Abstract

With the rapid development of electrical energy storage technologies, traditional battery systems are limited in practical applications by insufficient energy density and short cycle life. This review provides a comprehensive and critical summary of MXene or MXene-based composites as electrode materials for high-performance energy storage devices. By integrating the synthesis techniques of MXenes that have been studied, this paper systematically illustrates the physicochemical properties, synthesis strategies, and mechanisms of MXenes, and analyzes the bottlenecks in their large-scale preparation. Meanwhile, it collates the latest research achievements of MXenes in the field of metal–ion batteries in recent years, focusing on integrating their latest progress in lithium–ion, sodium–ion, lithium–sulfur, and multivalent ion (Zn2+, Mg2+, Al3+) batteries, and reveals their action mechanisms in different electrode material cases. Combining DFT analysis of the effects of surface functional groups on adsorption energy with experimental studies clarifies the structure–activity relationships of MXene-based composites. However, the development of energy storage electrode materials using MXenes and their hybrid compounds remains in its infancy. Future development directions for MXene-based batteries should focus on understanding and regulating surface chemistry, investigating specific energy storage mechanisms in electrodes, and exploring and developing electrode materials related to bimetallic MXenes.

1. Introduction

Over the past few decades, with rapid technological advances and the constant depletion of fossil fuels, there has been a growing demand for sustainable energy sources [1]. From various portable electronic devices to large-scale energy storage systems, rechargeable batteries have become the foundation of modern green life and progress [2]. However, current battery technology faces challenges such as low energy density, short cycle life, poor stability, and insufficient safety, which severely limits the application of batteries in high-power scenarios where they have to be charged and discharged quickly [3,4]. Therefore, it is urgent to further improve the performance of the battery, and traditional anode materials such as graphite are close to their theoretical capacity limits [5,6].

Metal–air batteries (zinc–air batteries) and metal–ion batteries (lithium, sodium, zinc plasma batteries) are the two major branches in the field of rechargeable batteries. Taking the zinc–air battery as an example, it stores energy through the electrochemical reaction between the zinc anode and oxygen in the air, and its theoretical energy density is much higher than that of a lithium–ion battery (5928 Wh/kg for lithium-air battery) [7]. However, its practical application is limited by the design of bifunctional catalysts (e.g., high cost of noble metal Pt/Ir and carbon carrier corrosion), CO2 sensitivity of the electrolyte, and cycling decay due to zinc dendrite growth [7]. In contrast, metal–ion eliminates the need for external oxygen and offers advantages in cycle life, power density, and process maturity.

Since its first report in 2011, MXene, an emerging two-dimensional material, has demonstrated remarkable potential in the field of electrochemical energy storage [8]. Characterized by a high specific surface area, excellent electrical conductivity, good mechanical properties, abundant surface functional groups, and a controllable layered structure, MXene offers higher theoretical capacity, faster ion transport efficiency, and better stability than traditional battery materials [9,10]. These advantages position MXene as a promising candidate for advancing next-generation energy storage technologies. However, there are still major challenges for its practical application. First, the process of large-scale preparation of MXene is immature, and most of the preparation methods are restricted to experiments. Second, MXene as an electrode material may produce accumulation between layers during charging and discharging, which may even lead to severe oxidative degradation at high current densities, affecting the performance of the battery [11,12]. Enhancing the interfacial compatibility of MXene with other active electrode materials to avoid side reactions is also one of the current keys to improve battery performance. To address these challenges, many strategies have been analyzed and proposed, including synthesizing and using a single extremely thin MXene lamella, extending the MXene lamella spacing to achieve tunability, constructing heterogeneous/composite electrode materials with MXene as the substrate and designing different electrode structures, and expanding the bridging between active materials and MXene [13,14]. By modifying and functionalizing MXene to improve its interfacial interaction with electrolytes, or by optimizing its surface functional groups to enable effective compositing with other high-capacity electrode materials, the cycling stability and charge transfer efficiency of MXene-based batteries can be significantly enhanced [15]. One of the most common applications of MXene is as a conductive substrate for composite electrodes, where its abundant surface functional groups enable the grafting or growth of other electrochemically active materials—such as transition metal oxides, sulfides, and other compounds—thereby constructing multidimensional conductive frameworks [15,16,17]. These materials are chemically synthesized by physical mixing, in situ growth, or solvothermal methods, or self-assembled into strong transition layers and covalently bonded heterogeneous structures by electrostatic interaction [18,19]. The special electronic structure and variable valence states of electrochemically active phases provide high-capacity storage sites, which effectively promote charge transfer and improve electrochemical performance [18,20].

In 2011, MXene was discovered and began to be noticed and used as a new material for metal–ion batteries; in 2014, a breakthrough was made in MXene-based aluminum–ion batteries (AIBs), which provided a direction for MXene to be explored in MVIBs; in 2016, preliminary lithium–ion research was launched, and MXene’s material properties were explored in depth; in 2018, MXene-based magnesium–ion batteries (MIBs) appeared and attracted attention; in 2019, the MXene-based zinc–ion battery (ZIB) was pioneered as an application of MVIB; in 2021, the multivalent¬–ion battery (MVIB) was commercialized, which could not be separated from the success of MXene’s many years of research accumulated in various ion battery systems. Currently, with the deepening of research, the performance of MXene combined with ion batteries has been optimized, and the application prospect is becoming more and more promising. These key points in chronological order clearly show the complete development of MXene and ion batteries from material discovery, and technological breakthroughs to application expansion and commercialization, as shown in Figure 1.

Figure 1.

Timeline of representative MXene breakthroughs in MIBs in recent years.

This review aims to systematically summarize the latest research advancements of MXene in the field of metal–ion batteries in recent years, detailing its structural-performance characteristics and synthesis methodologies. The synthesis approaches for MXene are categorized into three types based on fluorine usage: “fluorine-based etching”, “fluorine-free etching”, and “fluorine-free synthesis”. A comparative analysis is conducted to evaluate how different etching methods influence MXene’s surface functional groups and the number/thickness of its nanosheets. Additionally, the bottlenecks in large-scale MXene preparation are systematically analyzed, with a focus on deciphering the mechanisms of fluorine-free etching techniques to provide a theoretical foundation for green synthesis and functional modification. The review integrates the recent progress of MXene in lithium–ion, sodium–ion, lithium–sulfur, and multivalent ion (Zn2+, Mg2+, Al3+) batteries, revealing its multifunctional roles in different systems—such as anchoring polysulfides in lithium–sulfur batteries, regulating ion diffusion pathways, and inhibiting lithium dendrite growth. By combining density functional theory (DFT) analysis of surface group effects on adsorption energy with experimental results, the structure–activity relationships of MXene-based composites are clarified, highlighting the interplay between material structure and electrochemical performance. Finally, the review outlines future development directions for MXene-based batteries, proposing critical perspectives and suggestions to inspire research in electrochemical energy storage systems. These insights aim to guide advancements toward more efficient, sustainable, and high-performance energy storage technologies.

2. Properties of MXene

MXene materials have attracted considerable attention due to their exclusive properties, including high electrical conductivity, good mechanical properties, outstanding thermal stability, and hydrophilicity [21,22]. Moreover, they typically possess abundant surface functional groups (-OH, -O, -F, etc.), providing numerous active sites that endow them with remarkable surface reactivity and tunability. Coupled with their unique two-dimensional layered structure, these characteristics render MXene materials highly promising for wide applications in energy storage/conversion [23,24], sensors [25], catalysis [26], and electromagnetic shielding [27], etc.

2.1. Structure of MXene

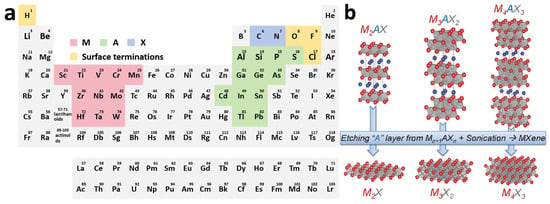

MXenes are transition metal carbides, nitrides, and carbon–nitrides with an Mn+1XnTx formula, whose precursors were commonly designated as MAX phases [28]. As shown in Figure 2a, M represents early transition metal atoms, including any one of Sc, Ti, V, Cr, Mn, Zr, Nb, Mo, Hf, Ta, and W; A mainly consists of metallic and nonmetallic elements between the second and the fourth main groups, such as Al, Si, P, S, Ga, Ge, As, Cd, In, Sn, T, and Pb; X sites can be occupied by carbon, nitrogen, or both; n can vary from 1 to 4, and Tx (where x is variable) indicates surface terminations on the surface of the outer transition metal layers [29].

Figure 2.

(a) Distribution of possible constituent elements of MXene in the periodic table. (b) Crystal structure of MXene obtained from MAX. Reproduced with permission [30]. Copyright 2013, Wiley-VCH.

The Mn+1AnX phase is a typical ternary layered ceramic, abbreviated as the MAX phase. MAX phases are classified into three distinct hexagonal crystal structures (space group P63/mmc) according to the value of n, as 211, 312, and 413 [30,31]. It is well displayed in Figure 2b that the number of atomic layers between two layers of A atoms varies, and there is always one less layer of X atoms than M atoms during the periodic arrangement of M atoms under different structures. The MAX phase exhibits an alternating stacking sequence of A atom layers and M(n+1)Xn layers in space, where (n + 1) close-packed layers of M atoms form octahedral coordination polyhedra with X atoms filling the octahedral interstitial sites [30,32]. For example, Ti2AlC is the simplest MAX phase. It is formed by the alternate stacking of Ti-Al-Ti-C atomic layers in space. The C atoms are distributed between two adjacent layers of Ti atoms, composing a three-atomic-layer-arranged Ti-C-Ti structural microdomain. These microdomains are periodically intercalated by monolayer Al atomic sheets [33]. Among them, the M-X bond in the MAX phase has the mixed characteristics of ionic, covalent, and metallic bonds, while the M-A bond is purely metallic in nature. Since the bond energy of the M-A bond is relatively weaker than that of the M-X bond, the M-X atomic layers can be retained by chemically etching the M-A bond, thereby obtaining a two-dimensional layered structure similar to graphene. However, unlike graphene, the M-A bond still belongs to a chemical bond, and its bond energy is much greater than the van der Waals force between the two-dimensional graphene layers, so it is difficult to separate it by mechanical methods [34]. About the predominant approach for MXene synthesis, the A layers with relatively weak bond energy in the MAX phase can be selectively etched by chemical means and replaced by active functional groups, resulting in three-layer or multi-layer M-X-M nanosheets with various functional groups on the surface, called Mn+1XTx.

