Additive Manufacturing of Alumina-Based Ceramic Structures by Vat Photopolymerization: A Review of Strategies for Improving Shaping Accuracy and Properties

Abstract

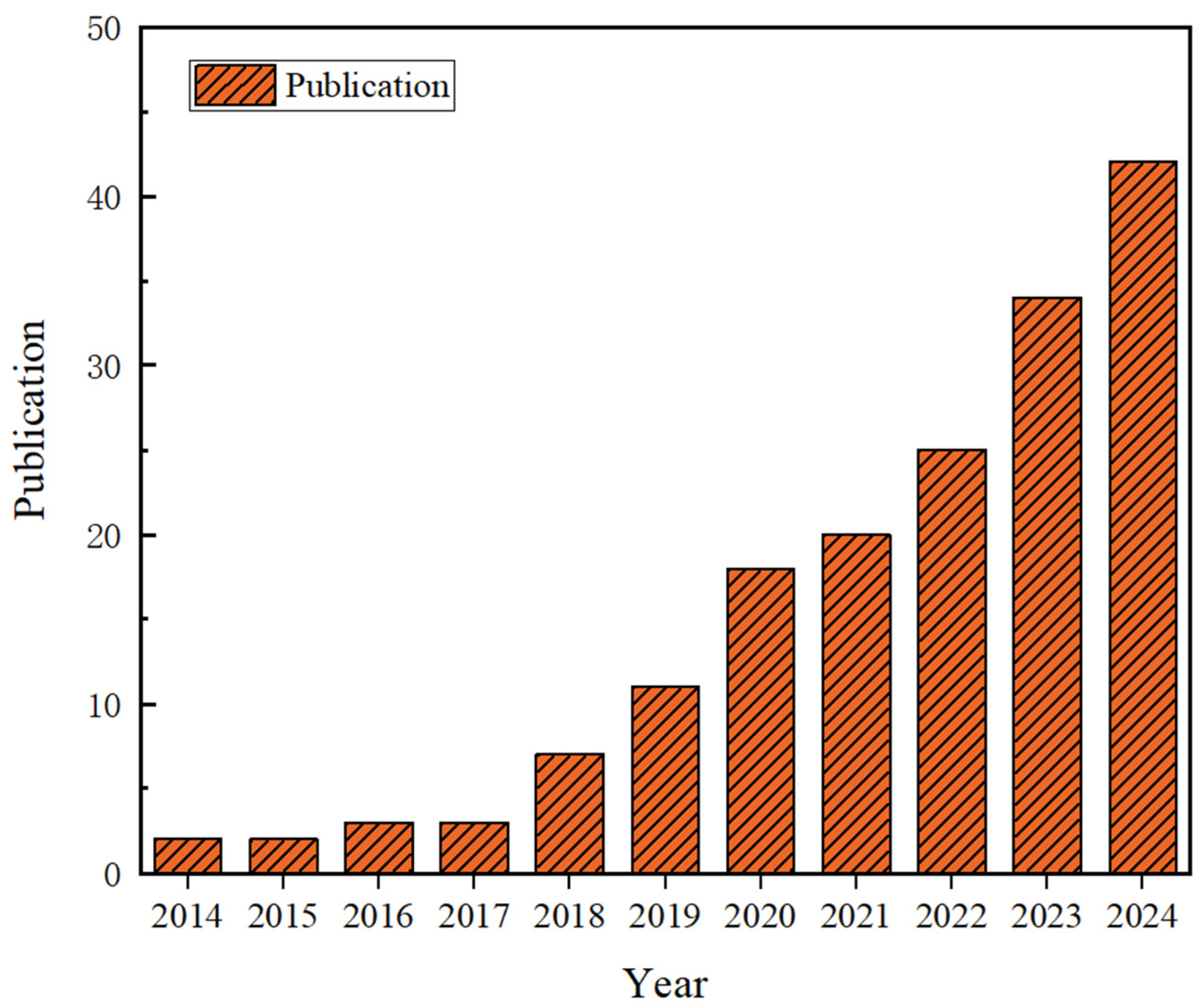

1. Introduction

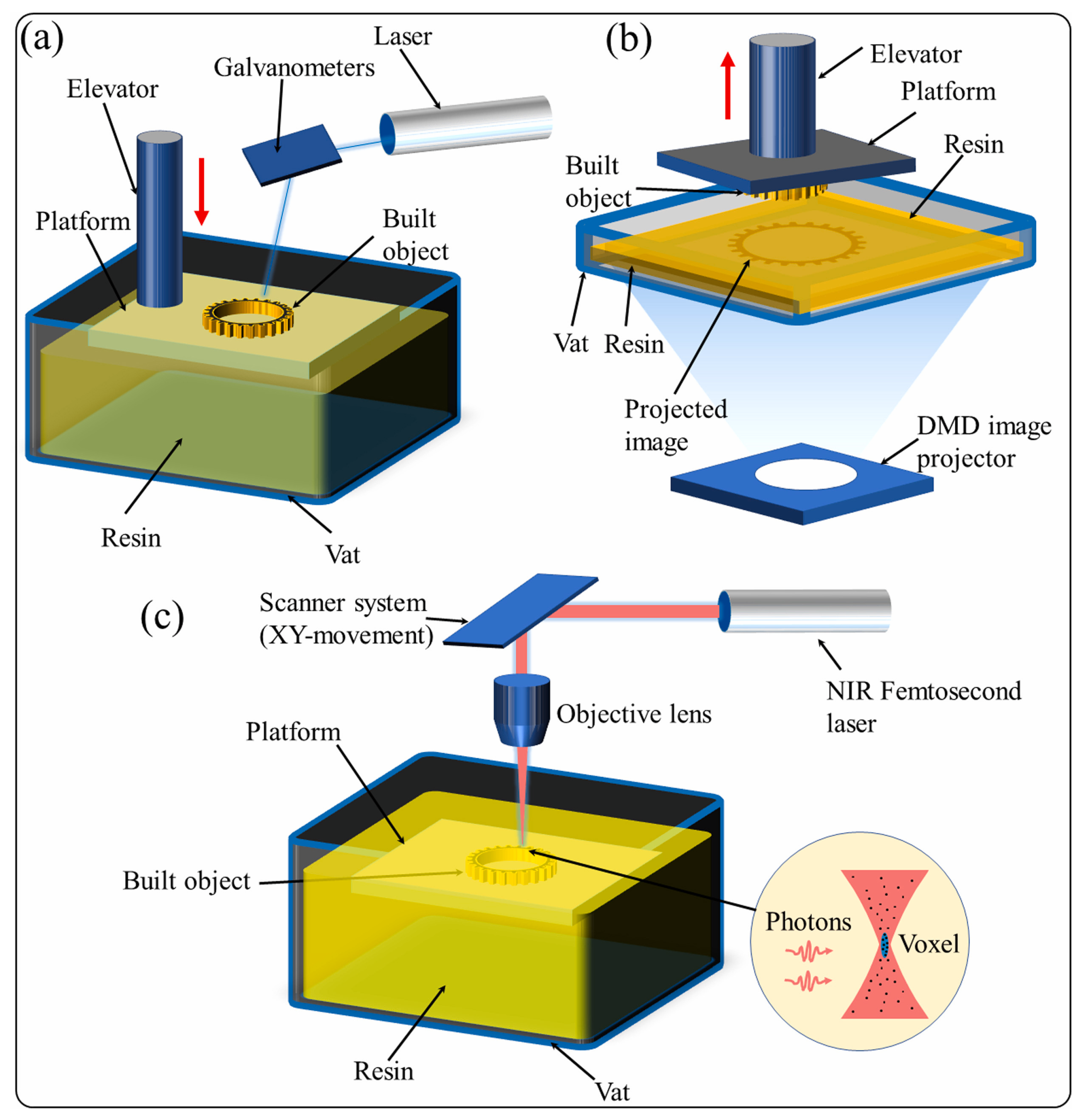

2. Principle of 3D Printing Ceramics Based on Vat Photopolymerization

| Method | Resolution | Advantage | Disadvantage | Refs. |

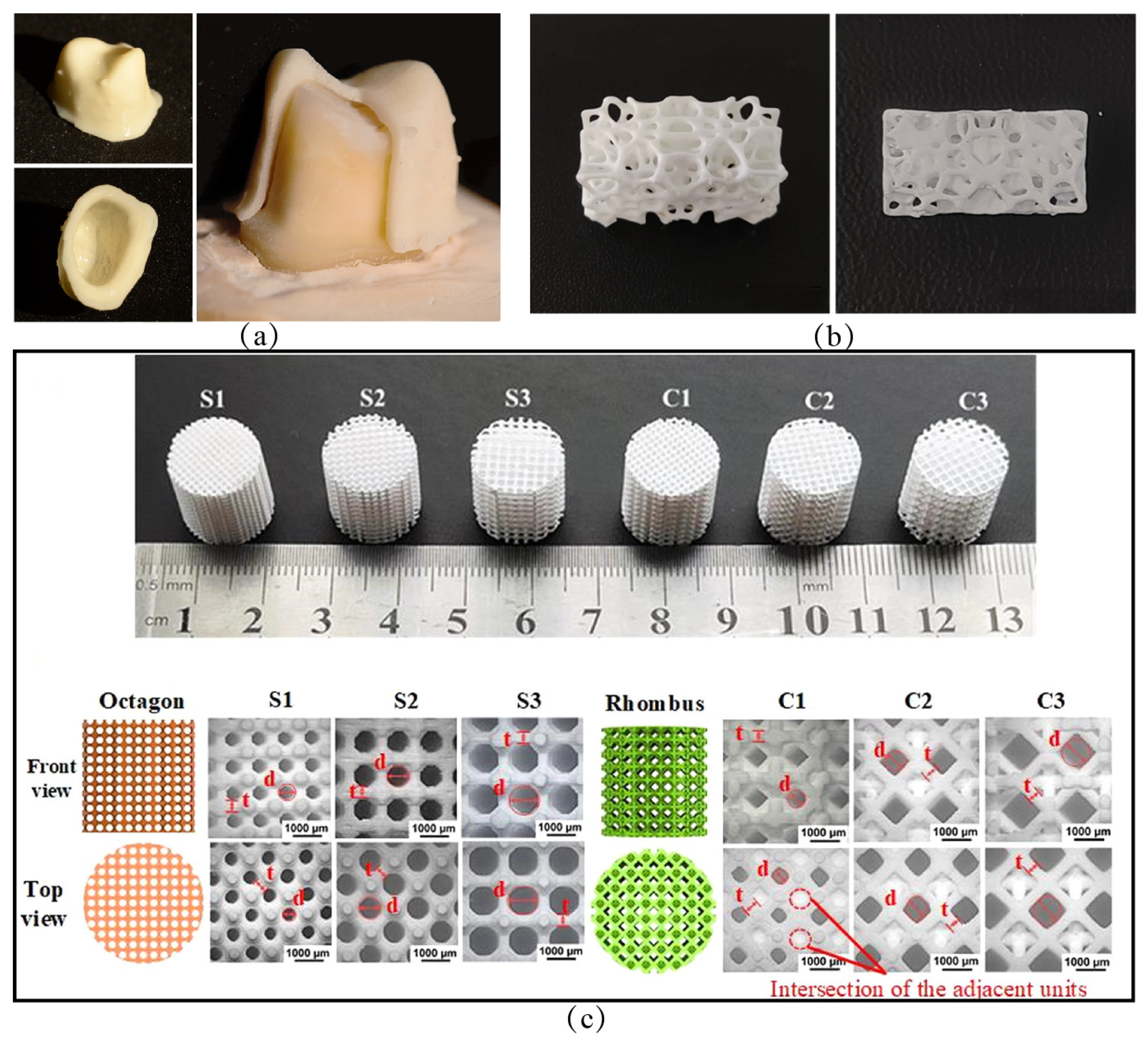

|---|---|---|---|---|

| SLA | 25–50 μm | High quality, high precision, and smooth surface | Slow speed, limited print size, and sensitivity to environmental conditions | [57] |

| DLP | 10–50 μm | High precision, high detail representation, and fast speed | Limited print size and high resin cost | [58,59,60] |

| LCD | 40–50 μm | Low cost and fast speed | Limited LCD screen lifespan and limited print size | [61] |

| TPP | Micro/sub-micron | Ultra-high precision, no support structures needed | Slow speed, high equipment cost complex technical complexity | [62,63] |

