Influence of Cu on the Mechanical and Shape Memory Properties of TiNi Alloys

Abstract

1. Introduction

2. Materials and Methods

2.1. Vacuum Arc Melting and Hot Rolling

2.2. Microstructure and Property Characterization

3. Results and Discussion

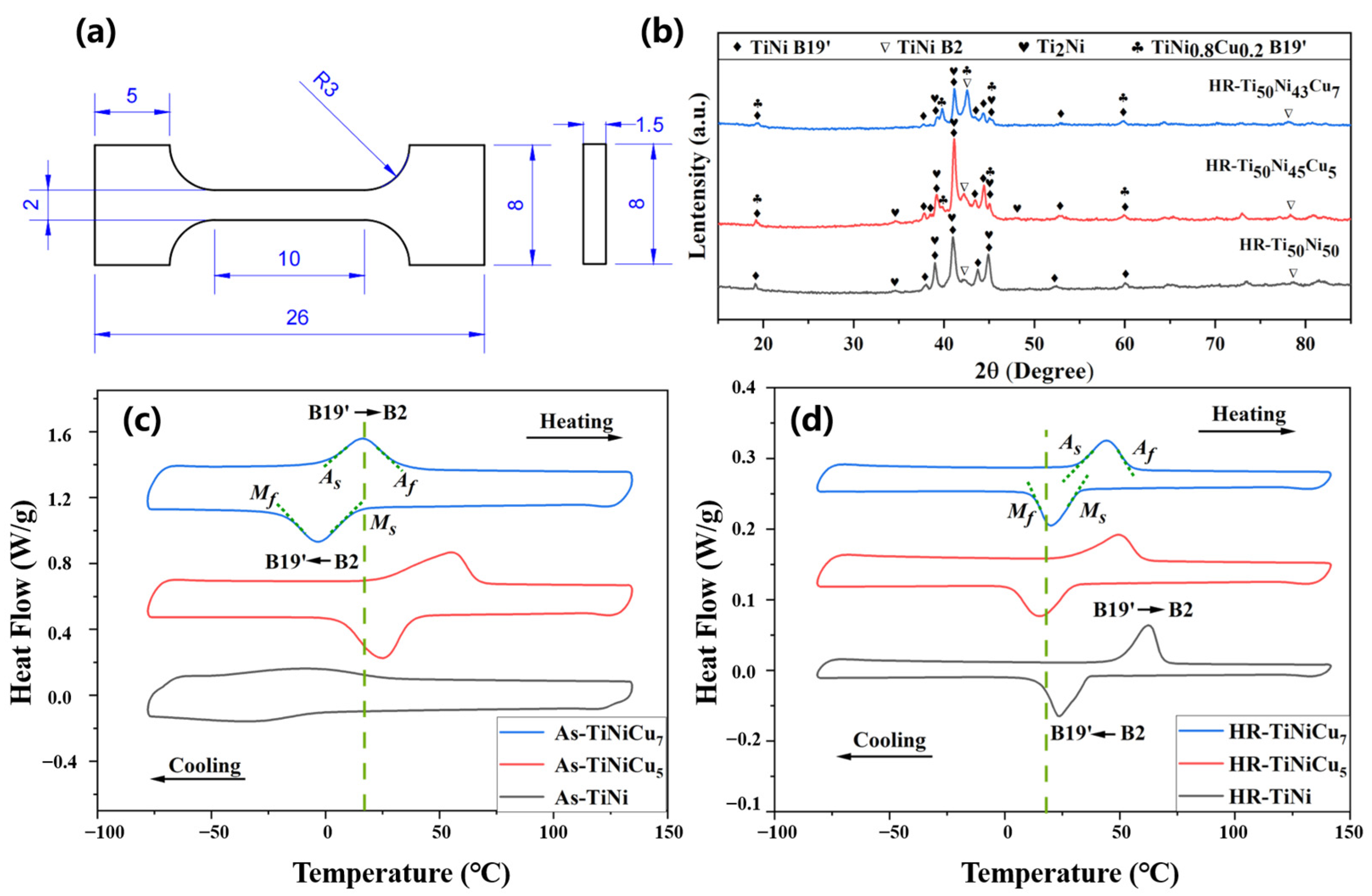

3.1. Impact of Cu Content on Phase Transformation Behavior

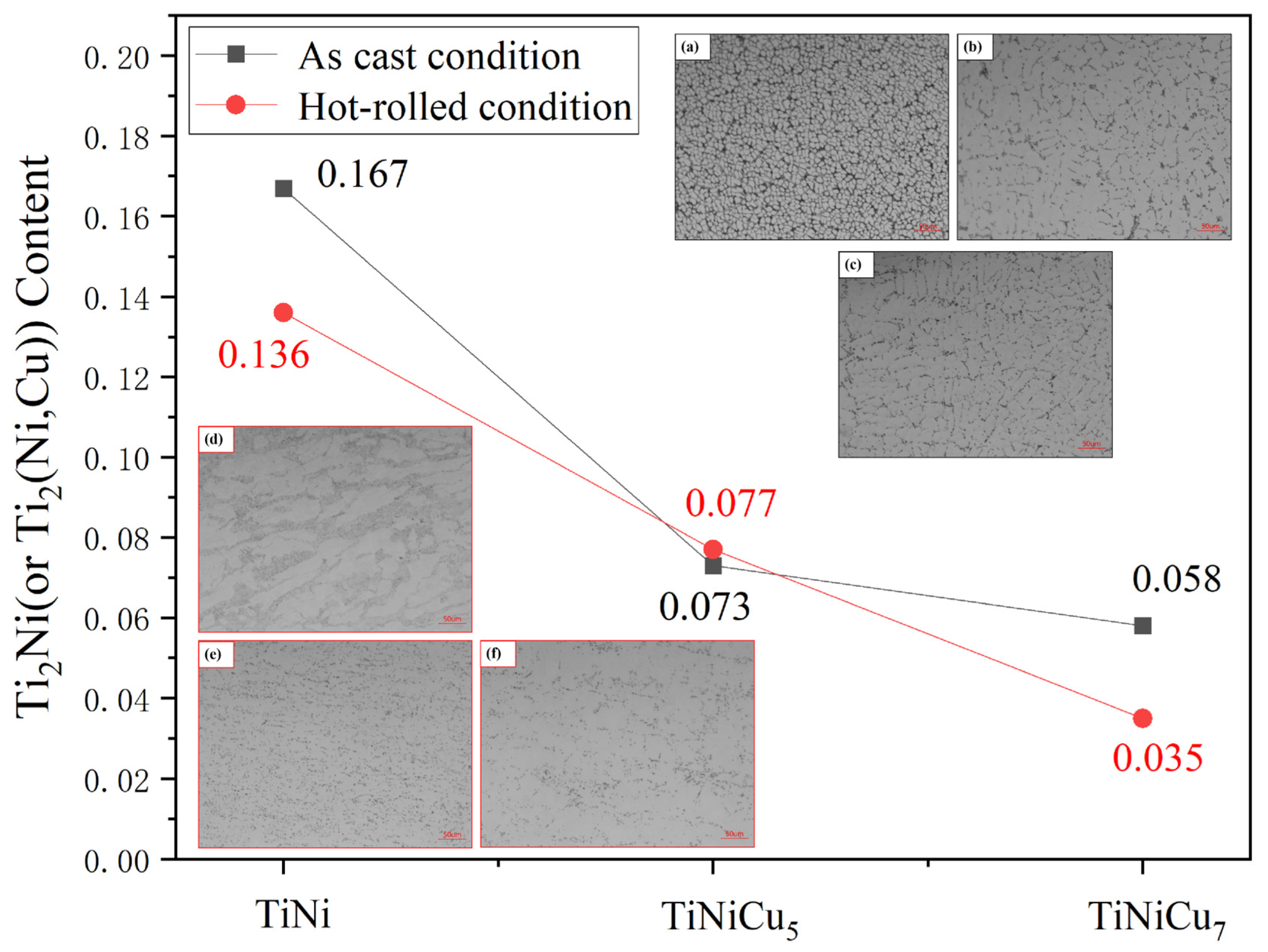

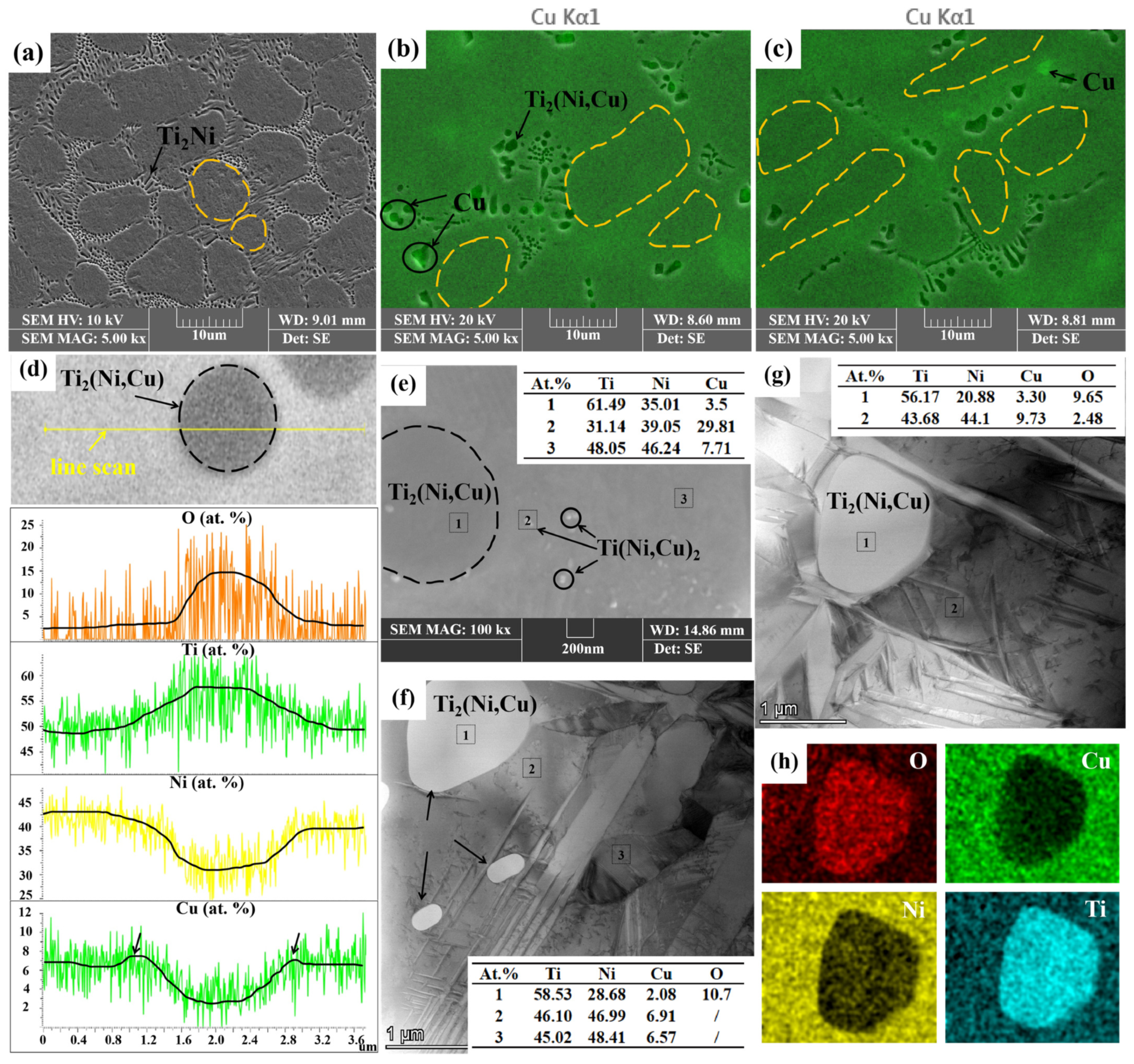

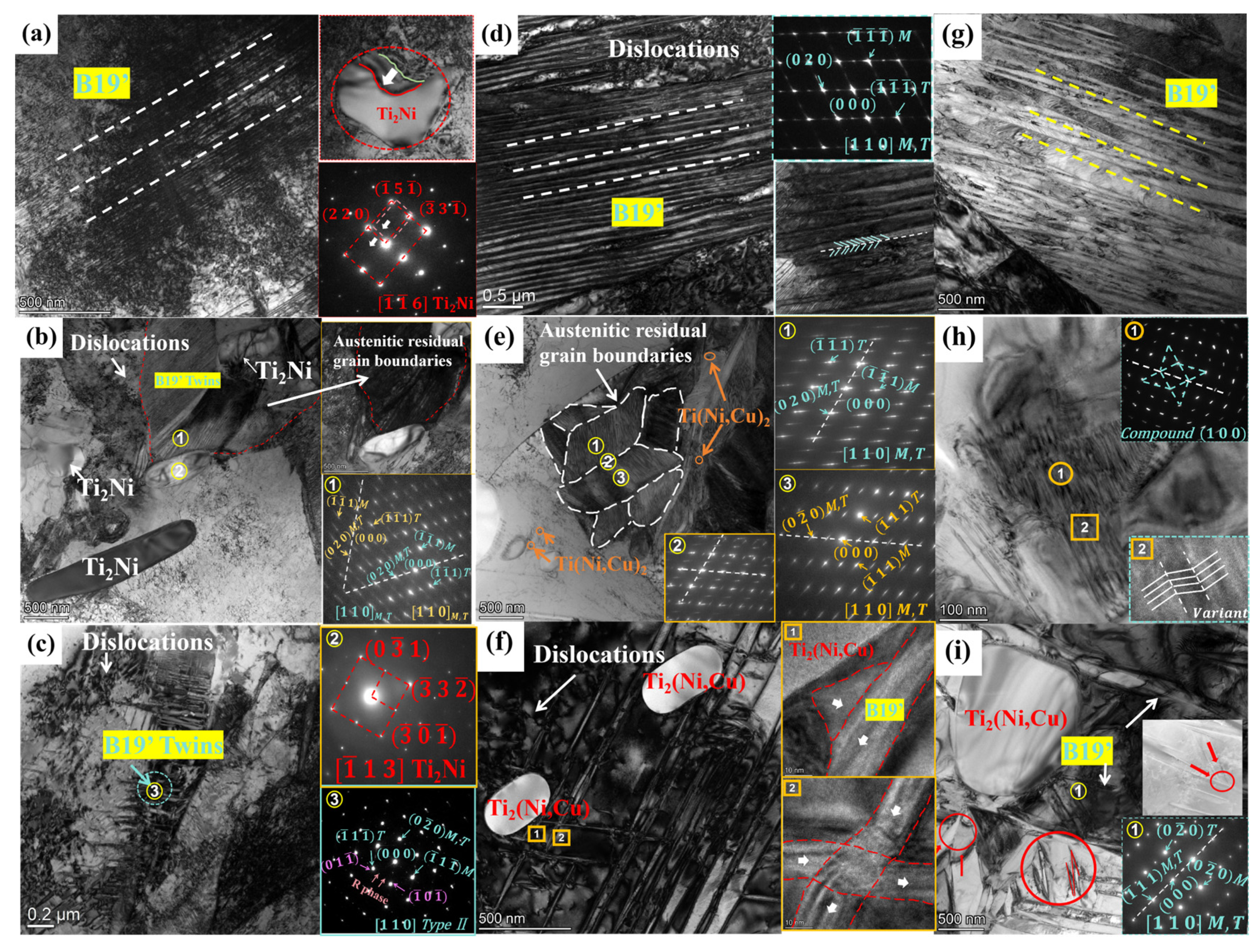

3.2. Effect of Cu Addition on the Formation and Evolution of Precipitate Phases

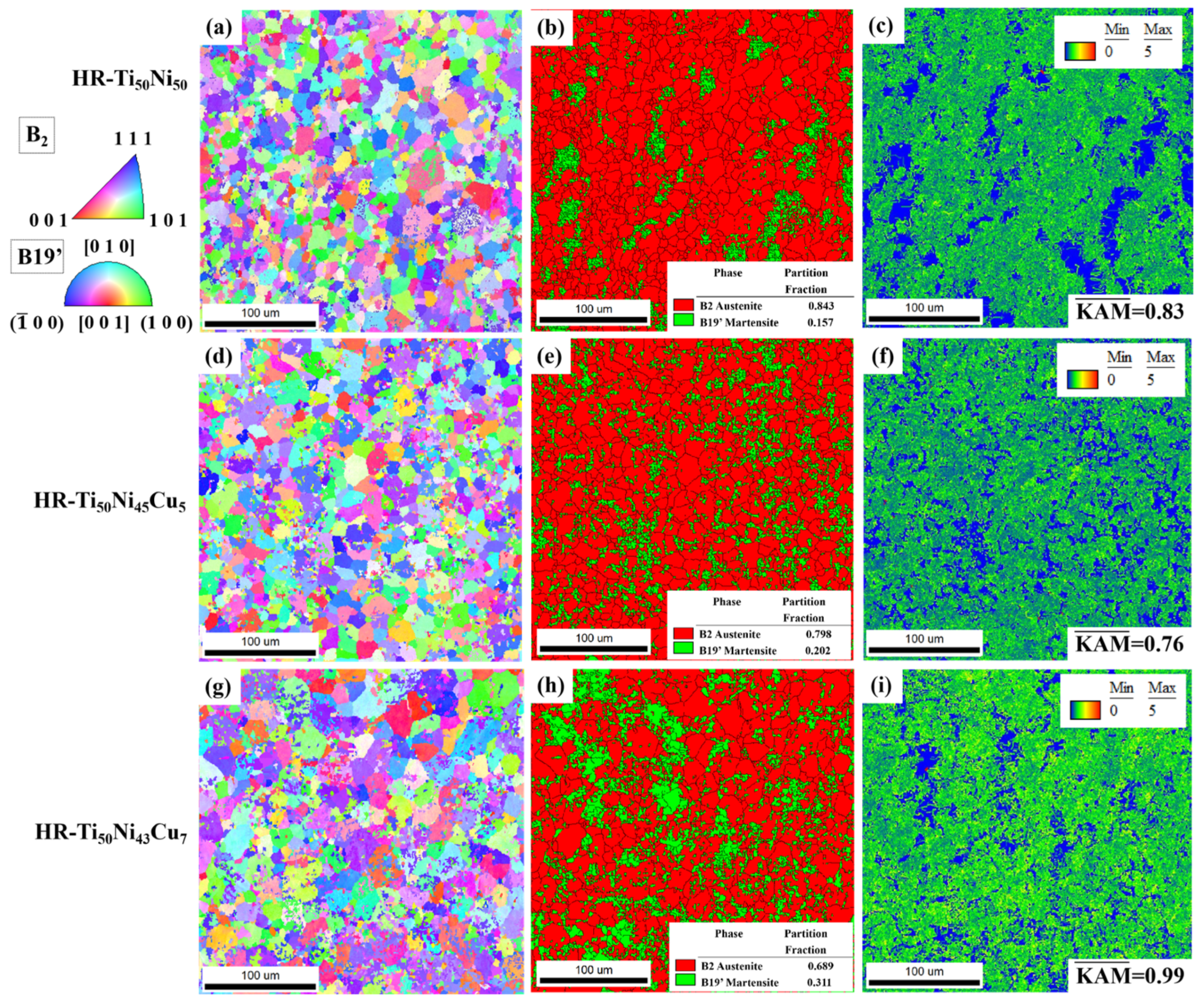

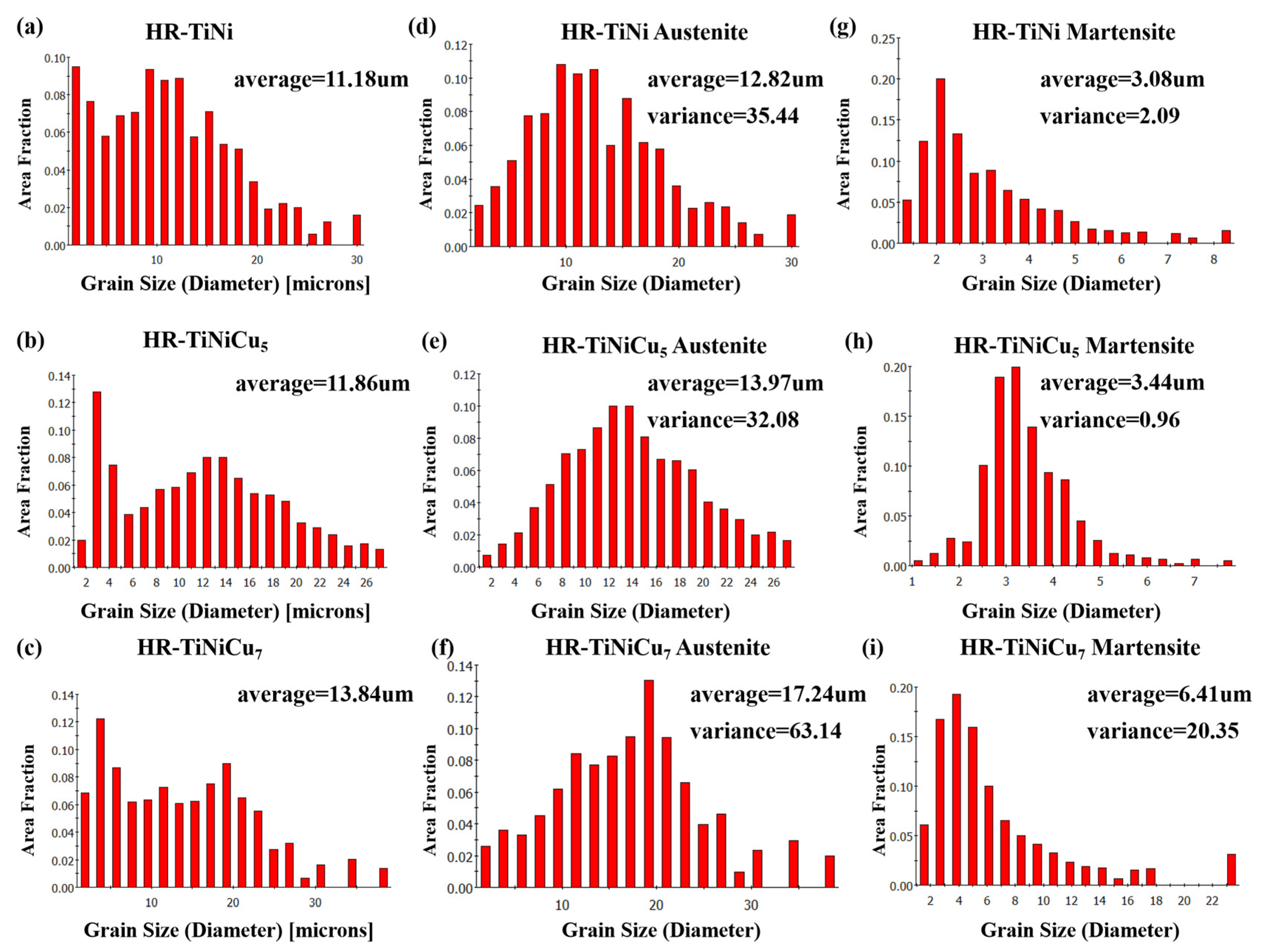

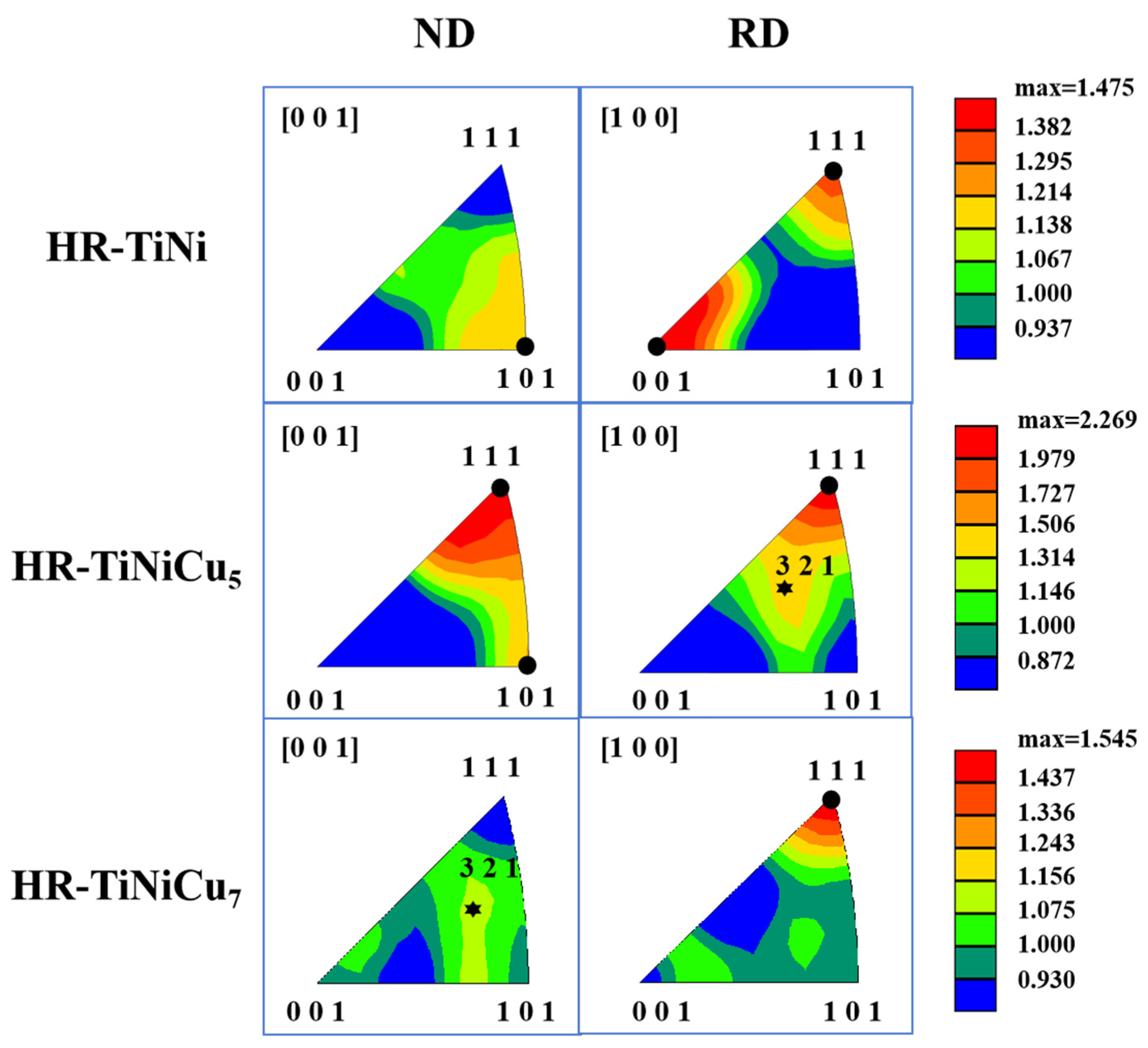