2.2. Conductivity

In 2004, Geim and Novoselov first isolated single-layer graphene, marking the advent of the two-dimensional materials era [35]. Two-dimensional materials have highly efficient heat and charge transfer in the in-plane direction. MXene is not only structurally similar to two-dimensional graphene, but its metal layers also possess excellent conductive properties [35]. MXene surface functional groups have a strong influence on the electrical conductivity. When electrons are transferred from M-metal to the surface of MXene, the Fermi energy level of Mn+1XnTx without surface functional groups will move downward, and the electrical conductivity will be reduced, and all MXenes without surface groups theoretically exhibit metallic properties. Therefore, the conductivity of MXenes can be adjusted by adjusting the type and number of surface functional groups [36,37]. R et al. [38] employed hydrogen plasma treatment to make the -OH groups on the surface of MXene react and neutralize with H atoms, obtaining the surface-exposed Ti3C2 MXene without terminal groups. It was found that the resistivity of MXene decreased from 5.64 μ Ω m to 4.62 μ Ω m. Subsequently, O2 plasma treatment was carried out to form new functional groups (=O) on the surface, and at this time, the resistivity increased to 5.71 μ Ω m. During the etching process, the M-A bonds will break, and the outermost electrons of the surface metal atoms are in an approximately unmatched transition state. At this moment, the surfaces of some MXenes will be terminated and transformed into semiconductors [38,39]. Therefore, the high conductivity of MXene materials mainly depends on the density of states near the Fermi level of the M-layer atoms. When the surface functional groups of MXenes are the same, their electrical conductivity mainly depends on the type of M atoms in MXene.

Moreover, in addition to the reactive groups with M atoms, X atoms also have a large effect on the electrical conductivity of MXene materials. Zhang et al. [40] calculated the DOS of Tin+1CnT2 and Tin+1NnT2 at the Fermi energy level (EF) (T = -F, =O, -OH; n = 1,2,3). The results show that the Fermi energy levels of the nitride MXenes are higher than those of the carbide MXenes regardless of the termination groups and that the nitride MXenes have higher electrical conductivity which can be attributed to the fact that N possesses more electrons than C [40,41]. This is due to the fact that the M and X atoms of MXene are covalently bonded, and the electrons within the covalent bond form an energy band structure, with the discrete electrons moving through the valence band to produce electrical conductivity. The N atom has more electrons than the C atom, which gives the nitride MXene a higher electrical conductivity [42].

2.3. Hydrophilicity

The principal factors defining the hydrophilicity of MXenes are the surface terminal groups’ hydrophilic capability. Therefore, the rational selection of the etching process is critical, as the chemical etching of MAX phases generates abundant hydrophilic functional groups (-OH, -O, and -F terminations) that can form a large number of hydrogen bonds with water molecules [43]. In aqueous ion batteries, these hydrogen bonds interact with electrolyte solvent molecules, significantly enhancing the electrode material’s wettability toward the electrolyte, and lead to the reduction of interfacial contact resistance, which consequently accelerates the transport of hydrated ions [44,45]. Notably, in multivalent ion batteries (MIBs), the electrostatic screening effect induced by polar functional groups can effectively suppress the Coulombic repulsion during the intercalation of high-valence ions (HVIs). In addition, hydrogen bonding between these hydrophilic functional groups reinforces interlayer adhesion to alleviate volume expansion and structural degradation during cycling, and enables hydration-mediated interlayer spacing expansion, which creates diffusion channels for large-radius ions (K+, Zn2+) and thereby enhances rate performance [44,45,46]. It is understood from the mentioned findings that the pronounced hydrophilicity of MXenes ensures both stable colloidal dispersion and rapid ion transport kinetics in aqueous electrolytes. For non-aqueous systems, however, precisely balanced amphiphilicity is required to prevent detrimental water absorption that would trigger particle aggregation or parasitic side reactions. Most nanomaterials exhibit intrinsic hydrophobicity, leading to mutual aggregation driven by van der Waals forces, which severely restricts their further applications. Consequently, MXenes emerge as a promising candidate for diverse nanocomposite architectures.

2.4. Mechanical Properties

The MXene lamellae themselves exhibit excellent mechanical properties due to their unique structure [47]. This is because after the A layer atoms are chemically etched away, the electrons are more concentrated between the M-phase and the X-phase. As mentioned above, the M-X bond is a chemical bond that is a mixture of multiple bonds and tends to be metallic, with a high binding strength. Its tensile stiffness ranges from 81.71 to 561.4 N/m, surpassing traditional two-dimensional materials including graphene [48]. It is worth noting that after etching, MXene can be transformed from multi-layer accordion-like MXene into single-layer or few-layer nanosheets by inserting organic molecules or other metal ions between the layers [49]. When the constituent elements are the same, the number of layers of different MXene lamellae will also affect their mechanical properties. However, due to the extremely small size of MXene nanosheets, the problem of stacking is highly likely to occur, leading to a decline in mechanical and electrochemical properties. Adding conductive spacers between MXene lamellae to construct a special layered structure is one of the effective ways to solve the above problems and effectively improve the mechanical properties of MXene-based composites. Jiao et al. successfully constructed a continuous honeycomb-like conductive network structure, a waterborne polyurethane/natural rubber/Ti3C2Tx (WPU/NR/MXene) composite film with flexibility and certain self-healing properties, by using electrostatic repulsion interaction and vacuum-assisted filtration [50]. Although the content of MXene is only 5.48 vol% compared with the WPU/NR film without MXene, the WPU/NR/MXene composite film has an increase of 10.3 times and 8.8 times in tensile strength and toughness, respectively. Similarly, Luo et al. employed a double-crosslinking method. They crosslinked and modified MXene with dopamine, and then introduced Ca2+ in situ into the obtained layered composite film to further form ionic bond crosslinking between CNF (Cellulose Nanofibrils) and MXene [51]. The results showed that this double-crosslinking composite film strategy enhanced both the toughness and strength of the film, increasing them from 72.66 MPa and 3.85 MJ/m3 to 142.2 MPa and 9.48 MJ/m3, respectively, significantly improving the mechanical stability.

3. Preparation Methods

The preparation of two-dimensional MXenes is mainly obtained by treating their precursor MAX phase. As can be seen from the above, in the MAX phase, the metallic M-A and M-X bonding energies are much larger than the van der Waals forces, which makes it difficult to fabricate MXenes by conventional mechanical stripping techniques; however, the metallic M-A bonding is weaker than that of the M-X bonding, which has a mixed bonding, and therefore the “A” layer can be selectively removed to form the Mn+1XnTx phase [30]. In 2011, Professor Gogotsi’s team at Drexel University successfully obtained an accordion-shaped Ti3C2Tx MXene through the use of HF etching of the aluminum atomic layer in Ti3AlC2 MAX, thereby paving the way for significant advancements in MXene materials research and applications [8]. Later, various etching methods have been used to prepare MXene with different structures, and these different etching methods can be categorized into two main groups according to whether they contain fluorine or not. In the early stage, the etchant for preparing MXene mainly involves fluorine-containing compounds, such as HF, LiF + HCl, and fluorine-containing molten salts [52]. Due to the properties of these compounds, three key surface termination groups of MXenes were identified, namely -F, -OH, and -O groups. Fluorine-containing etching methods appeared the earliest, with high yields suitable for large-scale production and various uses, including and not limited to HF etching, in situ generation of HF etching, fluorine-containing molten salt etching, and so on; as opposed to the earliest production of non-fluorinated MXenes using electrochemical etching as early as in 2017, and with this there has been the emergence of other fluorine-containing etching such as alkali etching, non-fluorine-containing molten salt etching, and recently emerging alternative fluorine-containing etching such as Lewis acid molten salt etching, and other emerging methods of substituting fluorine-containing etching [53,54,55]. In addition to the top-down etching methods mentioned above, CVD (chemical vapor deposition) for assembling MXene nanomaterials tailored to specific properties from atomic or molecular sizes is considered a special bottom-up synthesis method [56]. In this paper, MXene synthesis methods are categorized in detail according to the degree of fluorine usage. And the effects of different etching methods on the functional groups on the surface of MXene and the number/thickness of laminae were compared, as shown in Table 1.

Table 1.

Current methods of preparing MXene and the differences between the different routes.