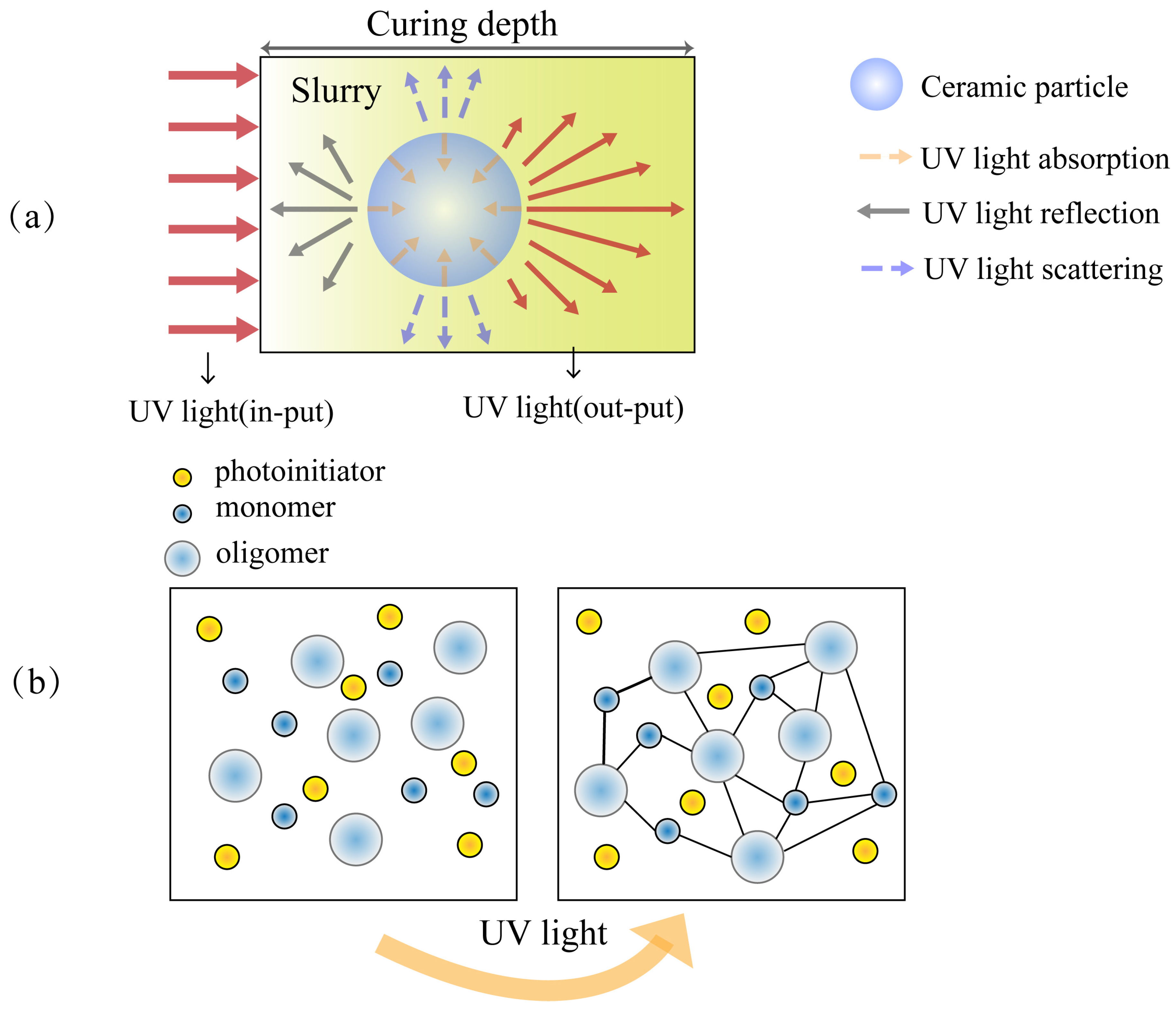

3. Optimization of Al2O3 Ceramic Slurry

3.1. Composition of Al2O3 Ceramic Slurry

3.2. Physical and Chemical Properties of Al2O3 Powders

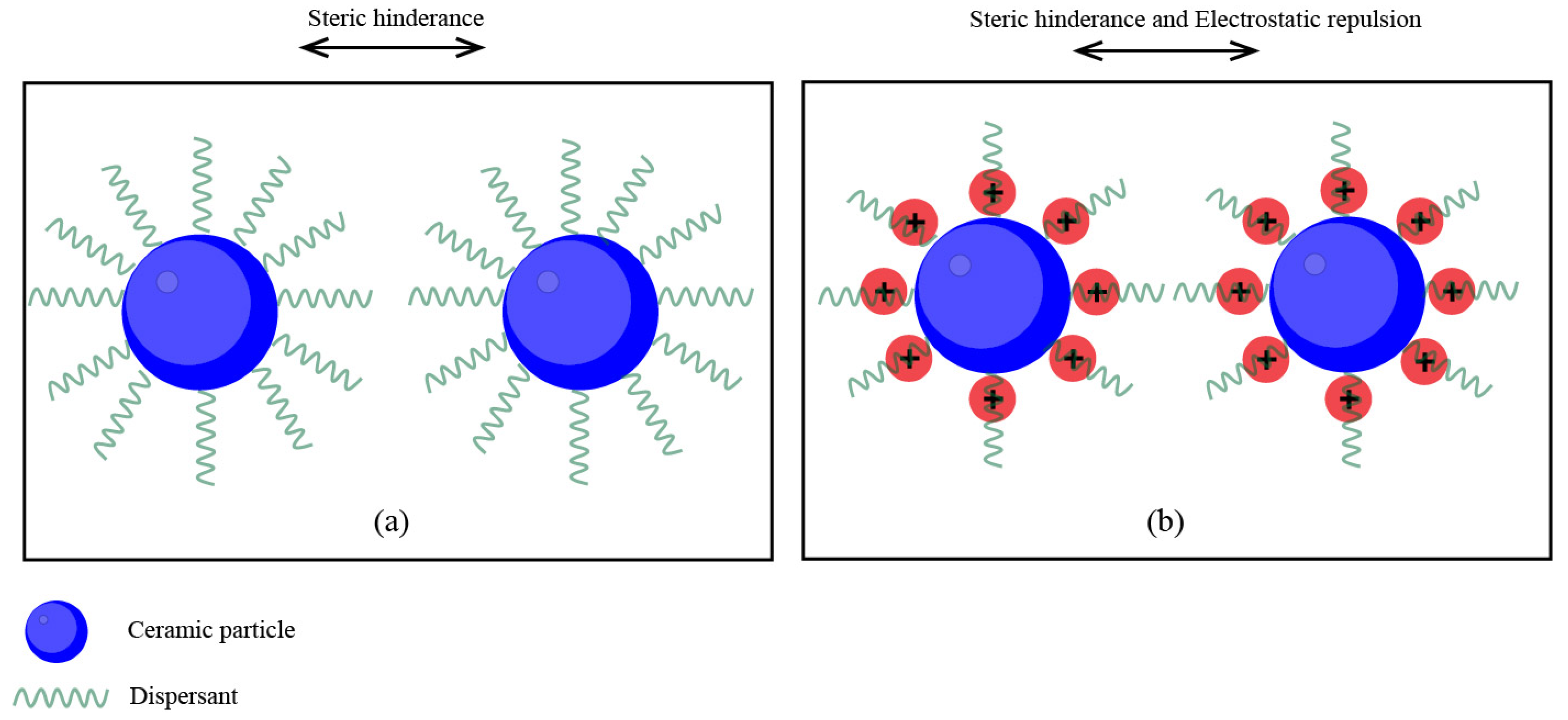

3.3. Resins and Dispersants

3.4. Al2O3-Based Composite Ceramic Slurry

4. Effect of VPP Process on Properties and Accuracy of 3D-Printed Al2O3 Ceramics

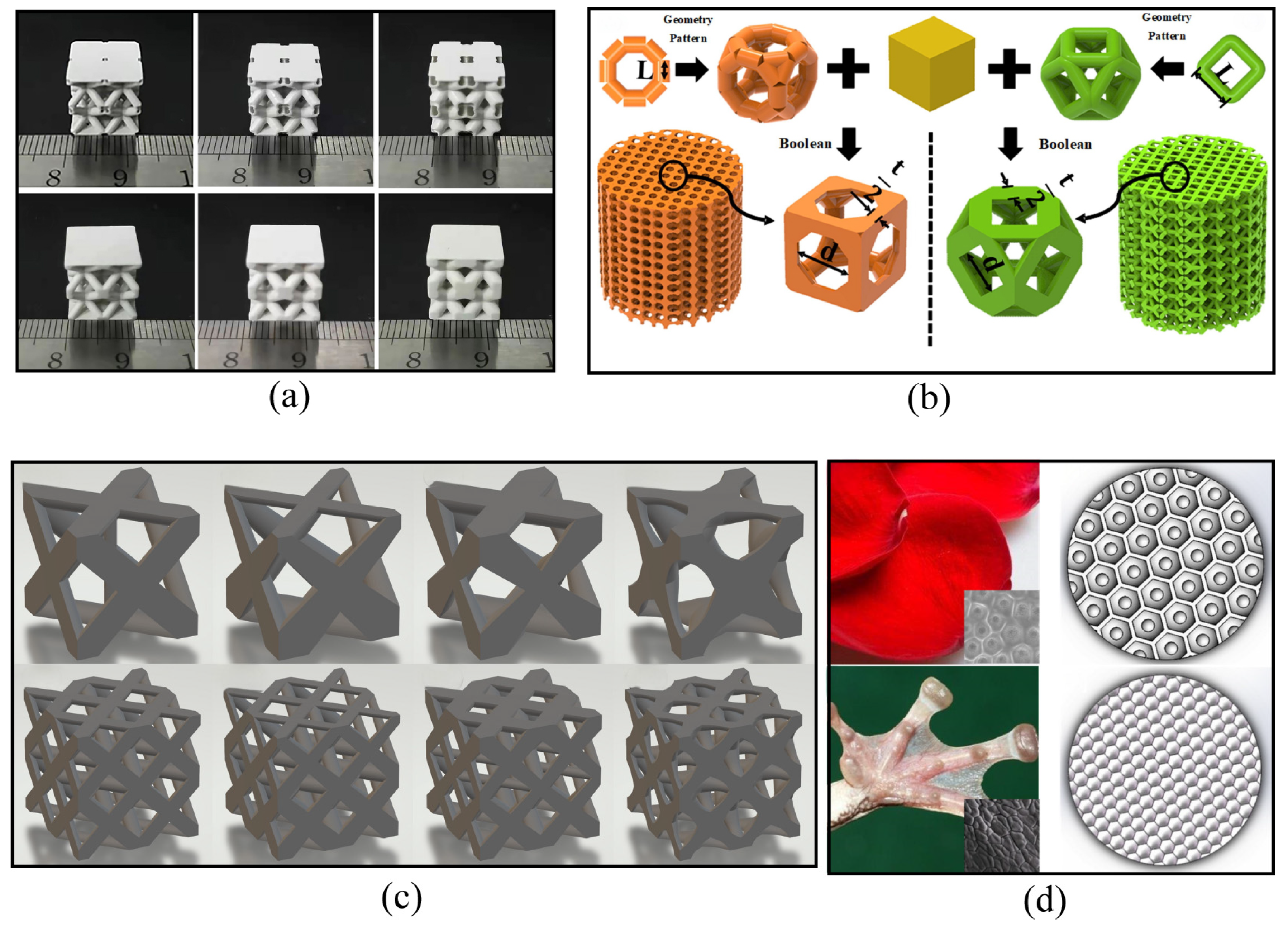

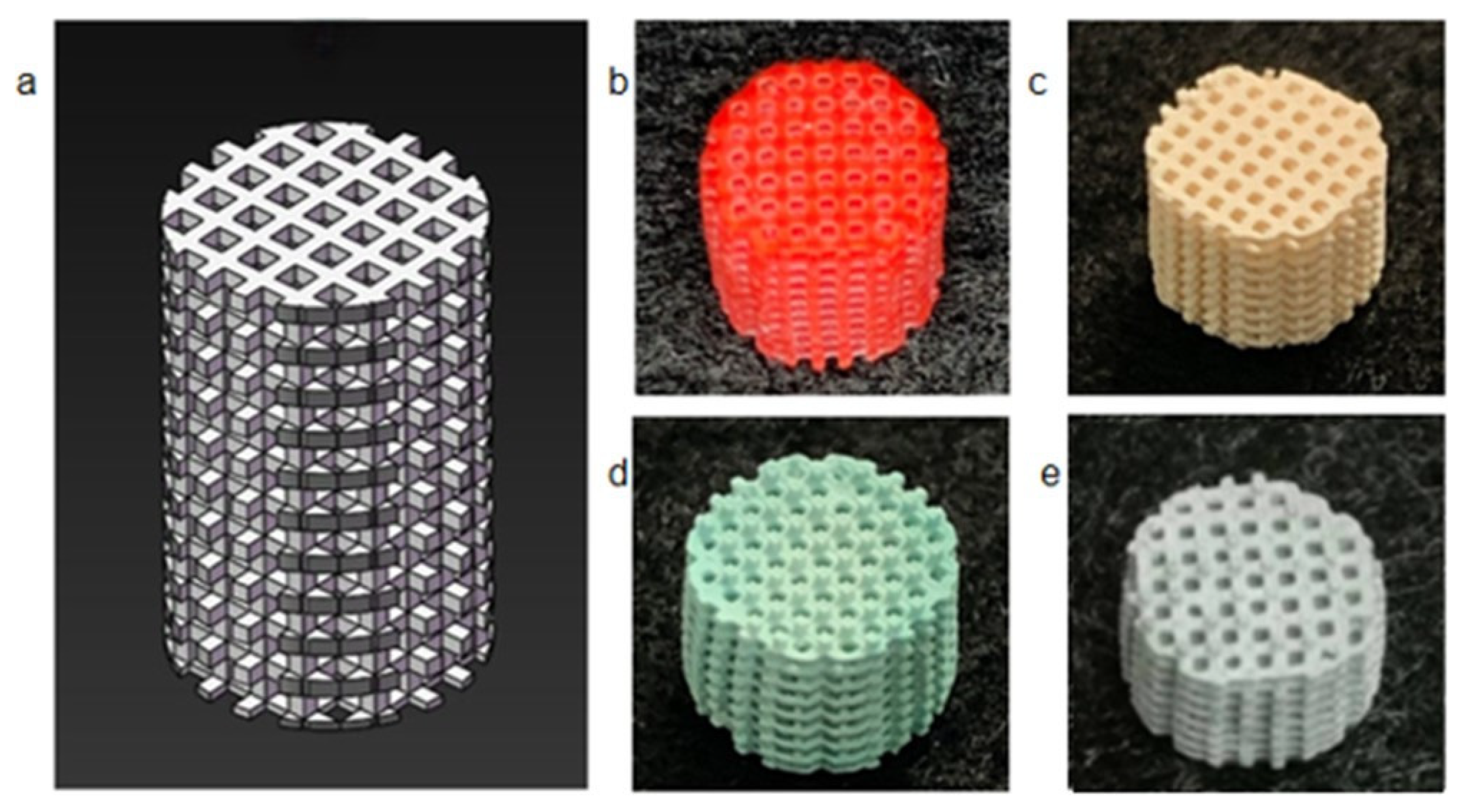

4.1. Structural Design and Printing Process Parameters

4.2. Influence of the Debinding Process for Al2O3 Ceramic Body via VPP

4.3. Influence of the Sintering Process for Al2O3 Ceramic Body via VPP

5. The Properties, Applications, and Challenges of Al2O3 Ceramic via VPP

5.1. Ceramic Core

| Approach | Porosity (%) | Flexural Strength (MPa) | Shrinkage X Axis | Shrinkage Y Axis | Shrinkage Z Axis | Ref. |

|---|---|---|---|---|---|---|

| Bimodal particle size ceramic slurry | 30.07 | 28.21 | 3.98% | - | - | [154] |

| Combining the VPP with sacrificial templating | 36.93 | 75.4 | 7.91% | 9.1% | 12.51% | [155] |

| Powder gradation design | 36.4 | 50.1 | 15.6% | - | - | [156] |

| Pore former and triple sintering | - | 39.8 | 3% | 4% | 3% | [132] |

