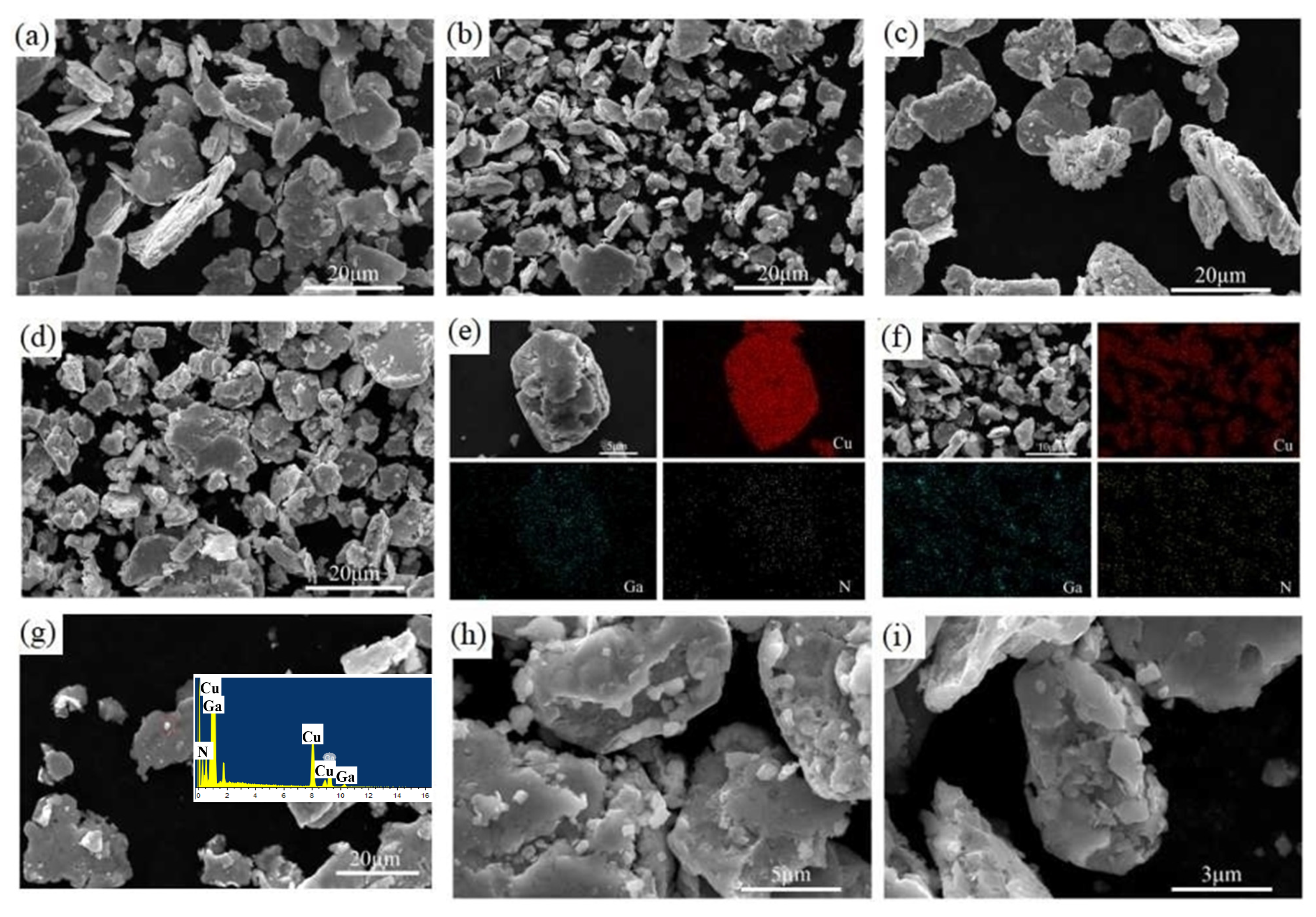

3.1. Microstructure and Phase Analysis of GaN-Cu Composite Powder

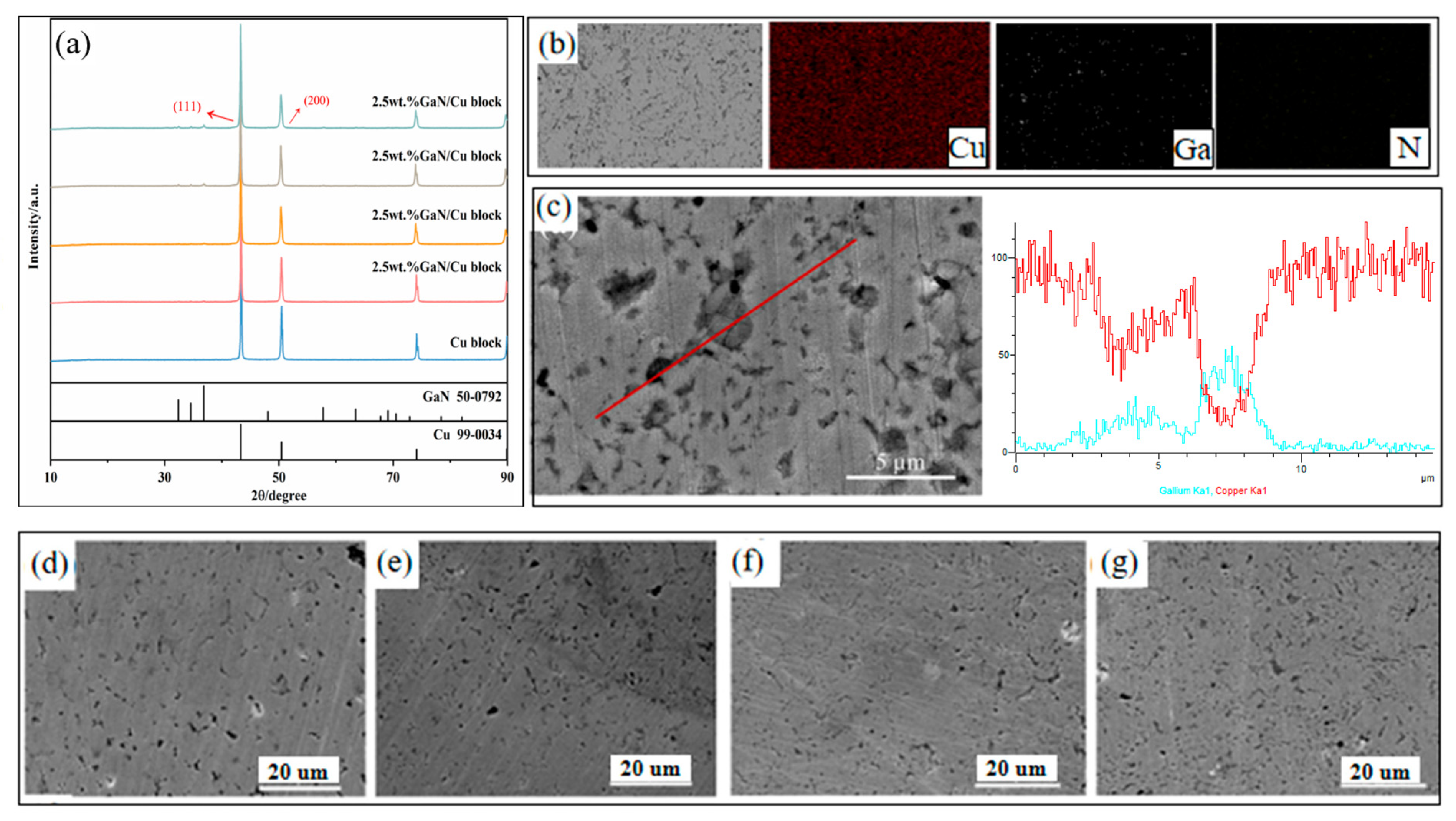

3.2. Microstructure and Phase Analysis of Sintered GaN-Cu Composites

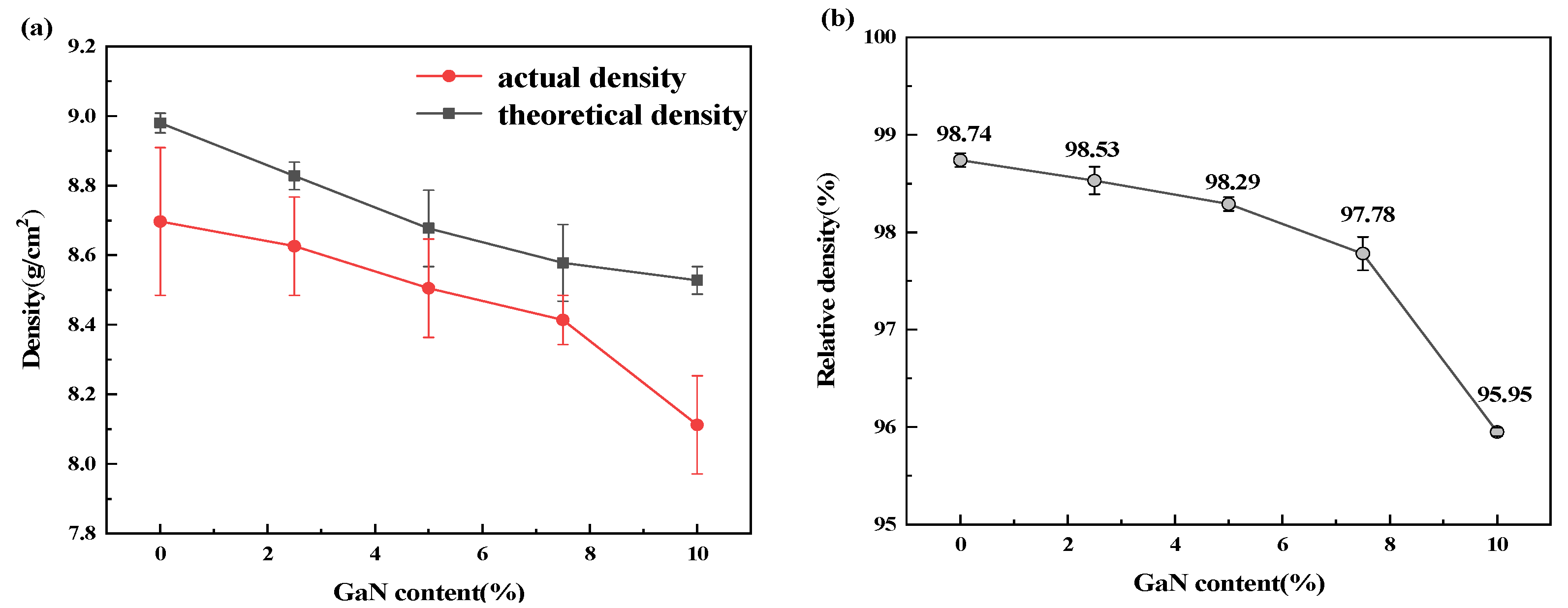

3.3. Density and Relative Density Analysis of GaN-Cu Composites

3.4. Microhardness Analysis of GaN-Cu Composites

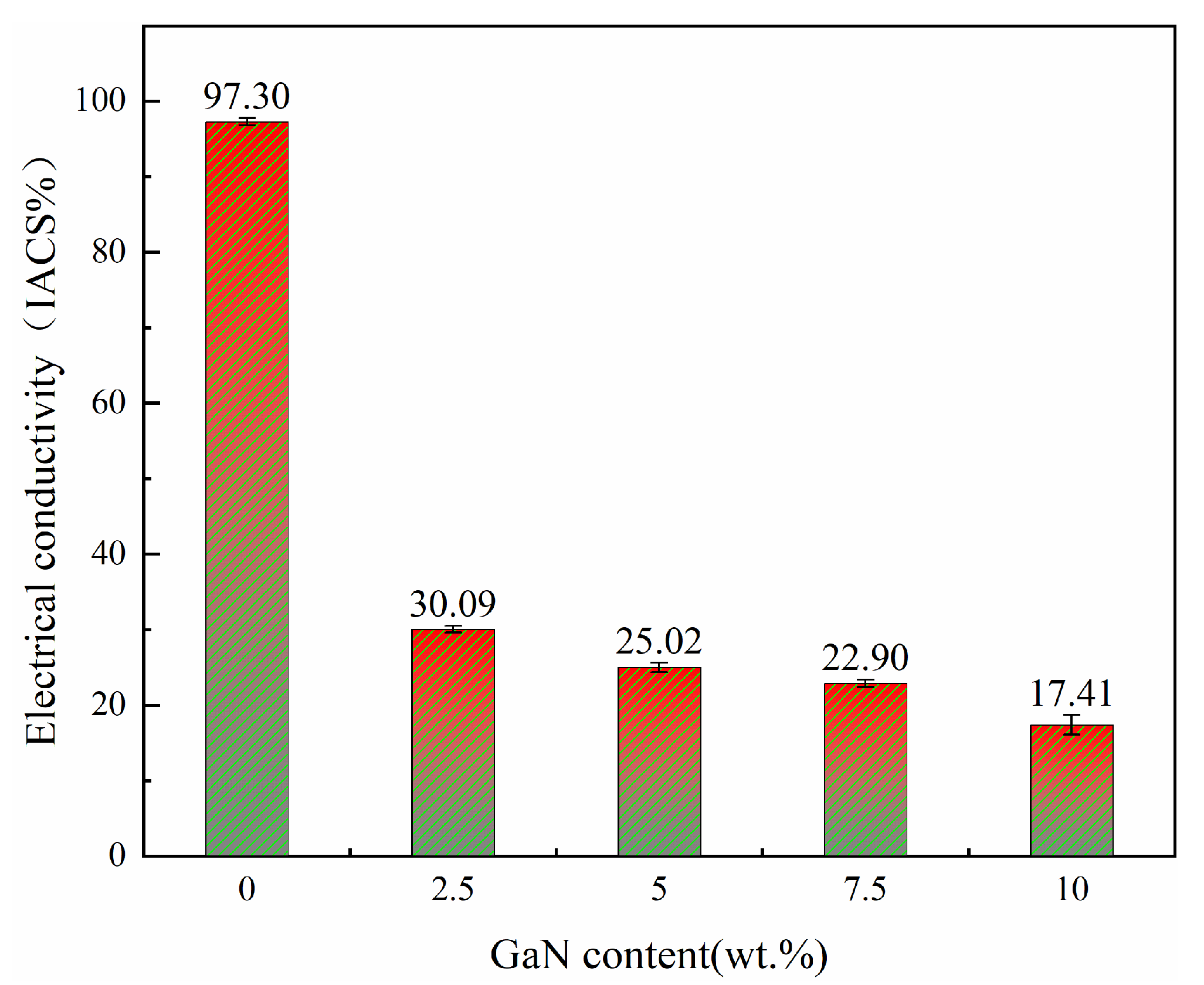

3.5. Electrical Conductivity Analysis of GaN-Cu Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, Y.X.; Yang, X.M.; Wang, R.R.; Li, M.X. Enhancement of the mechanical properties of graphene-copper composites with graphene-nickel hybrids. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2014, 599, 247–254. [Google Scholar] [CrossRef]