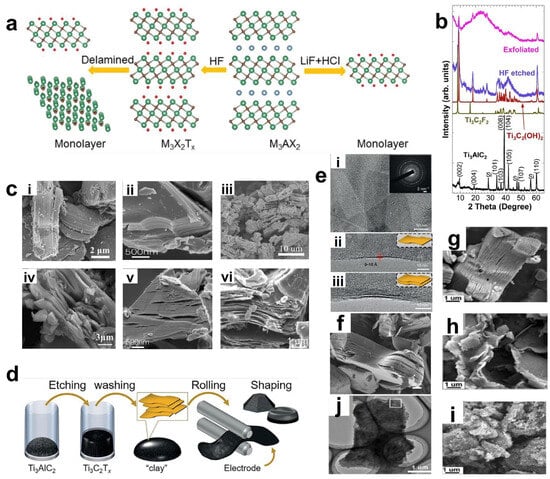

3.1. Etching with HF and F Salts

Naguib et al. first adopted HF to etch Ti3AlC2 [57]. The mechanism is shown in Figure 3a. Relying on the relatively strong reactivity between F ions and Al ions, the M-Al bonds are broken to form AlF3, thereby selectively etching away the aluminum layer. This process is accompanied by the generation of hydrogen gas at the same time, and finally the accordion-like MXene material is obtained [58]. The layers are mainly connected by van der Waals forces and hydrogen bonds of surface active groups. The reaction equation is shown as follows:

Ti3AlC2 + 3HF = AlF3 + 1.5H2 +Ti3C2

Ti3C2 + 2HF = Ti3C2(F)2 + H2

Ti3C2 + 2H2O = Ti3C2(OH)2+ H2

Ti3C2 + 2H2O = Ti3C2(O)2+ 2H2

First, the Al layer is selectively removed from the Ti3AlC2 MAX phase containing Al to generate an unsaturated structure of Ti3C2. After the Al atoms are selectively etched away by F ions, the Ti atoms with unsaturated charges on the surface of Ti3C2 are highly prone to bond with atoms such as -OH, -F, and -O, endowing its surface with abundant -OH and -F groups, thus generating a rich group of surface functional groups. With the in-depth progress of research, people have successfully etched a variety of MAX phases based on HF, resulting in many new MXene materials, such as Ti3C2Tx [59], Ti2CTx [60], V2CTx [61], Nb2CTx [62,63], Zr3Al3C5 [64], Ta4C3Tx [64], and Mo2C2Tx [65,66]. As shown in Figure 3c, the morphologies of several MAX phases (Ti2AlC, Mo2TiAlC2) and several MXene phases (Ti3C2Tx, Ti2CTx, Mo2TiC2Tx, V2CTx) are presented. It can be observed that they all exhibit similar accordion-like morphological characteristics, indicating that the products after etching with hydrofluoric acid possess a certain universality. Figure 3b shows the XRD patterns of the sample Ti3AlC2 before and after etching with hydrofluoric acid [57]. The disappearance of the characteristic peak at 39° is due to the fact that HF selectively etches away the Al layer in Ti3AlC2, causing the remaining Ti3C2 structure to be reorganized or deformed, and thus the original characteristics of the crystal structure disappear. Meanwhile, the diffraction peak of the (002) crystal plane shifts to a lower angle. According to the Bragg equation (nλ = 2d sinθ), the decrease in the diffraction angle means an increase in the interlayer spacing d. This increase may be attributed to the fact that the removal of the Al layer reduces the charge-balancing force between the layers, thereby weakening the force between the Ti3C2 layers and leading to an expansion of the interlayer spacing in the crystal structure. All these indications prove the generation of the new two-dimensional material MXene.

However, it is often difficult to obtain the desired single-layer MXene by this method. The greater the bond energy between M and A, the more and thicker the MAX phase lamellae are, the stricter the etching conditions with HF will be, and the lower the yield will be [67]. Although the direct use of HF etching has the advantages of simple process and high yield, the use of highly hazardous, highly polluting, and highly corrosive HF in the etching process is increasingly inconsistent with the concept of green development. Therefore, greener and safer preparation methods are needed for substitution.

Figure 3.

(a) Schematic of the principle of using HF etching or in situ generation of HF etching. Green, light blue, brown, and red balls represent M, A, X, and T atoms, respectively. XRD images of Ti3AlC2 before HF treatment (simulated as XRD of Ti3C2F2 and Ti3C2(OH)2) and after HF treatment and measured by ultrasonic stripping. Reproduced with permission [58]. Copyright 2022, The Royal Society of Chemistry. (b) XRD images of Ti3AlC2 before HF treatment (simulated as XRD of Ti3C2F2 and Ti3C2(OH)2 and after HF treatment and measured by ultrasonic stripping. Reproduced with permission [57]. Copyright 2011, Wiley-VCH. (c) SEM images of various MXene and MAX: (i) Ti2AlC(MAX). Reproduced with permission [60]. Copyright 2023, Springer Nature. (ii) Mo2TiAlC2(MAX). Reproduced with permission [65]. Copyright 2015, American Chemical Society. (iii) Ti3C2Tx. Reproduced with permission [59]. Copyright 2015, American Chemical Society. (iv) Ti2CTx. Reproduced with permission [68]. Copyright 2013, American Chemical Society. (v) Mo2TiC2Tx. Reproduced with permission [65]. Copyright 2015, American Chemical Society. (vi) V2CTx. Reproduced with permission [61]. Copyright 2013, American Chemical Society. (d) Schematic of the process: etching of the MAX phase in a solution of acid and fluoride salts and washing with water to adjust the pH to neutrality, the resulting precipitates have a clayey character. (e) (i) TEM image of a few thin sheets of Ti3C2Tx with transverse dimensions up to a few hundred nanometers. Very few defective regions are present. The inset shows the electron diffraction pattern of the entire selected region (ii,iii) TEM images of single and bilayer flakes in the longitudinal direction, respectively. (f) Accordion-like multilayered MXene particles. (d–f) Reproduced with permission. Reproduced with permission [69]. Copyright 2014, Springer Nature. (g–i) SEM images of (g) 8 h, (h) 16 h, and (i) 32 h etched Ti3AlC2 MAX phase and corresponding h-Ti3C2 MXene. (j) TEM micrograph of h-Ti3C2 flakes after 16 h etching. (g–j) Reproduced with permission [70]. Copyright 2022, Elsevier.

Based on the etching mechanism, researchers first came up with the idea of replacing the direct use of HF acid with the method of generating HF in situ during the etching process. Fluoride salts (such as LiF, NaF, KF, NH4F, etc.) are mixed with hydrochloric acid or sulfuric acid, etc. Similarly, the F ions are utilized to interact with the A atoms in the MAX phase to generate fluorides. It is worth noting that the cations in the fluoride salts will act as mild intercalating agents to insert between the lamellae to reduce the van der Waals forces, thereby obtaining few-layer or even single-layer MXene nanosheets [69]. However, since these cations act as mild intercalating agents, single-layer nanosheets can be efficiently obtained only when the van der Waals forces between the nanosheet layers are relatively small, that is, when there are only two or a few metal atom transition layers. Ghidiu et al. first used a mixture of HCl and LiF to prepare MXene [69]. The flowchart is shown in Figure 3d. Ti3AlC2 powder was etched at 40 °C, and then exfoliated through dimethyl sulfoxide intercalation and ultrasonic vibration, resulting in single-layer to multi-layer Ti3C2Tx MXene flakes (Figure 3e shows the TEM images of single-layer and double-layer nanosheets). Observed under a transmission electron microscope (TEM), it was found that the HCl/LiF mixture is similar to HF, and a similar accordion structure was also produced during the etching process. Moreover, the lateral size of the Ti3C2Tx flakes reaches from hundreds of nanometers to several micrometers, and the thickness is between 1 nm and dozens of nanometers (Figure 3f). Notably, the etching duration exerts profound influence on the resultant microstructure. When employing NaBF4/HCl as the etchant, multi-layer 2D flakes were obtained after 8 h (Figure 3g), while ultrathin nanosheets formed at 16 h (Figure 3h). Prolonged etching to 32 h yielded AlF3-coated agglomerates (Figure 3i), indicating structural degradation and undesirable byproduct formation. TEM characterization revealed transparent Ti3C2 nanosheets with optimal structural integrity after 16 h etching (Figure 3j), demonstrating this duration represents the processing optimum. Compared with HF etching, this method is milder, and the obtained MXene flakes have larger sizes and fewer defects, significantly optimizing the electrochemical properties and application potential of the material.

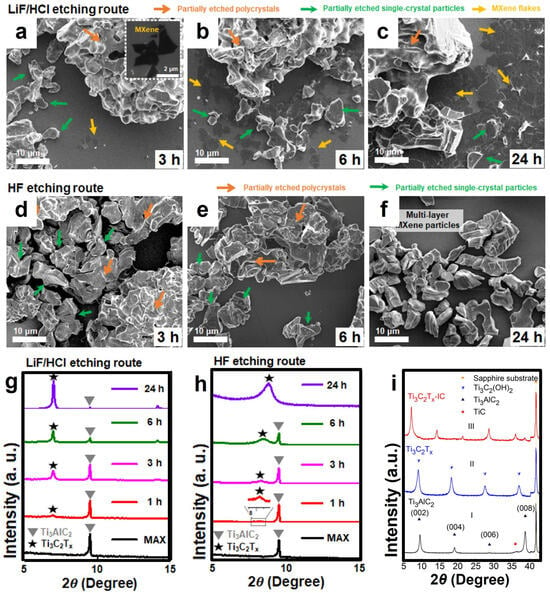

Figure 4.

(a–c) The SEM images of the samples etched by LiF/HCl for different durations, corresponding to the samples etched by HF for (d) 3 h, (e) 6 h, and (f) 24 h, respectively. (g) The XRD patterns of the samples etched by LiF/HCl and (h) those etched by HF. Reproduced with permission [71]. Copyright 2021, American Chemical Society. (i) (I) The XRD pattern of the Ti3AlC2 film. (II) Ti3C2Tx after being etched in 50% HF for 2 h and 40 min. (III) Ti3C2Tx -IC after being etched in 1 M NH4HF2 for 11 h. Reproduced with permission [72,73]. Copyright 2014, American Chemical Society.