| Using SiO2 and Y2O3 as mineralizer | 19.3 | 30.5 | 3.4% | 3.1% | 4.5% | [157] |

| Atmosphere-controlled in situ oxidation of aluminum powder | 45.02 | 72.7 | 0.3%. | - | 1.4% | [133] |

| Add CaO | 50.4 | 24 | 23.5% | 19.8% | 16.5% | [140] |

| Vacuum sol impregnation | - | 92.57 | - | - | - | [158] |

| Y3Al5O12 (YAG)-enhanced alumina-based ceramic cores | 40.8 | 16.1 | 3.8% | 3.7% | 4.8% | [159] |

| Buried combustion method | 36.71 | 25 | 6.45% | 7.67% | 4.92% | [160] |

| Control sintering temperature(1400 °C) | 35.1 | 20.3 | - | - | - | [161] |

| In situ mullite-reinforce | 40 | 25 | 5.2% | 6.5% | 6% | [162] |

5.2. Chemical Catalysis

5.3. Friction, Wear and Lubrication

5.4. Biomedical Applications

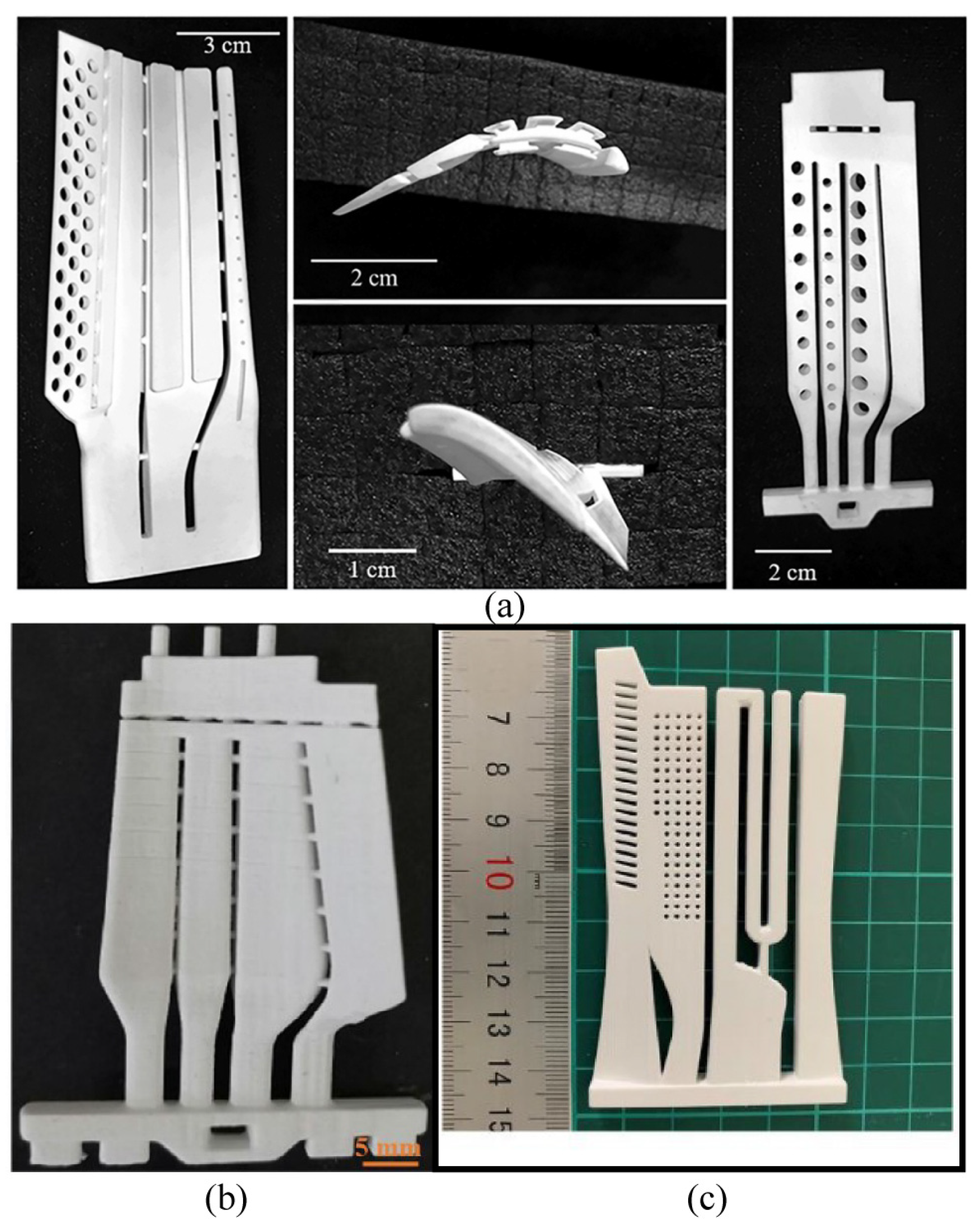

5.5. Large-Size Additive Manufacturing Based on VPP

5.6. Applications of VPP-Printed Al2O3 Ceramic Substrates in the Electronics Industry

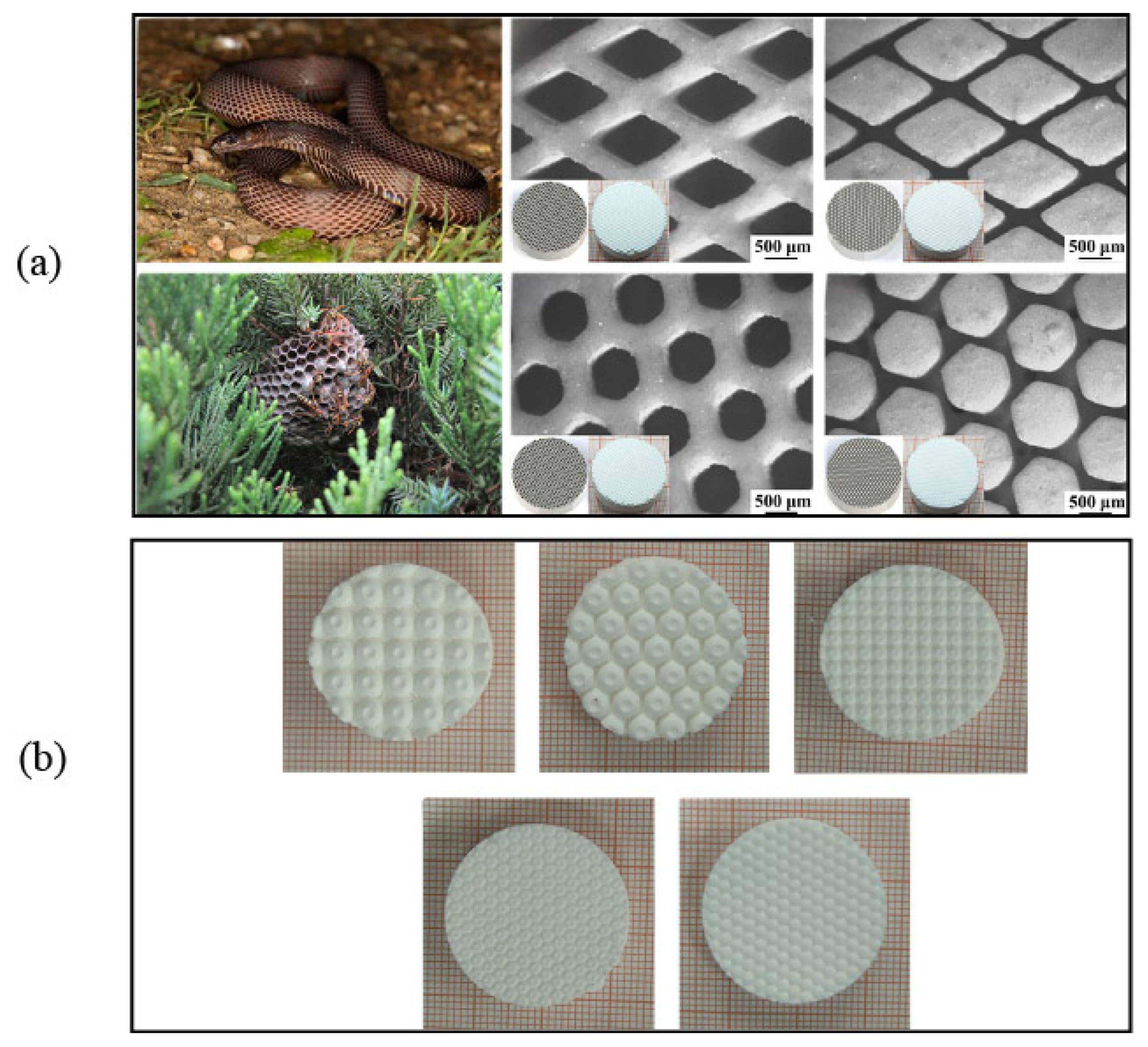

5.7. Ceramic Filter Membranes

6. Conclusions and Prospect

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, T.; Huang, G. State-of-the-art research progress and challenge of the printing techniques, potential applications for advanced ceramic materials 3D printing. Mater. Today Commun. 2024, 40, 110001. [Google Scholar] [CrossRef]