- Krsti, J.; Jovanovi, J.; Gajevi, S.; Miladinovic, S.; Vaxevanidis, N.M.; Kiss, I.; Stojanovic, B. Application of Metal Matrix Nanocomposites in Engineering Application of Metal Matrix Nanocomposites in Engineering. Adv. Eng. Lett. 2024, 3, 34–45. [Google Scholar] [CrossRef]

- Gajević, S.; Miladinović, S.; Stojanović, B. Chapter 8—Metallic nanocomposites: An Introduction. In Nanotechnology in the Automotive Industry; Elsevier Inc.: Amsterdam, The Netherlands, 2022; pp. 155–161. [Google Scholar] [CrossRef]

- Kasar, A.; Xiong, G.P.; Menezes, P.L. Graphene-Reinforced Metal and Polymer Matrix Composites. JOM 2018, 70, 829–836. [Google Scholar] [CrossRef]

- Moreira, R.C.S.; Kovalenko, O.; Souza, D.; Reis, R.P. Metal matrix composite material reinforced with metal wire and produced with gas metal arc welding. J. Compos. Mater. 2019, 53, 4411–4426. [Google Scholar] [CrossRef]

- Bajakke, P.A.; Malik, V.R.; Deshpande, A.S. Particulate metal matrix composites and their fabrication via friction stir processing-a review. Mater. Manuf. Process. 2019, 34, 833–881. [Google Scholar] [CrossRef]

- Naseer, A.; Ahmad, F.; Aslam, M.; Guan, B.H.; Harun, W.S.W.; Muhamad, N.; Raza, M.R.; German, R.M. A review of processing techniques for graphene-reinforced metal matrix composites. Mater. Manuf. Process. 2019, 34, 957–985. [Google Scholar] [CrossRef]

- Alem, S.A.A.; Latifi, R.; Angizi, S.; Hassanaghaei, F.; Aghaahmadi, M.; Ghasali, E.; Rajabi, M. Microwave sintering of ceramic reinforced metal matrix composites and their properties: A review. Mater. Manuf. Process. 2020, 35, 303–327. [Google Scholar] [CrossRef]

- Efe, G.C.; Ipek, M.; Zeytin, S.; Bindal, C. An investigation of the effect of SiC particle size on Cu-SiC composites. Compos. Part B Eng. 2012, 43, 1813–1822. [Google Scholar] [CrossRef]

- Hwang, S.J.; Wexler, D.; Calka, A. Mechanochemical synthesis of nanocrystalline Al2O3dispersed copper. J. Mater. Sci. 2004, 39, 4659–4662. [Google Scholar] [CrossRef]