To further explore the mechanism of the etching process of Ti3AlC and the intercalation effect of cations, Kim et al. summarized different fluorine-containing etching methods such as HF, NH4HF2, and LiF/HCl, and proposed that the etching proceeds step by step, that is, the etching of Al atoms in the inner layer only occurs when the adjacent outer layer is exfoliated [71]. As shown in Figure 4a–c, the SEM images of the HF etching process reveal that with continuous etching, the larger polycrystalline Ti3AlC2 particles gradually decompose into smaller single-crystal particles. After etching for 24 h, only single-crystal particles remain. By comparing the SEM images of the LiF/HCl etching process (Figure 4d–f), a phenomenon similar to that of HF etching can be observed, where the polycrystalline aggregates break down into finer crystals. However, compared with Ti3C2Tx prepared by HF etching, the interlayer distance of multi-layer Ti3C2Tx is significantly increased. Analyzing the XRD patterns of the two methods (Figure 4g,h), the complete disappearance of the (002) peak of the MAX phase etched by HF indicates that the exfoliation of the Ti3C2Tx layer has not been triggered. Similarly, NH4HF2 etching has an effect similar to that of HF, but NH4HF2 provides the non-fluorine cation NH4+ as an intercalating agent to enter the MXene layer and forms a water-soluble byproduct (NH4)3AlF6, and the interlayer distance of its multi-layer MXene is larger than that of HF. The same conclusion can be drawn from the analysis of the XRD pattern of Ti3C2Tx [72]. Figure 4i (II) shows the shift of the 000 peak to a lower angle, corresponding to the increase of the C lattice parameter from 18.6 Å of Ti3AlC2 to 19.8 Å of Ti3C2Tx. In the XRD pattern of Ti3C2Tx-IC (III, where IC represents the inserted species, namely NH3 and NH4+), the C lattice further increases to 24.7 Å. This indicates that the C lattice constant of Ti3C2Tx etched by NH4HF is 25% larger than that of Ti3C2Tx etched by HF.

It is worth noting that HF etching will attack the grain boundaries, causing the polycrystals to break into single crystals, with higher etching efficiency. However, it is difficult to obtain single-layer MXene nanosheets due to the lack of intercalating agents. When LiF/HCl is used for etching, initially only the surface reacts and most of the internal regions remain unetched. Moreover, during the delamination process of Li+ and water molecules embedding into the MXene flakes, incomplete exfoliation or impurity formation may occur, leaving incompletely etched MXene particles. Therefore, although the method of generating HF in situ significantly reduces the hazards caused by toxicity and high corrosiveness, it is only suitable for most MAX phases containing Al as the A atom layer, and the yield of fluoride ions is lower compared with the direct use of HF, and the etching range is limited. To completely convert the MAX phase into MXene, the etching conditions need to be adjusted rigorously. Research shows that the etching conditions are related to the atomic number of the M atom. Usually, the larger the atomic number, the higher the corresponding increase in the M-A bond energy, and the more stringent the required F ion concentration and etching time will be.

3.2. Alkali Etching

In order to avoid the harm caused by fluorine and improve the etching precision and the conductivity of MXene, researchers have further investigated the fluorine-free etching method known as the alkali etching method. Under a high temperature and high-concentration alkaline environment, the A phase containing amphoteric metal atoms, such as Al atoms, will react with OH- to generate the corresponding hydroxide, that is, Al(OH)4− ions, which will dissolve in the alkaline solution, thereby being removed from the MAX phase, and -OH functional groups will be formed on the surface of the transition metal layer by combination [71,72]. This process is endothermic. According to the principles of thermodynamics, a relatively high reaction temperature is one of the important factors affecting etching. Li et al. first achieved the synthesis of high-purity MXene by using the alkali etching method and explored the two main factors affecting hot alkali etching—temperature and alkali concentration [72,74]. They used a hot NaOH solution with a concentration of 27.5 mol/L at 270 °C to etch Ti3AlC2 and successfully prepared multi-layer Ti3C2TX without fluorine on the surface. The specific chemical reaction equations are as follows:

Ti3AlC2 + OH− + 5H2O → Ti3C2(OH)2 + Al(OH)4− + 2.5H2

Ti3AlC2 + OH− + 5H2O → Ti3C2O2 + Al(OH)4− + 2.5H2

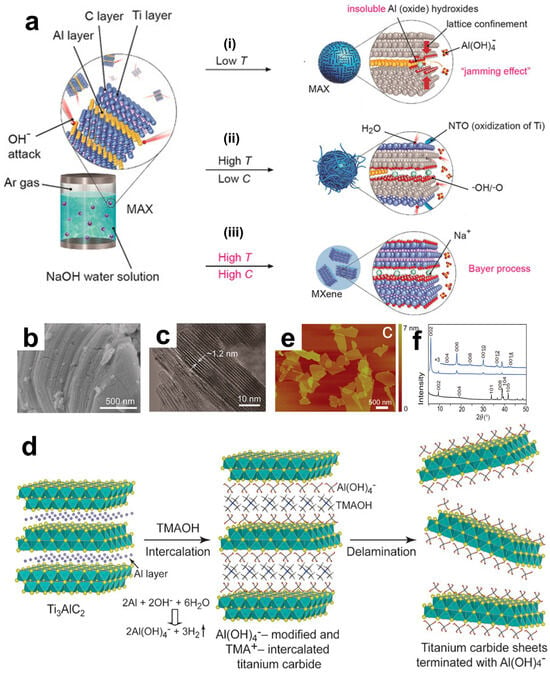

It was found that as the temperature decreases, the production rate of soluble Al(OH)4− will be greatly reduced, thereby significantly reducing the yield of MXene. It is even difficult to produce MXene at 220 °C. In addition, according to chemical kinetics, the concentration of hydroxide ions is another important factor affecting etching. Theoretically, the lower the concentration of hydroxide ions, the correspondingly lower the etching rate and yield. This is also the case in practice. The lower the concentration of NaOH and the higher the water content, the easier it is to cause the oxidation of Ti and generate a series of titanium oxides. Eventually, Li et al. found that by hydrothermal treatment with 27.5 M NaOH at 270 °C, multi-layer Ti3C2Tx with a purity close to 92% could be obtained. As shown in Figure 5a (i), at low temperatures, aluminum hydroxide is difficult to transform into soluble ions. (ii) At high temperatures but with low OH− concentrations, the higher water content leads to the oxidation of MXene and the generation of a large amount of oxide impurities. (iii) According to the Bayer process, the high temperature and high NaOH concentration of 27.5 M NaOH at 270 °C can most efficiently convert and dissolve aluminum or its oxides. Observing its surface morphology, as shown in Figure 5b,c, similar to Ti3C2Tx treated with low-concentration HF, the prepared Ti3C2Tx has a compact accordion-like structure. Besides using strong alkalis, milder and safer organic alkalis as etchants can also obtain relatively pure products. And due to the significant intercalation effect of organic cations, the thickness of the obtained nanosheets can be reduced. Based on the mechanism of hydroxide ions etching aluminum atoms, Xuan et al. used tetramethylammonium hydroxide (TMAOH) as an etchant, and the process is schematically shown in Figure 5d [75]. TMAOH reacts with the Al atom layer between the layers, causing the hydrolysis and breakage of the Ti-Al bond. The generated Al(OH)4− will modify the etched surface, and at the same time, the bulky TMA will be inserted between the layers as an intercalating agent. Looking at the AFM image in Figure 5e, ultimately, uniformly distributed and highly delaminated ultrathin nanosheets are obtained. Through X-ray diffraction analysis (Figure 5f), after the reaction in the TMAOH solution, new diffraction peaks are observed, indicating that the interlayer spacing has increased to 1.50 nm, successfully realizing the intercalation of TMA ions.

Figure 5.

(a) The etching process of Ti3AlC2 with NaOH aqueous solution under three different conditions. (i) Low temperature: at low temperature, insoluble Al oxides/hydroxides are formed. (ii) High temperature, low carbon: under high temperature and low carbon environment, H2O is involved in the reaction, Ti is oxidized to form NTO, OH- and -O are involved in the reaction process. (iii) High-temperature, high-carbon: MXene is finally formed. Through (b) SEM and (c) TEM for the microscopic structure observation of Ti3C2Tx flakes, where the bright spots in the figures indicate the positions of Ti. (a–c) Reproduced with permission [74]. Copyright 2018, Wiley-VCH. (d) The intercalation and delamination process of organic bases, demonstrating the representative bright-field of extremely thin nanosheets. (e) The AFM image after the intercalation and separation of Al(OH)4−. (f) The XRD patterns of the samples before and after the reaction in aqueous TMAOH, indicating that the basal plane spacing expands from 0.92 to 1.50 nm (d–f). Reproduced with permission [75]. Copyright 2016, Wiley-VCH.

Alkali etching also has considerable disadvantages. When the concentration of the alkali solution and the reaction temperature are relatively low, the corrosiveness to MAX is relatively weak, which easily causes the oxidation of the M and X skeletons, greatly reducing the integrity of the MXene structure, and is accompanied by the problem of insufficient reaction kinetics, only being able to etch its surface [64]. If the reaction temperature is too high, it may also bring certain safety hazards.

3.3. Electrochemical Etching Method

The electrochemical etching method is one of the fluorine-free etching methods. The principle lies in utilizing the conductivity of the MAX phase to apply a specific voltage to both ends of the MAX electrode in the electrolyte, thereby selectively etching away the A atom layer [76].