- Lu, X.; Liu, G.; Lu, J. Development of Ceramic 3D/4D Printing in China. Addit. Manuf. Front. 2024, 3, 200158. [Google Scholar] [CrossRef]

- Tian, X.; Li, D.; Lian, Q.; Wang, L.; Lu, Z.; Huang, K.; Wang, F.; Liang, Q.; Zhang, H.; Meng, Z.; et al. Additive Manufacturing of Integrated Micro/Macro Structures Driven by Diversified Functions–30 years of Development of Additive Manufacturing in Xi’an Jiaotong University. Addit. Manuf. Front. 2024, 3, 200140. [Google Scholar] [CrossRef]

- Wang, Y.; Bu, Y.; Wang, X. Advances in 3D printing of structural and functional ceramics: Technologies, properties, and applications. J. Eur. Ceram. Soc. 2024, 44, 116653. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Zhang, X.; Meng, Q.; Zhang, K.; Zhu, R.; Qu, Z.; Li, Y.; He, R. 3D-printed bioinspired Al2O3/polyurea dual-phase architecture with high robustness, energy absorption, and cyclic life. Chem. Eng. J. 2023, 463, 142378. [Google Scholar] [CrossRef]

- Ludwig, T.; von Seckendorff, J.; Troll, C.; Fischer, R.; Tonigold, M.; Rieger, B.; Hinrichsen, O. Additive Manufacturing of Al2O3-Based Carriers for Heterogeneous Catalysis. Chem. Ing. Tech. 2018, 90, 703–707. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E.; Tay, B.Y.; Zhao, Z.; Zhao, L.; Tian, Z.; Yang, S. Direct selective laser sintering and melting of ceramics: A review. Rapid Prototyp. J. 2017, 23, 611–623. [Google Scholar] [CrossRef]

- Solomon, I.J.; Sevvel, P.; Gunasekaran, J. A review on the various processing parameters in FDM. Mater. Today Proc. 2021, 37, 509–514. [Google Scholar] [CrossRef]

- Ndinisa, S.S.; Whitefield, D.J.; Sigalas, I. Fabrication of complex shaped alumina parts by gelcasting on 3D printed moulds. Ceram. Int. 2020, 46, 3177–3182. [Google Scholar] [CrossRef]

- Xie, H.; Yang, X.; Liu, P.; Xu, X.; Zhou, Z.; Zhao, W.; Shen, Z. 3D gel printing of alumina ceramics followed by efficient multi-step liquid desiccant drying. J. Eur. Ceram. Soc. 2021, 41, 6634–6640. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, J.; Jiang, P.; Liu, D.; Jia, X.; Wang, X.; Zhou, F. Direct ink writing of aluminum-phosphate-bonded Al2O3 ceramic with ultra-low dimensional shrinkage. Ceram. Int. 2022, 48, 864–871. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, J.; He, W.; Liu, Y.; Sang, X.; Liu, R. 3D printing of unsupported multi-scale and large-span ceramic via near-infrared assisted direct ink writing. Nat. Commun. 2023, 14, 2381. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Chen, X.; He, Y.; Cheng, L.; Huo, M.; Yin, J.; Hao, F.; Chen, S.; Wang, P.; et al. Additive manufacturing of structural materials. Mater. Sci. Eng. R Rep. 2021, 145, 100596. [Google Scholar] [CrossRef]

- Stumpf, M.; Travitzky, N.; Greil, P.; Fey, T. Sol-gel infiltration of complex cellular indirect 3D printed alumina. J. Eur. Ceram. Soc. 2018, 38, 3603–3609. [Google Scholar] [CrossRef]

- Wang, R.; Yuan, C.; Cheng, J.; He, X.; Ye, H.; Jian, B.; Li, H.; Bai, J.; Ge, Q. Direct 4D printing of ceramics driven by hydrogel dehydration. Nat. Commun. 2024, 15, 758. [Google Scholar] [CrossRef]

- Chaudhary, R.P.; Parameswaran, C.; Idrees, M.; Rasaki, A.S.; Liu, C.; Chen, Z.; Colombo, P. Additive manufacturing of polymer-derived ceramics: Materials, technologies, properties and potential applications. Prog. Mater. Sci. 2022, 128, 100969. [Google Scholar] [CrossRef]

- Li, Y.; Sheng, P.; Lin, L.; Wang, L.; Lu, D.; Lin, K.; Wu, H.; Wu, S. Vat Photopolymerization versus Conventional Colloidal Processing Methods in Structural Ceramics: Progress, Challenges, and Future Perspectives. Addit. Manuf. Front. 2024, 3, 200110. [Google Scholar] [CrossRef]

- Schwarzer-Fischer, E.; Abel, J.; Sieder-Katzmann, J.; Propst, M.; Bach, C.; Scheithauer, U.; Michaelis, A. Study on CerAMfacturing of Novel Alumina Aerospike Nozzles by Lithography-Based Ceramic Vat Photopolymerization (CerAM VPP). Materials 2022, 15, 3279. [Google Scholar] [CrossRef]

- Sheng, P.; Nie, G.; Li, Y.; Wang, L.; Chen, J.; Deng, X.; Wu, S. Enhanced curing behavior, mechanical and thermal properties of 3D printed aluminum nitride ceramics using a powder coating strategy. Addit. Manuf. 2023, 74, 103732. [Google Scholar] [CrossRef]

- Yao, Y.; Cui, H.; Wang, W.; Xing, B.; Zhao, Z. High Performance Dental Zirconia Ceramics Fabricated by Vat Photopolymerization Based on Aqueous Suspension. J. Eur. Ceram. Soc. 2024, 44, 116795. [Google Scholar] [CrossRef]

- Branco, A.C.; Colaco, R.; Figueiredo-Pina, C.G.; Serro, A.P. Recent Advances on 3D-Printed Zirconia-Based Dental Materials: A Review. Materials 2023, 16, 1860. [Google Scholar] [CrossRef]

- Fu, Q.; Sui, S.; Ma, Y.; Sun, S.; Wang, X.; Meng, Q.; Li, S.; Zhao, Y. Silicon carbide whiskers reinforced silicon carbide ceramics prepared by vat photopolymerization and liquid silicon infiltration. Ceram. Int. 2024, 50, 17747–17755. [Google Scholar] [CrossRef]

- Li, Y.; Wu, H.; Chen, X.; Huang, P.; Huang, Z.; Wu, S. Vat photopolymerization of complex-shaped silicon nitride ceramics with high mechanical and thermal performance by optimization sintering aids and kinetics. J. Eur. Ceram. Soc. 2025, 45, 117014. [Google Scholar] [CrossRef]

- Shen, M.; Fu, R.; Zhang, Y.; Sun, K.; Xu, W.; Jiang, Y.; Zhao, Z.; Liu, M. Defect-free Si3N4 ceramics by vat photopolymerization 3D printing with nitrogen-hydrogen debinding atmosphere. Ceram. Int. 2024, 50, 42709–42720. [Google Scholar] [CrossRef]

- Wang, Z.H.; Zhang, Y.Z.; Miao, W.J.; Wu, F.B.; Wang, S.Q.; Ouyang, J.H.; Wang, Y.M.; Zou, Y.C. Vat Photopolymerization-Based Additive Manufacturing of Si3N4 Ceramic Structures: Printing Optimization, Debinding/Sintering, and Applications. Materials 2025, 18, 1556. [Google Scholar] [CrossRef]

- Wen, X.; Zhang, B.; Wang, W.; Ye, F.; Yue, S.; Guo, H.; Gao, G.; Zhao, Y.; Fang, Q.; Nguyen, C.; et al. 3D-printed silica with nanoscale resolution. Nat. Mater. 2021, 20, 1506–1511. [Google Scholar] [CrossRef]

- Falegnami, A.; Tomassi, A.; Gunella, C.; Amalfitano, S.; Corbelli, G.; Armonaite, K.; Fornaro, C.; Giorgi, L.; Pollini, A.; Caforio, A.; et al. Defining conceptual artefacts to manage and design simplicities in complex adaptive systems. Heliyon 2024, 10, e41033. [Google Scholar] [CrossRef]

- Tomassi, A.; Falegnami, A.; Romano, E. Talking Resilience: Embedded Natural Language Cyber-Organizations by Design. Systems 2025, 13, 247. [Google Scholar] [CrossRef]

- Farrokhnemoun, D.; Sajjadivand, S.; Parapari, S.S.; Sturm, S.; Ow-Yang, C.W.; Gulgun, M.A. Influence of sodium hydroxide on phase transformation of gamma alumina to alpha alumina. J. Am. Ceram. Soc. 2023, 107, 3451–3463. [Google Scholar] [CrossRef]

- Wang, F.; Li, Z.; Lou, Y.; Zeng, F.; Hao, M.; Lei, W.; Wang, X.; Wang, X.; Fan, G.; Lu, W. Stereolithographic additive manufacturing of Luneburg lens using Al2O3-based low sintering temperature ceramics for 5G MIMO antenna. Addit. Manuf. 2021, 47, 102244. [Google Scholar] [CrossRef]

- Chen, T.; Wang, D.; Chen, X.; Qiu, M.; Fan, Y. Three-dimensional printing of high-flux ceramic membranes with an asymmetric structure via digital light processing. Ceram. Int. 2022, 48, 304–312. [Google Scholar] [CrossRef]

- Zhang, G.; Zou, B.; Wang, X.; Yu, Y.; Chen, Q. Design, manufacturing and properties of controllable porosity of ceramic filters based on SLA-3D printing technology. Ceram. Int. 2023, 49, 1009–1019. [Google Scholar] [CrossRef]

- Zhang, G.; Zou, B.; Wang, X.; Yu, Y.; Huang, C.; Zhu, H.; Yao, P.; Liu, H. The 3D-Printed building and performance of Al2O3 ceramic filters with gradient hole density structures. Ceram. Int. 2023, 49, 31496–31508. [Google Scholar] [CrossRef]

- Gomez, A.; Yelamanchi, B.; Maurel, A.; Martinez, A.C.; Feldhausen, T.; Shivakumar, J.; Rojas, E.; Lin, Y.; Cortes, P.; MacDonald, E.; et al. 3D Printed Alumina for Geometrically-Complex Electronic Substrates With High-Performance Printed Conductors. IEEE Access 2024, 12, 92295–92305. [Google Scholar] [CrossRef]

- Li, H.; Hu, Y.; Tang, X.; Zhao, Y.; Li, M.; Zhao, Y.; Luo, H.; Lai, Q.; Xing, H. Biomechanical and Biological Properties of Stereolithography-Based 3D-Printed Zirconia Interference Screws for Anterior Cruciate Ligament Reconstruction. Addit. Manuf. Front. 2024, 3, 200135. [Google Scholar] [CrossRef]

- Ye, Z.; Hao, Z.; Dou, R.; Wang, L.; Tang, W. Innovative ceramic paste for stereolithography additive manufacturing alumina core applied in turbine blade casting. Int. J. Appl. Ceram. Technol. 2024, 21, 2824–2831. [Google Scholar] [CrossRef]

- Yun, J.S.; Park, T.-W.; Jeong, Y.H.; Cho, J.H. Development of ceramic-reinforced photopolymers for SLA 3D printing technology. Appl. Phys. A 2016, 122, 629. [Google Scholar] [CrossRef]

- Li, X.; Chen, Y. Vat-Photopolymerization-Based Ceramic Manufacturing. J. Mater. Eng. Perform. 2021, 30, 4819–4836. [Google Scholar] [CrossRef]

- Medvedovski, E. Alumina–mullite ceramics for structural applications. Ceram. Int. 2006, 32, 369–375. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, K.; Chen, J.; Wei, K.; Liang, B.; He, R. Design and additive manufacturing of 3D-architected ceramic metamaterials with programmable thermal expansion. Addit. Manuf. 2021, 47, 102338. [Google Scholar] [CrossRef]

- Li, X.; Yan, L.; Guo, A.; Du, H.; Hou, F.; Liu, J. Lightweight porous silica-alumina ceramics with ultra-low thermal conductivity. Ceram. Int. 2023, 49, 6479–6486. [Google Scholar] [CrossRef]

- Chen, H.; Pan, Y.; Chen, B.; Li, J.; Gui, Z.; Chen, J.; Yan, H.; Zeng, Y.; Chen, J. Fabrication of porous aluminum ceramics beyond device resolution via stereolithography 3D printing. Ceram. Int. 2023, 49, 18463–18469. [Google Scholar] [CrossRef]