3.3. Effect of Cu on the Organization of Grains in Both Martensite and Austenite

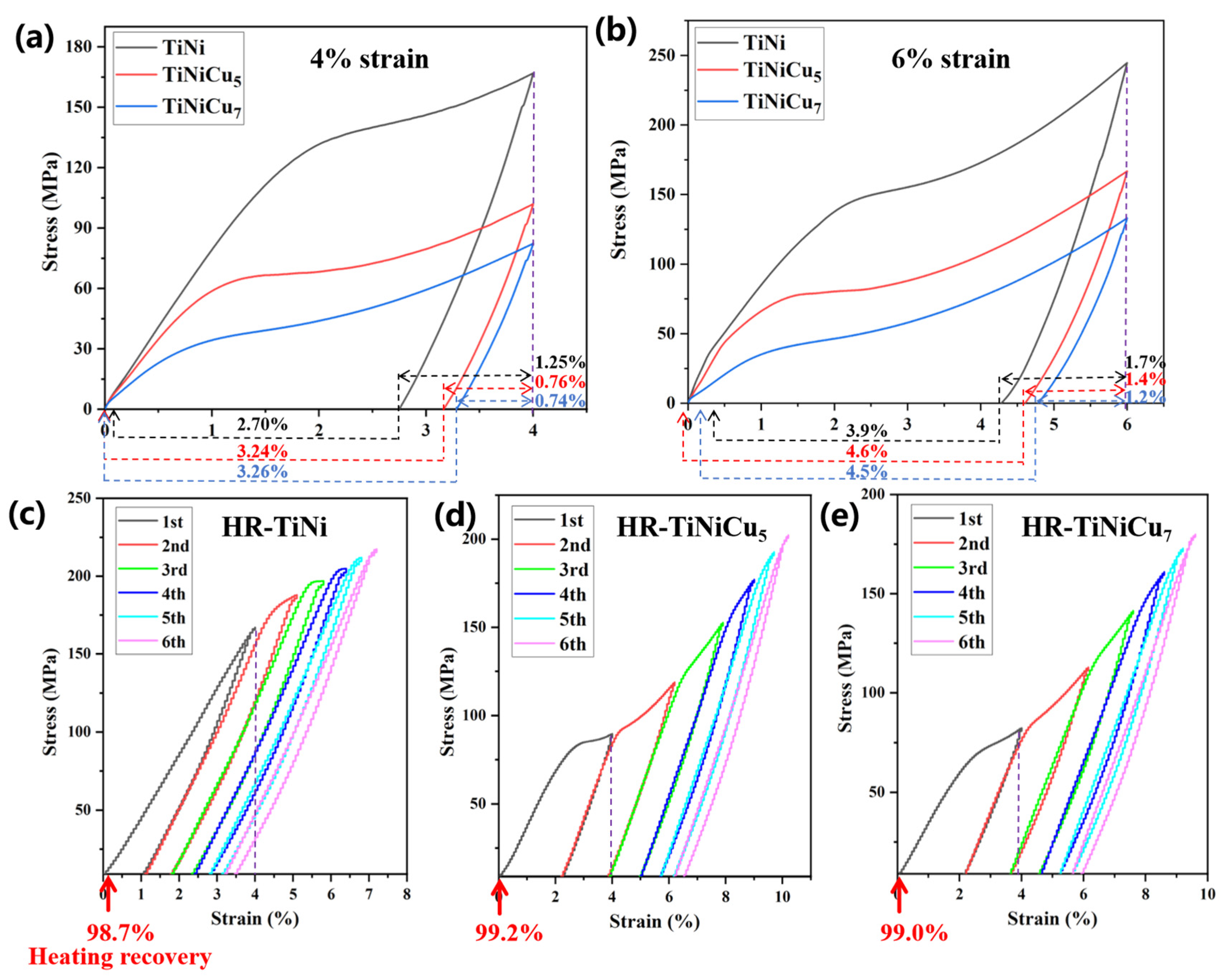

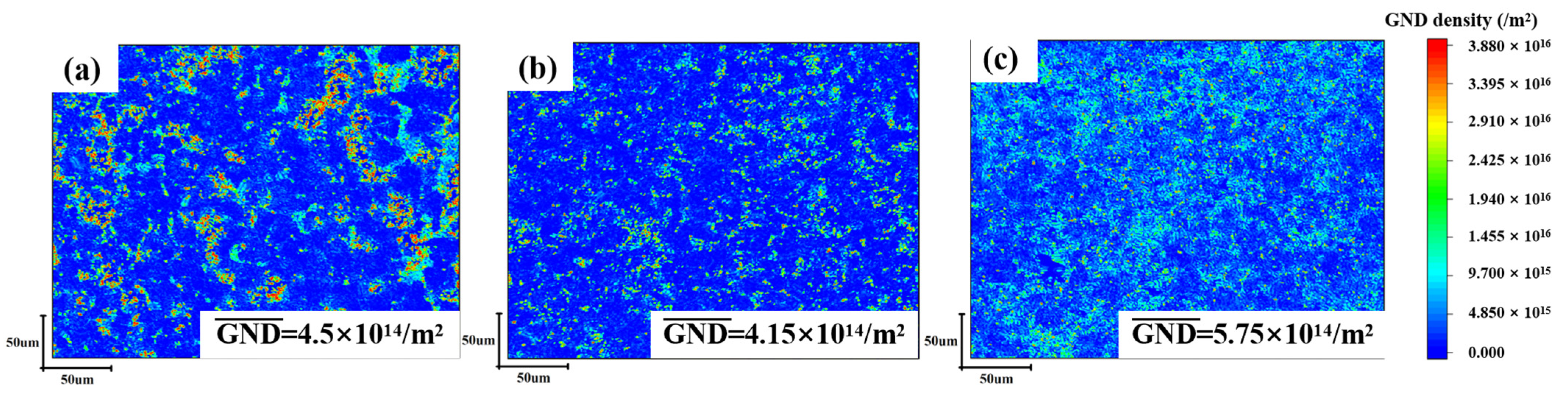

3.4. Tensile Properties and Shape Memory Effect

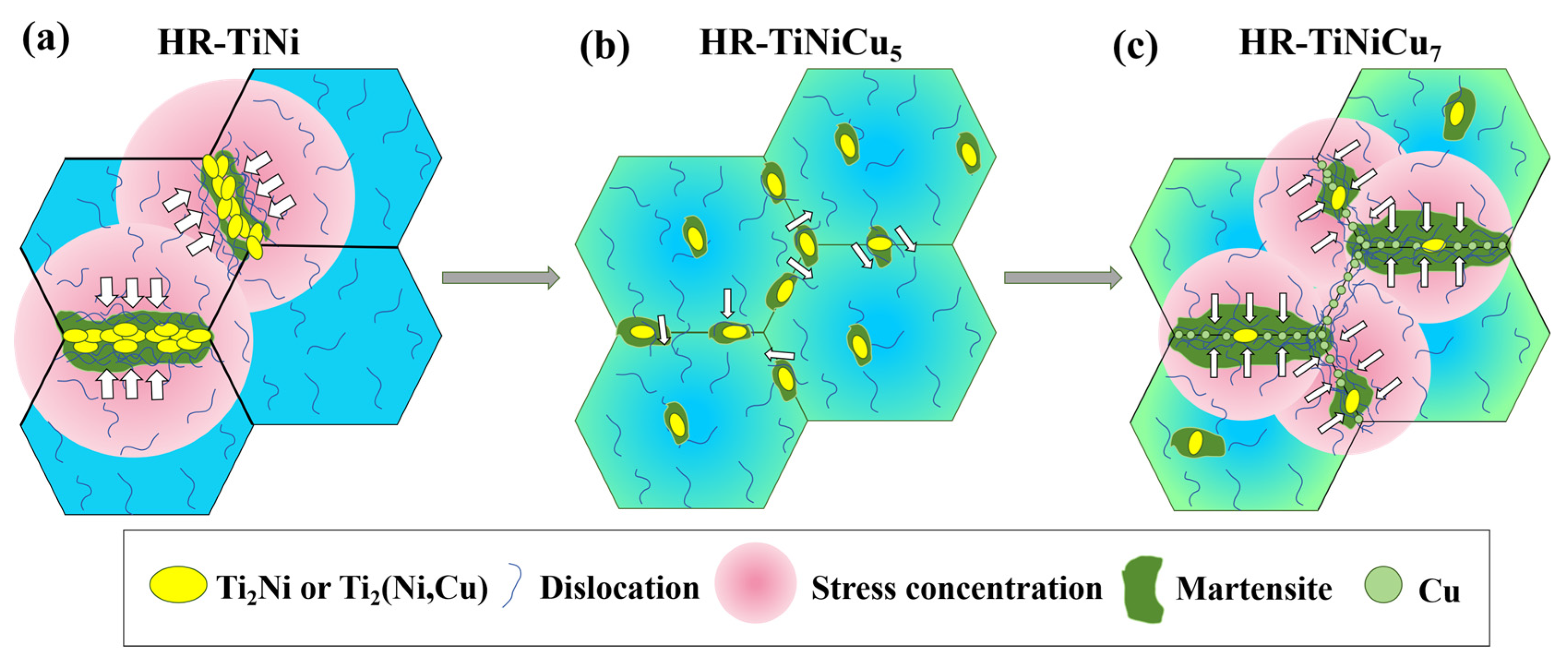

4. Discussion

5. Conclusions

- (1)

- The HR-TiNiCu5 shape memory alloy (SMA) demonstrates outstanding shape memory performance, achieving a recovery rate of 99.2% upon heating after six tensile cycles at 4% strain. Furthermore, it exhibits exceptional tensile properties, with an elongation of 44.9 ± 2% and an ultimate tensile strength of 924.6 MPa ± 20 MPa, outperforming most previously reported TiNiCu SMAs under comparable processing conditions.