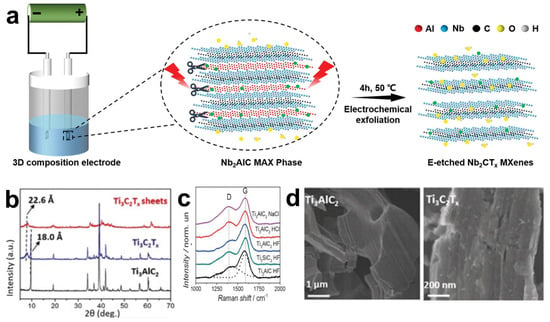

In 2018, Yang et al. first reported a fluoride-free electrochemical method. By using a binary aqueous electrolyte (0.1 M NH4Cl and 0.2 M TMAOH), a voltage was applied to the surface of the Ti3AlC2 electrode to selectively break the Ti-Al bonds, and the aluminum layer was successfully etched away [77]. Song and their team also adopted this fluoride-free electrochemical etching method and successfully synthesized 2D fluoride-free Nb2CTx MXene nanosheets in a standard three-electrode configuration [78]. The specific schematic diagram of the principle is shown in Figure 6a. It is worth noting that it is usually considered that the chloride ions in the electrolyte are the key to this method. When a voltage is applied, the Cl ions at the positive electrode can easily react with the A atom layer to selectively etch away the A layer and attach -OH end groups on the surface of the transition metal layer, forming Mn+1An(OH)X. However, there must be necessary catalysts in the electrolyte, so the surface of the produced MXene does not only have the -OH group, but also is related to the types of groups carried by the catalysts, such as -Cl, -F, and -O, etc. Figure 6c shows the Raman spectra of three MAX phases, namely Ti3AlC2, Ti3SiC2, and Ti2AlC, which are successfully converted into amorphous carbon CDCs in different electrolytes. When Ti3AlC2 is etched using dilute electrolytes such as NaCl, HCl, and HF, both titanium and aluminum atoms may be removed, thus generating amorphous carbon. While using a medium-concentration HCl solution will lead to the selective aluminum extraction on the surface of the bulk Ti3AlC2 and form a thin protective carbon layer on the surface, preventing the further progress of etching [79]. Meanwhile, the binary electrolyte TMAOH adopted by Yang et al. [77] was added as a certain amount of intercalating agent, which enlarged the distance between the lamellae, promoting a larger specific surface area inside the MAX phase to come into contact with the electrolyte, thereby reducing the differences caused by the inconsistent etching speeds between the surface and the interior. The XRD pattern in Figure 6b reveals the structural changes during the etching and delamination processes. The (002) peak of Ti3AlC2 shifts to a lower angle, corresponding to the increase of the C lattice parameter from 18.0 to 22.6 Å, indicating that TMAOH can be easily embedded into the interlayer of the MAX phase, thus increasing the efficiency of the electrolyte in etching the Al layer. When observing the SEM images (Figure 6d), it is found that after electrochemical etching, the multi-layer Ti3C2Tx powder is still tightly stacked, similar to the compact layered bulk Ti3AlC2, rather than the accordion-like structure produced by traditional hydrofluoric acid etching. This is because when a voltage is applied to both ends of the MAX precursor, and the precursor has a large volume and dense layers, the MAX phase on the surface layer close to the electrolyte is often preferentially converted into the MXene phase, while the middle part remains the MAX phase, which significantly reduces the yield.

Figure 6.

(a) A schematic illustration of the exfoliation and delamination process of the Nb2AlC MAX phase via electrochemical etching. The red lightning symbol indicates electrical drive. Reproduced with permission [78]. Copyright 2020, Wiley-VCH. (b) The X-ray diffraction patterns of Ti3AlC2, Ti3C2Tx, and Ti3C2Tx thin films. Reproduced with permission [77]. Copyright 2018, Wiley-VCH. (c) The Raman spectra of amorphous carbon CDC synthesized by etching the MAX phase (namely Ti3SiC2, Ti3AlC2 and Ti2AlC) in HCl, NaCl or HF electrolytes. The letters D and G represent Raman spectral peaks, the G peak corresponds to the vibration in the sp2 hybridized carbon plane, and the D peak is the defect-induced peak. Reproduced with permission [80]. Copyright 2014, Wiley-VCH. (d) The representative SEM images of Ti3AlC2 and Ti3C2Tx. Reproduced with permission [77]. Copyright 2018, Wiley-VCH.

In addition, during the etching process, besides selecting an appropriate electrolyte, it is also necessary to choose a suitable voltage so as to avoid the possible Ti etching phenomenon under high polarization and the formation of carbide-derived carbon (CDC). Liu and their team treated the prepared TiAlC MAX phase [81]. Through the in situ molten salt electrochemical etching method under low voltage conditions (1.3 V versus ref.), Al atoms were selectively removed from the MAX phase, and Ti2CTx MXene was successfully prepared. During this process, these Al atoms were oxidized to Al3+ and deintercalated from the Ti2AlC phase. Meanwhile, the Al3+ ions in the LiCl/KCl molten salt formed a volatile AlCl3 phase. The free Cl− in the molten salt will fill the vacant positions of Ti2C to form surface terminal groups -Cl. In addition, the free Li+/K+ ions in the molten salt will move towards the negative electrode and be reduced at the negative electrode to form Li/K metal deposits.

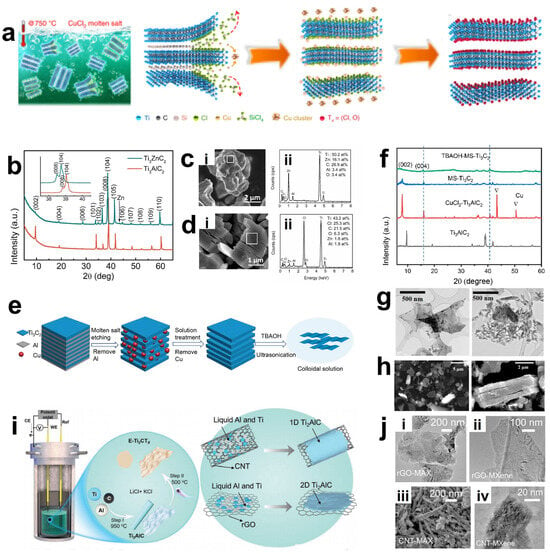

3.4. Molten Salt Etching

Most methods for obtaining MXene require the etching of Al atoms in aqueous systems. However, for MAX precursors without an Al layer or MAX phases containing nitrides, the etching process often needs to overcome a higher energy barrier, which significantly limits the types of MXene [82]. Therefore, researchers have explored placing the MAX phase precursors in molten salts with certain compositions. At this time, the A atom layer will be replaced by the atoms in the molten salts without changing the structural frameworks of M and X. Accordingly, it is possible to etch some MAX phases that are difficult to etch by traditional methods, such as those with the A atom layer composed of Si and some nitride MAX phases [83,84]. Li et al. [85] reported this preparation method with a similar mechanism to displacement reactions. Through the reaction between molten ZnCl2 and the Al element in the MAX phase precursor (such as Ti3AlC2), a new Zn-based MAX phase (such as Ti3ZnC2) was synthesized. As shown in the XRD diagrams of Ti3AlC2 and Ti3ZnC2 in Figure 7b and the EDS diagram of Ti3ZnC2 in Figure 7c, compared with Ti3AlC2, the XRD peaks of Ti3ZnC2 shift to lower angles, indicating that Zn atoms have successfully replaced Al atoms. Interestingly, at 550 °C, an excessive amount of molten ZnCl2 salt will react with the MAX phase to synthesize MXene terminated with -Cl or without terminal groups on the surface, pioneering the creation of a fluorine-free, green, efficient MXene with only -Cl terminal groups. However, according to the obtained EDS of Ti3C2Cl2 (Figure 7d), it shows that the elemental composition of Ti3C2Cl2 still contains a small amount of Zn (0.7 atomic%), Al (2.9 atomic%), and O (6.3 atomic%). This is because the -Cl terminal group can strongly bond to the MXene surface, but when there are steps such as the presence of oxygen-containing compounds or water washing, the -Cl terminal group is less competitive than the -O terminal group and is thus replaced. This is a problem that needs to be noted and avoided when using Lewis molten salt etching.

Figure 7.

(a) Schematic diagram of Ti3C2Tx MXene preparation. Reproduced with permission [86]. Copyright 2020, Springer Nature. (b) XRD patterns of Ti3AlC2 and Ti3ZnC2. (c) SEM image (i) of Ti3ZnC2 and the corresponding energy-dispersive spectroscopy (EDS) spectrum (ii). (d) SEM image (i) of Ti3C2Cl2 and the corresponding EDS spectrum (ii). (b–d) Reproduced with permission [85]. Copyright 2019, American Chemical Society. (e) Molten salt synthesis method and exfoliation process. (f) X-ray diffraction (XRD) patterns of MAX phase precursors (black), MXene after removal from the molten salt bath (red), MXene after washing in APS to remove residual Cu (blue), and MXene after TBAOH stripping treatment (green). The triangular symbols indicate the characteristic diffraction positions where Cu2+ is reduced to Cu monomers remaining in the sample. (g,h) SEM maps of MS-Ti3C2Tx MXene treated with DMSO followed by sonication, and MS-Ti3C2Tx MXene treated with TBAOH for 24 h and 72 h TEM images of MS-Ti3C2Tx. (e–h) Reproduced with permission [87]. Copyright 2021, American Chemical Society. (i) Schematic diagram of a molten salt cell with (Ti, Al, C) pellets as working electrode, glassy carbon as reference electrode, and graphite crucible as counter electrode and a schematic diagram of the process for the preparation of Ti2AlC by using carbon nanotubes and reduced graphene oxide as the carbon source. (j) Ti2AlC MAX (i,iii) obtained by using graphene oxide and carbon nanotubes as the carbon source and Ti2CCl2 MXene (ii,iv) TEM images of the Ti2CCl2 MXene. (i,j) Reproduced with permission [81]. Copyright 2022, Wiley-VCH.