- Man, Y.; Ding, G.; Xudong, L.; Xue, K.; Qu, D.; Xie, Z. A review on porous ceramics with hierarchical pore structure by 3D printing-based combined route. J. Asian Ceram. Soc. 2021, 9, 1377–1389. [Google Scholar] [CrossRef]

- Hu, K.; Zhao, P.; Li, J.; Lu, Z. High-resolution multiceramic additive manufacturing based on digital light processing. Addit. Manuf. 2022, 54, 102732. [Google Scholar] [CrossRef]

- Oezkan, B.; Sameni, F.; Karmel, S.; Engstrøm, D.S.; Sabet, E. A systematic study of vat-polymerization binders with potential use in the ceramic suspension 3D printing. Addit. Manuf. 2021, 47, 102225. [Google Scholar] [CrossRef]

- Dong, Y.; Dong, T.; Yang, Z.; Luo, A.; Hong, Z.; Lao, G.; Huang, H.; Fan, B. The influences of light scattering on digital light processing high-resolution ceramic additive manufacturing. Ceram. Int. 2024, 50, 9556–9562. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3D Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef]

- Yao, X.; Hu, J.; Li, X.; Wei, W.; Liu, R.; Liu, J. 3D printing of high solid Al2O3 ceramics based on green and renewable photosensitive resin with low viscosity and low shrinkage. Polym. Adv. Technol. 2024, 35, e6330. [Google Scholar] [CrossRef]

- Badev, A.; Abouliatim, Y.; Chartier, T.; Lecamp, L.; Lebaudy, P.; Chaput, C.; Delage, C. Photopolymerization kinetics of a polyether acrylate in the presence of ceramic fillers used in stereolithography. J. Photochem. Photobiol. A Chem. 2011, 222, 117–122. [Google Scholar] [CrossRef]

- Griffith, M.L.; Halloran, J.W. Freeform Fabrication of Ceramics via Stereolithography. J. Am. Ceram. Soc. 2005, 79, 2601–2608. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, X.; Shang, Y.; Xiong, K.; Xu, Z.; Guo, R.; Cai, S.; Zheng, C. Dense ceramics with complex shape fabricated by 3D printing: A review. J. Adv. Ceram. 2021, 10, 195–218. [Google Scholar] [CrossRef]

- Shaukat, U.; Rossegger, E.; Schlogl, S. A Review of Multi-Material 3D Printing of Functional Materials via Vat Photopolymerization. Polymers 2022, 14, 2449. [Google Scholar] [CrossRef]

- Deshmane, S.; Kendre, P.; Mahajan, H.; Jain, S. Stereolithography 3D printing technology in pharmaceuticals: A review. Drug Dev. Ind. Pharm. 2021, 47, 1362–1372. [Google Scholar] [CrossRef]

- Meana, V.; Zapico, P.; Cuesta, E.; Giganto, S.; Meana, L.; Martínez-Pellitero, S. Additive Manufacturing of Ceramic Reference Spheres by Stereolithography (SLA). Appl. Sci. 2024, 14, 7530. [Google Scholar] [CrossRef]

- Zakeri, S.; Vippola, M.; Levänen, E. A comprehensive review of the photopolymerization of ceramic resins used in stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar] [CrossRef]

- Nam, J.; Kim, M. Advances in materials and technologies for digital light processing 3D printing. Nano Converg. 2024, 11, 45. [Google Scholar] [CrossRef]

- Chen, Z.; Li, J.; Liu, C.; Liu, Y.; Zhu, J.; Lao, C. Preparation of high solid loading and low viscosity ceramic slurries for photopolymerization-based 3D printing. Ceram. Int. 2019, 45, 11549–11557. [Google Scholar] [CrossRef]

- Hussain, M.I.; Xia, M.; Ren, X.; Shen, Z.; Jamil, M.; Ge, C. Recent advances in photopolymerization 3D printing of alumina-ceramic. Prog. Nat. Sci. Mater. Int. 2025, 35, 1–30. [Google Scholar] [CrossRef]

- Chekkaramkodi, D.; Jacob, L.; Shebeeb, C.M.; Umer, R.; Butt, H. Review of vat photopolymerization 3D printing of photonic devices. Addit. Manuf. 2024, 86, 104189. [Google Scholar] [CrossRef]

- Mahmood, M.A.; Popescu, A.C. 3D Printing at Micro-Level: Laser-Induced Forward Transfer and Two-Photon Polymerization. Polymers 2021, 13, 2034. [Google Scholar] [CrossRef]

- Harinarayana, V.; Shin, Y.C. Two-photon lithography for three-dimensional fabrication in micro/nanoscale regime: A comprehensive review. Opt. Laser Technol. 2021, 142, 107180. [Google Scholar] [CrossRef]

- Zhang, F.; Zhu, L.; Li, Z.; Wang, S.; Shi, J.; Tang, W.; Li, N.; Yang, J. The recent development of vat photopolymerization: A review. Addit. Manuf. 2021, 48, 102423. [Google Scholar] [CrossRef]

- Chaudhary, R.; Fabbri, P.; Leoni, E.; Mazzanti, F.; Akbari, R.; Antonini, C. Additive manufacturing by digital light processing: A review. Prog. Addit. Manuf. 2022, 8, 331–351. [Google Scholar] [CrossRef]

- Hussain, M.I.; Xia, M.; Ren, X.; Ge, C.; Jamil, M.; Gupta, M.K. Digital light processing 3D printing of ceramic materials: A review on basic concept, challenges, and applications. Int. J. Adv. Manuf. Technol. 2023, 130, 2241–2267. [Google Scholar] [CrossRef]

- Wang, J.-C.; Dommati, H.; Hsieh, S.-J. Review of additive manufacturing methods for high-performance ceramic materials. Int. J. Adv. Manuf. Technol. 2019, 103, 2627–2647. [Google Scholar] [CrossRef]

- Truxova, V.; Safka, J.; Seidl, M.; Kovalenko, I.; Volensky, L.; Ackermann, M. Ceramic 3D Printing: Comparison of Sla and Dlp Technologies. MM Sci. J. 2020, 2020, 3905–3911. [Google Scholar] [CrossRef]

- Moshkovitz-Douvdevany, M.Y.; Reisinger, A.; Savraeva, D.; Magdassi, S. 3D printing of ceramics and glass based on photopolymerizable sol–gel compositions. MRS Commun. 2025. [Google Scholar] [CrossRef]

- Nohut, S.; Schlacher, J.; Kraleva, I.; Schwentenwein, M.; Bermejo, R. 3D-printed alumina-based ceramics with spatially resolved porosity. Int. J. Appl. Ceram. Technol. 2023, 21, 89–104. [Google Scholar] [CrossRef]

- Maleksaeedi, S.; Eng, H.; Wiria, F.E.; Ha, T.M.H.; He, Z. Property enhancement of 3D-printed alumina ceramics using vacuum infiltration. J. Mater. Process. Technol. 2014, 214, 1301–1306. [Google Scholar] [CrossRef]

- Hussain, M.I.; Xia, M.; Ren, X.; Ge, C.; Shen, Z. Microstructural evolution, enhanced mechanical properties, and complex shapes design in high solid content alumina ceramics through additive manufacturing. J. Manuf. Process. 2024, 129, 35–50. [Google Scholar] [CrossRef]

- Liu, W.; Li, M.; Nie, J.; Wang, C.; Li, W.; Xing, Z. Synergy of solid loading and printability of ceramic paste for optimized properties of alumina via stereolithography-based 3D printing. J. Mater. Res. Technol. 2020, 9, 11476–11483. [Google Scholar] [CrossRef]

- Yang, Y.K.; Yeh, T.L.; Chen, C.C.; Lee, C.K.; Lee, I.H.; Lee, L.C.; Jeffries, K.J. Psychiatric morbidity and posttraumatic symptoms among earthquake victims in primary care clinics. Gen. Hosp. Psychiatry 2003, 25, 253–261. [Google Scholar] [CrossRef]

- Camargo, I.L.d.; Morais, M.M.; Fortulan, C.A.; Branciforti, M.C. A review on the rheological behavior and formulations of ceramic suspensions for vat photopolymerization. Ceram. Int. 2021, 47, 11906–11921. [Google Scholar] [CrossRef]

- Xu, X.; Zhou, S.; Wu, J.; Liu, S.; Ma, S.; Cheng, T. Study of alumina ceramic parts fabricated via DLP stereolithography using powders with different sizes and morphologies. Int. J. Appl. Ceram. Technol. 2022, 20, 1167–1193. [Google Scholar] [CrossRef]

- Yang, K.; Xu, S.; Li, B. The influence mechanism of nano-alumina content in semi-solid ceramic precursor fluid on the forming performance via a light-cured 3D printing method. RSC Adv. 2020, 10, 41453–41461. [Google Scholar] [CrossRef]

- Yang, H.; He, T.; Lv, Q.; Huang, X.; San, Y.; Xu, X.; Xiong, J.; Liu, J. Effects of powder morphology on stereolithography additive manufactured Al2O3 ceramic. J. Mater. Res. Technol. 2024, 29, 504–510. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Tian, Y.; Xiao, S.; Li, J.; Han, G. Photosensitive Al2O3 slurry with high solid content and low viscosity. J. Korean Ceram. Soc. 2023, 60, 581–590. [Google Scholar] [CrossRef]

- Trembecka-Wojciga, K.; Ortyl, J. Enhancing 3D printed ceramic components: The function of dispersants, adhesion promoters, and surface-active agents in Photopolymerization-based additive manufacturing. Adv. Colloid Interface Sci. 2024, 332, 103251. [Google Scholar] [CrossRef]

- Xing, H.; Zou, B.; Lai, Q.; Huang, C.; Chen, Q.; Fu, X.; Shi, Z. Preparation and characterization of UV curable Al2O3 suspensions applying for stereolithography 3D printing ceramic microcomponent. Powder Technol. 2018, 338, 153–161. [Google Scholar] [CrossRef]

- Goswami, A.; Ankit, K.; Balashanmugam, N.; Umarji, A.M.; Madras, G. Optimization of rheological properties of photopolymerizable alumina suspensions for ceramic microstereolithography. Ceram. Int. 2014, 40, 3655–3665. [Google Scholar] [CrossRef]

- Tanurdjaja, S.; Tallon, C.; Scales, P.J.; Franks, G.V. Influence of dispersant size on rheology of non-aqueous ceramic particle suspensions. Adv. Powder Technol. 2011, 22, 476–481. [Google Scholar] [CrossRef]

- Singh, B.P.; Menchavez, R.; Takai, C.; Fuji, M.; Takahashi, M. Stability of dispersions of colloidal alumina particles in aqueous suspensions. J. Colloid Interface Sci. 2005, 291, 181–186. [Google Scholar] [CrossRef]

- Yu, Y.; Zou, B.; Wang, X.; Huang, C. Rheological behavior and curing deformation of paste containing 85 wt% Al2O3 ceramic during SLA-3D printing. Ceram. Int. 2022, 48, 24560–24570. [Google Scholar] [CrossRef]

- Morita, S.; Iijima, M.; Chen, Y.; Furukawa, T.; Tatami, J.; Maruo, S. 3D structuring of dense alumina ceramics using fiber-based stereolithography with interparticle photo-cross-linkable slurry. Adv. Powder Technol. 2021, 32, 72–79. [Google Scholar] [CrossRef]

- Alves, P.L.A.; Verza, J.R.; Luz, A.P. Rheological Behavior of Alumina Suspensions for Additive Manufacturing Using Digital Light Processing. Mater. Res. 2023, 26, e20230270. [Google Scholar] [CrossRef]

- Gan, M.; Yi, Y.; Li, T.; Chua, B.W. A simple preparation method and the rheological properties of high solid loading slurries for ceramic vat polymerization. Mater. Today Commun. 2023, 37, 107143. [Google Scholar] [CrossRef]

- De Camargo, I.L.; Erbereli, R.; Lovo, J.F.P.; Fortulan, R.; Fortulan, C.A. Digital light processing additive manufacturing of in situ mullite-zirconia composites. J. Eur. Ceram. Soc. 2022, 42, 6025–6032. [Google Scholar] [CrossRef]

- Sun, L.; Dong, P.; Zeng, Y.; Chen, J. Fabrication of hollow lattice alumina ceramic with good mechanical properties by Digital Light Processing 3D printing technology. Ceram. Int. 2021, 47, 26519–26527. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, Z.; Sun, H.; Sun, C.; Qiu, L.; Shi, Y.; Zhang, S.; Tu, R.; Huang, S.; Du, Y. Fabrication and mechanical properties of triply period minimal surface porous alumina ceramics based on Digital Light Processing 3D printing technology. Int. J. Adv. Manuf. Technol. 2023. [Google Scholar] [CrossRef]

