The Recrystallized Microstructures and Mechanical Properties of a Hypo-Eutectic Al13Ni36Cr10Fe40Mo1 High-Entropy Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Preparation

2.2. Alloy Testing and Characterization

3. Results

3.1. Initial Morphology

3.2. Microstructure and Phases

3.3. Mechanical Properties

4. Discussion

4.1. Grain Size Variation

4.2. Strengthening Mechanisms

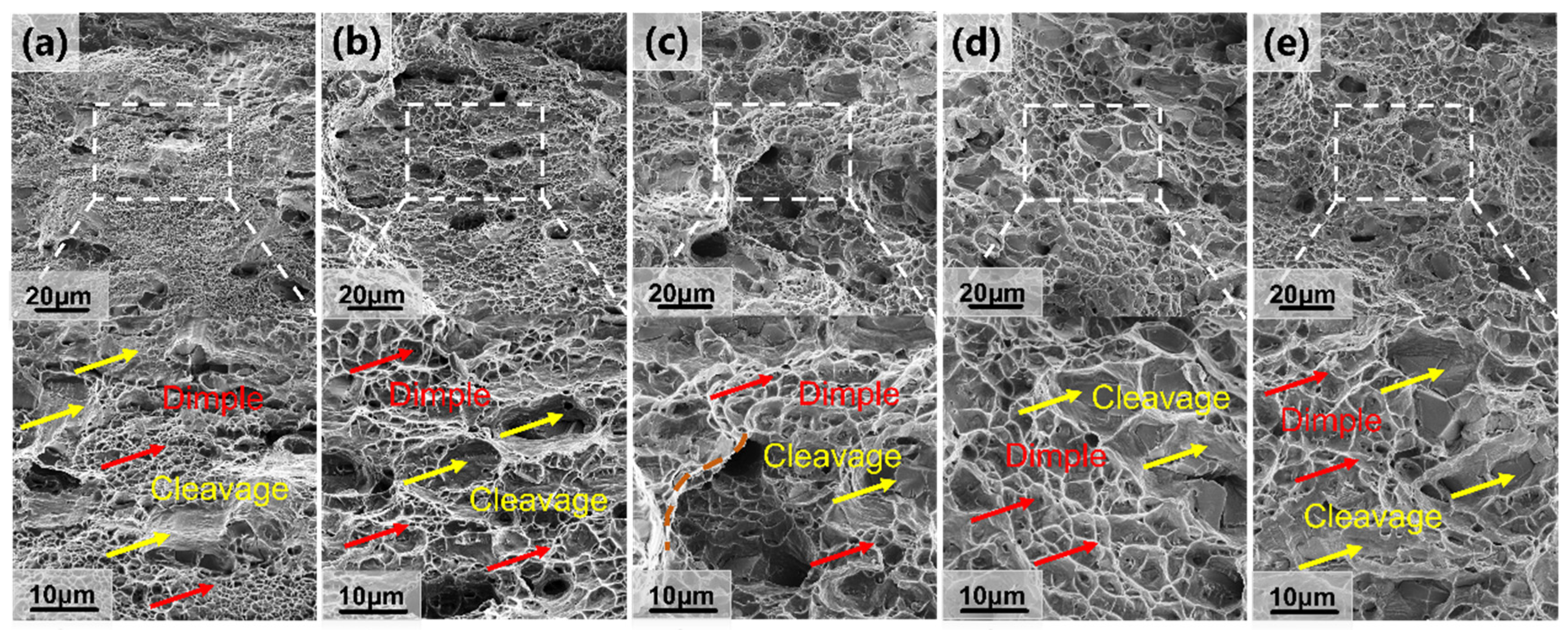

4.3. Fracture Surface

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- He, F.; Wang, Z.; Li, Y. Kinetic ways of tailoring phases in high entropy alloys. Sci. Rep. 2016, 6, 34628. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Z.; Wu, Q. A hypoeutectic high-entropy alloy with hierarchical microstructure for high-temperature application. Scr. Mater. 2023, 232, 115502. [Google Scholar] [CrossRef]

