Defect Recognition in Composite Materials Using Terahertz Spectral Imaging with ResNet18-SVM Approach

Abstract

1. Introduction

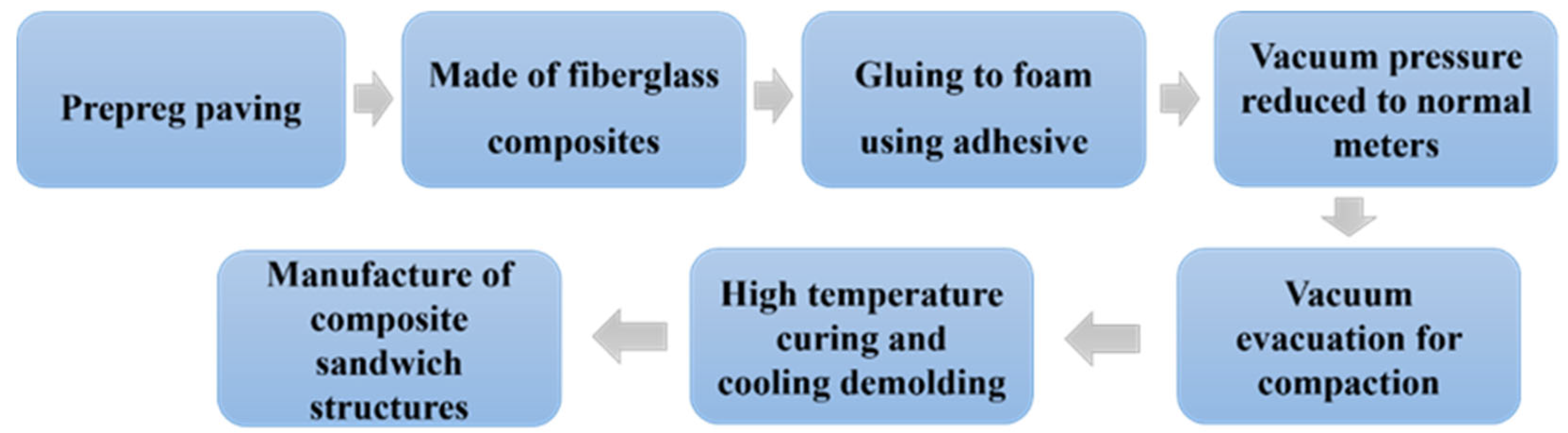

2. Experimental Design

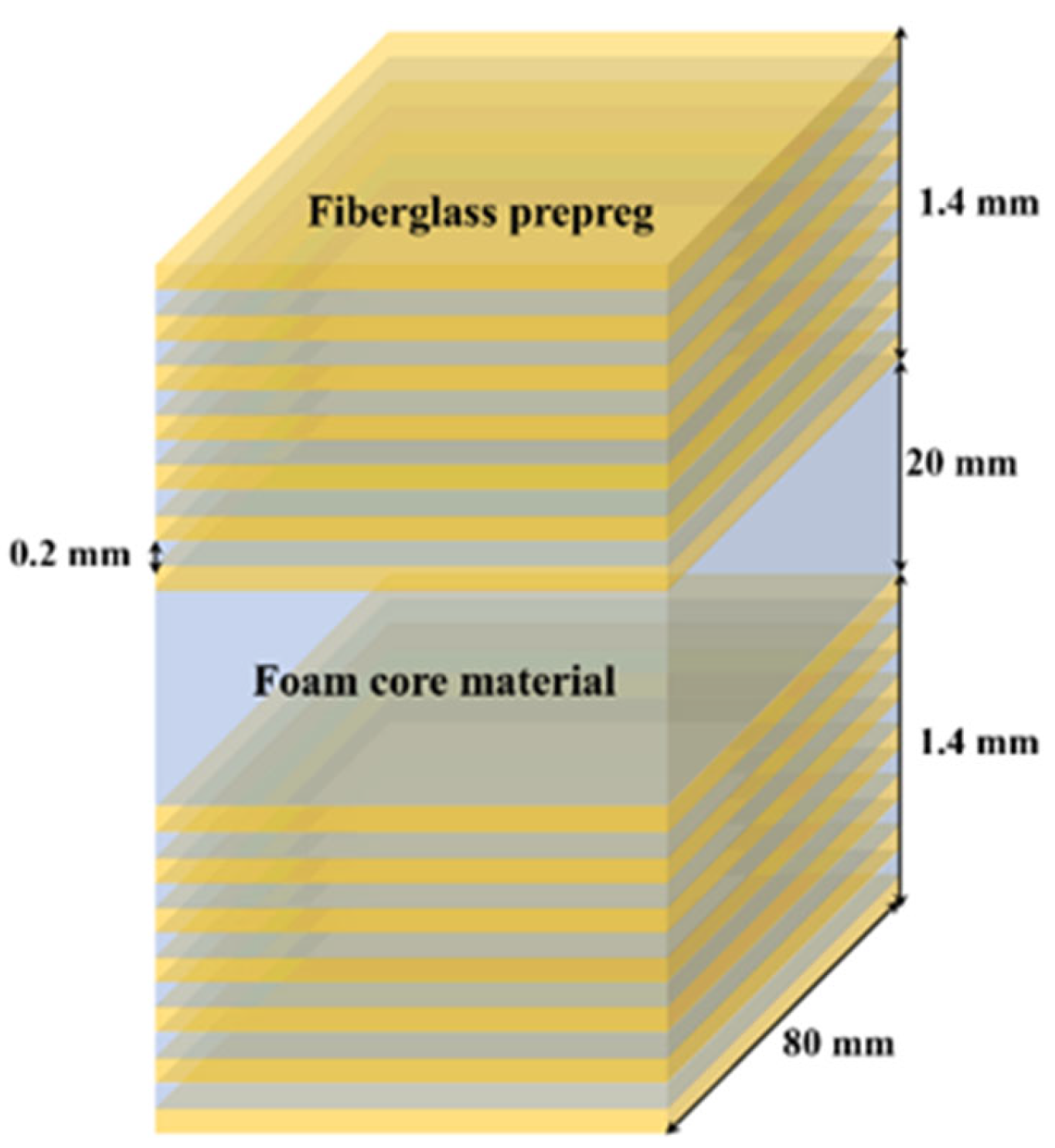

2.1. Structural Design

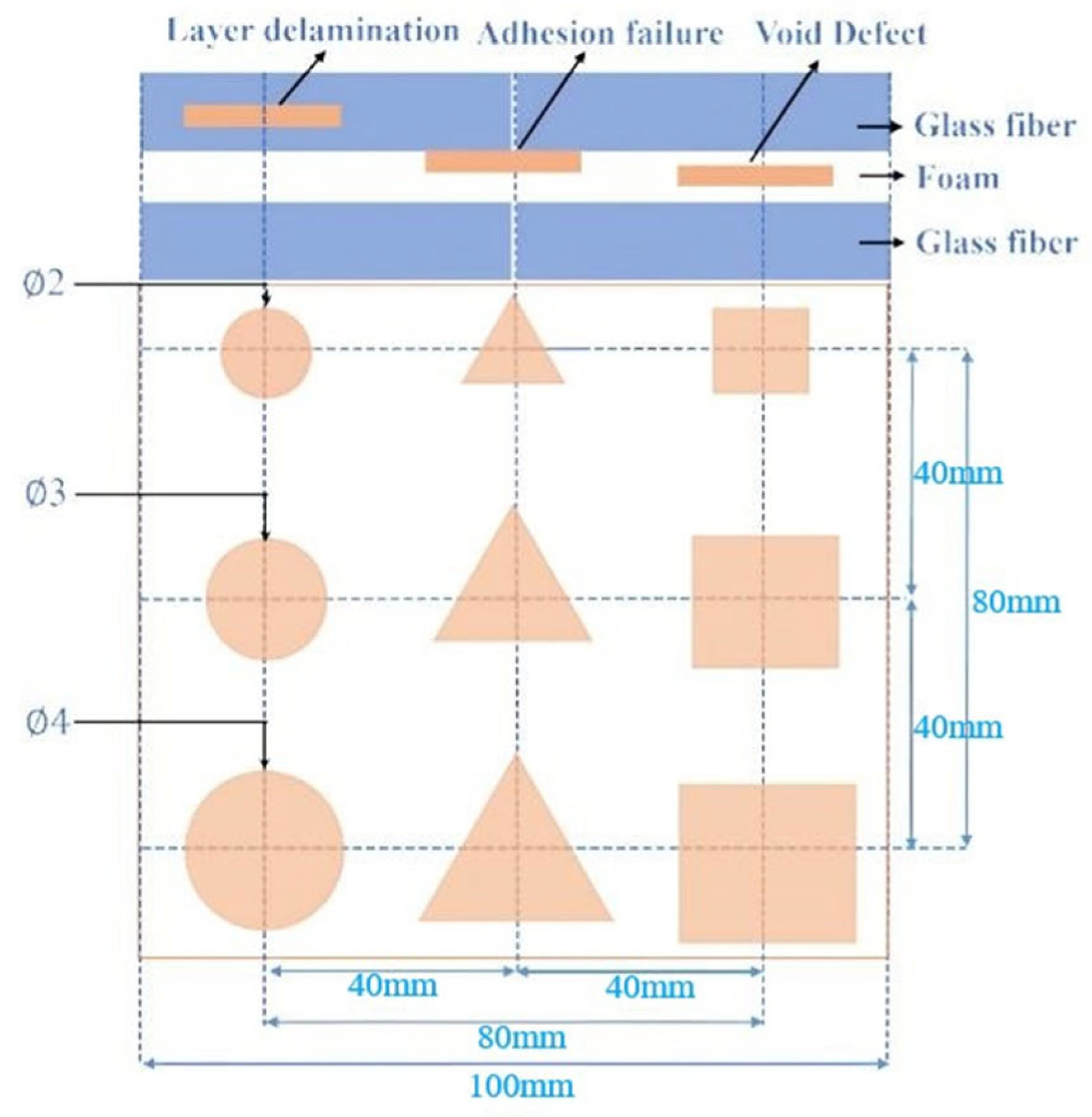

2.2. Manual Defect Preset

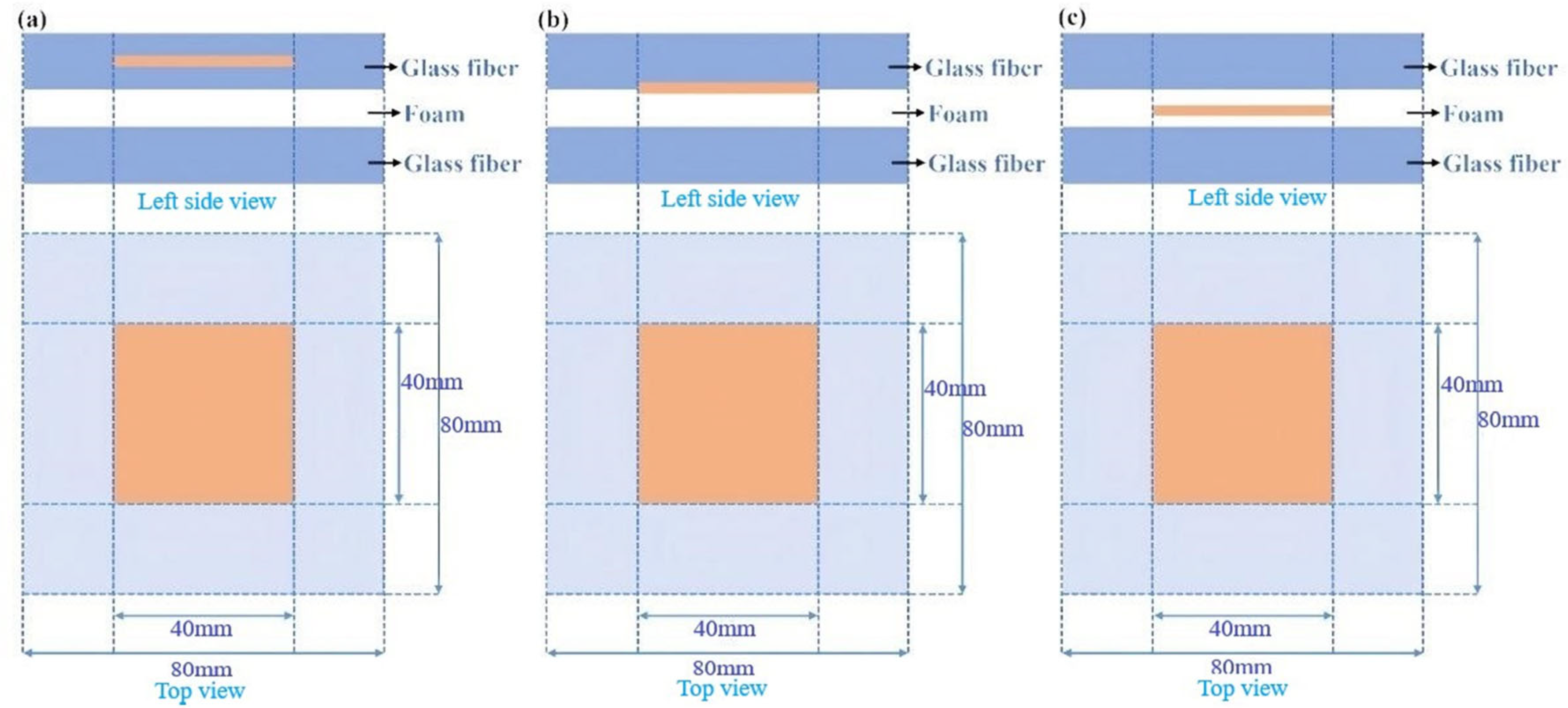

- Layer delamination: To simulate delamination defects commonly found in multilayer composite structures under real-world conditions, a 0.2 mm thick PTFE film was deliberately inserted between the third and fourth prepreg layers of the fiberglass composite as shown in Figure 2a.

- Adhesion failure: In this experiment, to simulate debonding defects in fiberglass materials bonded with foam adhesive, a 0.2 mm thick PTFE sheet was placed in a non-adhesive state, as shown in Figure 2b.

- Void defect: Cavities in different sizes, shapes, and depths were created on the surface of the foam material and are used to simulate cavity defects, as shown in Figure 2c.