- Zhang, D.; Liang, Z.; Chen, X.; Pang, C.; Guo, X.; Xu, X. Alumina Ceramics for Armor Protection via 3D Printing Using Different Monomers. Materials 2024, 17, 2506. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Y.; Sun, L.; Yao, H.; Chen, J. Fabrication of alumina ceramics with functional gradient structures by digital light processing 3D printing technology. Ceram. Int. 2022, 48, 10613–10619. [Google Scholar] [CrossRef]

- Hsiang, H.-I.; Lee, C.-Y.; Chen, C.-C.; Wang, J.; Tang, D.; Dong, Z. Polycrystalline alumina ceramic fabrication using digital stereolithographic light process. Ceram. Int. 2021, 47, 33815–33826. [Google Scholar] [CrossRef]

- Tanska, J.; Wieclaw-Midor, A.; Misiukiewicz, J.; Falkowski, P.; Zygmuntowicz, J.; Bulejak, W.; Wiecinska, P. Digital Light Processing Followed by Pressureless Sintering of Metal-Reinforced Ceramics: Adjustment of Process Parameters and Correlation with Composites Properties. Int. J. Precis. Eng. Manuf.-Green Technol. 2024, 12, 169–191. [Google Scholar] [CrossRef]

- Han, Z.; Liu, J.; Li, T.; Cao, Y.; Zhang, C.; Wang, Z. Dynamic mechanical properties of alumina prepared by vat photopolymerization based on high solid loading slurry. Addit. Manuf. 2025, 97, 104603. [Google Scholar] [CrossRef]

- Aktas, B.; Das, R.; Acikgoz, A.; Demircan, G.; Yalcin, S.; Aktas, H.G.; Balak, M.V. DLP 3D printing of TiO2-doped Al2O3 bioceramics: Manufacturing, mechanical properties, and biological evaluation. Mater. Today Commun. 2024, 38, 107872. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, W.; Wu, H.; Huang, R.; He, R.; Jiang, Q.; Chen, Y.; Ji, X.; Tian, Z.; Wu, S. Research into the mechanical properties, sintering mechanism and microstructure evolution of Al2O3-ZrO2 composites fabricated by a stereolithography-based 3D printing method. Mater. Chem. Phys. 2018, 207, 1–10. [Google Scholar] [CrossRef]

- Coppola, B.; Lacondemine, T.; Tardivat, C.; Montanaro, L.; Palmero, P. Designing alumina-zirconia composites by DLP-based stereolithography: Microstructural tailoring and mechanical performances. Ceram. Int. 2021, 47, 13457–13468. [Google Scholar] [CrossRef]

- Inserra, B.; Coppola, B.; Montanaro, L.; Tulliani, J.-M.; Palmero, P. Preparation and characterization of Ce-ZrO2/Al2O3 composites by DLP-based stereolithography. J. Eur. Ceram. Soc. 2023, 43, 2907–2916. [Google Scholar] [CrossRef]

- Gu, Q.; Sun, L.; Ji, X.; Wang, H.; Yu, J.; Zhou, X. High-performance and high-precision Al2O3 architectures enabled by high-solid-loading, graphene-containing slurries for top-down DLP 3D printing. J. Eur. Ceram. Soc. 2023, 43, 130–142. [Google Scholar] [CrossRef]

- Nie, G.; Li, Y.; Sheng, P.; Zuo, F.; Wu, H.; Liu, L.; Deng, X.; Bao, Y.; Wu, S. Microstructure refinement-homogenization and flexural strength improvement of Al2O3 ceramics fabricated by DLP-stereolithography integrated with chemical precipitation coating process. J. Adv. Ceram. 2021, 10, 790–808. [Google Scholar] [CrossRef]

- Wang, L.; Wu, H.; Guo, A.; Kong, D.; Zhao, Z.; Liu, C.; Yin, L.; Xia, G.; Su, X.; Chen, Z.; et al. Vat Photopolymerization of Ceramic Parts: Effects of Carbon Fiber Additives on Microstructure and Mechanical Performance. Materials 2024, 17, 3127. [Google Scholar] [CrossRef]

- Shen, W.; Wang, G.; Wang, S.; Kang, J.; Dong, X.; Yang, X.; Wen, D.; Zhang, Y. Effect of Al2O3 whiskers on forming accuracy, mechanical and tribological performances of translucent glass-ceramics formed by 3D printing. J. Eur. Ceram. Soc. 2024, 44, 3236–3246. [Google Scholar] [CrossRef]

- Yang, W.; Meng, X.; Ni, P.; Zhao, Z.; Deng, X.; Wu, S.; Qu, Z.; Jin, F. Additive manufacturing of Al2O3 coated diamond-resin composites via digital light processing. Ceram. Int. 2023, 49, 16891–16900. [Google Scholar] [CrossRef]

- Zhang, L.; Feih, S.; Daynes, S.; Chang, S.; Wang, M.Y.; Wei, J.; Lu, W.F. Pseudo-ductile fracture of 3D printed alumina triply periodic minimal surface structures. J. Eur. Ceram. Soc. 2020, 40, 408–416. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, X.; Meng, Q.; Zhang, B.; Qu, Z.; He, R. Failure Behavior and Mechanism of Vat Photopolymerization Additively Manufactured Al2O3 Ceramic Lattice Structures. Addit. Manuf. Front. 2024, 3, 200172. [Google Scholar] [CrossRef]

- Lei, H.; Song, C.; Liu, Z.; Deng, Z.; Yu, J.; Yuan, F.; Yang, Y. Rational design and additive manufacturing of alumina-based lattice structures for bone implant. Mater. Des. 2022, 221, 111003. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, Y.; Mei, H.; Kong, Z.; Mao, M.; Cheng, L. Excellent lubrication properties of 3D printed ceramic bionic structures. Ceram. Int. 2020, 46, 23463–23470. [Google Scholar] [CrossRef]

- Schlacher, J.; Lube, T.; Harrer, W.; Mitteramskogler, G.; Schwentenwein, M.; Danzer, R.; Bermejo, R. Strength of additive manufactured alumina. J. Eur. Ceram. Soc. 2020, 40, 4737–4745. [Google Scholar] [CrossRef]

- Zhou, W.X.; Chan-Park, M.B. Effect of oligomer length on the buckling of long and high aspect ratio microwalls UV embossed from oligomer/monomer mixtures. Sens. Actuators B Chem. 2007, 128, 12–22. [Google Scholar] [CrossRef]

- Wu, X.; Teng, J.; Ji, X.; Xu, C.; Ma, D.; Sui, S.; Zhang, Z. Research progress of the defects and innovations of ceramic vat photopolymerization. Addit. Manuf. 2023, 65, 103441. [Google Scholar] [CrossRef]

- Li, X.; Su, H.; Dong, D.; Jiang, H.; Liu, Y.; Shen, Z.; Guo, Y.; Zhang, Z.; Guo, M. Selection strategy of curing depth for vat photopolymerization 3D printing of Al2O3 ceramics. Addit. Manuf. 2024, 88, 104240. [Google Scholar] [CrossRef]

- Li, Q.; Qiu, Y.; Hou, W.; Liang, J.; Mei, H.; Li, J.; Zhou, Y.; Sun, X. Slurry flow characteristics control of 3D printed ceramic core layered structure: Experiment and simulation. J. Mater. Sci. Technol. 2023, 164, 215–228. [Google Scholar] [CrossRef]

- Zhao, D.; Su, H.; Hu, K.; Lu, Z.; Li, X.; Dong, D.; Liu, Y.; Shen, Z.; Guo, Y.; Liu, H.; et al. Formation mechanism and controlling strategy of lamellar structure in 3D printed alumina ceramics by digital light processing. Addit. Manuf. 2022, 52, 102650. [Google Scholar] [CrossRef]

- Negi, S.; Bhargava, P.; Gandhi, P. Investigation of processing the alumina slurry through an economic vat photopolymerization process. Open Ceram. 2023, 15, 100400. [Google Scholar] [CrossRef]

- Chen, S.; Wang, C.-S.; Zheng, W.; Wu, J.-M.; Yan, C.-Z.; Shi, Y.-S. Effects of particle size distribution and sintering temperature on properties of alumina mold material prepared by stereolithography. Ceram. Int. 2022, 48, 6069–6077. [Google Scholar] [CrossRef]

- Dang, M.; Yue, X.; Zhou, G.; Hu, S. Influence of resin composition on rheology and polymerization kinetics of alumina ceramic suspensions for digital light processing (DLP) additive manufacturing. Ceram. Int. 2023, 49, 20456–20464. [Google Scholar] [CrossRef]

- Schlacher, J.; Hofer, A.-K.; Geier, S.; Kraleva, I.; Papšík, R.; Schwentenwein, M.; Bermejo, R. Additive manufacturing of high-strength alumina through a multi-material approach. Open Ceram. 2021, 5, 100082. [Google Scholar] [CrossRef]

- Nurmi, N.; Frankberg, E.J.; Rinne, M.; Sandblom, T.; Konnunaho, P.; Levänen, E. Enabling fast debinding of ceramic vat photopolymerization prints with supercritical carbon dioxide as a solvent. Addit. Manuf. 2024, 84, 104143. [Google Scholar] [CrossRef]

- Nurmi, N.; Frankberg, E.J.; Ismailov, A.; Hautcoeur, D.; Zakeri, S.; Sarlin, E.; Levänen, E. Improved mechanical quality of ceramic vat photopolymerization prints by supercritical carbon dioxide extraction. Open Ceram. 2025, 21, 100753. [Google Scholar] [CrossRef]

- Huang, Z.; Shao, G.; Zhou, D.; Deng, X.; Qiao, J.; Li, L. 3D printing of high-precision and ferromagnetic functional devices. Int. J. Extrem. Manuf. 2023, 5, 035501. [Google Scholar] [CrossRef]

- Santoliquido, O.; Camerota, F.; Ortona, A. The influence of topology on DLP 3D printing, debinding and sintering of ceramic periodic architectures designed to replace bulky components. Open Ceram. 2021, 5, 100059. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.-S.; Liu, Y.-S.; Zeng, Q.-F.; Hu, K.-H.; Liang, J.-J.; Lu, Z.-G. Microstructure and properties of 3D-printed alumina ceramics with different heating rates in vacuum debinding. Rare Met. 2020, 39, 577–588. [Google Scholar] [CrossRef]

- Chen, J.; Yao, H.; Sun, L.; Zhang, Z.; Zeng, Y. Atmosphere Debinding Heat Treatment of 3D Printed Alumina Ceramics. J. Inorg. Mater. 2022, 37, 333–337. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Liu, Y.; Zeng, Q.; Hu, K.; Lu, Z.; Liang, J. Effect of debinding temperature under an argon atmosphere on the microstructure and properties of 3D-printed alumina ceramics. Mater. Charact. 2020, 168, 110548. [Google Scholar] [CrossRef]

- Wu, H.; Cheng, Y.; Liu, W.; He, R.; Zhou, M.; Wu, S.; Song, X.; Chen, Y. Effect of the particle size and the debinding process on the density of alumina ceramics fabricated by 3D printing based on stereolithography. Ceram. Int. 2016, 42, 17290–17294. [Google Scholar] [CrossRef]

- Kim, J.; Gal, C.W.; Choi, Y.-J.; Park, H.; Yoon, S.-Y.; Yun, H.-S. Effect of non-reactive diluent on defect-free debinding process of 3D printed ceramics. Addit. Manuf. 2023, 67, 103475. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, G.; Chen, A.; Su, J.; Liu, K.; Wang, C.; Zhang, Y.; Yan, C.; Shi, Y. Defect inhibition mechanism of 3D-printed ceramics via synergetic resin composition and debinding processing regulation. J. Am. Ceram. Soc. 2024, 108, e20168. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Liu, Y.; Zeng, Q.; Liang, J. Thermal Treatment of γ-Al2O3 for the Preparation of Stereolithography 3D Printing Ceramic Slurries. Front. Mater. 2019, 6, 295. [Google Scholar] [CrossRef]

- Shuai, X.; Zeng, Y.; Li, P.; Chen, J. Fabrication of fine and complex lattice structure Al2O3 ceramic by digital light processing 3D printing technology. J. Mater. Sci. 2020, 55, 6771–6782. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Colombo, P.; Li, W.; Liu, Y.; Hu, K.; Lu, Z. The influence of sintering procedure and porosity on the properties of 3D printed alumina ceramic cores. Ceram. Int. 2021, 47, 27668–27676. [Google Scholar] [CrossRef]