Li et al. further summarized and explored the Lewis molten salt etching method, and the schematic diagram of its preparation process is shown in Figure 7a [86]. The principle that the A atom layer can undergo substitution with the molten salt lies in the difference in their redox potentials. Transition metal halides can act as electron acceptors to react with the A layer in the molten state. The Lewis acid molten salt has a higher redox potential compared to the MAX phase, so it can etch the MAX phase. For example, in the molten CuCl2 salt at 700 °C, the redox potential of Cu/Cu2+ is −0.43 eV, which is greater than that of Si/Si4+ (−1.38 eV). Therefore, the molten Cu2+ can oxidize the Si atoms in the MAX phase into Si4+, which then enters the molten salt and combines with Cl− to form SiCl4, while Cu2+ is reduced to Cu atoms and remains outside the MAX phase. Then, the Cu element is removed by APS ((NH4)2S2O8). Finally, Cl−, Br−, I−, etc., in the molten salt combine with the M transition metal atoms, and depending on the type of molten salt, MXene with corresponding surface terminal groups can be obtained. However, the binding ability is generally weak, and subsequent substitution of functional groups can be carried out to flexibly adjust the surface functional groups, thereby obtaining MXene with other terminal groups or even without terminal groups. However, affected by the synthesis route and changes in surface groups, it often leads to a significant reduction in the rate of exfoliation and delamination of multi-layer MXene, making it difficult to obtain good electrochemical properties. Liu et al. successfully etched Ti3AlC2 using a mixed molten salt of KCl/CuCl2/NaCl at 680 °C in an argon atmosphere [87]. Subsequently, by inserting the organic molecule TBAOH (tetrabutylammonium hydroxide) and performing ultrasonic treatment, they successfully prepared MXene with fewer layers and improved electrochemical properties through the Lewis molten salt method. The etching and exfoliation processes of the Lewis acid molten salt method are illustrated in Figure 7e. The HF-MXenes obtained by traditional hydrofluoric acid etching usually use DMSO solvent as an intercalating agent for separation because of the matching of surface energy between DMSO and HF-MXene. However, the Ti3C2Tx treated with DMSO in the Lewis acid molten salt etching method is thicker and has more layers (as shown in Figure 7h), while the multi-layer MXene treated with TBAOH can be further exfoliated. The SEM images before and after exfoliation are displayed in Figure 7g. The Lewis molten salt etching is safer and more environmentally friendly compared to traditional etching methods and has the advantage of being able to regulate terminal functional groups. However, it is often difficult to obtain single-layer MXene through this redox reaction, and it is affected by the properties of the Lewis molten salt.

It is worth noting that in the past decade or so, most of the MXenes prepared in research have been derived from MAX phases. However, this process is time-consuming and complex, involving multiple steps such as the preparation of MAX, the etching from MAX to MXene, and the removal of metal impurities. To optimize this process, researchers have devoted a great deal of effort. Besides the bottom-up CVD deposition method, recently, Liu et al. proposed an innovative one-pot molten salt electrochemical etching method [81]. The specific process (Figure 7i) is divided into two processes: obtaining the MAX phase and etching the MAX phase to obtain MXene. First, an electrochemical cell containing a mixture of LiCl and KCl is heated to a stable molten state. Molten aluminum (melting point 660 °C) will wrap around the metal Ti (melting point 1668 °C) and form Ti-Al intermetallic compounds on the surface of Ti. Meanwhile, carbon nanotubes (CNTs) and reduced graphene oxide (rGO) are used as carbon sources to make TiC grow on the graphite side. Through the bottom-up growth mode, TiAlC MAX phase nuclei are generated on the carbon surface and continue to grow as TiC and Ti-Al intermetallic compounds are continuously consumed, and based on the structural framework of carbon as a template, TiAlC particles are obtained in a short time. Immediately after that, the temperature of the molten salt electrode is changed to 500 °C, and Ti2CCl2 MXene is obtained by electrochemically etching away the aluminum atom layer. The use of different carbon sources also has a significant impact on the morphology of the precursor and MXene. As shown in Figure 7j, both the Ti2AlC MAX phase and Ti2CCl2 MXene grown from different carbon sources retain the characteristics of CNT and GO. Compared with other methods, this method only requires a lower temperature and a shorter reaction time, greatly simplifying the preparation process.

3.5. Chemical Vapor Deposition (CVD) Method

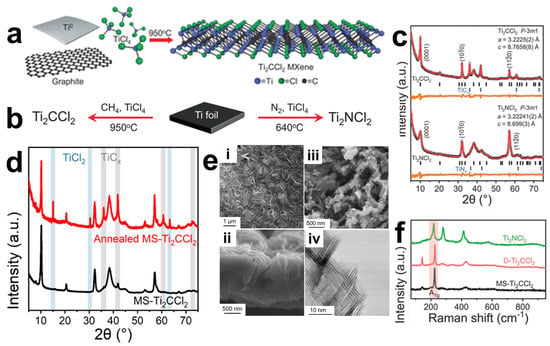

In the process of preparing MXenes, traditional methods such as the Lewis acid molten salt method or chemical and electrochemical etching require the use of harmful HF or energy-consuming Lewis acid molten salt. Chemical Vapor Deposition (CVD) is a typical bottom-up synthesis approach that operates at atomic/molecular scales, enabling direct growth of large-area two-dimensional materials [88]. An investigation has demonstrated the CVD synthesis of high-quality two-dimensional ultrathin Mo2C crystals, using methane as the carbon source at temperatures exceeding 1085 °C on layered Mo/Cu foil substrates [89]. Halim et al. [73] successfully synthesized Ti3AlC2 thin films via direct current (DC) magnetron sputtering using elemental Ti, Al, and C targets. Subsequent selective etching of the aluminum layers in aqueous HF or NH4HF2 solutions yielded Ti3C2 MXene films with a controlled thickness of approximately 19 nm. However, conventional CVD or magnetron sputtering techniques can only synthesize a limited number of MXene and strictly depend on specific substrates (such as Cu foils), failing to achieve controllable synthesis of termination-enriched MXene like Ti2CCl2 and Zr2CBr2. Wang et al. [90] reported a novel synthetic route by utilizing direct reactions between metal/metal halides and carbon/nitrogen sources without MAX phase precursors. As a representative case, Ti2CCl2 MXene was successfully grown on Ti substrates at 950 °C under an argon atmosphere using CH4 and TiCl4 as precursor gases, with the detailed synthesis process illustrated in Figure 8a,b. Through the structural analysis by XRD (Figure 8c,d) and Raman spectroscopy analysis (Figure 8f), it is revealed that the high-purity Ti2CCl2 MXene phase has been successfully prepared. Scanning electron microscopy (SEM) images showed a completely new growth morphology that dramatically diverges from conventionally synthesized counterparts. Wrinkled Ti2CCl2 MXene layers were observed to coat the substrate (Figure 8e), exhibiting vertically oriented growth to form carpet-like or spherical vesicular architectures. These nanosheets could be exfoliated into monodisperse colloidal suspensions. Notably, nitride-based MXenes may undergo dissolution in HF solutions due to insufficient chemical stability. In contrast, CVD at 640 °C using TiCl4 and N2 reactants on Ti foils enables the successful synthesis of pure-phase Ti2NCl2 MXene that is challenging to obtain through conventional approaches. Generally, directly synthesized MXenes (DS-MXenes) exhibit superior structural integrity with near-ideal stoichiometric coverage of chlorine terminations. The vertically aligned architecture achieved through CVD growth facilitates enhanced ion intercalation kinetics, resulting in exceptional rate capability in electrochemical applications.

Figure 8.

(a,b) Schematic of bottom-up direct synthesis of Ti2CCl2. (c) XRD patterns of CVD-Ti2CCl2 and CVD-Ti2NCl2. (d) Powder XRD pattern of the product of pure TiCCl MXene annealed at 950 °C for 1 day under vacuum. MXene partially decomposed into TiCl and TiC. XRD patterns of the final mixture were similar to that of DS-Ti2CCl2. (e) Front (i) and cross-section (ii) SEM images of CVD-Ti2CCl2. (iii) SEM image and (iv) STEM image showing that CVD-TiNCl exhibits a braided structure. (f) Raman spectra of CVD-Ti2CCl2 and CVD-Ti2NCl2 MXenes. [90]. Copyright 2023, American Association for the Advancement of Science (AAAS).

Thickness, morphology, and size of MXene is more controllable by this method. However, two critical challenges persist in the CVD synthesis of MXenes: the nucleation mechanisms and kinetic competitions remain poorly understood, precluding precise control over crystal dimensions and defect densities; and the validated precursor combinations are currently limited to select metal halides (TiCl4, ZrCl4) with carbon/nitrogen sources (CH4, N2), restricting exploration of alternative transition metals and functional surface terminations. Future research should focus on expanding the metal repertoire (V, Nb et al.) and surface functionalization, elucidating nucleation mechanisms and optimizing synthetic protocols, and achieving wafer-scale uniform synthesis for industrial-scale production. These advancements will facilitate practical applications in high-power energy storage devices, efficient catalysts, and flexible electronics, enabling transformative industrial breakthroughs.

4. Rechargeable Battery

With the global demand for sustainable and efficient energy systems, the limitations of traditional electrode materials in terms of energy density, cycle life, cost of use, and environmental impact are becoming more and more prominent [91]. In recent years, nanocomposite structures based on carbon materials, transition metal oxides or hydroxides, and conductive polymers have been extensively investigated with a focus on three key parameters: surface area, electrical conductivity, and pore structure of the electrode materials. However, outstanding issues such as limited specific capacitance, low conductivity, structural degradation, slow kinetics of redox reactions, and restricted ion and electron transport remain to be addressed [92]. Therefore, the development of new electrode materials and the search for efficient, safe, and sustainable electrochemical energy conversion and storage technologies is one of the hot spots in current research.

MXene materials have a unique two-dimensional structure, excellent physicochemical properties, outstanding electrical conductivity, high specific surface area, and high chemical stability. They are considered as revolutionary materials for batteries, supercapacitors, and various electrocatalytic reactions [93,94,95]. The larger layer spacing of MXenes can allow for larger ion embedding/de-embedding, which can enhance ion diffusion and storage capacity. At the same time, this layered structure helps maintain structural stability during cycling, reducing electrode degradation and extending battery life. In recent years, the electrochemical properties of MXenes have been rapidly studied and a large amount of related literature has been published, but there is a lack of systematic organization of the research results in recent years [96]. Therefore, this review aims to fill this gap by providing a comprehensive framework to understand and utilize the potential of MXene materials for electrochemical applications, while revealing key scientific issues and future research directions.