2.3. Signal Acquisition

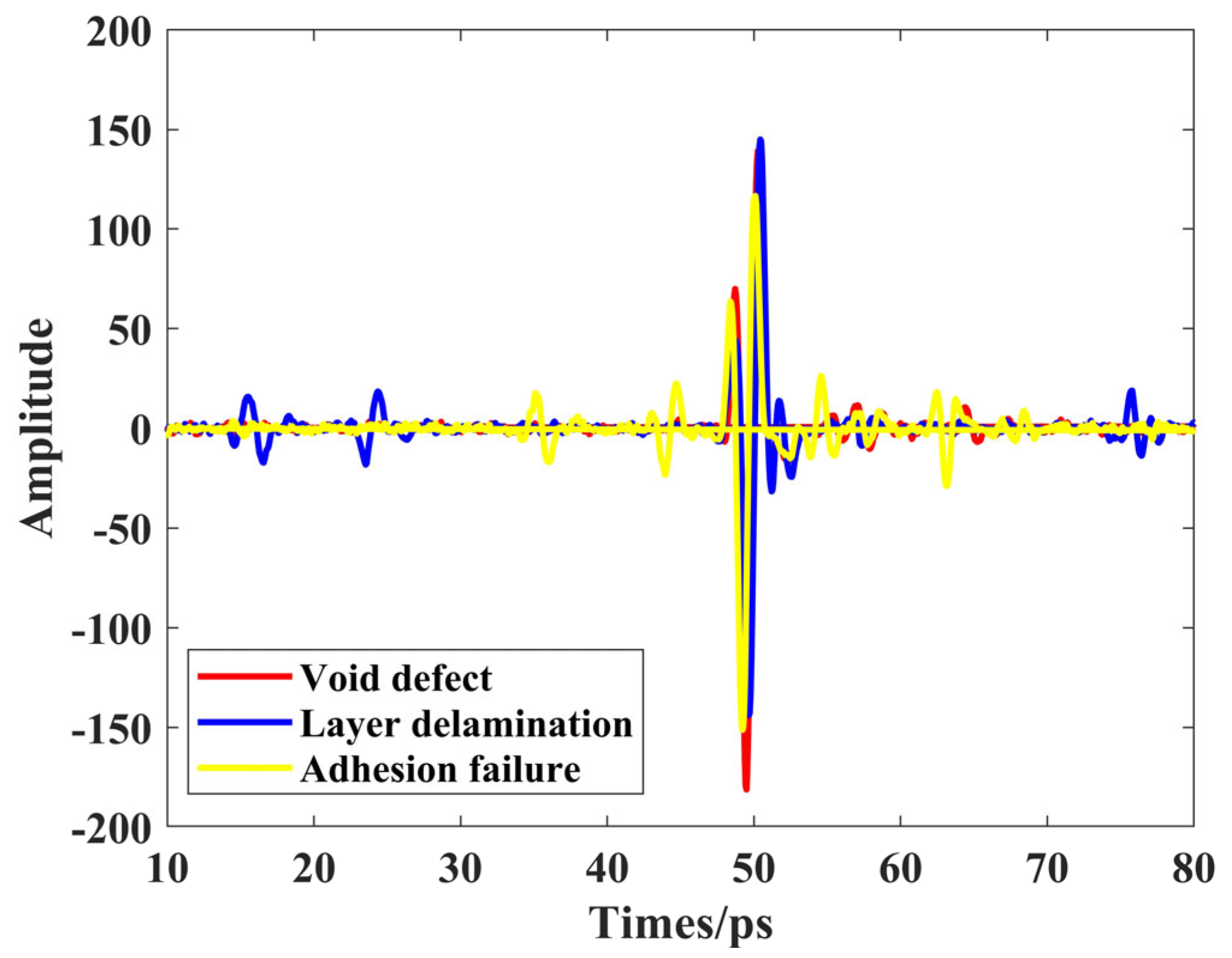

2.4. Terahertz Spectral Signal Feature Extraction

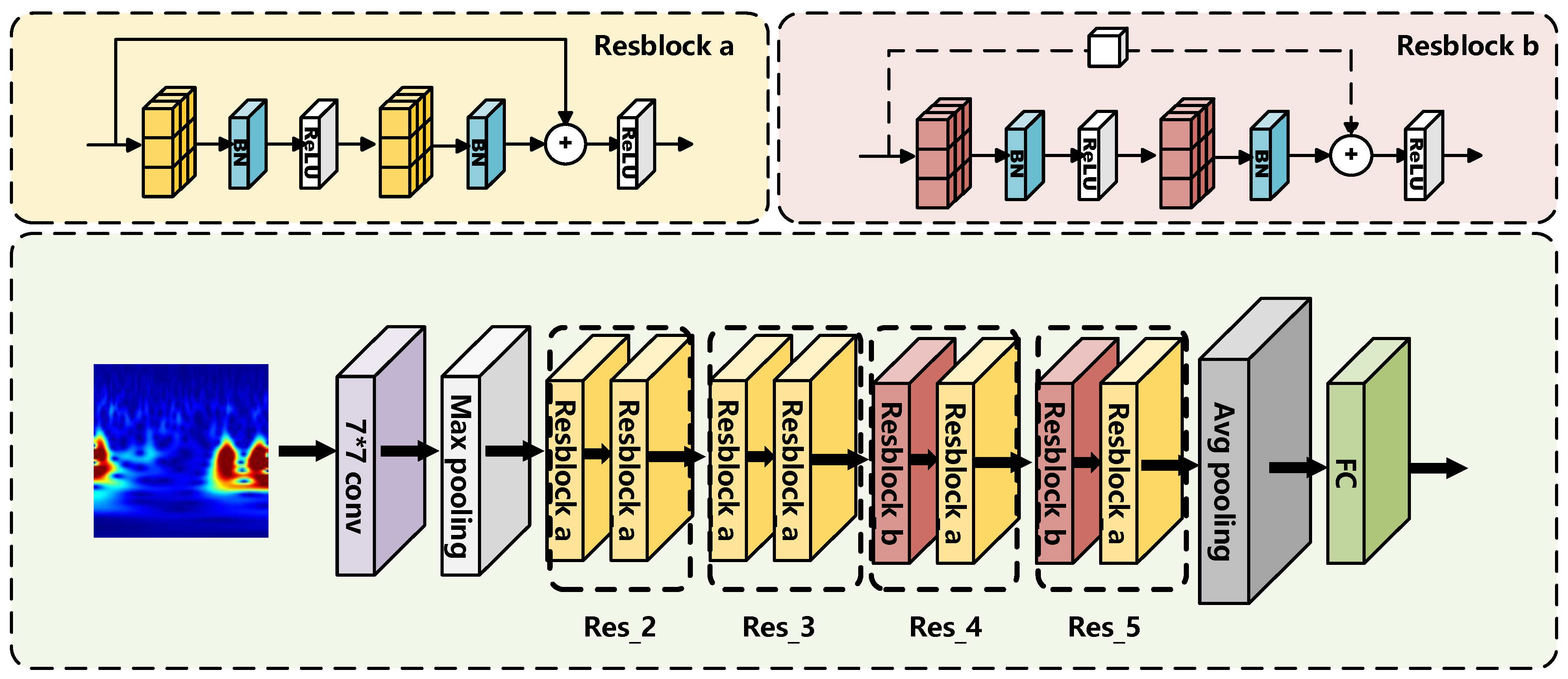

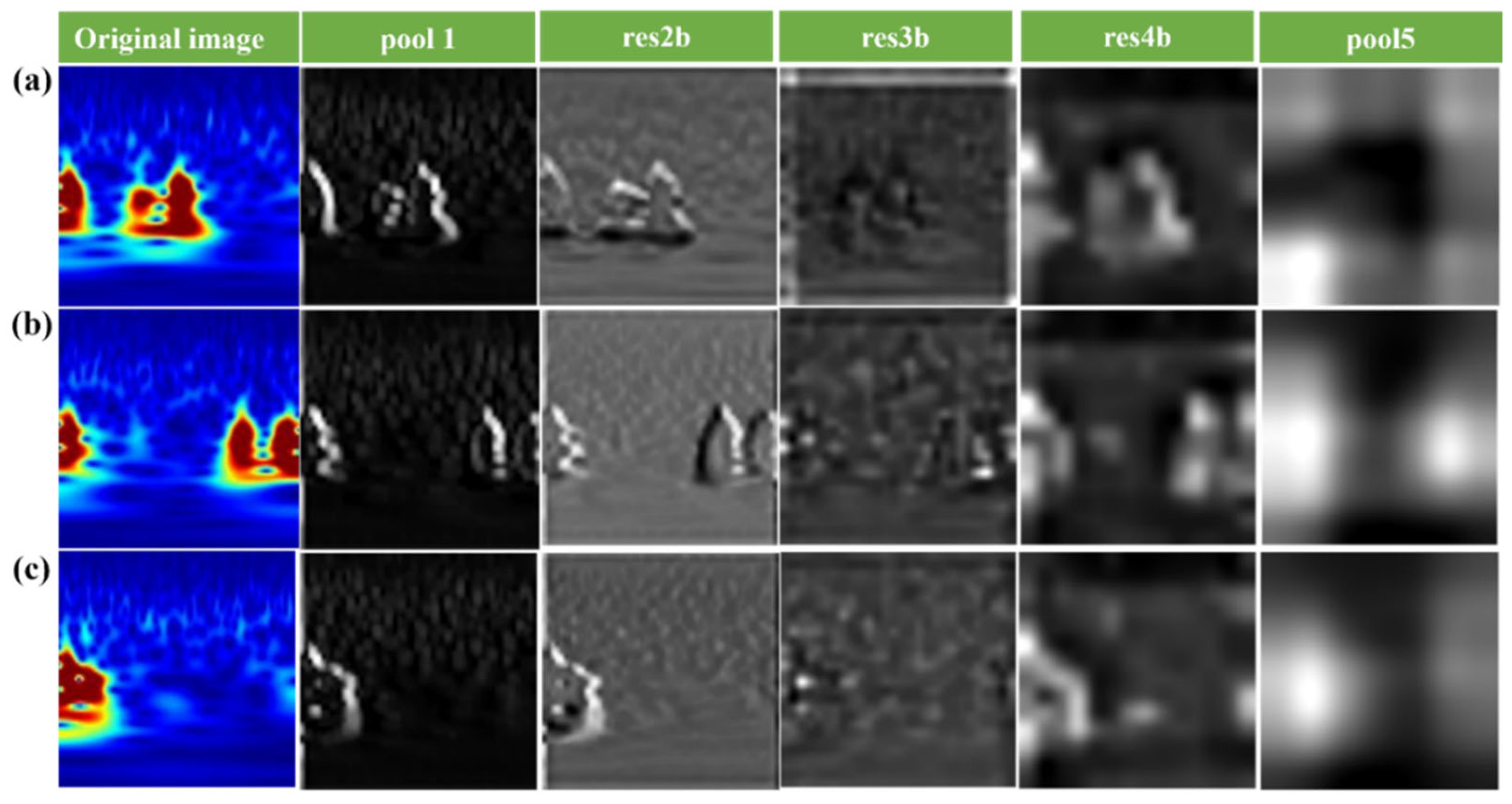

3. Convolutional Neural Network Design for Defect Detection in Terahertz Spectral Signal

3.1. Resnet18

3.2. Grid Structure

4. Experiment

4.1. Data Preparation

4.2. Model Testing and Analysis

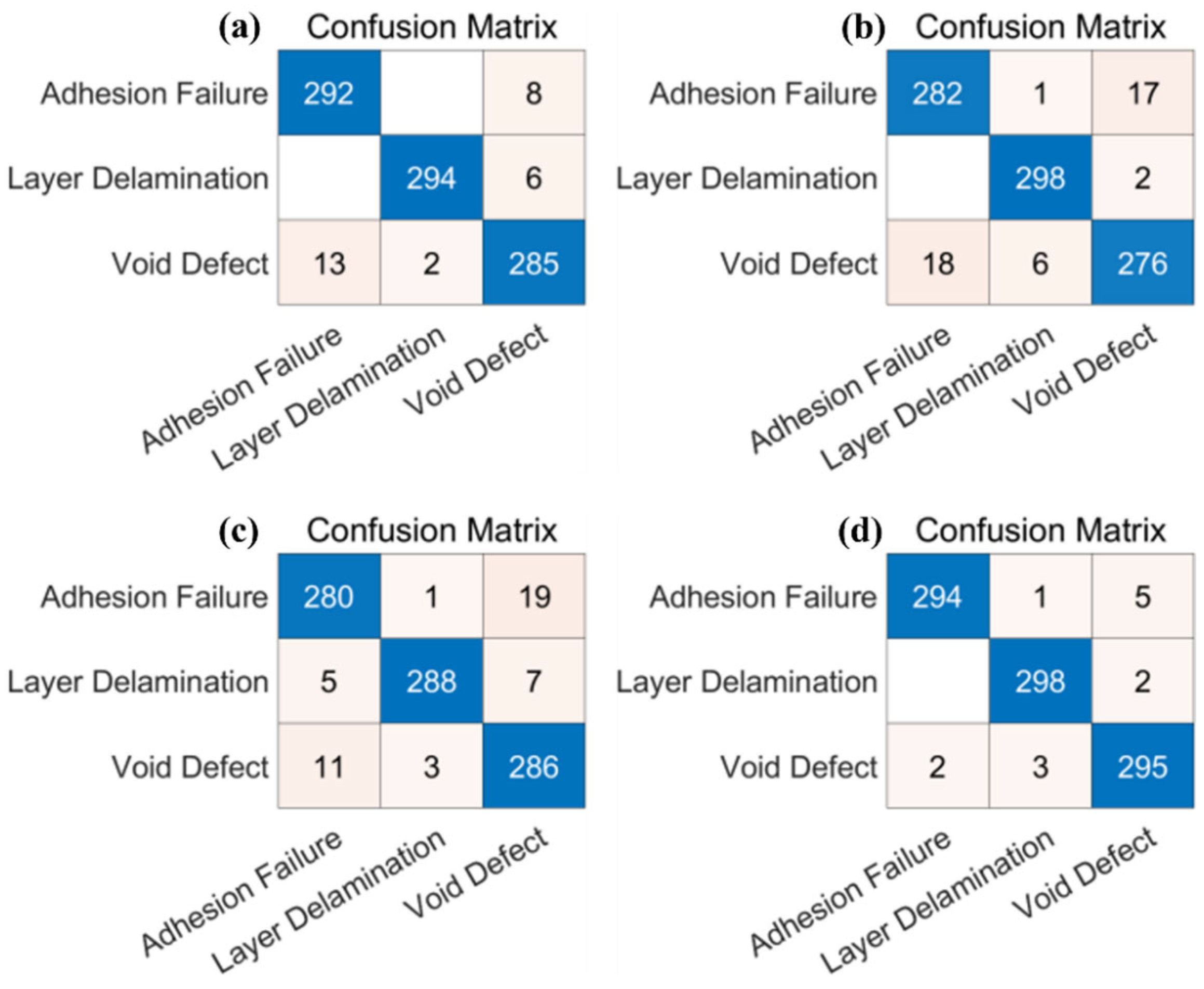

4.2.1. Impact of Different Machine Learning Algorithms on Model Performance

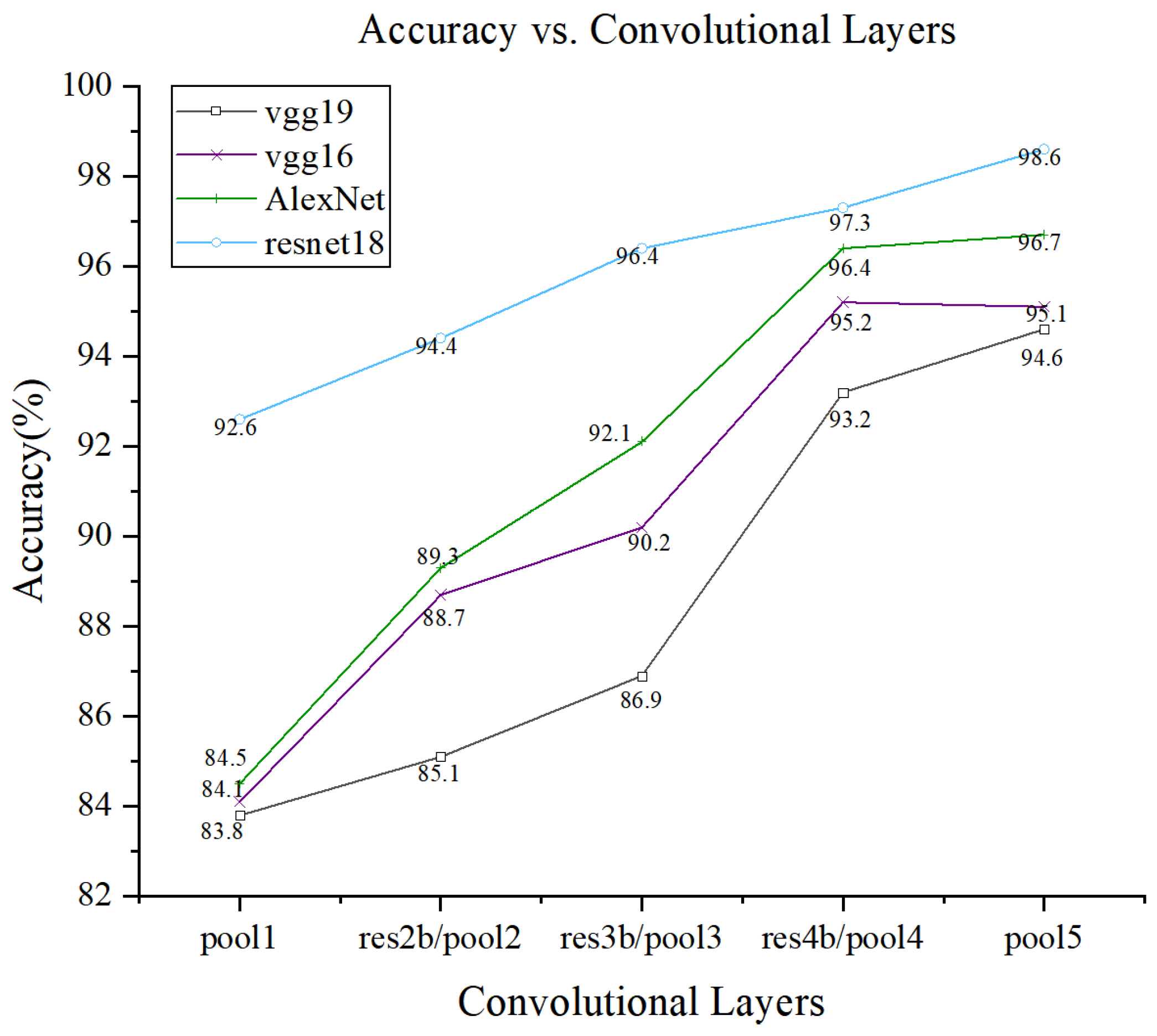