- Li, X.; Su, H.; Dong, D.; Jiang, H.; Liu, Y.; Shen, Z.; Guo, Y.; Hao, S.; Zhang, Z.; Guo, M. New approach to preparing near zero shrinkage alumina ceramic cores with excellent properties by vat photopolymerization. J. Mater. Sci. Technol. 2024, 193, 61–72. [Google Scholar] [CrossRef]

- Hofer, A.-K.; Kocjan, A.; Bermejo, R. High-strength lithography-based additive manufacturing of ceramic components with rapid sintering. Addit. Manuf. 2022, 59, 103141. [Google Scholar] [CrossRef]

- Carloni, D.; Zhang, G.; Wu, Y. Transparent alumina ceramics fabricated by 3D printing and vacuum sintering. J. Eur. Ceram. Soc. 2021, 41, 781–791. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, J.; Xiao, Z.; He, Y.; Liu, K.; He, B.; Xiang, B.; Zhai, J.; Kong, L. Effects of debinding condition on microstructure and densification of alumina ceramics shaped with photopolymerization-based additive manufacturing technology. Ceram. Int. 2022, 48, 14026–14038. [Google Scholar] [CrossRef]

- Zhang, F.; Zhou, S.; You, H.; Zhang, G.; Yang, J.; Shi, Y. 3D printing of ceramic matrix composites: Strengthening and toughening strategies. Compos. Part B Eng. 2025, 297, 112335. [Google Scholar] [CrossRef]

- Liu, X.; Zou, B.; Xing, H.; Huang, C. The preparation of ZrO2-Al2O3 composite ceramic by SLA-3D printing and sintering processing. Ceram. Int. 2020, 46, 937–944. [Google Scholar] [CrossRef]

- Wu, H.; Liu, W.; He, R.; Wu, Z.; Jiang, Q.; Song, X.; Chen, Y.; Cheng, L.; Wu, S. Fabrication of dense zirconia-toughened alumina ceramics through a stereolithography-based additive manufacturing. Ceram. Int. 2017, 43, 968–972. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Li, W.; Liu, Y.; Zeng, Q. The effect of sintering on the properties of calcium oxide promoted alumina-based ceramic cores via 3D printing. Mater. Chem. Phys. 2021, 263, 124443. [Google Scholar] [CrossRef]

- Obolkina, T.O.; Kotelnikov, N.L.; Goldberg, M.A.; Khayrutdinova, D.R.; Smirnov, S.V.; Utkin, D.A.; Antonova, O.S.; Egorov, A.A.; Ogarkov, A.I.; Mosolov, A.N.; et al. Adding MnO to Improve the Characteristics of Zirconia-Toughened Alumina Ceramic Parts Made Using the Digital Light Processing Method. Minerals 2024, 15, 10. [Google Scholar] [CrossRef]

- Li, H.; Elsayed, H.; Colombo, P. Enhanced mechanical properties of 3D printed alumina ceramics by using sintering aids. Ceram. Int. 2023, 49, 24960–24971. [Google Scholar] [CrossRef]

- Zhang, K.; He, R.; Ding, G.; Bai, X.; Fang, D. Effects of fine grains and sintering additives on stereolithography additive manufactured Al2O3 ceramic. Ceram. Int. 2021, 47, 2303–2310. [Google Scholar] [CrossRef]

- Wei, S.; Han, G.; Zhang, X.; Sun, J.; Zhang, J.; Wang, W.; Zhang, W.; Yang, L.; Li, J. Preparation of high performance dense Al2O3 ceramics by digital light processing 3D printing technology. Ceram. Int. 2024, 50, 2083–2095. [Google Scholar] [CrossRef]

- Wang, R.; Cui, Y.; Ye, H.; Cheng, J.; Zhang, H.; Zhu, P.; Tao, R.; Ge, Q. Vat photopolymerization 3D printing of alumina ceramics with low sintering temperature. Ceram. Int. 2024, 50, 42434–42443. [Google Scholar] [CrossRef]

- Shuangyu, L.; Hongtao, C.; Ping, L.; Fulong, Z.; Binhua, W.; Machibya, F.; Jun, G.; Chuanjin, H.; Xi, W.; Juan, H. Influence of the MgO content on zirconia-toughened alumina ceramic slurry properties and sintered body microstructure. Int. J. Appl. Ceram. Technol. 2025, 22, e15034. [Google Scholar] [CrossRef]

- Nefedovaa, L.A.; Ivkov, V.I.; Sychov, M.M.; Diachenko, S.V.; Gravit, M.V. Additive manufacturing of ceramic insulators. Mater. Today Proc. 2020, 30, 520–522. [Google Scholar] [CrossRef]

- Guo, A.; Zhou, X.; Kong, D.; Kong, H.; Wang, H.; Zhu, Y.; Qu, P.; Wang, S.; Hu, Y. An insight into the effects of epoxy coating agent and sintering temperature on vat photopolymerization-printed Al2O3 parts. Ceram. Int. 2023, 49, 19227–19240. [Google Scholar] [CrossRef]

- Liu, C.; Wu, H.; Guo, A.; Kong, D.; Zhao, Z.; Wang, L.; Yin, L.; Xia, G.; Su, X.; Hu, Y. Vat Photopolymerization of Sepiolite Fiber and 316L Stainless Steel-Reinforced Alumina with Functionally Graded Structures. Materials 2024, 17, 2973. [Google Scholar] [CrossRef]

- Wu, H.; Liu, W.; Lin, L.; Chen, Y.; Xu, Y.; Wu, S.; Sun, Z.; An, D.; Wei, S.; Xie, Z. Realization of complex-shaped and high-performance alumina ceramic cutting tools via Vat photopolymerization based 3D printing: A novel surface modification strategy through coupling agents aluminic acid ester and silane coupling agent. J. Eur. Ceram. Soc. 2023, 43, 1051–1063. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Liu, Y.; Zeng, Q.; Hu, K.; Lu, Z.; Liang, J.; Li, J. Influence of debinding holding time on mechanical properties of 3D-printed alumina ceramic cores. Ceram. Int. 2021, 47, 4884–4894. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, B.; Li, J.; Wang, J.; Wang, K.; Wang, Y.; Niu, S.; Li, X.; Xu, X. Solid loading optimization of ceramic slurry to achieve high-performance silica-based ceramic core through vat photopolymerization. Ceram. Int. 2024, 50, 55307–55316. [Google Scholar] [CrossRef]

- Zhai, X.; Chen, J.; Su, R.; Gao, X.; Zhang, X.; He, R. Vat photopolymerization 3D printing of Al2O3 ceramic cores with strip-shaped pores by using polyamide 6 fiber template. J. Am. Ceram. Soc. 2024, 107, 5400–5411. [Google Scholar] [CrossRef]

- Tang, W.; Zhao, T.; Dou, R.; Wang, L. Additive manufacturing of low-shrinkage alumina cores for single-crystal nickel-based superalloy turbine blade casting. Ceram. Int. 2022, 48, 15218–15226. [Google Scholar] [CrossRef]

- Zhai, X.; Chen, J.; Wang, Y.; Su, R.; Gao, X.; Zhang, X.; Jin, H.; He, R. Fabrication of Al2O3 ceramic cores with high porosity and high strength by vat photopolymerization 3D printing and sacrificial templating. Ceram. Int. 2023, 49, 32096–32103. [Google Scholar] [CrossRef]

- Li, X.; Su, H.; Dong, D.; Zhao, D.; Liu, Y.; Shen, Z.; Jiang, H.; Guo, Y.; Liu, H.; Fan, G.; et al. Enhanced comprehensive properties of stereolithography 3D printed alumina ceramic cores with high porosities by a powder gradation design. J. Mater. Sci. Technol. 2022, 131, 264–275. [Google Scholar] [CrossRef]

- Huo, M.; Li, Q.; Liu, J.; Zhang, X.; Yue, X.; Liang, J.; Li, J. In-situ synthesis of high-performance Al2O3-based ceramic cores reinforced with core-shell structures. Ceram. Int. 2022, 48, 33693–33703. [Google Scholar] [CrossRef]

- Li, H.; Sun, J.; Colombo, P. Effect of sol impregnation and changes in sol pH on mechanical properties of 3D printed alumina ceramics. Ceram. Int. 2024, 50, 34987–34998. [Google Scholar] [CrossRef]

- Li, X.; Su, H.; Dong, D.; Jiang, H.; Liu, Y.; Shen, Z.; Guo, Y.; Zhao, D.; Zhang, Z.; Guo, M. In-situ Y3Al5O12 enhances comprehensive properties of alumina-based ceramic cores by vat photopolymerization 3D printing. Addit. Manuf. 2023, 73, 103645. [Google Scholar] [CrossRef]

- Kong, D.; Guo, A.; Hu, Y.; Zhou, X.; Wu, H.; Li, X.; Qu, P.; Wang, S.; Guo, S. Alumina-based ceramic cores prepared by vat photopolymerization and buried combustion method. Mater. Today Commun. 2023, 37, 107434. [Google Scholar] [CrossRef]

- Li, Q.; An, X.; Liang, J.; Liu, Y.; Hu, K.; Lu, Z.; Yue, X.; Li, J.; Zhou, Y.; Sun, X. Balancing flexural strength and porosity in DLP-3D printing Al2O3 cores for hollow turbine blades. J. Mater. Sci. Technol. 2022, 104, 19–32. [Google Scholar] [CrossRef]

- Li, Q.; Meng, X.; Zhang, X.; Liang, J.; Zhang, C.; Li, J.; Zhou, Y.; Sun, X. Enhanced 3D printed Al2O3 core via in-situ mullite. Addit. Manuf. 2022, 55, 102826. [Google Scholar] [CrossRef]

- Huo, C.; Tian, X.; Nan, Y.; Li, D. Hierarchically porous alumina ceramic catalyst carrier prepared by powder bed fusion. J. Eur. Ceram. Soc. 2020, 40, 4253–4264. [Google Scholar] [CrossRef]

- Santoliquido, O.; Camerota, F.; Pelanconi, M.; Ferri, D.; Elsener, M.; Dimopoulos Eggenschwiler, P.; Ortona, A. Structured Alumina Substrates for Environmental Catalysis Produced by Stereolithography. Appl. Sci. 2021, 11, 8239. [Google Scholar] [CrossRef]

- Wang, H.; Wang, P.; Wang, Q.; Zhang, R.; Zhang, L. Preparation of a High-Precision Gama-Al2O3 Structured Catalyst by DLP 3D Direct Printing for Hydrogen Production from Methanol. Ind. Eng. Chem. Res. 2021, 60, 13107–13114. [Google Scholar] [CrossRef]

- Mastroianni, L.; Russo, V.; Eränen, K.; Di Serio, M.; Murzin, D.Y.; Salmi, T. Towards unconstrained catalyst shaping: High accuracy DLP printing of porous γ-Al2O3-based catalysts. Catal. Sci. Technol. 2024, 14, 1336–1348. [Google Scholar] [CrossRef]

- Kabakci, E.; Kostretsova, N.; Morales, E.M.; Diaz-Ruiz, J.; Tarancón, A.; Guilera, J.; Torrell, M. 3D printed structured catalyst supports for enhanced CO2 methanation. J. Environ. Chem. Eng. 2025, 13, 116047. [Google Scholar] [CrossRef]

- Miao, W.-J.; Wang, S.-Q.; Wang, Z.-H.; Wu, F.-B.; Zhang, Y.-Z.; Ouyang, J.-H.; Wang, Y.-M.; Zou, Y.-C. Additive Manufacturing of Advanced Structural Ceramics for Tribological Applications: Principles, Techniques, Microstructure and Properties. Lubricants 2025, 13, 112. [Google Scholar] [CrossRef]

- Chen, X.; Chen, A.; Zhang, L.; Yu, H.; Mao, Z.; Chen, Y.; Gu, J.; Yan, C.; Lu, J. Additive manufacturing of bionic interfaces: From conceptual understanding to renewable energy applications. Adv. Bionics 2025, 1, 57–82. [Google Scholar] [CrossRef]

- Zhao, Y.; Mei, H.; Chang, P.; Yang, Y.; Cheng, L.; Zhang, L. High-strength printed ceramic structures for higher temperature lubrication. Compos. Part B Eng. 2021, 221, 109013. [Google Scholar] [CrossRef]

- Zhu, W.; Ma, X.; Gou, M.; Mei, D.; Zhang, K.; Chen, S. 3D printing of functional biomaterials for tissue engineering. Curr. Opin. Biotechnol. 2016, 40, 103–112. [Google Scholar] [CrossRef] [PubMed]