- (2)

- This study posits that by adjusting the Cu content and utilizing the hot rolling process, the Ti2(Ni,Cu) phase can be modulated to optimize the dislocation slip mechanism, thereby improving the properties and functionality of TiNiCu alloys. This method provides novel insights into the modulation of precipitation phases.

- (3)

- In this paper, the effect of the Cu element on the precipitation phase, phase transition temperature, grain size, and martensitic twinning of the TiNi alloy is elaborated. The impact of Cu on microstructure evolution is substantiated. Furthermore, this study proposes an optimized Cu ratio for TiNiCu alloys, thus providing a valuable reference point for industrial applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, H.; Ma, H.; Luo, X.; Wang, Y.; Wang, J.; Lupoi, R.; Yin, S.; Yang, C. Microstructure, shape memory properties, and in vitro biocompatibility of porous NiTi scaffolds fabricated via selective laser melting. J. Mater. Res. Technol. 2021, 15, 6797–6812. [Google Scholar] [CrossRef]

- Frenzel, J.; George, E.P.; Dlouhy, A.; Somsen, C.; Wagner, M.F.X.; Eggeler, G. Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 2010, 58, 3444–3458. [Google Scholar] [CrossRef]

- Haenschke, T.; Davis, C.L.; Attallah, M.M. Influence of the microstructural inhomogeneities on the martensite-to-austenite phase transformation temperatures in TiNiCu-based shape-memory alloys. Mater. Chem. Phys. 2013, 141, 272–277. [Google Scholar] [CrossRef]

- Jiang, H.-J.; Ke, C.-B.; Cao, S.-S.; Ma, X.; Zhang, X.-P. Phase transformation and damping behavior of lightweight porous TiNiCu alloys fabricated by powder metallurgy process. Trans. Nonferrous Met. Soc. China 2013, 23, 2029–2036. [Google Scholar] [CrossRef]

- Nam, T.H.; Saburi, T.; Shimizu, K. Cu-content dependence of shape memony characienistics in TiN-cu aloys. MatelTrans. JLM 1990, 31, 959–967. [Google Scholar] [CrossRef]

- Strnadel, B.; Ohashi, S.; Ohtsuka, H.; Ishihara, T.; Miyazaki, S. Cyclic stress-strain characteristics of Ti-Ni and Ti-Ni-Cu shape memory alloys. Mater. Sci. Eng. A 1995, 202, 148–156. [Google Scholar] [CrossRef]

- Gou, L.; Liu, Y.; Ng, T.Y. An investigation on the crystal structures of Ti50Ni50−xCux shape memory alloys based on density functional theory calculations. Intermetallics 2014, 53, 20–25. [Google Scholar] [CrossRef]

- Seyyed Aghamiri, S.M.; Nili Ahmadabadi, M.; Shahmir, H.; Naghdi, F.; Raygan, S. Study of thermomechanical treatment on mechanical-induced phase transformation of NiTi and TiNiCu wires. J. Mech. Behav. Biomed. Mater. 2013, 21, 32–36. [Google Scholar] [CrossRef]