4.2.2. Impact of Different Pooling Layers on the Model

5. Conclusions

- The ResNet18 model excels in terahertz spectral signal defect detection, especially on condition that SVM is employed sequentially, achieving an accuracy of 98.56%;

- ResNet18 outperforms the other three deep learning models significantly in terahertz spectral signal defect detection thanks to the residual structure;

- The impact of pooling layers on model accuracy varies across architectures. While the choice of pooling layer can significantly influence performance in some models, ResNet18 shows stable accuracy regardless of the pooling layer used.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CWT | Continuous wavelet transform |

| SVM | Support vector machine |

| ResNet | Residual networks |

| Polymethacrylimide | PMI |

| PTFE | Polytetrafluoroethylene |

| THz-TDS | Terahertz time-domain spectroscopy |

| ReLU | Rectified Linear Units |

| VGG-16 | Visual Geometry Group 16-layer network |

| VGG-19 | Visual Geometry Group 19-layer network |

| KNN | K-Nearest Neighbors |

| DT | Decision Tree |

References

- Zheng, X.; Sun, Q.; Li, Y.; Chai, Y.; Cao, Z. Mechanical behavior and damage tolerance tests of composites through-thickness stitched foam sandwich panels. Fuhe Cailiao Xuebao Acta Mater. Compos. Sin. China 2006, 23, 29–36. [Google Scholar]

- Belingardi, G.; Martella, P.; Peroni, L. Fatigue analysis of honeycomb-composite sandwich beams. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1183–1191. [Google Scholar] [CrossRef]

- Helaly, R.; Messaoud, S.; Bouaafia, S.; Hajjaji, M.A.; Mtibaa, A. DTL-I-ResNet18: Facial emotion recognition based on deep transfer learning and improved ResNet18. Signal Image Video Process. 2023, 17, 2731–2744. [Google Scholar] [CrossRef]