- Dehurtevent, M.; Robberecht, L.; Hornez, J.C.; Thuault, A.; Deveaux, E.; Behin, P. Stereolithography: A new method for processing dental ceramics by additive computer-aided manufacturing. Dent. Mater. 2017, 33, 477–485. [Google Scholar] [CrossRef] [PubMed]

- Esteves, A.V.M.; Martins, M.I.; Soares, P.; Rodrigues, M.A.; Lopes, M.A.; Santos, J.D. Additive manufacturing of ceramic alumina/calcium phosphate structures by DLP 3D printing. Mater. Chem. Phys. 2022, 276, 125417. [Google Scholar] [CrossRef]

- Gu, Q.; Wang, H.; Gao, W.; Yu, J.; Zhou, X. Preparation of large-size alumina ceramic parts by DLP 3D printing using high-solid-loading paste and optimizing the debinding process. Ceram. Int. 2023, 49, 28801–28812. [Google Scholar] [CrossRef]

- Alhendi, M.; Alshatnawi, F.; Abbara, E.M.; Sivasubramony, R.; Khinda, G.; Umar, A.I.; Borgesen, P.; Poliks, M.D.; Shaddock, D.; Hoel, C.; et al. Printed electronics for extreme high temperature environments. Addit. Manuf. 2022, 54, 102709. [Google Scholar] [CrossRef]

- Negi, S.; Bhargava, P.; Gandhi, P.S. Thin alumina wafer fabrication by vat photopolymerisation based additive manufacturing. Ceram. Int. 2025, 51, 2891–2897. [Google Scholar] [CrossRef]

- Dang, M.; Hu, S.; Zhou, G.; Yue, X.; Wang, S. 3D printing of alumina ceramic heat sink with mini-channels for thermal management. Int. J. Appl. Ceram. Technol. 2023, 20, 1371–1377. [Google Scholar] [CrossRef]

- Ray, S.S.; Dommati, H.; Wang, J.-C.; Chen, S.-S. Solvent based Slurry Stereolithography 3D printed hydrophilic ceramic membrane for ultrafiltration application. Ceram. Int. 2020, 46, 12480–12488. [Google Scholar] [CrossRef]

- Wang, D.; Chen, T.; Zeng, Y.; Chen, X.; Xing, W.; Fan, Y.; Qiao, X. Optimization of UV-curable alumina suspension for digital light processing of ceramic membranes. J. Membr. Sci. 2022, 643, 120066. [Google Scholar] [CrossRef]

- Chen, T.; Nie, C.; Cao, Q.; Xiong, H.; Chen, X.; Fan, Y. Fabrication of alumina ceramic membrane supports using LCD 3D printing and titania nanoparticle doping. J. Eur. Ceram. Soc. 2024, 44, 3158–3169. [Google Scholar] [CrossRef]

| Al2O3 D50 (μm) | Resin | Dispersant | Photoinitiator | Solid Content | Viscosity (Pa·s) | Ref. |

|---|---|---|---|---|---|---|

| 0.4 | MA | PEI + OA | TPO | 35 vol.% | 10 at 100 s−1 | [86] |

| 0.3:3 = 3:7 | HDDA | MPDISP (4.1 wt.%) | TPO | 75 wt.% | 1 at 30 s−1 | [33] |

| 0.5 | HDDA | BYK103 (2 wt.%) | BAPO | 45 vol.% | 0.52 at 30 s−1 | [88] |

| 0.4 | PEGDA | BYK-111 | Photoinitiator 819 | 40 vol.% | 0.25 at 30 s−1 | [89] |

| 0.8 | MMA | Tetrahydrofuran (2 wt.%) | Camphor quinone | 83 wt.% | - | [90] |

| 1 | ACMO | MPDISP (2.23 wt.%) | TPO | 72.5 wt.% | 1 at 400 s−1 | [91] |

| 4 | HDDA:PUA= 1:1 | - | TPO-L | 56 vol.% | 0.52 at 50 r/min | [92] |

| 4.42 | HDDA,ETPTA | - | Camphor quinone | - | - | [93] |

| 0.18 | HDDA:EA= 4:1 | Disperbyk-111 (2.5 wt.%) | TPO | 40 vol.% | 0.5 at 10 s−1 | [94] |

| 0.18 | HDDA:PEG400DA = 1:4 | Disperbyk-111 (4.5 wt.%) | TPO | 40 vol.% | 1.5 at 10 s−1 | [94] |

| 5.1 | HDDA,TMPTA, NPG2PODA | BYK-111 | Irgacure 651 | - | 9.171 at 30 r/min | [44] |

| 0.15 | TEGDMA: PPGDMA: 2-EH = 1:1:1 | KD1 (1.5 wt.%) | Omnirad 819 | 45 vol.% | 1.9 at 10 s−1 | [95] |

| 1 | HDDA:HEMA:TMP3E0TA:PPTTA = 6:2:1:1 | KOS110 (5 wt.%) | TPO | 50 vol.% | 1.1 at 30 s−1 | [96] |

| Al2O3 D50 (μm) | Additives | Content | Solid Content | Viscosity (Pa·s) | Curing Depth (μm) | Ref. |

|---|---|---|---|---|---|---|

| 0.2 | TiO2 (0.2 μm) | 5 wt.% | 50 wt.% | 0.92 at 100 r/min | - | [97] |

| 0.2 | ZrO2 (0.2 μm) | 20 wt.% | 65 wt.% | 0.2 | - | [98] |

| 0.2 | ZrO2 (<0.2 μm) | 15 vol.% | 40 vol.% | - | 60 | [99] |

| 28.3 | Ce-ZrO2 | - | 62.5 wt.% | 10 at 10 s−1 | 45 | [100] |

| 0.39 | Graphene (3–10 nm) | 0.07 | 60 wt.% | 25 at 50 s−1 | 65 | [101] |

| 0.2 | Y2O3 (0.5 μm) | 5 wt.% | 79 wt.% | 1.97 at 13 s−1 | 83 ± 2.51 | [102] |

| Al2O3 D50 (μm) | Debinding | Sintering | Density | Flexural Strength (MPa) | Hardness (GPa) | Fracture Toughness (MPa·m1/2) | Porosity | Grain Size (μm) | Application | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| 60.85, 5.1 | 1050 °C (N2) | 2 °C/min 1700 °C, 1.5 h | 2.04 g/cm3 | 51.36 | - | - | 47.93% | 40–50 | High-resolution porous ceramics | [44] |

| 5.81: 1.14 = 9; 1 | 0.5 °C/min 600 °C, 2 h (Ar) 2 °C/min 600 °C, 2 h | 5 °C/min 1550 °C, 2 h | - | 78.15 ± 3.50 | - | - | 30.12% | 2–10 ※ | Alumina mold material | [117] |

| 4.42 | 1000 °C | 1600 °C, 4 h | - | 19.62 | - | - | - | 1–10 ※ | Functional gradient ceramics | [93] |

| 0.5 | 1000 °C, 1 h | 1600 °C, 5 h | 99% | 471 | 17.31 | - | - | 1–5 ※ | Mechanical components | [118] |

| 0.25 | - | 1 °C/min 1600 °C, 2 h | 3.986 g/cm3 | 650 | - | 3.13 | - | 4–10 ※ | Mechanical components | [119] |

| 0.18 | 1150 °C, 2 h | 1600 °C, 1.5 h | 3.86 g/cm3 | 540 | - | - | - | 0.2–1 ※ | - | [85] |

| Materials | Debinding | Sintering | Density | Flexural Strength (MPa) | Hardness | Fracture Toughness (MPa·m1/2) | Grain Size (μm) | Application | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Al2O3 (0.2 µm) +ZrO2 (0.2 µm, 15 vol.%) | 600 °C, 1 h | 1625 °C, 1 h | 4.22 ± 0.03 g/cm3 | 693 ± 87 | 21.14 ± 1.64 GPa | - | 0.75–2 ※ | Structural ceramics | [99] |

| Al2O3 (0.2 µm) +ZrO2 (0.2 µm, 20 wt.%) | 1000 °C, 0.5 h | 1600 °C, 1 h | 4.28 g/cm3 | - | 17.3 GPa | 5.1 | 0.5–2 ※ | - | [98] |

| Al2O3 (0.2 µm) +ZrO2 (0.2 µm, 15 vol.%) | 550 °C, 5 h | 1500 °C, 1 h | 3.75 g/cm3 | - | 14.1 GPa | 4.05 | 1–5 ※ | Ceramic gear | [138] |

| Al2O3 (0.2 µm) +ZrO2 (0.2 µm, 20 wt.%) | 1000 °C, 0.5 h | 1600 °C, 4 h | 4.26 g/cm3 | 530.25 | 17.76 GPa | 5.72 | 0.25–2.25 | - | [139] |

| Al2O3 (0.2 µm) +TiO2 (0.2 µm, 5 wt.%) | 1100 °C, 1 h | 1600 °C, 2 h | 2.96 g/cm3 | 4.24 | - | - | 0.2–0.3 | Bioceramics | [97] |

| Al2O3 (0.2 µm) +CaO (0.2 µm, 5 wt.%) | 550 °C, 2 h | 1650 °C, 2 h | 1.8 g/cm3 | 24 | - | - | 2–10 ※ | Ceramic core | [140] |

| Al2O3 (0.39 µm) +Graphene (0.07 wt.%) | - | 1650 °C, 1.5 h (vacuum) | 99.7% | - | 18.61 GPa | - | 4–20 ※ | - | [101] |

| Al2O3 (0.39 µm) +Cf (0.2 wt.%) | 1550 °C, 2 h | 700 °C | 3.2 g/cm3 | 15 | - | - | 1–5 ※ | - | [103] |

| ZTA (20 wt.%ZrO2)+MnO (0.5 wt.%) | 360 °C, 120 h (N2) | 1600 °C, 2 h | 4.0 g/cm3 | - | 1409 ± 50 HV | - | 0.8–4 ※ | Bioceramics | [141] |

| Sintering Aid | Effect | Density | Flexural Strength (MPa) | Shrinkage X Axis | Shrinkage Y Axis | Shrinkage Z Axis | Refs. |

|---|---|---|---|---|---|---|---|

| TiO2 (1.5 wt.%) | Enhance strength | 3.58 g/cm3 | 216.7 | 15% | 14% | 13.5% | [142,143] |

| CaCO3 (1.5 wt.%) | Reduce shrinkage and strength | 2.95 g/cm3 | 105.8 | 10.5% | 9.5% | 7% | [142] |

| MgO (1 wt.%) | Enhance density and strength | 2.99 g/cm3 | 111.1 | 10.8% | 10.7% | 9.6% | [143,144,146] |

| Y2O3 (1 wt.%)+ MgO (0.5 wt.%) | Enhance density and strength | 96.75% | 491.6 | 21.4% | 21.66% | 26.05% | [144] |

| CuO-Mg(OH)2-TiO2 (3.5 wt.%) | Reduce sintering temperature | 2.77 g/cm3 | 301 | 19.2% | 19.1% | 19.5% | [145] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.-J.; Zhang, Y.-Z.; Li, J.-H.; Wang, Z.-H.; Miao, W.-J.; Wu, F.-B.; Wang, S.-Q.; Ouyang, J.-H. Additive Manufacturing of Alumina-Based Ceramic Structures by Vat Photopolymerization: A Review of Strategies for Improving Shaping Accuracy and Properties. Materials 2025, 18, 2445. https://doi.org/10.3390/ma18112445

Zhao J-J, Zhang Y-Z, Li J-H, Wang Z-H, Miao W-J, Wu F-B, Wang S-Q, Ouyang J-H. Additive Manufacturing of Alumina-Based Ceramic Structures by Vat Photopolymerization: A Review of Strategies for Improving Shaping Accuracy and Properties. Materials. 2025; 18(11):2445. https://doi.org/10.3390/ma18112445

Chicago/Turabian StyleZhao, Jia-Jun, Yun-Zhuo Zhang, Jia-Hao Li, Zi-Heng Wang, Wei-Jian Miao, Fan-Bin Wu, Shu-Qi Wang, and Jia-Hu Ouyang. 2025. "Additive Manufacturing of Alumina-Based Ceramic Structures by Vat Photopolymerization: A Review of Strategies for Improving Shaping Accuracy and Properties" Materials 18, no. 11: 2445. https://doi.org/10.3390/ma18112445

APA StyleZhao, J.-J., Zhang, Y.-Z., Li, J.-H., Wang, Z.-H., Miao, W.-J., Wu, F.-B., Wang, S.-Q., & Ouyang, J.-H. (2025). Additive Manufacturing of Alumina-Based Ceramic Structures by Vat Photopolymerization: A Review of Strategies for Improving Shaping Accuracy and Properties. Materials, 18(11), 2445. https://doi.org/10.3390/ma18112445