4.1. Lithium–Ion Batteries

A lithium–ion battery is a high-performance secondary battery, relying on the movement of lithium ions between the positive and negative electrodes to achieve energy storage and release. Because of its high energy density, long life, and low self-discharge rate, it is widely used in the power supply system of all kinds of electronic equipment and grid energy storage [9,97,98]. This section focuses on summarizing the composite modes and structures of commonly used active electrode materials other than graphite-based anode materials with MXenes.

In order to fully utilize the unique properties of MXene materials and the anode materials, researchers have explored the use of a variety of composite methods. For example, physical mixing mechanical ball-milling mixing, wet dispersion freeze-drying mixing, the use of chemical methods, through the chemical vapor deposition on the surface of MXene in situ growth of anode materials, or the solvent thermal method of direct chemical synthesis of composite structures. Self-assembly of MXene and anode materials into multi-layer composite membranes can be realized by electrostatic interaction or other intermolecular forces. Alternatively, a specific functional group ligand can be designed to spontaneously self-assemble with MXene and the anode material to form a strong transition layer as well as a heterogeneous structure connected by covalent bonds.

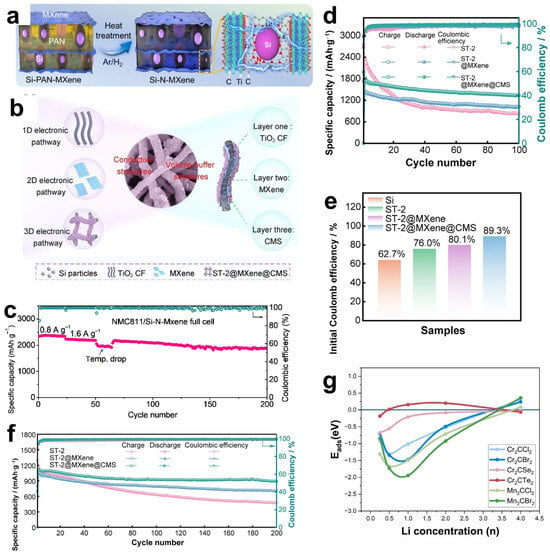

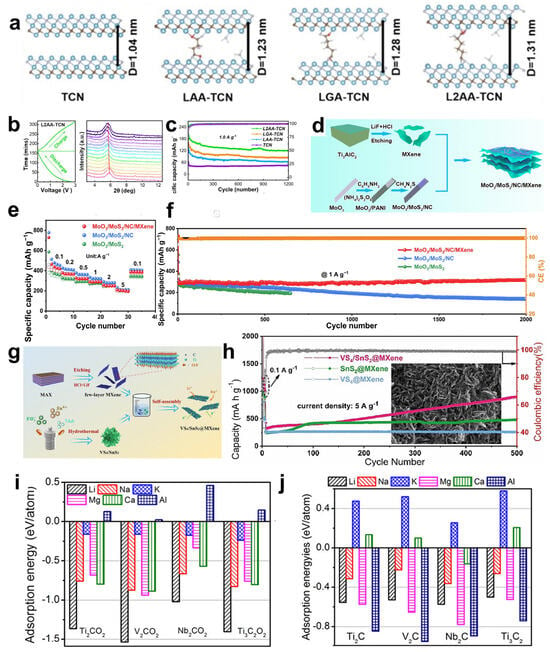

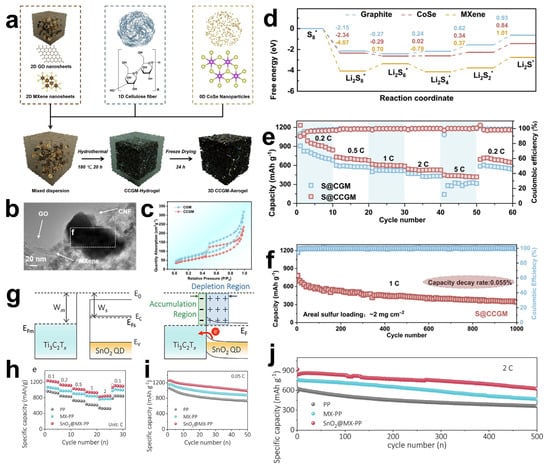

Graphite is the most commonly used anode material for lithium–ion batteries. However, due to the relatively low theoretical specific capacity of the graphite anode (usually 372 mAh g−1) [99], currently, the development of graphite electrodes has reached its theoretical limit, but it still cannot meet the requirements of technological progress for energy storage. Therefore, the search for new electrode materials is imminent. Studies have shown that in addition to graphite-based materials, silicon-based materials also have relatively high theoretical capacities [100]. Replacing the graphite anode with silicon not only effectively addresses the safety issues of the liquid electrolyte in lithium–ion batteries but also significantly improves the specific capacity of the batteries. It is regarded as one of the most promising electrode materials for next-generation high-energy lithium–ion batteries [101]. However, silicon electrodes will have a large volume change during the charge/discharge process, and this change will destroy the inherent layered structure of the electrodes, or the electrodes may even be crushed and pulverized, resulting in serious capacity loss. In order to solve the problem of volume change, the usual method is through the composite of certain conductive materials, and the formation of a multiple buffer structure or with multi-component composite, so as to inhibit the volume expansion of the electrode, enhance the mechanical stability and electrical conductivity, and effectively improve the cycling stability of the material [102]. Luckily, MXene not only has excellent mechanical properties and excellent electrical conductivity, its rich surface functional groups and layered structure can be more easily combined with the electrode material, so it is widely used as a substrate material and potential anode material composite [103,104,105]. Han et al. [106] designed a Si-N-MXene composite anode material through interface nitrogen engineering. They mixed a certain proportion of micron-sized Si powder, PAN (polyacrylonitrile), and Ti3C2Tx MXene and then cast the mixture onto a copper foil substrate followed by heat treatment. During the heat treatment process, PAN was converted into amorphous carbon that fixed Si and MXene, as shown in Figure 9a. Moreover, a chemical bond of N was formed to connect them, creating a solid interface nitrogen layer structure on the surfaces of Si and MXene, which could effectively enhance the adhesion between Si and MXene, thereby improving the mechanical properties. The structure of MXene creates a robust volumetric buffer layer to resist volume expansion of the silicon electrode. Si-N-MXene was used as the composite film electrode, lithium metal as the counter electrode, and 1M LiPF6 as the carbonate electrolyte to form a full cell. The capacity retention was 80.5% after 200 cycles (Figure 9c). The initial capacity and the capacity after 100 cycles are much larger than that of the single Si-C electrode. In solving the problem of the volume expansion phenomenon produced by Si during charging and discharging, Du et al. [104] have designed another special core-shell structure, as shown in Figure 9b. Si particles were confined in TiO2 carbon fibers by electrostatic spinning to obtain Si-x/TiO2 carbon fibers (ST-2), and ST-2 was successfully wrapped in Ti3C2Tx MXene under self-assembly. Then the cobalt and molybdenum salts were uniformly adsorbed on the surface of MXene in solution and then heated, and the hierarchical ST-2@Ti3C2Tx MXene@Co-MoS2 (CMS) fibers were successfully obtained, which presented a 3D electrode structure with interleaved composition. Utilizing titanium dioxide, which has a very low volume expansion rate, and MXene, which has high electrical conductivity, high specific capacity, and multiple active sites, a hierarchical and robust volumetric buffer layer was constructed together with CMS, which improves the volumetric change of Si particles in the core during charging and discharging. Through electrochemical performance testing, the ST-2@MXene@CMS electrode exhibited relatively excellent electrochemical performance. As shown in Figure 9d,f, its initial charging and discharging capacities reached 1849.9/2071.8 mAh g−1, and the initial Coulomb efficiency reached 89.3%, indicating a high effective utilization rate of the battery during the first charging and discharging. Moreover, at a high current density of 1.0 A/g, the reversible specific capacity reached 1333.1 mAh g−1 after 100 cycles. And there was still a reversible specific capacity of 891.3 mAh g−1 after 200 cycles. In contrast, the initial charging capacity of the pure ST-2 electrode was only 1518.9 m Ah g−1. And the reversible specific capacity decreased to 478.7 mAh g−1 after 200 cycles at 1.0 A g−1. This was mainly due to the limited buffering capacity of monolayer ST-2 and the structural rupture caused by the expansion of Si particles. The ST-2@MXene@CMS electrode was demonstrated to have great potential for high-energy storage, and the important role of MXenes in maintaining structural stability during their long-term cycling was also shown.

In addition, the influence of MXene surface functional groups on the energy storage properties has been extensively studied. Different groups affect the adsorption capacity by changing the binding energy and bond length of Li+ to MXene. Kim et al. [107] optimized the structure of M2CTX using density functional theory (DFT) to calculate the lattice parameters and density of states (DOS), focusing on the effect of surface groups on lithium adsorption, diffusion barriers, and storage capacity, as shown in Figure 9g. For small-sized, highly electronegative groups (-Cl, Br), which form short bond lengths (2.21–2.35 Å) and low adsorption energies (−1.31~−0.71 eV) with Li+, the electrons are highly delocalized and the adsorption stability is strong. Small groups (-Cl) diffuse faster due to low spatial site resistance. And the large groups (-Se, Te) still keep low potential barriers through the electron leaving domain effect. However, for the lithium storage performance, the capacity of the (-Cl, Br) group system is 190–287 mAh g−1 in monolayer adsorption, and the -Se group system (Cr2CSe2) achieves 391.3 mAh g−1 by bilayer adsorption. This is due to the fact that, at high concentrations, the -Cl, Br groups are susceptible to destabilization due to Li+ repulsion, whereas the Se- groups maintain stability by virtue of moderate electron delocalization (adsorption energy −0.033 eV). Overall, the surface groups are regulated by “adsorption stability-diffusion efficiency-storage capacity”, which determines the actual performance of MXene as an electrode. Future research can focus on the optimization of group combination to accelerate the translation of MXene from theory to practical application.