- Moustafa, S.F.; Abdel-Hamid, Z.; Abd-Elhay, A.M. Copper matrix SiC and Al2O3 particulate composites by powder metallurgy technique. Mater. Lett. 2002, 53, 244–249. [Google Scholar] [CrossRef]

- Khaloobagheri, M.; Janipour, B.; Askari, N.; Abad, E.S.K. Characterisation of powder metallurgy Cu-ZrO2 composites. Adv. Prod. Eng. Manag. 2013, 8, 242–248. [Google Scholar] [CrossRef]

- Hwang, J.; Yoon, T.; Jin, S.H.; Lee, J.; Kim, T.S.; Hong, S.H.; Jeon, S. Enhanced mechanical properties of graphene/copper nanocomposites using a molecular-level mixing process. Adv. Mater. 2013, 25, 6724–6729. [Google Scholar] [CrossRef]

- Li, M.X.; Che, H.W.; Liu, X.Y.; Liang, S.X.; Xie, H.L. Highly enhanced mechanical properties in Cu matrix composites reinforced with graphene decorated metallic nanoparticles. J. Mater. Sci. 2014, 49, 3725–3731. [Google Scholar] [CrossRef]

- Li, Y.L.; Li, Z.Y.; Luo, Y.F.; Li, B.H. Study on preparation of CNTs-Cu composites materials by hydrazine hydrate reduction-solid state sintering process. Ferroelectrics 2017, 521, 32–37. [Google Scholar] [CrossRef]

- Zuo, T.T.; Xue, J.L.; Ru, Y.D.; Gao, Z.S.; Zhang, L.; Da, B.; Han, L.; Xiao, L.Y. The improved softening resistance and high electrical conductivity of the 3D graphene enhanced copper-based composite fabricated by liquid carbon source. Mater. Lett. 2021, 283, 128895. [Google Scholar] [CrossRef]

- Roccaforte, F.; Greco, G.; Fiorenza, P.; Iucolano, F. An Overview of Normally-Off GaN-Based High Electron Mobility Transistors. Materials 2019, 12, 1599. [Google Scholar] [CrossRef]

- Zhilyaev, I.; Grabco, D.; Leu, D.; Botnariuc, V.; Raevskii, S. Mechanical properties and microstructure of microcrystalline GaN. Philos. Mag. A Phys. Condens. Matter Struct. Defects Mech. Prop. 2002, 82, 2217–2221. [Google Scholar] [CrossRef]

- Dai, J.-J.; Mai, T.T.; Wu, S.-K.; Peng, J.-R.; Liu, C.-W.; Wen, H.-C.; Chou, W.-C.; Ho, H.-C.; Wang, W.-F. High Hole Concentration and Diffusion Suppression of Heavily Mg-Doped p-GaN for Application in Enhanced-Mode GaN HEMT. Nanomaterials 2021, 11, 1766. [Google Scholar] [CrossRef]

- Drory, M.D. Mechanical properties of gallium nitride and related materials. Gallium Nitride Relat. Mater. II 1997, 468, 201–206. [Google Scholar] [CrossRef]

- Drygas, M.; Kapusta, K.; Janik, J.F.; Bucko, M.M.; Gierlotka, S.; Stelmakh, S.; Palosz, B.; Olejniczak, Z. Novel nanoceramics from in situ made nanocrystalline powders of pure nitrides and their composites in the system aluminum nitride AlN/gallium nitride GaN/aluminum gallium nitride Al0.5Ga0.5N. J. Eur. Ceram. Soc. 2020, 40, 5339–5348. [Google Scholar] [CrossRef]

- Akbarpour, M.R.; Mirabad, H.M.; Alipour, S. Microstructural and mechanical characteristics of hybrid SiC/Cu composites with nano-and micro-sized SiC particles. Ceram. Int. 2019, 45, 3276–3283. [Google Scholar] [CrossRef]

- Hsu, C.J.; Chang, C.Y.; Kao, P.W.; Ho, N.J.; Chang, C.P. Al-Al3Ti nanocomposites produced in situ by friction stir processing. Acta Mater. 2006, 54, 5241–5249. [Google Scholar] [CrossRef]

- Moustafa, E.B.; Taha, M.A. Evaluation of the microstructure, thermal and mechanical properties of Cu/SiC nanocomposites fabricated by mechanical alloying. Int. J. Miner. Metall. Mater. 2021, 28, 475–486. [Google Scholar] [CrossRef]