- Wang, D.; Meng, H.; Wang, J.; Wang, Z.; Ye, Y.; Dong, Z.; Wu, Y.; Wang, Y. Corrosion performance of a high-strength FeNiCrAl medium-entropy alloy compared with 304 stainless steel in KOH solution. Appl. Surf. Sci. 2024, 678, 161069. [Google Scholar] [CrossRef]

- Li, J.; Yang, X.; Zhu, R.; Zhang, Y. Corrosion and Serration Behaviors of TiZr0.5NbCr0.5VxMoy High Entropy Alloys in Aqueous Environments. Metals 2014, 4, 597–608. [Google Scholar] [CrossRef]

- Lu, Y.; Dong, Y.; Guo, S.; Jiang, L.; Kang, H.J.; Wang, T.M.; Wen, B.; Wang, Z.J.; Jie, J.C.; Cao, Z.Q.; et al. A Promising New Class of High-Temperature Alloys: Eutectic High-Entropy Alloys. Sci. Rep. 2014, 4, 6200. [Google Scholar] [CrossRef]

- Wu, Q.; He, F.; Li, J.; Kim, H.S.; Wang, Z.; Wang, J. Phase-selective recrystallization makes eutectic high-entropy alloys ultra-ductile. Nat. Commun. 2022, 13, 4697. [Google Scholar] [CrossRef]

- Jin, X.; Bi, J.; Zhang, L.; Zhou, Y.; Du, X.; Liang, Y.; Li, B. A new CrFeNi2Al eutectic high entropy alloy system with excellent mechanical properties. J. Alloys Compd. 2019, 770, 655–661. [Google Scholar] [CrossRef]

- Gwalani, B.; Soni, V.; Lee, M. Optimizing the coupled effects of Hall-Petch and precipitation strengthening in a Al0.3CoCrFeNi high entropy alloy. Mater. Des. 2017, 121, 254–260. [Google Scholar] [CrossRef]

- Chen, Z.; Ren, X.; Wang, P.; Wang, W.; Ge, C. Design and experimental investigation of the high-entropy alloys AlCrFeNiCu and AlCrFeNbMo. J. Mater. Res. Technol. 2023, 26, 3118–3135. [Google Scholar] [CrossRef]

- Jumaev, E.; Abbas, M.A.; Mun, S.C.; Song, G.; Hong, S.-J.; Kim, K.B. Nano-scale structural evolution of quaternary AlCrFeNi based high entropy alloys by the addition of specific minor elements and its effect on mechanical characteristics. J. Alloys Compd. 2021, 868, 159217. [Google Scholar] [CrossRef]

- Eshed, E.; Abd, E.M.S.; Bamberger, M. TEM and High Resolution TEM Investigation of Phase Formation in High Entropy Alloy AlCrFe2Ni2. Front. Mater. 2020, 7, 284. [Google Scholar] [CrossRef]

- Dong, Y.; Gao, X.; Lu, Y. A multi-component AlCrFe2Ni2 alloy with excellent mechanical properties. Mater. Lett. 2016, 169, 62–64. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Shi, X. Alloying behavior of W and Mo in the as-cast dual-phase FeNiCrAl multi-component alloys. J. Alloys Compd. 2023, 951, 169951. [Google Scholar] [CrossRef]

- Tripathy, B.; Malladi, S.R.K.; Bhattacharjee, P.P. Development of ultrafine grained cobalt-free AlCrFe2Ni2 high entropy alloy with superior mechanical properties by thermo-mechanical processing. Mater. Sci. Eng. A 2022, 831, 142190. [Google Scholar] [CrossRef]