- Wei, S.; Zhang, J.; Zhang, L.; Zhang, Y.; Song, B.; Wang, X.; Fan, J.; Liu, Q.; Shi, Y. Laser powder bed fusion additive manufacturing of NiTi shape memory alloys: A review. Int. J. Extrem. Manuf. 2023, 5, 032001. [Google Scholar] [CrossRef]

- Jia, C.; Xiong, Z.-P.; Yang, D.-Z.; Wang, Y.-W.; Cheng, X.-W. Effect of rolling temperature and reduction on brick-and-mortar Ti2Ni/TiNi composite. Trans. Nonferrous Met. Soc. China 2023, 33, 2064–2075. [Google Scholar] [CrossRef]

- Lu, H.Z.; Liu, L.H.; Yang, C.; Luo, X.; Song, C.H.; Wang, Z.; Wang, J.; Su, Y.D.; Ding, Y.F.; Zhang, L.C.; et al. Simultaneous enhancement of mechanical and shape memory properties by heat-treatment homogenization of Ti2Ni precipitates in TiNi shape memory alloy fabricated by selective laser melting. J. Mater. Sci. Technol. 2022, 101, 205–216. [Google Scholar] [CrossRef]

- Popa, M.; Daniel Apostol, V.; Monica Lohan, N.; Cimpoesu, N.; Cazacu, M.; Borza, F.; Bujoreanu, L.-G. Investigation of some thermomechanical processing effects on the structure and properties of a TiNiCu shape memory alloy. Mater. Today Proc. 2023, 72, 600–606. [Google Scholar] [CrossRef]

- Villa, F.; Nespoli, A.; Passaretti, F.; Villa, E. Microstructural and Thermo-Mechanical Characterization of Cast NiTiCu20 Shape Memory Alloy. Materials 2021, 14, 3770. [Google Scholar] [CrossRef]

- Liao, Y.; Song, Y.; Shu, N.; Niu, Y.; Zhang, H.; Sun, B.; Wang, Y.; Li, C.; Gu, J. Enhanced strength-ductility synergy in ferrous medium-entropy alloys via single-step hot rolling. Mater. Sci. Eng. A 2025, 926, 147920. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, Y.; Zuo, X.; Wan, J.; Rong, Y.; Chen, N.; Lu, J. Dislocations across interphase enable plain steel with high strength-ductility. Sci. Bull. 2021, 66, 1058–1062. [Google Scholar] [CrossRef]

- Silva, J.D.; Macieira, G.F.C.; dos Santos, D.S.; de Arruda Santos, L.; Buono, V.T.L. Role of Nb on the phase stability and morphology of Ti–Ni–Cu–Nb alloys. J. Mater. Res. Technol. 2022, 20, 1428–1436. [Google Scholar] [CrossRef]

- de Araújo, C.J.; da Silva, N.J.; da Silva, M.M.; Gonzalez, C.H. A comparative study of Ni–Ti and Ni–Ti–Cu shape memory alloy processed by plasma melting and injection molding. Mater. Des. 2011, 32, 4925–4930. [Google Scholar] [CrossRef]

- Cascadan, D.; Grandini, C.R. Effect of Oxygen in the Structure, Microstructure and Mechanical Properties of Ti-xNi (x = 5, 10, 15 and 20 wt%) Alloys. Metals 2020, 10, 1424. [Google Scholar] [CrossRef]

- Bahador, A.; Hamzah, E.; Kondoh, K.; Asma Abubakar, T.; Yusof, F.; Umeda, J.; Saud, S.N.; Ibrahim, M.K. Microstructure and superelastic properties of free forged Ti–Ni shape-memory alloy. Trans. Nonferrous Met. Soc. China 2018, 28, 502–514. [Google Scholar] [CrossRef]

- Stemper, L.; Tunes, M.A.; Dumitraschkewitz, P.; Mendez-Martin, F.; Tosone, R.; Marchand, D.; Curtin, W.A.; Uggowitzer, P.J.; Pogatscher, S. Giant hardening response in AlMgZn(Cu) alloys. Acta Mater. 2021, 206, 116617. [Google Scholar] [CrossRef]

- Menushenkov, A.P.; Grishina, O.V.; Yaroslavtsev, A.A.; Chernikov, R.V.; Bednarcik, J.; Shelyakov, A.V.; Sitnikov, N.N.; Zubavichus, Y.V.; Veligzhanin, A.A. Local crystal structure of TiNiCu shape memory alloys. J. Phys. Conf. Ser. 2013, 430, 012067. [Google Scholar] [CrossRef]

- Kim, J.-H.; Lim, J.-H.; Lee, W.-T.; Kim, J.G.; Oh, J.S.; Lee, T.; Li, S.; Nam, T.-H. Microstructures and mechanical behavior of Ti-(38+x)Ni-12Cu (at%) (x=0∼3) alloys. J. Alloys Compd. 2023, 938, 168664. [Google Scholar] [CrossRef]

- Hsu, Y.-T.; Wu, C.-T.; Chen, C.-H. Nanoscale-precipitate-strengthened (Ni,Cu)-rich TiNiCu shape memory alloy with stable superelasticity and elastocaloric performance. J. Alloys Compd. 2024, 997, 174937. [Google Scholar] [CrossRef]

- Shim, J.-H.; Kim, J.-H.; Lim, J.-H.; Kim, J.G.; Oh, J.S.; Lee, T.; Li, S.; Nam, T.-H. Improvement in the superelasticity of a Ti–35.5Ni–15Cu (at.%) alloy using Ti(Ni, Cu)2 phase. Mater. Sci. Eng. A 2022, 847, 143346. [Google Scholar] [CrossRef]

- Shuai, L.; Huang, T.; Yu, T.; Wu, G.; Hansen, N.; Huang, X. Segregation and precipitation stabilizing an ultrafine lamellar-structured Al-0.3%Cu alloy. Acta Mater. 2021, 206, 116595. [Google Scholar] [CrossRef]

- Haq, I.U.; Imran Khan, M.; Karim, R.A.; Raza, S.A.; Wadood, A.; Hassan, M. Effect of Various Thermal Treatments and Cu Contents on Precipitation Mechanism, Martensitic Growth, and Cold Workability of Ti50Ni50-xCux Ternary Shape Memory Alloys. J. Mater. Eng. Perform. 2021, 30, 451–466. [Google Scholar] [CrossRef]

- Shiva, S.; Yadaiah, N.; Palani, I.A.; Paul, C.P.; Bindra, K.S. Thermo mechanical analyses and characterizations of TiNiCu shape memory alloy structures developed by laser additive manufacturing. J. Manuf. Process. 2019, 48, 98–109. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, J.; Gong, B.; Zhao, J.; Yang, M.; Chen, L. Analyzing the effect of the mechanical stability of residual austenite on the wear performance. Tribol. Int. 2024, 192, 109326. [Google Scholar] [CrossRef]