- Du, X.; Li, K.; Lv, Y.; Qiu, S. Motor imaging EEG signal recognition of ResNet18 network based on deformable convolution. Electronics 2022, 11, 3674. [Google Scholar] [CrossRef]

- Yu, W.; Gong, K.; Li, Y.; Ding, B.; Li, L.; Xu, Y.; Wang, R.; Li, L.; Zhang, G.; Lin, S. Flexible 2D materials beyond graphene: Synthesis, properties, and applications. Small 2022, 18, 2105383. [Google Scholar] [CrossRef]

- Kopp, R.; Ni, X.; Nordin, P.; Hallander, P.; Selegård, L.; Wardle, B.L. Hygrothermal progressive damage in open-hole compression of composite laminates with aligned carbon nanotube interlaminar reinforcement studied by X-ray micro-computed tomography. Compos. Part B Eng. 2024, 278, 111391. [Google Scholar] [CrossRef]

- Fu, X.; Liu, Y.; Chen, Q.; Fu, Y.; Cui, T.J. Applications of terahertz spectroscopy in the detection and recognition of substances. Front. Phys. 2022, 10, 869537. [Google Scholar] [CrossRef]

- Limbacher, B.; Schoenhuber, S.; Wenclawiak, M.; Kainz, M.A.; Andrews, A.M.; Strasser, G.; Darmo, J.; Unterrainer, K. Terahertz optical machine learning for object recognition. APL Photonics 2020, 5, 126103. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Z.; Zhao, Z.; Zhang, L.; Kang, K.; Zhang, Y. Restoration of terahertz signals distorted by atmospheric water vapor absorption. J. Appl. Phys. 2009, 105, 103105. [Google Scholar] [CrossRef]

- Wang, Q.; Li, X.; Chang, T.; Hu, Q.; Yang, X. Terahertz spectroscopic study of aeronautical composite matrix resins with different dielectric properties. Optik 2018, 168, 101–111. [Google Scholar] [CrossRef]

- Zhong, S. Progress in terahertz nondestructive testing: A review. Front. Mech. Eng. 2019, 14, 273–281. [Google Scholar] [CrossRef]

- Hartwick, T.S.; Hodges, D.T.; Barker, D.H.; Foote, F.B. Far infrared imagery. Appl. Opt. 1976, 15, 1919–1922. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Xu, T.; Zhang, L.; Chang, T.; Zhang, J.; Yan, S.; Cui, H.-L. Nondestructive damage evaluation of composites based on terahertz and X-ray image fusion. NDT E Int. 2022, 127, 102616. [Google Scholar] [CrossRef]

- Hu, B.B.; Zhang, X.C.; Auston, D.H.; Smith, P.R. Free-space radiation from electro-optic crystals. Appl. Phys. Lett. 1990, 56, 506–508. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Z.; Yang, L.; Gao, R.X.; Yan, R. Wavelet-driven differentiable architecture search for planetary gear fault diagnosis. J. Manuf. Syst. 2024, 74, 587–593. [Google Scholar] [CrossRef]

- Zhou, H.; Xing, Y.; Feng, Y.; Geng, L.; Shang, Y.; Pei, Y.; Bi, X.; Gong, S. The influence of microstructure characteristics on thickness measurement of TBCs using terahertz time-domain spectroscopy. Coatings 2024, 14, 79. [Google Scholar] [CrossRef]

- Nsengiyumva, W.; Zhong, S.; Zheng, L.; Liang, W.; Wang, B.; Huang, Y.; Chen, X.; Shen, Y. Sensing and nondestructive testing applications of terahertz spectroscopy and imaging systems: State-of-the-art and state-of-the-practice. IEEE Trans. Instrum. Meas. 2023, 72, 4507483. [Google Scholar] [CrossRef]

- Machado, M.R.; Khalij, L.; Fabro, A.T. Dynamic analysis of a composite structure under random excitation based on the spectral element method. Int. J. Nonlinear Sci. Numer. Simul. 2019, 20, 179–190. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, H.; Xia, R.; Liu, Q.; Zhao, B.Y. Time segmented image fusion based multi- depth defects imaging method in composites with pulsed terahertz. IEEE Access 2020, 8, 155529–155537. [Google Scholar] [CrossRef]

- True, J.; Xi, C.; Jessurun, N.; Ahi, K.; Asadizanjani, N. Review of THz-based semiconductor assurance. Opt. Eng. 2021, 60, 060901. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Q.; Guo, J.; Liu, W.; Xia, R.; Yu, J.; Wang, X. A Transformer-based neural network for automatic delamination characterization of quartz fiber-reinforced polymer curved structure using improved THz-TDS. Compos. Struct. 2024, 343, 118272. [Google Scholar] [CrossRef]

- Liu, Z.; Kong, X.; Cai, C.; Peng, H.; Zhang, J. Internal defect characterization of bridge cables based on Terahertz time-domain spectroscopy and deep learning. Eng. Struct. 2024, 314, 118313. [Google Scholar] [CrossRef]

- Natarajan, V.; Samraj, R.; Duraivelu, J.; Paulraj, P. Experimental investigation on mechanical properties of A/GFRP, B/GFRP and AB/GFRP polymer composites. Mater. Plast. 2021, 58, 28–36. [Google Scholar] [CrossRef]

- Prabhu, P.; Balaji, A.; Jayabalakrishnan, D.; Velmurugan, N.; Vimalnathan, P.; Karthikeyan, B.; Balaji, V.; Dinesh, S. Study on machining parameters and mechanical properties of hybrid agave sisalana and glass fiber-reinforced polyester composites (A/GFRP). J. Nat. Fibers 2022, 19, 11644–11657. [Google Scholar] [CrossRef]

- Tighe, R.C.; Dulieu-Barton, J.M.; Quinn, S. Identification of kissing defects in adhesive bonds using infrared thermography. Int. J. Adhes. Adhes. 2016, 64, 168–178. [Google Scholar] [CrossRef]