- Wani, I.; Bhattacharjee, T.; Sheikh, S.; Clark, I.; Park, M.; Okawa, T.; Guo, S.; Bhattacharjee, P.; Tsuji, N. Cold-rolling and recrystallization textures of a nano-lamellar AlCoCrFeNi2.1 eutectic high entropy alloy. Intermetallics 2017, 84, 42–51. [Google Scholar] [CrossRef]

- Lv, Y.; Song, P.; Wang, Y.; Zhao, X.; Gao, W.; Zhang, J.; Lei, Y.; Chen, J. Improving Mechanical Properties of Fe-Mn-Co-Cr High-Entropy Alloy via Annealing after Cold Rolling. Materials 2024, 17, 9. [Google Scholar] [CrossRef]

- Reddy, S.; Yoshida, S.; Sunkari, U.; Lozinko, A.; Joseph, J.; Saha, R.; Fabijanic, D.; Guo, S.; Bhattacharjee, P.; Tsuji, N. Engineering heterogeneous microstructure by severe warm-rolling for enhancing strength-ductility synergy in eutectic high entropy alloys. Mater. Sci. Eng. A 2019, 764, 138226. [Google Scholar] [CrossRef]

- Reddy, S.; Sunkari, U.; Lozinko, A.; Saha, R.; Guo, S.; Bhattacharjee, P. Microstructural design by severe warm-rolling for tuning mechanical properties of AlCoCrFeNi2.1 eutectic high entropy alloy. Intermetallics 2019, 114, 106601. [Google Scholar] [CrossRef]

- Tripathy, B.; Ojha, P.K.; Bhattacharjee, P.P. Effect of warm-rolling on microstructure and superior mechanical properties of a cost-effective AlCrFe2Ni2 high entropy alloy. J. Alloys Compd. 2023, 948, 169783. [Google Scholar] [CrossRef]

- Liu, M.; Zuo, L.; Li, X.; Li, R.; Zhang, T. Microstructure and Mechanical Properties of Al25−xCr25+0.5xFe25Ni25+0.5x (x = 19, 17, 15 at%) Multi-Component Alloys. Adv. Eng. Mater. 2018, 20, 1701057. [Google Scholar] [CrossRef]

- Yu, W.; Huo, Y.; Wang, Z.; Yan, Z.; He, T.; Hosseini, S.R.E.; Ji, H.; Chen, H. Microstructure evolution and mechanical properties of NiAlCrFeMo high entropy superalloy after different annealing treatment. Intermetallics 2024, 175, 108494. [Google Scholar] [CrossRef]

- Qiu, Y.; Shi, X.; Liu, X.; Chen, Z.; Wang, J.; Liu, X.; Bai, X.; He, F.; Wang, Z. Effect of Annealing and Double Aging on the Microstructure and Mechanical Properties of Hot-Rolled Al17Cr10Fe36Ni36Mo1 Alloy. Metals 2024, 14, 726. [Google Scholar] [CrossRef]

- Chen, X.; Qi, J.; Sui, Y.; He, Y.; Wei, F.; Meng, Q.; Sun, Z. Effects of aluminum on microstructure and compressive properties of Al-Cr-Fe-Ni eutectic multi-component alloys. Mater. Sci. Eng. A 2017, 681, 25–31. [Google Scholar] [CrossRef]

- Qiao, L.; Zhu, J.; Teng, Y.; Bao, A.; Lai, Z.; Wang, Y. Dynamic solidification model of low-density FeCrNiAl multi-component alloy. Vacuum 2021, 184, 109873. [Google Scholar] [CrossRef]

- Jiang, Z.; Chen, W.; Xia, Z.; Xiong, W.; Fu, Z. Influence of synthesis method on microstructure and mechanical behavior of Co-free AlCrFeNi medium-entropy alloy. Intermetallics 2019, 108, 45–54. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, X.; Zhao, J.; Zeng, Q.; Xu, K.; Li, Y.; Wang, C.; Wang, L.; Li, J.; Wang, J.; et al. Discontinuous coarsening leads to unchanged tensile properties in high-entropy alloys with different recrystallization volume fractions. Int. J. Plast. 2024, 176, 103963. [Google Scholar] [CrossRef]