- Kumar, S.; Pai, N.N.; Manda, S.; Tewary, U.; Fullwood, D.T.; Giri, S.K.; Kundu, S.; Murty, S.V.S.N.; Anoop, C.R.; Samajdar, I. Austenite residual stress and lath martensite variant selection in low carbon steels. Acta Mater. 2025, 289, 120885. [Google Scholar] [CrossRef]

- Costanza, G.; Tata, M.E.; Libertini, R. Effect of temperature on the mechanical behaviour of ni-ti shape memory sheets. In Proceedings of the TMS Annual Meeting and Exhibition, Nashville, TN, USA, 14–18 February 2016. [Google Scholar]

- Timofeeva, E.E.; Panchenko, E.Y.; Zherdeva, M.V.; Eftifeeva, A.S.; Surikov, N.Y.; Tagiltsev, A.I.; Fatkullin, I.; Tokhmetova, A.; Yanushonite, E.I.; Chumlyakov, Y.I. Shape memory effect in TiNi single crystals with thermal-induced martensite transformation or strain glass transition. J. Alloys Compd. 2022, 922, 166275. [Google Scholar] [CrossRef]

- Chowdhury, P.; Sehitoglu, H. Deformation physics of shape memory alloys—Fundamentals at atomistic frontier. Prog. Mater. Sci. 2017, 88, 49–88. [Google Scholar] [CrossRef]

- Cui, S.; Wan, J.; Zuo, X.; Chen, N.; Rong, Y. Interface stress evolution of martensitic transformation in MnCu alloys: A phase-field study. Mater. Des. 2016, 109, 88–97. [Google Scholar] [CrossRef]

- Yi, J.; Wan, L.; Shu, T.; Zhang, X.; Liu, F.; Cheng, G.J. Unleashing multi-scale mechanical enhancement in NiTi shape memory alloy via annular intra-laser deposition with homogenized Ti2Ni nanoprecipitates. Acta Mater. 2024, 262, 119418. [Google Scholar] [CrossRef]

- Zhang, Q.; Shen, H.; Yang, Y.; Liu, Y.; Liu, Y.; Zhang, Z.; Cui, L.; Hao, S. In-situ TEM study on the effect of dislocations on phase transformation and cycling behaviors of laser powder bed fused TiNi alloy. J. Alloys Compd. 2025, 1013, 178450. [Google Scholar] [CrossRef]

- Zhu, C.; Xu, L.; Xie, H.; Shi, R.; Yin, L.; Wei, S. Effect of heat treatment processes on the microstructure and mechanical properties of 00Cr13Ni5Mo super martensitic stainless steel (SMSS). J. Mater. Res. Technol. 2024, 32, 2006–2021. [Google Scholar] [CrossRef]

| Scheme | Ti (at.%) | Ni (at.%) | Cu (at.%) | O (at.%) | H (at.%) | |

|---|---|---|---|---|---|---|

| Ti50Ni50 | Nominal composition | 50.00 | 50.00 | / | / | / |

| Actual component | 49.15 | 50.48 | / | 0.33 | 0.04 | |

| Ti50Ni45Cu5 | Nominal composition | 50.00 | 45.00 | 5.00 | / | / |

| Actual component | 50.03 | 44.85 | 4.91 | 0.33 | 0.04 | |

| Ti50Ni43Cu7 | Nominal composition | 50.00 | 43.00 | 7.00 | / | / |

| Actual component | 50.03 | 42.81 | 6.95 | 0.33 | 0.03 | |

| Sample | As (°C) | Af (°C) | Ms (°C) | Mf (°C) | ∆HMA (J/g) | ∆HAM (J/g) | DTH (°C) |

|---|---|---|---|---|---|---|---|

| As-Ti50Ni50 | −46.7 | 26 | −7.5 | −71.8 | 16.3 | −11.0 | 33.5 |

| As-Ti50Ni45Cu5 | 25.4 | 66.1 | 36.8 | 8.3 | 28.9 | −30.3 | 29.3 |

| As-Ti50Ni43Cu7 | 0.7 | 32 | 13 | −17.6 | 24.7 | −25.8 | 19 |

| HR-Ti50Ni50 | 51 | 68.4 | 36.3 | 15.9 | 3.8 | −4.2 | 32.1 |

| HR-Ti50Ni45Cu5 | 32.3 | 59.2 | 29.2 | 3.8 | 3.9 | −4.4 | 30 |

| HR-Ti50Ni43Cu7 | 32.2 | 54.3 | 32 | 12.6 | 3.5 | −3.7 | 22.3 |

| Composition | First Plateau Stress (MPa) | Tensile Strength (MPa) | Strain (%) | |

|---|---|---|---|---|

| As-Ti50Ni50 | 93.4 (±10) | 654.5 (±25) | 21.7 (±5) | |

| As-Ti50Ni45Cu5 | 166.2 (±10) | 565.2 (±25) | 18.3 (±5) | |

| As-Ti50Ni43Cu7 | 294.9 (±10) | 508.4 (±25) | 14.4 (±5) | |

| RD | HR-Ti50Ni50 | 186.2 (±5) | 976.4 (±15) | 29.2 (±2) |

| HR-Ti50Ni45Cu5 | 58.8 (±5) | 934.6 (±15) | 44.9 (±2) | |

| HR-Ti50Ni43Cu7 | 39.3 (±5) | 840.0 (±15) | 32.4 (±2) | |

| ND | HR-Ti50Ni50 | 185.8 (±5) | 967.6 (±15) | 28.3 (±2) |

| HR-Ti50Ni45Cu5 | 59.0 (±5) | 903.7 (±15) | 38.2 (±2) | |

| HR-Ti50Ni43Cu7 | 39.1 (±5) | 829.3 (±15) | 30.6 (±2) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, L.; Mann, W.; He, B. Influence of Cu on the Mechanical and Shape Memory Properties of TiNi Alloys. Materials 2025, 18, 2407. https://doi.org/10.3390/ma18102407

Dong L, Mann W, He B. Influence of Cu on the Mechanical and Shape Memory Properties of TiNi Alloys. Materials. 2025; 18(10):2407. https://doi.org/10.3390/ma18102407

Chicago/Turabian StyleDong, Luzhou, Weifang Mann, and Bo He. 2025. "Influence of Cu on the Mechanical and Shape Memory Properties of TiNi Alloys" Materials 18, no. 10: 2407. https://doi.org/10.3390/ma18102407

APA StyleDong, L., Mann, W., & He, B. (2025). Influence of Cu on the Mechanical and Shape Memory Properties of TiNi Alloys. Materials, 18(10), 2407. https://doi.org/10.3390/ma18102407