- Moradi, M.; Safizadeh, M.S. Experimental and numerical study of the effect of using polyurethane instead of Teflon strip to simulate debonding defect in composite patch repairs aluminum plate under thermography inspection. Compos. Part B Eng. 2019, 175, 107176. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Z.; Xu, Y.; Zhang, L.; Yan, R.; Chen, X. Real-time terahertz characterization of minor defects by the YOLOX-MSA network. IEEE Trans. Instrum. Meas. 2022, 71, 3521810. [Google Scholar] [CrossRef]

- Miao, R.; Gao, Y.; Ge, L.; Jiang, Z.; Zhang, J. Online defect recognition of narrow overlap weld based on two-stage recognition model combining continuous wavelet transform and convolutional neural network. Comput. Ind. 2019, 112, 103115. [Google Scholar] [CrossRef]

- Guo, Q.; Xie, K.; Ye, W.; Zhou, T.; Xu, S. A Sparse Bayesian Learning Method for Moving Target Detection and Reconstruction. IEEE Trans. Instrum. Meas. 2025, 74, 4505413. [Google Scholar] [CrossRef]

- Lopato, P. Automatic defect recognition for pulsed terahertz inspection of basalt fiber reinforced composites. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2016, 35, 1346–1359. [Google Scholar] [CrossRef]

- Liang, P.; Deng, C.; Cheng, Y.; Yang, Z. Intelligent fault diagnosis of rotating machinery via wavelet transform, generative adversarial nets and convolutional neural network. Measurement 2020, 159, 107768. [Google Scholar] [CrossRef]

- Strąg, M.; Swiderski, W. Defect detection in aramid fiber-reinforced composites via terahertz radiation. J. Nondestruct. Eval. 2023, 42, 9. [Google Scholar] [CrossRef]

- Park, H.; Son, J.H. Machine learning techniques for THz imaging and time-domain spectroscopy. Sensors 2021, 21, 1186. [Google Scholar] [CrossRef]

- Djenouri, Y.; Srivastava, G.; Lin, J.C.W. Fast and accurate convolution neural network for detecting manufacturing data. IEEE Trans. Ind. Inform. 2020, 17, 2947–2955. [Google Scholar] [CrossRef]

| Feature Extracting Model | Classification Algorithm | Accuracy (%) | Precision (%) | Sensitivity (%) | Specificity (%) | AUC |

|---|---|---|---|---|---|---|

| AlexNet | SVM | 96.7778 | 96.7933 | 96.7778 | 98.3889 | 0.8901 |

| KNN | 77.6667 | 81.0744 | 77.6667 | 88.8333 | 0.7591 | |

| DT | 70.5556 | 70.7305 | 70.5556 | 85.2778 | 0.6864 | |

| VGG-16 | SVM | 95.1111 | 95.0881 | 95.1111 | 97.5556 | 0.8769 |

| KNN | 67.0009 | 75.6655 | 67.0009 | 83.5002 | 0.7501 | |

| DT | 67.1111 | 67.225 | 67.1111 | 83.5556 | 0.6752 | |

| VGG-19 | SVM | 94.8889 | 94.9638 | 94.8889 | 97.4444 | 0.8010 |

| KNN | 66.0007 | 75.0675 | 66.0007 | 83.0006 | 0.7304 | |

| DT | 67.2222 | 67.2651 | 67.2222 | 83.6111 | 0.6944 | |

| ResNet18 | SVM | 98.5556 | 98.5606 | 98.5556 | 99.2778 | 0.9677 |

| KNN | 89.2222 | 89.3673 | 89.2222 | 94.6111 | 0.7383 | |

| DT | 68.4444 | 68.4734 | 68.4444 | 84.2222 | 0.6775 |

| Model | ML | Classes | Precision | Recall | F1_Score |

|---|---|---|---|---|---|

| AlexNet | SVM | Adhesion Failure | 0.9574 | 0.9733 | 0.9653 |

| Layer Delamination | 0.9932 | 0.9804 | 0.9866 | ||

| Void Defect | 0.9532 | 0.9502 | 0.9516 | ||

| VGG-16 | Adhesion Failure | 0.9401 | 0.9400 | 0.9401 | |

| Layer Delamination | 0.9771 | 0.9933 | 0.9851 | ||

| Void Defect | 0.9356 | 0.9204 | 0.9277 | ||

| VGG-19 | Adhesion Failure | 0.9460 | 0.9333 | 0.9396 | |

| Layer Delamination | 0.9863 | 0.9604 | 0.9730 | ||

| Void Defect | 0.9167 | 0.9533 | 0.9346 | ||

| ResNet18 | Adhesion Failure | 0.9932 | 0.9803 | 0.9866 | |

| Layer Delamination | 0.9868 | 0.9933 | 0.9900 | ||

| Void Defect | 0.9768 | 0.9833 | 0.9801 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Chen, J.; Xin, Y.; Guo, Y.; Li, Y.; Sun, H.; Yang, X. Defect Recognition in Composite Materials Using Terahertz Spectral Imaging with ResNet18-SVM Approach. Materials 2025, 18, 2444. https://doi.org/10.3390/ma18112444

Wang Z, Chen J, Xin Y, Guo Y, Li Y, Sun H, Yang X. Defect Recognition in Composite Materials Using Terahertz Spectral Imaging with ResNet18-SVM Approach. Materials. 2025; 18(11):2444. https://doi.org/10.3390/ma18112444

Chicago/Turabian StyleWang, Zhongmin, Jiaojie Chen, Yilong Xin, Yongbin Guo, Yizhang Li, Huanyu Sun, and Xiuwei Yang. 2025. "Defect Recognition in Composite Materials Using Terahertz Spectral Imaging with ResNet18-SVM Approach" Materials 18, no. 11: 2444. https://doi.org/10.3390/ma18112444

APA StyleWang, Z., Chen, J., Xin, Y., Guo, Y., Li, Y., Sun, H., & Yang, X. (2025). Defect Recognition in Composite Materials Using Terahertz Spectral Imaging with ResNet18-SVM Approach. Materials, 18(11), 2444. https://doi.org/10.3390/ma18112444