- Fan, J.; Ji, X.; Fu, L.; Wang, J.; Ma, S.; Sun, Y.; Wen, M.; Shan, A. Achieving exceptional strength-ductility synergy in a complex-concentrated alloy via architected heterogeneous grains and nano-sized precipitates. Int. J. Plast. 2022, 157, 103398. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Pharr, G.M.; George, E.P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014, 81, 428–441. [Google Scholar] [CrossRef]

- Xing, Z.; Pang, J.; Zhang, H.; Ji, Y.; Zhu, Z.; Zhang, L.; Li, H.; Wang, A.; Zhang, H. Effect of aging temperature on microstructure and mechanical properties of Fe–Ni–Cr–Al high entropy alloy. Intermetallics 2024, 165, 108159. [Google Scholar] [CrossRef]

- Liu, W.; Wu, Y.; He, J.; Nieh, T.; Lu, Z. Grain growth and the Hall–Petch relationship in a high-entropy FeCrNiCoMn alloy. Scr. Mater. 2013, 68, 526–529. [Google Scholar] [CrossRef]

- Wu, Q.; Jia, Y.; Wang, Z.; He, F.; Wei, Y.; Li, J.; Wang, J. Rapid alloy design from superior eutectic high-entropy alloys. Scr. Mater. 2022, 219, 114875. [Google Scholar] [CrossRef]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

| σ0.2, MPa | σb, MPa | εp, % | |

|---|---|---|---|

| 1200 °C/4 h | 70.5 | 422.2 | 49.9% |

| 1200 °C/4 h-70% | 1178.7 | 1302.6 | 2.9% |

| 1200 °C/4 h-70%-1100/10 min | 423 | 844 | 34.5% |

| 1200 °C/4 h-70%-1100/1 h | 426 | 877 | 41% |

| 1200 °C/4 h-70%-1100/2 h | 415 | 892 | 35.4% |

| 1200 °C/4 h-70%-1100/4 h | 365 | 873 | 36.5% |

| 1200 °C/4 h-70%-1100/8 h | 392 | 889 | 39.5% |

| Precipitates | Average Size (μm) | Volume Fraction (%) |

|---|---|---|

| FCC | 3.21 | 74 |

| B2 | 3.35 | 26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Wang, H.; Bai, X.; Yan, P.; Liu, L.; Wang, C.; Qiu, Y.; Wang, Z. The Recrystallized Microstructures and Mechanical Properties of a Hypo-Eutectic Al13Ni36Cr10Fe40Mo1 High-Entropy Alloy. Materials 2025, 18, 2454. https://doi.org/10.3390/ma18112454

Li H, Wang H, Bai X, Yan P, Liu L, Wang C, Qiu Y, Wang Z. The Recrystallized Microstructures and Mechanical Properties of a Hypo-Eutectic Al13Ni36Cr10Fe40Mo1 High-Entropy Alloy. Materials. 2025; 18(11):2454. https://doi.org/10.3390/ma18112454

Chicago/Turabian StyleLi, Hui, Han Wang, Xiaoyu Bai, Peng Yan, Linxiang Liu, Chuwen Wang, Yunji Qiu, and Zhijun Wang. 2025. "The Recrystallized Microstructures and Mechanical Properties of a Hypo-Eutectic Al13Ni36Cr10Fe40Mo1 High-Entropy Alloy" Materials 18, no. 11: 2454. https://doi.org/10.3390/ma18112454

APA StyleLi, H., Wang, H., Bai, X., Yan, P., Liu, L., Wang, C., Qiu, Y., & Wang, Z. (2025). The Recrystallized Microstructures and Mechanical Properties of a Hypo-Eutectic Al13Ni36Cr10Fe40Mo1 High-Entropy Alloy. Materials, 18(11), 2454. https://doi.org/10.3390/ma18112454