- Taha, M.A.; Nassar, A.H.; Zawrah, M.F. Improvement of wetability, sinterability, mechanical and electrical properties of Al2O3 -Ni nanocomposites prepared by mechanical alloying. Ceram. Int. 2017, 43, 3576–3582. [Google Scholar] [CrossRef]

- Youness, R.A.; Taha, M.A.; Ibrahim, M.A. Effect of sintering temperatures on the in vitro bioactivity, molecular structure and mechanical properties of titanium/carbonated hydroxyapatite nanobiocomposites. J. Mol. Struct. 2017, 1150, 188–195. [Google Scholar] [CrossRef]

- Taha, M.A.; Zawrah, M.F. Effect of nano ZrO2 on strengthening and electrical properties of Cu-matrix nanocomposits prepared by mechanical alloying. Ceram. Int. 2017, 43, 12698–12704. [Google Scholar] [CrossRef]

- Sorkhe, Y.A.; Aghajani, H.; Tabrizi, A.T. Mechanical alloying and sintering of nanostructured TiO2 reinforced copper composite and its characterization. Mater. Des. 2014, 58, 168–174. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D.L. Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength. Scripta Mater. 2006, 54, 1321–1326. [Google Scholar] [CrossRef]

- Mohamed, A.M. Mechanical alloying and spark plasma sintering of graphene reinforced Cu–Cr nanocomposites. Powder Technol. 2017, 321, 432–440. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, L. Interface structure and bonding mechanism of Cu/GaN multilayers synthesized by magnetron sputtering. Scr. Mater. 2006, 54, 1321–1326. [Google Scholar] [CrossRef]

- Wang, Y.; Ran, X.; Barber, G.; Zou, Q. Microstructure and sintering mechanism of C/Cu composites by mechanical alloying/spark plasma sintering. J. Compos. Mater. 2017, 51, 3065–3074. [Google Scholar] [CrossRef]

- ASTM F1529; Standard Test Method for Sheet Resistance Uniformity Evaluation by In-Line Four-Point Probe with the Dual-Configuration Procedure. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM B962-15; Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle. ASTM: West Conshohocken, PA, USA, 2017.

- Akbarpour, M.R.; Salahi, E.; Hesari, F.A.; Kim, H.S.; Simchi, A. Effect of nanoparticle content on the microstructural and mechanical properties of nano-SiC dispersed bulk ultrafine-grained Cu matrix composites. Mater. Des. 2013, 52, 881–887. [Google Scholar] [CrossRef]

- Rajkovic, V.; Bozic, D.; Devecerski, A.; Jovanovic, M.T. Characteristic of copper matrix simultaneously reinforced with nano- and micro-sized Al2O3 particles. Mater. Charact. 2012, 67, 129–137. [Google Scholar] [CrossRef]

- Akbarpour, M.R.; Salahi, E.; Hesari, F.A.; Yoon, E.Y.; Kim, H.S.; Simchi, A. Microstructural development and mechanical properties of nanostructured copper reinforced with SiC nanoparticles. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2013, 568, 33–39. [Google Scholar] [CrossRef]

- Malliaris, A.; Turner, D.T. Influence of Particle Size on the Electrical Resistivity of Compacted Mixtures of Polymeric and Metallic Powders. J. Appl. Phys. 1971, 42, 614–618. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Lu, X.T.; Xu, J.R.; Luo, H.J. Characterization and Tribological Properties of Graphene/Copper Composites Fabricated by Electroless Plating and Powder Metallurgy. Acta Metall. Sin. Engl. Lett. 2020, 33, 903–912. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, Y.; Ge, H.; Peng, Y. Preparation and Properties of Nanostructured GaN-Reinforced Cu Matrix Composites. Materials 2025, 18, 2489. https://doi.org/10.3390/ma18112489

Bai Y, Ge H, Peng Y. Preparation and Properties of Nanostructured GaN-Reinforced Cu Matrix Composites. Materials. 2025; 18(11):2489. https://doi.org/10.3390/ma18112489

Chicago/Turabian StyleBai, Yunlong, Hui Ge, and Yaoyang Peng. 2025. "Preparation and Properties of Nanostructured GaN-Reinforced Cu Matrix Composites" Materials 18, no. 11: 2489. https://doi.org/10.3390/ma18112489

APA StyleBai, Y., Ge, H., & Peng, Y. (2025). Preparation and Properties of Nanostructured GaN-Reinforced Cu Matrix Composites. Materials, 18(11), 2489. https://doi.org/10.3390/ma18112489