Figure 9.

(a) Schematic diagram of the synthesis process for the interfacial nitrogen layer between Si and MXene. Reproduced with permission [106]. Copyright 2022, Elsevier BV. (b) Schematic illustration of the cycling process of the ST2@MXene@CMS electrode. Reproduced with permission [104]. Copyright 2024, Springer Nature. (c) Long-life cycling performance of the NMC811/Si-N-MXene full battery. Reproduced with permission [106]. Copyright 2022, Elsevier BV. (e) Initial charge–discharge curves and bar chart of initial Coulombic efficiency for the ST2@MXene@CMS electrode. (d,f) Cycling performance curves of the electrode at current densities of 0.1 A g−1 and 1.0 A g−1. An arrow pointing in the direction of an increasing number of cycles indicates that the material will continue the current trend in subsequent cycles. (d–f) Reproduced with permission [104]. Copyright 2024, Springer Nature. (g) Trends in lithium adsorption energy with lithium concentration on Cr2CCl2, Cr2CBr2, Cr2CSe2, Cr2CTe2, Mn2CCl2, and Mn2CBr2 nanosheets. Reproduced with permission [107]. Copyright 2024, Elsevier.

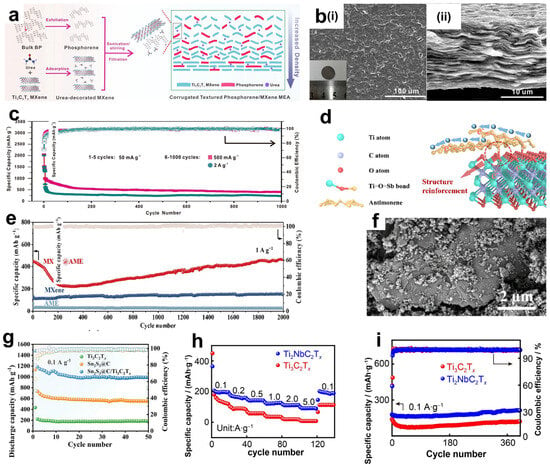

Phosphorus also has an excellent theoretical capacity and high electrical conductivity. Even the average discharge potential of phosphorus is higher than that of silicon, making it one of the most promising anode materials for lithium–ion batteries [108]. However, similar to silicon, phosphorus electrodes also have relatively large volume changes and slow kinetics. Research has already shown that through the liquid-phase exfoliation method, bulk black phosphorus can be exfoliated into phosphorene or black phosphorus quantum dots. The two-dimensional phosphorene has a very small volume change during the charging and discharging process, which can effectively avoid volume changes and form more lithium–ion channels, thereby significantly improving the electrochemical performance [109]. Based on this, Li et al. [110] developed a corrugated phosphorene/MXene heteronanocomposite electrode. The preparation process is shown in Figure 10a. After fully mixing and dispersing urea and Ti3C2Tx MXene, the mixture was dropped into a diphosphoric acid solution. In this regard, phosphorus is able to form stable P-O-Ti covalent bonds with -OH on the surface of Ti3C2Tx MXene, thereby making a membrane after self-assembly. The incorporation of polar urea molecules can avoid the concentration of phosphorus aggregating on the active sites on the MXene surface and promote a uniform distribution among the MXene lamellae, such as the corrugated protrusions in Figure 10b(i). In addition, the typical accordion-like lamellar structure of MXene is retained (Figure 10b(ii)). Through bridging and crosslinking, phosphene and MXene form stable ionic or charged 2D lamellar corrugated heterostructures. When electrons transition from the Fermi level of MXene to the Fermi level of phosphorene, a migration of the work function from a higher value to a lower value occurs, aligning the Fermi levels of the two materials. Moreover, changes in the electron concentration and vacancy concentration will occur at the heterostructure. These changes can improve the charge conductivity, reduce the energy barrier for the migration of the solid electrolyte interface (SEI) film of lithium ions on the electrode surface, and greatly enhance the electrochemical performance. The formed conductive framework can significantly increase the stability of the structure and volume changes. Electrochemical performance analysis was performed on a half-cell system consisting of a phosphorene/MXene nanocomposite film as the anode and a 1 M LiPF6-based carbonate mixed electrolyte solution, as shown in Figure 10c. At a current density of 100 mA g−1, the electrode delivers an ideal capacity of 1463.2 mAh g−1 and maintains a favorable reversible capacity of 848.3 mAh g−1 after 100 cycles. This demonstrates excellent cycling stability, which significantly surpasses that of pure MXene and phosphorene electrodes. All these data show its great potential as a new anode material for lithium–ion batteries. Antimony (Sb), similar to phosphorus, also has a unique monolayer two-dimensional structure, antimonene. Antimony also has high theoretical capacity with high lithium insertion potential. However, it has the same problems of large volume change and poor electronic conductivity during charging and discharging. Bo et al. [111] counted and synthesized covalently bonded Ti3C2Tx MXene@antimonene (MXene@AME) heteroanodes. Antimonene is self-assembled with the -OH groups on the surface of MXene, which serves as both a conductive matrix and a stress-absorbing layer. A strong heterostructure (Ti-O-Sb) is formed between the two under electrostatic action, schematically shown in Figure 10d. Similar to phosphene, it can greatly improve electrochemical performance. The MXene@AME anode exhibits outstanding cycling performance at both a lower current density of 0.2 A g−1 and a higher current density of 1 A g−1. As shown in Figure 10e, after 300 cycles at the low current density, it can still maintain a capacity of 455 mAh g−1, with a retention rate as high as 93.8%. The phenomenon that the capacity first decreases and then recovers, and is even higher than the initial capacity (447 mAh g−1), may be due to the formation of an unstable SEI layer in the initial charging and discharging cycles, the incomplete activation of the electrode material, or the degradation of the electrode structure. Subsequently, it is because of the stable reconstruction of the Ti-O-Sb bond and the formation of a stable SEI layer. In contrast, the reversible capacity of pure Ti3C2Tx MXene was only 81.7 mAh g−1 after 100 cycles under the same conditions. This may be attributed to the reduction of active sites due to the stacking of MXene layers, resulting in a faster capacity decay during cycling.

In addition, alloy-based anode materials also have high lithium storage capacity through alloying and de-alloying mechanisms [112,113]. But there are also problems such as poor electrical conductivity during charging and discharging, large volume changes, and dendrite growth during lithium–ion deposition [114]. Tin-based materials, featuring high theoretical specific capacity and energy density, have also attracted widespread attention. Guan et al. [115] synthesized a Sn2S3@C/Ti3C2Tx composite electrode material with a laminated leaf-like structure. Sn2S3 was uniformly dispersed on several layers of MXene nanosheets after being coated by nanosized C, as shown in Figure 10f. Interestingly, the mechanical ball-milling process employed in the preparation introduces certain defects on the surface of Ti3C2Tx. These defects facilitate the stable anchoring of Sn2S3@C onto the MXene surface and effectively mitigate the internal stress generated during charge–discharge cycles, thereby enhancing the overall stability of the composite structure. When Sn2S3@C/Ti3C2Tx composites were used as an anode for lithium–ion batteries (Figure 10g), the reversible specific capacity was 989.6 mAh g−1 after 50 cycles at a current density of 0.1 A g−1. Cheng et al. [116] employed a solvothermal method, adsorbing tin ions on the MXene surface to induce in situ nucleation and growth, and successfully prepared Sn-C bonded MXene/SnSe2 composite electrode materials. SnSe2 nanosheets vertically and completely cover the MXene surface, forming a laminar structure. However, electrodes of this structure are not stable under the action of high-density currents. Scanning electron microscopy (SEM) observations show that after 100 cycles at a current density of 2000 mA g−1, SnSe2 nanosheets undergo in situ fragmentation into nanoparticles that disperse between MXene layers. This structural evolution leads to a notable increase in battery capacity and enhancement in electrochemical performance. The underlying mechanism involves the fragmented particle structure significantly expanding the specific surface area of the electrode material, which not only enables more lithium ions to insert into the material but also provides abundant ion transport pathways. These pathways accelerate lithium–ion diffusion rates, thereby contributing to the capacity improvement.

Figure 10.

(a) Schematic illustration of the preparation process for corrugated phosphorene/Ti3C2Tx nanocomposites. (b) Typical corrugated patterns; (i,ii) SEM images of the surface and cross-sectional morphology of the as-prepared phosphorene/Ti3C2Tx, respectively. (c) Long-term cycling stability and corresponding Coulombic efficiency of the phosphorene/MXene electrode (1–5 cycles: 50 mA g−1; 6–1000 cycles: 500 mA g−1 and 2 A g−1). (a–c) Reproduced with permission [110]. Copyright 2024, Springer Nature. (d) Schematic diagram of the structural features of the MXene@AME heterostructure. The circles in the figure indicate titanium Ti-O-Sb bonds. (e) Cycling performance curves of MXene@AME, MXene, and AME at 1 A g−1 over 2000 cycles. (d,e) Reproduced with permission [111]. Copyright 2024, Elsevier BV. (f) SEM image of Sn2S3@C/Ti3C2Tx. (g) Cycling performance of Ti3C2Tx, Sn2S3@C, and Sn2S3@C/Ti3C2Tx at 0.1 A g−1. (f,g) Reproduced with permission [115]. Copyright 2024, Springer Nature. (h) Rate capability of Ti2NbC2Tx and Ti3C2Tx; (i) Cycling performance of Ti2NbC2Tx and Ti3C2Tx at 0.1 A g−1. (h,i) Reproduced with permission [117]. Copyright 2022, Springer Nature.